Ashley 1330E User Manual

Owner’s Installation and Operation Manual

Model 1330E

Wood Only Central Furnace

Report No. 0215WH056E

0215WH056S

This unit is certied UL-391(R2014)

U.S. ENVIRONMENTAL PROTECTION AGENCY

Certied to comply with the 2016 particulate

emission standards. Not approved for sale after

May 15, 2020

Installation is to be preformed by a

qualied installer.

SAVE THESE INSTRUCTIONS

United States Stove Company

227 Industrial Park Rd.

South Pittsburg, TN 37380

852816-4804F

CAUTION:

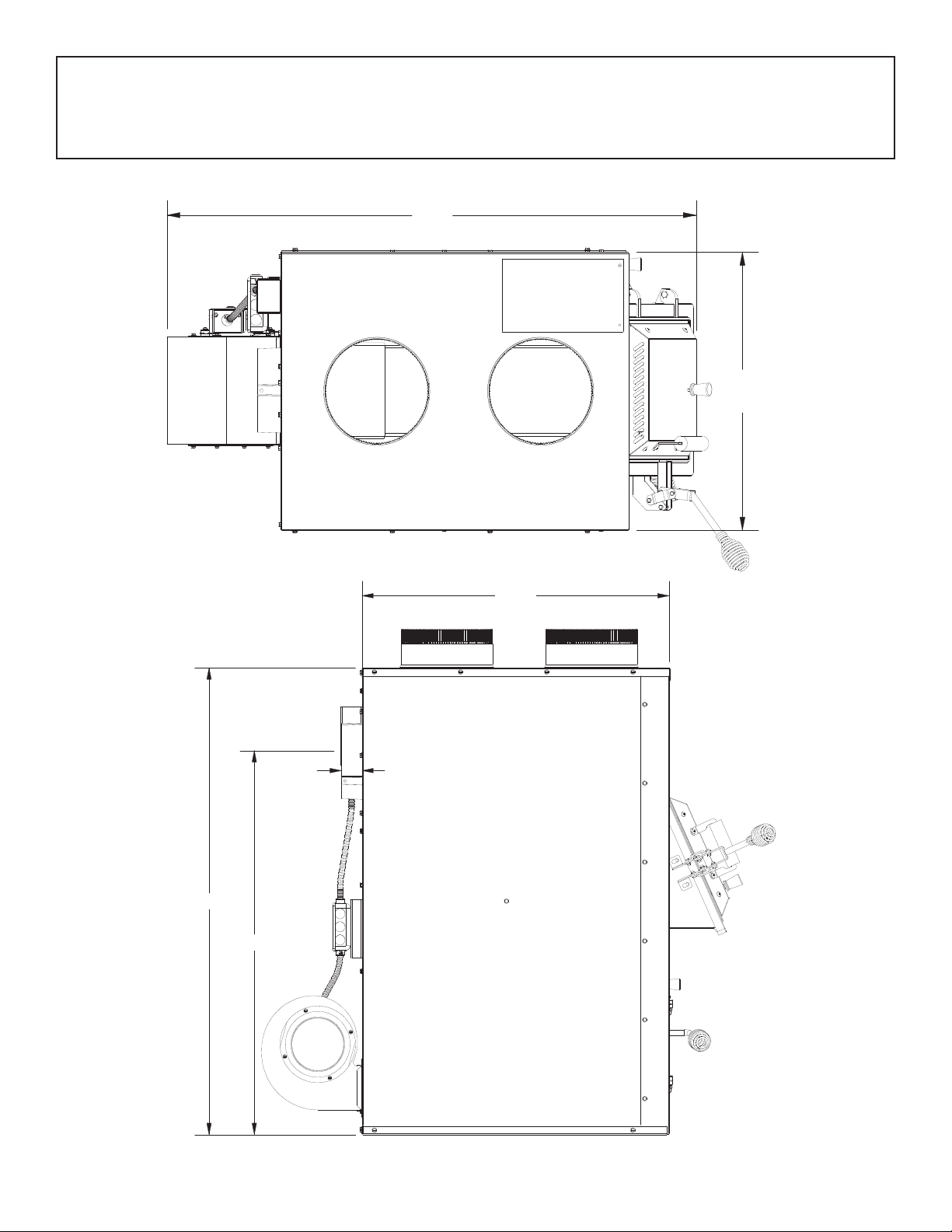

40.65

21.00

26-3/4

32-7/8

40

1.80

• Power source not controlled by furnace main disconnect.

• Respect all local and national codes when installing this unit.

• This unit is not to be connected to a chimney ue serving another appliance.

• This unit is designed to burn solid hardwood only.

-2-

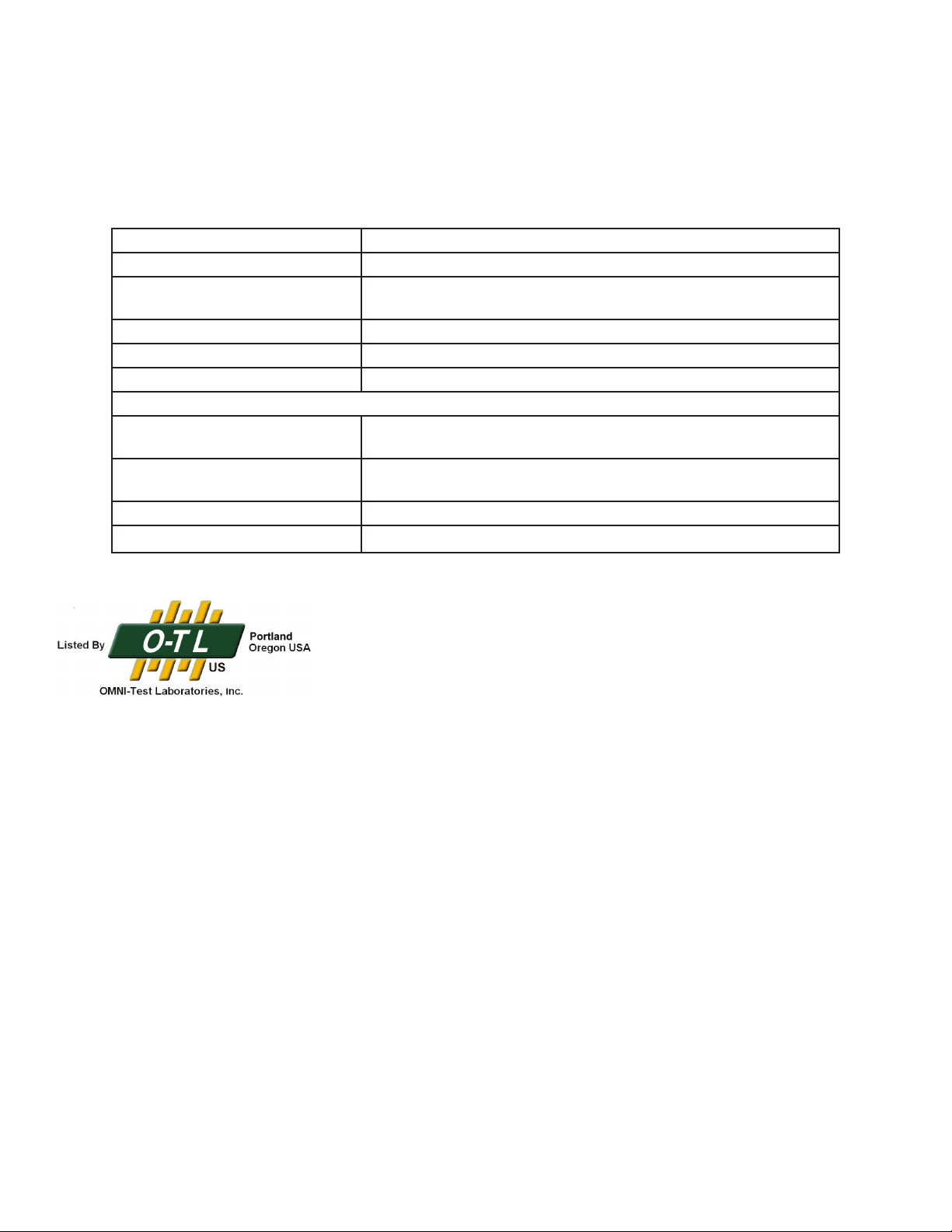

Specications

CONGRATULATIONS!

You’ve purchased a heater from North America’s oldest manufacturer of wood burning products.

By heating with wood you’re helping to CONSERVE ENERGY!

Wood is our only Renewable Energy Resource. Please do your part to preserve our wood supply. Plant at least

one tree each year. Future generations will thank you.

Combustible: Wood

Flue Pipe Diameter: 6” (153mm)

Flue Pipe Type: (Standard,

Single Wall, or Double Wall):

Minimum Chimney Height: 12’

Maximum Log Length: 20”

Electrical 120V, 60Hz, 2.6A

Dimensions

Combustion Chamber:

Width x Depth:

Volume:

Cubic Feet:

Door Opening: Width x Height: 11.6” X 11.5”

Weight (lbs): 350lbs

Black or Blued Steel 2100°F (650°C) Class “A”

12.8” X 20.3”

3.0 cubic feet

This manual describes the installation and operation of the Ashley, 1330E wood

heater. This heater meets the 2016 U.S. Environmental Protection Agency’s

emission limits for wood heaters sold after May 15, 2016. Under specic EPA

test conditions this heater has been shown to deliver heat at a rate of 18,850

– 56,000 BTU/hr. This heater achieved a particulate emissions rate of 0.509 lb/

0215WH056E

This wood heater has a manufacturer-set minimum low burn rate that must not be altered. It is against federal

regulations to alter this setting or otherwise operate this wood heater in a manner inconsistent with operating

instructions in this manual.

The operation of this wood heater in a manner inconsistent with the owner’s manual will void you warranty and

is also against federal regulations.

This heater is designed to burn natural wood only. Higher efciencies and lower emissions generally result when

burning air dried seasoned hardwoods, as compared to softwoods or to green or freshly cut hardwoods.

This wood heater needs periodic inspection and repair for proper operation. It is against federal regulations to

operate this wood heater in a manner inconsistent with operating instructions in this manual.

mmBtu when tested to method CSA B415.1-10 (*and an overall efciency of

60.01 %). The maximum overall heat output of this heater was tested to be

89,000 Btu/hr.

-3-

Safety

• WARNING: Do not operate with fuel loading or ash removal doors open.

• Do not connect this unit to a chimney ue serving another appliance.

• WARNING DANGER: Risk of re or explosion. Do not burn garbage, gasoline, naphtha, motor oil, or other

inappropriate materials. Do not use chemicals or uids to start the re.

• WARNING: Risk of re. Do not operate with ue draft exceeding .060” water column/14.93 Pascals. Do not

operate with fuel loading and ash removal doors open. Do not store fuel or other combustible materials

within marked installation clearances. Inspect and clean ues and chimney regularly.

• CAUTION: Hot surfaces. Keep children away. Do not touch during operation.

• The heat exchanger, ue pipe, and chimney must be cleaned regularly to remove accumulated creosote

and ash. Ensure that the heat exchanger, ue pipe, and chimney are cleaned at the end of the heating

season to minimize corrosion during the summer months. The appliance, ue pipe, and chimney must be

kept in good condition. These instructions also apply to a draft inducer if used. To prevent ame or smoke

spillage, the slide bafe must be pulled out and the fuel loading door left cracked for 10 seconds prior to

opening door fully. Load fuel carefully or damage may result.

• Hot while in operation. Keep children, clothing and furniture away. Contact may cause skin burns.

• Do not use chemicals or uids to ignite the re.

• Do not leave the furnace unattended when the door is slightly opened.

• Do not burn garbage, ammable uid such as gasoline, naphtha or motor oil.

• Always close the door after the ignition.

• Consult your municipal building department or re ofcials about permits, restrictions and installations

requirements in your area.

• INSPECT FLUE PIPES, FLUE PIPE JOINTS, AND FLUE PIPE SEALS REGULARLY TO ENSURE THAT SMOKE AND FLUE

GASES ARE NOT DRAWN INTO, AND CIRCULATED BY, THE AIR-CIRCULATION SYSTEM.

• CAUTION: CLEAN OUT OF THE HEAT EXCHANGER, FLUE PIPE CHIMNEY, AND DRAFT INDUCER, IF USED, IS

ESPECIALLY IMPORTANT AT THE END OF THE HEATING SEASON TO MINIMIZE CORROSION DURING THE SUMMER

MONTHS, CAUSED BY ACCUMULATED ASH.

-4-

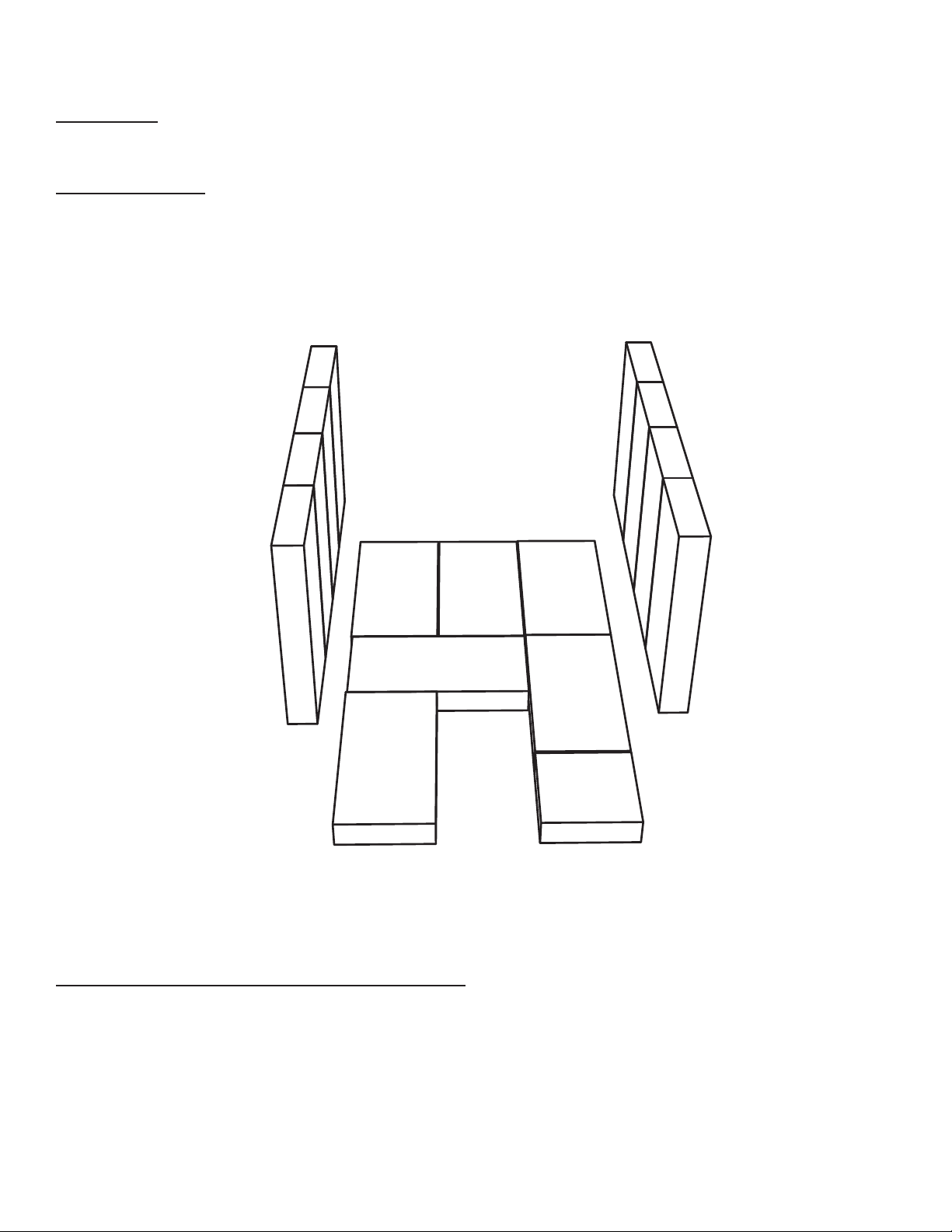

Unpacking And Preassemble

UNPACKING

1. Remove all packaging from the furnace.

2. Remove the supplied parts from the furnace.

BRICK ALIGNMENT

Inspect for any damage. Ensure that the bricks and ash plug are positioned correctly and not broken (see

illustration for proper brick arrangement).

Proper Fire Brick Alignment

TOOLS AND MATERIALS NEEDED FOR INSTALLATION

The following is a list of tools and materials needed to install your furnace.

• 7/16” socket wrench.

• 5/16” socket (Best if using a power drill and a socket bit).

• Pair of pliers or channel-locks.

• Power drill with an 1/8” drill bit to install sheet metal screws into connector pipe..

• Sheet metal screws.

• Non-combustible oor protector as specied in this manual.

• All chimney and chimney connector components required for your particular venting installation..

• Electrical wiring tools and supplies.

• Ductwork for supply and return air.

-5-

Furnace Installation

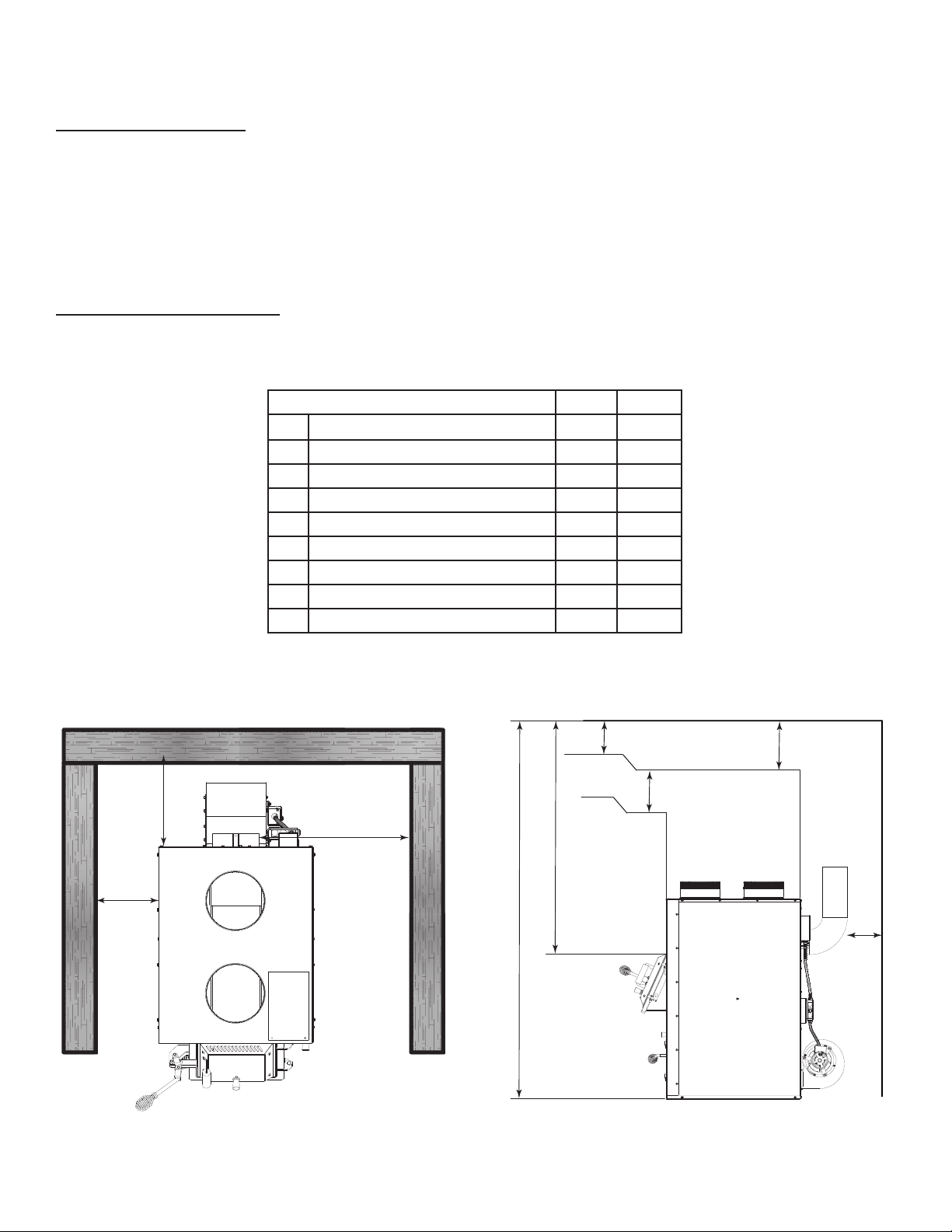

Ceiling

O

R

S

Ceiling

Floor Protector

ML

E

F

G

H

J

D

Q

O

R

P

S

S

INSTALLATION OPTIONS

The installation of this furnace includes supplying electrical power, return (fresh air) ductwork, and supply air

ductwork. This furnace may be installed in two different congurations.

1. Stand alone wood furnace

2. Add-on wood furnace

See kit installation section in this manual to ensure proper assembly, installation and operation of your new

furnace.

If installing in an area with a fan it should not be allowed to create negative pressure in the room where the

furnace is installed.

LOCATING YOUR FURNACE (INSURE THAT THE REQUIRED MAINTENANCE CLEARANCES ARE MAINTAINED)

Your furnace must be installed as shown in this manual and in compliance with all local and national codes.

It is of the utmost importance that the clearances to combustible materials be strictly adhered to during

installation of the furnace. Refer to the table and diagrams below for minimum required clearances.

Dimension Inch mm

A Backwall to Furnace 28 712

B Sidewall to Furnace 13 331

C Sidewall to Flue 21 534

D Backwall to Flue 18 458

E Supply Duct (rst 6 feet) 6 153

F Supply Duct (after rst 6 feet) 1 26

G Minimum Duct height 9.5 242

H Top of Door to Ceiling 48 1220

J Minimum Ceiling Height 77 1956

Back wall

F

A

C

H

G

E

B

Side wall

J

D

Floor Protector

CLEARANCE TO COMBUSTIBLESCLEARANCE TO COMBUSTIBLES

-6-

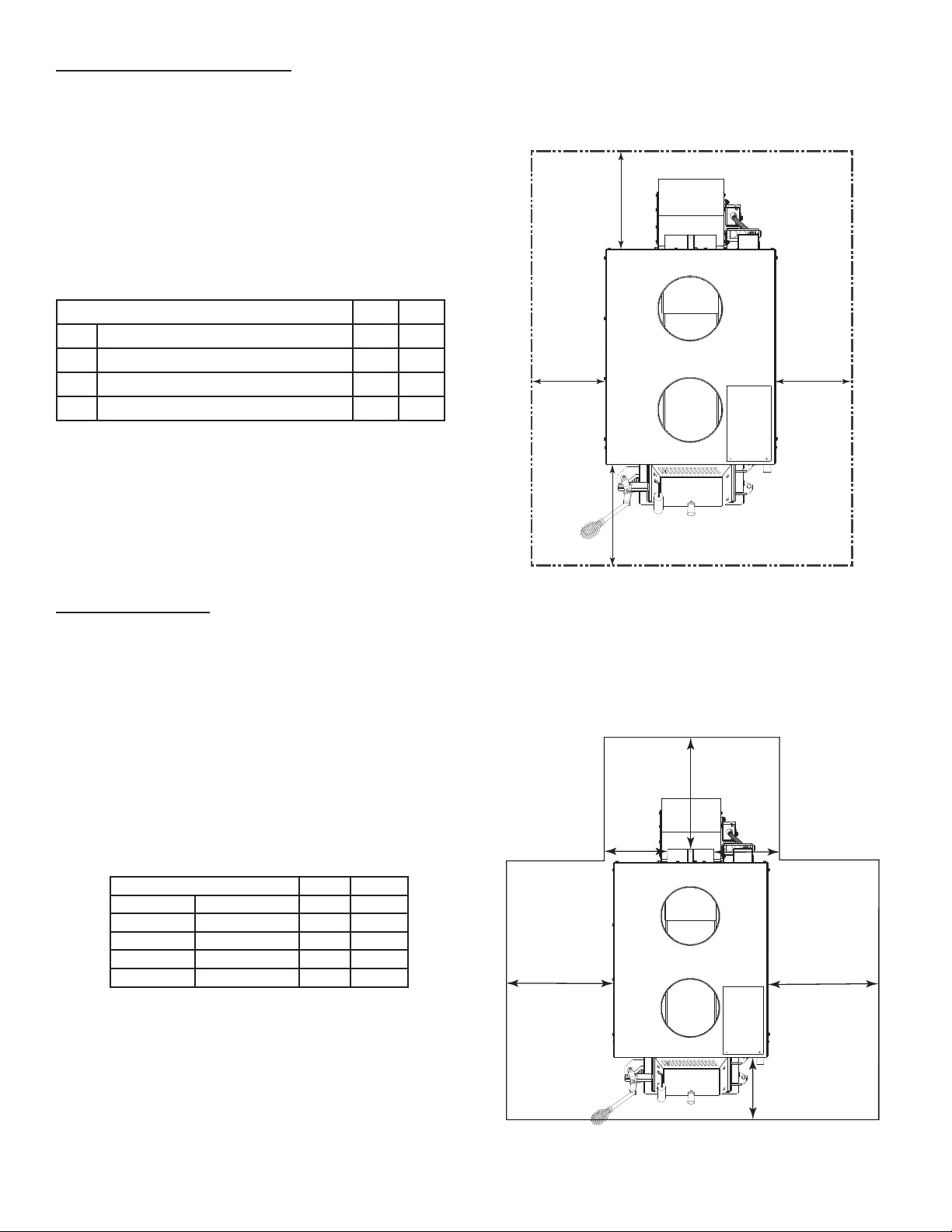

MAINTENANCE CLEARANCES

Q

O

R

P

S

S

Your furnace has recommended minimum maintenance clearance requirements. These clearances insure that

there is adequate room to preform maintenance and service your furnace. DO NOT store fuel within the specied

clearances. See the table and diagram below to determine the clearances for your furnace.

N

Dimension Inch mm

K Maintenance Clearance (Front) 24 610

L Maintenance Clearance (Left) 24 610

M Maintenance Clearance (Right) 24 610

N Maintenance Clearance (Rear) 36 915

ML

K

MAINTENANCE CLEARANCE

FLOOR PROTECTOR

The furnace must be placed on solid concrete, solid masonry, or when installed on a combustible oor, on a oor

protector. The oor protector is required to provide heat, live ember, and ash protection and must be of a noncombustible, continuous solid surface to protect against inltration of live embers and ash. Floor protection must

have and R-Value of at least 1.4. Refer to oor protector manufacturer’s instructions for installation directions.

The oor protector or non combustible oor must extend under the furnace and beyond each side as shown

below.

P

S

R

Dimension Inch mm

O* Front 16 407

P Flue rear 2 51

Q** Left 8 204

R** Right 8 204

S Flue Side 2 51

S

Q

-7-

O

FLOOR PROTECTOR REQUIREMENTS

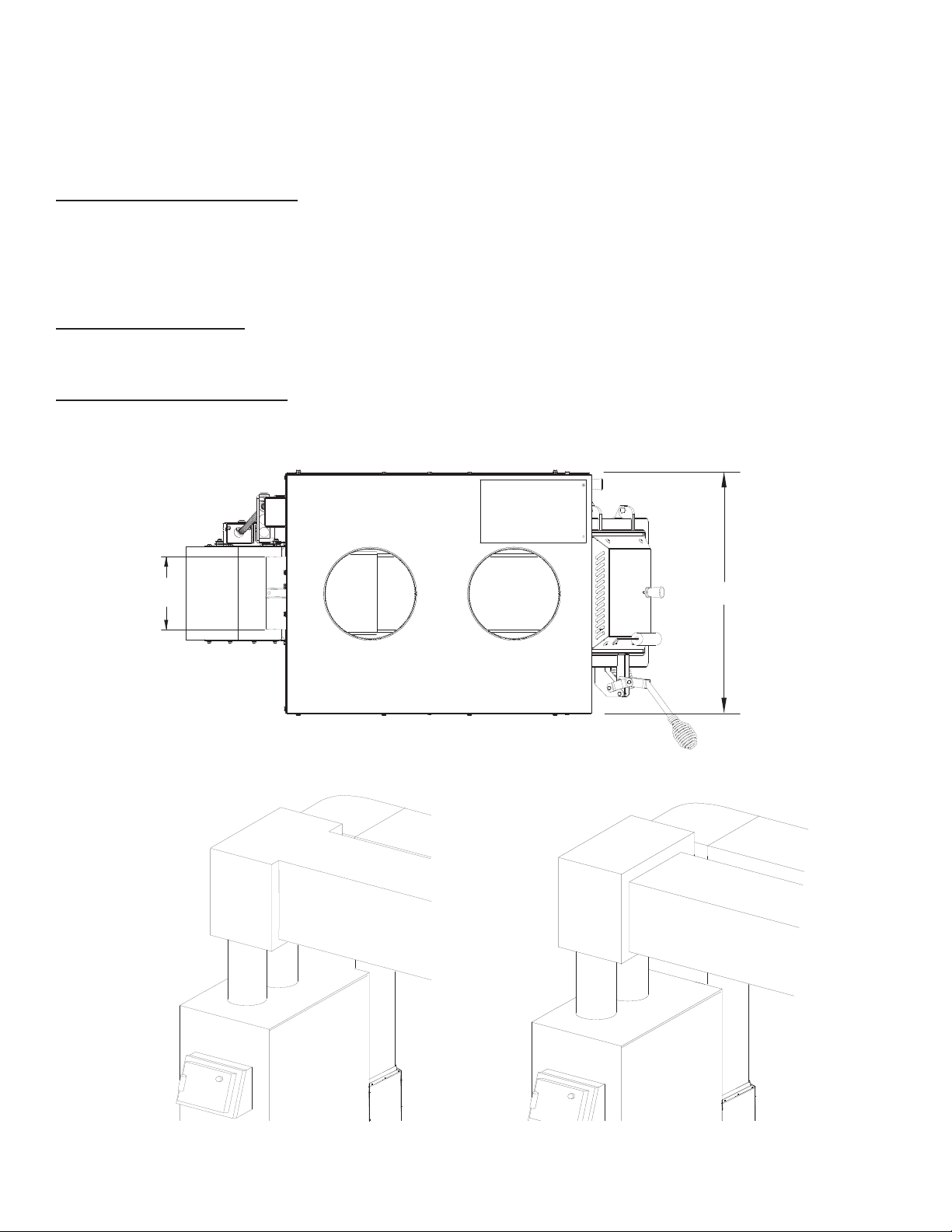

Duct Work Installation

We strongly recommend that the hot air ductwork be installed by a home heating specialist. If doing the

installation yourself, before you decide which installation will best suit your needs, consult a qualied heating

technician and follow his recommendations as to the safest and most efcient method of installation.

This furnace can be installed in two ways, as a stand alone or parallel unit, with an existing furnace.

SUPPLY AIR (HOT AIR) PLENUM

The warm-air supply duct shall be constructed of metal in accordance with NFPA 90B, 2-1.1. The plenums installed

to the furnace shall be constructed of metal in accordance with NFPA 90B, 2-1.3.

When installing this furnace the hot air plenum is to have a minimum height of 24” (610mm) if the top of the rst

vertical section is not ush with the top of the rst horizontal section of ductwork. If the top of the plenum is ush

with the top of the rst horizontal section of ductwork then the minium height is 15” (381mm).

RETURN AIR (FRESH AIR)

The return (fresh) air intake on the furnace is on the rear of the unit. The ductwork must be mechanically attached

to the unit or UFB908 blower box with sheet metal screws to ensure a proper operation.

STAND ALONE INSTALLATION

If installing this furnace as a stand alone unit, ensure all local codes and all instructions in this manual are followed,

including clearance to combustibles, oor protector specications and safety warnings.

6”

21”

Supply Air (Hot Air) Duct Work Outlet Size

Supply Air Plenum With

Minimum Height Of 15”

Supply Air Plenum Minimum

Height Of 24”

-8-

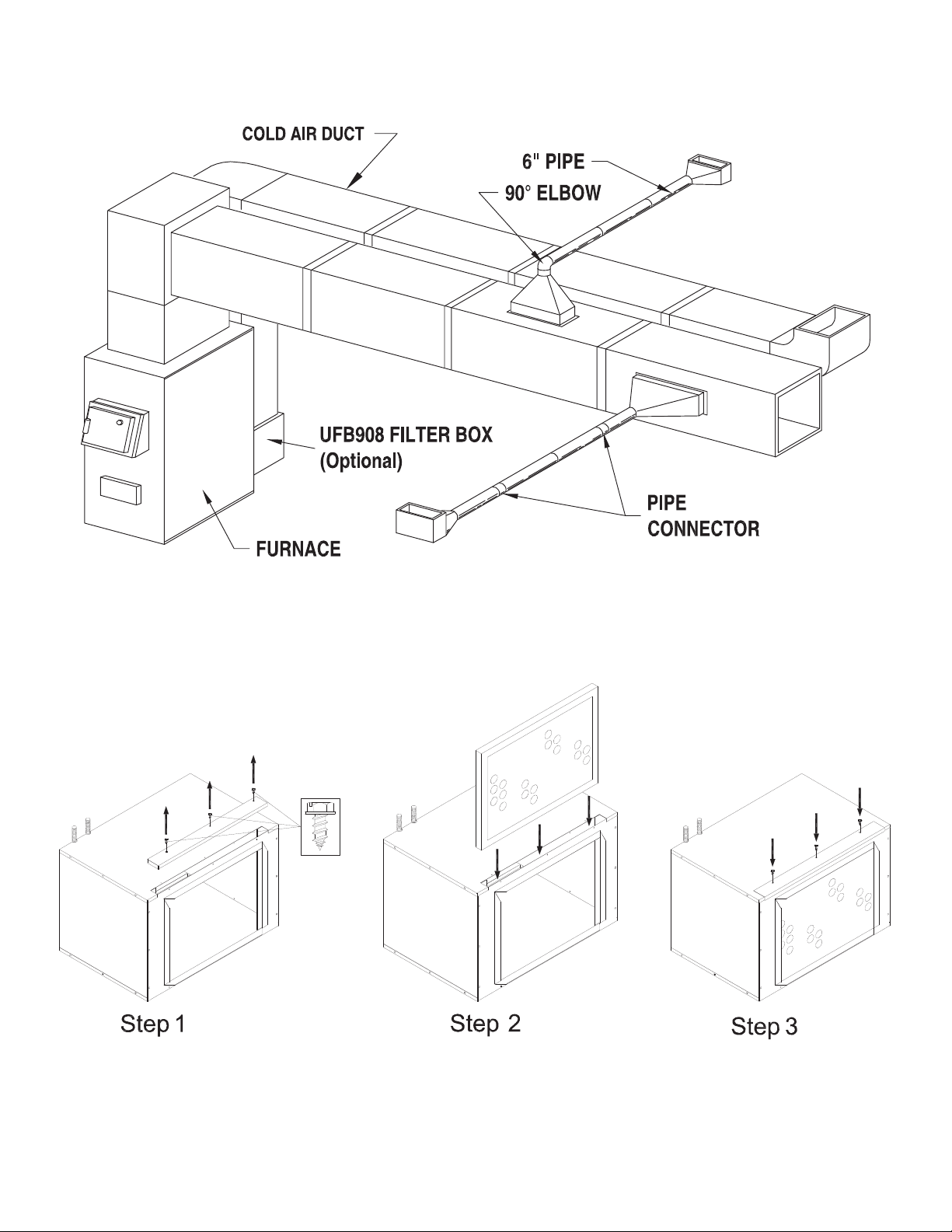

CENTRAL INSTALLATION

Air Filter Replacement

-9-

Loading...

Loading...