Page 1

Installation and Maintenance Instructions

for Ashcroft A-Series Miniature

Explosion Proof Pressure Switches

APA APA APS

SLIDE COVER DOWN TO ACCESS

SETPOINT ADJUSTMENT SLIDE COVER

UP TO CLOSE AND SEAL ADJUSTMENT

INTRODUCTION

The APS and APA pressure switch have 316 stainless steel

housing and process connections. The APS has a factory fixed

setpoint which cannot be changed in the field. The APA is field

adjustable and can easily be adjusted by following the instructions in the diaphragm above.

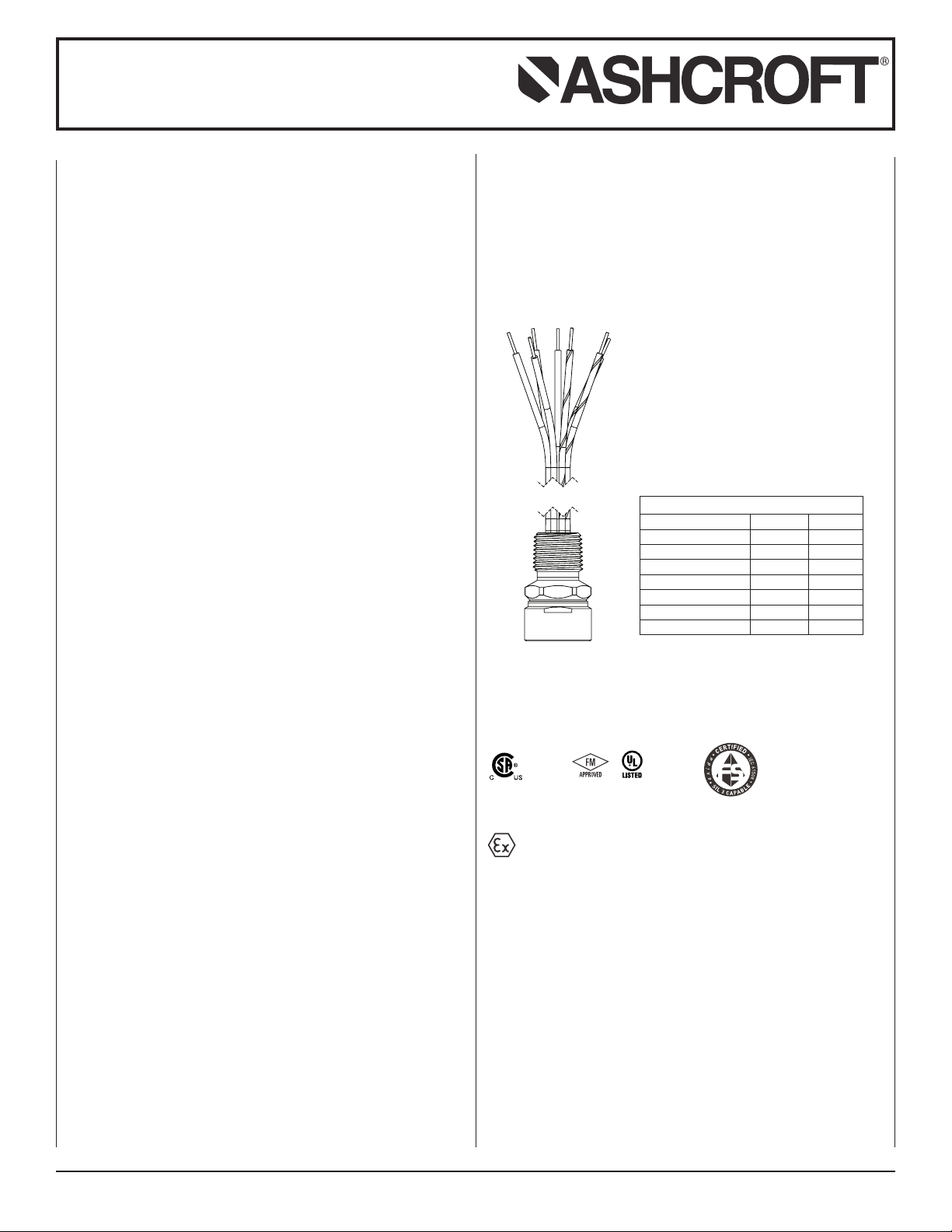

ELECTRICAL CONNECTION

The APS and APA switch is available with wire leads and conduit connections. Refer to the figure on other side for wiring

color codes.

ROTATE LEFT

<

SI L 3 CAP ABL E

TO INCREASE SETPOINT

ROTATE RIGHT

>

TO DECREASE SETPOINT

Ø .095 OR SMALLER TOOL

REQUIRED TO ROTATE NUT

Sira 13ATEX1123X

LO OK FO R THE SE MA RK S O N OUR P ROD UC TS

• Only trained and skilled personnel are allowed to attach the

wires to the electrical terminals of the switch.

• Cable couplers, glands and conduit connectors must have the

correct electrical approvals as required by local electrical

codes.

• The ground wire/connector is connected to the switch housing.

MICRO SWITCH RATINGS

CODE VAC RATING VDC RATING

H 5A @ 125/250VAC

5A @ 28Vdc resistive

3A @ 28Vdc inductive

P 3A @ 125VAC 2A @ 30Vdc resistive

G 0.1 A @ 125VAC 0.1A @ 30Vdc resistive

L 1A @125VAC

1A @ 28Vdc resistive

0.5A @ 28Vdc inductive

IECEx

CSA 13.0015X

© 2016 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale.

I&M009-10046 (250-2966) Rev. 03/16

Page 2

Installation and Maintenance Instructions

for Ashcroft A-Series Miniature

Explosion Proof Pressure Switches

INSTALLATION

• To minimize the risk of injury, the switch enclosure must be

selected according to the area classification and installed

according to the required safety and electrical codes.

• Torque should always be applied to the hex portion of the

body closest to pressure fitting, never to any other part of the

body for it may alter the setpoint. It is recommended that

Teflon tape or other sealant be used on the threads prior to

installing to prevent leaks in the system.

•

witch should be protected from excessive shock and vibration.

S

• The cover of the APA switch should be closed at all times

when the switch is in operation.

CAUTIONS

• Always close the cover of the APA switch after making any

setpoint adjustments.

• Do not exceed current or voltage limits.

• The protection degree of the switch is only valid when the

switch is installed in accordance with all safety and electrical

codes and regulations.

CLEANING

• Never use aggressive solvents.

• Do not use high pressure water to clean the switch.

MAINTENANCE/TROUBLESHOOTING

• All Ashcroft switches require little or no maintenance.

• Be sure the cover on the APA switch is closed at all times.

• When the switch is exposed to process media that may harden

and/or build up in the pressure port, the switch should be

removed and cleaned as required.

• If the switch does not function, only trained and skilled personnel should check on the wiring, power supply and/or mounting.

• If the problem cannot be solved, please contact one of the

Ashcroft affiliates or distributors.

FACTORY SETPOINTS

The APS switches and APA switches with a setpoint called out

in the product code are set at the factory as follows:

• Increasing Setpoint (R) Rising Pressure or Decreasing

Vacuum – Normally Open contact will close when the pressure is raised from 0 psig to the setpoint. The resetpoint is

then measured from the setpoint, reducing the pressure until

the Normally Open contact opens.

• Decreasing Setpoint (D) Decreasing Pressure or Increasing

Vacuum – Normally closed contact will close when the pressure is lowered from full range pressure to the setpoint. The

reset is then measured from the setpoint, increas-ing the pressure until the Normally Closed contact opens.

Note: When ordered as a –15/15 psi range switch, depending

on setpoint, the Normally Open contact may be closed

as received.

EXPECTED MECHANICAL LIFE

Leak free to 1 million pressure cycles on “B” or “V” seals, 400k

pressure cycles with “S” seals, and 1 million cycles of the microswitch enclosure diaphragm.

SPECIAL CONDITIONS FOR SAFE USE

This equipment utilizes a flexible Ex d wall. Do not exceed manufacturers maximum limit detailed in the instructions.

WIRE COLOR/FUNCTION

WIRE COLOR SWITCH FUNCTION

RED SW1 NC

WHITE SW1 C

BLUE SW1 NO

WHITE/BLACK SW2 C

RED/BLACK SW2 NC

BLUE/BLACK SW2 NO

GREEN – Ground

Safety Manual and SIL Certificate, CRN available on

www.ashcroft.com

APPROVALS:

FACTORY

SEALED

CLASS I DIV 1 GROUPS A, B, C, & D

CLASS II DIV 1GROUPS E, F, & G

Sira 13ATEX1123X

IECEx

CSA 13.0015X

SI L 3 CAP ABL E

II 2GD

Ex d IIC T6/T5 Gb

Ex tb IIIC T85°C/T100°C Db

Ta or Tp = -20/-40°C* to +74/89°C**

*Low ambient temperature is dependent upon Switch Code,

Pressure Range, Material Code and Temperature Code per

table in description. Only one low temperature is shown as

they are the same for both T6 and T5 Codes.

**High ambient temperature is dependent upon Switch Code,

and Temperature Code per table in description. Both high

temperature limits are listed as they may be different for the

T6 and T5 Codes. They are separated by a “/” as shown.

© 2016 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale.

I&M009-10046 (250-2966) Rev. 03/16

Loading...

Loading...