Page 1

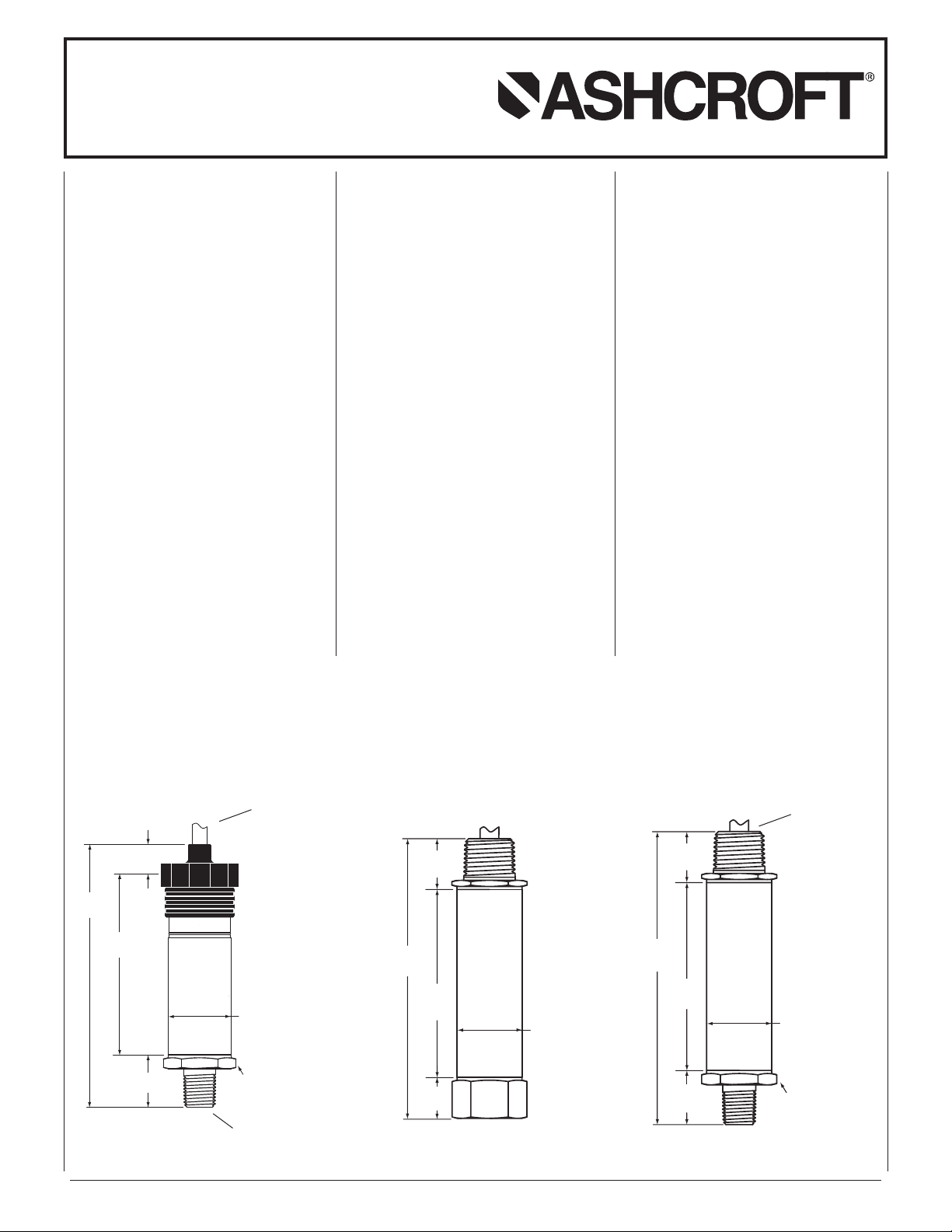

A4 INTRINSICALLY SAFE &

.50

3.065

4.45

.885

1.06

DIA.

1.06 Hex.

Common For All

Pressure Fittings

.887˝

4.78˝

3.065˝

.675˝

1.06˝

DIA.

(22.5)

(121)

(78)

(17)

(27)

.887˝

4.78˝

3.065˝

.885˝

1.06˝ (27) Hex.

Common For All

Pressure Fittings

(22)

(78)

(121)

(22.5)

1.06˝

DIA.

(27)

NON-INCENDIVE RATED

PRESSURE TRANSMITTER

INSTRUCTION SHEET

WARNING! READ

BEFORE INSTALLATION

1. GENERAL:

A failure resulting in injury or damage

may be caused by excessive overpressure, excessive vibration or

pressure pulsation, excessive instrument temperature, corrosion of the

pressure containing parts, or other

misuse. Consult Ashcroft Inc.,

Stratford, Connecticut, USA before

installing if there are any questions

or concerns.

2. OVERPRESSURE:

Pressure spikes in excess of the rated

overpressure capability of the transducer

may cause irreversible electrical

and/or mechanical damage to the

pressure measuring and containing

elements.

Fluid hammer and surges can destroy

any pressure transducer and must

always be avoided. A pressure snubber

should be installed to eliminate the

damaging hammer effects. Fluid hammer occurs when a liquid flow is suddenly stopped, as with quick closing

solenoid valves. Surges occur when

flow is suddenly begun, as when a

ump is turned on at full power or a

p

valve is quickly opened.

iquid surges are particularly damaging

L

to pressure transducers if the pipe is

originally empty. To avoid damaging

surges, fluid lines should remain full (if

possible), pumps should be brought up

to power slowly, and valves opened

slowly. To avoid damage from both fluid

hammer and surges, a surge chamber

should be installed.

Symptoms of fluid hammer and surge's

damaging effects:

• Pressure transducer exhibits an output at zero pressure (large zero offset).

• Pressure transducer output remains

constant regardless of pressure

• In severe cases, there will be no output.

FREEZING:

Prohibit freezing of media in pressure

port. Unit should be drained (mount in

vertical position with electrical termination upward) to prevent possible overpressure damage from frozen media.

3. STATIC ELECTRICAL CHARGES:

Any electrical device may be susceptible to damage when exposed to static

electrical charges. To avoid damage to

the transducer observe the following:

• Operator/installer should follow the

roper ESD (electrostatic discharge)

p

protection procedures before handling

the pressure transducer.

• Ground the body of the transducer

BEFORE making any electrical

connections

• When disconnecting, remove the

ground LAST!

Note: The shield and drain wire in the

cable (if supplied) is not connected to

the transducer body, and is not a suitable ground.

4. HAZARDOUS AREA SPECIFIC GUIDELINES

1. Do not open unit when energized.

2. Do not diconnect equipment unless

area is known to be non-hazardous.

Ashcroft®A4 Pressure Transmitter, Typical Dimensions and Construction*

Enclosure Option “S” Enclosure Option “W”

Cable style

electrical

termination

© 2011 Ashcroft Inc. All rights reser ved. 250 East Main Street, Stratford, CT 06614 USA Tel: 203-378-8281, Fax: 203-385-0402 www.ashcroft.com

All sales subject to standard terms and conditions of sale.

Threaded Male Process Connection

I&M011-10166-A4. Rev. 12/12

*

Dimensions and construction details may vary based on product specified.

Conduit style

electrical

termination

Page 2

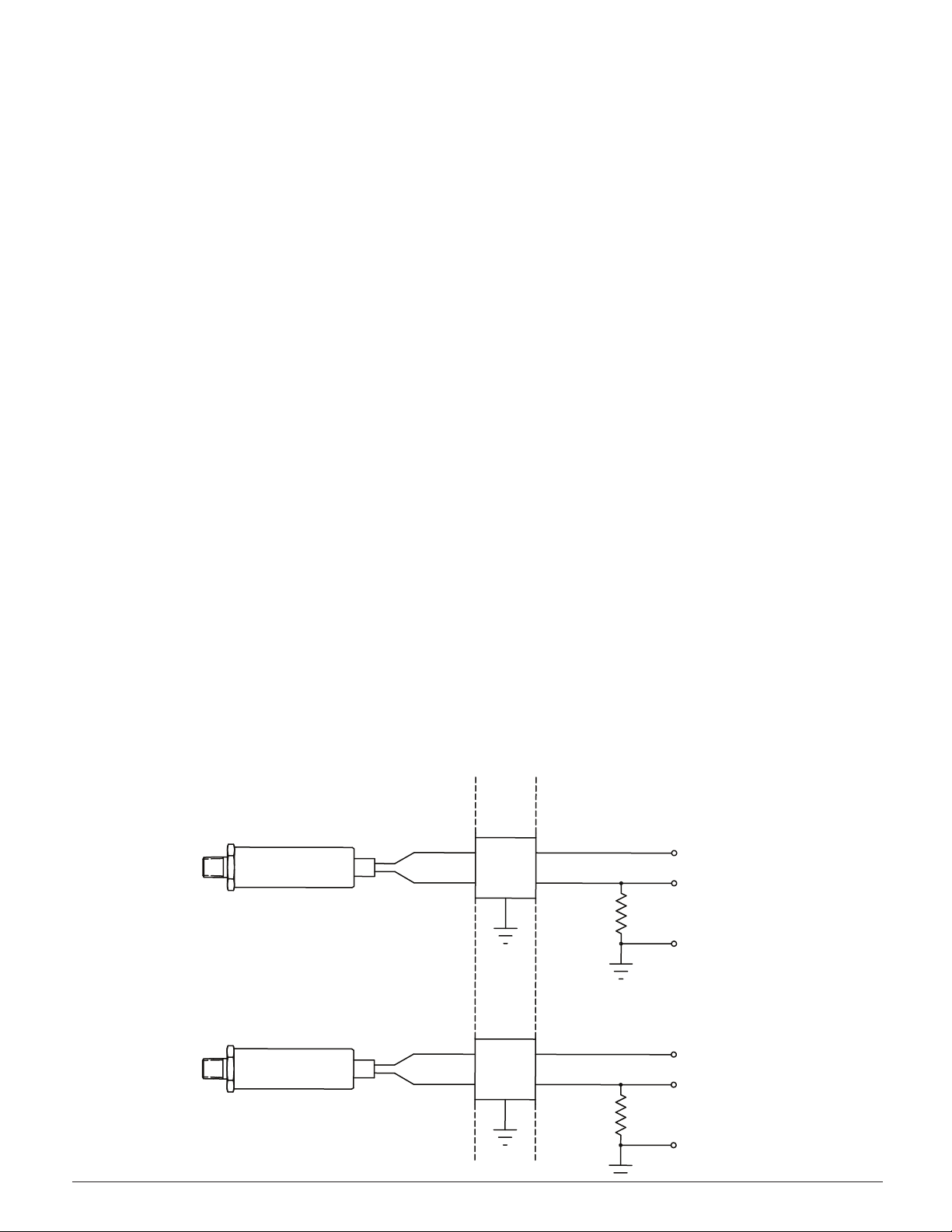

HAZARDOUS (CLASSIFIED) AREA

CLASS I, DIVISION 1 & 2,

GROUPS A, B, C, & D;

CLASS II, DIVISION 1 & 2,

GROUPS E, F & G, CLASS III

NON-HAZARDOUS

(UNCLASSIFIED) AREA

BARRIER

BARRIER

V+

V–

MODEL A2X & A4 SERIES

4-20MA TRANSMITTER

R LOAD

250 OHM

TYP.

R LOAD

250 OHM

TYP.

MODEL A2X & A4 SERIES

4-20MA TRANSMITTER

V+

V–

+24 VDC TYP.

+

–24 VDC TYP.

–

V OUT

(1-5 V TYP.)

V OUT

(1-5 V TYP.)

4.3 FM INSTALLATION GUIDELINES

INSTALLATION FOR FM

INTRINSICALLY SAFE CLASS 1, GROUPS A, B, C & D &

LASS ll, GROUPS E, F & G &

C

NSTALLATION NOTES≥

Voc OR Vt ≤30VDC

Isc OR It ≤100mA

Ca≥ 0.053uF + Ccable

La ≥ 0.364uH + Lcable

1. THE INTRINSIC SAFETY ENTITY CONCEPT ALLOWS THE INTERCONNECTION OF TWO INTRINSICALLY SAFE DEVICES FM

PPROVED WITH ENTITY PARAMETERS NOT SPECIFICALLY

A

EXAMINED IN COMBINATION AS A SYSTEM WHEN: Uo OR Voc

OR V≤t Vmax, Io OR Isc OR≤ It Imax, Ca OR Co ≥ Ci + Ccable, La

OR ≥Lo Li +Lcable≤, Po Pi.

2. THE NONINCENDIVE FIELD WIRING CONCEPT ALLOWS INTERCONNECTION OF NONINCENDING FIELD WIRING APPARATUS

WITH ASSOCIATED NONINCENDIVE FIELD APPARATUS USING

ANY OF THE WIRING METHODS PERMITTED FOR NON3HAZARDOUS (UNCLASSIFIED) LOCATIONS WHEN: Uo OR Voc OR Vt

Vmax, Io OR Isc OR It Imax, Ca OR Co + Ccable, La OR Lo Li

+Lcable, Po Pi.

3. FOR DIVISION 1 INSTALLATIONS, THE CONFIGURATION OF

ASSOCIATED APPARATUS SHALL BE FM APPROVED UNDER

ENTITY CONCEPT.

4. FOR DIVISION 2 INSTALLATIONS USING NONINCENDIVE FIELD

WIRING CONCEPTS THE ASSOCIATED APPARATUS SHALL BE FM

APPROVED UNDER THE ENTITY CONCEPT OR NONINCENDIVE

FIELD WIRING CONCEPT.

CLASS lll

. FOR DIVISION 2 INSTALLATIONS THE ASSOCIATED APPARATUS

5

IS NOT REQUIRED TO BE FM APPROVED UNDER ENTITY CONCEPT OR NONINCENDIVE FIELD WIRING CONCEPT IF THE

A2X(4-20mA) & A4 SERIES PRESSURE TRANSDUCER IS

INSTALLED IN ACCORDANCE WITH THE NATIONAL ELECTRICAL

CODE (ANSI/NFPA 70) FOR DIVISION 2 WIRING METHODS

EXCLUDING NONINCENDIVE FIELD WIRING.

. CONTROL EQUIPMENT CONNECTED TO THE ASSOCIATED APPA-

6

RATUS SHALL NOT USE OR GENERATE MORE THAN 250VRMS

OR VDC.

7. DIVISION 1 INSTALLATIONS SHOULD BE IN ACCORDANCE WITH

ANSI/ISA RP12.06.01, ``INSTALLATION OF INTRINSICALLY SAFE

SYSTEMS FOR HAZARDOUS (CLASSIFIED) LOCATIONS'' AND

THE NATIONAL ELECTRICAL CODE (ANSI/NFPA 70).

8. ASSOCIATED APPARATUS MANUFACTURERS INSTALLATION

DRAWING SHALL BE FOLLOWED WHEN INSTALLING THIS

EQUIPMENT.

9. RUN SHIELDED INTERCONNECTION CABLE WITH SHIELD CONNECTED TO FM APPROVED ASSOCIATED APPARATUS GROUND.

10. WARNING – DO NOT OPEN WHEN ENERGIZED.

11. WARNING – DO NOT DISCONNECT EQUIPMENT UNLESS AREA IS

KNOWN TO BE NON-HAZARDOUS.

© 2011 Ashcroft Inc. All rights reser ved. 250 East Main Street, Stratford, CT 06614 USA Tel: 203-378-8281, Fax: 203-385-0402 www.ashcroft.com

All sales subject to standard terms and conditions of sale.

I&M011-10166-A4. Rev. 12/12

Page 3

HAZARDOUS (CLASSIFIED) AREA

CLASS I, DIVISION 1 & 2,

GROUPS A, B, C, & D;

CLASS II, DIVISION 1 & 2,

GROUPS E, F & G, CLASS III

NON-HAZARDOUS

(UNCLASSIFIED) AREA

BARRIER

BARRIER

V+

V–

MODEL A2X & A4 SERIES

4-20MA TRANSMITTER

R LOAD

250 OHM

TYP.

R LOAD

250 OHM

TYP.

MODEL A2X & A4 SERIES

4-20MA TRANSMITTER

V+

V–

+24 VDC TYP.

+

–24 VDC TYP.

–

V OUT

(1-5 V TYP.)

V OUT

(1-5 V TYP.)

4.4 CSA INSTALLATION GUIDELINES

INSTALLATION FOR CSA

NTRINSICALLY SAFE CLASS 1, GROUPS A, B, C & D &

I

CLASS ll, GROUPS E, F & G &

CLASS llI

INSTALLATION NOTES:

Vmax 30VDC

Imax 100mA

Ci = 0.053uF

Li = 0.364uH

1. THE INTRINSIC SAFETY ENTITY CONCEPT ALLOWS THE INTERONNECTION OF TWO INTRINSICALLY SAFE DEVICES CSA CER-

C

TIFIED WITH ENTITY PARAMETERS NOT SPECIFICALLY EXAMINED IN COMBINATION AS A SYSTEM WHEN: Uo OR Voc Vmax,

Io OR Isc Imax, Ca OR Co Ci + Ccable, La OR Lo Li +Lcable, Po

Pi.

2. THE NONINCENDIVE FIELD WIRING CONCEPT ALLOWS INTER-

CONNECTION OF NONINCENDING FIELD WIRING APPARATUS

WITH ASSOCIATED NONINCENDIVE FIELD APPARATUS USING

ANY OF THE WIRING METHODS PERMITTED FOR NON3HAZARDOUS (UNCLASSIFIED) LOCATIONS WHEN:

Uo OR Voc Vmax, Io OR Isc Imax,

Ca OR Co + Ccable, La OR Lo Li +Lcable, Po Pi.

3. FOR DIVISION 1 INSTALLATIONS, THE CONFIGURATION OF

ASSOCIATED APPARATUS SHALL BE CSA CERTIFIED UNDER

ENTITY CONCEPT.

4. FOR DIVISION 2 INSTALLATIONS USING NONINCENDIVE FIELD

WIRING CONCEPTS THE ASSOCIATED APPARATUS SHALL BE

CSA CERTIFIED UNDER THE ENTITY CONCEPT OR NONINCEN-

IVE FIELD WIRING CONCEPT.

D

5. FOR DIVISION 2 INSTALLATIONS THE ASSOCIATED APPARATUS

IS NOT REQUIRED TO BE CSA CERTIFIED UNDER ENTITY CONCEPT OR NONINCENDIVE FIELD WIRING CONCEPT IF THEA2X

(4-20mA) & A4 SERIES PRESSURE TRANSDUCER IS INSTALLED

IN ACCORDANCE WITH THE CANADIAN ELECTRICAL CODE (CEC,

CAN/CSA3C22.1) FOR DIVISION 2 WIRING METHODS EXCLUD-

NG NONINCENDIVE FIELD WIRING.

I

6. CONTROL EQUIPMENT CONNECTED TO THE ASSOCIATED APPARATUS SHALL NOT USE OR GENERATE MORE THAN 250VRMS

OR VDC.

7. ASSOCIATED APPARATUS MANUFACTURERS INSTALLATION

DRAWING SHALL BE FOLLOWED WHEN INSTALLING THIS

EQUIPMENT.

8. RUN SHIELDED INTERCONNECTION CABLE WITH SHIELD CONNECTED TO FM APPROVED ASSOCIATED APPARATUS GROUND.

9. WARNING – SUBSTITUTION OF COMPONENETS MAY IMPAIR

INTRINSIC SAFETY

10. WARNING – TO PREVENT IGNITION OF FLAMMABLE OR COMBUSTIBLE ATMOSPHERES, DISCONNECT POWER BEFORE

SERVICING.

© 2011 Ashcroft Inc. All rights reser ved. 250 East Main Street, Stratford, CT 06614 USA Tel: 203-378-8281, Fax: 203-385-0402 www.ashcroft.com

All sales subject to standard terms and conditions of sale.

I&M011-10166-A4. Rev. 12/12

Page 4

A4 INTRINSICALLY SAFE &

+

+

–

POWER

SUPPLY

(+)

(–)

T

RANSDUCER

–

V+

V–

PIN 1

PIN 2

4-20mA

METER

OR OTHER DEVICE

.062

Z S

Z S

“Z” and “S” pots

NON-INCENDIVE RATED

PRESSURE TRANSMITTER

INSTRUCTION SHEET

Mounting

The A4 transmitter requires no special

mounting hardware, and can be mounted

in any plane with negligible position error.

Although the unit can withstand normal

vibration without damage or significant

output effects, it is always good practice

to mount the transducer where there is

minimum vibration.

For units with NPT type pressure fittings

apply Teflon

®

tape or an equivalent

sealant to the threads before installing.

When tightening, apply a wrench to the

hex wrench flats located just above the

pressure fitting. DO NOT tighten by using

a pipe wrench on the housing.

Power Supply

Power Supply Voltage

Output Signal Min Max

4-20mA* 12V** 30V

* Refer to Ashcroft drawing #825A022 for

supply voltage and load limit.

** The minimum voltage at the terminals is

12Vdc. However, the minimum supply

voltage should be calculated using the

following graph and formula.

Loop Supply Voltage vs. Loop Resistance

1000

30 Vdc max for

800

600

400

200

Loop Resistance (Ohms)

Vmin = 12V+ (.022A x RL) (includes a 10% safety factor)

RL = RS + RW

RL = Loop Resistance (ohms)

RS = Sense Resistance (ohms)

RW = Wire Resistance (ohms)

Intrinsically Safe

Installations

0

10

Loop Supply Voltage (Vdc)

Operating

Region

20 30

Noise

For minimum noise susceptibility, avoid

running the transducer’s cable in a conduit that contains high current AC power

cables. Where possible avoid running

the cable near inductive equipment.

Shielded Cable

Units with shielded cable electrical termi-

ation, connect the drain wire to the

n

guard terminal on the read out device or

measuring instrument, if available. In all

other cases connect to the ground or to

the power supply negative terminal.

Vent Tube (Cable Termination Only)

The cable has a clear Teflon

®

vent tube

required at pressure ranges below 500

psi to provide atmospheric reference.

The open end should be placed in a

dry area.

A4 Wiring Diagrams

A4 transducer has internal transient

protection: for safety, limit line-toground voltage to 36 Vdc max.

Zero and Span Adjustment

Instructions below apply to the particular

configurations noted. While Zero adjustment is not normally necessary, it may be

desirable to trim out any offset in the system. However, proper Span calibration

requires a pressure standard three to five

times more accurate than the accuracy of

the transducer, and there may also be

interaction of Span on Zero.

A4 configurations with enclosure “S”

offer Zero and Span potentiometer

ccess.

a

Access to “Z” and “S” pots via the top

(electrical termination end) of the unit is

tandard on all “S” enclosure units with 4-

s

20mA output. Access is gained by removing the black threaded cap, once removed

ou will see the pots indicated by “Z” and

y

“S” respectively as shown below. Using a

small trim pot tool, you can adjust zero

±10% of full scale and span ±10% of

full scale.

Recalibration Instructions:

1. Apply 0% full scale pressure.

2. Adjust the output using the zero adjust

trim pot.

3. Apply 100% full scale pressure.

4. Adjust the output using the span adjustment trim pot.

5. Repeat steps 1 through 4 as necessary.

HAZARDOUS AREA CERTIFICATIONS

Intrinsically Safe (applies to 4-20mA) FM/CSA:

Intrinsic Safety: Class I, II and III Div.1 and 2,

Non-Incendive: Class I, II and III Div.1 and 2,

Groups A, B, C, D, F and G per

entity requirements see Ashcroft

drawing # 825A022

Groups A, B, C, D, F and G, no

barriers needed

© 2011 Ashcroft Inc. All rights reser ved. 250 East Main Street, Stratford, CT 06614 USA Tel: 203-378-8281, Fax: 203-385-0402 www.ashcroft.com

All sales subject to standard terms and conditions of sale.

I&M011-10166-A4. Rev. 12/12

Page 5

A4 INTRINSICALLY SAFE &

.600

(4) PIN BENDIX STYLE

ELECTRICAL TERMINATION

SHELL SIZE 8

(B4), (H1), (L1), (P2)

PROCESS

FITTING

(REF.)

1.062

1.000

.830

PIGTAIL

ELECTRICAL TERMINATION

CONDUIT - 1/2 NPT MALE

(C1), (P7)

ELECTRICAL TERMINATIONS FOR

WELDED HOUSINGS ONLY

1.062

C

D

B

A

.71

M12

EL E CT RI CA L TE RM IN AT IO N

(EW), (E0), (E1), (E2)

1.320

.18

.64

DIN 43650-A

EL E CT RI CA L TE RM IN AT IO N

(CD), (DN), (D0), (D1), (D2)

1.320

.65

(4) PIN BENDIX STYLE

EL E CT RI CA L TE RM IN AT IO N

SHELL SIZE 8

(B4), (H1), (L1), (P2)

1.320

PIGTAIL

EL E CT RI CA L TE RM IN AT IO N

PLASTIC MOLDED

(F2), (P1)

1.320

.50

C

D

B

A

3

4

2

1

Key

2

1

3

Gnd.

NON-INCENDIVE RATED

PRESSURE TRANSMITTER

INSTRUCTION SHEET

oltage Current

in #

P

V

utput Output

O

A (+) Power (+) Power

B (+) Output None

C Field Gnd. Field Gnd.

D (-) Power (-) Power

ire Voltage Current

W

olor Output Output

C

Red (+) Power (+) Power

White (+) Output None

Black (-) Power (-) Power

Green Field Grd. Field Grd.

Bare Drain Wire Drain Wire

Pin Voltage Current Mating

No. Output Output Cable Color

1 (+) Power (+) Power Red

2 (+) Output None White

3 Field Gnd. Field Gnd. Green

4 (-) Power (-) Power Black

Pin Voltage Current Mating

No. Output Output Cable Color

1 (+) Power (+) Power Red

2 (-) Power (-) Power Black

3 (+) Output None White

GND Field Gnd. Field Gnd. Green

Pin Voltage Current Mating

No. Output Output Cable Color

A (+) Power (+) Power Red

B (+) Output None White

C Field Gnd. Field Gnd. Geen

D (-) Power (-) Power Black

© 2011 Ashcroft Inc. All rights reser ved. 250 East Main Street, Stratford, CT 06614 USA Tel: 203-378-8281, Fax: 203-385-0402 www.ashcroft.com

All sales subject to standard terms and conditions of sale.

I&M011-10166-A4. Rev. 12/12

Wire Voltage Current

Color Output Output

Red (+) Power (+) Power

White (+) Output None

Black (-) Power (-) Power

Green Field Gnd. Field Gnd.

Bare Drain Wire Drain Wire

Page 6

Visit our web site www.ashcroft.com

All sales subject to standard terms and conditions of sale. I&M011-10166-A4. Rev. 10/12

Ashcroft Inc.

250 East Main Street

Stratford, CT 06614-5145 USA

Tel: 203-378-8281 • Fax: 203-385-0402

email: info@ashcroft.com

www.ashcroft.com

Loading...

Loading...