ASME Unified Inch Screw User Manual

ASME B1.1-2019

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

[Revision of ASME B1.1-2003 (R2018)]

Unified Inch Screw

Threads (UN, UNR, and

UNJ Thread Forms)

AN AMERICAN NATIONAL STANDARD

ASME B1.1-2019

Two Park Avenue • New York, NY • 10016 USA

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

[Revision of ASME B1.1-2003 (R2018)]

Unified Inch Screw

Threads (UN, UNR, and

UNJ Thread Forms)

AN AMERICAN NATIONAL STANDARD

x

Date of Issuance: June 30, 2020

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

The next edition of this Standard is scheduled for publication in 2024. This Standard will become effective 1 year afterthe Dateof

Issuance.

Periodically certain actions of the ASME B1 Committee may be published as Cases. Cases are published on the ASME website

under the B1 Committee Page at http://go.asme.org/B1committee as they are issued.

Errata to codes and standards may be posted on the ASME website under the Committee Pages to provide corrections to

incorrectly published items, or to correct typographical or grammatical errors in codes and standards. Such errata shall be used

on the date posted.

The B1 Committee Page can be found at http://go.asme.org/B1committee. There is an option available to automatically receive

an e-mail notification when errata are posted to a particular code or standard. This option can be found on the appropriate

Committee Page after selecting “Errata” in the “Publication Information” section.

ASME is the registered trademark of The American Society of Mechanical Engineers.

This code or standard was developed under procedures accredited as meeting the criteria for American National Standards. The Standards

Committee that approved the code or standard was balanced to assure that individuals from competent and concerned interests have had an

opportunity to participate. The proposed code or standard was made available for public review and comment that provides an opportunity

for additional public input from industry, academia, regulatory agencies, and the public-at-large.

ASME does not “approve,” “rate,” or endorse any item, construction, proprietary device, or activity.

ASME does not take any position with respect to the validity of any patient rights asserted in connection with any items mentioned in this

document, and does not undertake to insure anyone utilizing a standard against liability for infringement of any applicable letters patent, nor

assume any such liability. Users of a code or standard are expressly advised that determination of the validity of any such patent rights, and the

risk of infringement of such rights, is entirely their own responsibility.

Participation by federal agency representative(s) or person(s) affiliated with industry is not to be interpreted as government or industry

endorsement of this code or standard.

ASME accepts responsibility for only those interpretations of this document issued in accordance with the established ASME procedures

and policies, which precludes the issuance of interpretations by individuals.

No part of this document may be reproduced in any form,

in an electronic retrieval system or otherwise,

without the prior written permission of the publisher.

The American Society of Mechanical Engineers

Two Park Avenue, New York, NY 10016-5990

Copyright ©2020 by

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

All Rights Reserved

Printed in U.S.A.

CONTENTS

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Committee Roster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Correspondence With the B1 Committee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Screw Thread Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Screw Thread Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Screw Thread Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5 Screw Thread Allowance and Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6 Screw Thread Designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

7 Dimensional Accommodation of Coating or Plating for 60-Deg Threads . . . . . . . . . . . . . 110

8 Limits of Size for Standard (UN, UNR, and UNJ) and Special (UNS, UNRS, and UNJS) Series of

Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

9 Thread Form Tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

10 Formulas and Nomenclature for Thread Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

11 Tables of Basic Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Nonmandatory Appendices

A Terminology and Identification of Unified Inch Screw Threads . . . . . . . . . . . . . . . . . . . . . . . 148

B Thread Strength Design Formulas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

C Unified Inch Screw Threads — Metric Translation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

D Special Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

E Changes to ASME B1.1-1989, Tables 3A and 3B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

F Special Lengths of Engagement Specifications and Designations . . . . . . . . . . . . . . . . . . . . . . 180

Figures

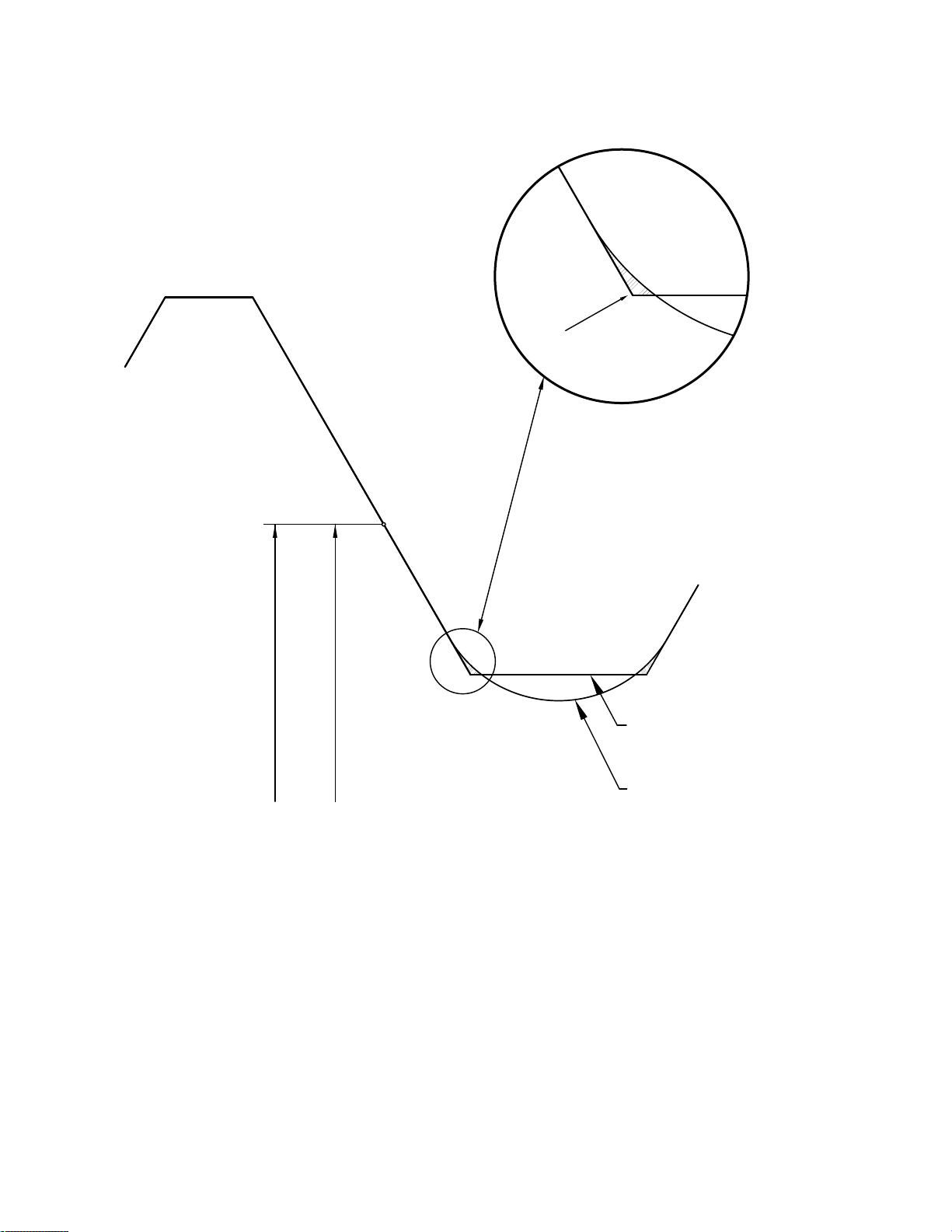

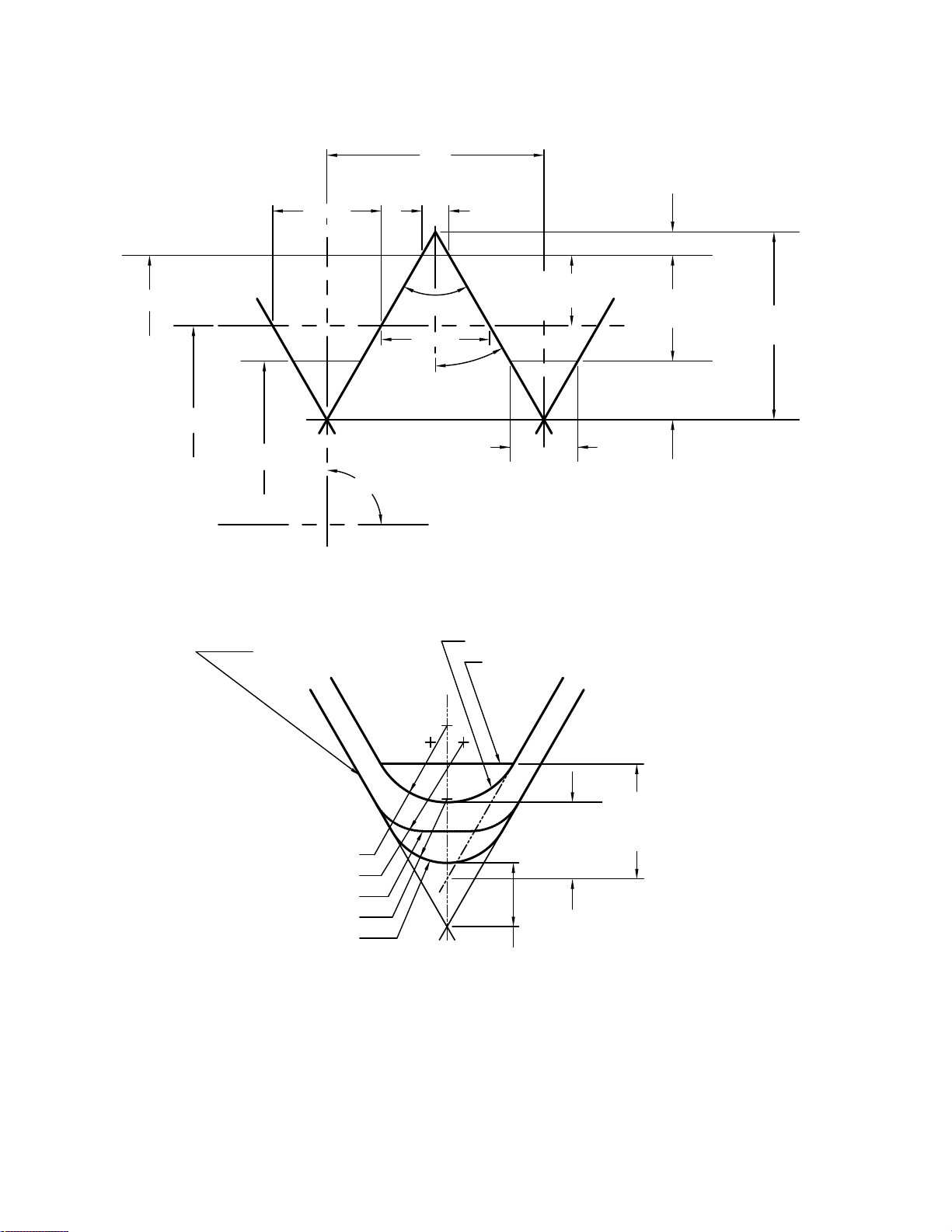

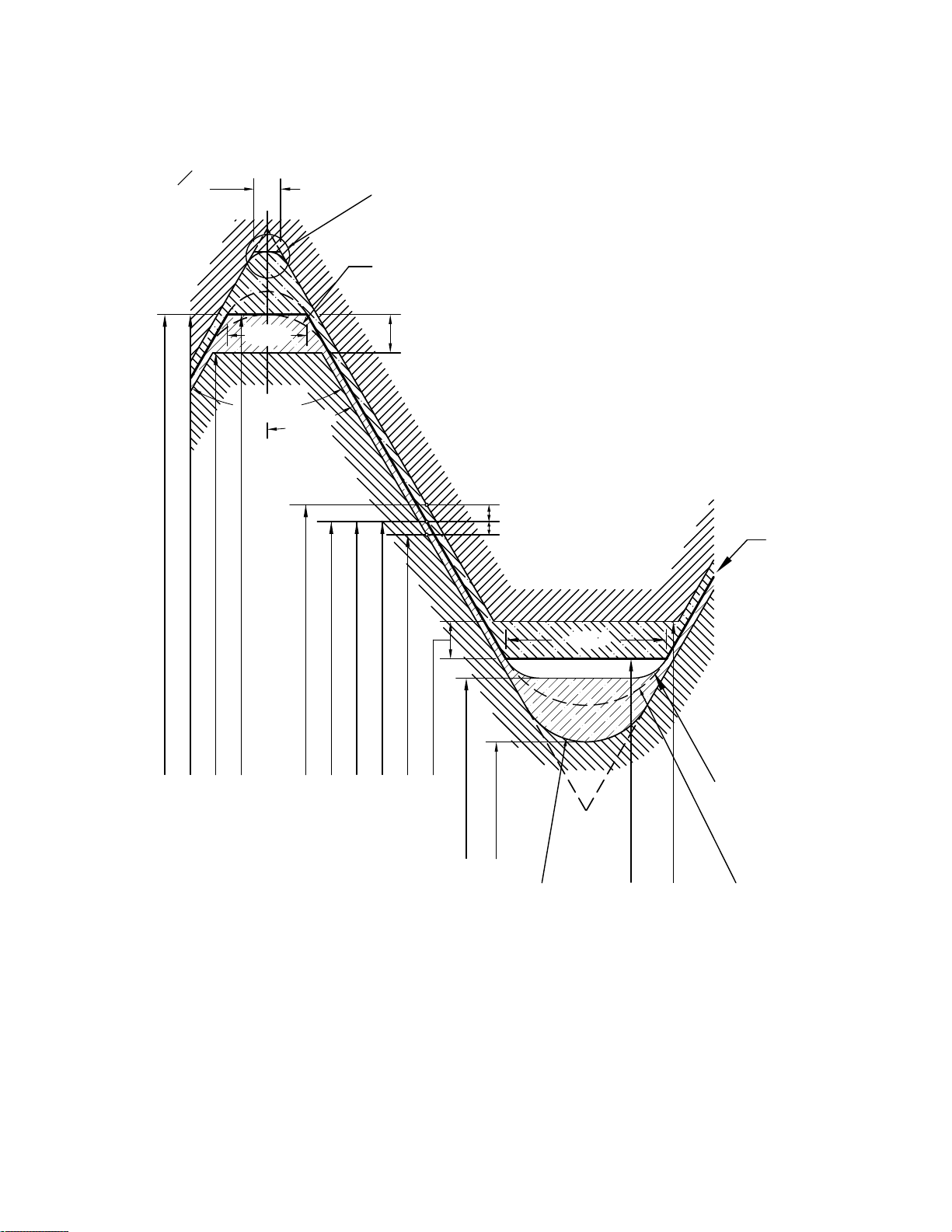

1 Illustration of Assembly Interference of UNJ-3A Thread and UN-3B Thread in the Maximum

Material Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

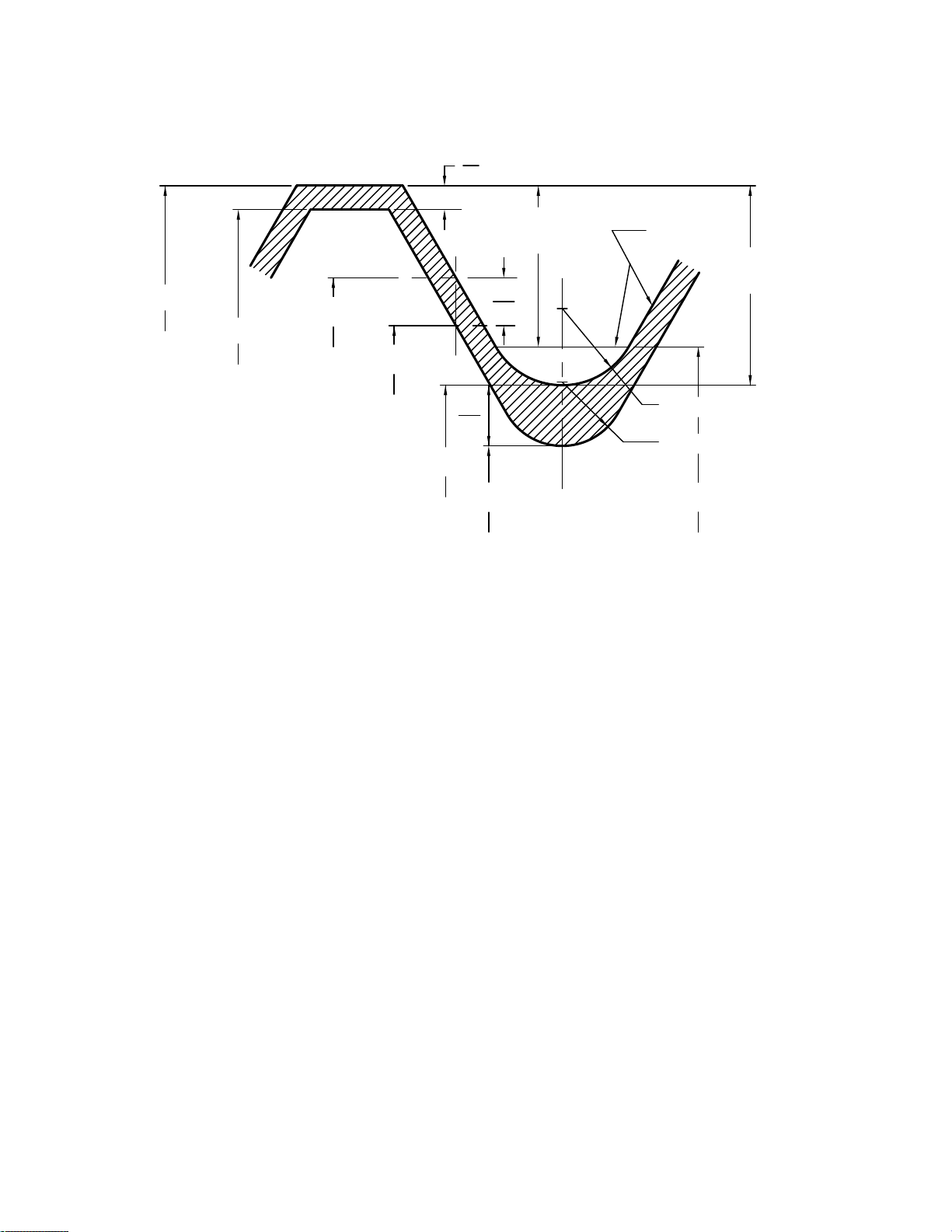

2 Basic Profile for UN and UNR Screw Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

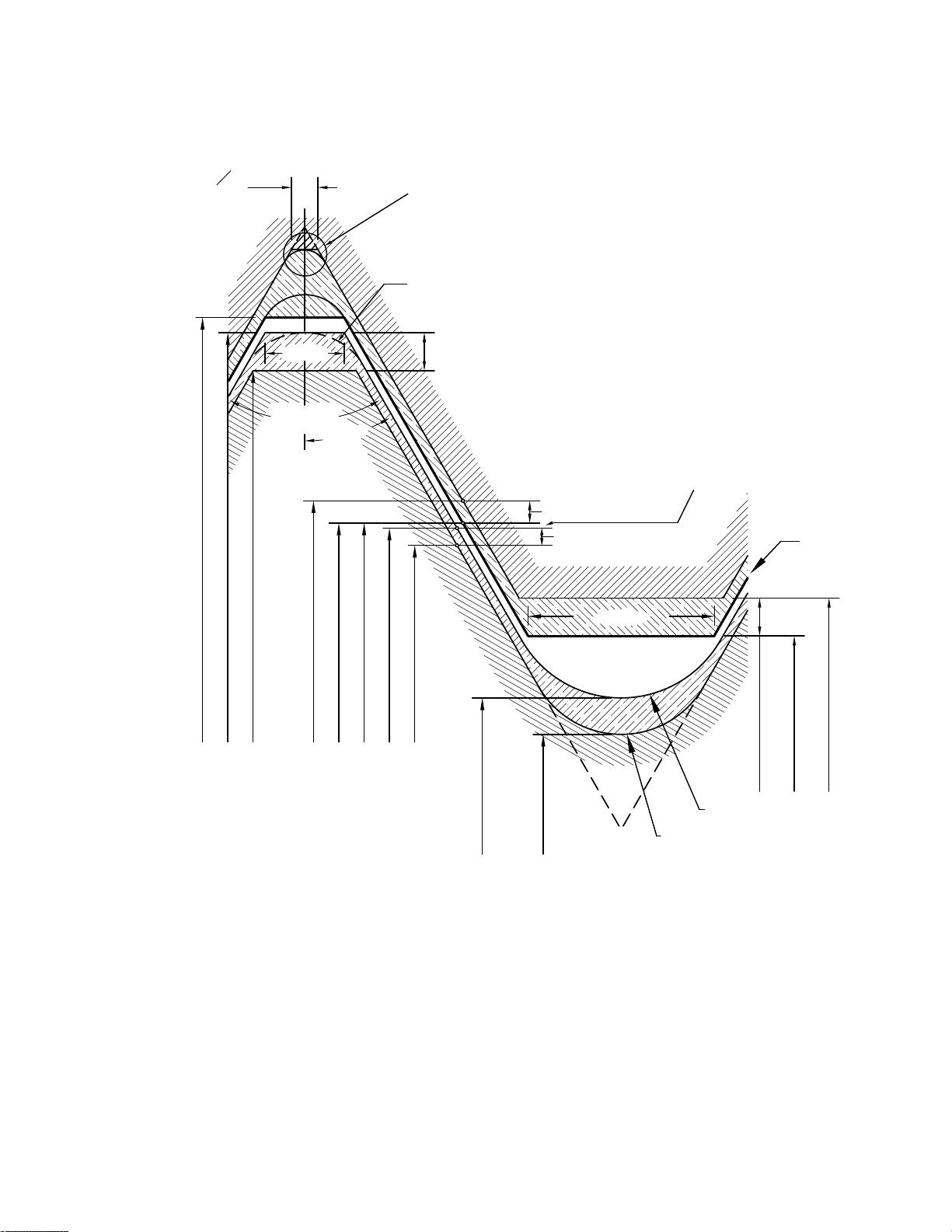

3 Basic Profile for UNJ Screw Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

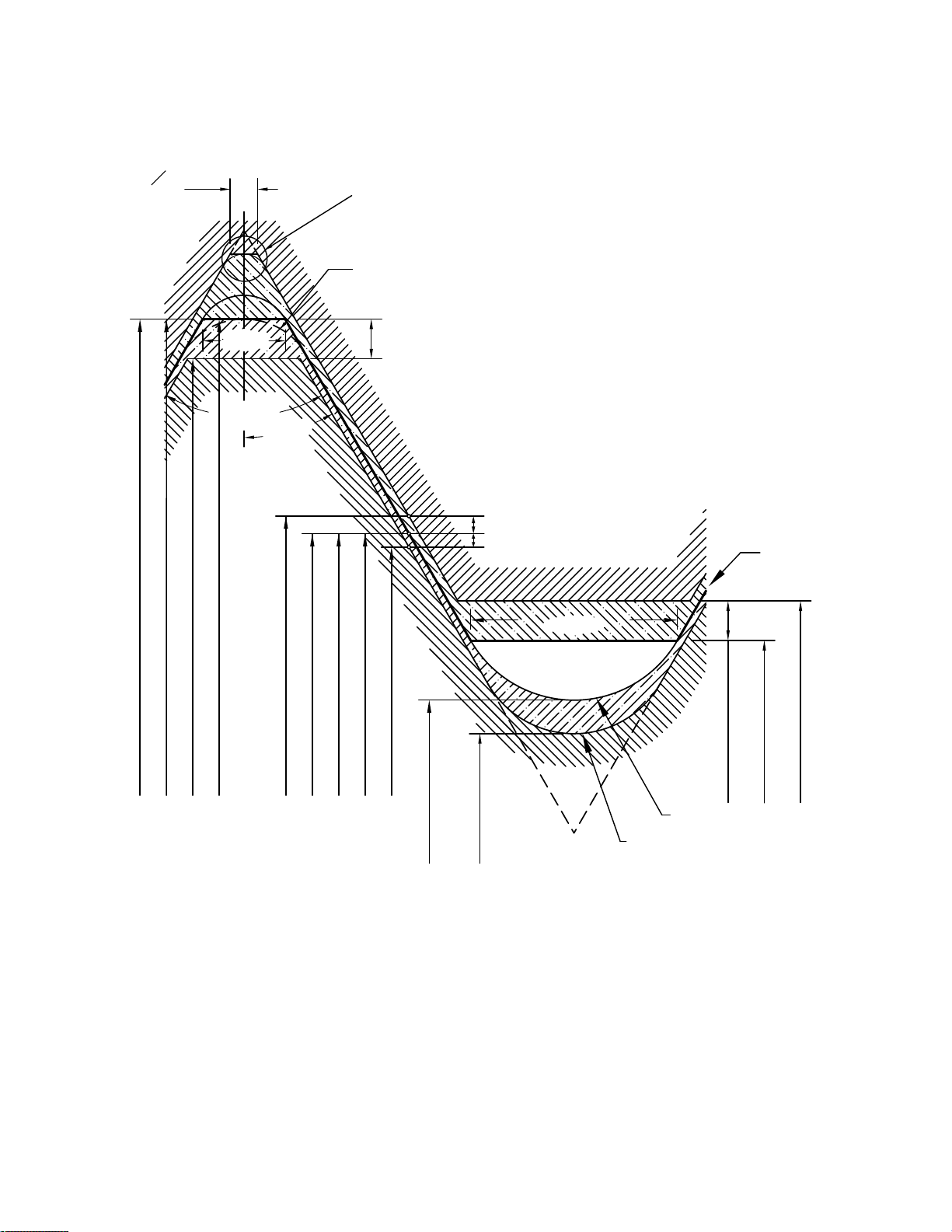

4 Root Radius of UNJ External Thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5 Disposition of Diametral Tolerances, Allowance, and Crest Clearance for Unified Inch Screw Thread

Series UN, Classes 1A, 2A, 1B, and 2B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6 Disposition of Diametral Tolerances and Crest Clearance for Unified Inch Screw Thread Series UN,

Classes 3A and 3B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7 Disposition of Diametral Tolerances, Allowance, and Crest Clearance for Unified Inch Screw Thread

Series UNR, Classes 1A and 2A, and Series UN, Classes 1B and 2B . . . . . . . . . . . . . . . . . . 8

8 Disposition of Diametral Tolerances and Crest Clearance for Unified Inch Screw Thread Series UNR,

Class 3A and Series UN, Class 3B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

9 External UNJ Thread Design Profile and Tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

iii

10 Disposition of Diametral Tolerances, Allowance, and Crest Clearance for Unified Inch Screw Thread

D

3

LE

P

2

3

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Series UNJ, Classes 2A and 2B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

11 Disposition of Diametral Tolerances and Crest Clearance for Unified Inch Screw Thread Series UNJ,

Classes 3A and 3B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

12 Internal UNJ Thread Design Profile and Tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

13 Basic Method of Designating Screw Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

14 Ratio of Pitch Diameter Change to Thickness of Coating on 60-deg Threads . . . . . . . . . . . . . 112

15 Effect of Electrodeposited Coating on 60-deg External Threads . . . . . . . . . . . . . . . . . . . . . . . 113

16 Application of General Thread Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

A-1 Identification of 60-deg Inch Screw Threads Within the Scope of the ASME B1 Committee . . . 148

Tables

1 Standard Series Threads (UN, UNR, and UNJ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2A Limits of Size for Standard Series External Threads (UN, UNR, and UNJ) . . . . . . . . . . . . . . . . 15

2B Limits of Size for Standard Series Internal Threads (UN and UNJ) . . . . . . . . . . . . . . . . . . . . 45

3 Allowable Variations in Lead and Equivalent Change in Functional Diameter . . . . . . . . . . . . . 80

4 Increments in Pitch Diameter Tolerance — Class 2A

(PD Tolerance = 0.0015

+ 0.0015

+ 0.015

) . . . . . . . . . . . . . . . . . . . . . . . . .

100

5 Basic Profile and Constants for Calculation Formulas of Thread Dimensions, in. . . . . . . . . . . . 102

6 Basic Dimensions for Coarse-Thread Series (UNC, UNRC, and UNJC) . . . . . . . . . . . . . . . . . . . 118

7 Basic Dimensions for Fine-Thread Series (UNF, UNRF, and UNJF) . . . . . . . . . . . . . . . . . . . . . 119

8 Basic Dimensions for Extra-Fine-Thread Series (UNEF, UNREF, and UNJEF) . . . . . . . . . . . . . . 120

9 Basic Dimensions for 4-Thread Series (UN, UNR, and UNJ) . . . . . . . . . . . . . . . . . . . . . . . . . . 121

10 Basic Dimensions for 6-Thread Series (UN, UNR, and UNJ) . . . . . . . . . . . . . . . . . . . . . . . . . . 123

11 Basic Dimensions for 8-Thread Series (UN, UNR, and UNJ) . . . . . . . . . . . . . . . . . . . . . . . . . . 125

12 Basic Dimensions for 12-Thread Series (UN, UNR, and UNJ) . . . . . . . . . . . . . . . . . . . . . . . . . 127

13 Basic Dimensions for 16-Thread Series (UN, UNR, and UNJ) . . . . . . . . . . . . . . . . . . . . . . . . . 130

14 Basic Dimensions for 20-Thread Series (UN, UNR, and UNJ) . . . . . . . . . . . . . . . . . . . . . . . . . 133

15 Basic Dimensions for 28-Thread Series (UN, UNR, and UNJ) . . . . . . . . . . . . . . . . . . . . . . . . . 135

16 Basic Dimensions for 32-Thread Series (UN, UNR, and UNJ) . . . . . . . . . . . . . . . . . . . . . . . . . 136

17A Outline Guide for Determining Limits of Size of External Threads . . . . . . . . . . . . . . . . . . . . . 137

17B Outline Guide for Determining Limits of Size of Internal Threads . . . . . . . . . . . . . . . . . . . . . 137

18A Examples of External Screw Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

18B Examples of Internal Screw Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

19 Allowable Variation in 30-deg Basic Half Angle of External and Internal Screw Threads . . . . . 145

20 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A-1 Identification of 60-deg Inch Screw Threads Within the Scope of the ASME B1 Committee . . . 149

D-1 Limits of Size for Selected Combinations of UNS/UNRS Series Threads . . . . . . . . . . . . . . . . . 153

E-1 Limits of Size for Standard Series Internal and External Threads as Listed in Table 3A of ASME B1.1-

1989 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

E-2 Limits as Listed in Table D-1 (Formerly 3B) Prior to ASME B1.1-2003 Edition . . . . . . . . . . . 174

iv

FOREWORD

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

ASME B1.1, Unified Inch Screw Threads, is an integrated system of threads for fastening purposes in mechanisms and

structures. Its outstanding characteristic is its general interchangeability of threads, achieved through the standardization of thread form, diameter-pitch combinations, and limits of size.

This Standardis the outgrowth of and supersedes previous editions that were published as ASME B1-1924, ASME B1.11935, ASME B1.1-1949, ASME B1.1-1960, ASME B1.1-1974, ASME B1.1-1982, ASME B1.1-1989, and ASME B1.1-2003.

The achievements represented by ASME B1.1 in development, standardization, and unification are the result of the

cooperation and coordination of many organizations, including The American Society of Mechanical Engineers (ASME),

SAE International (formerly Society of Automotive Engineers), National Institute of Science and Technology (formerly

National Bureau of Standards), Committee B1, the former National Screw Thread Commission, the former Interdepartmental Screw Thread Committee, British Standards Institution, CSA Group (formerly Canadian Standards Association),

and American National Standards Institute (ANSI).

This Standard has its basis in the work done more than a century ago by William Sellers in the United States and Sir

Joseph Whitworth in Great Britain. Through the intervening years, there have been many developments and revisions,

culminating in the Unified Thread Standard approved and adopted for use by all inch-using countries.

The unification of screwthread standards meets the needfor interchangeability among the billions of fasteners made in

different countries and used in the complex equipment of modern technology. Unification is equally important for the

international trade in mechanisms of all kinds and the servicing of transportation equipment that moves from country to

country. Unification is therefore not only highly advantageous but also essential.

Complete unification of certain thread series and six tolerance classes in sizes

1

∕4in. and larger was achieved with the

signing of an accord in Washington, D. C. on November 18, 1948. Since that time, unification has extended to smaller sizes.

Developed by Technical Committee No. 1 of the International Organization for Standardization (ISO), the unified inch

standard that was adopted as ISO 5864 is parallel to the ISO metric screw thread system. Both systems have a common

basic profile. The standard was subject to Quadripartite Standardization Agreement (QSTAG) 247 in the ABCA Army

Standardization Program of America, Britain, Canada, and Australia.

Throughout this history, special attention has been given to the practical aspects of thread standardization, and many

details of ASME B1.1 result from studies and tests based on real-world use. For example, users communicated the need for

free assembly in high-production industries and the desirability of providing for threads that require a coating. The

tolerance classes 2A and 2B were developed to meet these two major requirements as well as to provide a general

standard for externally and internally threaded fasteners. Thread symbols and nomenclature are now consistent with

ASME B1.7. Thread acceptability now follows ASME B1.3.

In 1992, ASME B1.30 implemented eight-place decimal and rounding rules that are mandatory for all new editions and

future revisions of ASME B1 documents. To comply with this decision, the 2003 edition, ASME B1.1-2003

(a) revised some of the values in Table 2 and created Table E-1 of Nonmandatory Appendix E, which identifies and lists

the revised dimensions from Table 2 in the ASME B1.1-1989 edition. The majority of the dimensional changes are within

±0.0001 in. As stated in para. 8.2.1, the values in this former Table 2, now Tables 2A and 2B, and Table E-1 should be

considered acceptable until a future revision of this Standard makes the values in Tables 2A and 2B the only acceptable

values.

(b) moved Table 3B, which provides calculated values for various UNS (unified specials), to Nonmandatory Appendix

D. The ASME B1 Committee strongly urges users to adopt the standard thread sizes in Tables 2A and 2B instead of those

listed in Table D-1.

(c) moved Tables 31 through 40, which include some values that differ from those derived by use of the formulas in

paras. 5 and 8, to Nonmandatory Appendix D and renamed these Tables D-2 through D-11. (All future special threads

should be based on calculations only.)

(d) eliminated all references to thread engagement from this Standard. Past changes in the thread form designation of

the “basic” thread height from 0.7500H to 0.62500H confused the calculation of percent of thread engagement.

(e) included the definition of “functional diameter” and added the term to Table 2 in the same column as “pitch

diameter,” since both characteristics have the same limits of size.

(f) explained in greater depth the effects of coating on threads (see section 7).

v

Changes to this 2019 edition include the splitting of ASME B1.1-2003 Table 2, which contained values for both internal

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

and external threads for UN and UNR only, into two tables, Table 2A: Limits of Size for Standard Series External Threads

(UN, UNR, and UNJ), and Table 2B: Limits of Size for Standard Series Internal Threads (UN, UNR, and UNJ). The metric

translation of this Standardwas removed, as were TablesD-2 through D-11 (formerly Tables31 through 40 in ASMEB1.1-

1989).

Finally, the UNJ thread profile, formerly defined in ASME B1.15, was added to this Standard. Following the U.S. Depart-

ment of Defense (DoD) approval of SAE AS8879C-2003, ASME B1 Subcommittee 15 recognized it would become the

standard used by the aerospace industry for this thread form. As a result, Subcommittee 15 recommended that the

technical information from ASME B1.15 be included in ASME B1.1 for non-aerospace applications.

The UNJ thread form havingthe enlarged root radius in the external thread was introduced to minimize size and weight

in parts for applications requiring high-fatigue strength under high working-stress levels, as in aerospace applications. It

is also appropriate for designs in commercial products where stresses are critical. To meet these requirements, the UNJ

external thread root radius is designed to be between 0.15011107P and 0.18042196P and the minor diameter of the

mating internal thread is increased to ensure the necessary clearance.

This Standard includes Classes 2A and 2B UNJ screw threads. Either Class 2A or Class 3A UNJ threads are appropriate for

commercial applications commensurate with the fatigue and stress levels required.

The UNJ thread form is the UN thread form modified to 0.562500H, which allows the 0.18042196P maximum root

radius in the external thread. The first known U.S. standard of similar thread form was SAE AS-82, published in March

1942, which describes a modified American National thread form to 75% h basic thread depth and specifies 0.10800P to

0.1800P root radius in the external thread. This thread was symbolized NR, National Round, and was developed for

aircraft engine applications.

Tension fatigue testing of aircraft fasteners in 1942 demonstratedthe importance of the external thread root contour in

the fatigue life of a screw thread rolled after heat treatment. Fatigue testing isolated the elements of good external thread

root design. The root should be radiused, not sharp. Theoretically, it should be a continuous circular arc, blending

smoothly with the thread flanks. The radius should be as large as possible within the allowable design form. The

root contour should also be smooth throughout and free of any imperfections, tool marks, or other minor notches.

Recognizing the need for improved 160,000 psi tensile strength bolts, the DoD published MIL-B-7838A, the bolt

procurement specification for aircraft applications based on the unified thread form of 0.62500H, in April 1952,

thus acknowledging a larger external root radius requires a shallower internal thread depth to clear the flank tangency

point.

The root radius of the external thread was increased to 0.15011107P minimum and 0.18042196P maximum for the

180,000 psi and higher tensile strength bolts. This external thread form was developed in 1955 by the aerospace fastener

industry and was known as the “Hi R” thread form.

Through coordinated effort with the SAE E-25 Engine and Propeller Standard Utility Parts Committee and the Aero-

space Industries Association National Aerospace Standards Committee (NASC), the DoD developed and published in

September 1960 the thread specification MIL-S-8879, which features the “Hi R” thread root radius in the external thread

and the internal thread modified to 0.562500H basic. In aircraft gas turbine engines, the high-temperature threaded

fasteners exhibited better elevated temperature performance using MIL-S-8879 UNJ thread root radius, as the stressrupture life of bolts was greatly improved.

The UNJ thread form has been adopted by the aerospace industry as the all-purpose thread standard, except for

electrical hardware and thread sizes 0.1380 and smaller, which may use the UN thread form.

The UNJ profile as defined in this Standard is similar to SAE AS8879C-2003 (superseding MIL-S-8879C) and equivalent

to ISO 3161:1977 for thread Classes 3A and 3B. British Standards Institution BS 4084:1978, including Amendment 1, is

technically identical to ISO 3161:1977, except for Appendix A, which provides information for a 20-UNJ constant pitch

series for diameters through 3 in.

ASME B1.1-2019 was approved by the American National Standards Institute (ANSI) on August 26, 2019.

vi

ASME B1 COMMITTEE

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Standardization and Unification of Screw Threads

(The following is the roster of the Committee at the time of approval of this Standard.)

STANDARDS COMMITTEE OFFICERS

A. L. Barrows, Chair

STANDARDS COMMITTEE PERSONNEL

D. S. George, Vice Chair

D. Papert, Secretary

A. L. Barrows, Swanson Tool Manufacturing, Inc.

K. Bly, Vermont Thread Gage

L. Borowski, Greenslade & Co., Inc.

H. J. Cox, Frank Cox Metrology, Ltd.

G. A. Cuccio, Capitol Manufacturing Co.

R. Dodge, Pennoyer Dodge Co.

D. Everett, National Institute of Standards and Technology

J. O. Gehret III, Gehret Gage, LLC

D. S. George, Michigan Metal Coating

J. R. Gervasi, Kerr Lakeside, Inc.

P. Holahan, Fastenal Co.

L. C. Johnson, Johnson Gage Co.

D. D. Katz, Precision Fittings

D. R. Maisch, PMC Lone Star

SUBCOMMITTEE 1 — UNIFIED SCREW THREADS

A. L. Barrows, Chair, Swanson Tool Manufacturing, Inc.

D. Miskinis, Vice Chair, Consultant

K. Bly, Vermont Thread Gage

L. Borowski, Greenslade & Co., Inc.

R. Dodge, Pennoyer Dodge Co.

D. S. George, Michigan Metal Coating

J. R. Gervasi, Kerr Lakeside, Inc.

P. Holahan, Fastenal Co.

L. C. Johnson, Johnson Gage Co.

P. Larouche, Johnson Gage Co.

M. Oliver, M. Oliver Consulting

D. Miskinis, Consultant

D. Papert, The American Society of Mechanical Engineers

J. R. Popovic, Cleveland Specialty Inspection Services, Inc.

M. W. Rose, Glastonbury Southern Gage

P. Larouche, Alternate, Johnson Gage Co.

R. J. Hukari, Contributing Member, SPS Technologies

R. P. Knittel, Contributing Member, Consultant

D. R. Oas, Contributing Member, Seaway Bolt & Specials Corp.

E. Schwartz, Contributing Member, Consultant

B. F. Sheffler, Contributing Member, Consultant

D. Skierski, Contributing Member, Sterling Gage & Calibration, LLC

R. D. Strong, Contributing Member, Lear Corp.

C. J. Wilson, Contributing Member, Consultant

S. Brahimi, Contributing Member, Industrial Fasteners Institute

M. Cox, Contributing Member, Consultant

R. J. Hukari, Contributing Member, SPS Technologies

J. C. Jennings, Contributing Member, Naval Surface Warfare Center,

Philadelphia Division

X. Li, Contributing Member, China Productivity Center for Machinery

Industry

E. Schwartz, Contributing Member, Consultant

B. F. Sheffler, Contributing Member, Consultant

R. D. Strong, Contributing Member, Lear Corp.

C. J. Wilson, Contributing Member, Consultant

vii

CORRESPONDENCE WITH THE B1 COMMITTEE

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

General. ASME Standards are developed and maintained with the intent to represent the consensus of concerned

interests. As such, users of this Standard may interact with the Committee by requesting interpretations, proposing

revisions or a case, and attending Committee meetings. Correspondence should be addressed to:

Secretary, B1 Standards Committee

Proposing Revisions. Revisions are made periodically to the Standard to incorporate changes that appear necessary

or desirable, as demonstrated by the experience gained from the application of the Standard. Approved revisions will be

published periodically.

This Standard is always open for comment, and the Committee welcomes proposals for revisions to this Standard. Such

proposals should be as specific as possible, citing the paragraph number(s), the proposed wording, and a detailed

description of the reasons for the proposal, including any pertinent documentation.

Proposing a Case. Cases may be issued to provide alternative rules when justified, to permit early implementation of

an approved revision when the need is urgent, or to provide rules not covered by existing provisions. Cases are effective

immediately upon ASME approval and shall be posted on the ASME Committee web page.

Requests for Cases shall provide a Statement of Need and Background Information. The request should identify the

Standard and the paragraph, figure, or table number(s), and be written as a Question and Reply in the same format as

existing Cases. Requests for Cases should also indicate the applicable edition(s) of the Standard to which the proposed

Case applies.

The American Society of Mechanical Engineers

Two Park Avenue

New York, NY 10016-5990

http://go.asme.org/Inquiry

Attending Committee Meetings. The B1 Standards Committee regularly holds meetings and/or telephone confer-

ences that are open to the public. Persons wishing to attend any meeting and/or telephone conference should contact the

Secretary of the B1 Standards Committee. Future Committee meeting dates and locations can be found on the Committee

Page at http://go.asme.org/B1committee.

viii

ASME B1.1-2019

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

UNIFIED INCH SCREW THREADS (UN,

UNR, AND UNJ THREAD FORMS)

1 GENERAL

1.1 Scope

This Standard specifies the thread form, series, class,

allowance, tolerance, and designation for unified screw

threads. (In order to emphasize that unified screw

threads are based on inch modules, they may be

denoted unified inch screw threads.) Several variations

in thread form have been developed for unified

threads; however, this Standard covers only UN, UNR,

and UNJ thread forms.

The metric translation of this Standard that was in the

2003 edition has been removed (see Nonmandatory

Appendix C). Nonmandatory Appendices D through F

contain information that is supplementary to the sections

of this Standard.

1.2 Unified Screw Thread Standards

The standards for unified screw threads published in

this Standard are in agreement with formal standards

of the International Organization for Standardization

(ISO) for diameter-pitch combinations, designations,

and tolerances for 60-deg triangular form inch screw

threads. The unified screw thread symbols UN, UNC,

UNF, and UNEF were derived by the addition of the

letter “U”preceding the thread symbols used for American

National screw threads N, NC, NF, and NEF.

Unified screw threads have their origin in an accord

signed in Washington, D.C. on November 18, 1948 by

representatives of standardizing bodies of Canada, the

United Kingdom, and the United States and have subsequently superseded American National screw threads.

1.3 Thread Forms

UN applies to both internal and external threads. UNR

applies only to external threads; the difference between

UN and UNR threads, in addition to designation, is that a

flat or rounded root contour due to tool wear is specified

for UN threads, while only a defined rounded root contour

is specified for UNR threads. Basic thread height is

0.54126588P.

The UNJ screw thread is designed for use on highly

stressed applications requiring high-fatigue strength.

For aerospace applications, only Classes 3A and 3B

should be used. Basic thread height is only

0.48713929P to permit a root radius larger than that

of the UN and UNR forms.

1.4 Interchangeability

1.4.1 UN and UNR. Unified (UN/UNR) and its prede-

cessor American National (N) screw threads have

substantially the same thread form, and threads of

both standards having the same diameter and pitch

are mechanically interchangeable. The principal differences between these standards relate to the application

of allowances, the variation of tolerances with size, differences in the amounts of pitch diameter tolerances for

external and internal threads, and differences in thread

designations. Unified inch and ISO metric screw

threads are not mechanically interchangeable.

1.4.2 UNJ. UN and UNJ threads are interchangeable

with the exception of UNJ-3A external threads, which

at maximum material condition will not assemble with

a UN internal thread of any class at maximum material

condition (see Figure 1).

1.5 Designations

Unified thread sizes (specific combinations of diameter

and pitch shown in Table 1) are identified by the letter

combination “UN” in the thread symbol. In the unified

standards, the pitch diameter tolerances for external

threads differ from those for internal threads; for this

reason the letter “A” is used in the thread symbol to

denote an external thread and the letter “B,” an internal

thread. Where the letters “U,” “A,” or “B” do not appear in

the thread designation, the threads conform to the

outdated American National screw threads. Details

regarding thread designations are given in section 6.

1.6 References

The following is a list of publications referenced in this

Standard. Unless otherwise specified, the latest edition

shall apply. The following documents form a part of

this Standard to the extent specified herein.

ASME B1.2, Gages and Gaging for Unified Inch Screw

Threads

ASME B1.3, Screw Thread Gaging Systems for Accept-

ability: Inch and Metric Screw Threads

1

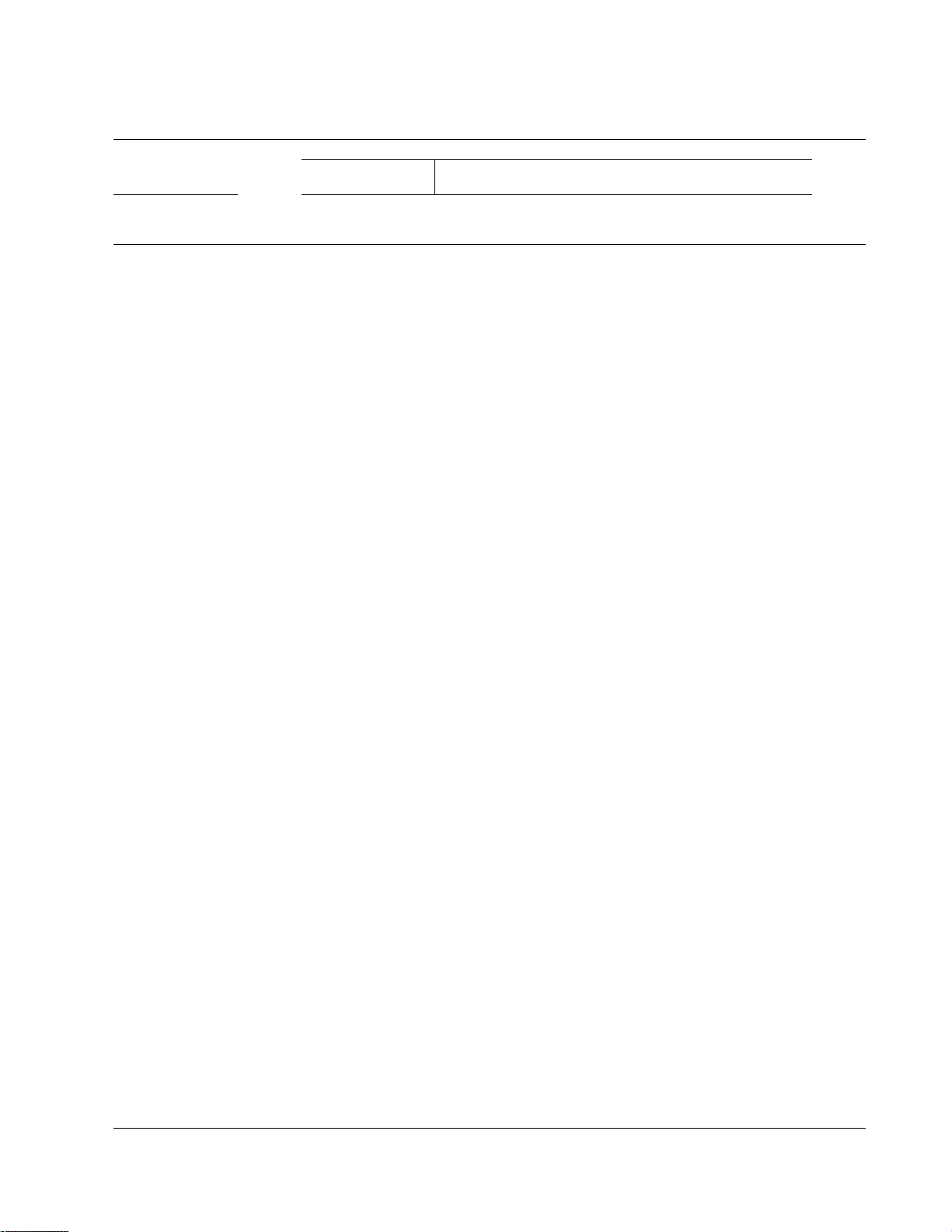

Maximum pitch diameter of external

Minimum pitch diameter of internal

Maximum minor diameter of

UNJ-3A external thread

Minimum minor diameter of

UN-3B internal thread

Interference

Detail

ASME B1.1-2019

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Figure 1 Illustration of Assembly Interference of UNJ-3A Thread and UN-3B Thread in the Maximum Material Condition

ASME B1.7, Screw Threads: Nomenclature, Definitions,

and Letter Symbols

ASME B1.30, Screw Threads: Standard Practice for Calcu-

lating and Rounding Dimensions

ASME B47.1, Gage Blanks

ASME B94.11M, Twist Drills

ASME Y14.5, Dimensioning and Tolerancing

Publisher: The American Society of Mechanical Engineers

(ASME), Two Park Avenue, New York, NY 10016-5990

(www.asme.org)

ISO 68, General Purpose Screw Threads — Basic Profile

Publisher: International Organization for Standardization

(ISO), Central Secretariat, Chemin de Blandonnet 8, Case

Postale 401, 1214 Vernier, Geneva, Switzerland

(www.iso.org)

1.7 Acceptability

Acceptability of product threads shall be in accordance

with ASME B1.3. Gages and gaging shall be in accordance

with ASME B1.2.

1.8 Reference Temperature

The reference temperature is 68°F for dimensions

defined by this system.

2

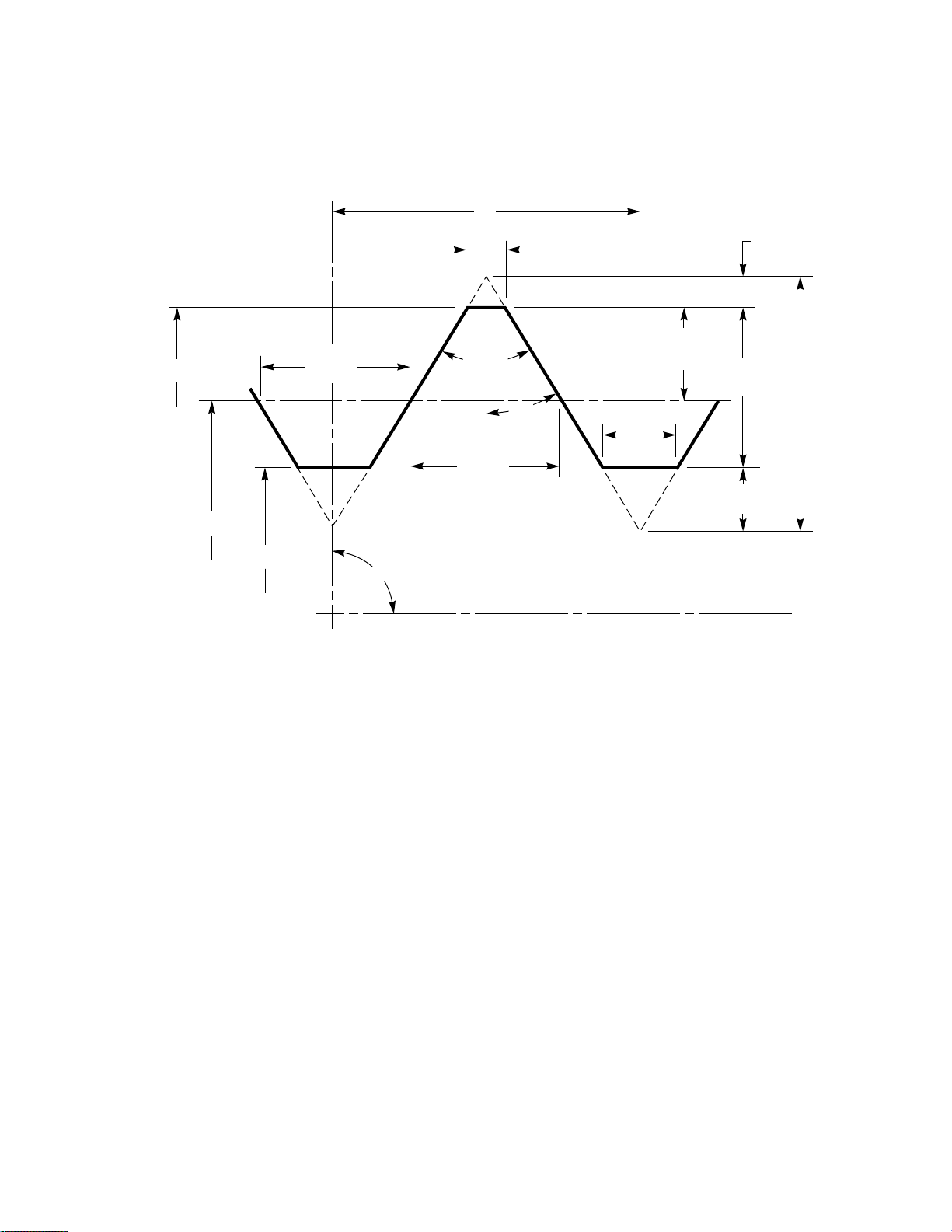

0.86602540P

(H)

P

60 deg

30

deg

90 deg

Axis of screw thread

D bsc, d bsc

D2 bsc, d2 bsc

D1 bsc, d1 bsc

0.125P

0.10825318P

(0.125H )

0.32475953P

(0.375H )

0.54126588P

(0.625H )

0.21650635P

(0.25H )

0.250P

0.500P

0.500P

ASME B1.1-2019

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

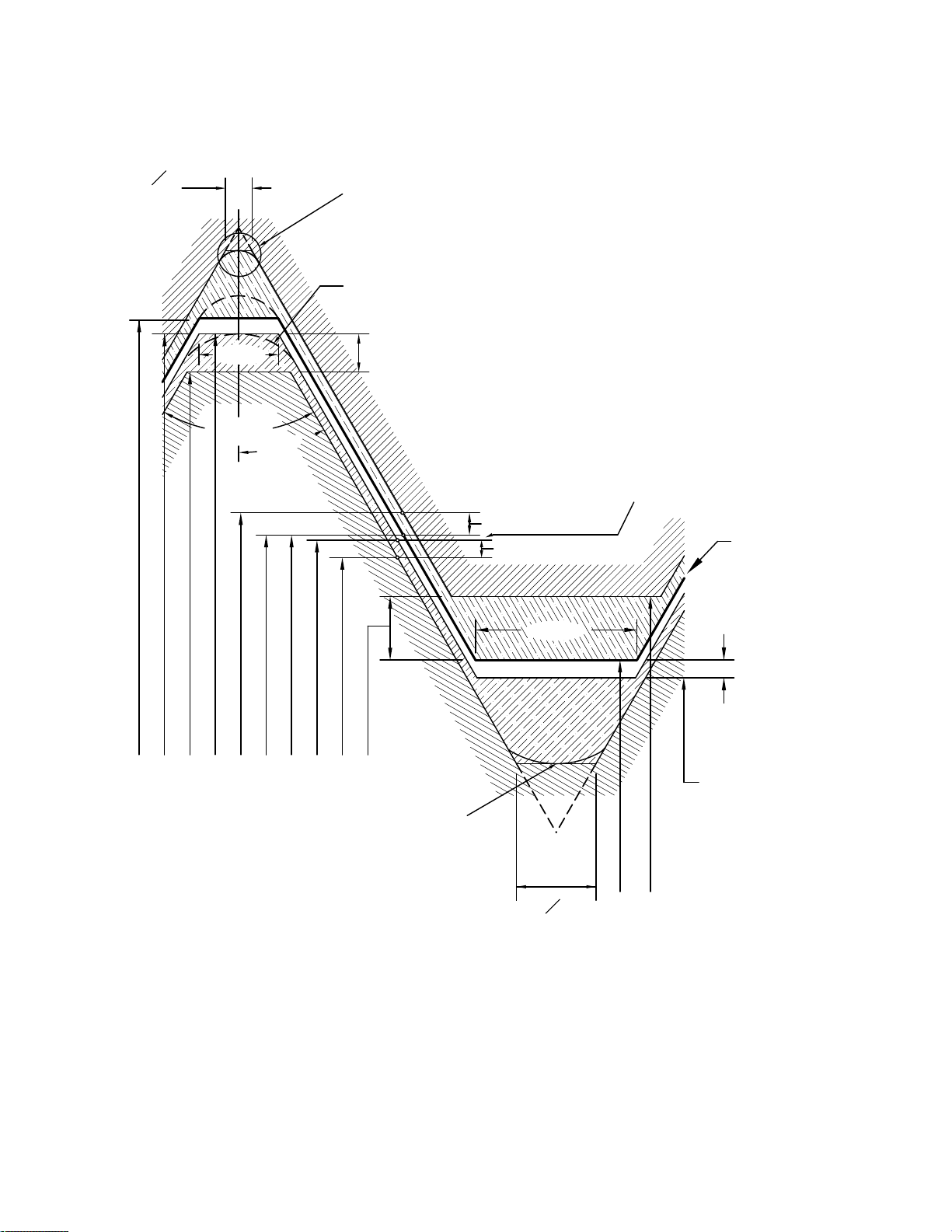

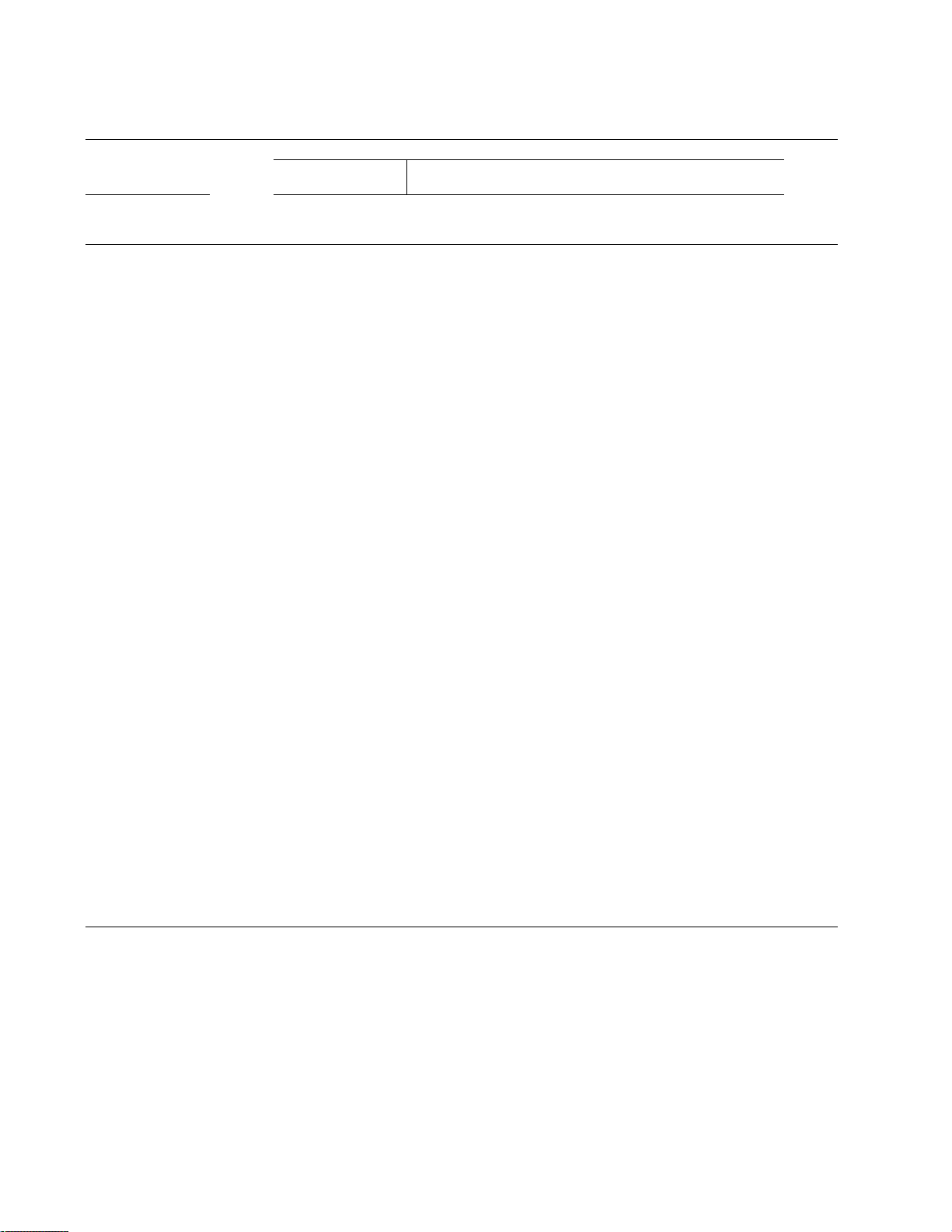

Figure 2 Basic Profile for UN and UNR Screw Threads

1.9 Units of Measure

All dimensions in this Standard, including all tables, are

in inches unless otherwise specified.

1.10 Federal Government Use

When this Standard is approved by the Department of

Defense and federal agencies and is incorporated into

FED-STD-H28/2, Screw-Thread Standards for Federal

Services, para. 2, the use of this Standard by the

federal government will be subject to all the requirements

and limitations of FED-STD-H28/2.

2 SCREW THREAD PROFILE

2.1 Scope

The basic profile and design profiles are defined in this

Section and are the basis of all thread dimensions given in

this Standard.

2.2 Basic Profile

2.2.1 UN and UNR. The basic profile for UN screw

threads is identical to that for UNR screw threads and

is shown in Figure 2. Profile applies to an axial plane.

For reference, the basic profile for UN and UNR screw

threads is identical to that for ISO metric screw threads

shown in ISO 68.

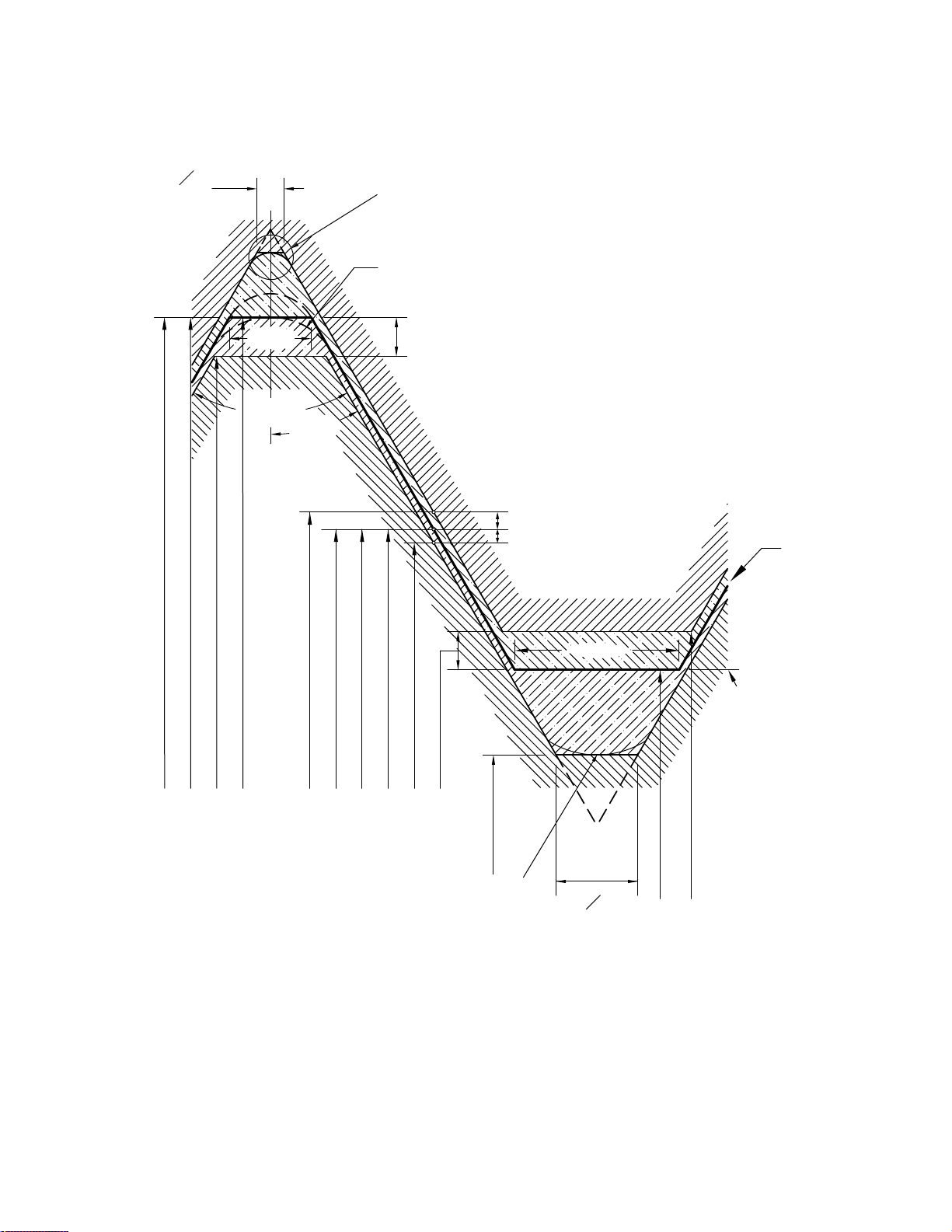

2.2.2 UNJ. The basic profile for UNJ screw threads is

shown in Figure 3. It is the theoretical profile corresponding to the basic dimensions of the thread major

diameter, pitch diameter, and minor diameter. This

profile includes a 0.15011107P to 0.18042196P radius

at the root of the external thread as shown in Figure

4. This also requires that the minor diameter of the

external and internal threads be larger than the UN

and UNR thread forms to accommodate the external

thread maximum root radius. It is similar to but not

the same as the profile for UN and UNR.

2.3 Design Profiles

ditions for external and internal threads with no allowance and are derived from the basic profile. The design

profiles of both external and internal screw threads

The design profiles define the maximum material con-

vary from the basic profile.

3

0.12500P0.500P

P

60

deg

30

deg

0.500P

Axis of thread

90 deg

0.312500P

0.32475953P

(0.3750H)

0.10825318P

(0.1250H)

0.48713929P

(0.5625H)

0.27063294P

(0.3125H)

0.86602540P

(H)

D bsc, d bsc

D bsc, d bsc

2

2

D bsc, d bsc

1

1

Basic UNJ profile

Basic limit profile

Minimum material limit

0.27063294P

(0.3125H)

[Note (4)]

0.18042196P

(0.2083H)

[Note (3)]

0.15011107P

(0.1733H)

[Note (2)]

r max. = 0.18042196P

Lower limit profile

[Note (1)]

(X)

r min. = 0.15011107P

ASME B1.1-2019

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Figure 3 Basic Profile for UNJ Screw Threads

NOTES:

(1) Optional profile comprised of two circular arcs (X) tangential to the flanks and flat at the root.

(2) Minimum truncation.

(3) Maximum truncation.

(4) Tangent flank radii (minor diameter).

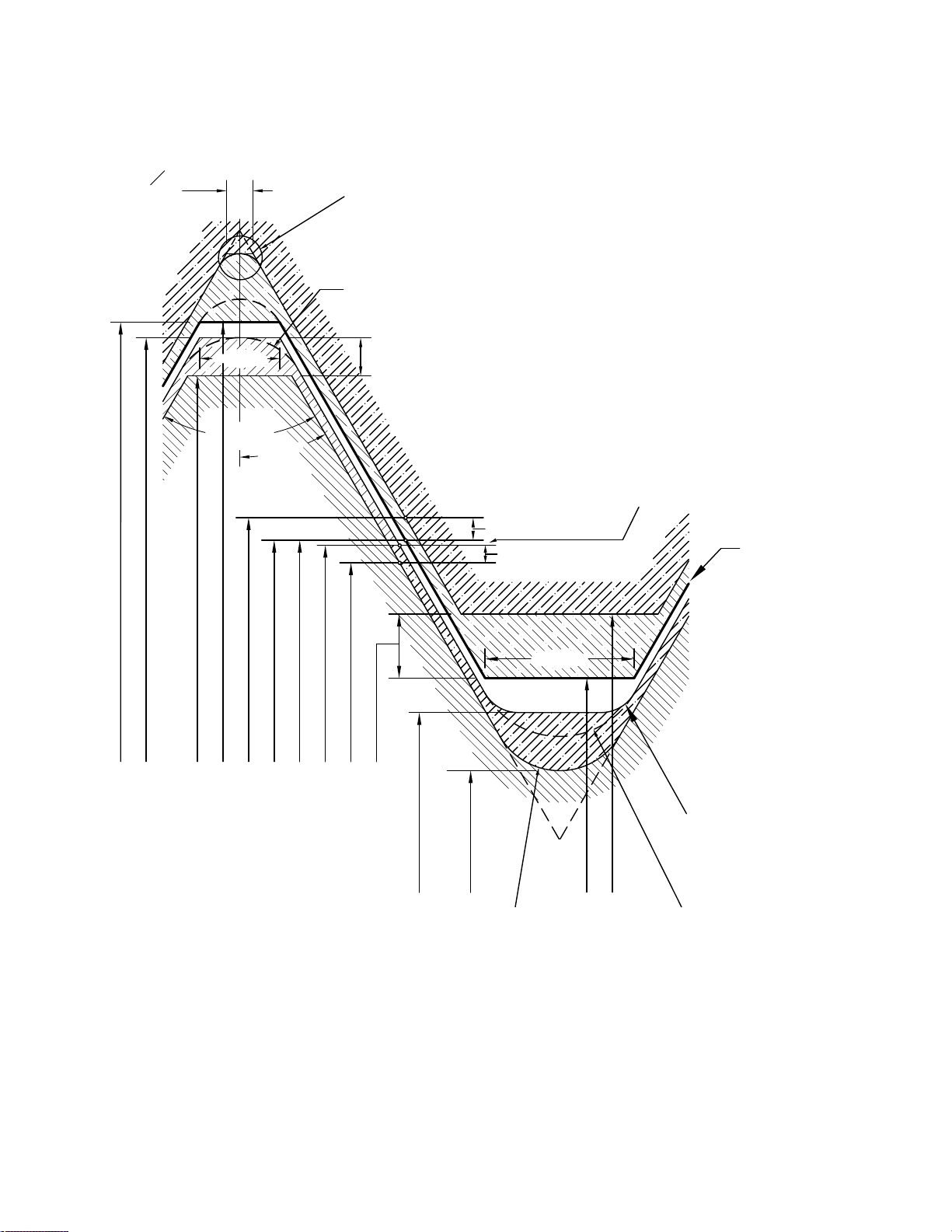

Figure 4 Root Radius of UNJ External Thread

4

ASME B1.1-2019

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

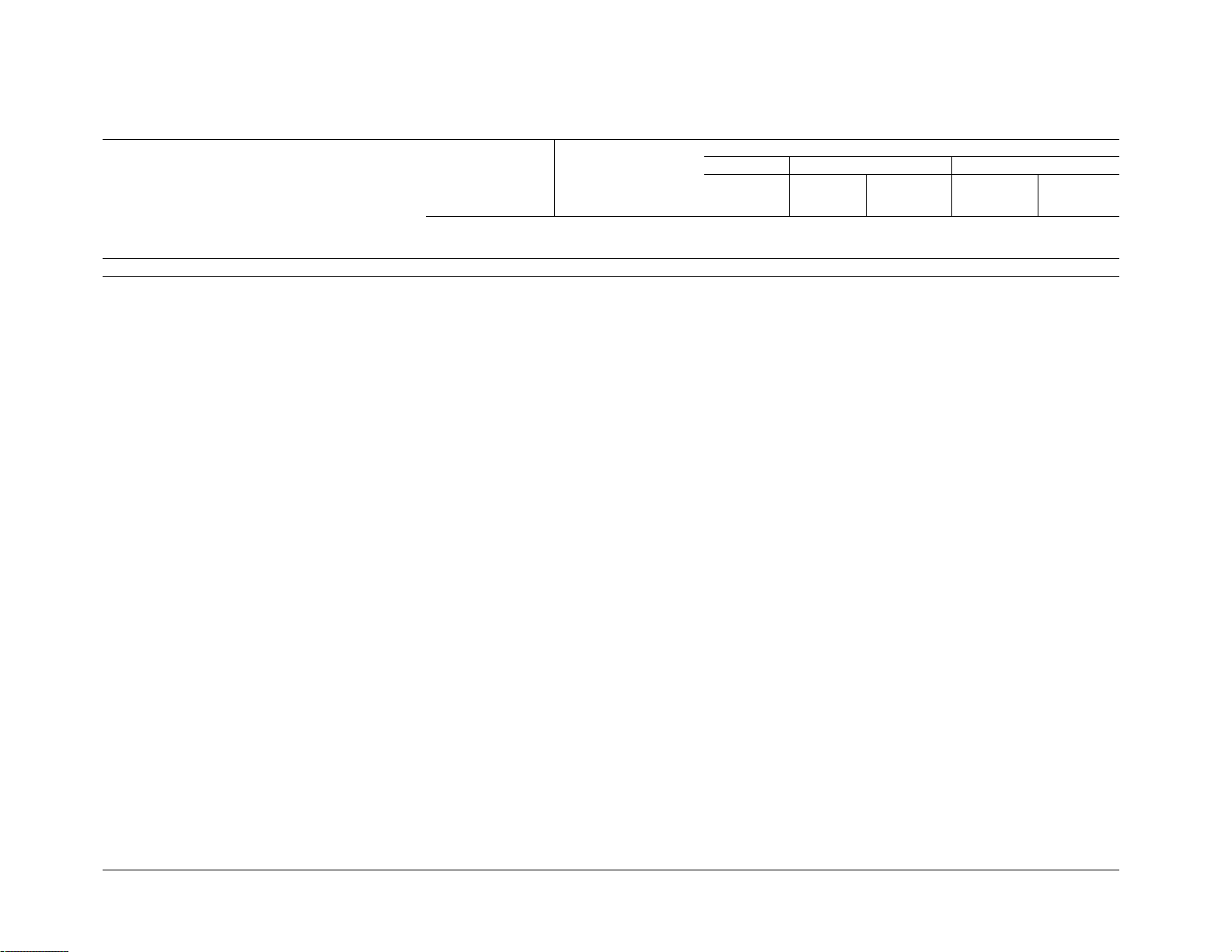

2.3.1 Design Profiles of External Threads

2.3.1.1 UN and UNR. The design profiles of external

UN and UNR screw threads are included in Figures 5

through 8. A flat root contour is specified for UN

threads; however, it is permissible to provide for some

threading tool crest wear. Therefore, a rounded root

contour cleared beyond the 0.2500P flat width of the

basic profile is optional. The rounded root also reduces

the rate of threading tool crest wear and improves

is necessary to provide for some threading tool crest

wear resulting in a profile that may be flat or partially

or fully rounded; therefore, the root of the design

profile is rounded and cleared beyond the 0.12500P

flat width of the basic profile. No root radius is specified.

2.4 Formulas and Nomenclature

The formulas and nomenclature pertaining to the basic

profile and the design profiles are given in section 10.

fatigue strength over that of a flat root thread.

(a) At the least material condition (LMC), the root form

3 SCREW THREAD SERIES

of the UNR external thread shall be a full root radius of not

less than 0.10825318P. At maximum material condition

(MMC), the root form of the UNR external thread may be

one of the following types:

(1) a full root radius of not more than 0.14433757P,

which makes the point of tangency between the radius and

the flanks at a point 0.54126588P below the basic major

diameter (the equivalent of a 0.2500P width of flat).

(2) a “rounded form” consisting of a combination of

flats and radii not less than 0.10825318P, as shown in

Figures 7 and 8. When the root is the rounded form,

the radii may exceed 0.14433757P so long as the point

of tangency between the radii and the flanks is no less

than 0.54126588P below the basic major diameter (the

equivalent of a 0.2500P width of flat).

(b) The design profiles of external UN and UNR screw

threads have flat crests. However, in practice, product

thread crests may be flat, partially rounded, or fully

rounded. A rounded crest tangent at a 0.12500P flat is

shown as an option in Figures 5 through 8.

2.3.1.2 UNJ. The design profile of the external UNJ

screw thread specifies that the actual root of the

thread shall lie within the root radius tolerance zone

3.1 Thread Series Definition

Thread series are groups of diameter-pitch combinations distinguished from each other by the number of

threads per inch applied to a series of specific diameters.

There are two general series classifications: standard and

special.

3.1.1 Standard Series. The standard series consists of

three series with graded pitches (coarse, fine, and extra

fine) and eight series with constant pitches (4, 6, 8, 12, 16,

20, 28, and 32 threads per inch). The standard series is

shown in Table 1.Limits of size are shown in Tables 2A and

2B and discussed in section 8.

3.1.2 Special Series. The special series consists of all

threads with diameter-pitch combinations that are not

included in the standard series. When allowances and

tolerances of special series threads are derived from

unified formulation as shown in section 5, the threads

are designated UNS, UNJS, or UNRS. If allowance and tolerance are not derived from unified formulation, the threads

are designated “SPL 60-deg Form.” (See para. 6.1 and

Figure 13 for details of designation.)

shown in Figures 4 and 9. The limit dimensions of the

root radius, r, are shown in Figures 10 and 11 and

their values are specified in Table 2A. The profile shall

be a continuous smoothly blended non-reversing

curve, no part of which shall have a radius of less than

0.15011107P and which is tangent to the thread flanks

at not less than 0.48713929P basic thread depth. The

profile may comprise tangent flank circular arcs that

are tangent to the flanks and a flat at the minor diameter

provided that the minor diameter, d

, is within the zone

3

3.2 Order of Selection

Wherever possible, selection should be made from

Table 1, preference being given to the coarse- and

fine-thread series. As second choice, if the threads in

the standard series in Table 1 do not meet the requirements of the design, special thread sizes should be selected

from Table E-1 and their limits calculated using the

formulas in section 8. The limits in Table D-1 are for reference only and are not recommended for new applications.

established in Figures 10 and 11. Unless otherwise specified, the runout or incomplete UNJ threads on externally

threaded parts shall be no less than 1 pitch nor more than 2

pitches in length. The threads shall runout onto the shank

without any abrupt change in cross-sectional area. The

root radius shall be no less than the minimum radius

of the full thread section.

2.3.2 Design Profile of Internal Threads. The design

profiles of the internal UN and UNJ screw threads are

included in Figures 2, 5 through 8, and 10 through 12

3.3 Coarse-Thread Series Applications

The coarse-thread series (UNC, UNRC, or UNJC) is

generally used for the bulk production of screws, bolts,

and nuts. It is commonly used in materials such as cast

iron, aluminum, magnesium, brass, bronze, and plastic,

because the coarse-thread series provides more resistance to internal thread stripping than the fine- or

extra-fine-thread series. The coarse-thread series is

advantageous where rapid assembly or disassembly is

(there is no internal UNR screw thread). In practice, it

5

½ PD tolerance on internal

½ PD tolerance on external

½ allowance (external)

Maximum pitch diameter of internal

Minimum pitch diameter of internal

Basic pitch diameter

Maximum pitch diameter of external

Minimum pitch diameter of external

Internal Thread

In practice, roots of internal threads

may be flat or partially or fully rounded

(see para. 2.3.2)

Maximum major diameter of external

Minimum major diameter of internal

Minimum major diameter of external

Basic major diameter

60 deg

3

0

d

e

g

External Thread

UN note: external root may be flat

or rounded [see para. 2.3.1.1(a)]

½ allowance

(external only)

Basic

form

½ tolerance on major

diameter of external

In practice, crests may be partially

or fully rounded [see para. 2.3.1.1(b)]

0.12500P

½ tolerance on minor

diameter of internal

0.2500P

Maximum minor

diameter of internal

Minimum minor

diameter of internal

UN (maximum) minor

diameter of external

(minimum reference)

(minimum reference)

P

24

P

8

ASME B1.1-2019

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Figure 5 Disposition of Diametral Tolerances, Allowance, and Crest Clearance for Unified Inch Screw Thread Series UN,

Classes 1A, 2A, 1B, and 2B

GENERAL NOTE: Lead and angle tolerances are defined in section 9.

6

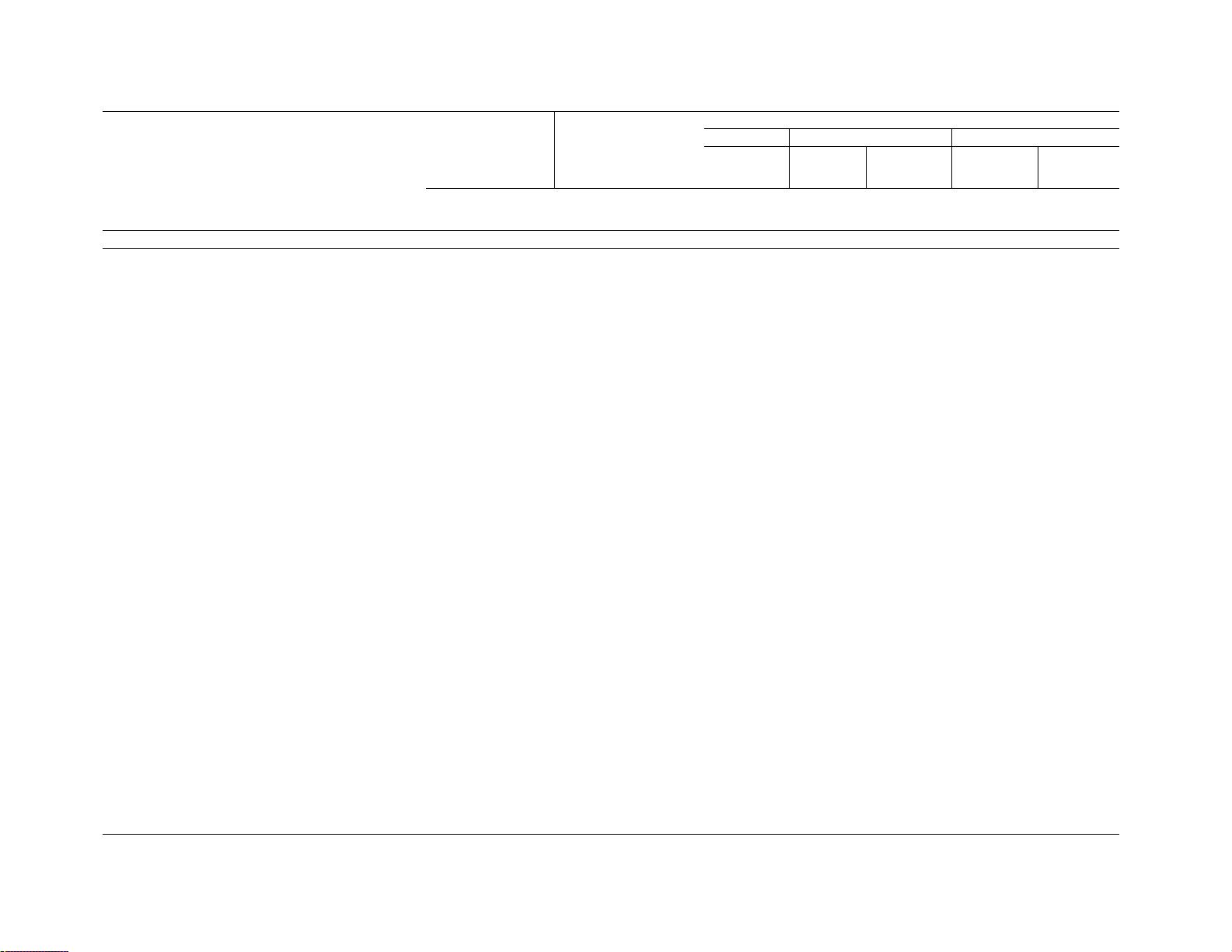

Internal Thread

External Thread

0.12500P

½ tolerance on major diameter of external

Basic

form

Basic major diameter of external and internal

Minimum major diameter of external

Maximum major diameter of external

Minimum major diameter of internal

Maximum pitch diameter of internal

Minimum pitch diameter of internal

Basic pitch diameter of external and internal

Maximum pitch diameter of external

Minimum pitch diameter of external

½ tolerance on minor

diameter of internal

Minimum minor

diameter of external

UN (maximum) minor

diameter of external

Maximum minor

diameter of internal

Minimum minor

diameter of internal

½ PD tolerance on internal

½ PD tolerance on external

0.2500P

In practice, crests may be partially

or fully rounded [see para. 2.3.1.1(b)]

UN note: external root may be flat

or rounded [see para. 2.3.1.1(a)]

In practice, roots of internal threads

may be flat or partially or fully rounded

(see para. 2.3.2)

(minimum reference)

(minimum reference)

P

24

P

8

60 deg

3

0

d

e

g

ASME B1.1-2019

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Figure 6 Disposition of Diametral Tolerances and Crest Clearance for Unified Inch Screw Thread Series UN,

Classes 3A and 3B

GENERAL NOTE: Lead and angle tolerances are defined in section 9.

7

External Thread

UNR note: external root is defined as a

continuous rounded contour with a radius

not less than 0.10825318P

Maximum minor

diameter of external

Minimum minor

diameter of external

Minimum minor

diameter of internal

Maximum minor

diameter of internal

Basic

form

½ PD tolerance on internal

½ PD tolerance on external

½ allowance (external)

Maximum pitch diameter of internal

Minimum pitch diameter of internal

Basic pitch diameter

Maximum pitch diameter of external

Minimum pitch diameter of external

½ tolerance on minor

diameter of internal

In practice, roots of internal threads

may be flat or partially or fully rounded

(see para. 2.3.2)

In practice, crests may be partially

or fully rounded [see para. 2.3.1.1(b)]

Internal Thread

½ tolerance on major

diameter of external

Basic major diameter

Min

imum major diameter of external

Maximum major diameter of external

Minimum major diameter of internal

0.2500P

0.12500P

UNR theoretical

maximum full root radius

is 0.14433757P

Maximum UNR root form

[see para. 2.3.1.1(a)]

(minimum reference)

P

24

60 deg

3

0

d

e

g

ASME B1.1-2019

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Figure 7 Disposition of Diametral Tolerances, Allowance, and Crest Clearance for Unified Inch Screw Thread Series

UNR, Classes 1A and 2A, and Series UN, Classes 1B and 2B

GENERAL NOTE: Lead and angle tolerances are defined in section 9.

8

Internal Thread

External Thread

0.12500P

Basic

form

Basic major diameter of external and internal

Minimum major diameter of external

Maximum major diameter of external

Minimum major diameter of internal

Maximum pitch diameter of internal

Minimum pitch diameter of internal

Basic pitch diameter of external and internal

Maximum pitch diameter of external

Minimum pitch diameter of external

½ PD tolerance on internal

½ PD tolerance on external

Minimum minor

diameter of external

Maximum minor

diameter of internal

Minimum minor

diameter of internal

0.2500P

In practice, crests may be partially

or fully rounded [see para. 2.3.1.1(b)]

UNR note: external root is defined as a

continuous rounded contour with a radius

not less than 0.10825318P

½ tolerance on minor

diameter of internal

½ tolerance on major diameter of external

In practice, roots of internal threads

may be flat or partially or fully rounded

(see para. 2.3.2)

Maximum minor

diameter of external

UNR theoretical

maximum full root radius

is 0.14433757P

Maximum UNR root form

[see para. 2.3.1.1(a)]

(minimum reference)

P

24

60 deg

3

0

d

e

g

ASME B1.1-2019

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Figure 8 Disposition of Diametral Tolerances and Crest Clearance for Unified Inch Screw Thread Series UNR, Class 3A

and Series UN, Class 3B

GENERAL NOTE: Lead and angle tolerances are defined in section 9.

9

d bsc

1

r max. = 0.18042196P

r min. = 0.15011107P

Td

3

2

d min.

3

d max.

3

d min.

2

d max. = d bsc

2

2

d max. = d bsc

Td

2

Td

2

2

Basic profile

2

d min.

0.48713929P

(0.5625H)

0.57735027P

(0.6667H)

ASME B1.1-2019

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Figure 9 External UNJ Thread Design Profile and Tolerances

GENERAL NOTE: Rounded crest is optional (see para. 7.1.2.2).

required, or if corrosion or damage from nicks due to

handling or use is likely.

3.4 Fine-Thread Series Applications

The fine-thread series (UNF, UNRF, or UNJF) is

commonly used for bolts and nuts in high-strength applications. This series has less thread depth and a larger

minor diameter than the coarse-thread series. Consequently, thinner walls are permitted for internal

threads and more strength is available to external

threads than for coarse-thread series of the same

nominal size. In order to prevent internal thread stripping,

a longer length of engagement is required for fine-thread

series than for coarse-thread series for thread materials of

the same strength levels. However, for both fine- and

coarse-thread series, length of engagement in tapped

holes must be selected to meet strength requirements.

This also allows for finer adjustment in cases such as a

slotted nut and cotter pin assembly.

3.5 Extra-Fine-Thread Series Applications

The extra-fine-thread series (UNEF, UNREF, or UNJEF)

is used particularly for equipment and threaded parts that

require fine adjustment, such as bearing retaining nuts,

adjusting screws, etc., and for thin-wall tubing and thin

nuts.

3.6 Constant-Pitch-Thread Series Applications

The various constant-pitch series (UN, UNR, or UNJ)

with 4, 6, 8, 12, 16, 20, 28, and 32 threads per inch

(see Table 1) offers a comprehensive range of

diameter-pitch combinations for those purposes where

the threads in the coarse-, fine-, and extra-fine-thread

series do not meet the particular requirements of the

design. The primary sizes of the 8-UN, 12-UN, and 16UN series shown in Table 1 are the most commonly used.

Whenever a thread in a constant-pitch series also

appears in the UNC, UNF, or UNEF series, the symbols

and tolerances for limits of size of those standard

series are applicable.

3.6.1 8-Thread Series. The 8-thread series (8-UN) is a

uniform-pitch series used for large diameters or as a

compromise between coarse- and fine-thread series.

Although originally intended for high-pressure-joint

bolts and nuts, it is now widely used as a substitute

for the coarse-thread series for diameters larger than

1 in.

is a uniform-pitch series for large diameters requiring

threads of medium-fine pitch. Although originally

intended for boiler practice, it is now used as a continuation of the fine-thread series for diameters larger than

1

1

10

3.6.2 12-Thread Series. The 12-thread series (12-UN)

∕2in.

r max.

0.18042196P

r min.

0.15011107P

½ minor diameter tolerance

of internal thread

Minimum minor diameter

of internal thread

Maximum minor diameter

of internal thread

Basic

form

Maximum minor

diameter of external

Minimum minor

diameter of external

External Thread

Maximum pitch diameter of internal

Minimum pitch diameter of internal

Maximum pitch diameter of external

Minimum pitch diameter of external

½ PD tolerance on internal

½ PD tolerance on external

½ allowance (external)

Maximum major diameter of external

Minimum major diameter of internal

Minimum major diameter of external

0.12500P

0.312500P

½ tolerance on major diameter of external

In practice, crests may be partially

or fully rounded [see para. 2.3.1.1(b)]

In practice roots of internal threads

may be flat or partially or fully rounded

(see para. 2.3.2)

Basic pitch diameter of internal

Internal Thread

(minimum reference)

P

24

60 deg

3

0

d

e

g

ASME B1.1-2019

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Figure 10 Disposition of Diametral Tolerances, Allowance, and Crest Clearance for Unified Inch Screw Thread Series

UNJ, Classes 2A and 2B

GENERAL NOTE: Lead and angle tolerances are defined in section 9.

11

Internal Thread

External Thread

Basic

form

Basic major diameter of external and internal

Minimum major diameter of external

Maximum major diameter of external

Minimum major diameter of internal

Maximum pitch diameter of internal

Minimum pitch diameter of internal

Basic pitch diameter of external and internal

Maximum pitch diameter of external

Minimum pitch diameter of external

½ PD tolerance on internal

½ PD tolerance on external

Minimum minor

diameter of external

½ minor diameter tolerance

of internal thread

Minimum minor diameter

of internal thread

Maximum minor diameter

of internal thread

0.312500P

0.12500P

Maximum minor

diameter of external

In practice, crests may be partially

or fully rounded [see para. 2.3.1.1(b)]

½ tolerance on major diameter of external

In practice roots of internal threads

may be flat or partially or fully rounded

[see para. 2.3.2]

r max.

0.18042196P

r min.

0.15011107P

(minimum reference)

P

24

60 deg

3

0

d

e

g

ASME B1.1-2019

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Figure 11 Disposition of Diametral Tolerances and Crest Clearance for Unified Inch Screw Thread Series UNJ,

Classes 3A and 3B

GENERAL NOTE: Lead and angle tolerances are defined in section 9.

12

ASME B1.1-2019

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Table 1 Standard Series Threads (UN, UNR, and UNJ)

Threads/in.

Nominal

Size, in.

Basic

Major

Primary Secondary

Diameter

0 … 0.0600 … 80 … … … … … … … … … 0

… 1 0.0730 64 72 … … … … … … … … … 1

2 … 0.0860 56 64 … … … … … … … … … 2

… 3 0.0990 48 56 … … … … … … … … … 3

4 … 0.1120 40 48 … … … … … … … … … 4

5 … 0.1250 40 44 … … … … … … … … … 5

6 … 0.1380 32 40 … … … … … … … … UNC 6

8 … 0.1640 32 36 … … … … … … … … UNC 8

10 … 0.1900 24 32 … … … … … … … … UNF 10

… 12 0.2160 24 28 32 … … … … … … UNF UNEF 12

Series With Graded

Pitches Series With Constant Pitches

Extra

Coarse

UNC

Fine

Fine

UNF

UNEF 4–UN 6–UN 8–UN 12–UN 16–UN 20–UN 28–UN 32–UN

Nominal

Size, in.

1

∕

4

5

∕

16

3

∕

8

7

∕

16

1

∕

2

9

∕

16

5

∕

8

…

3

∕

4

…

7

∕

8

…

… 0.2500 20 28 32 … … … … … UNC UNF UNEF

… 0.3125 18 24 32 … … … … … 20 28 UNEF

… 0.3750 16 24 32 … … … … UNC 20 28 UNEF

… 0.4375 14 20 28 … … … … 16 UNF UNEF 32

… 0.5000 13 20 28 … … … … 16 UNF UNEF 32

… 0.5625 12 I8 24 … … … UNC 16 20 28 32

… 0.6250 11 18 24 … … … 12 16 20 28 32

11

∕

16

0.6875 … … 24 … … … 12 16 20 28 32

0.7500 10 16 20 … … … 12 UNF UNEF 28 32

13

∕

16

0.8125 … … 20 … … … 12 16 UNEF 28 32

… 0.8750 9 14 20 … … … 12 16 UNEF 28 32

15

∕

16

0.9375 … … 20 … … … 12 16 UNEF 28 32

1 … 1.0000 8 12 20 … … UNC UNF 16 UNEF 28 32 1

1

… 1

11∕

8

… 13∕

11∕

4

… 15∕

13∕

8

… 17∕

11∕

2

… 19∕

15∕

8

… 111∕

13∕

4

∕

16

… 1.1250 7 12 18 … … 8 UNF 16 20 28 … 11∕

16

… 1.2500 7 12 18 … … 8 UNF 16 20 28 … 11∕

16

… 1.3750 6 12 18 ... UNC 8 UNF 16 20 28 ... 13∕

16

… 1.5000 6 12 18 … UNC 8 UNF 16 20 28 … 11∕

16

… 1.6250 … … 18 … 6 8 12 16 20 … … 15∕

… 1.7500 5 … … … 6 8 12 16 20 … … 13∕

1.0625 … … 18 … … 8 12 16 20 28 … 11∕

1.1875 … … 18 … … 8 12 16 20 28 … 13∕

1.3125 … … 18 … … 8 12 16 20 28 … 15∕

1.4375 … … 18 … 6 8 12 16 20 28 … 17∕

1.5625 … … 18 … 6 8 12 16 20 … … 19∕

1.6875 … … 18 … 6 8 12 16 20 … … 111∕

16

1

∕

4

5

∕

16

3

∕

8

7

∕

16

1

∕

2

9

∕

16

5

∕

8

11

∕

16

3

∕

4

13

∕

16

7

∕

8

15

∕

16

16

8

16

4

16

8

16

2

16

8

16

4

… 113∕

17∕

8

… 115∕

… 1.8750 … … … … 6 8 12 16 20 … … 17∕

1.8125 … … … … 6 8 12 16 20 … … 113∕

16

1.9375 … … … … 6 8 12 16 20 … … 115∕

16

2 … 2.0000 41∕

… 2

1

∕

2.1250 … … … … 6 8 12 16 20 … … 21∕

8

… … … 6 8 12 16 20 … … 2

2

13

16

8

16

8

ASME B1.1-2019

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Table 1 Standard Series Threads (UN, UNR, and UNJ) (Cont’d)

Threads/in.

Nominal

Size, in.

Basic

Major

Primary Secondary

1

2

∕

4

… 23∕

21∕

2

… 25∕

23∕

4

… 27∕

Diameter

… 2.2500 41∕

2.3750 … … … … 6 8 12 16 20 … … 23∕

8

… 2.5000 4 … … UNC 6 8 12 16 20 … … 21∕

2.6250 … … … 4 6 8 12 16 20 … … 25∕

8

… 2.7500 4 … … UNC 6 8 12 16 20 … … 23∕

2.8750 … … … 4 6 8 12 16 20 … … 27∕

8

3 … 3.0000 4 … … UNC 6 8 12 16 20 … … 3

… 3

31∕

4

… 33∕

1

∕

3.1250 … … … 4 6 8 12 16 … … … 31∕

8

… 3.2500 4 … … UNC 6 8 12 16 … … … 31∕

3.3750 … … … 4 6 8 12 16 … … … 33∕

8

Series With Graded

Pitches Series With Constant Pitches

Extra

Coarse

UNC

Fine

Fine

UNF

UNEF 4–UN 6–UN 8–UN 12–UN 16–UN 20–UN 28–UN 32–UN

… … … 6 8 12 16 20 … … 21∕

2

Nominal

Size, in.

4

8

2

8

4

8

8

4

8

31∕

2

… 35∕

33∕

4

… 37∕

… 3.5000 4 … … UNC 6 8 12 16 … … … 31∕

3.6250 … … … 4 6 8 12 16 … … … 35∕

8

… 3.7500 4 … … UNC 6 8 12 16 … … … 33∕

3.8750 … … … 4 6 8 12 16 … … … 37∕

8

2

8

4

8

4 … 4.0000 4 … … UNC 6 8 12 16 ... ... ... 4

… 4

41∕

4

… 43∕

41∕

2

… 45∕

43∕

4

… 47∕

1

∕

4.1250 … … … 4 6 8 12 16 … … … 41∕

8

… 4.2500 … … … 4 6 8 12 16 … … … 41∕

4.3750 … … … 4 6 8 12 16 … … … 43∕

8

… 4.5000 … … … 4 6 8 12 16 … … … 41∕

4.6250 … … … 4 6 8 12 16 … … … 45∕

8

… 4.7500 … … … 4 6 8 12 16 … … … 43∕

4.8750 … … … 4 6 8 12 16 … … … 47∕

8

8

4

8

2

8

4

8

5 … 5.0000 … … … 4 6 8 12 16 … … … 5

1

∕

… 5

51∕

4

… 53∕

51∕

2

… 55∕

53∕

4

… 57∕

… 5.2500 … … … 4 6 8 12 16 … … … 51∕

… 5.5000 … … … 4 6 8 12 16 … … … 51∕

… 5.7500 … … … 4 6 8 12 16 … … … 53∕

5.1250 … … … 4 6 8 12 16 … … … 51∕

8

5.3750 … … … 4 6 8 12 16 … … … 53∕

8

5.6250 … … … 4 6 8 12 16 … … … 55∕

8

5.8750 … … … 4 6 8 12 16 … … … 57∕

8

8

4

8

2

8

4

8

6 … 6.0000 … … … 4 6 8 12 16 … … … 6

GENERAL NOTE: Series designation shown indicates the UN thread form; however, the UNJ thread form may be specified by substituting

applicable symbol in place of UN in all designations for both internal and external use and the UNR thread form may be specified by substituting

applicable symbol in place of UN in all designations for external use only.

14

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

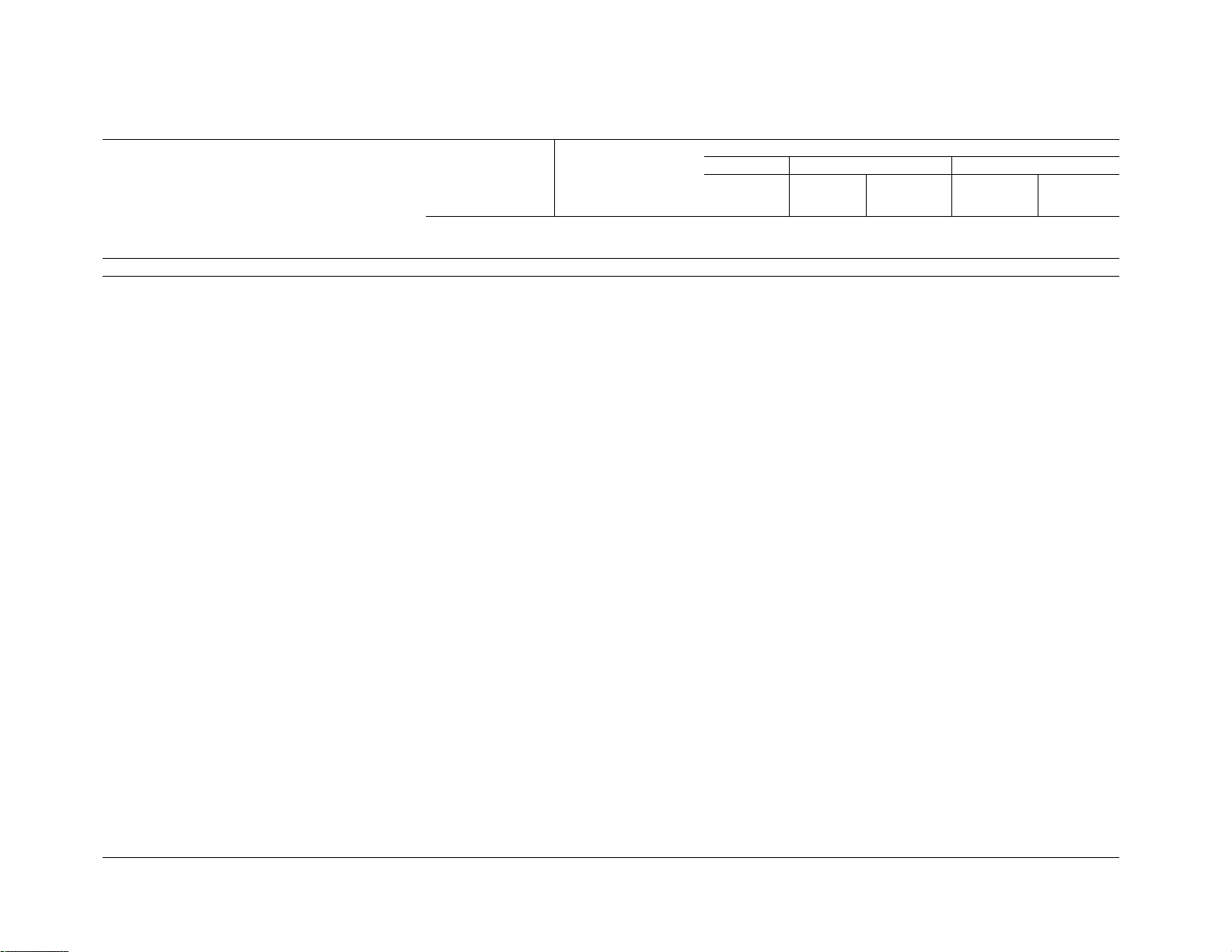

Table 2A Limits of Size for Standard Series External Threads (UN, UNR, and UNJ)

Minor Diameter, d

Reference

Diameter

[Note (6)] Radius Diameter Radius

Nominal Size

and

Threads/in.

Series

Designa-

tion

Class

[Note

(1)]

Allowance,

es

Major

Diameter,

Max.

[Note

(2)] Min.

Pitch Diameter,

d

, and

2

Functional

Diameter

Max.

[Note

(2)] Min.

[Note (4)]

Tolerance,

Td

2

[Note (5)] Max. Min. Max. Min. Max. Min. Max. Min. Max. Min.

d

Min.

[Note

(3)]

UN UNR UNJ

Reference

Diameter

[Notes (6), (7)]

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

0 – 80 or 0.0600 – 80 UNF 2A 0.0005 0.0595 0.0563 ... 0.0514 0.0496 0.001762 0.0460 0.0415 0.0446 ... 0.0018 0.0014 0.0451 0.0425 0.0023 0.0019

80 3A 0.0000 0.0600 0.0568 … 0.0519 0.0506 0.0013 0.0465 0.0425 0.0451 … 0.0018 0.0014 0.0456 0.0435 0.0023 0.0019

(8) 1 – 64 or 0.0730 – 64 UNC 2A 0.0006 0.0724 0.0686 ... 0.0623 0.0603 0.001970 0.0555 0.0502 0.0538 … 0.0023 0.0017 0.0544 0.0515 0.0028 0.0023

(8) 64 3A 0.0000 0.0730 0.0692 ... 0.0629 0.0614 0.0015 0.0561 0.0513 0.0544 … 0.0023 0.0017 0.0550 0.0526 0.0028 0.0023

(8) 1 – 72 or 0.0730 – 72 UNF 2A 0.0006 0.0724 0.0689 ... 0.0634 0.0615 0.001899 0.0574 0.0525 0.0559 … 0.0020 0.0015 0.0564 0.0536 0.0025 0.0021

(8) 72 3A 0.0000 0.0730 0.0695 ... 0.0640 0.0626 0.0014 0.0580 0.0536 0.0565 … 0.0020 0.0015 0.0570 0.0547 0.0025 0.0021

2 – 56 or 0.0860 – 56 UNC 2A 0.0006 0.0854 0.0813 ... 0.0738 0.0717 0.002127 0.0661 0.0601 0.0641 … 0.0026 0.0019 0.0648 0.0616 0.0032 0.0027

56 3A 0.0000 0.0860 0.0819 ... 0.0744 0.0728 0.0016 0.0667 0.0612 0.0647 … 0.0026 0.0019 0.0654 0.0627 0.0032 0.0027

/Root Radius

1

ASME B1.1-2019

15

(8) 2 – 64 or 0.0860 – 64 UNF 2A 0.0006 0.0854 0.0816 ... 0.0753 0.0733 0.002040 0.0685 0.0632 0.0668 … 0.0023 0.0017 0.0674 0.0645 0.0028 0.0023

(8) 64 3A 0.0000 0.0860 0.0822 ... 0.0759 0.0744 0.0015 0.0691 0.0643 0.0674 … 0.0023 0.0017 0.0680 0.0656 0.0028 0.0023

3 – 48 or 0.0990 – 48 UNC 2A 0.0007 0.0983 0.0938 ... 0.0848 0.0825 0.002302 0.0757 0.0690 0.0735 … 0.0030 0.0023 0.0743 0.0707 0.0038 0.0031

48 3A 0.0000 0.0990 0.0945 ... 0.0855 0.0838 0.0017 0.0764 0.0703 0.0742 … 0.0030 0.0023 0.0750 0.0720 0.0038 0.0031

3 – 56 or 0.0990 – 56 UNF 2A 0.0007 0.0983 0.0942 ... 0.0867 0.0845 0.002191 0.0790 0.0729 0.0770 … 0.0026 0.0019 0.0777 0.0744 0.0032 0.0027

56 3A 0.0000 0.0990 0.0949 ... 0.0874 0.0858 0.0016 0.0797 0.0742 0.0777 … 0.0026 0.0019 0.0784 0.0757 0.0032 0.0027

4 – 40 or 0.1120 – 40 UNC 2A 0.0008 0.1112 0.1061 ... 0.095 0.0925 0.002507 0.0841 0.0763 0.0814 … 0.0036 0.0027 0.0824 0.0784 0.0045 0.0038

40 3A 0.0000 0.1120 0.1069 ... 0.0958 0.0939 0.0019 0.0849 0.0777 0.0822 … 0.0036 0.0027 0.0832 0.0798 0.0045 0.0038

4 – 48 or 0.1120 – 48 UNF 2A 0.0007 0.1113 0.1068 ... 0.0978 0.0954 0.002361 0.0887 0.0819 0.0865 … 0.0030 0.0023 0.0873 0.0836 0.0038 0.0031

48 3A 0.0000 0.1120 0.1075 ... 0.0985 0.0967 0.0018 0.0894 0.0832 0.0872 … 0.0030 0.0023 0.0880 0.0849 0.0038 0.0031

5 – 40 or 0.1250 – 40 UNC 2A 0.0008 0.1242 0.1191 ... 0.1080 0.1054 0.002562 0.0971 0.0892 0.0944 … 0.0036 0.0027 0.0954 0.0913 0.0045 0.0038

40 3A 0.0000 0.1250 0.1199 ... 0.1088 0.1069 0.0019 0.0979 0.0907 0.0952 … 0.0036 0.0027 0.0962 0.0928 0.0045 0.0038

5 – 44 or 0.1250 – 44 UNF 2A 0.0007 0.1243 0.1195 ... 0.1095 0.1070 0.002484 0.0997 0.0922 0.0972 … 0.0033 0.0025 0.0980 0.0941 0.0041 0.0034

44 3A 0.0000 0.1250 0.1202 ... 0.1102 0.1083 0.0019 0.1004 0.0935 0.0979 … 0.0033 0.0025 0.0987 0.0954 0.0041 0.0034

6 – 32 or 0.1380 – 32 UNC 2A 0.0008 0.1372 0.1312 ... 0.1169 0.1141 0.002820 0.1034 0.0938 0.1000 … 0.0045 0.0034 0.1011 0.0964 0.0056 0.0047

(8) 32 3A 0.0000 0.1380 0.1320 ... 0.1177 0.1156 0.0021 0.1042 0.0953 0.1008 … 0.0045 0.0034 0.1019 0.0979 0.0056 0.0047

6 – 40 or 0.1380 – 40 UNF 2A 0.0008 0.1372 0.1321 ... 0.1210 0.1184 0.002614 0.1101 0.1022 0.1074 … 0.0036 0.0027 0.1084 0.1043 0.0045 0.0038

40 3A 0.0000 0.1380 0.1329 ... 0.1218 0.1198 0.0020 0.1109 0.1036 0.1082 … 0.0036 0.0027 0.1092 0.1057 0.0045 0.0038

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Table 2A Limits of Size for Standard Series External Threads (UN, UNR, and UNJ) (Cont’d)

Minor Diameter, d

Reference

Diameter

[Note (6)] Radius Diameter Radius

Nominal Size

and

Threads/in.

Series

Designa-

tion

Class

[Note

(1)]

Allowance,

es

Major

Diameter,

Max.

[Note

(2)] Min.

Pitch Diameter,

, and

d

2

Functional

Diameter

Max.

[Note

(2)] Min.

[Note (4)]

Tolerance,

Td

2

[Note (5)] Max. Min. Max. Min. Max. Min. Max. Min. Max. Min.

d

Min.

[Note

(3)]

UN UNR UNJ

Reference

Diameter

[Notes (6), (7)]

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

8 – 32 or 0.1640 – 32 UNC 2A 0.0009 0.1631 0.1571 ... 0.1428 0.1399 0.002916 0.1293 0.1196 0.1259 … 0.0045 0.0034 0.1270 0.1222 0.0056 0.0047

(8) 32 3A 0.0000 0.1640 0.1580 ... 0.1437 0.1415 0.0022 0.1302 0.1212 0.1268 … 0.0045 0.0034 0.1279 0.1238 0.0056 0.0047

8 – 36 or 0.1640 – 36 UNF 2A 0.0008 0.1632 0.1577 ... 0.1452 0.1424 0.002804 0.1331 0.1244 0.1301 … 0.0040 0.0030 0.1312 0.1267 0.0050 0.0042

36 3A 0.0000 0.1640 0.1585 ... 0.1460 0.1439 0.0021 0.1339 0.1259 0.1309 … 0.0040 0.0030 0.1320 0.1282 0.0050 0.0042

(8) 10 – 24 or 0.1900 – 24 UNC 2A 0.0010 0.1890 0.1818 ... 0.1619 0.1586 0.003319 0.1439 0.1315 0.1394 … 0.0060 0.0045 0.1409 0.1350 0.0075 0.0063

24 3A 0.0000 0.190 0.1828 ... 0.1629 0.1604 0.0025 0.1449 0.1333 0.1404 … 0.0060 0.0045 0.1419 0.1368 0.0075 0.0063

10 – 32 or 0.1900 – 32 UNF 2A 0.0009 0.1891 0.1831 ... 0.1688 0.1658 0.003004 0.1553 0.1455 0.1519 … 0.0045 0.0034 0.1530 0.1481 0.0056 0.0047

32 3A 0.0000 0.1900 0.1840 ... 0.1697 0.1674 0.0023 0.1562 0.1471 0.1528 … 0.0045 0.0034 0.1539 0.1497 0.0056 0.0047

/Root Radius

1

ASME B1.1-2019

16

12 – 24 or 0.2160 – 24 UNC 2A 0.0010 0.2150 0.2078 ... 0.1879 0.1845 0.003400 0.1699 0.1574 0.1654 … 0.0060 0.0045 0.1669 0.1609 0.0075 0.0063

24 3A 0.0000 0.2160 0.2088 ... 0.1889 0.1863 0.0026 0.1709 0.1592 0.1664 … 0.0060 0.0045 0.1679 0.1627 0.0075 0.0063

12 – 28 or 0.2160 – 28 UNF 2A 0.0010 0.2150 0.2085 ... 0.1918 0.1886 0.003224 0.1763 0.1654 0.1725 … 0.0052 0.0039 0.1738 0.1684 0.0064 0.0054

28 3A 0.0000 0.2160 0.2095 ... 0.1928 0.1904 0.0024 0.1773 0.1672 0.1735 … 0.0052 0.0039 0.1748 0.1702 0.0064 0.0054

(8) 12 – 32 or 0.2160 – 32 UNEF 2A 0.0010 0.2150 0.2090 ... 0.1947 0.1915 0.003183 0.1812 0.1712 0.1778 … 0.0045 0.0034 0.1789 0.1738 0.0056 0.0047

32 3A 0.0000 0.2160 0.2100 ... 0.1957 0.1933 0.0024 0.1822 0.1730 0.1788 … 0.0045 0.0034 0.1799 0.1756 0.0056 0.0047

1

∕4– 20 or 0.2500 – 20 UNC 1A 0.0011 0.2489 0.2367 ... 0.2164 0.2108 0.0056 0.1948 0.1783 0.1894 … 0.0072 0.0054 ... ... ... ...

20 2A 0.0011 0.2489 0.2408 0.2367 0.2164 0.2127 0.003731 0.1948 0.1802 0.1894 … 0.0072 0.0054 0.1911 0.1844 0.0090 0.0075

20 3A 0.0000 0.2500 0.2419 ... 0.2175 0.2147 0.0028 0.1959 0.1822 0.1905 … 0.0072 0.0054 0.1922 0.1864 0.009 0.0075

1

∕4– 28 or 0.2500 – 28 UNF 1A 0.0010 0.2490 0.2392 ... 0.2258 0.2208 0.0050 0.2103 0.1976 0.2065 … 0.0052 0.0039 ... ... ... ...

28 2A 0.0010 0.2490 0.2425 ... 0.2258 0.2225 0.003322 0.2103 0.1993 0.2065 … 0.0052 0.0039 0.2078 0.2023 0.0064 0.0054

28 3A 0.0000 0.2500 0.2435 ... 0.2268 0.2243 0.0025 0.2113 0.2011 0.2075 … 0.0052 0.0039 0.2088 0.2041 0.0064 0.0054

1

∕4– 32 or 0.2500 – 32 UNEF 2A 0.0010 0.2490 0.2430 ... 0.2287 0.2255 0.003228 0.2152 0.2052 0.2118 … 0.0045 0.0034 0.2129 0.2078 0.0056 0.0047

32 3A 0.0000 0.2500 0.2440 ... 0.2297 0.2273 0.0024 0.2162 0.2070 0.2128 … 0.0045 0.0034 0.2139 0.2096 0.0056 0.0047

5

∕16– 18 or 0.3125 – 18 UNC 1A 0.0012 0.3113 0.2982 ... 0.2752 0.2691 0.0061 0.2512 0.2330 0.2451 … 0.0080 0.0060 ... ... ... ...

18 2A 0.0012 0.3113 0.3026 0.2982 0.2752 0.2712 0.004041 0.2512 0.2351 0.2451 … 0.0080 0.0060 0.2471 0.2398 0.0100 0.0083

18 3A 0.0000 0.3125 0.3038 ... 0.2764 0.2734 0.0030 0.2524 0.2373 0.2463 … 0.0080 0.0060 0.2483 0.2420 0.0100 0.0083

5

(8)

∕16– 20 or 0.3125 – 20 UN 2A 0.0012 0.3113 0.3032 ... 0.2788 0.2747 0.004060 0.2572 0.2422 0.2518 … 0.0072 0.0054 0.2535 0.2464 0.0090 0.0075

(8) 20 3A 0.0000 0.3125 0.3044 ... 0.2800 0.2770 0.0030 0.2584 0.2445 0.2530 … 0.0072 0.0054 0.2547 0.2487 0.0090 0.0075

Copyrighted material licensed to University of Toronto by Clarivate Analytics (US) LLC, subscriptions.techstreet.com, downloaded on 2020-08-15 07:29:54 +0000 by University of Toronto User.

No further reproduction or distribution is permitted.

Table 2A Limits of Size for Standard Series External Threads (UN, UNR, and UNJ) (Cont’d)

Minor Diameter, d

Reference

Diameter

[Note (6)] Radius Diameter Radius

17

Nominal Size

and

Threads/in.

Series

Designa-

tion

Class

[Note

(1)]

Allowance,

es

Major

Diameter,

Max.

[Note

(2)] Min.

Pitch Diameter,

d

, and

2

Functional

Diameter

Max.

[Note

(2)] Min.

[Note (4)]

Tolerance,

Td

2

[Note (5)] Max. Min. Max. Min. Max. Min. Max. Min. Max. Min.

d

Min.

[Note

(3)]

UN UNR UNJ

Reference

Diameter

[Notes (6), (7)]

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

5

∕16– 24 or 0.3125 – 24 UNF 1A 0.0011 0.3114 0.3006 ... 0.2843 0.2788 0.0055 0.2663 0.2517 0.2618 … 0.0060 0.0045 ... ... ... ...

24 2A 0.0011 0.3114 0.3042 ... 0.2843 0.2806 0.003660 0.2663 0.2535 0.2618 … 0.0060 0.0045 0.2633 0.2570 0.0075 0.0063

24 3A 0.0000 0.3125 0.3053 ... 0.2854 0.2827 0.0027 0.2674 0.2556 0.2629 … 0.0060 0.0045 0.2644 0.2591 0.0075 0.0063

5

(8)

∕16– 28 or 0.3125 – 28 UN 2A 0.00100 0.3115 0.3050 ... 0.2883 0.2848 0.003495 0.2728 0.2616 0.2690 … 0.0052 0.0039 0.2703 0.2646 0.0064 0.0054

(8) 28 3A 0.0000 0.3125 0.3060 ... 0.2893 0.2867 0.0026 0.2738 0.2635 0.2700 … 0.0052 0.0039 0.2713 0.2665 0.0064 0.0054

5

(8)

∕16– 32 or 0.3125 – 32 UNEF 2A 0.0010 0.3115 0.3055 ... 0.2912 0.2879 0.003301 0.2777 0.2676 0.2743 … 0.0045 0.0034 0.2754 0.2702 0.0056 0.0047

(8) 32 3A 0.0000 0.3125 0.3065 ... 0.2922 0.2897 0.0025 0.2787 0.2694 0.2753 … 0.0045 0.0034 0.2764 0.2720 0.0056 0.0047

3