Page 1

Instructions for use and maintenance of gas,

gas-electric and electric cookers. Series:

50N

Page 2

GB

Index

Introduction

Technical data and

specifications............................. 33

Installation.......................... 34 - 36

Ventilation......................................34

Positioning.....................................34

Gas connection .............................34

Adapting to different types

of gas ............................................35

Replacing the injectors ..................35

Regulating the air ..........................35

Minimum setting ............................35

Electrical connection .....................36

Safety device.................................36

For the user....................... 37 - 40

Ventilation......................................37

Igniting the burners....................... 37

Igniting the gas oven .................... 37

Igniting the gas grill .......................37

Safety device.................................37

Using the gas hob .........................37

Using the electric hot-plates ..........37

Using the gas oven........................38

Using the gas or electric grill ........ 38

Using the conventional

electric oven .................................. 38

Using the conventional

multifunction electric oven .............39

Oven with thermostat ....................39

Warming compartment ..................39

Advice and precautions .................39

Figures .............................. 41 - 43

- Thank you for choosing one of our quality

products, capable of giving you the very

best service. T o make full use of its performance features, read the parts of this

manual which refer to your appliance

carefully. The Manufacturer declines all

responsibility for injury or damage

caused by poor installation or improper

use of the appliance.

- To ensure its appliances are always at the

state of the art, and/or to allow constant

improvement in quality, the manufacturer

reserves the right to make modifications

without notice, although without creating

difficulties for users.

- When ordering spare parts, inform your

dealer of the model number and serial

number punched on your appliance’s

nameplate, visible inside the warming

compartment or on the back of the cooker.

- APPLIANCE COMPLYING WITH THE

FOLLOWING DIRECTIVES:

- EEC 90/396

- EEC 73/23 and 93/88

- EEC 89/336 (radio-frequency inter-

ference)

- EEC 89/109 (contact with foods)

FOREWORD

- Refer only to the headings and sections

covering accessories actually installed on

your cooker.

32

Page 3

GB

Technical data and specifications

Nominal external Cookers

dimensions 50x50

Height at hob cm 85

Height with lid raised cm 133

Height w. glass lid raised cm 133,3

Depth with door closed cm 50

Depth with door open cm 96

Width cm 50

Usable Oven

dimensions

Width cm. 39,5

Depth cm. 43,0

Height cm. 32,0

Volume l. 54

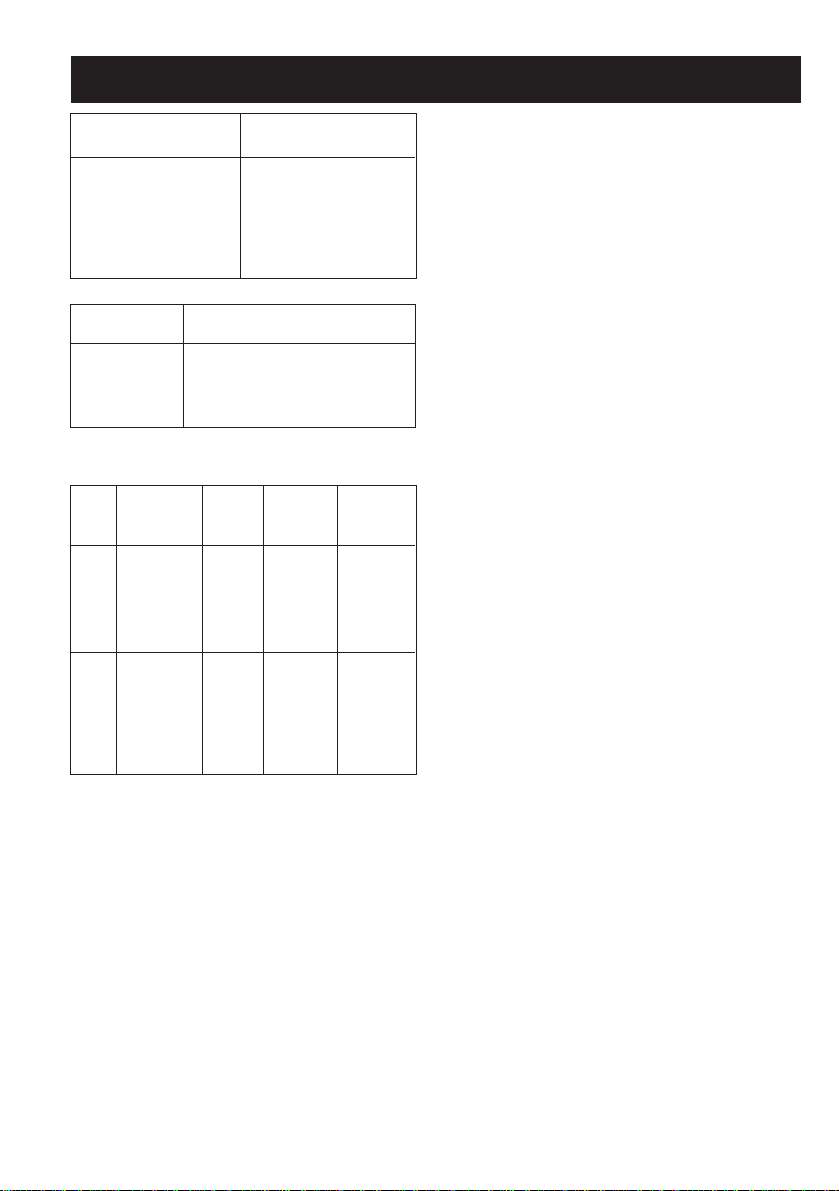

GAS BURNERS (injectors and flow-rates)

Gas Burner Injector low nominal

flow-rate flow-rate

(kW) (kW)

G20 auxiliary 70 0,40 0,90

20 semi-rapid 99 0,40 1,85

mbar rapid 126 0,85 3,00

oven 130 1,00* 3,00

grill 110 2,00

G30 auxiliary 48 0,40 0,90

28-30 semi-rapid 68 0,40 1,85

mbar rapid 86 0,85 3,00

G31 oven 86 1,00* 3,00

37 grill 70 2,00

mbar

* For thermostat. In case of oven with tap: 1.3 kW

EQUIPMENT

All models are equipped with safety device

for oven and grill burners.

Depending on the models, cooker may also

have:

- Oven thermostat (or tap)

- Electric oven lighting

- Grill burner or element

- One or more electric hotplates

For the LAYOUT OF HOB BURNERS see

the models illustrated in figure 1 at the back

of this manual.

For the ELECTRIC WIRING DIAGRAM see

figure 2 at the back of this manual.

The electrical power is stated on the nameplate visible inside the warming compartment

(if present) or on the back of the cooker.

A copy of the nameplate is glued to the cover

of this manual (for gas or gas-electric products only).

ELECTRIC HOTPLATES

ø 145 1,0 kW - Normal hotplate

1,5 kW - Rapid hotplate

ø 180 1,5 kW - Normal hotplate

2,0 kW - Rapid hotplate

ELECTRIC OVEN POWER

Oven: (1,1kW bottom

0,7kW top element) 2,2 kW

Grill: 2,0 kW

Cat.: see nameplate on cover; Class 1 or 2.1

Type “X” cookers

33

Page 4

GB

Installation

INSTALLATION

The appliance must be installed by qualified

staff working in accordance with the regulations in force.

Before installing, ensure that the appliance

is correctly preset for the local distribution

conditions (gas type and pressure).

The presettings of this appliance are indicated on the nameplate shown on the cover.

This appliance is not connected to a flue gas

extractor device. It must be installed and

connected in accordance with the regulations

in force.

This appliance may only be installed and may

only operate in rooms permanently ventilated

in accordance with national regulations in

force.

VENTILATION

The rooms in which gas appliances are installed must be well ventilated in order to allow correct gas combustion and ventilation.

The air flow necessary for combustion is at

least 2 m3/h for each kW of rated power.

POSITIONING

Remove the packaging accessories, including the films covering the chrome-plated and

stainless steel parts, from the cooker.

Position the cooker in a dry , convenient and

draft-free place. Keep at an appropriate distance from walls which may be damaged by

heat (wood, linoleum, paper, etc.).

The cooker may be free-standing (class 1)

or between two units (in class 2 st 2-1) the

sides of which must withstand a temperature of 100°C and which must not be higher

than the working table.

CONNECTING TO THE GAS SUPPLY

Before connecting the cooker, check that it

is preset for the gas to be used. Otherwise,

make the conversion as described in the

section headed “Adapting to different gas

types”. The connection is on the right; if the

pipe has to pass behind the cooker, it must

be kept low down where the temperature is

about 50°C.

- Rigid connection (see fig. 3 A + B)

The connection to the mains gas supply

may be made using a rigid metal pipe or

with a metal hose. Remove the hose connector (if already fitted) and screw the rigid

union onto the threaded connection of the

gas train (see fig. 3A). The union for rigid

connection may already be fitted on the gas

train, or may be amongst the cooker accessories. Otherwise, it can be obtained

from your dealer.

If national regulations permit, a metal hose

complying with the national standards can

be screwed directly onto the threaded connection of the gas train, fitting a seal (see

fig. 3B). However, users are strongly recommended always to fit the rigid union.

- Connection using a rubber hose (see fig.

3C). (For butane/propane gas only).

Connect a rubber hose carrying the conformity mark currently in force to the hose

connector. The hose must be replaced at

the date indicated at the latest, and must

be secured at both ends using standard hose clamps. It must be absolutely

accessible to allow its condition to be

checked along its entire length.

CAUTION:

- Use of the hose connector is only permitted for free-standing installation. If

the appliance is installed between two

class 2 st. 2-1 unions, the rigid union is

the only form of connection permitted.

IMPORTANT:

- After installation, check that the connections are airtight.

- For operation with butane/propane, check

that the gas pressure is as indicated on the

nameplate.

- Use only standard rubber hoses. For LPG,

use a hose which complies with the national

regulations in force.

- Avoid sharp bends in the pipe and keep it

well way from hot surfaces.

References to the regulations covering the

gas connection to the appliance: ISO 7-1.

34

Page 5

GB

Installation

ADAPTING TO DIFFERENT TYPES OF

GAS

If the cooker is not already preset to operate

with the type of gas available, it must be converted. Proceed as follows:

- Replace the injectors (see table on page

33);

- regulate the primary air flow;

- regulate the minimum settings.

N.B.: every time you change the type of gas,

indicate the new type of gas on the serial

number label.

REPLACING THE HOB BURNER INJECTORS (fig. 4)

- Remove the lid of the cooker by lifting it off

its supports;

- remove the grids, burner caps and burners, lifting them off;

- unscrew the 2 screws (above) or nuts (below) at the back which secure the work top,

and pull it out forward.

- remove the mixer pipes and replace the

injectors using a 7 mm socket wrench.

REPLACING THE OVEN BURNER INJECTOR (Fig. 5)

- Loosen the screw which secures the bottom of the oven;

- remove the oven bottom (pulling it forward);

- remove the oven burner, after taking out

the screw which secures it;

- replace the injector using a 7 mm socket

wrench.

REPLACING THE GRILL BURNER INJECTOR (Fig. 6)

- Remove the burner after taking out the two

screws which secure it;

- replace the injector using a 7 mm socket

wrench.

IMPORTANT:

- Never over-tighten the injectors;

- after replacing, check that all the injectors

are airtight.

REGULATING THE BURNER AIR

Refer to the table below (indicative values)

for regulation of the gap H in mm (fig. 4 for

the hob, fig. 6 for the grill).

Burner G20 20mbar G30 28-30mbar

G31 37mbar

Auxiliary 3 4

Semi-rapid 3 3

Rapid 4 6

Oven - Grill 3 8

Check operation of the burner:

- Ignite the burner at maximum flame;

- the tongue of the flame must be clear and

with no yellow tip, and must adhere closely

to the burner. If too much air is supplied,

the flame detaches from the burner and

may be dangerous. If the air supply is insufficient, the flame has a yellow tip and

soot may form.

SETTING HOB BURNER MINIMUM LEVELS

If the cooker is to work on bottled gas (butane/propane), the tap by-pass must be

screwed right down.

The cooker may be equipped with type A

taps, with by-pass inside (accessed by inserting a small screwdriver into the rod) or

type B taps, with by-pass on the outside on

the right (accessed directly). See figure 7.

If the cooker is to work on natural gas, proceed as follows for both types of tap:

- Ignite the burner at maximum flame;

- pull off the knob, without using a lever

against the control panel, which might be

damaged;

- access the by-pass with a small screwdriver

and back off by about 3 turns (turning the

screwdriver anti-clockwise);

- turn the tap rod anti-clockwise again until it

stops: the burner will be at maximum flame;

- screw the by-pass slowly back in, without

pushing the screw-driver, until the flame has

apparently shrunk to 1/4 of the maximum

size, checking that it is sufficiently stable

35

Page 6

GB

Installation

even in quite strong draughts.

SETTING OVEN BURNER MINIMUM LEVELS

If the cooker is to work on bottled gas (butane/propane), the thermostat by-pass must

be screwed right down.

If the cooker is to work on natural gas, proceed as follows:

- Remove the oven bottom (loosen the screw

to remove the bottom);

- ignite the oven burner, turning the knob

pointer to the maximum setting;

- shut the oven door;

- access the thermostat or tap by-pass (see

fig. 8);

- back off the thermostat by-pass by about 3

turns;

- after 5 or 6 minutes, turn the knob pointer

to the minimum setting;

- slowly re-tighten the by-pass, watching the

flame decrease in size through the window

in the closed oven door until the tongue of

the flame is about 4 mm long. Never keep

the flame too low. It must be stable even

when the oven door is opened or closed

quickly;

- turn off the burner and replace the oven

bottom.

CONNECTING TO THE ELECTRICAL

MAINS

Before making the connection, check that:

- the mains voltage is as indicated on the

nameplate;

- the earth connection is in good working order.

If the socket is not easily accessible, the installation engineer must provide a switch with

a contact breaking gap of 3 mm or more.

If the appliance power lead is not fitted with

a plug, use an approved standard type, remembering that:

- the green-yellow wire must be used for the

earth connection;

- the blue wire is the neutral;

- the brown wire is live;

- the lead must never touch hot surfaces over

about 75 degrees C;

- replacement leads must be of type H05RRF or H05V2V2-F of suitable size (see diagrams in fig. 2).

- if the appliance is supplied without lead,

using type H05RR-F or H05V2V2-F cable

of suitable size (see diagrams in fig. 2).

IMPORTANT: the manufacturer declines all

liability for damage due to failure to comply

with the regulations and standards in force.

Check that the appliance is correctly connected to the earth (see diagrams in fig. 2 at

the back of the manual).

THE SAFETY DEVICE

The correct gap between the end of the thermocouple sensor and the burner is shown in

figures 5 and 6.

To check that the valve is working properly,

proceed as follows:

- ignite the burner and leave it to work for

about 3 minutes;

- turn off the burner by returning the knob to

off position ( );

- after 60 seconds for oven and grill burners,

turn the knob pointer to the "on" position;

- release the knob in this position and move

a burning match towards the burner; IT

MUST NOT IGNITE.

Time needed to excite the magnet during

ignition: 10 seconds approx.

Automatic tripping time, after flame has been

turned off: not more than 60 seconds for oven

and grill burners.

IMPORTANT

- Before doing any work inside the cooker, disconnect the mains plug and shut the gas tap.

- Never use matches to check the gas circuit for leaks. If a specific control device is

not available, foam or very soapy water can

be used.

- When re-closing the hob, check that the

electrical wires of the spark plugs (if

present) are not close to the injectors, so

that they cannot run across them.

36

Page 7

GB For the user

HOW TO USE THE COOKER

VENTILATION

All gas cooking appliances produce heat and

moisture in the rooms where they are installed. Take care to ensure that the kitchen

is well ventilated; keep the ventilation openings unobstructed or install an extractor hood

with fan.

In case of intensive or prolonged use, additional ventilation may be required; open a

window, or increase the extractor fan power.

IGNITING THE HOB BURNERS

- Press the knob and turn it anti-clockwise

until it reaches the

panel (maximum flame position);

- at the same time, move a burning match

towards the burner head;

- to reduce the flame, turn the knob further

in the same direction until its pointer is

against the

sition).

IGNITING THE OVEN BURNER

- Open the oven door;

- press the knob and turn it anti-clockwise to

the maximum flame position;

- move a burning match towards the hole in

the centre of the oven bottom and press

the knob right down (see fig. 9);

- check that the burner has ignited, looking

through the hole in the centre of the bottom, keeping the knob pressed all the time;

- after about 10 seconds, release the knob

and check that the burner remains on. Otherwise, repeat the operation.

IGNITING THE GRILL BURNER (GAS

GRILLS)

- Fit the control knob guard as shown in fig.

12;

- press the oven knob and turn it to the right

until it reaches the stop;

- move a burning match towards the perforated burner pipe and press the knob right

down (see fig. 10);

symbol on the control

symbol (minimum flame po-

- check that the burner has ignited, keeping

the knob pressed down;

- after about 10 seconds, release the knob

and check that the burner remains on. Otherwise, repeat the operation.

IMPORTANT

- Difficulty in igniting burners is normal if the

cooker has been out of use for some time.

The air accumulated in the pipes will be

expelled in a few seconds;

- Never allow too much unburnt gas to flow

from the burners. If ignition is not achieved

within a relatively short time, repeat the procedure after returning the knob to the off

position (

- when the oven and grill are lit for the first

time, a smell may be noticed and smoke

may come out of the oven. This is because

of the surface treatment and oily residues

on the burners.

SAFETY DEVICE

Burners equipped with this device have the

advantage that they are protected if they

accidentally go out. If this occurs, the supply

of gas to the burner concerned is automatically cut off, preventing the hazards deriving

from a leak of unburnt gas. The gas supply

must be cut off within no more than 60 seconds for the oven and grill burners.

HOW TO USE THE HOB BURNERS

Use pans of diameter suitable for the burner

type. The flames must not project beyond

the base of the pan. Recommended sizes:

- for auxiliary burners = pans of at least 8 cm

- for semi-rapid burners = pans of at least 14 cm

- for rapid burners = pans of at least 22 cm.

N.B.: Never keep the knob at settings between the maximum flame symbol

off position

FOR COOKERS EQUIPPED WITH ELECTRIC HOTPLATES

The different heat settings are obtained as

follows:

);

and the

( ).

37

Page 8

GB

For the user

- 1 = minimum setting for all hotplates;

- 6 = maximum setting for normal and rapid

hotplates (with red disc);

- 0 = off.

Pans must never be smaller in diameter than

the hotplates and their bottoms must be as

flat as possible (see fig. 11).

IMPORTANT :

- Never leave hotplates on without pans,

except when first used; leave for about 10

minutes to dry oil or moisture residues;

- if the hotplate is to be out of use for a long time,

apply a little grease to its painted surface;

- do not allow spills to burn onto the hotplate,

requiring the use of abrasive cleaners.

HOW TO USE THE GAS OVEN

- After igniting the burner, leave the oven to

heat up for about 10 minutes;

- place the food for cooking in an ordinary oven

dish and place it on the chrome-plated shelf;

- place the food in the oven, using the shelf

on the third pair of runners whenever possible, and turn the knob pointer to the desired

setting;

- cooking can be observed through the window

in the door with the oven light on. This will

avoid opening and closing the door frequently,

unless oil or fat has to be added to the dish.

IMPORT ANT: never place foods directly on

the drip tray for cooking; it is there only to

collect any drips of fat during grilling.

N.B.: For cookers without thermostat:

- with the knob on the maximum setting

270 degrees C

- with the knob on the minimum setting

150 degrees C

- All other temperatures between 150 and

270 degrees C are obtained approximately

by positioning the knob between the maximum and minimum settings.

Never leave the knob in positions between the

maximum symbol

and the off setting

(

- ignite the burner and wait a few minutes to

allow it to warm up, or switch on the heating element;

- place the foods on the chrome-plated shelf;

- insert on the highest runner;

- insert the drip tray on the bottom runner;

- gently close the oven door, resting it against

the knob guard;

- after a few minutes, turn the food to expose

the other side to the infrared radiation (the

cooking time depends on the type of food

and personal taste).

N.B.: the first time the grill is used smoke

will come out of the oven. Before inserting

foods for cooking, wait until any oil residues

on the burner have completely burnt away.

The grill must only be used at its full rated heat.

IMPORTANT: accessible parts may be hot

when the grill is in use! Keep children well

away.

The grill element in the top of the oven is

switched on by turning the thermostat knob

clockwise to the grill symbol on the control

panel.

The red light will come on to show the element is in operation.

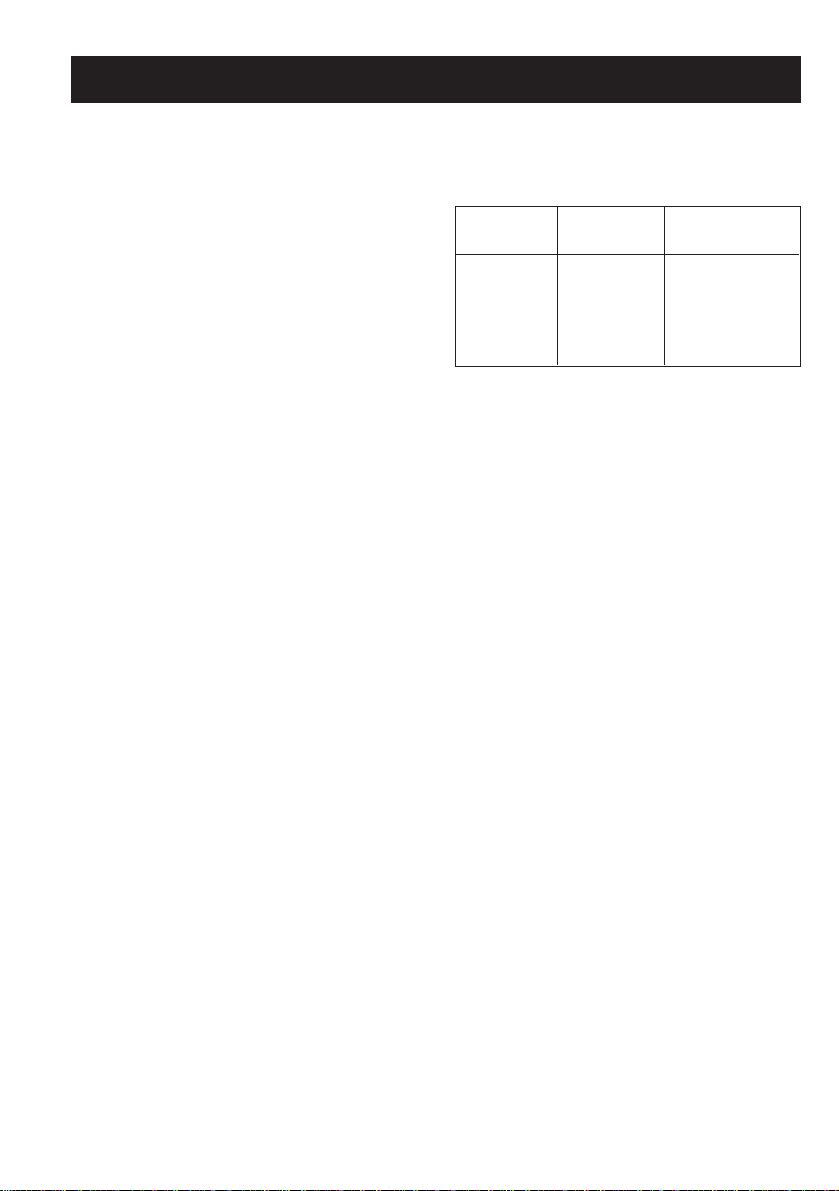

The table below will serve as a guide; bearing in mind that cooking times and temperatures may vary depending on the type and

amount of foods cooked and personal taste.

Food to be Time (minutes)

grilled 1st side 2nd side

=

Thin pieces of meat 6 4

=

).

Fairly thick pieces of

meat 8 5

Thin fish or fish

without scale 10 8

Fairly thick fish 15 12

Sausages 12 10

Toasted sandwiches 5 2

Small poultry 20 15

HOW TO USE THE GAS OR ELECTRIC

GRILL

- fit the knob guard (see fig. 12);

CONVENTIONAL ELECTRIC OVEN

- The oven shelf is designed to take normal

oven dishes for cooking sweets or roasts,

38

Page 9

GB

For the user

or is used without a pan for cooking foods

under the grill.

- The drip tray is only there to collect any juice

from foods and must never be used as a

cooking surface.

There is a single control knob for the oven

or grill.

Starting from the 0 (off) position, the knob can

be turned clockwise to the following settings:

- symbol: oven lamp on (it will remain on

even if the knob pointer is turned to the

other settings).

- Setting from 60 to 250 degrees C: oven

heat settings, with thermostat control.

- or symbol: grill on (in roof of oven)

Turn the knob anti-clockwise to return to the

0 (off) position.

N.B. - The yellow light switches on and off

as the thermostat is tripped.

Before placing food inside, allow the oven to

heat up for at least 10 minutes.

CONVENTIONAL MUL TIFUNCTION ELECTRIC OVEN

Thanks to the various heating elements controlled by a selector knob, this oven offers

several cooking modes.

Starting from the 0 (off) position and turning

the knob clockwise, the settings encountered

are:

- symbol: conventional “static” oven cooking at half power (max. temperature 120°C

approx.).

- symbol: top element on (max. temperature 155°C approx.).

-

symbol: bottom element on (max. tem-

perature 235°C approx.).

- symbol: conventional “static” oven cooking at full power (max. temperature 295°C

approx.).

-

symbol: grill on.

With all settings except zero the red light illuminates to indicate that the oven or grill is

on.

Before putting food in to be cooked, the oven

should be pre-heated for at least 10 minutes.

- The oven shelf is designed to take normal

oven dishes for cooking sweets or roasts,

or is used without a pan for cooking foods

under the grill.

- The drip tray is only there to collect any juice

from foods and must never be used as a

cooking surface.

OVENS WITH THERMOSTAT

If cooking temperatures are not as set, call

in an engineer to check the thermostat.

WARMING COMPARTMENT

T o open the warming compartment, open the

flap door with one hand (see figure 13).

To close the warming compartment, simply

press the flap door back into place.

GENERAL PRECAUTIONS

- Always disconnect the power supply before

any work inside the oven or where live parts

may be accessed.

- Never use the warming compartment for

storing inflammable liquids or items which

do not withstand heat, such as wood, paper, aerosol cans, matches, etc.

- Make frequent checks on the rubber connection hose, ensuring that it is well away

from hot surfaces, that there are no sharp

bends or kinks, and that it is in good condition. The hose must be replaced at the latest at the indicated date and must be secured at both ends using a standard hose

clamp.

- If taps become stiff to operate over time,

contact the After-Sales service.

- Wash enamelled or chrome-plated parts

with soapy lukewarm water or non-abrasive

detergents. A metal brush may be used to

remove deposits from hob burners and

flame caps. Dry thoroughly.

- Never use abrasives to clean enamelled or

chrome-plated parts.

- Do not use too much water when washing

the hob. Take care that no water or other

substances enter the burner housing holes,

as this may be dangerous.

39

Page 10

GB For the user

- The spark plugs for electric ignition must

be kept clean and dry; always check after

use, particularly if there have been drips or

overflows from pans.

- Never close glass lids until the hob burners or hotplates have cooled completely; it

might shatter or crack.

- Never knock enamelled parts or ignition

spark plugs (where present).

- The main or wall gas tap should be turned

off when the cooker is not in use.

- Never lift the cooker by taking hold of the

oven door handle.

No liability is accepted for injury or damage

caused by poor installation or improper use

of the cooker.

In case of malfunctions, particularly gas

leaks or short-circuits, contact your engineer without delay.

40

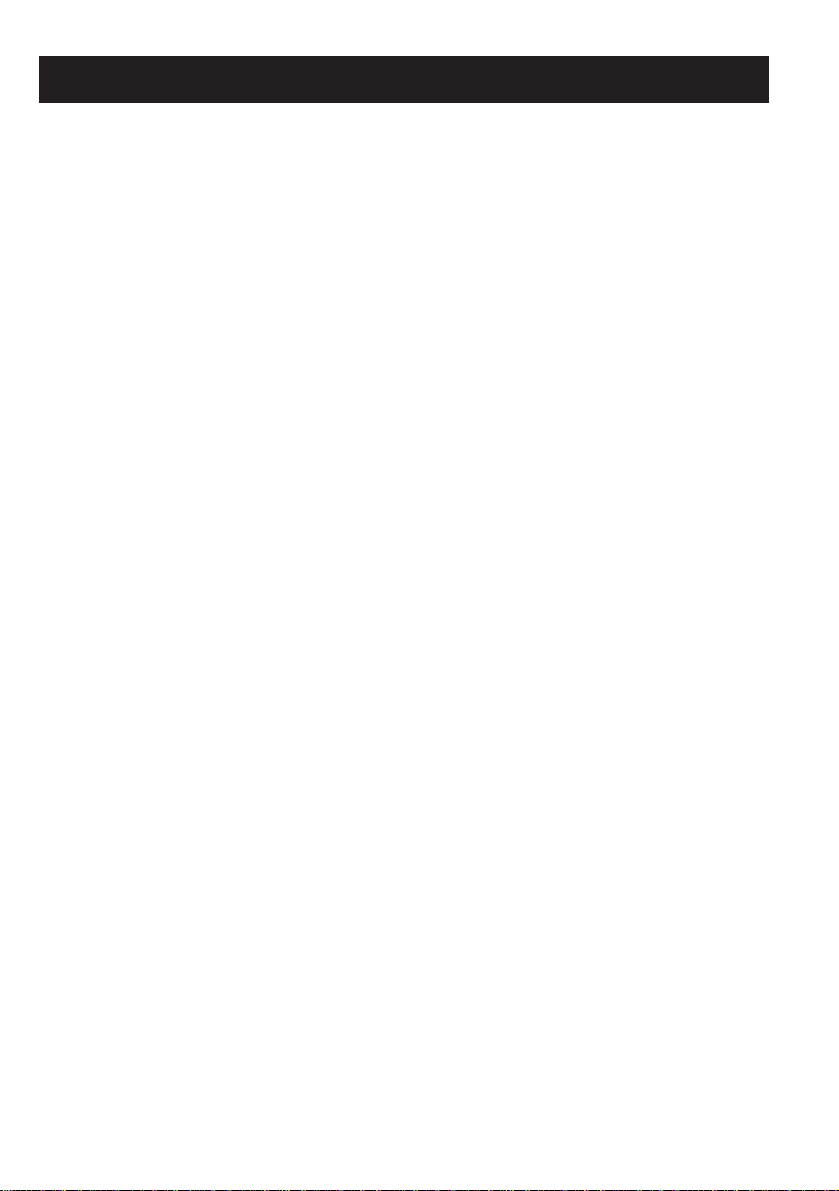

Page 11

Figuras / Figures / Figuras / Figures

CUADRO DE CONEXIONES

SCHEMA DES BRANCHEMENTS

SR

ESQUEMA DE LIGAÇÃO

CONNECTION DIAGRAM

A = AUXILIAR

= AUXILIAIRE

= AUXILIAR

= AUXILIARY

A

SR

A

P1 SR

A

SR

SR = SEMIRRÁPIDO

R

R

R

= SEMI-RAPIDE

= SEMI-RÁPIDO

= SEMI-RAPID

230 V BIFASICO / BIPHASE / BIFÁSICO / TWO-PHASE

400 V MONOFASICO + NEUTRO / MONOPHASE + NEUTRE /

MONOFÁSICO + NEUTRO / SINGLE-PHASE + NEUTRAL

13452

L

230 V TRIFASICO / TRIPHASE / TRIFÁSICO / THREE-PHASE

N

13452

LLL

400 V TRIFASICO + NEUTRO / TRIPHASE + NEUTRE /

TRIFÁSICO + NEUTRO / THREE-PHASE + NEUTRAL

13452

L

LN

L

Sección cable

Section câble

Sec. cabo

Wire gauge:

3x6 mm

Sección cable

Section câble

Sec. cabo

Wire gauge:

4x4 mm

Sección cable

Section câble

Sec. cabo

Wire gauge:

5x2,5 mm

2

2

2

R = RÁPIDO

= RAPIDE

= RÁPIDO

= RAPID

P1 = PLACA Ø 180

= PLAQUE Ø 180

= DISCO Ø 180

= HOTPLATE Ø 180

P2 = PLACA Ø 145

= PLAQUE Ø 145

= DISCO Ø 145

= HOTPLATE Ø 145

230 V BIFASICO / BIPHASE / BIFÁSICO / TWO-PHASE

12

LN

> 3,5 kW 3x2,5 mm

2,2 - 3,5 kW 3x1,5 mm

0 - 2,2 kW 3x1 mm

1

Sección cable

Section câble

Sec. cabo

Wire gauge:

2

2

2

2

41

Page 12

Figuras / Figures / Figuras / Figures

A

C D

B

1,5 mm

2 mm

4 mm

AB

TERMOPAR

A =

THERMOCOUPLE

B = BUJÍA / BOUGIE D'ALLUMAGE / VELA DE IGNIÇÃO /

SPARK PLUG

/ THERMOCOUPLE /

TERMOPAR

/

5

B

H

TERMOPAR

A =

THERMOCOUPLE

B = BUJÍA DE ENCENDIDO / BOUGIE D'ALLUMAGE /

VELA DE IGNIÇÃO / SPARK PLUG

/ THERMOCOUPLE /

A

TERMOPAR

mm 3 mm 3

/

mm 3

mm 2 - 4

B

A

H

A = TERMOPAR / THERMOCOUPLE / TERMOP AR /

THERMO-COUPLE

B = BUJÍA / BOUGIE / VELA / SPARK PLUG

3

6

7

4

8

42

Page 13

9

10

Figuras / Figures / Figuras / Figures

13

11

12

43

Page 14

ED. 09.02.1999 334813

B1/44

Loading...

Loading...