Page 1

Important:

Read all Instructions before using the appliance.

The machine must be Installed by a qualified

electrician.

The machine must not be started until the transit

packing has been removed. (It prevents the tub from

shaking while the machine Is being transported.)

to Use th

Printi

Page 2

Contents:

How to use the machine 2

Guide to parts

The controi panel 3

Opening the door 3

Sorting the washing 4

Detergent 5

Which program should 1 use?

Program examples

Care of the machine 8

Safety 9

If the machine won't work 9

Technical details

Installation

6-7

10

10-11

Removing the transport braces

Adjusting the feet

Building in the machine

Electrical installation

Water supply

Draining connection

Problems ans Solutions 12-14

IMPORTANT SAFETY INSTRUCTIONS14

Warranty 15

Instructions summary 16

How to use the machine

Choosing the right program

How to use

the machine

Follow the figures in the strip through this

booklet for brief instructions on how to use

the machine.

Full detaiis and comments can be found below the strip and must be fully read before operating the washing machine.

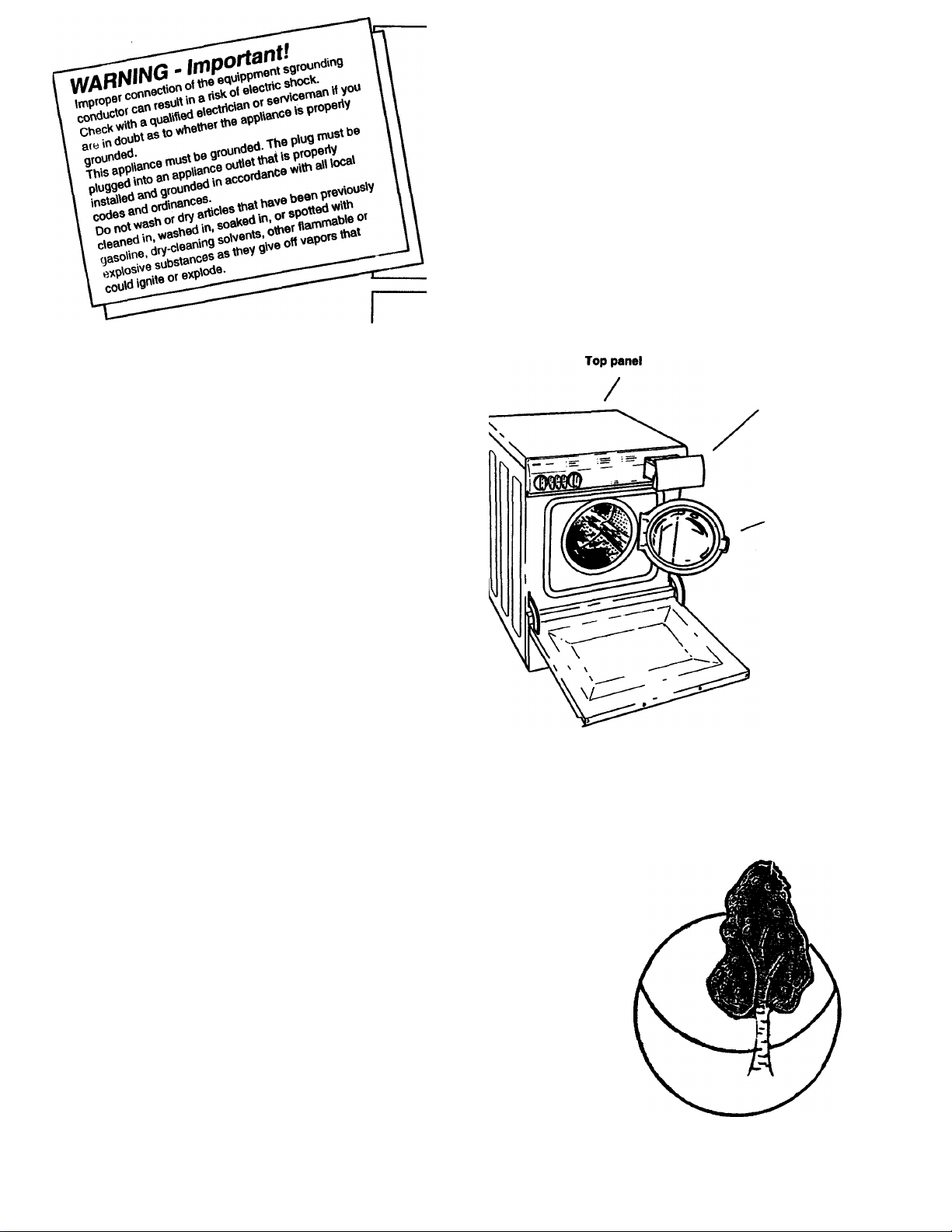

Guide to parts

2

6

Detergent and fabric

conditioner compartment

Door

Environment facts

Choose the right program

You can save considerable energy by not using ’stronger’ programs

than necessary.

• Using the normal cycle of this washer wiil enable the higher spin

speed to be used to reduce the amount of moisture that must be

removed by tumble drying the clothes.

Detergent

Using more detergent does not improve the washing performance, but

merely imposes an extra load on the environment.

Try reducing the amount of detergent you use, and increase it only if

the results are unsatisfactory.

Page 3

The control panel

Indicating lamp

Lights to

show that

the power is

turned on.

Program control knob

The program control knob

must be turned clockwise

only.

ASKO Artaks in Swsáan

r\

V-y

wash Quick Open Cold

Temperature

options

X-Hot He« WarmlMI-

r\ r\

|MI

Icati

Off

Permanent

Program selector

with On/Off switch

Main ON/OFF Switch

Must not be on "Off"

when opening the door

Temperature

You can select four different temperatures:

Extra hot: Gives 160° F, during main wash, works only when

Hot is pressed as well

Hot: Gives 140° F, during main wash

Warm: Gives 105° F, during main

wash

Cold: Gives cold water during main wash

Quick

When you put in the Quick-button you get a short program, with three

rinses and a short spin.

ifO

The door can be opened oniy when the program control knob is at

the end of a program. If it has stopped anywhere else, turn it drain

to pump out the water. The door can be opened about two minutes

after pumping out.

Page 4

... and press the door shut.

(It cannot be slammed

shut.)

Sort the washing

Sort clothes by color, fiber content, amount of soil, lint

shedding properties (cotton, chenile, and terrycioth

shed), lint attracting properties (permanent press,

corduroy, velveteen, flannel and synthetics attract) and

those requiring a delicate cycle. Most clothes and other

washable items have permanent care labels. Read

these labels carefullyl Care label instructions and

warnings should be followed for the best cleaning

results.

Load the Washer Properly

The following chart shows how full to load the washer

for the best results. The load size depends on what

types of fabrics you are washing.

Permanent press items need room to move freely

during washing for the most wrinkle-free results.

Therefore, fill the machine only half full for permanent

press loads. These items should only have a brief spin

cycle after which they should be promptly removed from

the washer for drying, follow the guidelines on the

Program Charts for "permanent press, synthetics*.

How much is in a full load ?

If the drum is filled without packing it tightly, it will hold the

equivalent of two sheets, pillow cases and mattress pad

or thin blanket off of a queen size bed or two king size

sheets, two pillow cases and two to four bath towels.

Water level in the washer

There is no need to set a load size or water level because

the Asko Automatic Level Control System automatically

selects the correct amount of water for each load.

Preparing ciothes for washing

• Turn delicate items, sweaters and t-shirts inside out to

prevent pilling and to protect the prints.

• Empty pockets and turn them inside out.

• Remove any sharp ornaments, pins or buckles to prevent

snags.

• Close zippers and hooks to prevent snagging

• Tie saches and strings to prevent tangling.

• Mend any small rips or tears to prevent them from getting

Machine washable wool loads should only be one-third

full for the cleanest results in this shortened cycle.

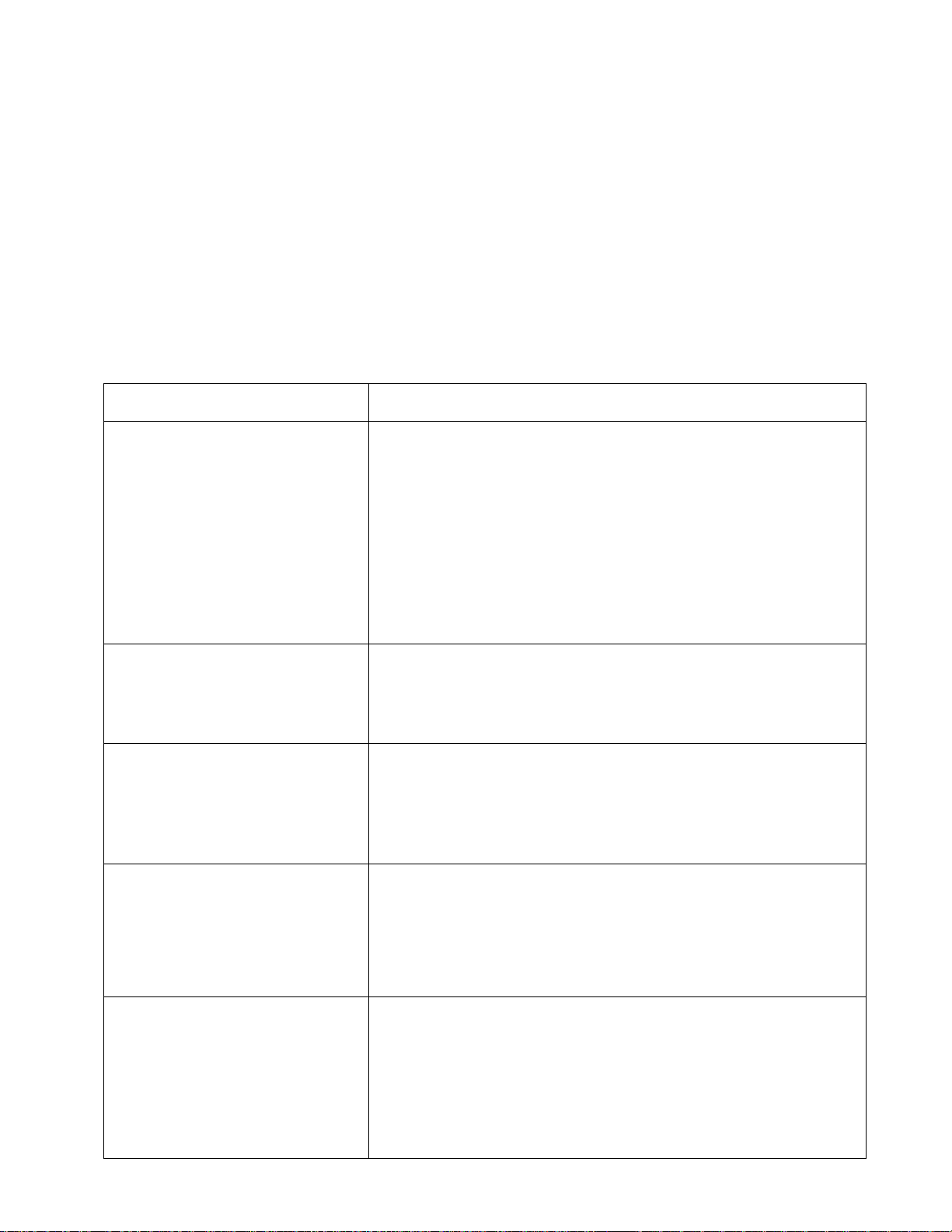

Recommended load sizes

Full load

Cotton

Linen

Half load

Permanent Press

Synthetics

Acrylics

Special finish

cottons

^

-------------

Full load

Third Load

Wool (machine washable)

Silk

Acetates

9

:

m

Half load

O

1/3 load

New colored items

Read labels carefully! If a label says “Wash Separately",

the item will lose color (excess dye) for the first few

washings. To minimize the possibility of this color

transferring to white or lighter colored items, wash new

colored garments with items of similar color or alone

before wearing. Bright reds and oranges on cottons are

the dyes most likely to transfer colors to the wash load.

Fluorescent colors should always be washed separately.

Prewash or not?

When washing items that are only slightly soiled, the

prewash cycle can be omitted. Starting the machine at

the main wash stage will save about 25 minutes.

Page 5

4. Pour detergent (and fabric

conditioner if used) into the

appropriate sections of the

detergent compartment.

Detergents - What kind - How much?

Use oniy sudsing iaundry detergents!

Detergents are available in low, normal and full sudsing formulas. A detergent's ability to clean Is not relate, to the amount of

suds it produces. Excess suds in a front loading washer actually interfere with cleaning action because they cushion the

tumbling of clothes. High sudsing detergents are also more difficult to completely rinse out.

Use 1/4 to 1/2 of the recommended U.S. detergents

Because of the Asko washer's low water consumption and the fact that all

the wash wafer and detergent are completely circulated repeatadly through

the laundry, ensuring that all the detergent is fully utilized, detergent usage

is cut by 50% to 75%.

Different brands of detergents recommend using different amounts. Read

all package labels carefully. The first time you use any detergent, start

with 1/4 of the recommended amount. (For example: If the label says use

1 cup, use 1/4 cup.)

If the detergent produces a good, low level of suds, you may add slightly

more detergent if you have very hard water or if your clothes are not

getting perfectiy ciean. It is advisable to check your water hardness with

the local water department.

Recommended detergents

Avoid normai and fuil sudsing detergents. The chart below lists several low

sudsing detergents that have been successfully tested in the Asko washer,

aiong with the recommended amounts.

Recommended Detergente

Fab (powder)

Amway SA8 (powder)

Fresh Start (powder)

All (powder)

Main Wash Detergent Amount*

1/4 cup to 1/2 cup

1-2 tablespoons (1/6 cup)

2 tablespoons (1/8 cup) to 1/4 cup

1/4 cup to 1/2 cup

‘ Add sNghlly less additional detergent lor prewash

in general, liquid detergents tend to be higher sudsing than powders. Do

not use powder detergents that do not wash completely out of the

detergent cup as the machine fills with water.

Liquid detergents

Liquid detergents tend to more suds than powder

detergents. When trying a detergent for the first

time, start out with a very smail amount, such as 1

to 2 tablespoons.

Liquid detergent can used for all programs without

pre-wash. Add it into the main wash compartment.

Bleach

The use of bleaches is not necessary with these

machines, nor is it recommended.

Note: Detergents: Using more detergent does not

improve the washing performance, but merely

imposes an extra load on the environment. Try

reducing the amount of detergent you use, and

increase it only if the results are unsatisfactory.

Pre-wash detergent

Fabric

condition(

Fabric softeners

Use 1/3 to 1/2 of the recommended amount of

fabric softener, because of the low water usage

of the Asko washer. Fabric softeners are

available in several concentrations.Read the

labels carefully and use only 1/3 to 1/2 of the

recommended amount. (For example: If the

label says to use 1 capful, use 1/4 capful.) If

more softening is desired, try adding slightly

more the next time.

Oversudsing

The use of anything other than a low sudsing

detergent can cause severe oversudsing. If this

happens, run the wash through one or more

rinse programs (starting on 5) until Items are

thoroughly rinsed. Then, run the empty washer

through an entire wash program (starting on 1)

to clear the machine of any remaining high

sudsing detergent.

Clean the detergent

compartment regularly

1. Pull out the compartment and

remove the fabric conditioner

insert.

2. Seiect any program.

3. Clean the compartment with a

brush while water flows through

it.

4. When finished, select Drain to

pump the water out of the

machine.

Main wash

detergent

Page 6

5. Press the required

temperature button

X-HOT HOT

WARM

6. Turn the program knob

to the point where you

want the machine to

start.

w

QUICK

a

OPEN COLD

What the figures on the program knob mean

Spin

1-5 minutes at 800

or 1000 rpm

depending on

program selection

Drain

Pumping out

Drain

Prewash

If you want a program

with prewash, you can

select between three

start-points: 12, 9,6 or 3

minutes of Prewash

Remember - turn the program knob

clockwise only.

Rinse

Four rinses or less

of cold water,

depending on

program selection.

Main wash

8 startpoints give 24,

21,18,15,12, 9,6or3

minutes of Main wash.

(Cold water inlet)

У V

Page 7

7. The machines starts and

works through the stages

shown below.

If you change your mind ...

... and want a different program:

Turn the program knob and program selector to the required

positions, and press any temperature switches that you want.

... or want to interrupt the program

Turn the program knob to Drain to make the machine pump

out. After about two minutes, you can open the door. If you

add more washing and restart the machine, check that there

is detergent left in the detergent compartment.

Which program should I choose?

You can naturally select a standard program or, by combining

your prefered temperature setting, program and option

selection, produce p program to suit your requirements.

Program

Normal

Permanent

Press

Delicate

Prewash

1 11 1

1 11 1

1 11

Main wash Rinses

□ □□

□ □□□

□ □□

Spin

1000 rpm

® 800 rpm

^ 800 rpm

Point to note: Before starting to spin, the machine checks that the load

is evenly distributed in the drum. If not, it redistributes the

load by turning at normal drum speed and then makes

another attempt to start spinning.

Action

Normal

Normal

Gentle Normal

Water level

Normal

Normal

Page 8

8 When the machine has stopped:

Open the door by pressing

I

Open

User -Maintenance instructions - Care of the machine

Check the needie trap and outiet pump

The machine has a needle trap which

will trap needles, hairpins, coins and

similar items. Clean it at intervals as

follows:

1. Open the lower cover in front of the

pump, pull the small drain hose and

drain off water into a shallow bowl

after removing the plug from the end

of the hose (1).

2. Turn the pump cover anticlockwise to

the position shown in (2). This un

covers the drain holes and water will

run out into the bowl.

3. When the water has finished draining

out, turn the pump cover further and

pull it off. Clean out the needle trap,

and clean the pump rotor at the back

of the pump housing (3).

4. Check that there is no grii or small

objects in the pump, and replace the

pump cover. Turn it clockwise in two

stages: when you hear a click, turn it

a little more to Its end stop, as shown

in (4).

(D

Bottom

Closed

Bottom

0

Access openings under the drum paddles

If an object has fallen between the drum and the outer

container, you can get it out as follows:

1. Undo the screw on top of the paddle with a screwdriver

(three turns).

2. Pull the paddle towards you and lift it upwards.

3. Remove the object. Be careful not to bend the immersion

heater elements.

4. Locate the paddle in its fixing hole, with the F-mark to the

front (i.e. facing you). Slide the paddle backwards as far

as it will go. Check that its clips are properly located in the

slots In the drum, and retighten the screw.

Page 9

9. After use:

Safety

Turn off the machine at the

On/Off button.

NB! Don't close the door after using the machine: leave it ajar.

The machine incorporates a door safety

switch which prevents it from being

started if the door is open. The door is

also interlocked to prevent it from being

opened when the machine is running or

when it has stopped with water in.

If the machine won’t work

Problem

The door will not open. 1. Check that the main On/Off switch is turned on.

Response

2. If the indicater lamp is not lit, there is no power supply. Check the plug and

fuses. The door cannot be opened normally if there is no power supply.

3. If the door cannot be opened in the normal manner, it can be opened as

follows. Insert a small screwdriver in the hole to the left of the door and

press the door catch upwards to release the door.

If the door still cannot be opened in the normal way afterwards, call a sen/ice

engineer.

The machine does not fill with water

when started.

The machine does not start when the

program knob is turned to the starting

position.

The machine wiil not spin.

A lot of foam in the final rinse water, or

water ieft in the machine after spinning

and pumping out.

1. Is the tap In the supply line open?

2. Is the strainer in the inlet connection blocked? Unscrew the hose and check.

Remember to turn off the water supply first.

1. Is the door properly closed? Press it shut firmly - don't slam it.

2. Is the main On/Off switch turned on?

3. Has the power supply failed? Check the plug and fuses.

1. Is the pump or outlet hose blocked? Clean if necessary, as described on

page 8.

2. Has the power supply failed? Check the plug and fuses.

3. The machine will make up to 30 attempts to start, redistributing the washing

if the drum is out of balance. After that, it passes on to the next stage of the

program.

1. Is anything blocking the outlet hqse? A button or a coin can do so. Make

sure that no part of the hose (including any joints) is less than 15 mm in

diameter.

2. Is the pump blocked? Clean it as described on page 8.

3. Is the outlet hose kinked?

9

Page 10

Technical data

Dimensions, mm 34 1/4" X 23 1/2" X

23 1/2"

Weight 170 lbs

Spin speed 800/1000 r/min

Installation Instructions

Removing the shipping brace

The shipping brace consists of two tubes

which prevent the barrel from moving

around inside the machine during

transport. The tubes are secured to a

cross beam at the back of the machine.

Two tubes

inside

the machine

Rated load 3505 W/240 V

3240 W/230 V

Supply voltage 208-240 V, 60 Hz

single-phase

Heater rating 3265W/240V

3000 W/230 V

Material of drum

and barrel

Material of

outer casing

Mounting

Water suppiy

hose

Supply pressure 0.1-1 MPa

Stainless steel

Stove-enamelled

hot-dip-galvanised

steel sheet

Stationary: four

adjustable rubbercovered feet

5 ft pex hose

(10-100 N/cm*,

1-10 kp/cm*,

15-146 PSI)

Remove the shipping brace as follows:

1. Remove the bolts and special

washers which retain the beam,

and remove the beam.

2. Replace the washers on the flattened

part of the tubes. Use them as tools

to turn the tubes through about 45°,

as shown in the drawing, and pull out

the tubes.

3. Turn the washers so that

they cover the holes

where the tubes were

fitted and replace the

bolts.

Save the tubes and cross beam,

which will be needed if the machine

has to be transported elsewhere.

Fit them in the reverse order to that

described above.

Cross beam

Boit

Washer

Tube

Outlet 5.5 ftof poly-

propene hose,

3/4" internal

diameter

Accessories

The machine is supplied with:

• Operating instructions and

installation instructions.

• Guarantee card.

• Type-approved inlet hose for

connection to water supply.

Optional extras:

• Decor frames

• Edging frame by stacked

machines

• Frame set with pull-out shelf by

stacked machines.

Adjusting the feet

It is important that the machine

does not move around when it is

spinning. This means that it must

be standing firmly and level on the

floor. The four feet are individually

adjustable. Set them carefully so

that the machine is standing level,

and tighten the locknuts securely.

Positioning the machine

The machine can be installed beneath a

worktop with a height of 33 1/2"-35 1/2".

There must be a gap of about 1/4" all round

the machine, including between the rear ^

edge of the machine top panel and the wall

behind. This is important: if no space is left,

the machine may hit the wall when it starts

to spin.

Lock nut

NOTE

Height adjustment: 32 1/4"-33 1/2'

Do noty raise Higher than 33 1/2*

10

Page 11

Electrical installation

The machine is delivered ready-fitted with a plug, and is

intended for connection to an Asko Dryer. The Asko Dryer is

equipped with a matching receptical. The plug supplied with

the washer can only be used with an Asko Dryer. If the

washer is used seperately or with another dryer, it must be on

its own separate 220 V single phase circuit.

If the machine is to be used in a wet area, the supply must be

protected by a residual current device.

Connection to a permanently wired supply point must be

made only by a qualified electrician.

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of malfunction or breakdown, grounding will reduce the risk

of electric shock by providing a path of least resistance for electric current. This appliance is equipped with

a cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into an

appropriate outlet that is properly Installed and grounded in accordance with all local codes and ordinances.

WARNING - Improper connection of the equipment-grounding conductor can resuit in a risk of electric

shock. Check with a quaiified electrician or senriceman if you are in doubt as to whether the appliance is

property grounded.

Do not modify the piug provided with the appliance - if it will not fit the outlet, have a proper outlet Installed

by a qualified electrician.

As supplied:

208-240 V, 60 Hz

3265 W heater rating,

15 A fuse required

Water supply connection

The water supply connections must be made by

a person having the necessary competence.

Water pressure must be in the range

15-146 PSI.

A tap must be fitted in the supply pipe for the

hose.

If a new supply pipe has been installed for the

machine, it should be flushed through thoroughly

in order to remove any particles of dirt which

might otherwise block the strainer in the water

inlet of the machine.

Drain outlet connection

The machine is supplied with the outlet hose

ready fitted. The hose should be hung over a

suitable sink edge or drain pipe at a height of

15 3/4"-35 1/2“ above the floor: the lower

height is preferable. Make sure that the hose

is not kinked.

NB! If the hose is extended, the internal

diameter of the coupling must not be less

than 1/2“.

Cold water supply

15 3/4"-35 1/2"

11

Page 12

Problems ?

Try the following remedies. Poor result may not always be caused by the machine.

Read through the chart below before contacting your servicer.

Problem

Door will not open

Machine wiil not start

Machine wili not fill with water

Foam in final rinse,water left in

machine

Water leaks

Extrem vibration during spin

cycle

Oversudsing

Washer stops during cycle

Possible Cause

Hoses

Transit packing not

removed

Machine not level

Wrong detergent Use only low sudsing detergents. See page 5. Run clothes

Too much detergent

Nomal pauses

Suggested Remedy

See "If the machine doesen't work", page 9.

All hoses, especially the inlet hose should be inspected at

least once a year. Replace if they show signs of cracking.

Check to see if hose connections at faucets are tight.

Properly insert and secure end of drain facility.

Remove transit packing. See page 10.

Adjust machine feet and tighten locknuts.

throough extra rinse cycles.

Run empty machine through complete cycle

Use recommended amounts. See page 5.

It is normal for the machine to pause occasionally during

operation, especially between cycles and during the

delicate wash program.

Greying clothes

Lint, residue left on clothes

Not enough detergent

Water not hot enough

Improperly prewashed or

presoaked

Washer overloaded

Soap used In hard water

areas.

Improper sorting of

clothes

Nonphosphate detergent

Non-phosphate detergents

Fabric softener used

improperty

You may need to add slighly more detergent if clothes are

heavily soiled, have oily stains, or if your water is very hard.

Select hot temperature setting for each type of load. See

charts page 6 and 16.

Be sure to add a prewash and/or presoak for heavily soiled

oily items.

Once wet, the clothes must have room to tumble freely,

especially synthetics and permanent press.

Be sure you use a laundry "detergent" and not a "soap".

Soaps react with the minerals in hard water to form a soap

curd, which can be desposited on clothes.

Separate clothes that shed lint (cheniie and terrycloth)

from clothes that attract lint (synthetics, corduroy,

velveteen).

can combine with minerals in hard water and form a

preciptate which can appear to be lint. Use a tow

phosphate detergent, if possible. Install a water softener.

Read labels. Most softeners should only be used in the

final rinse. Add softener to the softener compartment, if

added to the wash cycle, softeners can have a reaction

with detergents producing a white residue.

12

Piiling

Pilling, which can look like lint, is produced by normal

wear on cotton/polyester blend fabrics. To reduce, wash

synhetics and cotton /polyester blends inside out. For

the best results, wash cotton/polyester knits using the

delicate cycle.

Page 13

Problems ?

Tt7 the following remedies. Poor result may not always be caused by the machine.

Read through the chart below before contacting your servicer.

Problem

Yellowing of clothes

Shrinkage

Knit shrinkage

Rips,snags,excess wear

Possible Cause

Not enough detergent,

water not hot enough

Iron or manganese in

water

Improver washing or

drying

Overheating

Delayed or gradual

shrinkage

Poor construction

Sharp objects in pockets

Hooks,

snaps,zippers,buckles

Suggested Remedy

Caused by body oils not completely removed. Use hoHest

recommended temperature for each type of load and add

slightly more detergent.

Install a filter to remove iron or manganese from water. A small

amount of Calgon or other non-precipitating water conditioner

added once a week is advisable in hard water areas.

Follow garment car label instructions carefully. Some fabrics

will shrink no matter how they are washed. Some may be

machine washed but not machine dried.

KnHs tend to shrink more than woven fabrics. If a knit has been

heat shaped, wash in cool or warm water. Dry with the low

setting.

Can occur when special stabilizing finishes are reduced from

wear or repeated washings. Garment may sometimes be

reshaped by pressing after washing and drying.

Shrinkage can occur If the knit fabric was not stretched

properly by the manufacturer. Press back into shape

each time garment is washed and dried.

Empty all pockets and turn inside out before laundering.

Fasten all hooks,snaps and zippers before laundering to avoid

snags. Remove sharp buckles. Turn knits inside out.

Fading and discoloring

Stains not removed

Harsh chemicals

Existing rips and tears

Permanent press Kerns

Inproper sorting

Crayons or pens in

pockets.

Water too hot

Incorrect water

temperature

Protein stains, such as

Before washing, rinse harshchemicals, such as battery acid,

permanent wave solution, hair bleach, dyes and toilet bowl

cleaners, from towels and other articles to avoid holes in

fabrics. Do not allow these unrinsed items to contact other

fabrics.

Mend all garments before laundering to prevent

enlarging of rips.

These items fray at edges from the permanent press process

and from normal wear, not from the washer. Only wash in half

loads. Do not wash in the same load with very heavy items,

such as towels or jeans.

Dark clothes, especially cottons, can bleed excess dyes

into wash water. White or light colored clothes can

absorb the dye and discolor. Separate light from dark

items.

Empty all pockets before washing.

Cool or cold water Is best for retaining dark or bright colors.

milk,egg,blood and soy formula should be removed in

cold water. Oily stains should be washed in the hottest

water recommended for each fabric type.

Old stains The longer a stain remains on a fabric, the harder it is to

remove. Treat stains promptly. Do not set stains by

machine drying or ironing fabrics until stains are

completely removed.

13

Page 14

IMPORTANT SAFETY INSTRUCTIONS

WARNING - To reduce the risk of fire, electric shock, or injury to persons when using your

appliance, follow basic precautions, including the following:

1. Read all instructions before using the appliance.

2. Do not wash or dry articles that have been previously cleaned in, washed in, soaked in, or

spotted with gasoline, dry-cleaning solvents, other flammable or explosive substances as they

give off vapors that could ignite or explode.

3. Do not allow children to play on or in the appliance. Close supervision of children is necessary

when the appliance is used near children.

4. Before the appliance is removed from service or discarded, remove the door to the washing or

drying compartment.

5. Do not reach into the appliance if the drum is moving.

6. Do not install or store this appliance where it will be exposed to the weather.

7. Do not tamper with controls.

8. Do not repair or replace any part of the appliance or attempt any servicing unless specifically

recommended in the user-repair instructions or in published user-repair instructions that you

understand and have the skills to carry out.

9. Do not add gasoline, dry-cleaning solvents, or other flammable or explosive substances to the

wash water. These substances give off vapors that could ignite or explode.

10. Under certain conditions, hydrogen gas may be produced in a hot water system that has not

been used for 2 weeks or more. HYDROGEN GAS IS EXPLOSIVE. If the hot water system has

not been used for such a period, before using a washing machine or combination washer-dryer,

turn on all water faucets and let the water flow from each for several minutes. This will release

any accumulated hydrogen gas. As the gas is flammable, do not smoke or use an open flame

during this time.

14

Page 15

m

ASKO Product Warranty

Home Clothes Washers and Dryers

For Residential Installations

Length of warranty

ONE YEAR FULL

WARRANTY

From date of purchase

FIVE YEAR LIMITED

WARRANTY

One year full plus second through

fifthyear limited from date of purchase.

TWENT-FIVE YEAR LIMITED

WARRENTY

One year full plus second through

twentyfive year limited from date of

purchase.

For Non-Residential Installations

SIX MONTHS FULL WARRANTY

FROM DATE OF PURCHASE

ASKO will pay for:

ASKO replacement parts and/or repair labor to correct

defect in materials or workmanship. Service must be

provided by an authorized ASKO sen/ice outlet.

ASKO replacement parts (repair labor costs not included)

for any defective solid state controls, timers,motors,

pumps.

ASKO replacement parts (repair labor costs not included)

for the stainless steel inner and outer drum/tub if it fails

to hold water due to a manufacturing defect such as cracking

or rusting.

ASKO replacement parts and/or labor to correct defect in

materials or workmanship. Service to be provided by an

authorized ASKO service outlet.

ASKO will not pay for:

A. Service calls to; 1. Correct the installation of the washer or dryer

2. Instruct how to use the washer or dryer

3. Replace house fuses or correct housing wiring

4. Correct house plumbing

5. Cleaning or senricing of the button trap, outlet pump of the washer

6. Cleaning or serving of the lint filter or condensing unit of the dryer

B. Repair and/or parts for failure of product if washer or dryer is used in other than normal use.

C. Damage resulting from accident, fire, floods, acts of God, alteration, misuse abuse, improper

installation or instailation not in accordance with local electrical or plumbing codes.

D. Any labor or shipping costs for parts during the limited warranty.

E. Replacement parts or repair labor costs for units operated outside the Continetal United States.

F. Pick-up and delivery. ASKO products are designed to be repaired in the home.

IN NO EVENT SHALL ASKO INC. BE RESPONSIBLE FOR ANY

INCIDENTAL OR CONSEQENTIAL DAMAGES.

Some states will not allow the exclusion or limitation of incidental or consequential damages, so this

exclusion or limitation may not apply to you. This warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

For warranty service, contact the dealer from whom you purshased the unit or an authorized ASKO service

outlet. Service will be provided during normal business hours. Should you have a service problem that is not

resolved locally write:

ASKO USA INC.

PO Box 851805

Richardson, TX 75085-1805

15

Page 16

Summary of washing instructions

OI

Turn the main p ^

On/Off selector to the L i

required program.

b~

___

2

Open the door

by pushing

u

Open

Load the washing and ic:r

close the door firmly. |

Set the temperature with

the thermostate buttons, p

When the machine stops:

* After a program that has finished by pumping out the

water, you can open the door after about two

minutes.

Open the door by pressing

IlM

M

i

Omu *

1

u

Open

Pour detergent and

fabric conditioner

into the detergent

compartment.

Turn the program

N

o

knob to the required

start and the machine

wiil start.

After using the machine:

Turn off the main switch,

* |o«s-

LbT

UJ

Choosing

the right

program

Program

Normai

Permanent

Press

Deiicate

We reserve the right to make changes.

Prewaah

1 1

1 1

1 1 1 1

Main waah RInaaa

1 J

1 1

□ □ □ □

□ □ □

□ □ □

Spin

1000 rpm

800 rpm

800 rpm

Action

Normal

Normal

Gentle

Watar laval

Normal

Normal

Normal

Art nr 80 623 30

WM 140

CM

'1’

(Ó

o>

<

Û

z

Ü

s

Loading...

Loading...