Page 1

Installation and Maintenance Instructions

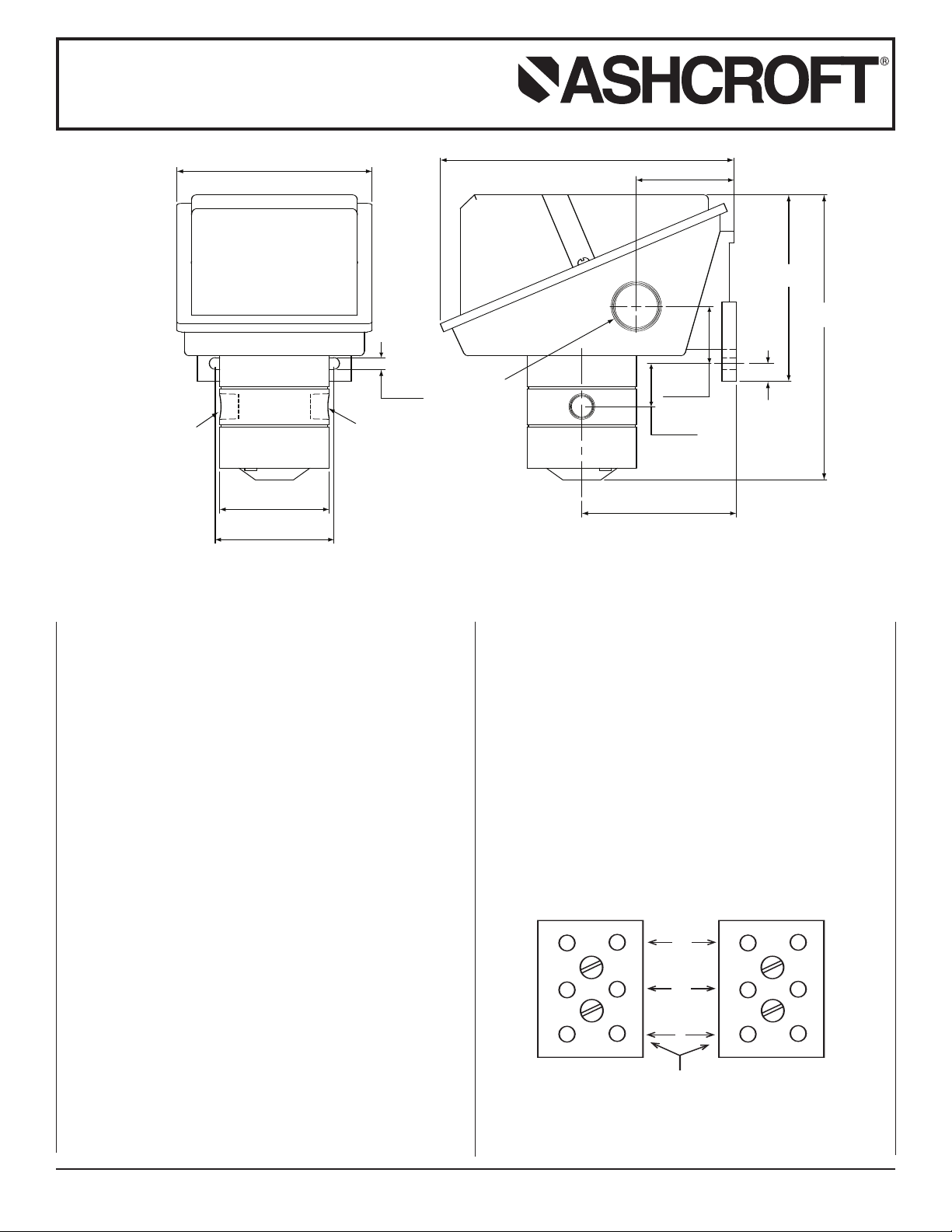

2.06

(52)

1.21

(31)

0.38 (10)

3.94

(

100)

3.26

(83)

0.91

(23)

6

.02

(153)

6

.09

(

155)

3/4 NPT

4

.12

(105)

0.25

(

6)

2.50

(64)

Ø2. 3 1

( 5 9 )

1 / 4N PT

LOW

L

H

F

EMALE

PRESSURE

PORT

1/ 4NP T

HIGH

FEMALE

P RESSURE

P

ORT

1 2 3

1 2 3

LEFT SWITCH

TERMINAL BLOCK

RIGHT SWITCH

TERMINAL BLOCK

SERVICE LEADS TO THESE TERMINALS

NC

NO

C

for ASHCROFT®L-Series Snap Action

Switches for Differential Pressure Control

OPERATION

The ASHCROFT®differential pressure control is a precision

device which features a snap action switch. Fixed deadband is

available with single or dual SPDT independently adjustable

switches with various electrical ratings.Adjustable deadband is

available with a SPDT switch with various electrical ratings.

Several wetted material constructions for compatibility with

pressure media may be obtained.

Series LD-S switches have a fixed deadband which will be

within the limits noted on the nameplate.

Series LD-D switches may be set to operate simultaneously or

up to 85 percent of the range apart. The deadband of each

witch will be within the limits noted on the nameplate.

s

ies LD-A switches may be set to operate with any dead-

Ser

band within the limits shown on the nameplate.

MOUNTING

The “L”Series ASHCROFT®snap action differential pressure

switch has a NEMA-4X enclosure which is an epoxy coated

aluminum casting.

Two holes in the integral bracket are used to surface mount

the control.

Location of these holes is shown on the gener

dimension drawings.An optional pipe mounting bracket is also

available. Mount on a vibration free surface or pipe in any

ientation.

or

PRESSURE CONNECTIONS

For operation as a differential pressure control – connect the

high pressure to the side port marked “H” and the low pressure

to the side port marked “L.”

2007 Ashcroft Inc., 250 East Main Street, Str

©

All sales subject to standard terms and conditions of sale. I&M009-10016-10/00 (250-2871) AMR 12/07

4.1 lbs.

STANDARD RANGES

30, 60, 90, 200, 400 psid

CONDUIT CONNECTIONS

One 3⁄

4 NPT hole fitted with a shipping plug, and two additional

knock outs are provided. The knockouts may be removed by

placing a screwdriver in the slot and rapping sharply with a

hammer.It is recommended that Teflon tape or other sealant be

used on conduit bushing or plug threads to ensure integrity of

the enclosure.

ELECTRICAL CONNECTION

Remove cover, held in place by two screws.

On all units except one with terminal blocks – wire directly to

the switch according to circuit requirements.Units with terminal

locks – wire directly to ter

b

are mar

closed (NC).

al

atford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

ked common (C), normally open (NO) and normally

minal blocks as required.Terminals

Page 2

Installation and Maintenance Instructions

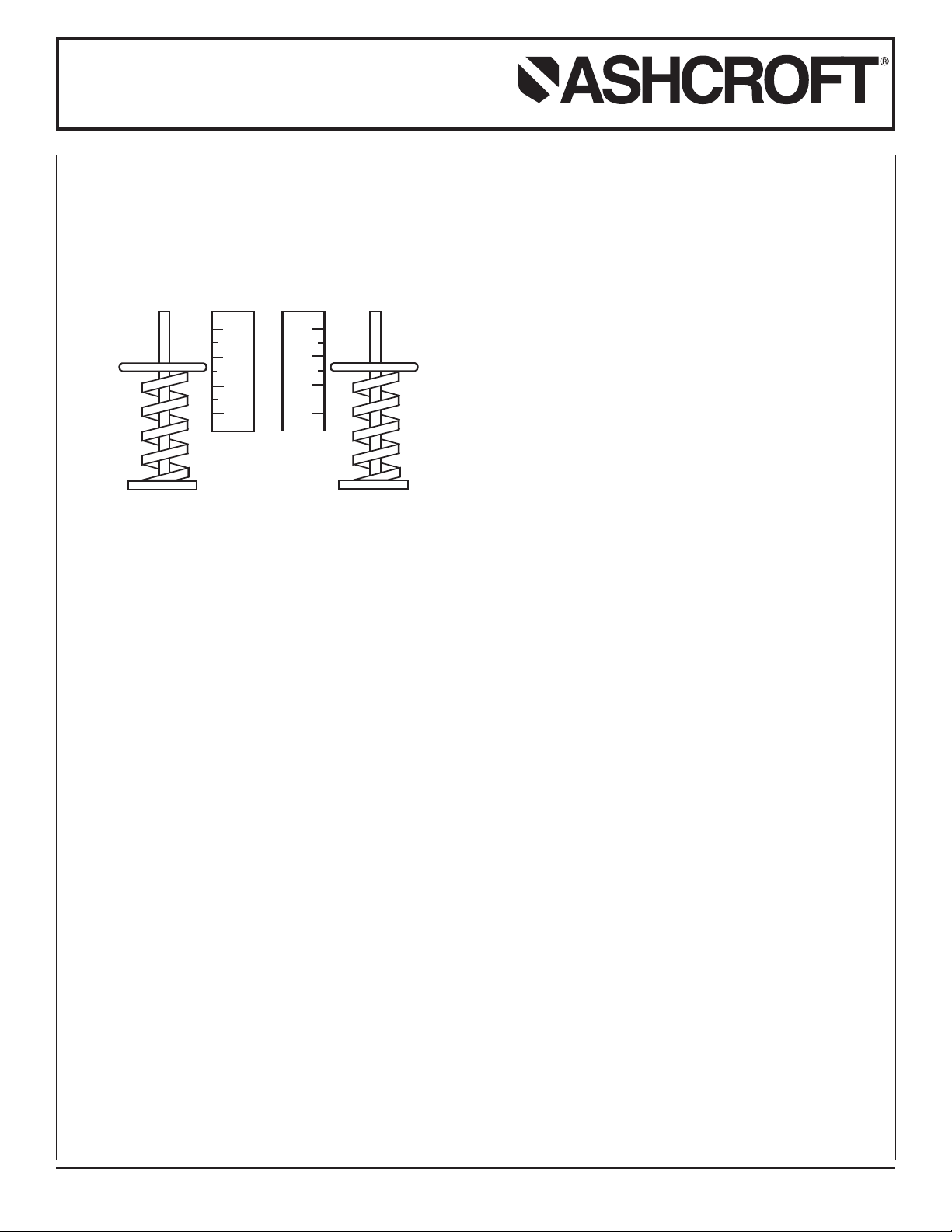

A

B

0

20

40

60

0

20

40

60

for ASHCROFT®L-Series Snap Action

Switches for Differential Pressure Control

SETPOINT ADJUSTMENTS

Setpoints are changed by means of the setpoint adjusters.The

LD-S single switch has one adjuster and the LD-A adjustable

deadband and LD-D dual switches each have two adjusters. On

witches with two adjusters, the one on the left is referred to as

s

A” and the right one is referred to as “B”; see illustration.

“

etpoints can be adjusted from 20 to 100 percent of full range

S

on increasing pressure.

SERIES LD-S SINGLE SWITCH

Remove cover.For setpoint adjustment on either increasing or

decreasing pressure to within ±1% of nominal range, mount the

switch on a calibration stand and use a suitable reference such

as an ASHCROFT® Duragauge or test gauge. Monitor switch

with a light or meter.

Apply

Low pressure. Then apply High pressure equal to the

low pressure plus the differential pressure setpoint. If setpoint is

on increasing differential pressure, turn adjuster so that switch

operates (if common-normally closed circuit is being monitored

light goes off). If setpoint is on decreasing differential pressure,

turn adjuster so that switch resets (if common – normally closed

circuit is being monitored light comes on).When the setpoint

has been achiev

ed, raise and lower the high pressure to ensure

that the setpoint is correct.

The deadband (difference between the operate and reset

pressures) may be verified at this time to be between the values

noted on the nameplate label.

ERIES LD-D DUAL SWITCH

S

emove cover.For setpoint adjustment to within ±1% of nominal

R

range, mount the switch on a calibration stand and use the suitable reference such as an ASHCROFT

®

Duragauge or test

gauge. Monitor switch with a light or meter.

Apply

Low pressure. Then apply High pressure to the higher

of the two required setpoints.Turn adjuster “B” until the

switch operates or resets as required.See discussion of

ncreasing or decreasing differential pressure setpoints and

i

eadband verification under Series LD-S Single Switch.When

d

he setpoint has been achieved, raise and lower the

t

igh

H

pressure.Then reduce the High pressure to the lower setpoint

differential pressure and turn adjuster “A” until the switch operates or resets as required.Verify this setpoint by raising and

lowering the

High pressure.Now increase the High pressure to

the higher setpoint and make final adjustment on “B.”

SERIES LD-A ADJUSTABLE DEADBAND SWITCH

Remove cover.Adjuster “B”controls the operating point of the

switch on increasing pressure.Adjuster “A”controls the re-setpoint of the switch on decreasing pressure.

For accurate setpoint adjustment, mount the switch on a calibration stand and use a suitable reference such as an

ASHCROFT

light or meter.Apply

®

Duragauge or test gauge.Monitor switch with a

Low pressure. Then apply High pressure to

the required setpoint pressure.

Turn adjuster “B” until switch operates.Then lower differential

pressure to the re-setpoint and turn adjuster “A” until the switch

resets.Now increase pressure to the operating point and make

final adjustment on “B”.Raise and lower pressure to ensure that

the setpoint and re-setpoint are correct.

SOME PRECAUTIONS TO OBSERVE

Do not loosen the screws holding the precision switch

element(s) or mounting bracket in place.

Nameplate

PROOF pressure should not be exceeded.

Intermittent operation up to proof pressure is permissible, however, some change of setpoint may be noted.

Operation and correct setpoint actuation should be routinely

tested.

© 2007 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax:203-385-0499, www.ashcroft.com

All sales subject to standard ter

ms and conditions of sale

I&M009-10016-10/00 (250-2871) AMR 12/07

.

Loading...

Loading...