Page 1

Installation and Maintenance Instructions

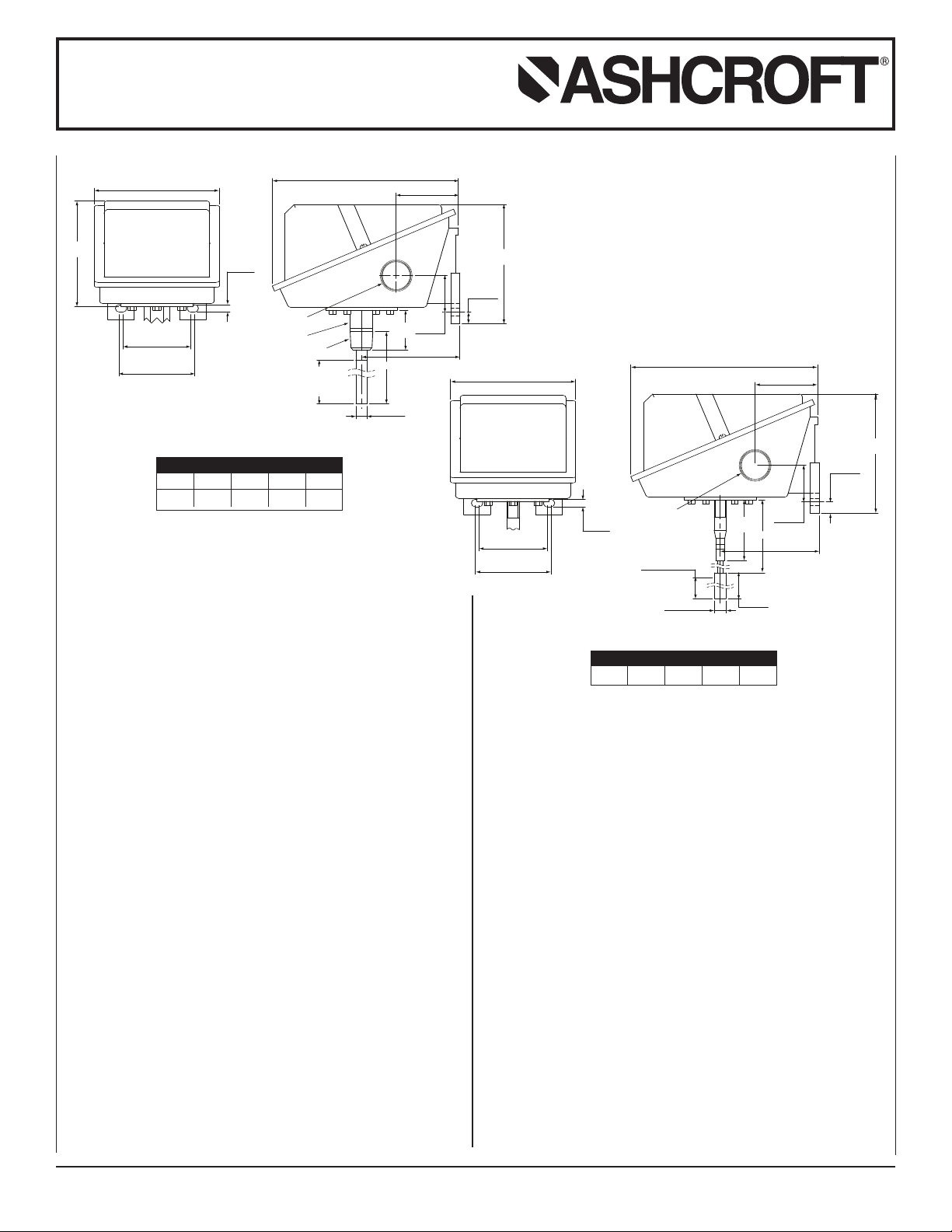

(105)

2.25

(57)

2.50

(64)

0.25

(6)

3.47

(88)

2.06

(52)

1.21

(31)

0.38

(

10)

3.94

(100)

1

.31

(33)

“S”

Ø 0 . 3 7

(

9 )

2

. 3 1

ACTIVE BULB

LENGTH

( 5 9 )

3 . 2 6

(

8 3 )

6 . 0 9

( 1 5 5 )

3 /4 NPT

7/8 HEX

1 /2 NPT MALE

4 . 1 2

2.31

ACTIVE BULB

LENGTH

(59)

2.06

(52)

0

.38

(10)

3.94

(100)

3.26

(83)

“L”

3 . 0 0

( 76 )

2 . 5 0

(

6 4 )

Ø 0 . 3 7

( 9 )

1 . 2 1

( 3 1 )

6 . 0 9

( 1 5 5 )

3

/4 NPT

4

. 1 2

( 1 0 5 )

0 . 2 5

( 6 )

2 . 2 5

( 5 7)

2 . 5 0

( 6 4 )

for ASHCROFT®L-Series Snap Action

Switches for Temperature Control

irect Mount

D

3.5 lbs.

TEM LENGTH (S)

S

IN.

23⁄

4 4 6 9 12

MM

(70) (102) (152) (229) (305)

Remote Mount

OPERATION

The ASHCROFT®temperature control is a precision device

which features a snap action switch. Fixed deadband is available

with single or dual SPDT independently adjustable switches

with various electrical ratings. Adjustable deadband is available

with a SPDT switch with various electrical ratings. Bulb material

is stainless steel.

Series LT-S switches have a fixed deadband which will be

within the limits noted on the nameplate.

Series LT-D switches may be set to operate simultaneously or

up to 85 percent of the range apart. The deadband of each

switch will be within the limits noted on the nameplate.

Series LT-A switches may be set to operate with any deadband within the limits sho

wn on the nameplate.

MOUNTING

The “L” Series ASHCROFT®snap action temperature switch has a

NEMA-4 enclosure which is an epoxy coated aluminum casting.

Two holes in the integral bracket are used to surface mount

the control. Location of these holes is shown on the general

wings. An optional pipe mounting bracket is also

dimension dr

a

available. Mount on a vibration free surface or pipe in any

orientation.

Good piping pr

actice requires the use of a well f

where pressure ma

y be applied to the ther

or installation,

mal system, f

or protection against physical damage as well as corrosive effects of

media flow. Use of a well also facilitates removal of the bulb

from the process line without disturbing the process. Standard

well materials include brass, and stainless steel; other materials

are available on application. Selection should be based on corrosion resistance requirements and process pressure.

4.5 lbs.

LINE LENGTH

FT.

5 10 15 20 25

B. REMOTE MOUNTED CONTROLS

Two types of union bushings are available to install a

ell or other

remote-

mounted control bulb into a ther

NPT threaded

A non-pressure-tight type consists of a

.

hole

mow

bushing, split grom-met and compression nut. To use this, the

bulb is inserted through the nut and the split grommet is

slipped into the capillary between the compression nut and

the bushings. After positioning the bulb as desired, tighten

the compression n

ut to the b

ushing. This will lock the capillary at the desired location. The pressure-tight type is

clamped to the bulb after insertion by tightening a compres-

ut. T

sion n

threaded hole

NPT

o use this, the union b

. The compression nut and sleeve are

ushing is screwed into the

slipped onto the bulb which is then inserted into the union

bushing. Bulb is then positioned and compression nut is

hand tightened plus 2

1

⁄

2 turns. This will lock the bulb at the

desired location.

1

⁄

2

1

⁄

2

STEM MOUNTED CONTR

A.

These controls ha

attached directly (or indirectly by means of a thermowell) to

e a

v

equipment to be controlled.

REMOVING CONTROL ALWAYS USE THE WRENCH

FLATS OR HEX ABOVE THE THREADS. DO NOT TWIST

2007 Ashcroft Inc., 250 East Main Street, Str

©

All sales subject to standard ter

THE HOUSING.

ms and conditions of sale

OLS

1

⁄

2 NPT threaded adapter and ma

ALLING OR

I&M009-10018-10/00 (250-2873) AMR 12/-07

.

WHEN INST

ord, CT 06614-5145, USA,

atf

203-378-8281, F

el:

T

y be

CONDUIT CONNECTIONS

One 3⁄

4 NPT hole fitted with a shipping plug, and two additional

k outs are pro

knoc

placing a scre

wdr

The knoc

vided.

iver in the slot and rapping sharply with a

kouts may be removed by

hammer. It is recommended that Teflon tape or other sealant be

used on conduit b

ushing or plug threads to ensure integ

the enclosure.

203-385-0499, www

ax:

.ashcroft.com

ity of

r

Page 2

Installation and Maintenance Instructions

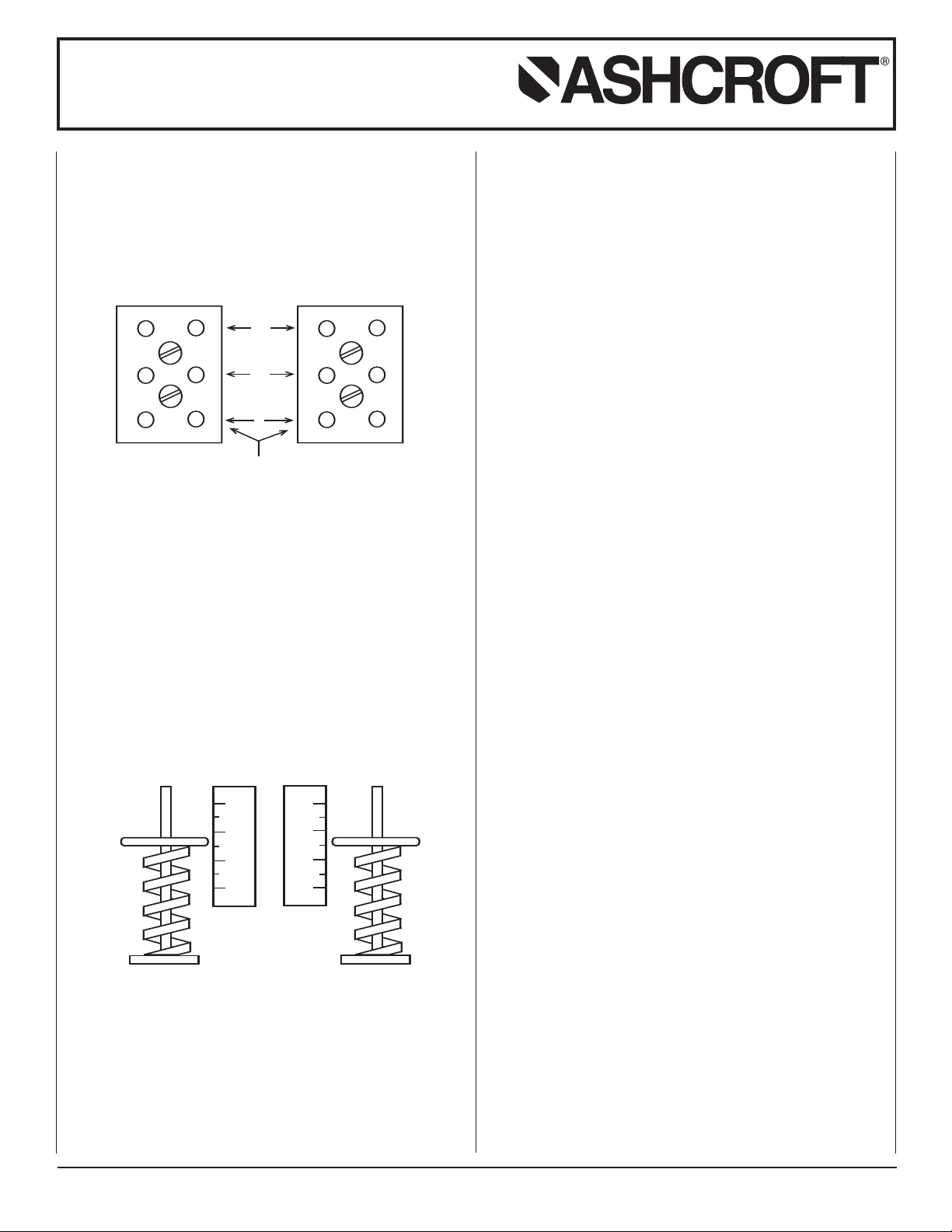

1 2 3

1 2 3

LEFT SWITCH

TERMINAL BLOCK

RIGHT SWITCH

T

ERMINAL BLOCK

SERVICE LEADS TO THESE TERMINALS

NC

NO

C

A

B

0

20

40

60

0

20

40

60

for ASHCROFT®L-Series Snap Action

Switches for Temperature Control

ELECTRICAL CONNECTION

Remove cover, held in place by two screws.

On all units except one with terminal blocks – wire directly to

the switch according to circuit requirements. Units with terminal

blocks – wire directly to terminal blocks as required. Terminals

are marked common (C), normally open (NO) and normally

closed (NC).

SETPOINT ADJUSTMENTS

Setpoints are changed by means of the setpoint adjusters. The

LT-S single switch has one adjuster and the LT-A adjustable

deadband and LT-D dual switch each have two adjusters. On

switches with two adjusters, the one on the left is referred to as

“A” and the right one is referred to as “B”; see illustration. setpoints can be adjusted from 20 to 100 percent of full range on

increasing temperature.

When adjusting temperature controls optimum performance

will be obtained if the bulb is fully immersed. After initially inserting a bulb into a controlled bath, allow five minutes for stabilization. Whenever setpoint adjustment requires a bath temperature

to be varied (such as to observe setpoint and re-setpoint values) the rate of change in temperature should not exceed 1°F

per minute. Switch operation should be monitored with a suitable light or meter.

SERIES LT-S SINGLE SWITCH

Remove cover. For setpoint adjustment on either increasing or

decreasing temperature, the bulb of the control should be immersed in a bath at the desired setpoint temperature. Optimum

erformance will be obtained if bulb is fully immersed. Allow five

p

minutes for initial stabilization. Monitor switch with a light or meter.

If setpoint is on increasing temperature, turn adjuster so that

switch operates (if common-normally closed circuit is being

monitored light goes off). If setpoint is on decreasing temperature, turn adjuster so that switch resets (if common-normally

closed circuit is being monitored light comes on). When the

setpoint has been achieved, raise and lower the temperature to

ensure that the setpoint is correct.

The deadband (difference between the operate and reset

temperatures) may be verified at this time to be between the

values noted on the nameplate label.

SERIES LT-D DUAL SWITCH

Remove cover. Immerse the bulb and monitor the switch as

described under Series LT-S Single Switch. Also see discussion

of increasing or decreasing setpoints and deadband verification.

The initial bath temperature should be the higher setpoint. Turn

adjuster “B” until the switch operates or resets as required.

When the setpoint has been achieved, raise and lower the bath

temperature to ensure that the setpoint is correct. Then reduce

the bath temperature to the lower setpoint and turn adjuster “A”

until the switch operates or resets as required. Verify this setpoint by raising and lowering bath temperature. Now increase

the temperature to the higher setpoint and make final adjustment on “B.”

SERIES LT-A ADJUSTABLE DEADBAND SWITCH

Remove cover. Adjuster “B” controls the operating point of the

switch on increasing temperature. Adjuster “A” controls the resetpoint of the switch on decreasing temperature.

Immerse the bulb and monitor the switch as described under

single switch setpoint adjustment. With the bath at the required

setpoint temperature, turn adjuster “B” until switch operates.

Then lower the bath temperature to the re-setpoint and turn

adjuster “A” until the switch resets. Now increase the temperature to the operating point and make final adjustment on “B.”

er temperature to ensure that the setpoint and

Raise and lo

w

re-setpoint are correct.

© 2007 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard ter

ms and conditions of sale. I&M009-10018-10/00 (250-2873) AMR 12/-07

SOME PRECAUTIONS TO OBSERVE

Do not loosen the screws holding the precision switch element(s) or mounting bracket in place.

Nameplate PROOF temper

ature should not be e

xceeded.

Intermittent operation up to proof temperature is permissible,

however, some change of setpoint may be noted.

ation and correct setpoint actuation should be routinely

Oper

tested.

Loading...

Loading...