Page 1

INSTALLATION AND MAINTENANCE

INSTRUCTIONS FOR ALL ASHCROFT

BIMETAL DIAL THERMOMETERS

®

GENERAL

In removing the thermometer out of the packing box,

handle it by the case or case outlet. Avoid handling it by

the stem.

INSTALLATION OF THERMOMETERS

The thermometer should be mounted at any convenient

location where it will be subjected to the average temperature variations to be indicated.

For an EVERYANGLE CONNECTION PLEASE REFER

TO THE REVERSE SIDE OF THIS DOCUMENT

before beginning the installation.

Avoid bending the stem as this will cause misalignment

of the internal parts, resulting in undue frictional errors.

To tighten the thermometer to the apparatus, use a

wrench applied to the hexagon head of the threaded

connection located just outside of the case.

INSTALLATION

Locate the stem so that at least two inches will be subjected to the average temperature to be measured.

Exposing the stem to a temperature in excess of the

highest dial reading should be avoided.

The thermometer is normally provided with a threaded

connection. To tighten the thermometer to the apparatus or into the well, use an open-end wrench applied to

the hexagon head of the threaded connection.Turn until

reasonably tight, then tighten still further in the same

manner as a pipe elbow or similar pipe fitting until the

scale is in the desired position for reading. DO NOT

TIGHTEN BY TURNING THE THERMOMETER CASE.

Install the dry type thermometer so that the maximum

case temperature is kept below 200°F at all times.

Install the liquid filled type thermometer so that the

maximum case temperature is kept below 150°F at all

times.

When a thermometer is equipped with a well, the well

should be installed onto the apparatus first. The stem of

the thermometer should then be coated with a heat

conducting medium (a mixture of glycerin and graphite

or vaseline or any other heavy lubricant may be used),

after which the thermometer stem is inserted, and tightened into the well.

CAUTION:

Thermowells should be used on all pressurized applications, to protect the thermometer from corrosion or

physical damage, and to facilitate removal of the thermometer without disturbing the process.

TESTING

Ashcroft Bimetal Dial Thermometers are carefully calibrated at the factory and under most operating conditions will retain their accuracy indefinitely. However, as

in the case of all instruments, it is well to make periodic

checks for accuracy against known standards.

ADJUSTMENT

If it is necessary to make an adjustment to the thermometer proceed as follows:

On thermometers fitted with an “External Adjustment”

– Use a small wrench, small screwdriver or a coin to

turn the slotted hexagon head in the back of the case

until the pointer indicates the proper temperature on

the dial.

MAINTENANCE OF

DIAL THERMOMETERS

Aside from occasional testing, little or no maintenance

is required.

Be sure that the gasketed glass cover is on the case at

all times, as moisture and dirt inside the case will eventually cause the thermometer to lose its accuracy. (See

caution note below.)

If the thermometer is used for measuring the temperature of a material that may harden and build up an

insulating layer on the stem, the thermometer should

be removed from the apparatus occasionally, and the

stem cleaned. Observe this precaution to ensure the

sensitivity of the instrument.

CAUTION:

Bimetal Thermometers operating below freezing must

have a perfectly tight case to prevent entrance of moisture

which eventually will condense and freeze inside the stem.

This condition shows up as a failure of the thermometer to

read accurately below 32°F or 0°C. For this reason it is

important to avoid damage to the glass front while the

stem temperature is at freezing or below. All thermometers

are hermetically sealed in a dry atmosphere at the factory

and require no further maintenance.

© 2011 Ashcroft Inc., 250 East. Main Street, Stratford, CT 06614-5145, USA Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale.

I&M008-10187 Rev 01/14

Page 2

INSTALLATION AND MAINTENANCE

INSTRUCTIONS FOR ASHCROFT

®

BIMETAL

THERMOMETERS WITH EVERYANGLE

This thermometer was designed to be positioned to face the direction of easiest reading.

A

B

Reset

Harness

Stem

Sensitive

Portion

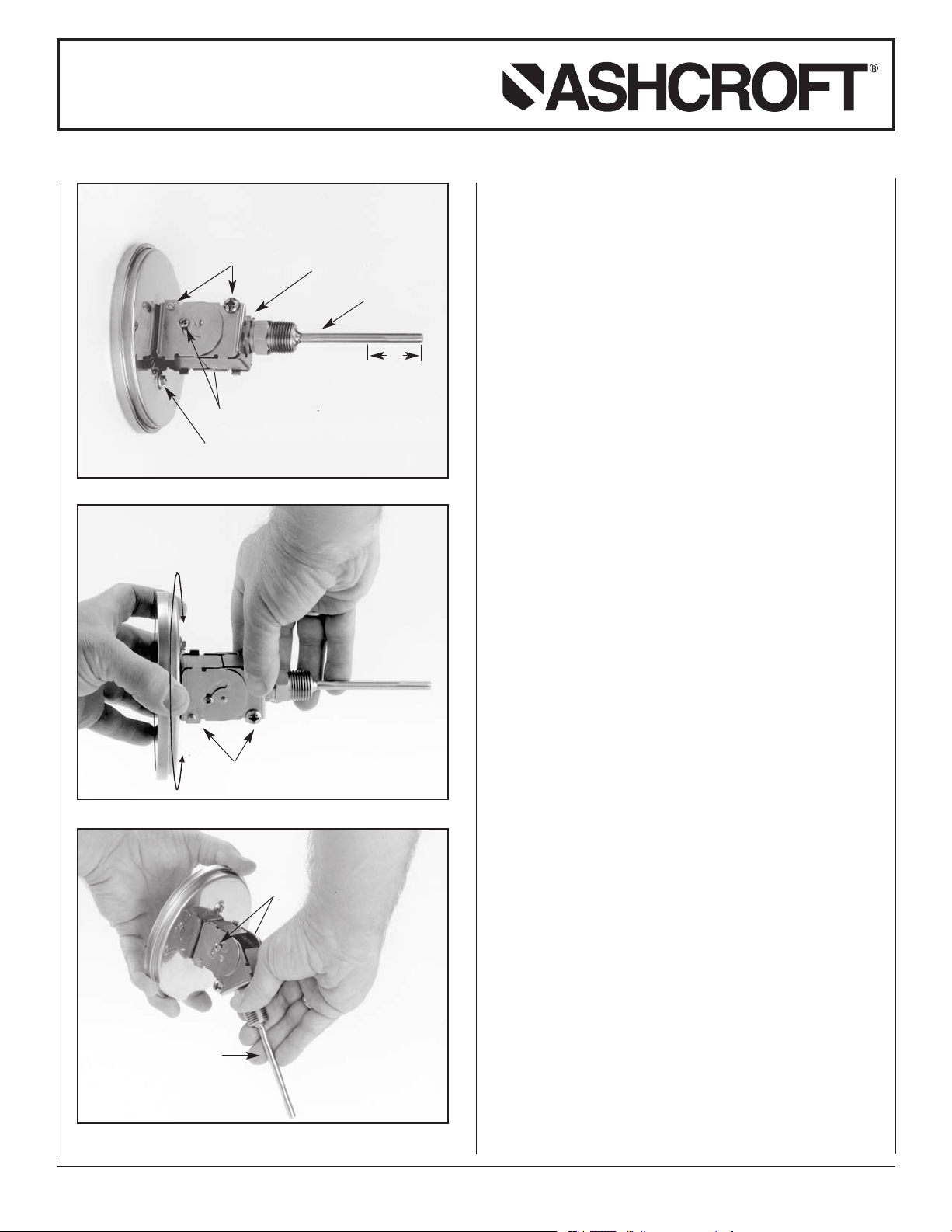

Figure 1

2˝

™

CONN.

CAUTION: To assure longest life, the “EVERY- ANGLE”

joint should be operated only when necessary during

installation or removal of the thermometer.

POSITIONING THE STEM

Before installation, the stem should be set to the

desired angle as follows:

Figure 1: Loosen the four screws labeled “A” and “B” in

Figure 1, until the harness revolves freely without twist-

ing the flexible housing.

Figure 2: While holding the case, revolve the harness

clockwise or counterclockwise, as indicated by arrows

in Figure 2, to place the harness in a position that will

permit flexing the stem in the desired direction with

respect to the case. Then lock the two screws labeled “A.”

Figure 3: Flex the stem to the desired angle with

respect to the face of the thermometer, as shown in

Figure 3, then lock the two screws labeled “B.”

INSTALLATION

The lower 2˝ of the stem is the sensitive portion. Be

sure this part of the stem is exposed to the temperature

to be measured.

Tighten the thermometer to the apparatus or into the

thermometer well, using an open-end wrench applied to

the hexagon head of the connection bushing. Turn until

reasonably tight, then tighten further (in the same man-

ner as a pipe fitting) until the scale is in the desired

position for reading.

A

Figure 2

TER CASE OR THE HARNESS. INSTALL THE DRY

TYPE EVERYANGLE THERMOMETER SO THAT

THE MAXIMUM CASE TEMPERATURE IS KEPT

BELOW 200°F. INSTALL THE LIQUID-FILLED TYPE

EVERYANGLE THERMOMETER, SO THAT THE

MAXIMUM CASE TEMPERATURE IS KEPT BELOW

150°F.

DO NOT TIGHTEN BY TURNING THE THERMOME-

B

THERMOMETER WELLS

When the thermometer is equipped with a well, the well

should first be removed from the ther mometer and

screwed into the apparatus.

Stem

Figure 3

© 2011 Ashcroft Inc., 250 East. Main Street, Stratford, CT 06614-5145, USA Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale.

I&M008-10187 Rev 01/14

Loading...

Loading...