Aspen Manufacturing CA User Manual

DX-TREME CA SERIES

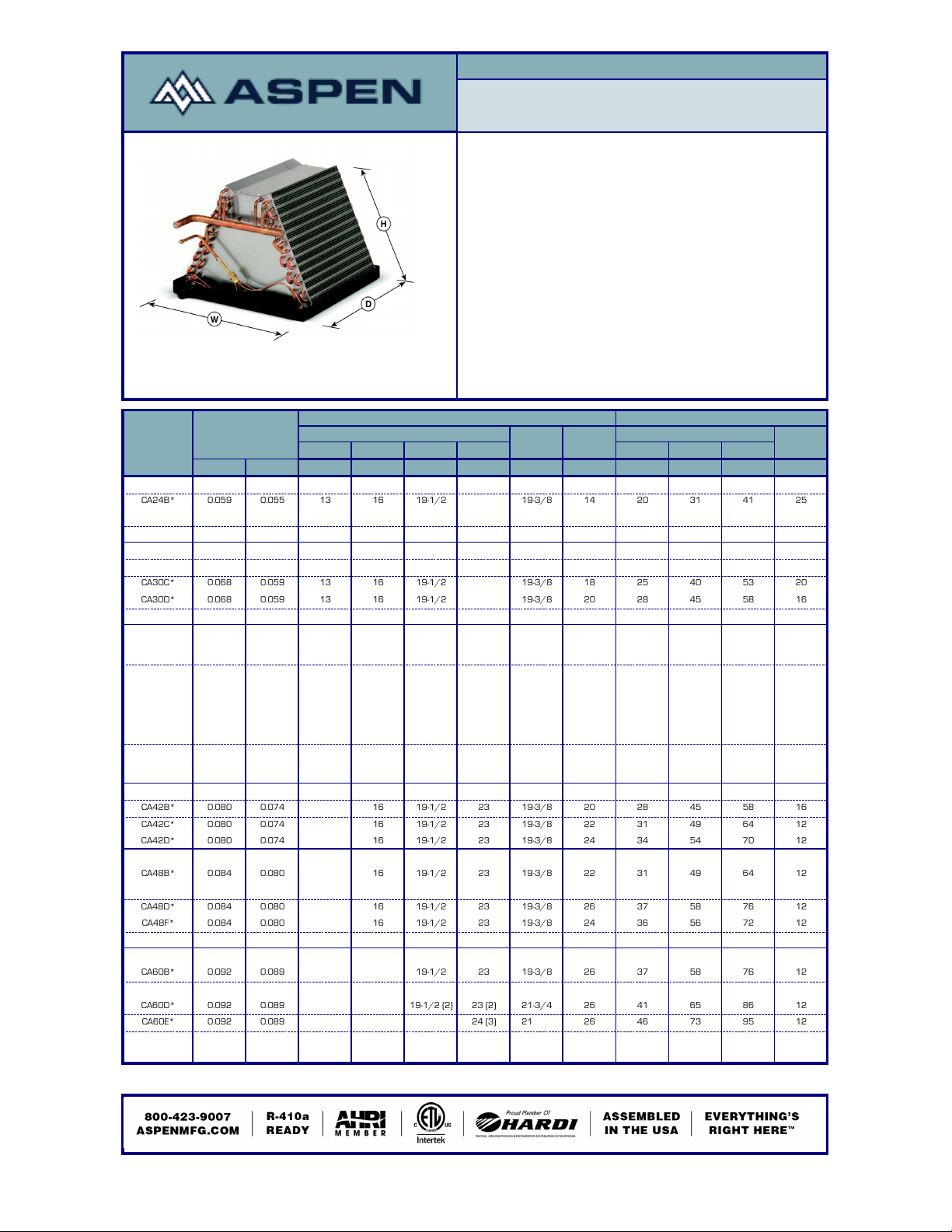

UNCASED UPFLOW / DOWNFLOW COILS

DIMENSIONS SHIPPING INFORMATION

PAN WIDTHS (W) SHIPPING WEIGHT

13 16 19-1/2 23 2 ROW 3 ROW 4 ROW

R22

R410a

CA24A* 0.059 0.055 13 16 19-1/2 19-3/8 12 17 27 35 30

CA24B* 0.059 0.055 13 16 19-1/2 19-3/8 14 20 31 41 25

CA24C* 0.059 0.055 13 16 19-1/2 19-3/8 16 23 36 47 25

CA24D* 0.059 0.055 13 16 19-1/2 19-3/8 18 25 40 53 20

CA30A* 0.068 0.059 13 16 19-1/2 19-3/8 14 20 31 41 25

CA30B* 0.068 0.059 13 16 19-1/2 19-3/8 16 23 36 47 25

CA30C* 0.068 0.059 13 16 19-1/2 19-3/8 18 25 40 53 20

CA30D* 0.068 0.059 13 16 19-1/2 19-3/8 20 28 45 58 16

CA30E* 0.068 0.059 13 16 19-1/2 19-3/8 20 30 47 60 16

CA36A* 0.074 0.068

13 for 2, 3R;

16 for 4R

16 19-1/2 19-3/8 16 23 36 47 25

CA36B* 0.074 0.068

13 for 2, 3R;

16 for 4R

16 19-1/2 19-3/8 18 25 40 53 20

CA36C* 0.074 0.068

13 for 2, 3R;

16 for 4R

16 19-1/2 19-3/8 20 28 45 58 16

CA36D* 0.074 0.068

13 for 2, 3R;

16 for 4R

16 19-1/2 19-3/8 22 31 49 64 12

CA42A* 0.080 0.074 16 19-1/2 23 19-3/8 18 25 40 53 20

CA42B* 0.080 0.074 16 19-1/2 23 19-3/8 20 28 45 58 16

CA42C* 0.080 0.074 16 19-1/2 23 19-3/8 22 31 49 64 12

CA42D* 0.080 0.074 16 19-1/2 23 19-3/8 24 34 54 70 12

CA48A* 0.084 0.080 16 19-1/2 23 19-3/8 20 28 45 58 16

CA48B* 0.084 0.080 16 19-1/2 23 19-3/8 22 31 49 64 12

CA48C* 0.084 0.080 16 19-1/2 23 19-3/8 24 34 54 70 12

CA48D* 0.084 0.080 16 19-1/2 23 19-3/8 26 37 58 76 12

CA48F* 0.084 0.080 16 19-1/2 23 19-3/8 24 36 56 72 12

CA48G* 0.084 0.080 16 19-1/2 23 19-3/8 26 39 60 78 12

CA60A* 0.092 0.089 19-1/2 23 19-3/8 24 34 54 70 12

CA60B* 0.092 0.089 19-1/2 23 19-3/8 26 37 58 76 12

CA60C* 0.092 0.089 19-1/2 (2) 23 (2) 21-3/4 24 38 60 79 12

CA60D* 0.092 0.089 19-1/2 (2) 23 (2) 21-3/4 26 41 65 86 12

CA60E* 0.092 0.089 24 (3) 21 26 46 73 95 12

CA60F* 0.092 0.089 19-1/2 23 19-3/8 24 41 62 80 12

CA60G* 0.092 0.089 24 (3) 21 26 48 75 97 12

Notes: 1) Do not use heavy duty polypropylene drain pans on oil furnaces or other applications where outlet temperatures may exceed 300°F. Specify metal drain pans for these

applications. 2) Metal drain pan. 3) Metal drain pan. Slab rotated 90°. Refrigerant and plumbing connections still exit in front.

Revised 3/4/09. In keeping with its policy of continuous progress and product improvement, Aspen reserves the right to make changes without notice and without incurring obligation.

PRODUCT DIMENSIONS & SPECIFICATIONS

Representative drawing only. Some models may vary in

appearance.

FLOW RATER

SIZE

COIL

MODEL

PAN DEPTH

(D)

BARE SLAB

HEIGHT (H)

SKID QTY

STANDARD SPECIFICATIONS

• Rifled copper tubing, enhanced aluminum fins.

• Immersion-tested at 500 psi, then nitrogen-pressurized and sealed.

• Left- or right-hand refrigerant and plumbing connections.

• Liquid line - 3/8" ODS, suction line - 7/8" ODS.

• Externally mounted flowrater body with Schrader valve for hiss-testing.

• Heavy duty polypropylene drain pans on most models.

• Upflow without field modification. Downflow applications require plate kit,

included.

• ARI certifiable with all brands of A/C and heat pump systems.

• ETL listed for use with both R-22 and R-410a when proper metering device is

used.

• Ten-year limited warranty.

AVAILABLE OPTIONS:

• Factory or field-installable TXV.

• Powder painted stainless steel drain pan.

• Schrader mounted on suction manifold, external to cabinet.

Loading...

Loading...