Page 1

MODEL DXLdp DIFFERENTIAL

5.29

+

P

–P

Z

ero

S

pan

Z

ero

V+ V– Out

Test

+

–

.89

3.92

3.18

Model: DXLdp

4.96

Span

Zero

V+ V– Out

.89

3

.92

3.18

M

odel: DXLdp

PRESSURE TRANSMITTER

OPERATING & INSTRUCTION SHEET

WARNING! READ

BEFORE INSTALLATION

1. GENERAL:

A failure resulting in injury or damage may

be caused by excessive overpressure,

excessive vibration or pressure pulsation,

excessive instrument temperature, corrosion

f the pressure containing parts, or other

o

misuse. Consult Ashcroft Inc., Stratford,

Connecticut, USA before installing if there are

any questions or concerns.

2. OVERPRESSURE:

Pressure spikes in excess of the rated overpressure capability of the transducer may

cause irreversible electrical and/or mechanical

damage to the pressure measuring and containing elements.

3. STATIC ELECTRICAL CHARGES:

Any electrical device may be susceptible to

damage when exposed to static electrical

charges. To avoid damage to the transducer

the operator/installer should follow proper

ESD (electrostatic discharge) protection

procedures before handling the pressure

transducer.

Description:

Congratulations on your purchase of the

®

Ashcroft

transmitter. The DXLdp utilizes the same highly

reliable variable capacitance sensor used in traditional Ashcroft XLdp family of low differential

transmitters. A selection of both unidirectional

and bi-directional pressure ranges are offered,

accuracy’s of 1%, 0.5% and 0.25% and a wide

assortment of output signals. Refer to CT-5 specification sheet for more information.

The DIN rail-mounting package offers a new and

efficient use of mounting space for enclosure

mount applications. Optional features such as the

SpoolCal™ process valve actuator, LED’s with

front access test sockets and 2:1 turn down provide added value when validating a process on

line or calibrating the unit. These options are

available through suffixed (X) variations on the

part number. Contact the factory for DXLdp

upgrades.

Model DXLdp low differential pressure

Media:

The DXLdp is designed to measure clean, dry

non-corrosive gases. (Consult with factory for

se on other media). Not for use on liquids.

u

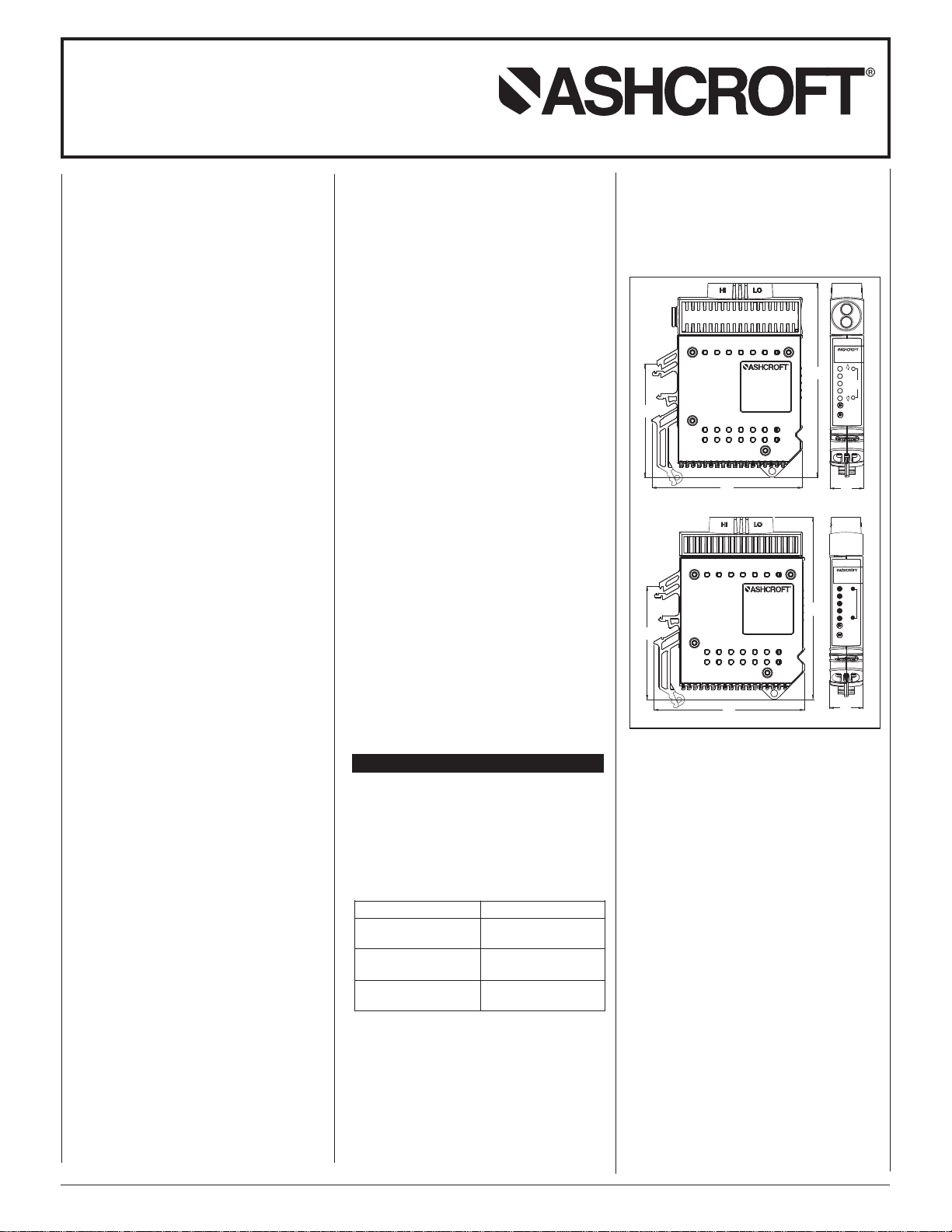

Mounting:

The unit can mount to three types of Din sizes

ncluding EN50022, EN50035 & EN50045 (not

i

included). When securing to EN50022 rail first

hook the top portion of the rear clip onto the top

of the rail and push gently into place. To remove

simply place finger behind lower rear lever and

pull forward. To remove from the EN50035 rail,

grasp the unit, push up and rotate the bottom out.

For the EN50045, pull down and rotate the bottom

out.

Multiple units can be stacked accross the rail.

Internal circuitry is vented through the bottom of

each unit. Tag holes are fabricated into the lower

rear lever and the housing below the terminal

strip for calibration reference tagging and/or ID

location. Refer to Drawing #1.

Power requirements:

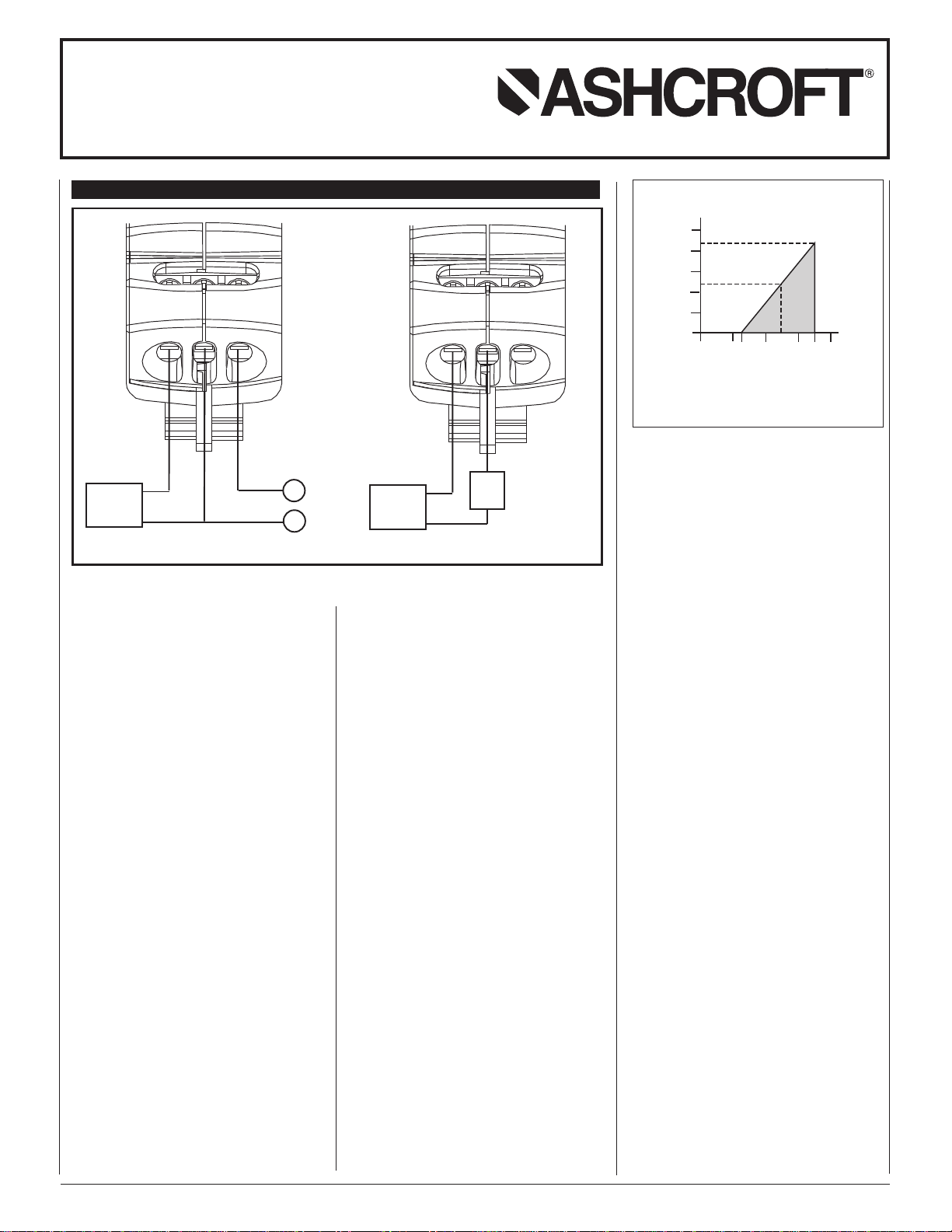

The DXLdp is wired (3 wire) (2 wire) for Voltage

and Current output respectively. Reference

Drawing #2.

Voltage Output

The DXLdp will operate on any supply voltage

from 12-36Vdc drawing less than 10mA in full

function LED variations (24Vdc typical).

Current Output

The voltage required for a 4-20mA output is

dependent on the loop resistance of the circuit.

Refer to Drawing #3 showing the minimum supply voltage (Vmin) required for a given Loop

Resistance (RL).

OPTIONS

The three options available include LED (XDL),

SpoolCal™ (XPV) and 2:1 Turn down (X21).

OPTION: LED RANGE INDICATION (XDL)

Provides a quick visual in/out of range status or

diagnostic indication. Not to be used for calibration

reference. This feature includes front access test

jacks for uninterrupted signal reference.

LED INDICATION

TYPICAL ACCURACY

Amber

Zero Pressure

Green

In Range Pressure

Red

Out of Range Pressure

±3% on

nominal zero

Beyond ±3% to

±106% of range

Beyond ±106%

of range

LED Activation:

Unidirectional ranges Bidirectional ranges

• Red, top & bottom LED • Red, top & bottom LED

• Green, top LED • Green, top & bottom LED

• Amber, center LED • Amber, center LED

S

tandard Mounting Position

DXLdp dimension with SpoolCal and LED options

DXLdp dimension for basic unit

Drawing #1

Front Access Test Jacks:

Provides on-line process reference signal or calibration signal without disconnecting power supply

wiring. Measurements can be made using a standard multi-meter or data collection instrument.

Contact the factory for more information on the

Ashcroft ATE handheld calibrator. Reference signals through the test jacks are made in series for

4-20mA output and in parallel for voltage output.

Gold plated contacts accept standard 0.08˝

microtip test leads, snapping in place for secure

measurements.

© 2011 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614, USA • Tel: 203-378-8281, Fax: 203-385-0402 • email: info@ashcrfoft.com, www.ashcroft.com. All specifications subject to change without

notice. All sales subject to standard terms and conditions of sale I&M011-10074 Rev A 5/11

Page 2

MODEL DXLdp DIFFERENTIAL

+

–

+

–

POWER

SUPPLY

+

–

POWER

S

UPPLY

R

S

0

10

12 20 30 36

40

1

250

1091

1000

750

500

250

0

545

24

PRESSURE TRANSMITTER

OPERATING & INSTRUCTION SHEET

ELECTRICAL CONNECTIONS

Voltage Output

Current Output

Load Limitations 4-20mA Output

Loop Resistance (Ω)

V

= 12V+ [.022A*(R L)]

min

*

includes a 10% safety factor

RL = RS + R

W

RL = Loop Resistance (ohms)

RS = Sense Resistance (ohms)

RW =

Wire Resistance (ohms)

Drawing #3

Drawing #2

OPTION: SPOOLCAL™ (XPV)

The rotating process valve actuator in conjunction

with the SpoolCal™ actuator tool provides two

types of tests including Calibrate (CAL) and

Monitor (MON) through the appropriate Hi and Lo

Port of the SpoolCal actuator tool. In the (CAL)

mode the DXLdp is isolated from the process and

allows externally generated test pressure input for

calibration. In the (MON) mode the system pressures can be monitored with an Ashcroft ATE

Calibrator or other handheld instrument without

physically unplugging the process tubes. In this

mode an on-line measurement can be captured. In

conjunction with the (XDL) option, a reference signal can also be captured without process interruption.

The (XPV) option supplies a SpoolCal™ actuator

tool and 7˝ of silicon tubing. The actuator tool

identifies the above positions and tests, including

high (HI) and low (LO) differential pressure reference.

From the (OFF) position the SpoolCal™ actuator

tool can be inserted and removed. The following

tests can be performed:

Calibration (CAL):

Both zero and Span adjustment pots are non interactive and accessible from the front of the unit.

Note: Due to the sensing technology used rarely

are actual zero and span adjustments needed.

Zero and span pots are available on the basic unit.

Requires XDL and XPV options.

• Insert SpoolCal™ actuator tool.

• A 90-degree clockwise rotation isolates the

DXLdp from the process.

© 2011 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614, USA • Tel: 203-378-8281, Fax: 203-385-0402 • email: info@ashcrfoft.com, www.ashcroft.com. All specifications subject to change without

notice. All sales subject to standard terms and conditions of sale I&M011-10074 Rev A 5/11

• Apply zero pressure. This can be best produced

by shorting the HI and LO ports on the SpoolCal™

actuator tool using the silicon tubing supplied.

Verify or make zero adjustment.

• An external pressure generator can be used to

produce the required span pressure. Verify or

make span adjustment.

• Measure record signal via front access test jacks,

option (XDL).

Monitor (MON):

Provides on line or uninterrupted measurement

point capability when XPV option is again selected

in combination with the (XDL) option, including

the front access test jacks.

• Insert SpoolCal™ actuator tool

• A 90-degree counterclockwise rotation tee’s the

process to both the DXLdp sensor and out

through the SpoolCal™ actuator tool, to provide

external measurement or recording capabilities.

OPTION: 2:1 TURN DOWN (X21)

Provides optional in field scalability via internal

jumpers.

Example: Given a 1.0˝ DXLdp with 4-20mA output.

The unit can be adjusted to operate full scale at

0.5˝. In addition, the 4-20mA reference output

remains in calibration.

Steps (Following instructions on label):

1. Lay unit on right side. Remove reusable left side

label.

2. Pry off access door and discard.

3. Using needle nose pliers or twisters, move

jumper from top to bottom position.

4. Reattach label.

5. Reverse range label on face of unit.

ASHCROFT, INC.

250 EAST MAIN STREET, STRATFORD, CT 06614

TEL: 203-378-8281 • FAX: 203-378-0499

EMAIL: INFO@ASHCROFT.COM

www.ashcroft.com

Loading...

Loading...