Ashcroft KM15 User Manual

KM15 PRESSURE TRANSDUCER

INSTRUCTION SHEET

WARNING! READ

BEFORE INSTALLATION

1. GENERAL:

A failure resulting in injury or damage may be caused by excessive

overpressure, excessive vibration or

pressure pulsation, excessive instrument temperature, corrosion of the

pressure containing parts, or other

misuse. Consult Ashcroft Inc.,

Stratford, Connecticut, USA before

installing if there are any questions

or concerns.

2. OVERPRESSURE:

Pressure spikes in excess of the rated

overpressure capability of the transducer may cause irreversible electri-

cal and/or mechanical damage to the

pressure measuring and containing

elements.

Fluid hammer and surges can destroy

any pressure transducer and must

always be avoided. A pressure snubber should be installed to eliminate the

damaging hammer effects. Fluid hammer occurs when a liquid flow is suddenly stopped, as with quick closing

solenoid valves. Surges occur when

flow is suddenly begun, as when a

pump is turned on at full power or a

valve is quickly opened.

Liquid surges are particularly damaging to pressure transducers if the pipe

is originally empty. To avoid damaging

surges, fluid lines should remain full (if

possible), pumps should be brought up

to power slowly, and valves opened

slowly. To avoid damage from both fluid

hammer and surges, a surge chamber

should be installed.

Symptoms of fluid hammer and surge's

damaging effects:

• Pressure transducer exhibits an output at zero pressure (large zero offset).

• Pressure transducer output remains

onstant regardless of pressure

c

• In severe cases, there will be no output.

FREEZING:

Prohibit freezing of media in pressure

port. Unit should be drained (mount in

vertical position with electrical termination upward) to prevent possible

overpressure damage from frozen

media.

3. STATIC ELECTRICAL CHARGES:

Any electrical device may be susceptible to damage when exposed to static

electrical charges. To avoid damage to

the transducer observe the following:

• Ground the body of the transducer

BEFORE making any electrical connections.

• When disconnecting, remove the

ground LAST!

Note: The shield and drain wire in the

cable (if supplied) is not connected to

the transducer body, and is not a suitable ground.

Mounting

The KM15 transducer requires no special

mounting hardware, and can be mounted

in any plane with negligible position error.

Although the unit can withstand normal

vibration without damage or significant

output effects, it is always good practice

to mount the transducer where there is

minimum vibration.

For units with NPT type pressure fittings

apply Teflon

sealant to the threads before installing.

®

tape or an equivalent

When tightening, apply a wrench to the

hex wrench flats located just above the

pressure fitting. DO NOT tighten by using

a pipe wrench on the housing.

Noise

For minimum noise susceptibility, avoid

running the transducer’s cable in a conduit that contains high current AC power

cables. Where possible avoid running the

cable near inductive equipment.

Shield Wiring

(Cable Termination Only)

Connect the braided shield to the guard

terminal on the reading instrument

(meter, etc.) if available or to ground or to

the power supply negative terminal.

Vent Tube (Cable Termination Only)

The cable will have a clear Teflon

tube that's required at pressure below

500 psi to provide atmospheric reference. The open end should be placed in

a dry area.

Output Type Excitation Supply Current

0.5/4.5 V

Ratiometric

1/5V 8-32 Vdc 10mA typ

Teflon is a registered trademark of E. I. DuPont

RoHS Compliant

5V±.5 Vdc 10mA typ

®

vent

© 2011 Ashcroft Inc., 250 E. Main St., Stratford, CT 06614-5145, Tel: 203-378-8281, Fax: 203-385-0408, www.ashcroft.com

All sales subject to standard terms and conditions of sale.

I&M011-10168. Rev. A 5/11

KM15 PRESSURE TRANSDUCER

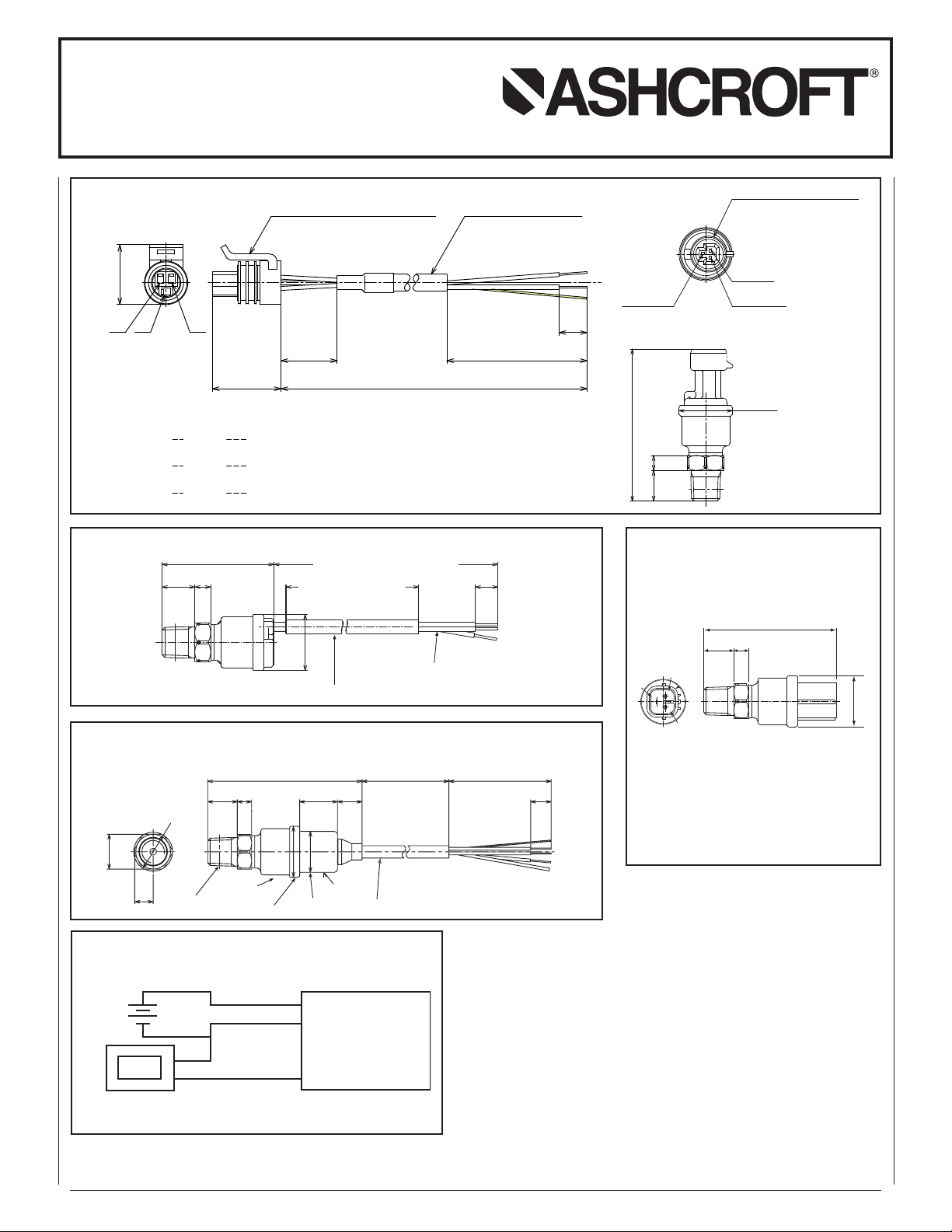

(10)(7)(14.5)

(25) DIA.

(49.5)

L

ead Length As Specified By Customer

Lead Length Less 50mm (2˝)

.28˝

.58˝

2˝

1˝

Protective Sleeve

Red : Power (+)

White: Output (+)

Black : Common

.

4˝

0.5mm

2

20 A

WG Leads

2 ft.

Standard Length

(25)

DIA.

.57˝ .28˝

(64)

1.00˝

2.5˝

(14.5) (7)

1

2

3

3

2

1

+

+

–

–

POWER

SUPPLY

(Common)

(+ Power)

(+ Output)

METER

TRANSDUCER

METER OR

OTHER DEVICE

(21.3)

(

B) (C) (A)

C

ommon

Power(+)

B

lack

Red(B)

(

A)

M

ETRI-PACK 150 Series SHIELDED CABLE

O

utPut(+)White(C)

MAT ING CONNECTOR

(

20) (50)

(10)

(24.5)

(.84")

(

.97")

(.79")

.

39"

1.97"

L

ead Length As Specified By Customer

OPTIONAL

1

2065287

PIN

METRI-PACK 150 Series

OUTPUT(+)

P

OWER(+)

COMMON

(25 DIA.)

(7)(14.5)

(71.6)

.27".57"

(2.8")

.

98" DIA.

MATE S TO OPTIONAL METRI-PACK

CONNECTOR 12065287

Cab

le

Housing

Fitting

(870) 34

Std.

(10)

( )

(50)

(14.5))(7)

( )

(75.5)

(20) DIA.

.78

(12)

(25) DIA.

.98

(9)

(18.5)

SS Case

.57

.73

3

(

1

9

)

IA

.

(17)

Red :Power (+)

White: Output (+)

Black : Common

.7

5

˝

.

3

5

˝

.

6

7

˝

INSTRUCTION SHEET

METRI-PACK

imension Drawing

D

Dimensions

in ( ) are mm

FLYING LEAD STYLE

Dimension Drawing

Dimensions

in ( ) are mm

SHIELDED CABLE TERMINATION

Dimension Drawing

(Height may vary slightly depending on process connection)

WIRING DIAGRAM FOR ALL KM15 TRANSDUCERS

Dimensions

in ( ) are mm

CONNECTOR STYLE TERMINATION

Dimension Drawing

(Height may vary slightly depending

on process connection)

Dimensions

n ( ) are mm

i

Mating Connector

Mates to HW090 Connector by Sumitomo Wiring

Systems. Made of PBT (polybutylene terephthalate).

Flying Leads : 20AWG, 3 ft. (.9m) standard

PIN Color Function

1 Red Supply (+)

2 White Output (+)

3 Black Common

© 2011 Ashcroft Inc., 250 E. Main St., Stratford, CT 06614-5145, Tel: 203-378-8281, Fax: 203-385-0408, www.ashcroft.com

All sales subject to standard terms and conditions of sale.

3-Wire Voltage

I&M011-10168. Rev. A 5/11

Loading...

Loading...