Page 1

Installation and Maintenance Instructions for

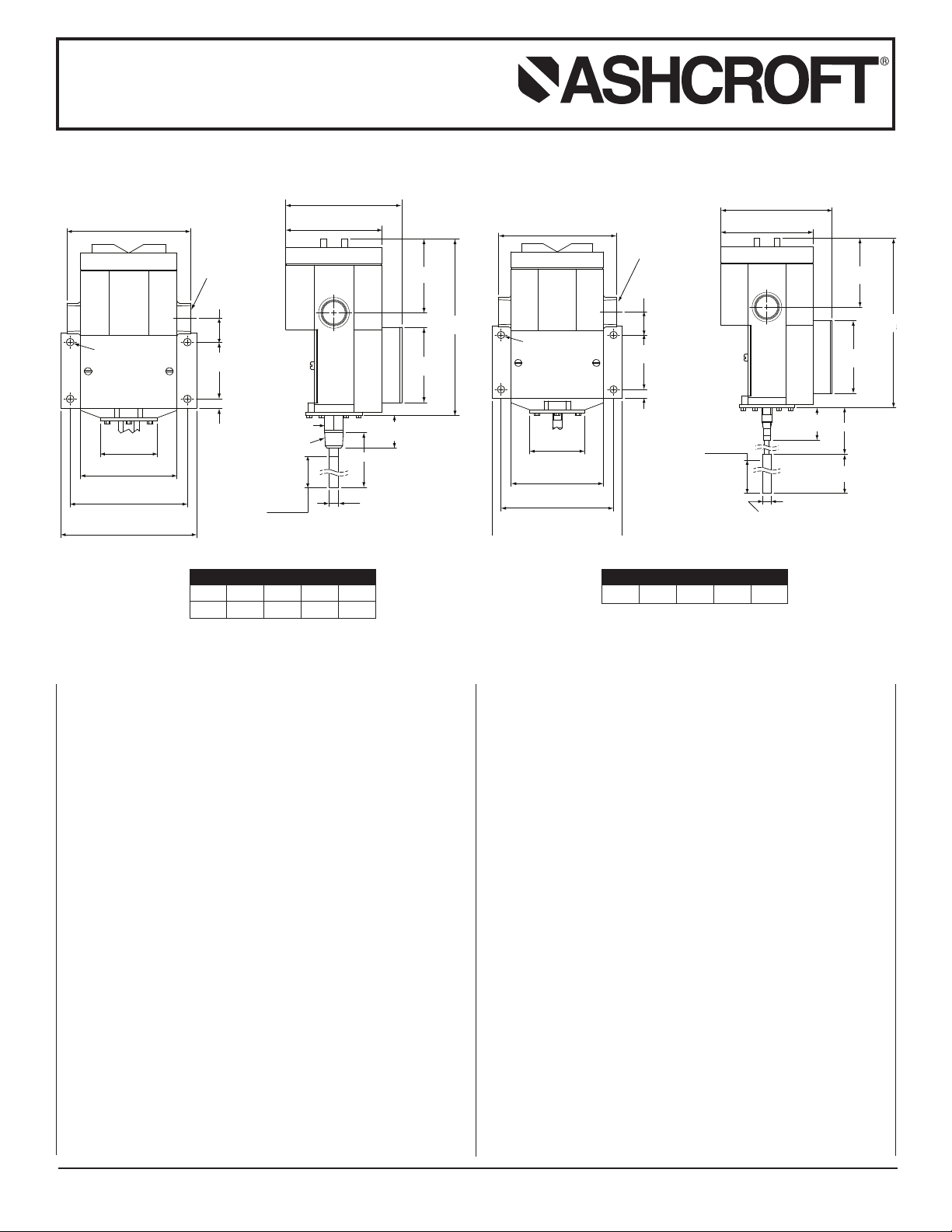

1.06

(27)

2.30

(

58)

0.38

(10)

4

.75

(

121)

3.88

(

99)

5

.50

5

.00

(

1 27 )

Ø0.3 1X 4 HOLES

(8 )

Ø

2.3 1

(5 9 )

3

/4 NPT

T

YP

2.3 1

(59 )

A

CTIVE

L

ENGTH

Ø 3. 90

(

9 9 )

4

. 7 0

(

1 1 9 )

3

. 0 6

(

7 8)

2

. 9 0

(7 4 )

7. 1 6

(

1 8 2 )

2

.5 0

(

6 4 )

“

L”

3

.0 0

(7 6 )

Ø0 . 3 7

(

9)

BULB

1.06

(27)

2.30

(

58)

0

.38

(10)

4.75

(121)

3.88

(99)

5.50

(140)

5.0 0

(

1 27 )

Ø0.31X 4 HOLES

(8 )

Ø2. 31

(59 )

3

/4 NPT

TYP

Ø3 .90

(

99 )

4

.7 0

(

119 )

3. 06

(

7 8)

2

. 90

(7 4)

7. 16

(1 82 )

“S”

Ø0.3 7

(9 )

2

. 3 1

(5 9 )

ACTIVE

LENGTH

1 /2 NPT

7 /8 HEX

1

. 31

MALE

B

ULB

(33)

ASHCROFT®P-Series Snap Action

Switches for Temperature Control

Direct Mount Remote Mount

N4 – 5.8 lb. (2.6)

N7 – 6.4 lb. (2.9)

STEM LENGTH (S)

IN.

23⁄

4 4 6 9 12

MM

(70) (102) (152) (229) (305)

INTRODUCTION

The Ashcroft temperature control is a precision device which

general dimension drawings.An optional pipe mounting bracket

is also available. Mount on a vibration free surface or pipe.

features a snap action switch.Fixed deadband is available with

single or dual SPDT independently adjustable switches with

arious electrical ratings. Adjustable deadband is available with

v

a SPDT s

witch with various electrical ratings. Bulb material is

stainless steel.

The “P” Series Ashcroft snap action pressure switch is available

in both standard NEMA-4 and explosion-proof NEMA 7 & 9 configurations.The enclosure is an epoxy coated aluminum casting.

INSTALLATION

This control is a precision instrument and should never be left

with inter

co

where pressure ma

tection against physical damage as well as corrosive effects of

media flow. Use of a well also facilitates removal of the bulb

nal components exposed.

vers are in place and conduit openings are sealed.

Good piping practice requires the use of a well for installation

y be applied to the ther

During installation insure that

mal system, f

from the process line without disturbing the process. Standard

well materials include brass,, steel, and stainless steel; other

materials are available on application.Selection should be based

on corrosion resistance requirements and process pressure

or pro-

.

A. STEM MOUNTED CONTROLS

These controls ha

attached directly (or indirectly b

equipment to be controlled.WHEN INSTALLING OR

REMOVING CONTROL ALWAYS USE THE WRENCH

FLATS OR HEX ABOVE THE THREADS.DO NOT TWIST

THE HOUSING.

B. REMOTE MOUNTED CONTROLS

Two types of union bushings are available to install a remotemounted control b

hole. A non-pressure-tight type consists of a bushing, split

ed

grommet and compression nut.To use this, the bulb is inserted through the n

capillary between the compression nut, and the bushing.

After positioning the bulb as desired, tighten the compression

nut to the bushing.This will lock the capillary at the desired

location.The pressure-tight type is clamped to the bulb after

insertion by tightening a compression nut.To use this, the

ushing is scre

union b

compression nut and sleeve are slipped onto the bulb which

MOUNTING

our holes in the br

F

mounting of the control. Location of these holes is shown on the

© 2007 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax:203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale. I&M009-10012-10/00 (250-2551) AMR 12/07

et supplied are used in surf

k

ac

ace

is then inserted into the union bushing. Bulb is then positioned and compression n

This will lock the bulb at the desired location.

N4 – 6.8 lb. (3.1)

N7 – 7.4 lb. (3.4)

LINE LENGTH

FT.

5 10 15 20 25

1

ve a

⁄

2 NPT threaded adapter and ma

ulb into a thermo

ut and the split g

wed into the

ut is hand tightened plus 2

y means of a ther mowell) to

y be

well or other

1

⁄

2 NPT thread

rommet is slipped onto the

1

⁄

2 NPT threaded hole

1

⁄

4 tur

.

The

ns

-

.

Page 2

Installation and Maintenance Instructions for

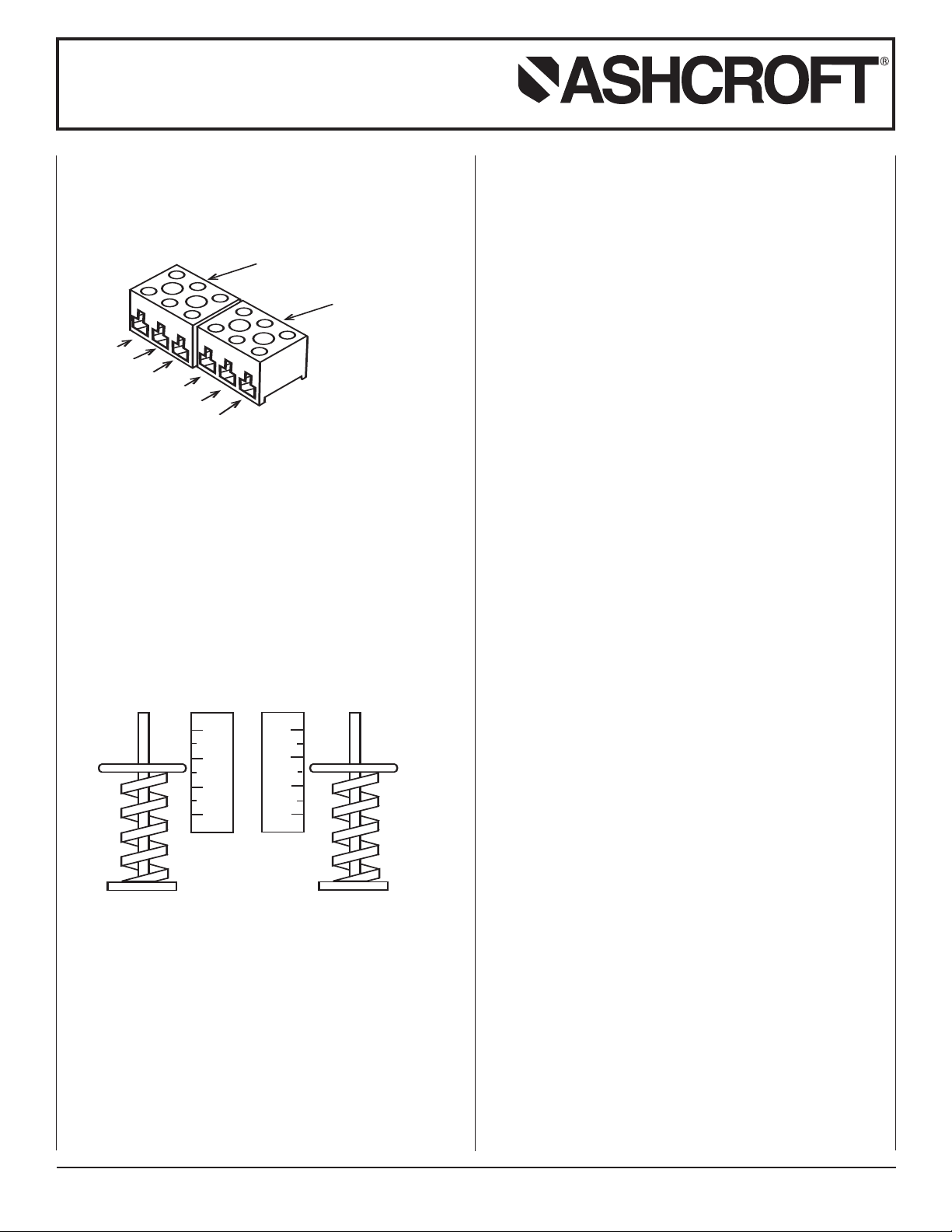

TERMINAL BLOCK

SWITCH A

TERMINAL BLOCK

SWITCH B

2

1

3

2

1

3

N

C

NO

C

NC

NO

C

A

B

0

20

40

60

0

20

40

60

ASHCROFT®P-Series Snap Action

Switches for Temperature Control

LECTRICAL CONNECTION

E

emove top cover, cover unscrews (CCW).

R

On all units except one with terminal blocks – wire directly to

the switch according to circuit requirements.Units with terminal

blocks – wire directly to terminal blocks as required.Terminals

are marked common, norm open and norm closed.

CONDUIT CONNECTIONS

Two 3⁄

4 NPT holes are provided, one fitted with a plug, the other

with a cap.It is recommended that Teflon tape or of her sealant

be used on conduit bushing or plug threads to ensure integrity

of the enclosure. NEMA 7 & 9 enclosures require proper conduit

seals and breathers as per the National Electrical Code.

SETPOINT ADJUSTMENTS

General Considerations

trols optimum performance will be obtained if the bulb is fully

immersed. After Initially inserting a bulb into a controlled bath

allow five minutes for stabilization.Whenever setpoint adjustment requires a bath temperature to be varied (such as to

observe setpoint and re-setpoint values) the rate of change In

temperature should not exceed 1°F per minute.Switch operation should be monitored with a suitable pilot light or meter.

– When adjusting temperature con-

Series PT-S Single Switch – Remove front cover, held in place

by two screws.Immerse bulb In a bath at the desired setpoint

temperature.Adjust setpoint by rotating the adjustment wheel

until the switch changes mode.It is desirable to recheck actua-

ion point by varying the temperature of the bath as required

t

nd noting operate and reset values.

a

Series PT-D Dual Switch – Remove front cover, held in place

by two screws.There are two setpoint adjusting wheels.The

adjusting wheel on the left (labeled A) controls the left switch.

The adjusting wheel on the right (labeled B) controls the right

switch.The switches are set independently.

Note: Control is calibrated at the factory such that for proper

operation switch B setpoint must be set higher than

switch A setpoint.

Immerse bulb in a bath at the desired setpoint temperature.

Adjust setpoint by rotating the adjustment wheel until the switches change mode. It is desirable to recheck actuation points by

varying the temperature of the bath as required and noting operate and reset values.This must be done for both setpoint A and

setpoint B.

Series PT-A Adjustable Deadband Switch – Remove front

cover, held in place by two screws.The setpoint adjusting wheel

labeled A controls the resetpoint of the switch.The adjusting

wheel labeled B controls the setpoint of the switch.

Note: The units are calibrated at the factory such that for proper

operation setpoint B is always higher than re-setpoint A.

Preset adjusting wheel A to a value less than the desired reset

temperature.Preset adjusting wheel B to a value higher than the

desired setpoint. Immerse bulb in a bath at the desired setpoint

temperature.Adjust setpoint by rotating the adjustment wheel B

until the switch changes mode.Then decrease the bath temperature to the desired resetpoint. Adjust resetpoint by rotating

adjustment wheel A until s

witch changes mode (resets).

Recheck these points by varying bath temperature.

© 2007 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax:203-385-0499, www.ashcroft.com

All sales subject to standard ter

ms and conditions of sale. I&M009-10012-10/00 (250-2551) AMR 12/07

Loading...

Loading...