Page 1

PRODUCT DIMENSIONS & SPECIFICATIONS

ABW SERIES WALL MOUNT HYDRONIC

Representative image only. Some models may vary in

appearance. Due to continuous product improvement,

specifications are subject to change without notice.

HEAT DX COOL AIR HANDLERS

STANDARD FEATURES

APPLICATION VERSATILITY

Front or bottom return air. Offset hanging brackets attach to unit and wall to

allow hanging inside closet. Can be AHRI matched with most brands of air conditioners or heat pumps. ETL listed for use with either R22 or R410a when a

proper metering device is used.

LOW LEAKAGE CABINET

Less than 2% air leakage from cabinet when tested in accordance with

ASHRAE standard 193. Unit must be installed according to Aspen installation

instructions. Sturdy, fully insulated galvanized steel cabinet; stick pins ensure

1/2” insulation remains in place. Unit ships with disposable filter.

MODULAR HYDRONIC HEAT KITS

Heat kits available with either circuit breakers or terminal blocks. Available in 2,

3 & 4 row, providing 16,000 to 59,000 BTU’s of heat. Heat kits are easily installed in the field using molex plugs or can be ordered factory-installed. Freeze

stat is standard, wired into circulating pump control circuit. Controls are accessible from the front for easy service. Electrical connections can be made

from the top or left. Disconnect does not protrude through the wall panel. Fan

time delay relay standard for increased efficiency. Heat kits are available with

or without circulating pump and check valve. Units are provided with auxiliary

relay for remote pump. Schrader ports are standard on water-out manifold,

hose bib available as an option. Totally lead free constructed coil. Suitable for

potable applications.

BLOWER

Direct drive multi-speed blowers circulate air quietly and efficiently. Motor

speeds can be easily selected via motor terminals. Swing mounted blowers

can be easily removed for service.

Phone: 281.441.6500

Toll Free: 800.423.9007

Fax: 281.441.6510

www.aspenmfg.com

ELECTRONIC CONTROL BOARD

An electronic board controls the functioning of the system reducing moving

parts. The board provides for various hot water supply source connections

and the blower time delay to maximize heat/cool extraction. As an enhanced

feature the pump circulates hot water every 6 hours to prevent coil freeze

during off cycle.

DX COIL

High efficiency rifled copper tubes/enhanced aluminum fins provide maximum

heat transfer. All coils immersion tested at 500 psi then nitrogen pressurized and factory sealed for maximum reliability. Liquid-line Schrader allows

pre-installation pressure testing. Available with either check style flowrater or

TXV metering device. Field-installable TXVs are also available. Galvanized metal

drain pan with bottom primary and secondary drain connections or alternate

right side primary. All connections 3/4” FPT. Access door allows for coil cleaning.

WARRANTY

Five-year limited parts warranty.

OPTIONS

See options menu.

* For complete warranty details visit www.aspenmfg.com.

Revised 12/01/17. In keeping with its policy of continuous progress and product improvement, Aspen reserves the right to make changes without notice and incurring obligation. © 2017

Page 2

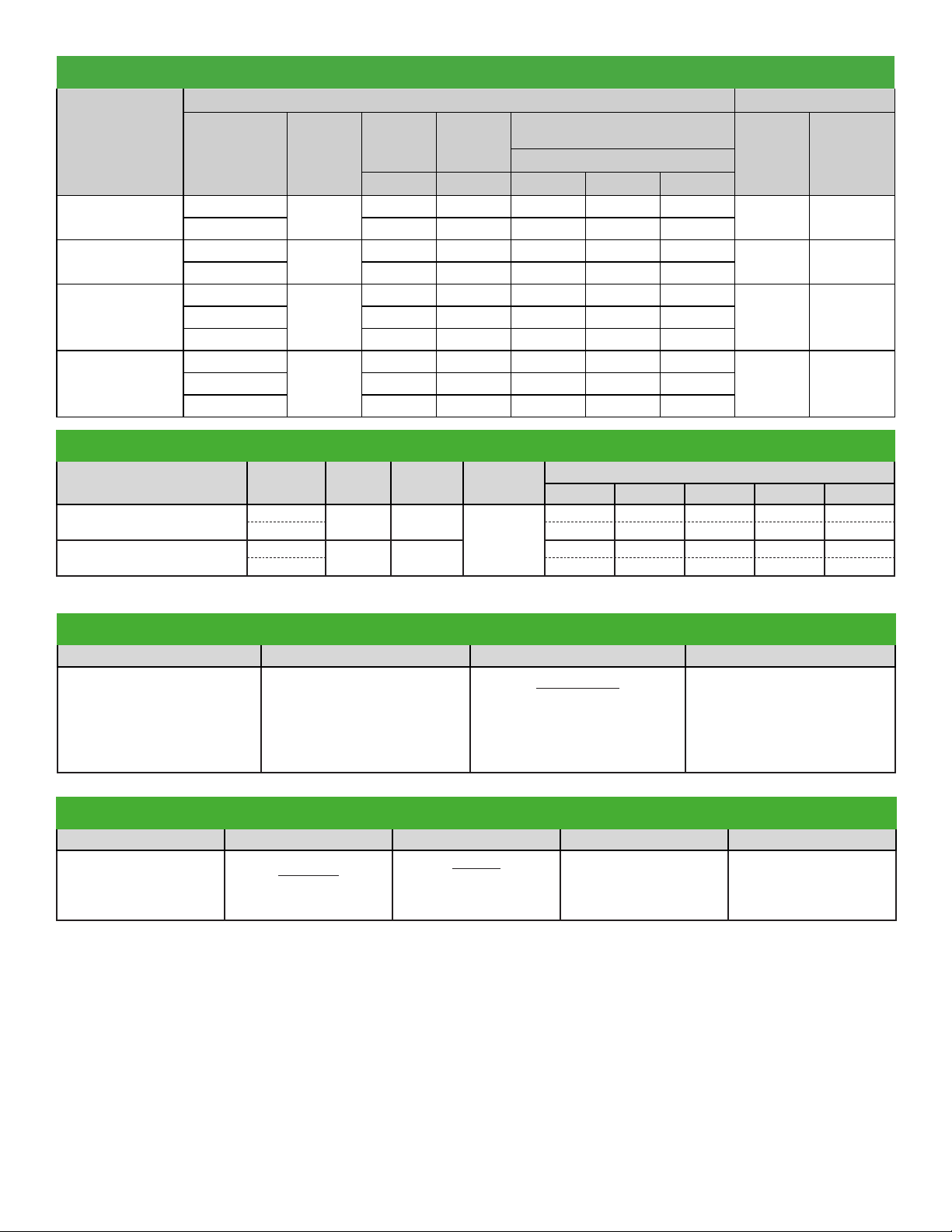

MODEL

ABW 18

ABW 24

ABW 30

ABW 36

ABW18 & ABW 24

ABW30 & ABW36

* Dry coil

UNIT

MODEL

HEATING AND COOLING PERFORMANCE AND ELECTRICAL DATA

PERFORMANCE DATA ELECTRICAL DATA

HYDRONIC HEAT

KIT MODEL

U(C,T)2S(P,L)

U(C,T)3S(P,L) 3 1.8 21,600 30,400 48,500

U(C,T)2S(P,L)

U(C,T)3S(P,L) 3 1.8 24,700 34,800 55,600

U(C,T)2S(P,L)

U(C,T)4S(P,L) 4 1.1 28,300 40,100 64,000

U(C,T)2S(P,L)

U(C,T)4S(P,L) 4 1.1 30,400 43,000 68,800

NOMINAL

COOLING

(BTUS)

18,000

24,000

30,000

36,000

HEATING

COIL

ROW Ft .Water 120º 140º 180º

Hydronic Coil

Delta P.

2 3 18,800 26,600 42,300

2 3 21,000 30,100 48,000

2 3 23,200 32,800 52,500

2 3 24,700 35,000 56,000

Heating Capacity(BTU)

@ 3.5 GPM

ENTERING WATER TEMP

BLOWER DATA

MOTOR

SPEED

LOW

HIGH 829 784 732 663 600

LOW

HIGH 1210 1190 1160 1130 1070

MOTOR HPMOTOR

AMPS

1/5 2.8

1/3 5.4

MOTOR

VOLTAGE

120

0.10 0.20 0.30 0.40 0.50

772 736 690 633 574

1000 980 920 870 800

CFM V. EXTERNAL STATIC*

MINIMUM

CIRCUIT

AMPACITY

(MCA)

MAX BREAKER

OR FUSE SIZE

4.1 15

4.1 15

7.4 15U(C,T)3S(P,L) 3 1.8 27,000 38,200 61,100

7.4 15U(C,T)3S(P,L) 3 1.8 29,900 41,000 65,500

AIR HANDLER CHASSIS NOMENCLATURE

ABW 18 F -001

Metering device

F = R22 Flo-rater

G = R410a Flo-rater

ABW = 120V PSC Motor

Vertical Wall Mount

Nominal tonnage (MBTUH)

4 = non-bleed A/C or H/P R410 TXV

B = 20% bleed A/C or H/P R22 TXV

X = non-bleed A/C or H/P R22 TXV

HYDRONIC HEAT KIT NOMENCLATURE

U C 2 S P

Wall Mount

Hydronic Heat

Interruption

C = Circuit Breaker

T = Terminal Block

# of rows

2 = 2 rows

3 = 3 rows

4 = 4 rows

S = 18 - 36

Option Code

P = with pump

L = less pump

Page 3

DIMENSIONS AND SPECIFICATIONS (In. [mm]) (Fig 1)

3

2

1

MODEL A B C D E

ABW18*

ABW24*

ABW30*

ABW36*

44-1/2

(113)

44-1/2

(113)

44-1/2

(113)

44-1/2

(113)

22

(56)

22

(56)

22

(56)

22

(56)

18-3/4

[48]

18-3/4

[48]

18-3/4

[48]

18-3/4

[48]

17-5/8

(45)

17-5/8

(45)

17-5/8

(45)

17-5/8

(45)

10-1/2

(27)

10-1/2

(27)

10-1/2

(27)

10-1/2

(27)

FILTER

SIZE

20X20 0.055 110 4

20X20 0.059 110 4

20X20 0.068 118 4

20X20 0.074 118 4

PISTON

SIZE

SHIP

WEIGHT

(LBS)

SKID

QTY

Fig 1

INSTALLATION CLEARANCES

OPERATION SERVICE

TOP 0” 0”

FRONT 0” 30”

SIDES 0” 0”

REAR 0” 0”

Fig 2

Note: Code may require installer to use conduit inside

cabinet to electrical enclosure.

9.31"3.31"

1.00" (Primary Drain)

1.48" (Secondary Drain)

DIMENSIONS AND SPECIFICATIONS (Fig 2)

PANEL

MODEL

WAD-9(S/L) ABW Embossed 22 1/4 46 24 1/4 48 24 1/8 47 7/8 1

WAD-10(S/L) ABW Embossed 22 1/4 52 24 1/4 54 24 1/8 53 7/8 1

WAD-16(S/L) ABW Smooth 22 1/4 52 24 1/4 54 24 1/8 53 7/8 1

WAD-17(S/L) ABW Smooth 22 1/4 46 24 1/4 48 24 1/8 47 7/8 1

FOR USE WITH FINISH

OPENING SIZE PANEL DIMENSION FRAME DIMENSION

A” B” C” D” E” F”

# OF

PANELS

Phone: 281.441.6500

Toll Free: 800.423.9007

Fax: 281.441.6510

www.aspenmfg.com

Loading...

Loading...