Page 1

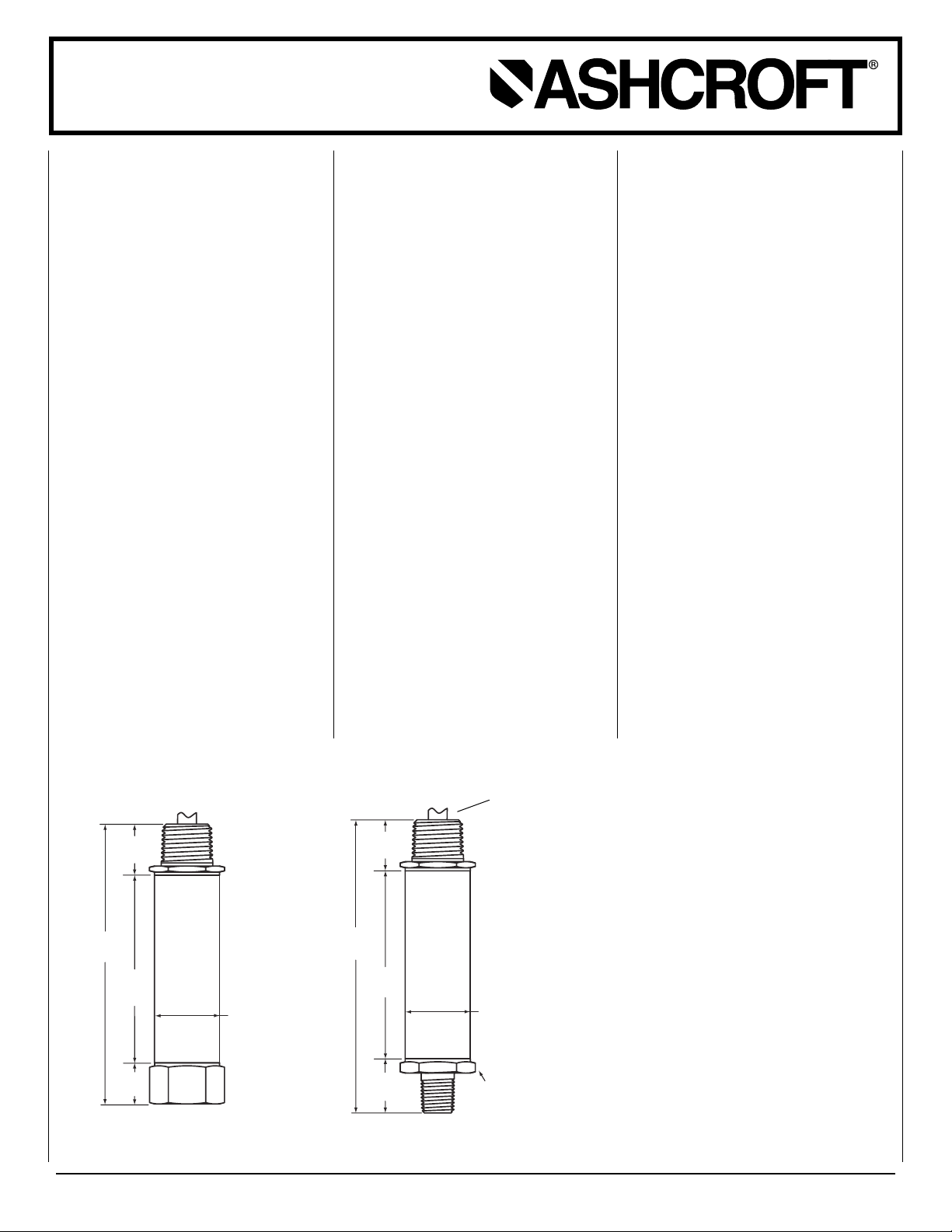

A2X EXPLOSION/FLAME PROOF

.887˝

4.78˝

3.065˝

.885˝

1.06˝ (27) Hex.

Common For All

Pressure Fittings

(22)

(78)

(121)

(22.5)

1.06˝

DIA.

(27)

PRESSURE TRANSDUCER

INSTRUCTION SHEET

m WARNING! READ m

BEFORE INSTALLATION

1. GENERAL:

A failure resulting in injury or damage

may be caused by excessive overpres

sure, excessive vibration or pressure

pulsation, excessive instrument tem

perature, corrosion of the pressure

containing parts, or other misuse.

Consult Ashcroft Inc., Stratford,

Connecticut, USA before installing if

there are any questions or concerns.

2. OVERPRESSURE:

Pressure spikes in excess of the rated

overpressure capability of the transducer

may cause irreversible electrical and/

or mechanical damage to the pressure

measuring and containing elements.

Fluid hammer and surges can destroy

any pressure transducer and must always

be avoided. A pressure snubber should

be installed to eliminate the damaging

hammer effects. Fluid hammer occurs

when a liquid flow is suddenly stopped,

as with quick closing solenoid valves.

Surges occur when flow is suddenly

begun, as when a pump is turned on at

full power or a valve is quickly opened.

Liquid surges are particularly damaging

to pressure transducers if the pipe is originally empty. To avoid damaging surges,

fluid lines should remain full (if possible),

pumps should be brought up to power

-

slowly, and valves opened slowly. To

avoid damage from both fluid hammer

and surges, a surge chamber should be

installed.

Symptoms of fluid hammer and surge’s

damaging effects:

• Pressure transducer exhibits an output

at zero pressure (large zero offset).

-

• Pressure transducer output remains

constant regardless of pressure

• In severe cases, there will be no output.

FREEZING:

Prohibit freezing of media in pressure

port. Unit should be drained (mount in

vertical position with electrical termination upward) to prevent possible overpressure damage from frozen media.

3. STATIC ELECTRICAL CHARGES:

Any electrical device may be susceptible

to damage when exposed to static electrical charges. To avoid damage to the

transducer observe the following:

• Operator/installer should follow the

proper ESD (electrostatic discharge)

protection procedures before handling

the pressure transducer.

• Ground the body of the transducer

BEFORE making any electrical

connections

• When disconnecting, remove the

ground LAST!

Note: The shield and drain wire in the

cable (if supplied) is not connected to

the transducer body, and is not a suitable

ground.

4. WARNING/AVERTISSEMENT

• DO NOT OPEN UNIT WHEN

ENERGIZED

NE PAS OUVRIR L’APPAREIL

LORSQU’IL EST SOUS TENSION

• SUBSTITUTION OF COMPONENTS

MAY IMPAIR INTRINSIC SAFETY

LA SUBSTITUTION DE COMPOSANTS

PEUT COMPROMETTRE LA

SÉCURITÉ INTRINSÈQUE”

• EXPLOSION HAZARD - DO NOT

DISCONNECT WHILE CIRCUIT IS

LIVE UNLESS AREA IS KNOWN TO

BE NON-HAZARDOUS

RISQUE D’EXPLOSION. NE PAS

DÉBRANCHER TANT QUE LE

CIRCUIT EST SOUS TENSION, À

MOINS QU’lL NE S’AGISSE D’UN

EMPLACEMENT NON DANGEREUX

• EXPLOSION HAZARD –

SUBSTITUTION OF COMPONENTS

MAY IMPAIR SUITABILITY FOR

CLASS I, DIVISION 2

RISQUE D’EXPLOSION – LA

SUBSTITUTION DE COMPOSANTS

PEUT RENDRE CE MATÉRIEL

INACCEPTABLE POUR LES

EMPLACEMENTS DE CLASSE I,

DIVISION 2

Ashcroft® A2X Pressure Transmitter, Typical Dimensions and Construction*

Conduit

electrical

termination

1.06˝

(27)

DIA.

1.06˝ (27) Hex.

Common For All

Pressure Fittings

4.78˝

(121)

.887˝

(22.5)

3.065˝

(78)

.885˝

(22)

.887˝

(22.5)

1.06˝

(27)

DIA.

4.78˝

(121)

3.065˝

(78)

.675˝

(17)

*

Dimensions and construction details may vary based on product specified.

©2019 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale. a2x_transducer_im_ RevC_Ltr_01-16-19 (I&M009-10167-A2X)

Page 2

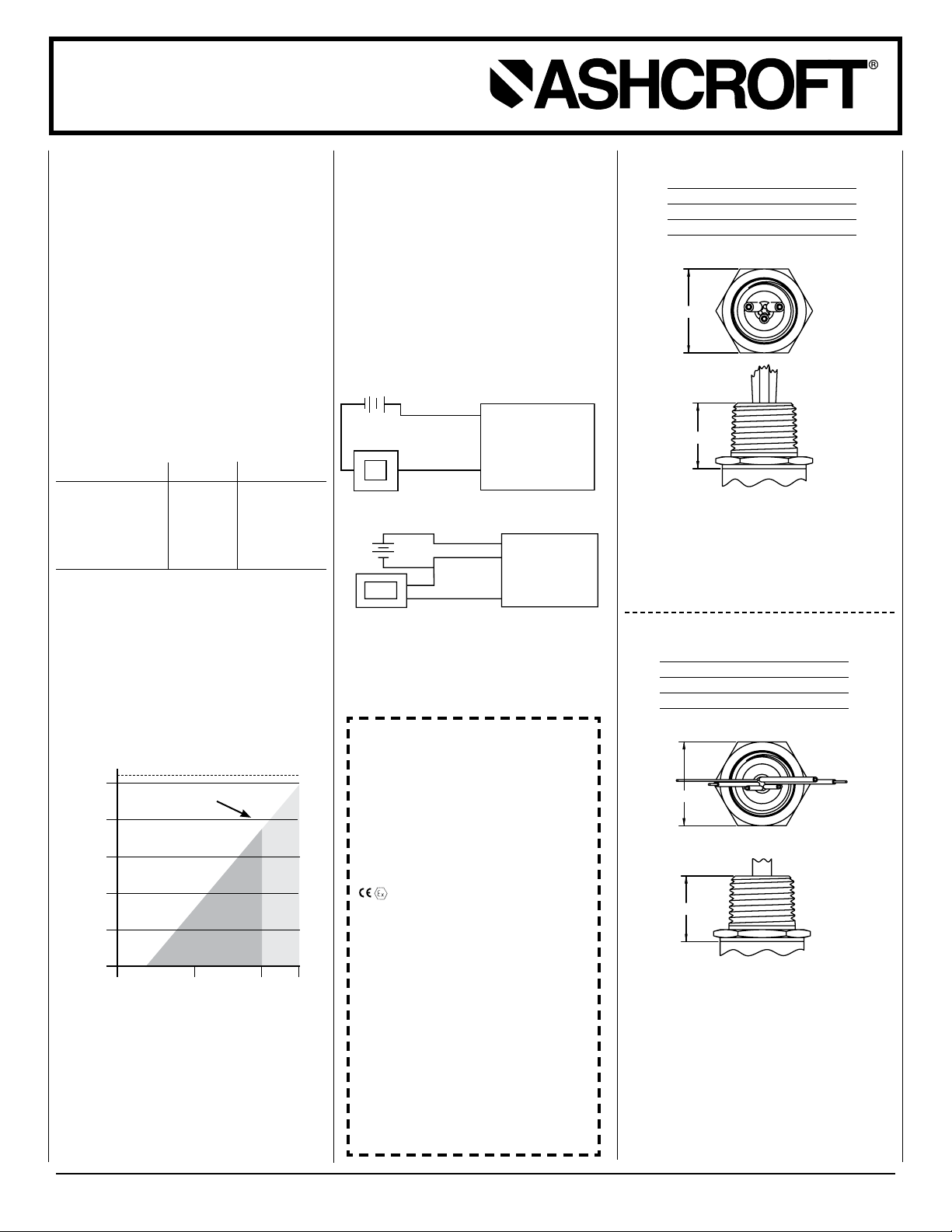

A2X EXPLOSION/FLAME PROOF

OR OTHER DE

.830

FLYING LEADS

ELECTRICAL TERMINATION

CONDUIT - 1/2 NPT MALE

(C2), (C5)

1.062

PRESSURE TRANSDUCER

INSTRUCTION SHEET

Mounting

The A2X transmitter requires no special

mounting hardware, and can be mounted in

any plane with negligible position error.

Although the unit can withstand normal

vibration without damage or significant

output effects, it is always good practice to

mount the transducer where there is minimum vibration.

For units with NPT type pressure fittings

apply Teflon

®

tape or an equivalent sealant

to the threads before installing.

When tightening, apply a wrench to the

hex wrench flats located just above the

pressure fitting. DO NOT tighten by using a

pipe wrench on the housing.

Power Supply

Power Supply Voltage

Output Signal Min Max

0-5Vdc 10V 30V

1-5Vdc 10V 30V

1-6Vdc 10V 30V

0-10V 14V 30V

4-20mA* 12V 30V**

* For transmitters with 4-20mA output

signal, the minimum voltage at the teminals is 12Vdc. However, the minimum

supply voltage should be calculated using

the following graph and formula.

** For Intrinsically Safe Installations max,

supply voltage is 30Vdc. Refer to Ashcroft

drawing #825A022 for wiring and installation requirements.

Loop Supply Voltage vs. Loop Resistance

1000

30 Vdc max for

800

600

400

200

Loop Resistance (Ohms)

Vmin = 12V+ (.022A x RL) (includes a 10% safety factor)

RL = RS + RW

RL = Loop Resistance (ohms)

RS = Sense Resistance (ohms)

RW = Wire Resistance (ohms)

Intrinsically Safe

Installations

0

10

Loop Supply Voltage (Vdc)

Operating

Region

20 30

36

Noise

For minimum noise susceptibility, avoid

running the transducer’s leads in a conduit that contains high current AC power

cables. Where possible avoid running the

cable near inductive equipment.

Sintered Metal Filter

All units less than 500 psi include a small

metal sintered filter at the top of the unit.

This is necessary to equalize the internal

pressure with atmospheric pressure but

can be a point of moisture ingress.

A2X Wiring Diagrams

POWER

SUPPLY

+

–

–

METER

+

POWER

SUPPLY

–

METER

OR OTHER DEVICE

PIN 1

PIN 2

+

VICE

4-20mA

PIN 1

PIN 2

–

PIN 3

+

3-Wire Voltage

(+)

V+

(–)

V–

(+ Power)

(Common)

(+ Output)

TRANSDUCER

TRANSDUCER

A2X transducer has internal transient

protection: for safety, limit line-toground voltage to 36 Vdc max.

HAZARDOUS AREA CERTIFICATIONS

Explosion Proof* – cUL: Specify A2X

Class I, Div. 1 & 2, Groups A, B, C and D

Class II, Div. 1 & 2, Groups E, F and G

Flame Proof* – ATEX: Specify A2X

Compliance with standards

EN 60079-0: 2012

and

EN 60079-1: 2007

II 2 G

Ex d IIC T4 Gb

-40°C ≤ Tamb. ≤ 125°C

DEMKO 04 ATEX 0237942

Intrinsically Safe (applies to 4-20mA) FM/CSA:

Intrinsic Safety: Class I, II and III Div.1 and 2,

Non-Incendive: Class I, II and III Div.1 and 2, Groups A,

Groups A, B, C, D, F and G per

entity requirements see Ashcroft

drawing # 825A022

B, C, D, F and G, no

barriers needed

* Model A2X enclosure is intended for

installation using metallic conduit and

requires installer to comply with appropriate codes to complete proper installation to meet the assigned hazardous

area designation.

Wire Voltage Current

Color Output Output

Red (+) Power (+) Power

White (+) Output None

Black (-) Power (-) Power

1.062

.830

FLYING LEADS

ELECTRICAL TERMINATION

CONDUIT - 1/2 NPT MALE

(C2), (C5)

* Installation of conduit leads should be limit-

ed to 3m to maintain CE compliance

Wire Voltage Current

Color Output Output

Red (+) Power (+) Power

White (+) Output None

Black (-) Power (-) Power

1.062

.830

SHIELDED CABLE (PIG TAIL)

PIGTAIL

ELECTRICAL TERMINATION

ELECTRICAL TERMINATION

CONDUIT - 1/2NPT MALE

CONDUIT - 1/2 NPT MALE

(C1), (C6), (C7), (P7)

(C1), (P7)

©2019 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale. a2x_transducer_im_ RevC_Ltr_01-16-19 (I&M009-10167-A2X)

Loading...

Loading...