Aspen Manufacturing AAN, AEN Installation Manual

INSTALLATION GUIDE

AAN & AEN Series - Manufactured Housing

Electric Furnace

1. Safety Instruction

Potential safety hazards are alerted using the following symbols. The symbol is used in conjunction with terms

that indicate the intensity of the hazard.

`

WARNING

!

This symbol indicates a potentially hazardous situation, which if not avoided,

could result in serious injury, property damage, product damage or death.

CAUTION

!

Certied technicians or those individuals

WARNING

!

and product damage or personal injury hazard may occur

without such background.

WARNING

!

age.

WARNING

!

installer’s responsibility to ensure that product is installed

in strict compliance with national and local codes. Manufacturer takes no responsibility for damage (personal, product

or property) caused due to installations violating regulations. In absence of local/state codes, refer to National Electric Code: NFPA 90A & 90B Uniform Mechanical Code.

meeting the requirements specied by

NATE may use this information. Property

All power sources should be disconnected prior to servicing. Failure to do so may

cause personal injury or property dam-

Product designed and manufactured to

permit installation in accordance with local and national building codes. It is the

This symbol indicates a potentially hazardous situation, which if not avoided,

may result in moderate injury or property damage.

2. Inspection

ü On receiving the product, visually inspect it for any major shipping

related damages. Shipping damages are the carrier’s responsibility.

Inspect the product labels to verify the model number and options

are in accordance with your order. Manufacturer will not accept damage claims for incorrectly shipped product.

3. Installation Preparation

Read all the instructions in this guideline carefully while paying special attention to the WARNING and CAUTION alerts. If any of the

instructions are unclear; clarify with certied technicians. Gather all

the tools needed for successful installation of the unit prior to beginning the installation.

3A. Clearances

This unit is designed for zero clearance installation on three sides

and adequate clearance to provide access for service in the front. A

minimum of 18” (alcove) or 6” (closet) clearance is recommended on

the front end (Fig 3A-1).

0”

6”

0”

When this unit is installed in an enclosed

WARNING

!

(i.e. automobile, space heater, water heater etc.) ensure that

the enclosed area is properly ventilated.

CAUTION

!

these instructions. Some localities may require a licensed

installer/service personnel.

WARNING

!

WARNING

!

damages caused due to modication of the unit to operate

with alternative power sources.

# 123117

area, such as a garage or utility room with

any Carbon Monoxide producing devices

Only factory authorized kits and accessories should be used when installing or

modifying this unit unless it is so noted in

Unit is not approved for outdoor installations.

The unit is designed for operation with

208/240 V, single phase, 60 Hz power

supply. Aspen will not be responsible for

6” for Closet

18” for Alcove

Fig 3A-1. Minimum Clearance for Electric Furnace

For closet installation, the return air opening can be on the front door,

above the furnace casing on a wall, or on the electric door’s louvered

door (If applicable.)

A minimum clearance of six inches is required, on the return side, in

order to allow for proper airow.

1

Ensure that the unit is adequately sized.

CAUTION

!

These units are designed to be installed in a closet or an alcove.

If installing the electric furnace into a closet or an alcove, the unit

must leave front clearance to service the unit. The bottom of the unit

should also rest on a sturdy platform or oor.

The tonnage of the outdoor unit should

never exceed the tonnage of this unit.

3C. Ductwork and Duct Connector3B. Closet and Alcove Installation

Duct systems should be installed in accordance with standards for

air-conditioning systems, National Fire Protection Association Pamphlet No. 90A or 90B. They should be sized in accordance with National Environmental System Contractors Association Manual K, or

whichever is applicable. It is recommended that installers refer to

the “Manufactured Housing Duct System Guide to Best Practices”

by MHI-MHRA.

On any job, non-ammable exible collars should be used for the

return air and discharge connections to prevent transmission of vibration. Although these units have been specially designed for quiet,

vibration-free operation, air ducts can act as soundboards if poorly

installed.

All main supply and return air drops should be properly sized as

determined by the designer of the duct system and should not nec-

essarily be the size of the duct ange openings of the unit. (The duct

size should never be smaller than the ange openings of the electric

furnace supply and return air openings.)

To install the duct connector:

- Attach duct connector foam gasket along the perimeter of the duct

opening to seal the duct connector to the top of the duct.

- To connect the duct connector, insert it into the oor opening and

bend back the tabs inside the duct. Fold the tabs over 90 degrees to

ensure a secure connection. Seal around the duct connector.

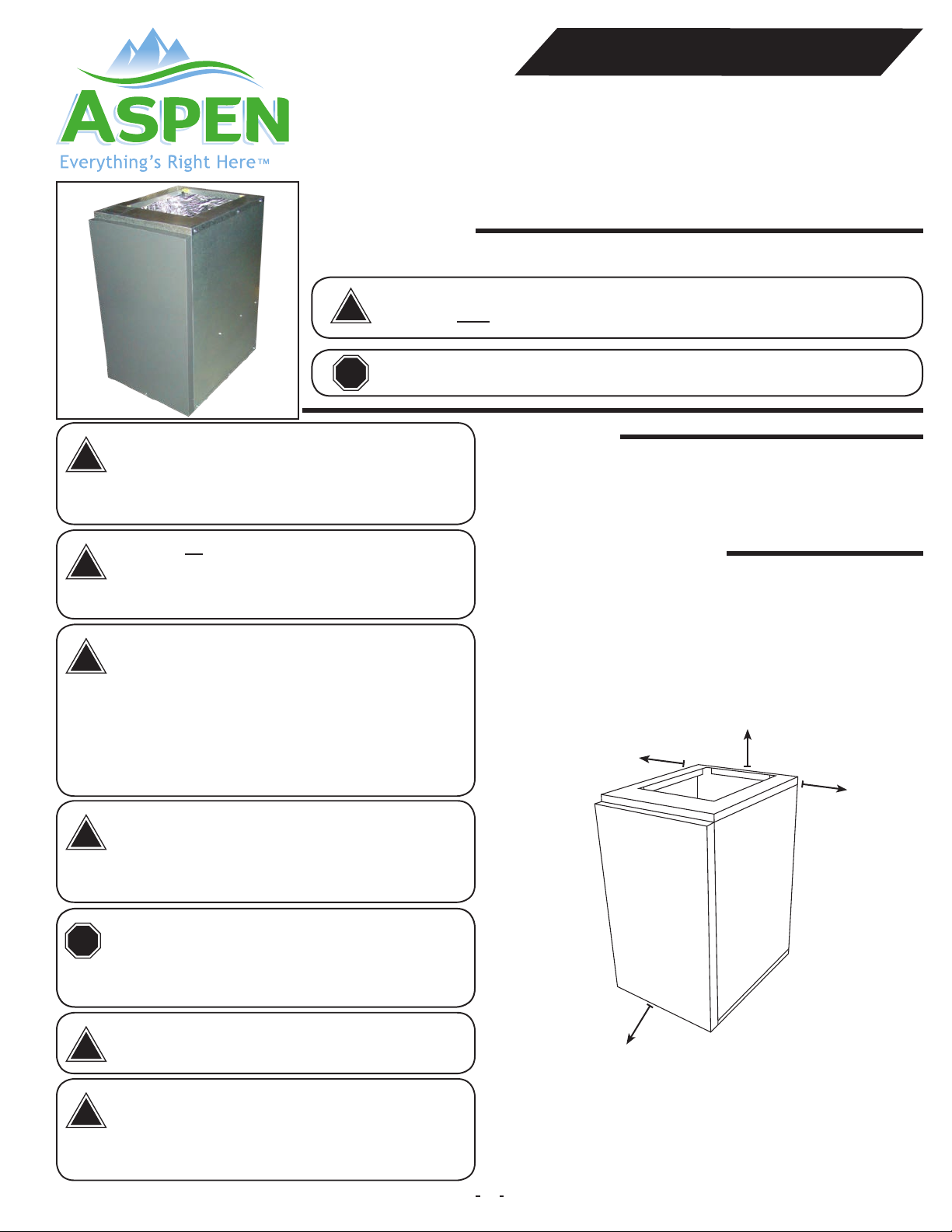

Wall Mount Return Air Grille

Fig 3B-2. Closet Installation

Airow must be made available to the electric furnace’s return. Not

doing so may cause improper heating as well as premature heating

element failure.

Coil

- Slit the corners of the duct connector that stick up above the oor,

and then bend the sides over onto the oor surface.

- Insulate between the oor base and the oor when used on a combustible oor. Be sure to cut the insulation around the perimeter of

the duct connector opening.

- Install the oor base over the oor opening with the anges on the

11 x 13 inch opening facing down.

- Use four screws to secure the oor base to the oor.

It is recommended that wherever supply and return air sheet metal

ducts pass through unconditioned areas, they be insulated to prevent excessive heat loss during heating operation. When applied in

conjunction with summer air conditioning, sheet metal duct routed

through unconditioned areas should be insulated and have an outside vapor barrier to prevent formation of condensation.

4. Electrical Line Voltage Wiring

These units are designed for single or three phase 208/240 volts, 60

HZ power supply. Wire selection and wiring must be in accordance

with the National Electric Code and/or local codes. Unit terminals are

designed to accommodate copper and aluminum wiring. If aluminum

wiring is used: please observe special precautions relative to sizing,

wire connections and corrosion protection.

Wall Mount Return Air Grille

Front of Electric Furnace

Fig 3B-3. Alcove Installation

All models with 5,8 or 10 kW electric heat are arranged for single

circuit connections. Models larger than 10 kW are arranged for multicircuit protection. Refer to top part of wiring diagram at the end of this

guide for detailed information.

2

# 123117

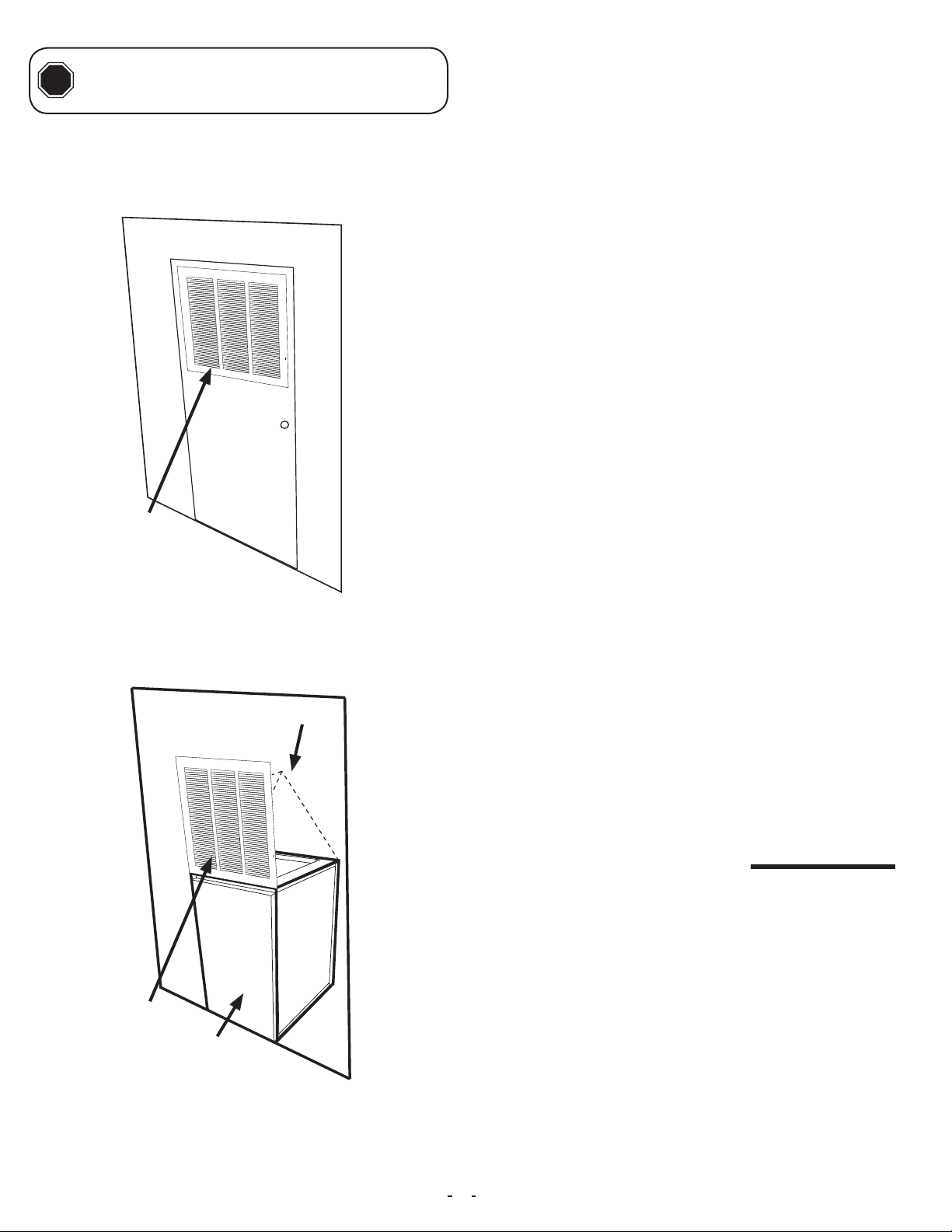

Line voltage wiring should be

routed through the access holes

at the top of the electric furnace. Proper electrical conduit

connection ttings should be

used. Connect the power wiring

to the line side connections on

the electric furnace. The electrical ground wire should be connected to the grounding lug.

Ensure both the eld supplied

ground wire and electric furnace

GREEN ground wire are both

secured to the grounding lug of

the electric furnace.

208VAC

Tap

240VAC

Tap

If the line voltage being supplied to the electric furnace is

208 volt single phase, the line

voltage tap on the low voltage

transformer needs to be moved

from the 240 volt tap to the 208

volt tap. If this is not done, the

secondary output voltage of the

transformer will be too low.

5. Low Voltage Connections

5A. Single Stage Cooling with Electric Heat

The electric furnace comes factory setup for a single stage cooling system. If factory installed accessory electric heaters are preinstalled, the unit will also have a low voltage wire for the electric heat

(Fig 5A-1).

Fig 5A-2.

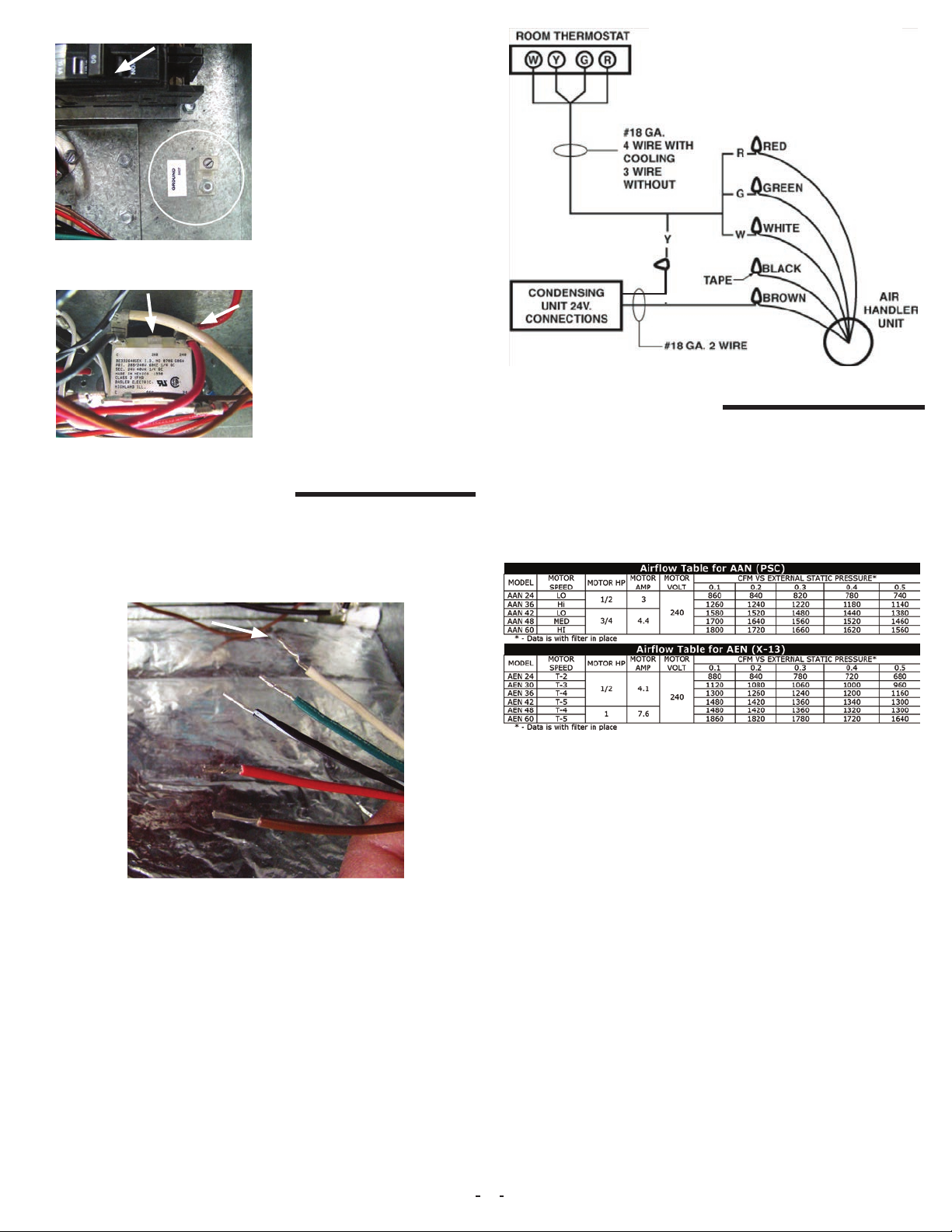

6. Air Volume Adjustment

Air volume needs to be set to the level recommended by the outdoor

unit equipment manufacturer. Most systems will require around 400

CFM of indoor air for every 1 ton of system cooling capacity. The air

volume must be set prior to attempting system charge.

This electric furnace uses a 240V PSC motor. The air volume level

produced by the electric furnaces at varying external static pressure

levels is shown in Table 6-1.

Fig 5A-1.

During cooling mode operation, the indoor blower G wire will energize a time delay relay inside the electric furnace. After a short time

delay period, the time delay relay contacts will close and apply power

to the blower motor. Fan delay periods are 7 seconds ON delay and

65 seconds OFF delay. (See Schematic)

The Y wire from the thermostat is not connected at the electric furnace. This wire goes directly to the outdoor unit 24 volt wiring to turn

on the outdoor condensing unit when a call for cooling takes place.

The 24 volt common for the outdoor unit circuits is connected at the

electric furnace Brown wire.

The electric heater low voltage wiring W terminal is wired directly

from the thermostat to the electric furnace. The blower will delay a

heat call ON for a period of 5 seconds. The OFF delay period is 60

seconds.

Table 6-1.

Use a Magnehelic Gauge with a 1” scale and two static pressure

tips to measure the static pressure during the air volume adjustment

procedure. The high port static pressure tip should be placed in the

supply duct near the outlet of the electric furnace. The low port static

pressure tip should be placed in the return air duct near the entrance

to the electric furnace. The factory provided air lter should be in

place inside of the electric furnace.

1. Select a starting speed tap from the CFM table.

2. Call for fan only operation at the thermostat.

3. Read the external static pressure level on the Magnehelic gauge.

4. Make speed tap selection changes to get the air volume as close

as possible to the required level.

5. If the static pressure is above .5” wc , excessive turbulence or duct

friction needs to be reduced. (Obstructions in the duct system can

also cause excessive static pressure.)

6. When proper air volume is established, move on to the charging

procedure.

# 123117

3

Loading...

Loading...