Page 1

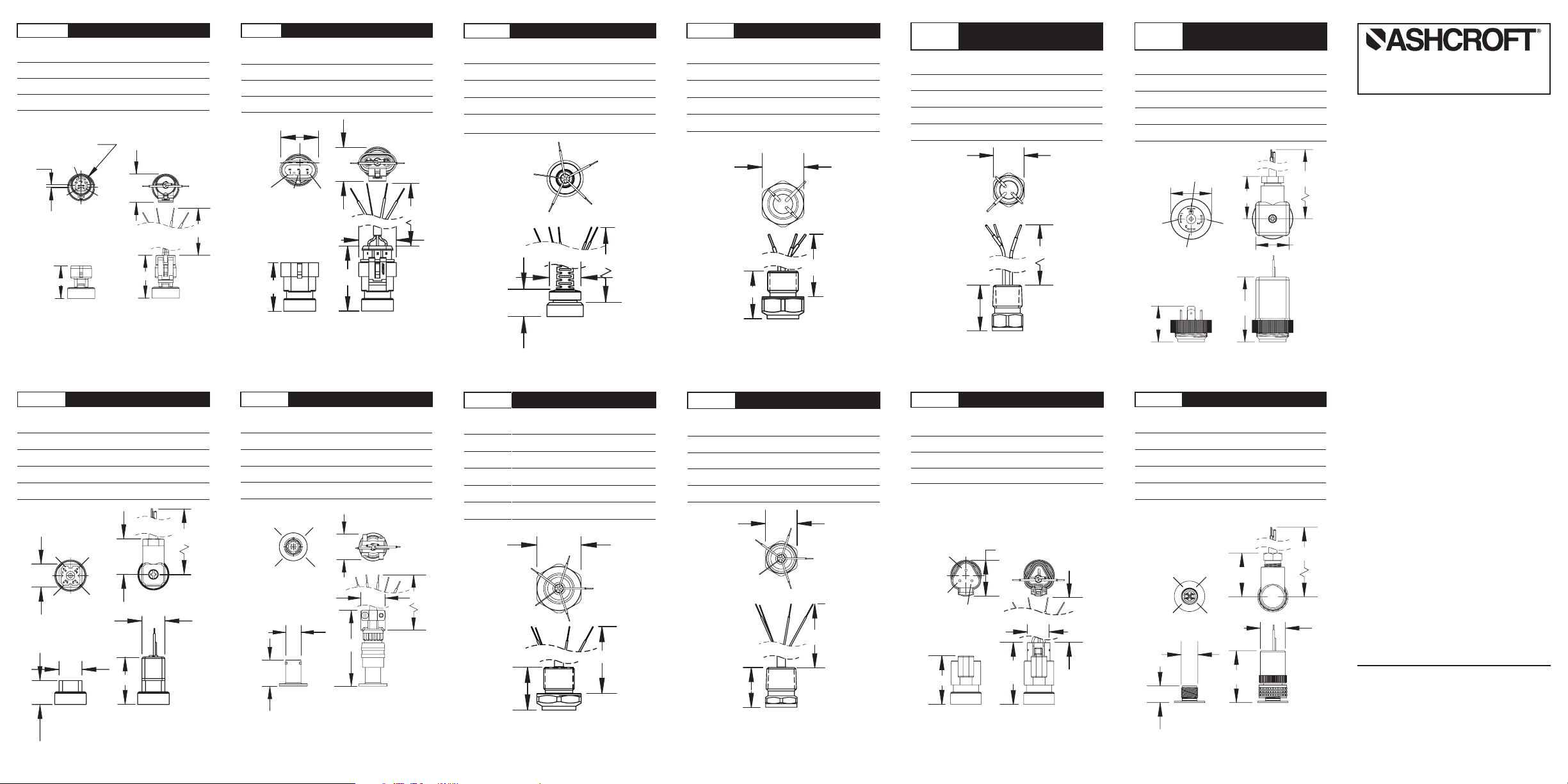

GNN 3-Pin Metri Pack

.63

Code "AP"

Ø.47

Code "B4"

Ø.75

Code "FC/FV"

1.10

1.142

Code "MC/MV"

1.30

1.142

1.10

.875

.875

1.36

1.01

Code "DT"

.08

Ø.47

Code "EW"

Ø 1.34

Code "DA"

Voltage

Pin

HM Mini-Hirschmann GW41F

Pin

Ouput

A Common V- Black

B V+ V+ Red

C Output V- White

Ø .63

C

B A

1.04

Metri-pack

3-pin

Code "GN"

Voltage

Ouput

1 V+ V+ Red

2 Common V- Black

3 Output V- White

4 Case GND Case GND Green

1

3

4-20mA

Output

.90

1.36

4-20mA

Output

.98

4

2

.63

.66

Mini

Hirschmann

Code "HM"

1.31

with Mate

"GN"

with Mate

.63

"HM"

½˝ NPT Conduit With Flying

Leads

Voltage

Ouput

- V+ V+ Red

- Common V- Black

- Case GND Case GND Green

- Ouput N/A White

4-20mA

Output

Wire

Color

Hex.

DA

Pin

GND Case GND Case GND Green

Wire

Color

AP AMP Superseal 3-Pin

Voltage

Pin

Ouput

1 Common V- Black

2 Output V- White

3 V+ V+ Red

4-20mA

Output

1.02

.92

3

2 1

Wire

Color

FC, FV Over-mold Cable

Voltage

Pin

Ouput

- V+ V+ Red

- Common V- Black

- Output N/A White

- Case GND Case GND Green

4-20mA

Output

Wire

Color

MF M20 Conduit Flying Leads

Voltage

Pin

Ouput

- V+ V+ Red

- Common V- Black

- Output N/A White

- Case GND Case GND Green

4-20mA

Output

Wire

Color

Hex.

CF

Pin

L

L

1.31

1.02

AMP

Superseal

3-pin

1.77

"AP"

with Mate

L

L

L

.65

Overmold

Cable

M20 Conduit

w/ Flying Leads

Code "MF"

½ NPT Conduit

w/ Flying Leads

Code "CF"

B4 MIL DTL 26482 4-Pin

Wire

Color

Voltage

Pin

Ouput

A V+ V+ Red

B Output N/A White

C Case GND Case GND Green

D Common V- Black

C

L

B

4-20mA

Output

.78

A D

.75

Wire

Color

L

MC, MVV M20 Conduit With Cable

Voltage

Pin

Ouput

- V+ V+ Red

- V- V- Black

- Output Output White

- Case GND Case GND Green

- N/C N/C Drain

Hex.

4-20mA

Output

Color

Wire

CC, CV ½˝ NPT Conduit With Cable

Voltage

Pin

Ouput

- V+ V+ Red

- V- V- Black

- Case GND Case GND Green

- N/C N/C Drain

4-20mA

Output

Wire

Color

Hex.

DT DEUTSCH DT06-3S

Voltage

Pin

Ouput

1 V+ V+ Red

2 Output V- White

3 Common V- Black

4-20mA

Output

2

3

Wire Color

EW M12 4-PIN

Pin

1

.81

MIL-DTL-26482

8-4

2.33

"B4"

with Mate

M20 Conduit

w/Cable

L

½ NPT Conduit

w/ Cable

Code "CC/CV"

L

DT04-3P

.62

1.75

with Mate

L

.47

"DT"

Hirschmann EN 175301-803

Form A

Voltage

Ouput

1 V+ V+ Red

2 Common V- Black

3 Output N/A White

GND

1

3

1.16

EN 175301-803

Form A

Voltage

Ouput

1 V+ V+ Red

2 Output N/A White

3 Case GND Case GND Green

4 Common V- Black

1

2

4

3

4-20mA

Output

1.37

2

2.11

4-20mA

Output

1.24

Ø.71

"DA"

with Mate

Wire

Color

L

1.08

Wire

Color

L

1.47

M12

4-pin

"EW"

with Mate

E2 PRESSURE TRANSDUCER

INSTALLATION MANUAL

WARNING! READ

⚠ ⚠

BEFORE INSTALLATION

A failure resulting in injury or damage may be

caused by excessive overpressure, excessive

vibration or pressure pulsation, excessive

instrument temperature, corrosion of the

pressure containing parts, or other misuse.

Consult Ashcroft Inc., Stratford, Connecticut,

USA before installing if there are any questions or concerns.

OVERPRESSURE:

Pressure spikes in excess of the rated overpressure capability of the transducer may

cause irreversible electrical and/or mechanical damage to the pressure measuring and

containing elements.

Fluid hammer and surges can destroy any

pressure transducer and must always be

avoided. A pressure snubber should be installed to eliminate the damaging hammer

effects. Fluid hammer occurs when a liquid

flow is suddenly stopped, as with quick closing solenoid valves. Surges occur when flow

is suddenly begun, as when a pump is turned

on at full power or a valve is quickly opened.

Liquid surges are particularly damaging to

pressure transducers if the pipe is originally

empty. To avoid damaging surges, fluid lines

should remain full (if possible), pumps should

be brought up to power slowly, and valves

opened slowly. To avoid damage from both

fluid hammer and surges, a surge chamber

should be installed.

Symptoms of fluid hammer and surge’s damaging effects:

• Pressure transducer exhibits an output at

zero pressure

(large zero offset).

• Pressure transducer output remains constant regardless of pressure

• In severe cases, there will be no output.

©2019 Ashcroft Inc., 250 East Main Street,

Stratford, CT 06614-5145, USA,

Tel: 203-378-8281, Fax: 203-385-0499,

www.ashcroft.com

All sales subject to standard terms and

conditions of sale.

e2 _ t r a nsduc e r_i& m_ R evB _ 0 8 -13 -19

Page 2

FREEZING:

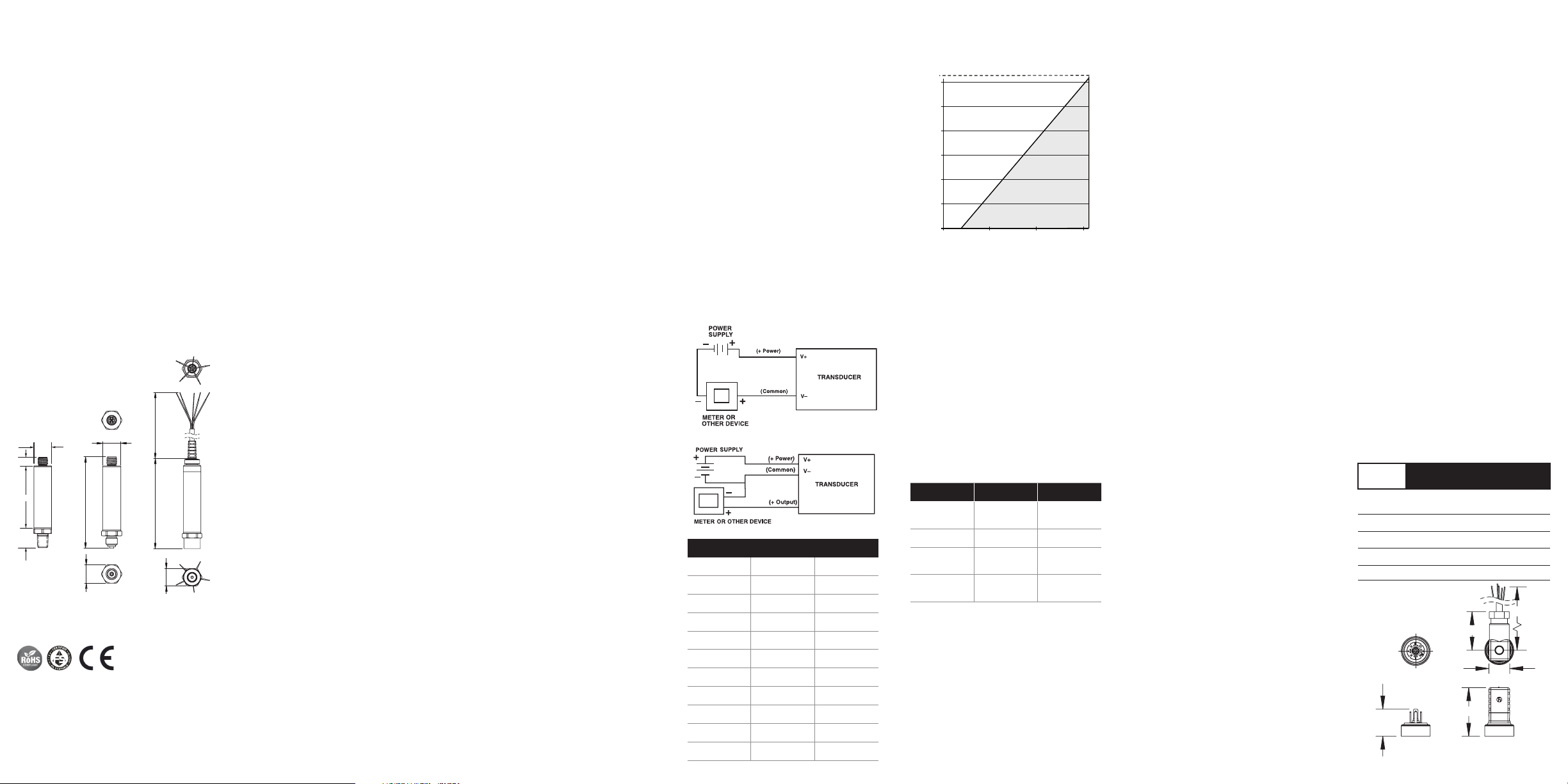

Ø.866

4.45

Cable Length

4.34

0.875

.81

53

Loop Resistance (Ohms)

V Supply: Rloop:

Min 9 0

Typ 24 681.8181818

Max 36 1227.272727

Prohibit freezing of media in pressure port.

Unit should be drained (mount in vertical

position with electrical termination upward) to

prevent possible over- pressure damage from

frozen media.

STATIC ELECTRICAL CHARGES:

Any electrical device may be susceptible to

damage when exposed to static electrical

charges. To avoid damage to the transducer,

observe the following:

• Operator/installer should follow the proper

ESD (electrostatic discharge) protection

procedures before handling the pressure

transducer.

• Ground the body of the transducer BEFORE

making any electrical connections

• When disconnecting, remove the ground

LAST!

Note: The shield and drain wire in the cable

(if supplied) is not connected to the transducer body, and is not a suitable ground.

ASHCROFT® E2 PRESSURE TRANSMITTER,

TYPICAL DIMENSIONS AND CONSTRUCTION

Ø 0.87

.47

3.00

.98

¼ NPT Male

Code "M02"

0.875

ASHCROFT® E2 PRESSURE TRANSMITTER,

AVAILABLE OPTIONAL HAZARDOUS LOCATION

APPROVALS

DESCRIPTION

The Ashcroft® Model E2 is ideal for a broad

range of pressure sensing requirements

found in general and heavy industrial applications as well as applications in test

and measurement. The E2 offers a wide

variety of material, process and electrical

connections to meet your application requirements. It is designed for use with both

liquids and gases it provides an accurate,

reliable and highly repeatable output. This is

accomplished through the use of an onboard

microprocessor that is programmed during

a unique digital compensation process to

provide an extremely linear performance

over the entire specified pressure and temperature range.

SPECIFICATIONS

Reference condition: 70°F (21°C)

Accuracy: ±0.25%, ±0.50% or ±1.00%

of Span Terminal Point (* includes linearity,

hysteresis, repeatability zero offset and span)

Repeatability: ≤ ±0.1 % of Span

Stability: ±0.25% of Span / Year

Zero / Span Adjustment: ±5% of Span

Standard Ranges: VAC to 20,000 psi

ENVIRONMENTAL SPECIFICATIONS

Enclosure Rating: IP66 standard, IP67 and

IP69K Consult Factory

Temperature Limits:

Storage Temp: -50 to 125°C

Operating Ambient Temp: -40 to 125°C

Media Temp: -40 to 125°C

* (0-100% R.H. non-condensing)

Temperature Coefficients: Zero & Span

±0.009%/°C within -40 to 125°C

Vibration: Random: 10g RMS 20-2000 Hz

Shock: 80g Peak, 6 msec, 3 axes, haversine

Proof pressure: 1.2X -2X the range

Burst pressure: 3X-8X the range minimum

FUNCTIONAL SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

Analog Output: 4-20 mA, 20-4 mA (2-wire),

1-5Vdc, 1-6Vdc, 0-5Vdc, 0-10Vdc, 1-11Vdc,

0.1-5Vdc, 0.1-10Vdc, 0.5V-4.5Vdc

Supply Voltage:

9-36Vdc: (4-20mA, 1-5Vdc, 1-6Vdc,

0.1-5Vdc, 0.1-10Vdc)

14-36Vdc: (0-10Vdc, 0-11Vdc, 0.1-10Vdc)

Supply Current: <8 mA (Vout)

Response Time (Output): 4msec <8 mA

Power-Up Response Time: 100msec

Current Source/Sink for Voltage Output: 1

mA (Source) / 0.1mA (Sink) maximum

Withstand/Breakdown: 100 Vdc / 100 Vac.

Optional 500Vdc / 500Vac

EMC: CE Industrial EN 61326-1, EN 613262-3, EN 61326-3

ESD: 4KV Contact/8kV Air IEC 61000-4-2

RFI: 10V/m 80-1000MHz IEC 61000-4-3

EFT: IEC 61000-4-4

Surge: IEC 61000-4-5 (shielded cable)

Common Mode: IEC61000-4-6

Radiated Power Frequency: IEC61000-4-8

Conducted Emissions: EN55011/FCC

CE: EMC

Insulation Resistance: >100M @ 30V

RoHS2: Yes

MECHANICAL SPECIFICATIONS

Process Connections: Male NPT (1⁄8, ¼ and

½), Female NPT (1⁄8, ¼ and ½), 7⁄16-20 UNF

SAE (Male and Female), MIL 33656 (UNJF

7

⁄16-20 w/ 37° Cone), G¼˝ B EN837-1, G½˝ B

EN837-1,

G¼˝ A DIN3852-E, Autoclave HP 7⁄16˝

(AMINCO), 1⁄8˝ BSP Tapered Thread, ¼˝ BSP

Tapered Thread, ½˝ BSP Tapered Thread, ¼˝

Male VCR, ¼˝ Female VCR, R1⁄8 ISO 7/1

Electrical Connections: Cable (vented and

non-vented), ½˝ Conduit with shielded cable:

24AWG+drain vented or non-vented, ½˝

Conduit with Flying Leads: 18AWG 3 conductor, non-vented, M20 Conduit with Cable/

Flying Leads, Mini Hirschmann G, Bendix

4-pin MIL-DTL-26482(3112), M12 (4-pin),

Form A EN175301-803 (DIN A43650), Form

C EN 175301-803 (DIN C 43650), Deutsch

DT04-3P or DTM04-3P, AMP Superseal, Metri-Pack 3-Pin Packard.

Diaphragm Materials: 17-4PH SS, 316SS

or A286

INSTALLATION AND ASSEMBLY

All supply lines should be arranged so that

there are no mechanical forces acting on

the device.

For units with NPT type pressure fittings

apply Teflon

®

tape or an equivalent sealant

to the threads before installing. When tightening, apply a wrench to the hex wrench

flats located just above the pressure fitting.

DO NOT tighten by using a pipe wrench on

the housing.

Process connection:

• By authorized and qualified personnel only.

• All lines need to be depressurized when

the instrument is being connected.

•

Appropriate steps must be taken to protect the device from pressure surges.

•

Check the suitability of the device for the

media to be measured.

• Maximum pressures shall be observed.

• Check that all connections are tight before

use.

If during installation the pressure measuring

lines are already under pressure, the zero

point cannot be checked and no settings

can be adjusted. In these cases, the device

should only be connected electrically first.

Electrical connection:

• By authorized and qualified personnel only.

•

The electrical connection of the device

shall be performed according to local

electrical codes

•

Turn off power before connecting the device.

•

Connect only to Class 2 power supply

2 Wire 4-20mA

3 Wire Voltage

Power Supply Requirements

Output Signal Min Supply Max Supply

0-5Vdc 9Vdc 36Vdc

1-5Vdc 9Vdc 36Vdc

1-6Vdc 9Vdc 36Vdc

0-10Vdc 14Vdc 36Vdc

1-11Vdc 14Vdc 36Vdc

0.1-5Vdc 9Vdc 36Vdc

0.1-10Vdc 14Vdc 36Vdc

0.5-4.5Vdc 9Vdc 36Vdc

4-20mA 9Vdc 36Vdc

20-4mA 9Vdc 36Vdc

FOR TRANSMITTERS WITH 4-20mA OUTPUT

SIGNAL, THE MINIMUM VOLTAGE AT THE

TERMINAL IS 9VDC

Loop Supply Voltage vs. Loop Resistance

1200

1000

800

600

400

200

0

5152

Loop Supply Voltage (Vdc)

V

= 9V + (0.022*A x R

MIN

R

= R

+ R

LOOP

SENSE

R

= Loop Resistance (Ohms)

LOOP

R

SENSE

R

WIRING

WIRING

= Sense Resistance (Ohms)

= Wire Resistance (Ohms)

Operating

Region

) (*includes a 10% safety factor)

LOOP

5

Noise

For minimum noise susceptibility, avoid running the transducers cable in a conduit that

contains high current AC power cables. Where

possible avoid running the cable near inductive equipment.

Shielded Cable

Units with shielded cable electrical termination, connect the drain wire to the guard

terminal on the read out device or measuring

instrument, if available. In all other cases

connect to the ground or to the power supply

negative terminal.

Range Type Offset Value Span Value

0 to Positive

Pressure Range

0 to Vacuum Vacuum 0

Compound (Vac

to pressure range)

Absolute Absolute Zero

0 Full Range

Vacuum Full Range

Full Range

Absolute

Offset and Span adjustments

1. WARNING! Disconnect the E2G transducer

from the control system prior to performing offset and span adjustments.

2. Activate calibration mode by first cycling

power off and on, and then within 30 seconds tap the Ashcroft calibration magnet

near the specified area on the E2G label.

The initial code to enter the calibration

mode is 1-3-1 (Tap the unit for one second, release. Tap unit for three seconds,

release, tap unit for one second, release).

When the calibration mode has been activated the output signal on the transducer

will drive from over range to under range.

3. At the offset pressure record output offset

to be used in the span adjustment in step

4. Increase pressure to 100% of span,

this will allow you to adjust the span of

the unit. The span is adjustable to +/- 5%

of full scale.

4. Tap the magnet near specified area on

the E2G label. Adjust span to desired span

value plus the offset value recorded in

step 3. (The span will increase from its

current value up to +5% of scale. Once

the output has reached the max value,

the span will jump to -5% and continue

to increase. (Note - holding the magnet

in position while adjusting the span will

increase the speed at which the span increases or decreases. Once you get close

to your desired setting you should tap the

magnet against the unit for finer adjustment. If you scroll past your desired value,

repeat step three until you have reached

your desired span value.

5. Decrease the pressure to 0% of span,

this will allow you to adjust the zero of

the unit. The offset is adjustable to

+/- 5% of full scale.

6. Tap magnet near specified area on the

E2G label. Adjust the offset to the desired

value. (The offset will increase from its

current value up to +5% of scale. Once

the offset output has reached the max

value, the zero will jump to -5% and continue to increase. (Note - holding the magnet in position while adjusting the offset

will increase the speed at which the offset

increases or decreases. Once you get

close to your desired setting you should

release the magnet and tap it against the

unit for finer adjustment. If you scroll past

your desired value, repeat step 6 until you

have reached your desired offset value.

7. Once you have completed step 6, you can

repeat step 3 through 6 to adjust or check

your calibration

8. Once you have verified the calibration, the

unit will exit the calibration mode after 30

seconds of magnetic inactivity. This will be

signaled by the output of the transducer

driving to over range, under range and

back to the normally calibrated output.

MAINTENANCE

The device does not require maintenance. In

order to ensure reliable operation and a long

service life of the device we recommend

regular checking of the device as follows:

• Check the function in connection with system components.

• Check the tightness of the pressure connection lines.

• Check the electrical connections.

The exact test cycles have to be adapted to

the operating and environmental conditions.

The operating manuals of all other devices

are also to be observed if there is an interaction of different device components.

TRANSPORT

The product must be protected against severe

impacts therefore transport is to be effected

only in the packaging intended for transport.

SERVICE

All defective or faulty devices are to be sent

directly to Ashcroft Inc. We would ask you to

coordinate all device returns with our inside

sales department. Our inside sales department will issue an RMA number and give

instructions on how to ship the return.

WARNING

Remaining process media in and on dismantled measuring instruments may cause danger to persons, environment and equipment.

Take reasonable precautions! Clean the

instrument thoroughly if necessary. To return

the unit please choose the original packaging or a packaging intended for transport.

DISPOSAL

Incorrect disposal can put the environment

at risk. Kindly help us protecting the environment and dispose of or recycle the used

products in accordance with the relevant

regulations.

DC

Pin

GND Case GND Case GND Green

Hirshman EN 175301-803

Form C

Voltage

Ouput

1 V+ V+ Red

2 Common V- Black

3 Output N/A White

GND

1

3

EN 175301-803

Form C

2

4-20mA

Output

1.15

1.45

.62

"DC"

with Mate

Wire

Color

L

Loading...

Loading...