Page 1

Quick Start Function Summary Instructions

Note: Holding the

3 seconds returns to

Pressure

Unit Monitor

Measured

Data

Arbitrary

Unit Monitor

MODE key

DOWN key

UP key

CH+ CH–

PSI

M

GC51

Test

Terminals

1

2

3

4 5

6

for ASHCROFT

(See Complete I&M Manual for Further Detail)

®

GC51 Version 6.03

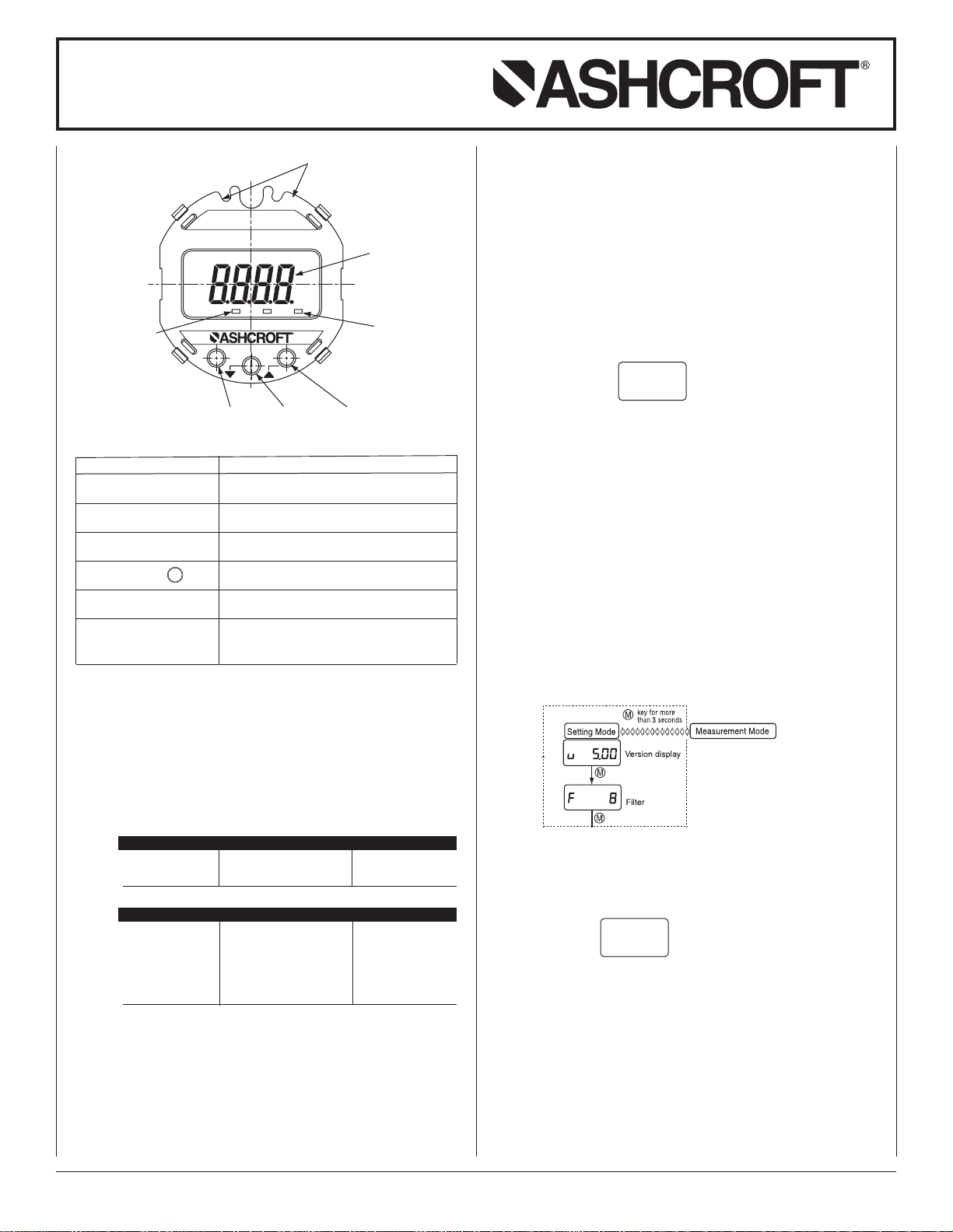

DISPLAY OVERVIEW

Designation

Measured Data Display

Pressure unit monitor

Arbitrary unit monitor

MODE button M

DOWN button #

UP button $

Pressure, linear scaling value, hold value (max./

min), are displayed.

When either indicator is ON, the display is reading in PSI.

When this indicator is ON, the linear scaling value

of an arbitrary unit is indicated on the display.

Used to switch the setting mode, the measurement mode and the setting item.

Used to change (decrease) and select the set

value and to zero-reset the hold function.

Used to change (increase) and select the set

value and to shift from the measurement mode

to the zero adjustment mode.

Function

1. Upon Power-Up the unit enters “Measure Mode” – displaying

applied pressure.

2. Four functions available to the user in “Measure Mode”.

A. Zero Adjustment Mode: Hold the UP$button for more than

3 seconds.This is not to be used for scaling of the output.

• If the zero point adjustment is performed correctly the

message “ADJ” will be displayed for 2 seconds, and

the display will return to the measurement mode.

B. Key Lock

Function Key Manual Indicator

Setting of key lock MODE+

Release of key lock MODE+$one second UnL (Key invalidity)

Operation during keylock

Function Key Manual Indicator

Zero adjust. mode

Hold value reset

Setting mode M key greater than 3 sec LoC (Key invalidity)

Peak indicator

Bottom indicator

$

#

$

#

one second LoC (Key invalidity)

$

key greater than 3 sec LoC (Key invalidity)

key greater than 3 sec LoC (Key invalidity)

one push Peak indicator

one push Bottom indicator

C. Minimum Value “Capture”*: Press DOWN#button to

display the minimum value. The letter “L” will follow the

reading indicating this is the minimum value. Press the

DOWN button again to return to Measurement Mode.

Note: Press the button and release, do not “hold” the but-

ton down (will reset the values).

D. Maximum Value “Capture”*: Press UP$button to dis-

play the maximum value. The letter “H” will follow the

reading indicating this is the maximum value. Press the

UP$button again to return to Measurement Mode.

Note: If the button is held for 3 seconds it will go into

zero adjustment mode.

Minimum/Maximum Reset

The Minimum/Maximum values can be reset when in

either Minimum/ Maximum display by holding the DOWN

button for more than three seconds, “clr” will appear

#

on the display for two seconds and the Minimum and

Maximum values will be removed.

Note: Values are maintained even if unit is powered OFF.

Hold reset

message

clr

• When first using unit be sure to Reset values to clear

values in memory from the factory calibration

process.

• Values are captured starting one minute after Reset,

thus if unit is powered OFF during the one minute the

values during that period will not be kept in memory.

3. Four functions available to the User via “Setting Mode”. To

enter the “Setting Mode” hold “M” key for more than 3 seconds.

(See last page for complete Setting Mode menu.)

A. Filter (Damping)

The filter is based on the moving average of the pressure

data to decrease display “bounce” and to smooth the

analog output due to system pressure fluctuations at the

user’s discretion.

Five selections: 0, 2, 4, 8 and 16 where 0=30ms (and in

this case the filter is not active), 2=60ms, 4=120ms,

8=240ms, 16=480ms, use

keys to change value.

$#

B. Re-scaling in “psi” units: “Pressure Display Mode”

allows for zero (4mA) and span (20ma) adjustment of

–10 to +110% Span respectively.

Note: 1. See menu schematic on last page for detail.

2. Must be in “Pressure Display Mode” option within

“Setting Mode,” this is noted on the screen by

-

n non

Use

keys to move between “Pressure

$#

Display Mode” and “Linear Display Mode” which

is for re-scaling in “Arbitrary” units.

3. To adjust Output Zero Point (4mA) and Output

Span Point (20mA) must be in the functional area

as noted below and then adjustment is via

$#

keys. The value shown is a percentage of the

pressure range (span) as noted on the product

label (ex. If product was supplied as a 0-100psi

range and the user desired the Output Zero Point

to be “moved” from 0 psi to 50 psi then Output

Zero Point would be 50.0 which is 50%.

© 2008 Ashcroft Inc., 250 East Main St., Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale. 02/11 I&M011-10163_GC51_Rev. C_Ver. 6.03

Page 2

Quick Start Function Summary Instructions

Note: Holding the button for more than

3 seconds returns to display mode.

for ASHCROFT

(See Complete I&M Manual for Further Detail)

®

GC51 Version 6.03

Notes shown below are from I&M manual.

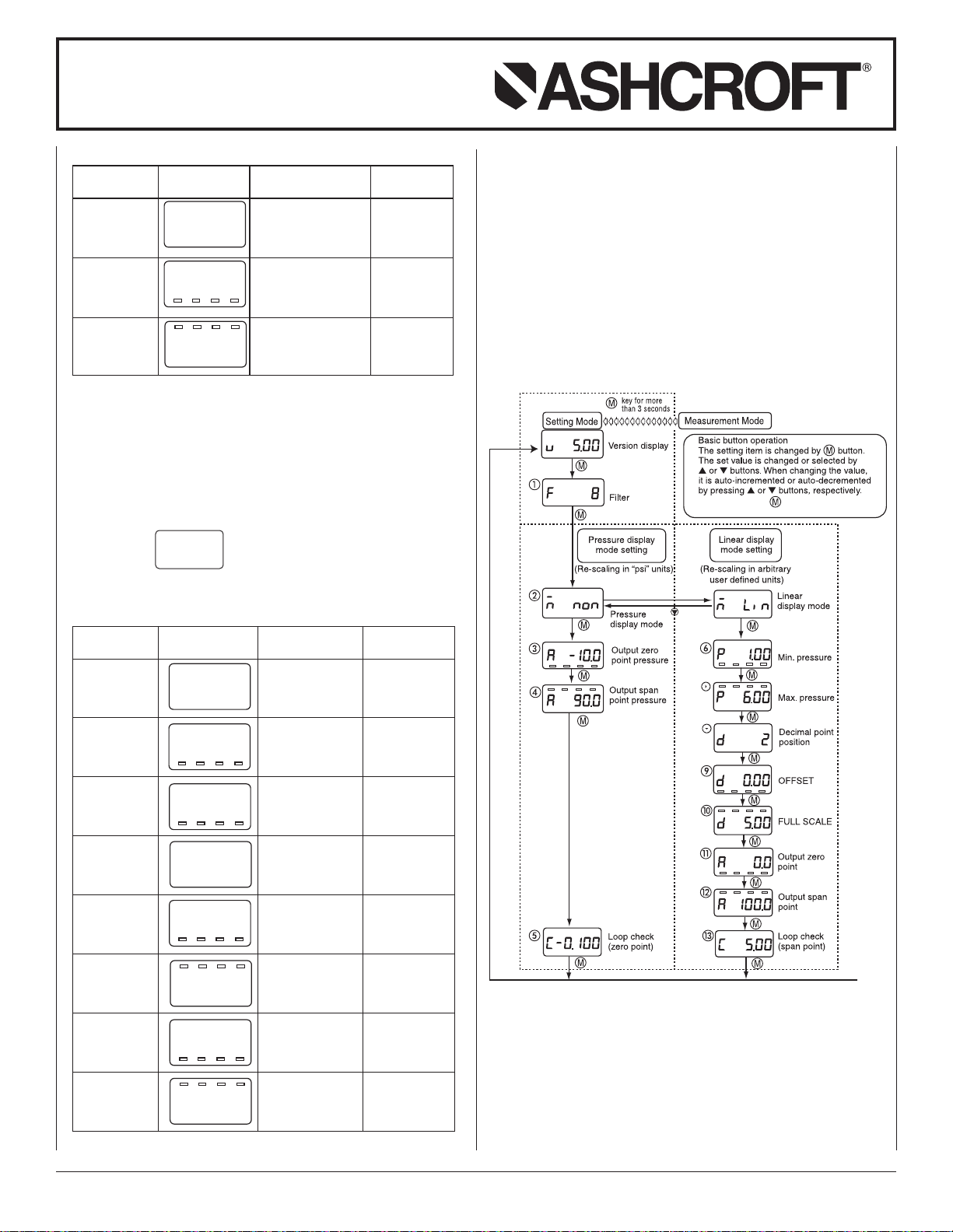

Setting LCD Setting Setting

Item Display Description Range

Display Selection of non:pressure

mode pressure display display mode

Output Analog Pressure

zero point output zero point range:–10

.

Output Analog Pressure

span point output span point range:–10

Note: For setting of zero point and span point in the analog

output, input the percent value over the pressure range.

C. Re-scaling in “Arbitrary” units: “Linear Display Mode”.

This function allows the user to establish a linear relationship from the standard “psi” unit to any user defined unit.

Note: See menu schematic at end, must be in “Linear

Use

and “Pressure Display Mode.”

-

n non

a 10.0

a 90.0

Display Mode” option within “Setting Mode”, this is

noted on the screen by

-

n L;n

keys to move between “Linear Display Mode”

$#

mode : non Lin: linear

display mode

(4mA) : 10.0 (%Span) to 110% Span

(20mA) : 90.0 (%Span) to 110% Span

D. Loop Check: Use to send a 4-20mA signal meant to

simulate applied pressure, can be accessed either

through Pressure Display Mode or Linear Display Mode.

See “Complete Setting Mode Menu” at end. Loop Check

is noted on the screen with a prefix

is indicating in actual units and starts at the zero

(4mA) point.

If$button continues to be pressed, the linear display

will auto-increment by linkage between the linear display

and the analog output. By continuing to press#button,

auto decrement will occur. Release the button at the

desired indication.

Complete Setting Mode Menu

“

”

. The display

(

Setting LCD Setting Setting

Item Display Description Range

Display Selection of non:pressure

mode pressure display display mode

Minimum Min. pressure Pressure range

pressure corresponding to 0 to 75% Span

Maximum Max. pressure Pressure range

pressure corresponding to 25 to 100% Span

Decimal Display after 0,1,2,3 digit

point decimal point

position Number of digits

OFFSET OFFSET –1999 to 1999

FULL FULL SCALE –1999 to 1999

SCALE corresponding to

Output Analog output Max. display

zero point zero point (4mA) span: –10

Output Analog output Max. display

span point span point (20mA) span: –10

-

n L;n

p 10.0

p 60.0

mode : Lin Lin:Linear display

OFFSET 9

: 10 (psi)

FULL SCALE 10

: 60 (psi)

d 2

d 0.00

d 5.00

a 0.0

a 100.0

corresponding to

min. pressure 6

: 0.00 (ton)

mAX. pressure 7

: 5.00 (ton)

: 0.0 ( %Span) to 110% Span

: 100.0 (%Span) to 110% Span

mode

: 2 (digit)

Notes: Actual values shown are based upon the examples

shown in the I&M Manual.

Changes made within the Setting Mode are saved

by returning to Measurement Mode before powering

the unit “off.”

Note: Values shows are from example in I&M manual.

© 2008 Ashcroft Inc., 250 East Main St., Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale. 02/11 I&M011-10163_GC51_Rev. C_Ver. 6.03

Page 3

Quick Start Function Summary Instructions

CASE

DISPLAY

CAP

Inside sensor Line

LCD holder

Notch

Transmission cable

(Twist)

Sheath

+

−

Terminal box

Display (board)

Shield

Power source

+−

Receiver

Transmission cable

Display

Wire terminals

Wire

Turn with a screwdriver

LCD clips (4)

Display board

Power supply

terminal block

1000

750

500

250

0

0 322010

1020

30

Load Limitations 4-20mA Output Only

12 24

545

OPERATING

REGION

Loop Resistance (V)

for ASHCROFT

(See Complete I&M Manual for Further Detail)

4. Wiring

Power supply requirements, 12-36Vdc, note installation

recommendations as follows:

Terminal Strip: SMKDSP1.5/2-5.08 Phoenix contact

A. Cable Requirements

• Two core shielded cable

• Cable outer diameter: 0.35˝ to 0.47˝ (9-12mm)

Required for proper installation with cable gland option

• Wire Gauge: 14-22 AWG (multi-strand or solid)

B. Wiring Instructions

• Do not run pressure transmitter cable / wires within the same

conduit as high voltage (line power) line to reduce the

potential for noise (interference). Use dedicated conduit on

GC51 cables / wires for optimum results.

• Cable diameter, specified above, must be maintained when

using the Cable Gland termination to retain environmental

ratings.

• When connecting shield / drain wire, only connect one end

which should be at the received ground.

• Wire stripping instructions; remove cable jacket 2-3˝ and

strip wires 0.25˝. Shield / drain wire should not be exposed

at the pressure transmitter termination.

®

GC51 Version 6.03

• Remove cover and carefully remove the display to access

the terminal strip, take care not to mishandle the display and

associated electronics.

• Turn display over to expose terminal strip, make positive and

negative connections; insert wire equal to the recommended

strip length (0.25˝).

• After completing connections, align the retaining clips of the

display with the housing’s notches and carefully place into

the housing. Be sure that the internal sensor ribbon cable

does not cross the power supply lines just installed.

• Be sure to properly tighten the sealing grommet when using

the Cable Gland before applying tension to the cable; the

cable gland provides strain relief and environmental sealing.

• Tighten GC51 cover to maintain environmental rating.

• Connect to power source and receiver, than apply power to

confirm correct wiring.

• Power Supply Requirements: Although the 4-20mA signal

can travel over long distances, a very common issue to arise

involves inadequate power at the pressure transmitter – this

results in voltage drop across the loop. Be sure to review the

accompanying table to determine whether the 12-36Vdc has

been received at the pressure transmitter.

LOOP SUPPLY VOLTAGE

min

V

= 12V+[.022A*RL)]

*Includes a 10% safety factor

RL= RS+ R

RL= Loop Resistance (ohms)

R

R

W

S

= Sense Resistance (ohms)

W

= Wire Resistance (ohms)

© 2008 Ashcroft Inc., 250 East Main St., Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale. 02/11 I&M011-10163_GC51_Rev. C_Ver. 6.03

LOOP SUPPLY VOLTAGE

Page 4

© 2008 Ashcroft Inc., 250 East Main St., Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale. 02/11 I&M011-10163_GC51_Rev. C_Ver. 6.03

Loading...

Loading...