Page 1

Aspect Medical Systems

TM

A-2000

BISPECTRAL INDEX

(BIS

) MONITORING SYSTEM

S E R V I C E M A N U A L

Caution:

U.S. Federal law restricts this device

to sale by or on the order of a physician.

© Copyright, 1999, Aspect Medical Systems. All rights reserved. Copying or other reproduction of

this document is prohibited without prior written consent of Aspect Medical Systems.

2 Vision Drive

Natick, MA 01760-2059

U.S.A.

508-653-0603

800-442-7688

bis_info@aspectms.com

www.aspectms.com 075-0002 1.00

Aspect Medical Systems, Inc.

Page 2

TABLE OF CONTENTS

1. INTRODUCTION .............................................................................. 1-1

1.1 ABOUT THIS MANUAL ....................................................................................1-1

1.2 INTRODUCING THE A-2000 BIS MONITORING SYSTEM ............................. 1-2

1.2.1 Principal Components ................................................................................1-2

1.2.2 How The A-2000 Works .............................................................................1-3

1.3 INSTRUMENT IDENTIFICATION .....................................................................1-3

1.3.1 A-2000 Monitor ...........................................................................................1-3

1.3.2 A-2000 Digital Signal Converter .................................................................1-3

1.3.3 Software Revision Numbers .......................................................................1-3

1.4 PROPRIETARY INFORMATION AND DEVICES.............................................1-3

2. SAFETY PRECAUTIONS................................................................. 2-1

2.1.1 WARNINGS, CAUTIONS, AND NOTES .................................................... 2-1

2.1.2 Warnings: ...................................................................................................2-1

2.1.3 Cautions: ....................................................................................................2-3

2.2 KEY TO SYMBOLS ..........................................................................................2-5

3. PRINCIPLES OF OPERATION........................................................ 3-1

3.1 SYSTEM ARCHITECTURE............................................................................... 3-1

3.1.1 The Digital Signal Converter (DSC)............................................................3-1

3.1.2 The A-2000 Monitor....................................................................................3-7

3.1.3 A-2000 Printer ............................................................................................3-8

4. PREPARATION FOR USE AND INSTALLATION ........................... 4-1

4.1 ENVIRONMENT ................................................................................................4-1

4.1.1 Shipping and Storage Environment............................................................4-1

4.1.2 Operating Environment...............................................................................4-1

4.1.3 Power Requirements and System Grounding ............................................4-2

4.1.4 Site Preparation..........................................................................................4-2

4.2 INSTRUMENT CONNECTIONS .......................................................................4-3

4.2.1 Digital Signal Converter Connections.........................................................4-3

4.2.2 Power Cord Connections............................................................................4-3

4.2.3 Printer Connector .......................................................................................4-3

4.3 INSTALLATION AND VERIFICATION PROCEDURE .....................................4-4

4.4 REPACKAGING FOR SHIPPING AND STORAGE.......................................... 4-4

Page 3

5. PREVENTIVE MAINTENANCE, CARE AND CLEANING ............... 5-1

5.1 CARE AND CLEANING ....................................................................................5-1

5.1.1 Cleaning the Monitor and Digital Signal Converter.....................................5-1

5.1.2 Disinfecting the Monitor and Digital Signal Converter ................................5-1

5.1.3 Cleaning the Monitor Display......................................................................5-1

5.2 ROUTINE MAINTENANCE ...............................................................................5-2

5.2.1 Checking the Battery ..................................................................................5-2

5.2.2 Checking Leakage Current.........................................................................5-2

5.2.3 Monitor System Checkout Procedure.........................................................5-4

5.2.4 DSC Checkout Procedure ..........................................................................5-5

5.2.5 Patient Interface Cable (PIC) Checkout Procedure....................................5-5

6. DIAGNOSTICS AND TROUBLESHOOTING................................... 6-1

6.1 GENERAL TROUBLESHOOTING.................................................................... 6-1

6.2 THE A-2000 DIAGNOSTIC PROCEDURES.....................................................6-4

6.2.1 Power-Up Diagnostics ................................................................................6-4

6.2.2 Automatic Diagnostics ................................................................................6-8

6.2.3 Manual Diagnostics ..................................................................................6-13

7. DISASSEMBLING AND REASSEMBLING THE A-2000................. 7-1

7.1 REQUIRED TOOLS AND SUPPLIES...............................................................7-2

7.2 THE MONITOR CASE.......................................................................................7-3

7.2.1 Opening the Monitor Case..........................................................................7-3

7.2.2 Closing the Monitor Case ...........................................................................7-3

7.3 THE ELECTRO/LUMINESCENT DISPLAY......................................................7-7

7.3.1 Removing the E/L Display Board................................................................7-7

7.3.2 Reattaching the E/L Display Board.............................................................7-7

7.4 THE FRONT PANEL SWITCH SET..................................................................7-9

7.4.1 Removing the Switch Set ...........................................................................7-9

7.4.2 Installing the New Switch Set .....................................................................7-9

7.5 THE PRINTED CIRCUIT BOARD ASSEMBLY ..............................................7-11

7.5.1 Removing the Printed Circuit Board assembly ......................................... 7-11

7.5.2 Installing the Printed Circuit Board Assembly...........................................7-11

7.6 THE MAIN PCB...............................................................................................7-14

7.6.1 Removing the Main PCB ..........................................................................7-14

7.6.2 Installing the Main PCB ............................................................................7-14

7.7 THE POWER SUPPLY PCB ...........................................................................7-19

7.7.1 Removing the Power Supply PCB............................................................7-19

7.7.2 Installing the Power Supply PCB..............................................................7-19

Page 4

7.8 THE BATTERY................................................................................................ 7-22

7.8.1 Removing the Battery ...............................................................................7-22

7.8.2 Installing the Battery .................................................................................7-22

7.9 THE FAN .........................................................................................................7-24

7.9.1 Removing the Fan ....................................................................................7-24

7.9.2 Installing the Fan ......................................................................................7-24

7.10 THE CLAMP SHOE ASSEMBLY.................................................................... 7-26

7.10.1 Removing the Clamp Shoe Assembly ...................................................... 7-26

7.10.2 Installing the Clamp Shoe Assembly ........................................................ 7-26

7.11 FUSE REPLACEMENT...................................................................................7-27

8. A-2000 SPECIFICATIONS.............................................................. 8-1

8.1 GENERAL SPECIFICATIONS:.........................................................................8-1

8.1.1 Type of Protection against Electric Shock of the System: .......................... 8-3

8.1.2 Degree of Protection against Electric Shock of the System: ......................8-3

8.1.3 Degree of Protection against the Ingress of Water: ...................................8-3

8.1.4 Mode of Operation of the System:..............................................................8-3

8.1.5 Classification: .............................................................................................8-3

8.2 OPTIONS AND ACCESSORIES:......................................................................8-3

8.3 Digital Signal Converter (DSC) Connector....................................................8-4

8.4 WARRANTY......................................................................................................8-5

9. APPENDICES .................................................................................. 9-1

9.1 APPENDIX I - A-2000 PARTS LIST................................................................ 9-1

9.2 APPENDIX II - SENSOR SIMULATOR - INSTRUCTIONS FOR USE ...........9-2

Page 5

TABLE OF FIGURES

Figure 1-1 The A-2000 BIS Monitoring System................................................................1-4

Figure 1-2 Rear View of Monitor .....................................................................................1-5

Figure 3-1 The A-2000 System Block Diagram................................................................3-2

Figure 3-2 The A-2000 Signal Flow Diagram...................................................................3-3

Figure 3-3 The Digital Signal Converter (DSC)................................................................3-6

Figure 7-1 Opening the Monitor Case............................................................................7-5

Figure 7-2 The E/L Display Cable ...................................................................................7-5

Figure 7-3 The Keypad Cable Tension Flange ...............................................................7-6

Figure 7-4 The Four Mounting Screws............................................................................7-8

Figure 7-5 The Cable Access Port ................................................................................7-10

Figure 7-6 Remove the covering on the back of the new switch set.............................7-10

Figure 7-7 Place rear case assembly face down on a scratch free work surface.........7-13

Figure 7-8 Fan Cable ....................................................................................................7-13

Figure 7-9 Release standoff tab by squeezing with needle-nose pliers........................7-15

Figure 7-10 The L bracket.............................................................................................7-15

Figure 7-11 Gently pull and flex to separate PCBs .......................................................7-16

Figure 7-12 Line up Interconnect PCB pins to Main PCB socket..................................7-16

Figure 7-13 Align standoffs and push in until standoff tabs snap into place .................7-17

Figure 7-14 Install L bracket by holding long side; short side connects to Main PCB...7-17

Figure 7-15 The L Bracket Installed ..............................................................................7-18

Figure 7-16 Gently flex and pull Power Supply PCB free of pins ..................................7-20

Figure 7-17 Remove four screws on rear of Power Supply PCB..................................7-20

Figure 7-18 Remove shield from rear of Power Supply PCB........................................7-21

Figure 7-19 Battery and cable.......................................................................................7-23

Figure 7-20 Fan wiring orientation and Clamp Shoe screws ........................................7-25

Figure 7-21 Updated System with 2 Fan Mounting screws and Copper Tape..............7-25

Figure 7-22 Releasing the plastic locking tabs of the fuse holder.................................7-28

Figure 7-23 Re-installing the fuse holder ......................................................................7-28

Page 6

SECTION I INTRODUCTION

SECTION I

1.

INTRODUCTION

1.1

This Service Manual contains information necessary to diagnose, troubleshoot and repair

the Aspect Medical Systems A-2000™ BIS Monitoring System. Also included are

instructions for the unit’s installation, maintenance, care and cleaning. A parts list is

provided in the appendices at the back of the manual.

This manual is intended for Aspect Medical Systems service technicians and/or

authorized Aspect distributors who have been trained by Aspect to perform the service

procedures described within this manual. It assumes prior knowledge and experience

with the internal workings of medical devices and electronics.

Section I provides a functional overview of the A-2000, its principal components, and

instrument identification.

Section II discusses important safety precautions. Before attempting to set up or service

the A-2000, please familiarize yourself with the safety information provided in this section.

Section III describes the A-2000 monitor hardware and how it operates. Included are the

assemblies and parts that make up the monitor and the Digital Signal Converter (DSC).

Section IV provides preparation for use and installation instructions, including

environmental considerations, instrument connections and system setup and check out.

Section V describes normal maintenance, care and cleaning procedures.

Section VI describes the A-2000 diagnostic tools and provides tables to aid in

troubleshooting the system.

Section VII describes the removal and replacement procedure for each subassembly.

Section VIII contains the A-2000 specifications.

Appendix I contains a list of replaceable parts and subassemblies.

Appendix II contains the Sensor Simulator instructions for use.

ABOUT THIS MANUAL

Caution:

Refer to the section on disassembling and reassembling before

attempting to service the inside of the A-2000.

Note:

This manual was not designed for repairing the unit to the level of its

individual components (e.g. the chips on the main board). The manual is

intended solely for the troubleshooting and replacement of its

subassembly modules (e.g. the electro-luminescent display and power

supply).

- 1-1 -

Page 7

SECTION I INTRODUCTION

1.2

Aspect Medical Systems A-2000 BIS Monitoring System is a user-configurable patient

monitoring system designed to monitor the hypnotic state of the brain based on

acquisition and processing of EEG signals. The A-2000 processes raw EEG signals to

produce a single number, called the Bispectral Index, or BIS, which correlates to the

patient’s level of hypnosis. It operates from an AC power source of 100V to 240V,

47/63Hz, and provides a minimum 20 minutes of automatic back-up battery power.

The monitor is menu-driven with fixed keys for choosing the options available.

1.2.1

The system is composed of a monitor and a digital signal converter, with a patient

interface cable (PIC), and BIS Sensor.

1.2.1.1 Monitor

The monitor contains the operator control panel, an electro-luminescent display screen,

and connectors for the digital signal converter and printer.

Front Panel Controls:

INTRODUCING THE A-2000 BIS MONITORING SYSTEM

Principal Components

The [SILENCE] key toggles audible alarms on and off.

The left [←] and right [→] arrow keys are used to enter Review

mode and to scroll data back and forth while in Review mode.

The [MENU/EXIT] key is used to enter and exit the Setup Menu.

In Review mode it will return the user to the main screen. It is

also used to halt certain procedures, such as the sensor check,

and to answer "no" to a question.

The up [↑] and down [↓] arrows are used to move from one

menu selection to another.

The [SELECT] key is used to move between menu selections, to

confirm an entry, and to answer "yes" to a question.

- 1-2 -

Page 8

SECTION I INTRODUCTION

1.2.1.2 Digital Signal Converter (DSC)

The Digital Signal Converter is about the size of a computer mouse. It contains the EEG

amplifiers and analog filters. The DSC digitizes EEG waveforms for transmission to, and

processing by, the monitor. The DSC’s long flexible Monitor Interface Cable connects to

the front of the monitor, and the shorter “DSC pigtail” cable connects to the Patient

Interface Cable (PIC).

The attachment clip on the DSC is used to secure it in a convenient location near the

patient’s head. The patient connection is accomplished by attaching the Aspect BIS

Sensor to the PIC.

1.2.2

A detailed description of how the A-2000 works is contained within Section V of the A2000 Operating Manual and will not be discussed in this Service Manual. Please refer to

the A-2000 Operating Manual (070-0015) for additional information.

1.3

1.3.1

Monitor identification information is permanently marked on the rear panel. This

information includes instrument model and serial numbers, power ratings, cautions, and

the Aspect Medical Systems shipping address.

1.3.2

The A-2000 Digital Signal Converter identification information is permanently marked on

the rear panel of the Digital Signal Converter. This information includes instrument model

and serial numbers and cautions.

1.3.3

Software revision numbers are displayed in the Diagnostic Menu.

1.4

Information and descriptions contained in this guide are the property of Aspect Medical

Systems and may not be copied, reproduced or distributed without prior written

permission. Portions of the A-2000 design are proprietary and are the subject of patents

and patents pending.

How The A-2000 Works

INSTRUMENT IDENTIFICATION

A-2000 Monitor

A-2000 Digital Signal Converter

Software Revision Numbers

PROPRIETARY INFORMATION AND DEVICES

- 1-3 -

Page 9

SECTION I INTRODUCTION

Figure 1-1 The A-2000 BIS Monitoring System

- 1-4 -

Page 10

SECTION I INTRODUCTION

Potential

Equalization

Terminal

Clamp

Shoe

Fuse

Holder

Serial

Port

Figure 1-2 Rear View of Monitor

- 1-5 -

Page 11

SECTION I INTRODUCTION

- 1-6 -

Page 12

SECTION II SAFETY PRECAUTIONS

SECTION II

2.

SAFETY PRECAUTIONS

INTRODUCTION

Caution:

Carefully read the entire A-2000 Operating Manual before using the monitor in a

clinical setting.

2.1.1

The terms warning, caution, and note have specific meanings in this manual.

• A WARNING advises against certain actions or situations that could result in personal

• A CAUTION advises against actions or situations that could damage equipment,

• A NOTE provides useful information regarding a function or procedure.

KEY TO SYMBOLS

A key to the symbols used on the A-2000 appears at the end of this section.

2.1.2

EXPLOSION HAZARD: DO NOT USE THE A-2000 IN A FLAMMABLE ATMOSPHERE

OR WHERE CONCENTRATIONS OF FLAMMABLE ANESTHETICS MAY OCCUR.

FOR PROPER GROUNDING, THE POWER RECEPTACLE MUST BE A THREE-WIRE

GROUNDED OUTLET. A HOSPITAL GRADE OUTLET IS REQUIRED. NEVER

ADAPT THE THREE-PRONG PLUG FROM THE MONITOR TO FIT A TWO-SLOT

OUTLET. IF THE OUTLET HAS ONLY TWO SLOTS, MAKE SURE THAT IT IS

REPLACED WITH A THREE-SLOT GROUNDED OUTLET BEFORE ATTEMPTING TO

OPERATE THE MONITOR.

IF THE INTEGRITY OF THE EXTERNAL PROTECTIVE EARTH GROUND IS IN

DOUBT, THE A-2000 SHALL BE OPERATED FROM ITS INTERNAL BATTERY

POWER SOURCE ONLY.

GROUND WIRE LEAKAGE CURRENT MUST BE CHECKED WHENEVER

INSTRUMENT CASE IS OPENED BY A QUALIFIED BIOMEDICAL ENGINEERING

TECHNICIAN.

ELECTRICAL SHOCK HAZARD: THE MANUFACTURER’S INSPECTION OF THIS

APPARATUS VERIFIED THAT THE GROUND LEAKAGE CURRENT AND THE

PATIENT SAFETY CURRENT WERE LESS THAN THE SPECIFIED LIMITS

ESTABLISHED BY THE APPLICABLE SAFETY STANDARDS. AS A MATTER OF

SAFE PRACTICE, THE INSTITUTION SHOULD CONDUCT PERIODIC TESTS TO

VERIFY THESE CURRENTS. WHENEVER AN EVENT SUCH AS SPILLAGE OF

BLOOD OR SOLUTIONS OCCURS, RE-TEST BEFORE FURTHER USE.

WARNINGS, CAUTIONS, AND NOTES

injury or death.

produce inaccurate data, or invalidate a procedure, although personal injury is

unlikely.

Warnings:

- 2-1 -

Page 13

SECTION II SAFETY PRECAUTIONS

UNIVERSAL PRECAUTIONS SHALL BE OBSERVED TO PREVENT CONTACT WITH

BLOOD OR OTHER POTENTIALLY INFECTIOUS MATERIALS. PLACE

CONTAMINATED MATERIALS IN REGULATED WASTE CONTAINER.

DO NOT MIX DISINFECTING SOLUTIONS (e.g. BLEACH AND AMMONIA) AS

HAZARDOUS GASES MAY RESULT.

ELECTRICAL SHOCK HAZARD: DO NOT REMOVE MONITOR COVERS DURING

OPERATION OR WHILE POWER IS CONNECTED TO MONITOR.

FOR CONTINUED PROTECTION AGAINST FIRE OR DAMAGE, ALWAYS REPLACE

OLD FUSE WITH THE SAME FUSE TYPE AND RATING.

ANY PROCEDURES THAT REQUIRE THE REMOVAL OF THE MONITOR’S COVER

AND INTERNAL PARTS SHOULD BE PERFORMED BY A QUALIFIED BIOMEDICAL

ENGINEERING TECHNICIAN. POWER OFF THE UNIT USING THE POWER SWITCH.

UNPLUG THE MONITOR BEFORE DISASSEMBLING/ REASSEMBLING THE

A-2000.

IF METAL COMES IN CONTACT WITH THE TERMINALS ON THE BATTERY, IT

COULD RESULT IN PERMANENT DAMAGE TO THE BATTERY AND IS AN

ELECTRICAL SHOCK HAZARD.

DUE TO THE BATTERY OPERATION POSSIBLE WITH NO AC CONNECTED,

EXTREME CARE MUST BE USED WHEN DISASSEMBLING AND ASSEMBLING THE

A-2000 MONITOR. WITH AC DISCONNECTED AND BATTERY POWER ON, HIGH

VOLTAGE IS PRESENT ON THE E/L DISPLAY AND POWER SUPPLY PCB. DO NOT

ACTIVATE POWER ON SWITCH WITH CASE OPEN!

SHOCK HAZARD: DO NOT ATTEMPT TO DISCONNECT THE POWER CORD WITH

WET HANDS. MAKE CERTAIN THAT YOUR HANDS ARE CLEAN AND DRY BEFORE

TOUCHING THE POWER CORD.

FOR A-2000s USED OUTSIDE OF NORTH AMERICA: A HARMONIZED LINE CORD

WITH CONDUCTORS HAVING A CROSS SECTIONAL AREA GREATER THAN 0.75

MM2 MUST BE USED.

THE CONDUCTIVE PARTS OF ELECTRODES OR SENSOR AND CONNECTORS,

INCLUDING THE NEUTRAL ELECTRODE, SHOULD NOT CONTACT OTHER

CONDUCTIVE PARTS INCLUDING EARTH.

TO REDUCE THE HAZARD OF BURNS IN THE HIGH FREQUENCY SURGICAL

NEUTRAL ELECTRODE CONNECTION, THE SENSOR OR ELECTRODES SHOULD

NOT BE LOCATED BETWEEN THE SURGICAL SITE AND THE ELECTRO-SURGICAL

UNIT RETURN ELECTRODE.

TO MINIMIZE THE RISK OF PATIENT STRANGULATION, THE PATIENT INTERFACE

CABLE (PIC) MUST BE CAREFULLY PLACED AND SECURED.

BE SURE MONITOR IS MOUNTED SECURELY IN PLACE TO AVOID PERSONAL

INJURY.

- 2-2 -

Page 14

SECTION II SAFETY PRECAUTIONS

WHEN CONNECTING EXTERNAL EQUIPMENT (e.g. DATA CAPTURE COMPUTER),

THE SYSTEM LEAKAGE CURRENT MUST BE CHECKED AND MUST BE LESS

THAN THE IEC601-1-1 LIMIT.

THE USE OF ACCESSORY EQUIPMENT NOT COMPLYING WITH THE EQUIVALENT

SAFETY REQUIREMENTS OF THIS EQUIPMENT MAY LEAD TO A REDUCED LEVEL

OF SAFETY OF THE RESULTING SYSTEM. CONSIDERATION RELATING TO THE

CHOICE SHALL INCLUDE:

• USE OF THE ACCESSORY IN THE PATIENT VICINITY;

• EVIDENCE THAT THE SAFETY CERTIFICATION OF THE ACCESSORY HAS

BEEN PERFORMED IN ACCORDANCE TO THE APPROPRIATE IEC 601-1

AND/OR IEC 601-1-1 HARMONIZED NATIONAL STANDARD.

FAN WIRE MUST BE POSITIONED AS SHOWN IN FIG. 7-21. INCORRECT ROUTING

OF FAN WIRE MAY RESULT IN A HAZAROUS CONDITION.

2.1.3

Cautions:

U.S. Federal law restricts this device to sale by or on the order of a physician.

Refer to the section on disassembling and reassembling before attempting to

service the inside of the A-2000.

Carefully read the entire A-2000 Operating Manual before using the monitor in a

clinical setting.

Periodically check the battery by operating an A-2000 that has been disconnected

from the wall socket and which has been charging the battery for at least four

hours. After long periods of storage (e.g. > 1 month) it may be necessary to cycle

(discharge, then charge) the battery a few times to get full charge capacity. If the A2000 fails to operate reliably from the battery for twenty minutes, battery

replacement is required.

The A-2000 contains an internal Nickel-Metal-Hydride battery. The battery must be

removed by a qualified service technician and disposed of or recycled in

accordance with the national laws of the country. Contact Aspect Medical Systems,

Inc. or the local distributor for a replacement battery.

A burned out fuse usually indicates a serious problem with the electrical system of

the A-2000 unit. Call service before attempting to remove and replace a fuse.

If metal comes in contact with the battery terminals, permanent damage to the

battery and other connecting parts could result.

Do not autoclave the Digital Signal Converter or Monitor. Autoclaving will seriously

damage both components.

Do not submerge.

Do not block fan output. Keep at least three full inches of unobstructed space

between rear of instrument and wall and other instruments. Do not allow other

instruments to block airflow. Do not block ventilation inlet holes on the underside

of monitor.

- 2-3 -

Page 15

SECTION II SAFETY PRECAUTIONS

Do not open Digital Signal Converter for any reason. The seal to prevent liquids

from entering the Digital Signal Converter may be damaged if opened. Service or

repairs must be performed only by qualified biomedical technicians.

The A-2000 has been designed to operate with a disposable BIS Sensor. The

sensor is a silver/silver chloride electrode array that utilizes Aspect’s patented

Zipprep

electrodes may result in intermittent loss of signal or poor signal quality.

Continuous impedance checking may need to be disabled if the 1 nanoampere 128

Hz impedance check signal interferes with other equipment, e.g., evoked potential

monitors.

VERY IMPORTANT! Use only the Loctite number specified. Using the incorrect

Loctite will damage plastic components.

Use only the parts and tools specified. Use of any others may damage the

instrument.

Failure to position E/L Display screen gasket properly may result in a monitor that

will allow fluid to leak in when the display is cleaned.

Replace battery only with same type of approved battery. Use of non-approved

battery may result in incorrect operation or damage to the monitor.

technology and uses a proprietary connector. Use of incorrect types of

A-2000 is a trademark and Bispectral Index, BIS and Zipprep are registered trademarks

of Aspect Medical Systems, Inc.

- 2-4 -

Page 16

SECTION II SAFETY PRECAUTIONS

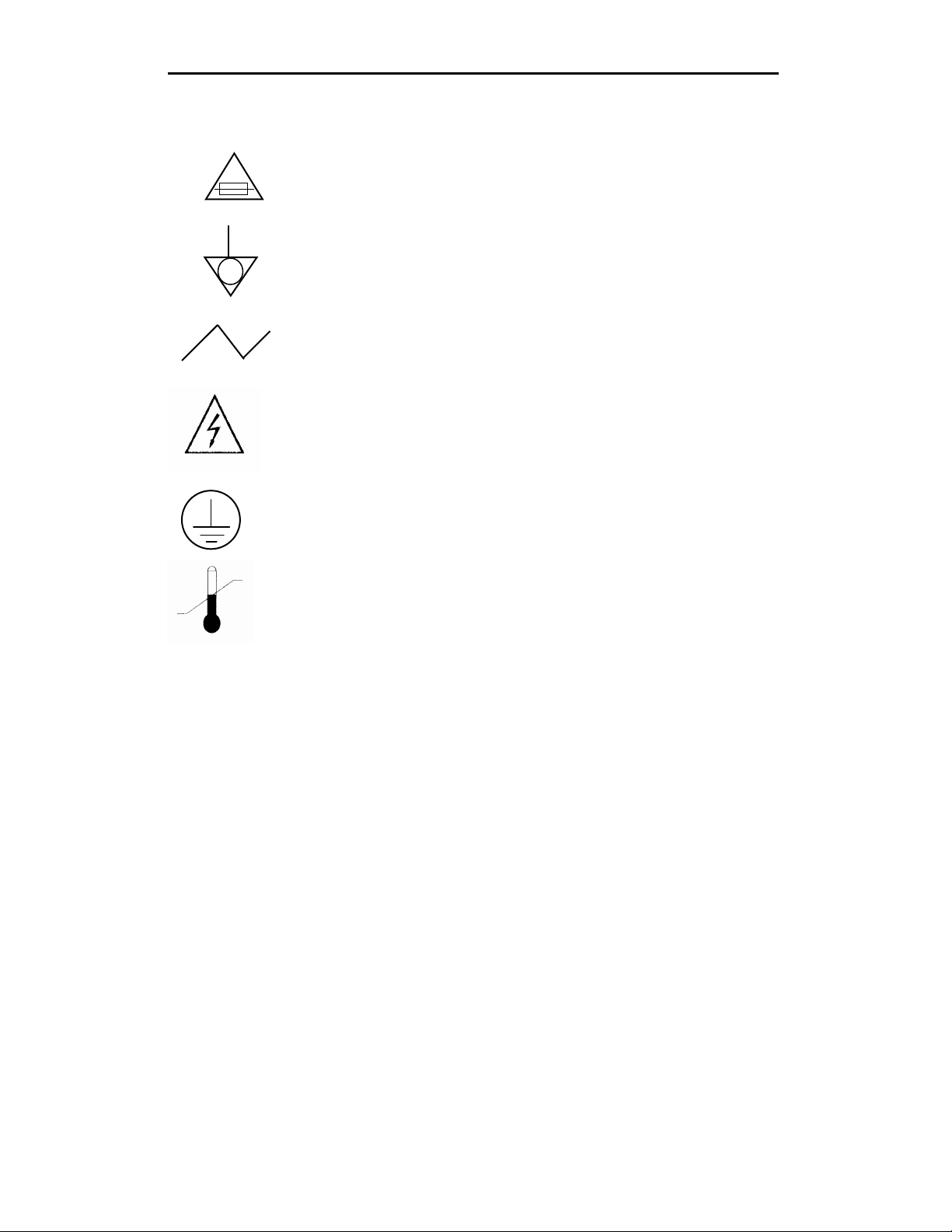

2.2

KEY TO SYMBOLS

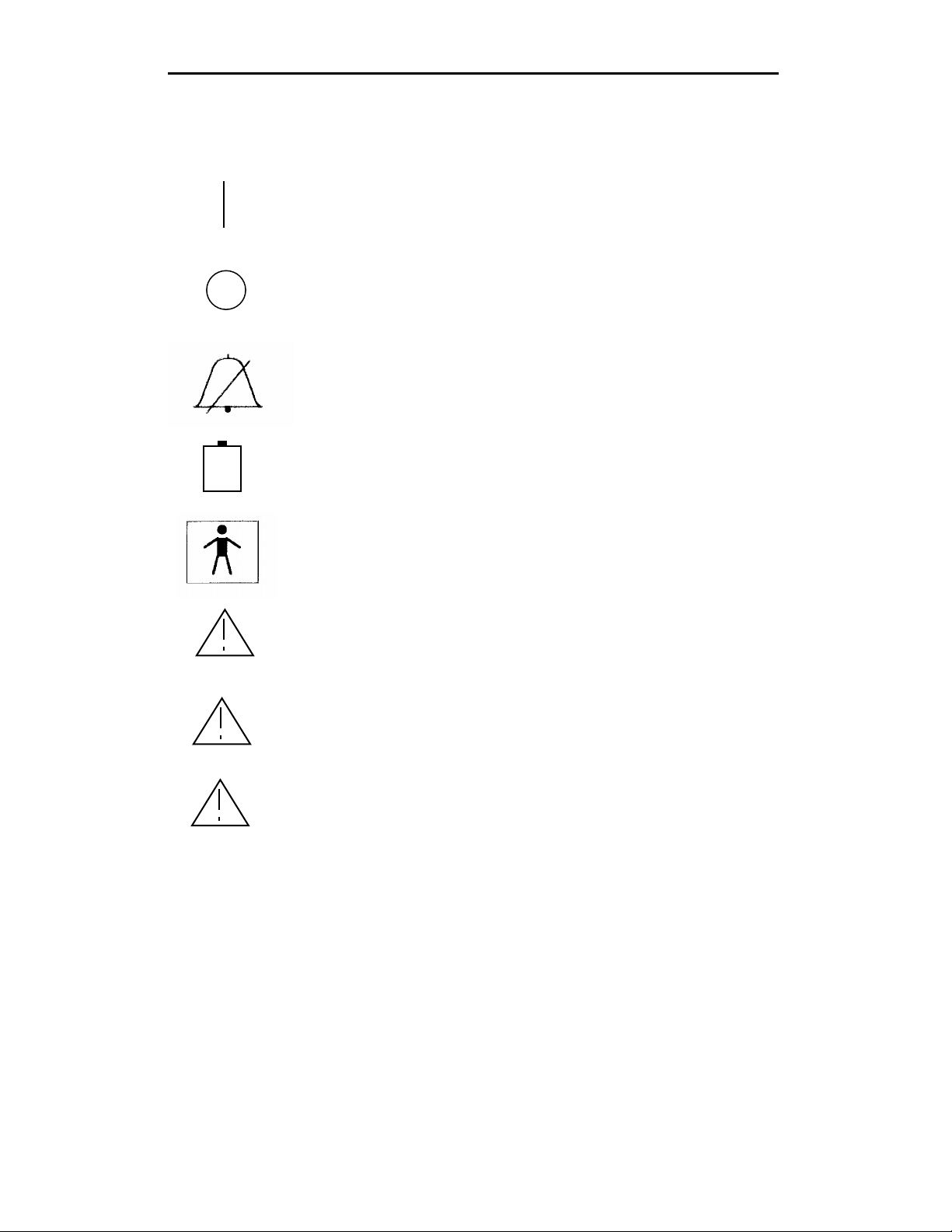

ON (power; connection to the mains)

OFF (power; disconnection from the mains)

Audible Alarm Silenced

Operating on Battery

Type BF Equipment

J1

J2

Attention, Consult Accompanying Documents

Attention, J1 RS-232 Serial Port, Consult

Accompanying Documents

Attention, J2 Printer Port, Consult Accompanying

Documents

- 2-5 -

Page 17

SECTION II SAFETY PRECAUTIONS

Fuse, Replace only with same Type and Rating

Equipotential

Alternating Current

Dangerous Voltage

Protective Earth (ground)

Storage Temperature Limits

- 2-6 -

Page 18

SECTION III PRINCIPLES OF OPERATION

SECTION III

3.

PRINCIPLES OF OPERATION

The A-2000 BIS Monitoring System consists of:

• The BIS monitor with built-in battery backup and detachable power cord

• The Digital Signal Converter (DSC)

• Aspect’s BIS Sensor Patient Interface Cable (PIC) and BIS Sensor

This section describes the architecture of the A-2000 monitor and DSC and how their

constituent parts interact.

3.1

SYSTEM ARCHITECTURE

Hardware is divided into two main components: the monitor and the digital signal

converter (DSC). The A-2000 monitor contains the circuits for digitally processing the

EEG data, computing the processed parameters, and displaying the waveforms and

processed parameters. The circuits to acquire and digitize the EEG signals reside in the

Digital Signal Converter (DSC).

The monitor also contains the circuits for powering the monitor, DSC, and companion

printer. Integral to these circuits is a battery backup. Printer function is not available

while on battery backup.

A block diagram depicting the monitor subassemblies appears in Figure 3-1. A signal flow

diagram appears in Figure 3-2.

After passing through input protection circuits in the DSC, the EEG signals are differentially

amplified and filtered to remove DC and high frequency components. The signals are

digitized by separate one bit sigma-delta analog to digital converters. The outputs from the

converters are multiplexed onto the DSC communications line and de-multiplexed in the

monitor prior to being fed to the Digital Signal Processor (DSP). The DSP filters the signals

and computes the processed variables. The results are passed to the host CPU for display.

3.1.1

The Digital Signal Converter (DSC)

The DSC contains the inputs, amplifiers, and digitizers for two channels of EEG. It has a

single point connection that connects via a Patient Interface Cable (PIC) to a BIS Sensor.

The A-2000 is designed to process one channel using the BIS Sensor, the A-2000 and DSC

hardware is capable of two channels. The sensor and PIC contains circuits for identifying

them to the monitor. This permits the monitor to configure automatically.

The DSC constantly monitors the combined source impedance at its inputs, and also has

facility for measuring the individual impedance of the channel and ground electrodes. There

are circuits for injecting self-test voltages into the amplifier inputs.

- 3-1 -

Page 19

SECTION III PRINCIPLES OF OPERATION

Figure 3-1 The A-2000 System Block Diagram

- 3-2 -

Page 20

SECTION III PRINCIPLES OF OPERATION

Figure 3-2 The A-2000 Signal Flow Diagram

- 3-3 -

Page 21

SECTION III PRINCIPLES OF OPERATION

3.1.1.1 The DSC’s Preamplifier Board

The preamplifier board contains the input protection circuits, montage mode switches,

differential amplifiers, filter and gain amplifiers, impedance test circuits, self test circuits, and

parts of the sensor ID circuit.

3.1.1.2 DSC Signal Conditioning

The input protection circuits are designed to protect the inputs from destruction by electric

shock from sources such as electrostatic discharge (ESD) or defibrillation. The protection

circuits also reduce the effects of high frequency ambient noise from sources such as

electro-cautery and other devices.

The montage mode switches follow the protection circuits. These switches configure the

inputs appropriately for the sensor. The signals are amplified by instrumentation amplifiers

which have a fixed gain. The amplifiers have DC servos which remove the signals below

high pass cutoff frequency. In the event of amplifier overload, the servos are changed to a

higher frequency to facilitate fast recovery (blocking) under control of the host processor.

Each channel is further amplified to the level required by the A/D converters. The amplifiers

also serve as filters to prevent aliasing by the converters.

3.1.1.3 DSC Impedance Testing

In the default state of the DSC the combined channel electrodes’ impedance is continuously

checked. A small current (approximately 1 nanoampere) is injected into each electrode at

128 Hz, just above the EEG band. The resulting voltages are measured. Equal but opposite

currents are injected into the (+) and (-) electrodes simultaneously while the digital signal

processor measures the resulting voltage. BIS monitoring is performed while combined

impedance is checked.

The DSC can also measure the individual electrode impedance by injecting current into the

REF electrode only. Individual electrode impedance is derived by subtracting the resulting

value from the combined value. BIS monitoring is interrupted while individual impedance is

checked.

The ground electrode impedance is also measured while injecting current into the REF

electrode. BIS monitoring is interrupted while the ground impedance is checked.

The impedance check signal can occasionally interfere with other monitoring equipment

connected to the patient. Evoked potential monitors are particularly susceptible because

they use a wide bandwidth. The automatic impedance check feature can be turned off by

selecting “Impedance Checking – OFF” in the Diagnostics Menu (See Operating Manual for

specific instructions).

- 3-4 -

Page 22

SECTION III PRINCIPLES OF OPERATION

3.1.1.4 The DSC Communications Board

The communications board contains the analog to digital (A/D) converter for each channel,

the monitor interface, the sensor interface and the power supply circuits. A crystal controlled

DSC master clock is on this board. This clock is the system’s BIS processing clock.

A/D Conversion (Patented technology)

The communications board contains sigma-delta modulators for the two channels. These

run at 16384 samples per second.

Test Signal

A calibrated test signal is generated on the communications board during DSC self test.

The signal is a 2 Hz square wave of approximately +/-50µV. It is applied to the inputs of the

differential amplifiers, resulting in a test of the entire signal path except for the input

connections and protection circuits. During self test noise, gain and frequency response are

checked.

Interface to the Monitor (Patented technology)

The outputs from the two channels are multiplexed in a field programmable gate array

(FPGA). Multiplexed with the EEG data is status information such as DSC identification,

mode (bipolar or referential), lead off indication, and power supply faults. The status

information is only transmitted on command from the host. The output is transformer

coupled onto a balanced twisted pair line. The transformer provides the required patient

isolation.

The communications board decodes the control information coming from the host via a

command line. Commands such as “block” amplifier saturation and conduct impedance

tests are transmitted.

DSC Power Supply (Patented technology)

The DSC derives power from the command line. The line is balanced twisted pair coupled

via a transformer on the communications board. The isolated signal is rectified and linearly

regulated to provide DSC power.

3.1.1.5 The DSC Mechanicals

The DSC is contained in a small custom designed plastic case about the size of a computer

mouse (see Figure 3-3). It is connected to the monitor via a narrow, highly flexible cable.

The case has one large eyelet at the corner to allow the user to use a strap to hang the DSC

or pin it to the bed sheets. The patient connection is accomplished with an Aspect BIS

Sensor for low and balanced impedance. The Patient Interface Cable pigtail and the monitor

cables are strain relieved and permanently attached to the case. A proprietary connector is

used for the patient interface cable connection and a high quality plastic connector is used

for connection to the monitor.

There are no ventilation holes in the DSC case. It will not leak when splashed with liquids.

The case is electrically shielded both to prevent spurious emissions from the DSC and to

prevent externally caused interference with the DSC circuits.

- 3-5 -

Page 23

SECTION III PRINCIPLES OF OPERATION

Cable (PIC)

Monitor

Interface

Cable

DSC - 2

DSC pigtail

Patient Interface

Figure 3-3 The Digital Signal Converter (DSC)

- 3-6 -

Page 24

SECTION III PRINCIPLES OF OPERATION

3.1.2

The A-2000 Monitor

The A-2000 monitor contains the circuits for digitally processing the EEG data, computing

the processed parameters, and displaying the waveforms and processed parameters.

The circuits for acquiring the EEG signal and digitizing them reside in the digital signal

converter (DSC).

The monitor also contains the circuits for powering the monitor, DSC, and companion

printer. Printer function is not available on battery backup.

A block diagram depicting the monitor subassemblies appears in Figure 3-1. A signal flow

diagram appears in Figure 3-2. The signals are acquired and digitized by the DSC. The

DSC multiplexes the signals onto the DSC communications line. The EEG signals are demultiplexed in the monitor and fed to the Digital Signal Processor (DSP). The processor

filters and down-samples them, calculates the processed parameters, and outputs the

data display.

3.1.2.1 The Main Board

The Main board contains the Digital Signal Processors, the Host processor, data memory,

real time clock, and DSC interface.

All software and firmware can be downloaded through the serial port.

3.1.2.2 Digital Signal Processor

The functions of the DSP include: decimation filters for up to 2 channels of EEG data,

computation of processed EEG parameters, control of the DSC, and interface with the

host.

3.1.2.3 Host Processor

The functions of the host processor include: control of the display, interface with the

keypad, serial port, and printer, control of monitor boot up and download, control of

memory.

An on board annunciator is included for generating alarm sounds.

The display interface is a 4-bit LCD type.

The serial port is standard RS-232.

The printer interface is a non-standard serial type with extra lines for printer keys and

printer control and status. It is designed to interface with a Seiko printer interface board.

3.1.2.4 The Digital Signal Converter (DSC) Interface

The DSC interface is composed of two unidirectional bi-phase encoded serial lines, one

going to the DSC and another bringing data from the DSC.

The power to the interface is under software control. An overcurrent detector circuit

monitors current to the DSC. If the current exceeds the expected value, the power is shut

off to the DSC by the hardware, and the DSP is notified.

- 3-7 -

Page 25

SECTION III PRINCIPLES OF OPERATION

3.1.2.5 The Interconnect Board

The A-2000 monitor is designed with a minimum of internal cabling. The Interconnect

board provides the physical mounting and electrical connections for the major

subassemblies of the A-2000. It has mounted to it the power input module (connector for

the AC power cord and associated fuses), the equipotential stud, the power switch, and

connectors for the printer (external), the serial port (external) and the various internal

connectors for the Main PCB, Switch pad, battery, and fan.

3.1.2.6 The Power Supply

The power supply runs from ac power from 100-240 VAC, 50-60 Hz. It provides +5 V (at

6 A) and +12 V (at 0.72 A) outputs and charges the battery (6-cell NiMH) 7.2 V (nominal),

1800 mA. Signals are provided to the processor to indicate AC FAIL, RESET, and LOW

BATTERY.

The power supply switches the rectified AC line at 125 kHz. The output drives the primary

of a step-down transformer that also provides isolation from the ac line. The left side of

the power supply is referenced to AC line and the right side to ground. The transformer

secondary has two outputs which are rectified and filtered to create + 5 V and + 10 V

outputs. The +10 V signal drives a DC-to-DC converter to create the +12 V output and

charges the battery.

The battery driven supply switches the +10 V output at 125 kHz using a pulse width

modulated buck circuit to create the +5 V output. The battery voltage feeds the input of

the same DC-to-DC converter to create the +12 V output.

3.1.2.7 The Battery

The battery is for backup use only. Its life is approximately 5 years or 200 charge and

discharge cycles, whichever occurs first. The battery is a six-cell arrangement including

temperature and current control elements, and has a nominal output of 7.2 volts DC. The

battery is charged only when the A-2000 Monitor is turned on and running from AC power.

It is capable of supporting monitor operation for a minimum of 20 minutes. Printer use is

not enabled during battery operation.

3.1.2.8 The Fan

A fan is located on the rear panel of the chassis. The fan keeps the temperature rise inside

the chassis to within approximately 10 degrees of the ambient temperature.

3.1.3

A-2000 Printer

The printer is fastened to the monitor bottom and is connected mechanically and

electrically (no cable required). The printer interface is compatible only with the optional

A-2000 printer.

- 3-8 -

Page 26

SECTION IV PREPARATION FOR USE AND INSTALLATION

SECTION IV

4.

PREPARATION FOR USE AND INSTALLATION

INTRODUCTION

This section provides installation instructions for the Aspect A-2000 BIS Monitor, Digital

Signal Converter and accessories including:

• Site preparation

• Instrument connections

• Installation and verification procedure

• Repackaging for shipping and storage

4.1

4.1.1

The monitor and its accessories can be stored or shipped within the following

environmental limits. Note that these limits apply to non-operational storage and shipping

situations.

Temperature -20 oC to +60 oC

Humidity 15 % to 95 % (non-condensing)

Pressure 360 mmHg to 800 mmHg

Protect the monitor from sudden temperature changes which can lead to condensation

within the instrument. To minimize condensation, avoid moving the system between

heated buildings and outside storage. Once moved inside, allow the monitor to stabilize

in the unopened shipping container at the inside ambient temperature before unpacking

and placing into service. Before operation, wipe down all visible condensation and allow

the system to reach equilibrium at room temperature.

4.1.2

The A-2000 is not designed for use in areas containing flammable gases or vapors.

Temperature. The Aspect A-2000 Monitor is designed to operate safely at a room

temperature of 5 degrees C to 40 degrees C. Conditions that exceed these limits could

affect reliability.

Humidity. The monitor is designed to operate within specifications at a relative noncondensing humidity of 15% to 95%.

Pressure. The monitor will operate satisfactorily at or above sea level, and is unaffected

by extremes or changes in altitude within atmospheric pressures of 360 mmHg to 800

mmHg.

ENVIRONMENT

Shipping and Storage Environment

Operating Environment

WARNING:

EXPLOSION HAZARD: DO NOT USE THE A-2000 IN A FLAMMABLE

ATMOSPHERE OR WHERE CONCENTRATIONS OF FLAMMABLE

ANESTHETICS MAY OCCUR.

- 4-1 -

Page 27

SECTION IV PREPARATION FOR USE AND INSTALLATION

4.1.3

The A-2000 BIS Monitor requires a power source of 100-240 VAC, 50-60Hz. Current

consumption is 1 ampere maximum (including printer load).

To protect operating personnel and patients, the monitor must be properly grounded.

Accordingly, the monitor is equipped with a hospital grade line cord. The power cord

grounds the system to the power line ground when plugged into an appropriate 3-wire

receptacle.

4.1.4

The compact size of the monitor allows it to be easily installed in most hospital OR

settings without special site preparation. Optional mounting accessories (see Section

2.2.5 of the Operating Manual) are available to secure the monitor to an anesthesia cart

or IV pole, or to allow for secure and stable placement of the monitor on a flat surface.

Power Requirements and System Grounding

WARNING:

FOR PROPER GROUNDING, THE POWER RECEPTACLE MUST BE A

THREE-WIRE GROUNDED OUTLET. A HOSPITAL GRADE OUTLET IS

REQUIRED. NEVER ADAPT THE THREE-PRONG PLUG FROM THE

MONITOR TO FIT A TWO-SLOT OUTLET. IF THE OUTLET HAS ONLY

TWO SLOTS, MAKE SURE THAT IT IS REPLACED WITH A THREE-SLOT

GROUNDED OUTLET BEFORE ATTEMPTING TO OPERATE THE MONITOR.

IF THE INTEGRITY OF THE EXTERNAL PROTECTIVE EARTH GROUND IS

IN DOUBT, THE A-2000 SHALL BE OPERATED FROM ITS INTERNAL

BATTERY POWER SOURCE ONLY.

FOR A-2000s USED OUTSIDE OF NORTH AMERICA: A HARMONIZED LINE

CORD WITH CONDUCTORS HAVING A CROSS SECTIONAL AREA

GREATER THAN 0.75 MM2 MUST BE USED.

Site Preparation

- 4-2 -

Page 28

SECTION IV PREPARATION FOR USE AND INSTALLATION

4.2

Detailed connection instructions are provided in the A-2000 Operating Manual, Section III.

4.2.1

The long flexible cable from the A-2000 Digital Signal Converter connects to the

electrically isolated digital signal converter connector on the front panel of the monitor.

Once connected, the DSC need not be disconnected again. However, if you wish to

disconnect the DSC cable from the monitor, carefully reach as far as possible into the port

opening with your thumb and index finger, squeeze and pull back on the gray cylindrical

connector housing. Do not twist or pull on cord.

4.2.2

The A-2000 is designed to use only 3 - conductor IEC hospital-grade power cords. Check

for a firm connection.

4.2.3

This printer port connector is designed to connect only to the Aspect A-2000 printer for

screen prints. To connect:

1. Turn OFF the monitor.

2. Align the printer connectors located on the bottom of the monitor and top of the printer

3. Secure the printer to the monitor with the mounting screw located in the base of the

4. Turn on the monitor.

INSTRUMENT CONNECTIONS

Digital Signal Converter Connections

Power Cord Connections

Printer Connector

so that they mate correctly.

printer. Use caution not to cross-thread the mounting screw.

- 4-3 -

Page 29

SECTION IV PREPARATION FOR USE AND INSTALLATION

4.3

1. Open packages and inspect for all components:

You will also need a BIS Sensor or Sensor Simulator.

2. Connect power cable to monitor, plug power connector into appropriate wall outlet.

3. Power up monitor by pressing power button (lower right side of case).

4. Connect DSC, with PIC and Sensor. (Refer to the A-2000 Operating Manual, Section

5. Exit from SENSOR CHECK screen by passing impedance check or by exiting with

6. Disconnect power cord.

7. Reconnect power cord.

8. Do keyboard checkout:

9.

4.4

If it becomes necessary to return the monitor to the factory, use the original shipping

container to protect the product. Seal the package with reinforced packing tape rather

than plastic or masking tape. Mark shipping or storage container FRAGILE.

INSTALLATION AND VERIFICATION PROCEDURE

• Monitor with power cable

• DSC (Digital Signal Converter)

• PIC (Patient interface cable)

• Verify beep tone as power button is activated

• Verify fan (rear case wall) moves air outward.

• Verify that self-test procedure completes successfully (approx. 30 seconds).

• Verify next screen says ‘CONNECT DSC CABLE TO FRONT OF MONITOR’

III for detailed instructions.)

• Verify that DSC test completes

• Verify SENSOR CHECK screen displays.

MENU/EXIT key.

• Verify ‘OPERATING ON BATTERY BACKUP (E33)’ is displayed.

• Verify battery icon displays in BIS banner (top left corner of screen).

• Verify battery icon is not displayed in BIS banner.

• Verify no ‘OPERATING IN BATTERY BACKUP (E33) DISPLAY

• Press SILENCE key Verify icon shows at BIS banner

• Press Review ARROW BACK key Verify REVIEW MODE Menu displays

• Press MENU/EXIT key Verify REVIEW MODE MENU exits,

• Press Review ARROW AHEAD key Verify REVIEW MODE Menu displays

• Press MENU/EXIT key Verify REVIEW MODE MENU exits

• Press MENU/EXIT key Verify Setup Menu displays

• Press UP ARROW key Verify highlight bar moves up with each

press.

• Press DOWN ARROW key Verify highlight bar moves down with

each press.

• Press SELECT key Verify that highlighted menu line is

selected.

• Press MENU/EXIT Verify that Setup Menu exits

End of installation.

REPACKAGING FOR SHIPPING AND STORAGE

- 4-4 -

Page 30

SECTION V PREVENTIVE MAINTENANCE, CARE AND CLEANING

SECTION V

5.

INTRODUCTION

This section describes:

• Care and cleaning procedures

• Routine maintenance

PREVENTIVE MAINTENANCE, CARE AND CLEANING

5.1

5.1.1

Clean any spillage of blood or solutions on either the monitor or Digital Signal Converter

as soon as possible. Dried blood is very difficult to remove. Use lint-free absorbent

towels for spill cleanups. Dampen the towel with detergent and lukewarm water to aid in

cleaning.

5.1.2

Use lint free absorbent towels dampened with 10% bleach solution, or a commercial

disinfectant (e.g. Lysol Professional Disinfectant Foam Cleaner Spray or PDI Germicidal

Disposable Wipes).

After cleaning, dry all areas except the monitor display screen (see below) with a lint-free

absorbent paper towel.

5.1.3

Clean the monitor display screen with a mild solution of detergent and warm water, or a

commercial display screen cleaner, available through personal computer dealers. To

avoid scratching the screen, never use abrasive cleaners.

CARE AND CLEANING

WARNING:

UNIVERSAL PRECAUTIONS SHALL BE OBSERVED TO PREVENT

CONTACT WITH BLOOD OR OTHER POTENTIALLY INFECTIOUS

MATERIALS. PLACE CONTAMINATED MATERIALS IN REGULATED

WASTE CONTAINER.

Cleaning the Monitor and Digital Signal Converter

Disinfecting the Monitor and Digital Signal Converter

WARNING:

WHENEVER AN EVENT SUCH AS SPILLAGE OF BLOOD OR

SOLUTIONS OCCURS, RE-TEST GROUND LEAKAGE CURRENT

BEFORE FURTHER USE.

DO NOT MIX DISINFECTING SOLUTIONS (e.g. BLEACH AND

AMMONIA) AS HAZARDOUS GASES MAY RESULT.

Caution:

Do not autoclave the Digital Signal Converter or Monitor.

Autoclaving will seriously damage both components.

Do not submerge.

Cleaning the Monitor Display

- 5-1 -

Page 31

SECTION V PREVENTIVE MAINTENANCE, CARE AND CLEANING

5.2

The A-2000 monitor is designed so that no periodic adjustment or calibration is required.

5.2.1

The battery must be tested periodically to verify that the A-2000 will continue to operate

during power outages. To test:

1. Charge the A-2000 by leaving it plugged in with the power ON for 4 hours.

2. Disconnect the A/C cord from wall supply

3. Verify that the A-2000 operates reliably for a minimum of 20 minutes.

4. Recharge the battery.

5.2.2

Leakage current is a primary indicator of electrical shock hazard to personnel making

contact with any exposed outer surface of the equipment. Each A-2000 BIS Monitor is

carefully checked at the factory to verify that leakage current meets the UL2601 and

IEC601-1 safety standards.

The A-2000 should be routinely checked for leakage current at least once a year.

Always check the leakage current after a saline or blood spill, or immediately after a major

surge in the house electrical system and after every time the monitor case has been

opened.

Keep in mind that liquids such as saline and Ringer’s as well as blood are all excellent

conductors of electricity. Avoid touching any part of the system with wet hands. Always

work with clean, dry hands.

ROUTINE MAINTENANCE

Checking the Battery

Caution:

Periodically check the battery by operating an A-2000 that has been

disconnected from the wall socket and which has been charging the battery

for at least four hours. After long periods of storage (e.g. > 1 month) it may

be necessary to cycle (discharge, then charge) the battery a few times to get

full charge capacity. If the A-2000 fails to operate reliably from the battery for

twenty minutes, battery replacement is required.

The A-2000 contains an internal Nickel-Metal-Hydride battery. The battery

must be removed by a qualified service technician and disposed of or

recycled in accordance with the national laws of the country. Contact Aspect

Medical Systems, Inc. or the local distributor for a replacement battery.

WARNING:

ELECTRICAL SHOCK HAZARD: DO NOT REMOVE MONITOR COVERS

DURING OPERATION OR WHILE POWER IS CONNECTED TO MONITOR.

GROUND WIRE LEAKAGE CURRENT MUST BE CHECKED WHENEVER

INSTRUMENT CASE IS OPENED BY A QUALIFIED BIOMEDICAL

ENGINEERING TECHNICIAN.

Checking Leakage Current

WARNING:

SHOCK HAZARD: DO NOT ATTEMPT TO DISCONNECT THE

POWER CORD WITH WET HANDS. MAKE CERTAIN THAT YOUR

HANDS ARE CLEAN AND DRY BEFORE TOUCHING THE POWER

CORD.

- 5-2 -

Page 32

SECTION V PREVENTIVE MAINTENANCE, CARE AND CLEANING

WARNING:

ELECTRICAL SHOCK HAZARD: THE MANUFACTURER’S INSPECTION OF

THIS APPARATUS VERIFIED THAT THE GROUND LEAKAGE CURRENT AND

THE PATIENT SAFETY CURRENT WERE LESS THAN THE SPECIFIED LIMITS

ESTABLISHED BY THE APPLICABLE SAFETY STANDARDS. AS A MATTER

OF SAFE PRACTICE, THE INSTITUTION SHOULD CONDUCT PERIODIC

TESTS TO VERIFY THESE CURRENTS. WHENEVER AN EVENT SUCH AS

SPILLAGE OF BLOOD OR SOLUTIONS OCCURS, RE-TEST BEFORE

FURTHER USE.

- 5-3 -

Page 33

SECTION V PREVENTIVE MAINTENANCE, CARE AND CLEANING

5.2.3

The following test procedure should be performed periodically to ensure that the A-2000

is functioning properly.

1. Connect power cable to monitor, plug power connector into appropriate wall outlet.

2. Power up monitor by pressing power button (lower right side of case).

3. Connect DSC, with PIC and Sensor. (Refer to Sensor Check, section 5.2.5.).

4. Exit from SENSOR CHECK screen by passing impedance check or by exiting with

5. Disconnect power cord.

6. Reconnect power cord.

7. Perform keyboard checkout:

8.

Monitor System Checkout Procedure

• Verify beep tone as power switch is activated

• Verify fan (rear case wall) moves air outward.

• Verify that all self tests complete successfully (approx. 30 seconds).

• Verify next screen says ‘CONNECT DSC CABLE TO FRONT OF MONITOR’

• Verify that DSC test completes

• Verify SENSOR CHECK screen displays.

MENU/EXIT key.

• Verify ‘OPERATING ON BATTERY BACKUP (E33)’ is displayed.

• Verify battery icon displays in BIS banner (top left corner of screen).

• Verify battery icon is not displayed in BIS banner

• Verify no ‘OPERATING IN BATTERY BACKUP (E33)’ display.

• Press SILENCE key Verify icon shows at BIS banner

• Press Review ARROW BACK key Verify REVIEW MODE Menu displays

• Press MENU/EXIT key Verify REVIEW MODE MENU exits,

• Press Review ARROW AHEAD key Verify REVIEW MODE Menu displays

• Press MENU/EXIT key Verify REVIEW MODE MENU exits

• Press MENU/EXIT key Verify Setup Menu displays

• Press UP ARROW key Verify highlight bar moves up with each

press.

• Press DOWN ARROW key Verify highlight bar moves down with

each press.

• Press SELECT key Verify that highlighted menu line is

selected.

• Press MENU/EXIT Verify that Setup Menu exits

End of checkout procedure.

- 5-4 -

Page 34

SECTION V PREVENTIVE MAINTENANCE, CARE AND CLEANING

5.2.4

Periodically the DSC and associated cables and connectors should be inspected for

physical damage.

1. Inspect the DSC case to ensure the plastic is not cracked or broken.

2. Inspect the gasket seal around the perimeter of the DSC to verify the physical

3. Inspect the cables and strain relief mechanism.

4. Inspect the connector that plugs into the monitor for damage or poor strain relief.

5. Inspect Patient Interface Cables (PIC) for damage to cable or connectors.

6.

5.2.5

The sensor check can be done using a Sensor Simulator (P/N 186-0105), following the

instructions in Appendix 9.2. If a simulator is not available, use the following procedure to

make a test sensor:

1. Remove a new sensor from its plastic carrier sheet and place on flat surface with the

2. Place the end of a small paper clip at the midpoint of electrode element 1 then lay it

3. Fold electrode element 3 over onto electrode 2, pressing adhesive surfaces together

4. Fold electrode 1 over on itself, securing the other end of the paper clip and pressing

5. Connect this test sensor to the sensor PIC. All impedance tests should complete

DSC Checkout Procedure

integrity of the seal.

Perform DSC Self Test. See section 6.2.3.1.

Patient Interface Cable (PIC) Checkout Procedure

adhesive facing up.

Be careful that gel does not leak onto hands or connector during this

procedure.

across element 2. (Elements 1 and 2 are the two closest together.)

and making sure the paper clip remains in place.

adhesive surfaces together. If necessary, secure it in place by wrapping a piece of

tape around the outside.

successfully, with low impedance values. Typical values using this alternative test

sensor are less than 5 Kohms.

Note:

- 5-5 -

Page 35

SECTION V PREVENTIVE MAINTENANCE, CARE AND CLEANING

- 5-6 -

Page 36

SECTION VI DIAGNOSTICS AND TROUBLESHOOTING

SECTION VI

6.

DIAGNOSTICS AND TROUBLESHOOTING

INTRODUCTION

This section explains:

• General troubleshooting

• The A-2000 power-up, automatic and manual diagnostic procedures

• Failure messages, causes, and corrective actions

• Diagnostic codes and their meanings

6.1

GENERAL TROUBLESHOOTING

Using Table 6.1, the technician can troubleshoot the A-2000 monitor by matching a

symptom to the list of probable causes and recommended corrective procedures. The

corrective procedures include replacing assemblies. Corrective actions are arranged

according to probability of cause.

Table 6.1 Troubleshooting the A-2000 Monitor

Symptoms:

No display, no fan ON/OFF switch is OFF

Causes:

Corrective Procedures:

Press power button on right

side of monitor

Battery drained, unit

unplugged

Power supply defective

No display, fan running

Main board defective Replace Main board

E/L display defective

Plug in unit, then press

power button

Replace power supply

Replace E/L display

No main display

Any

Reboot to run boot

diagnostic

Main display cabling

Display driver circuit

defective

Check cables

Replace Main board

Main board defective

Replace Main board

- 6-1 -

Page 37

SECTION VI DIAGNOSTICS AND TROUBLESHOOTING

Table 6.1 CONTINUED

Symptoms:

No speaker sound Alarms silenced

Main board defective

Keypad inoperative

Keypad defective

Main board defective

All keys inoperative

Printer inoperative Printer out of paper

Causes:

Corrective Procedures:

Enable alarms

Replace main board

Cable disconnected or

defective

Reconnect or replace

cables

Replace keypad

Replace main board

Main board defective Replace main board

Replace printer paper

Printer off-line Place printer on-line

A-2000 in battery backup

mode

Replace A/C line cord

power

Printer defective

Main board defective

Interconnect board

defective

Replace printer

Replace main board

Replace Interconnect board

DSC disconnected error

message

DSC is disconnected

Connect DSC to the monitor

DSC wire connection within

cable connector is defective

Replace DSC

DSC cable to monitor is

defective

Replace DSC

DSC is defective

Replace DSC

Main board defective Replace main board

- 6-2 -

Page 38

SECTION VI DIAGNOSTICS AND TROUBLESHOOTING

Table 6.1 CONTINUED

Symptoms: Causes: Corrective Procedures:

DSC overcurrent error

message

DSC is defective

DSC cable to monitor is

defective

Replace DSC

Replace DSC

Main board defective Replace main board

Noisy EEG Interference from other

equipment (e.g. electrocautery)

Initiate DSC self-test

diagnostic.

Electrode impedance too

high

Initiate impedance check;

re-prep or replace sensor

as required

DSC is defective

Fails impedance test Electrode impedance too

Notch filter OFF

high

Check notch filter setting

Replace DSC

Initiate impedance check;

re-prep or replace sensor

as required

Patient Interface Cable

(Electrode lead wires) is

defective

Replace PIC

(Patient Interface Cable)

DSC is defective

Replace DSC

Fails to recognize sensor PIC defective Replace PIC

DSC pigtail defective

Replace DSC

DSC fails self test Electro-cautery used during

self test

Restart monitor when

electro-cautery not in use.

(Self test runs when the

DSC is first connected, and

again when sensor is

connected.)

- 6-3 -

Page 39

SECTION VI DIAGNOSTICS AND TROUBLESHOOTING

6.2

THE A-2000 DIAGNOSTIC PROCEDURES

The A-2000 has three built-in diagnostic procedures:

• Power-Up

• Automatic

• Manual

These procedures check the A-2000 unit’s operability and report software and hardware

malfunctions.

The power-up diagnostics run automatically each time you turn on the A-2000 unit. These

procedures check the software (FLASH), system memory, speaker, display, serial ports,

timer/counters, FPGA, BIS Engine, real-time clock, Data Memory and Setup Memory.

The automatic diagnostics run continuously in the background while the unit operates.

These procedures check the Digital Signal Converter for the following conditions:

interface faults, disconnect, lead off and power faults. The automatic diagnostics also

check for problem states within the BIS Engine and printer and can be used to check for

impedance.

The manual diagnostics are operator initiated using the A-2000 keys and menu choices.

These procedures check for the proper functioning of the Digital Signal Converter, the

display, and all BIS processing circuits.

Note:

The diagnostics can be run safely while the patient is connected to the A2000 unit; however, running the diagnostics will temporarily disrupt

monitoring. Do not run DSC self test during electro-cautery as it may

erroneously indicate a failure.

6.2.1

Power-Up Diagnostics

To run power-up diagnostics, turn the unit on using the ON/OFF button on the lower

corner of the unit. Two screens will be displayed successively on the display. The first

screen contains the following information:

BIS Monitor

Model A-2000

Boot Rev. x.xx

Boot Block .................. OK (xxxxxxxx)

Annunciator..................TESTED

Display ...................…...TESTED

Internal RAM ...............OK

External RAM ..............OK

Serial Port ..............….OK

Counter/Timers ........…OK

FPGA........................…...OK

Serial Number ............…xxxxxx

Hardware Rev ............…x.xx

Main Program ............…OK (xxxxxxxx)

- 6-4 -

Page 40

SECTION VI DIAGNOSTICS AND TROUBLESHOOTING

The second screen contains the following information:

BIS Monitor

Model A-2000

System Rev. x.xx

Host Rev. .................…..x.xx

Printer Port...............…..OK

Diagnostic Port..............OK

FPGA Rev..................…..x.xx

FPGA ......................…….OK

BIS Engine Rev. ............x.xx

BIS Engine ..............….OK

Real-Time Clock ............OK

Data Memory ................. OK

Setup Memory ................OK

In addition to these two screens, the A-2000 also uses audible tones to signal fatal errors.

These are especially useful if a hardware failure prevents the display from working. Each

audible error code consists of a long tone followed by one or more short tones, and finally

another long tone. The specific error condition is indicated by the number of short tones:

Table 6.2 Summary of Error Conditions

Error Condition # of short tones

in beep code

FLASH Boot Block Failed Checksum 1

Main Program Checksum Check Failed 2

Software Update Serial Comm. Error 3

Software Update FLASH Error 4

Counter/Timer Test Failed 5

FPGA Init/Test Failed 6

Serial Port UART Loopback Failed 7

Host External RAM Failed 8

Host Internal RAM Failed 9

- 6-5 -

Page 41

SECTION VI DIAGNOSTICS AND TROUBLESHOOTING

MESSAGES, CAUSES AND CORRECTIVE ACTIONS

The power-up diagnostics identify a number of problems involving the A-2000’s software

and hardware. Table 6.3 shows the messages associated with these diagnostics as well

as the cause of the failure and the corrective action to take. Messages are arranged and

listed in the following categories: RAM, program memory, I/O devices, BIS Engine, realtime clock, data memory, and setup memory. Corrective actions are arranged according

to probability of cause.

Table 6.3 Power-Up Failure Messages, Causes and Corrective Actions

Failure Messages: Causes: Corrective Actions:

RAM Checks:

8 short tones (no display) Host DRAM failure. Replace main board.

9 short tones (no display) Host SRAM failure. Replace main board.

Program Memory Checks:

1 short tone (no display) Bad checksum or signature

Replace main board.

in Boot Block

Main

Program............FAILED

Bad checksum or signature

in Main Code area.

1. Reload Main Code again.

2. Replace main board.

(2 short tones)

I/O Device Checks:

Serial

Port..................FAILED

(7 short tones)

Serial Port UART failed

loopback test or interrupt

test.

Replace main board

Counter/Timers.......FAILED

(5 short tones)

Counter/timer(s) in Host

processor failed.

Replace main board.

FPGA......................FAILED

(6 short tones)

FPGA failed download or

test.

1. Reload boot code and/or

main code again.

2. Replace main board.

Printer

Port.................FAILED

Printer Port UART failed

loopback test or interrupt

Replace main board.

test.

Diagnostic

Port..........FAILED

Diagnostic Port UART failed

loopback test or interrupt

Replace main board.

test.

- 6-6 -

Page 42

SECTION VI DIAGNOSTICS AND TROUBLESHOOTING

Table 6.3 Power-Up Failure Messages, Causes and Corrective Actions

(CONTINUED)

Failure Messages: Causes: Corrective Actions:

BIS Engine Initialization:

BIS

Engine.................FAILED

Problem with BIS Engine on

main board.

Replace main board.

Real-Time Clock Checks:

Real-Time

Clock........FAILED

SYSTEM HALTED

Real-time clock failed RAM

test.

Replace main board.

Real-Time

Clock......ERASED

RTC TIME/DATE LOST

Time/date was corrupted in

real-time clock.

1. Set time/date.

2. Check real-time clock

battery.

Real-Time

Clock......ERASED

RAM was corrupted in realtime clock.

Check real-time clock

battery.

RTC RAM DATA LOST

Data Memory:

Data

Memory.............FAILED

SYSTEM HALTED

Data Memory failed erase

or write.

Replace main board.

Data

Memory............ERASED

DATA MEMORY LOST

Check Time/Date

Data Memory, or its control

structure in the real-time

clock RAM, is corrupted.

1. Check time/date.

2. Check real-time clock

battery.

3. Replace main board.

Test Clock Battery

Setup Memory:

Setup

Memory...........FAILED

SETUP MEMORY LOST

Setup Memory failed erase

or write.

1. Check setup.

2. Replace main board.

Default settings in effect

Setup

Memory..........ERASED

Setup Memory was

corrupted.

Check setup.

SETUP MEMORY LOST

Default settings in effect

Setup

Memory..........ERASED

Main code has been

updated.

Check setup.

NEW SYSTEM

SOFTWARE REVISION

Setup Memory invalid

Default settings in effect

- 6-7 -

Page 43

SECTION VI DIAGNOSTICS AND TROUBLESHOOTING

6.2.2

Automatic Diagnostics

The A-2000 monitor contains a series of diagnostics that run constantly in the background

checking for problem conditions. When a problem condition occurs, the monitor signals

with alarm tones (two beeps, sounds like “Uh-oh”) and a status message that appears in

the Message Region of the display. Each error message is numbered (E01, E02, etc.) for

easy reference. In Table 6.4 the error messages are numbered consecutively and

grouped into categories. Corrective actions are arranged according to probability of

cause.

Table 6.4 Automatic Diagnostic Error Messages, Causes and Corrective Actions

Failure Messages: Causes: Corrective Actions:

DSC

E01

DSC Disconnected

1. DSC disconnected.

2. Defective DSC cable.

3. Defective DSC.

4. Defective monitor.

1. Verify all cable

connections.

2. Inspect / repair cable at

connector end.

3. Replace the DSC.

4. Replace the main board.

E02

DSC Overcurrent

1. Defective DSC cable.

2. Defective DSC.

3. Defective monitor.

1. Replace the DSC.

2. Replace the DSC.

3. Replace the main board.

E03

DSC Power Regulation

1. Defective DSC.

2. Defective DSC cable.

Replace DSC.

E04, E05, E06, E07, E08

DSC Error

1. Defective DSC.

2. Defective monitor.

1. Replace the DSC.

2. Replace the main board.

E09

DSC Shut Down

1. Defective DSC cable.

2. Defective DSC.

3. Defective monitor.

1. Replace the DSC.

2. Replace the DSC.

3. Replace the main board.

E10

Illegal DSC Type

1. Incorrect DSC in use.

2. Defective DSC.

3. Defective monitor

1. Connect the correct DSC.

2. Replace the DSC.

3. Replace the main board.

E11

DSC Failed Self Test

1. Defective DSC.

2. Defective monitor.

3. Electro-cautery

equipment used during self

test.

1. Replace the DSC.

2. Replace the main board.

3. Restart monitor when

electro-cautery equipment

not in use. (Note that selftest runs when the DSC is

first connected and again

when the sensor is

connected.)

- 6-8 -

Page 44

SECTION VI DIAGNOSTICS AND TROUBLESHOOTING

Table 6.4 Automatic Diagnostic Error Messages, Causes and Corrective Actions

(CONTINUED)

Failure Messages: Causes: Corrective Actions:

Sensor

E12

Illegal Sensor Type

1. Defective Sensor.

2. Defective PIC.

3. Defective DSC.

4. Defective monitor.

1. Replace the Sensor.

2. Replace the PIC.

3. Replace the DSC.

4. Replace the main board.

E13, E15

Re-prep Sensor

1. Poor sensor connections.

2. Sensor impedance too

high.

3. Defective Patient

Interface Cable (PIC).

1. Check sensor

connections.

2. Re-prep / replace sensor.

3. Replace the PIC.

E14

Sensor Not Connected

1. Disconnected Sensor

2. Disconnected PIC.

3. Defective PIC.

4. Defective DSC.

5. Defective monitor.

1. Connect the Sensor

2. Connect the PIC.

3. Replace the PIC.

4. Replace the DSC.

5. Replace the main board.

E16

Last Sensor Check Failed

BIS

Engine

E17, E19, E20, E21, E22,

E23, E24

BIS Engine Comm. Error

1. At least one electrode

has too high impedance.

2. Poor lead connection.

3. Defective PIC.

4. Defective DSC.

5. EXIT pressed

prematurely.

Error in communication

between BIS Engine and

Host.

1. Check impedance, reprep/ replace electrodes.

2. Check lead connections.

3. Replace the PIC.

4. Replace the DSC.

5. Repeat check electrode

test.

1. Update the software.

2. Replace the main board.

E18

BIS Engine Not Functional

Fatal BIS Engine error

detected.

1. Turn monitor off, then on

again.

2. Update the software.

3. Replace the main board.

E45

No Updates from BIS

Engine

No data received from BIS

Engine in last 15 seconds.

1. Turn monitor off, then on

again.

2. Update the software.

3. Replace main board.

E46

BIS Engine Not Responding

BIS Engine has not

responded to a command

within 12 seconds.

1. Turn monitor off, then on

again.

2. Update the software.

3. Replace main board.

- 6-9 -

Page 45

SECTION VI DIAGNOSTICS AND TROUBLESHOOTING

Table 6.4 Automatic Diagnostic Error Messages, Causes and Corrective Actions

(CONTINUED)

Failure Messages: Causes: Corrective Actions:

EEG Signal

E25

Left Side SQI Bad

E26

Right Side SQI Bad

With 2-channel montage,

left side signal quality is

bad.

With 2-channel montage,

right side signal quality is

bad.

1. Re-prep the Sensor.

2. Check impedances.

1. Re-prep the Sensor.

2. Check impedances.

E27

Poor Signal Quality

The Signal Quality Index is

less than 50% and the

numeric display becomes

1. Re-prep the Sensor.

2. Check impedances.

“hollow”.

This may occur as the result

of artifact such as those

generated from motion or

the presence of

electrocautery devices.

E28

Bad Signal Quality

The Signal Quality Index is

unacceptable. The Primary

Trend variable cannot be

1. Re-prep the Sensor.

2. Check impedances.

calculated and therefore the

numeric display is blanked.

This may occur as the result

of artifact such as those

generated from motion or

the presence of

electrocautery devices.

E29

BIS < Low Alarm Limit

The BIS has fallen below

the low alarm limit set by

the user. The numeric