Ashcroft 700 Specifications

Type 702, 703 & 740, 741

High Displacement Diaphragm Seal

Type 702 – Low Pressure Flanged

1

⁄2, 3⁄4, 1, 11⁄2, 2, 3 NPT

Type 741 – Threaded

(w/flushing conn.)

1

⁄4, 1⁄2, 3⁄4, 1 NPT

Features:

• For pressure instruments ranging

rom 30˝ H

f

• Used in instruments with large

displacement actuators

• For applications requiring an

impermeable metallic diaphragm

• Available in many material combinations

• Diaphragm electron beam welded

to isolator body

• Furnished with fill/bleed connection

to 750 psi

O

2

SPECIFICATIONS

Model Number: Type 702, 703 Flanged

Raised Face, 740, 741 Threaded

Process

Connection

Size: Threaded: 1⁄

Flanged: 1⁄

Instrument

Connection 1⁄

1

4,

⁄

2 NPT

4 — 1

2

— 3

Diaphragm

Material: 316SS, Tantalum, Titanium

Hastelloy B, Hastelloy C 276,

K-Monel

Bottom Housing

Material: 316SS, Tantalum, Titanium

Hastelloy B, Hastelloy C 276,

Monel, Carpenter 20

Top Housing

Material: • 316 stainless steel standard,

• Monel top housing standard

with Monel diaphragm

• Titanium top housing standard

with Titanium diaphragm

Filling Fluid: Glycerin, Silicone,

Halocarbon, Syltherm

OPTIONS Code

Pipe plugs for flushing PU

connections – pipe

plugs are available

in the same materials

as bottom housings

per Table C

Welded instrument to DU

diaphragm seal

Ring joint (Flanged seal only) RJ

Flat face (Flanged seal only) FF

Clean for gaseous oxygen 6B

or strong oxidizing agent

applications.

BULLETIN DS-700

All specifications are subject to change without notice.

All sales subject to standard terms and conditions.

© Ashcroft Inc. 2 015 01/ 15

Ashcroft Inc., 250 East Main Street, S tratford, CT 06614 USA

Tel: 203-378-8281 • Fax: 203-385-0408

email: info@ashcroft.com • www.as hcro ft.c om

Type 702, 703 & 740, 741

C

A

B

(Type 741 Only)

Bottom of Housing

t

o

C

L

of 1/4 NPT

Flushing Port

D

“D”

Bottom of Housing

to C of 1/4 NPT

F

lushing Port

(Type 703 only)

L

A

B

C

High Displacement Diaphragm Seal

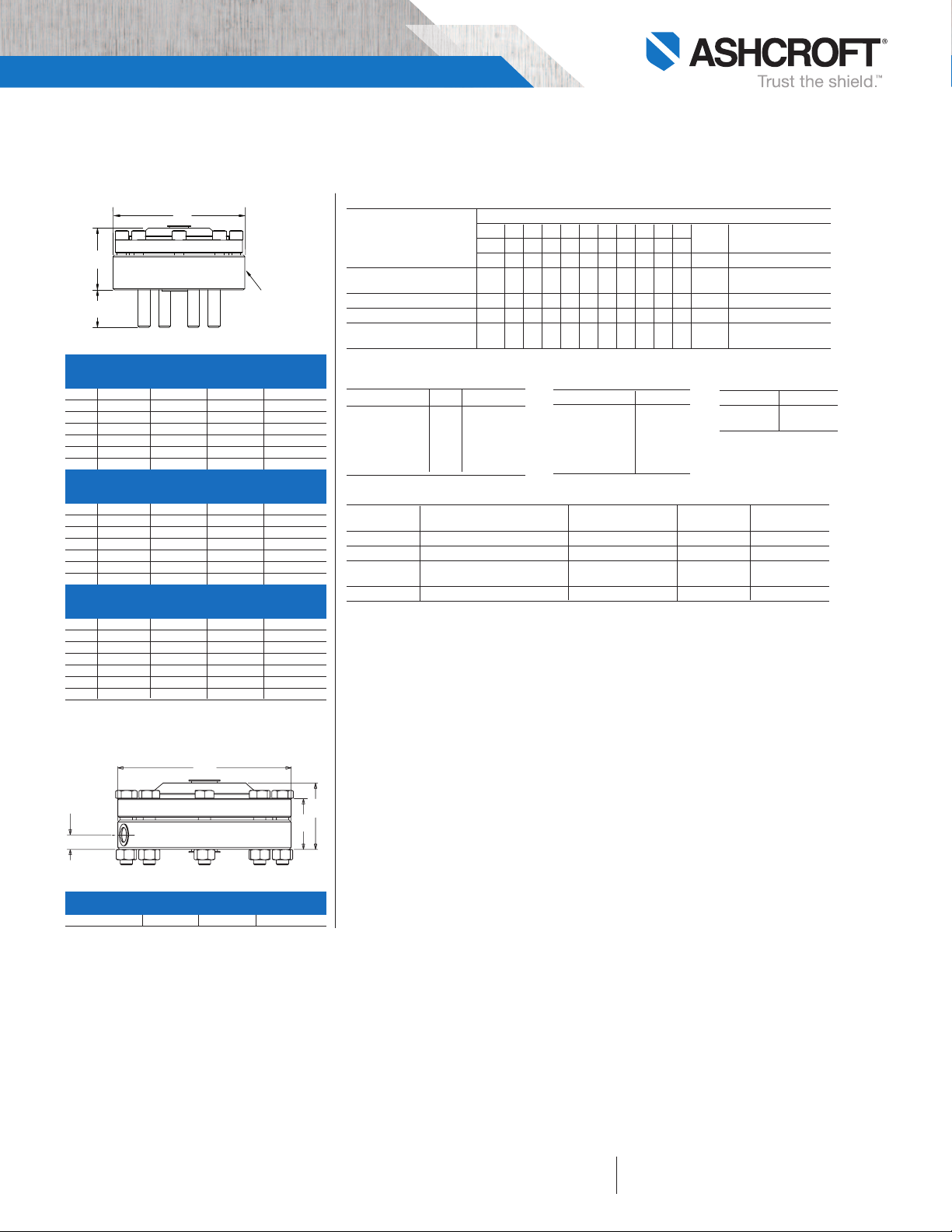

Dimensions: Types 702, 703* Flanged

1

langed

F

F

150 Class ABCD

F

300 Class ABCD

R

600 Class ABCD

*with flushing connection

through 3˝

⁄2˝

lange Rating 702, 703

Size in. mm in. mm in. mm in. mm

1

⁄2˝ 5.94 (135) 2.56 (65) 1.47 (37) 1.06 (27)

3

⁄4˝ 5.94 (135) 2.56 (65) 1.47 (37) 1.06 (27)

1˝ 5.94 (135) 2.50 (64) 1.47 (37) 1.00 (25)

11⁄2˝ 5.94 (135) 2.50 (64) 1.47 (37) 1.00 (25)

2˝ 6.00 (152) 2.63 (67) 2.06 (52) 1.13 (29)

21⁄2˝ 7.50 (191) 2.50 (64) 2.06 (52) 1.00 (25)

3˝ 7.50 (191) 2.38 (60) 2.06 (52) 1.06 (27)

lange Rating 702, 703

Size in. mm in. mm in. mm in. mm

1

⁄2˝ 5.94 (135) 2.56 (65) 1.47 (37) 1.06 (27)

3

⁄4˝ 5.94 (135) 2.75 (70) 2.06 (52) 1.06 (27)

1˝ 5.94 (135) 2.75 (70) 2.06 (52) 1.00 (25)

11⁄2˝ 6.50 (165) 2.75 (70) 2.69 (68) 1.00 (25)

2˝ 6.50 (165) 2.63 (67) 2.06 (52) 1.13 (29)

21⁄2˝ 7.50 (191) 2.63 (67) 2.69 (68) 1.00 (25)

3˝ 8.50 (216) 2.63 (67) 2.69 (68) 1.06 (27)

ating Rating 702, 703

Size in. mm in. mm in. mm in. mm

1

⁄2˝ 5.94 (135) 23⁄4 (70) 211⁄16 (68) 1.06 (27)

3

⁄4˝ 5.94 (135) 23⁄4 (70) 211⁄16(68) 1.06 (27)

1˝ 5.94 (135) 23⁄4 (70) 211⁄16(68) 1.00 (25)

11⁄2˝ 6.50 (165) 23⁄4 (70) 211⁄16(68) 1.00 (25)

2˝ 6.50 (165) 25⁄8 (67) 21⁄16(52) 1.13 (29)

21⁄2˝ 7.50 (191) 25⁄8 (67) 21⁄16(52) 1.00 (25)

3˝ 8.50 (216) 25⁄8 (67) 21⁄16(52) 1.06 (27)

Dimensions: Types 740, 741 Threaded

Table A – Process Connection/Type Number

rocess Connection Size/Code – Inches

P

1

1

ize

S

3

⁄

4

⁄

2

⁄

4 1

1

1

⁄

2 2

(1)(2)

3468 Type Pressure

Process Connection Code 25 50 75 10 15 20 30 40 60 80 No. Rating(1,6)

Threaded–female NPT ••• • 740 30 in.H2O to 750 psi

Threaded–female NPT

(with flushing connection)

(

2)

•••• 741 30 in.H2O to 750 psi

Type No. Flange Rating

Raised Face Flange •••••• 702 150 to 600 class

aised Face Flange

R

(with flushing connection)

(2)

Table B

Diaphragm Materials(3)

Material Code Top Material

316L stainless steel S 316L SS

Hastelloy B G 316L SS

Hastelloy C 276 H 316L SS

antalum U 316L SS

T

K-Monel P Monel 400

itanium TI Titanium

T

•••••• 703 150 to 600 class

Table C

Bottom Housing Materials

aterial Code

M

16L stainless steel S

3

Hastelloy B G

Hastelloy C 276 H

Carpenter 20 D

Monel M

itanium TI

T

Table D

Instrument Connection

Size – NPT Code

1

⁄

4 02T

1

⁄

2 0

4T

Table E – Filling Fluid

onnection Temperature

Filling Service to Instrument Range °F Code

(

4)

lycerin

G

ilicone Pressure/Vacuum Direct or Flexible Line –40/600 CK

S

alocarbon

H

Pressure/Vacuum in presence

(

5)

ressure Direct Only 0/400 CG

P

f strong oxidizing agents

o

C

irect or Flexible Line –70/300 CF

D

Syltherm Pressure/Vacuum Direct or Flexible Line –40/750 HA

NOTES:

(1) Per ASME B16.5.

(2) 741 and 703 seal supplied with 1/4˝ flushing connection.

(3) Diaphragms welded to top housing.

(4) Glycerin not recommended for vacuum, compound or inches of water ranges.

(5) Halocarbon required on applications involving strong oxidizing agents.

(6) Type 5503 Differential Pressure gauge only. 10 psi min.

HOW TO ORDER:

1. From Table A...select TYPE NUMBER and process connection size (e.g., 1⁄

2. From Table B...select DIAPHRAGM MATERIAL. (e.g., Tantalum–code U)

3. From Table C...select BOTTOM HOUSING MATERIAL. (e.g., Hastelloy C 276–code H)

4. From Table D...select INSTRUMENT CONNECTION size. (e.g.,

1

5. From Table E...select FILLING FLUID, if diaphragm seal will be attached to instrument. (e.g., Halocarbon–code CF)

Coded order: 50-740-UH-04T-CF

4˝ process–code 50-740)

⁄

2 NPT–code 04T)

1

Threaded

⁄4˝ through 1˝

ABC D

in. mm in. mm in. mm in. mm

5.25 (133) 1.5 (38) 2.0 (51) .437 (11)

BULLETIN DS-700

All specifications are subject to change without notice.

All sales subject to standard terms and conditions.

© Ashcroft Inc. 2 015 01/ 15

Ashcroft Inc., 250 East Main Street, S tratford, CT 06614 USA

Tel: 203-378-8281 • Fax: 203-385-0408

email: info@ashcroft.com • www.as hcro ft.c om

Loading...

Loading...