Ashcroft 400, 500 Specifications

Data Sheet

400-401/500-501 Threaded All-Welded Diaphragm Seals

FEATURES

All welded construction ensures a leak-tight,

tamper-proof seal

All 316L SS construction resists corrosive attack

from a wide variety of process media

Flushing connection optional

TYPICAL USES

Oil and Gas

Refineries

Chemical and Petrochemical

Water and Wastewater

NACE Compliant Processes

Biogas and Biodiesel

SPECIFICATIONS

Fill Fluid: Glycerin, Silicone, Halocarbon®, Syltherm®

(see Table 2 on page 2 for more fill fluid options)

Pressure Rating

(MAWP):

Connection Style: 400, 500: Threaded

Process Connection

Size:

Instrument Connection

Size:

Added Tolerance: ±0.5% typical

Approvals: CRN, NACE

WETTED COMPONENTS

Diaphragm Bottom Housing

316L SS

Hastelloy® C-276

Monel® 400

Titanium

Tantalum

NON-WETTED COMPONENTS

Top Housing Bolts/Clamp Rings Nuts

316L SS

Hastelloy® C-276

Monel®

Titanium

400/401: 4,400 psi

400 (XHP OPT.): 9,000 psi

401 (XHP OPT.): 5,000 psi

500/501: 500 psi

401, 501: Threaded with flushing port

1

⁄4 to 11⁄2 NPT Female

1

⁄4 to 1 NPT Male

1

⁄4 or 1⁄2 NPT Female

316L SS

Hastelloy® C-276

Hastelloy® C-22

Monel®

Titanium

Carbon steel SS

400

Threaded All-Welded

Diaphragm Seal

KEY BENEFITS

• Continuous duty design

• Minimized fill volume

• Suitable for pressures up to 9,000 psi

500

Threaded All-Welded

Diaphragm Seal

All speci fications are subject to change without notice.

All sales subject to standard terms and conditions.

©2018 Ashcroft Inc. 400-500_ds1_seal _LR , Rev D, 04/18

of 41

ashcroft.com

info@ashcroft.com

1.800.328.8258

Data Sheet

400-401/500-501 Threaded All-Welded Diaphragm Seals

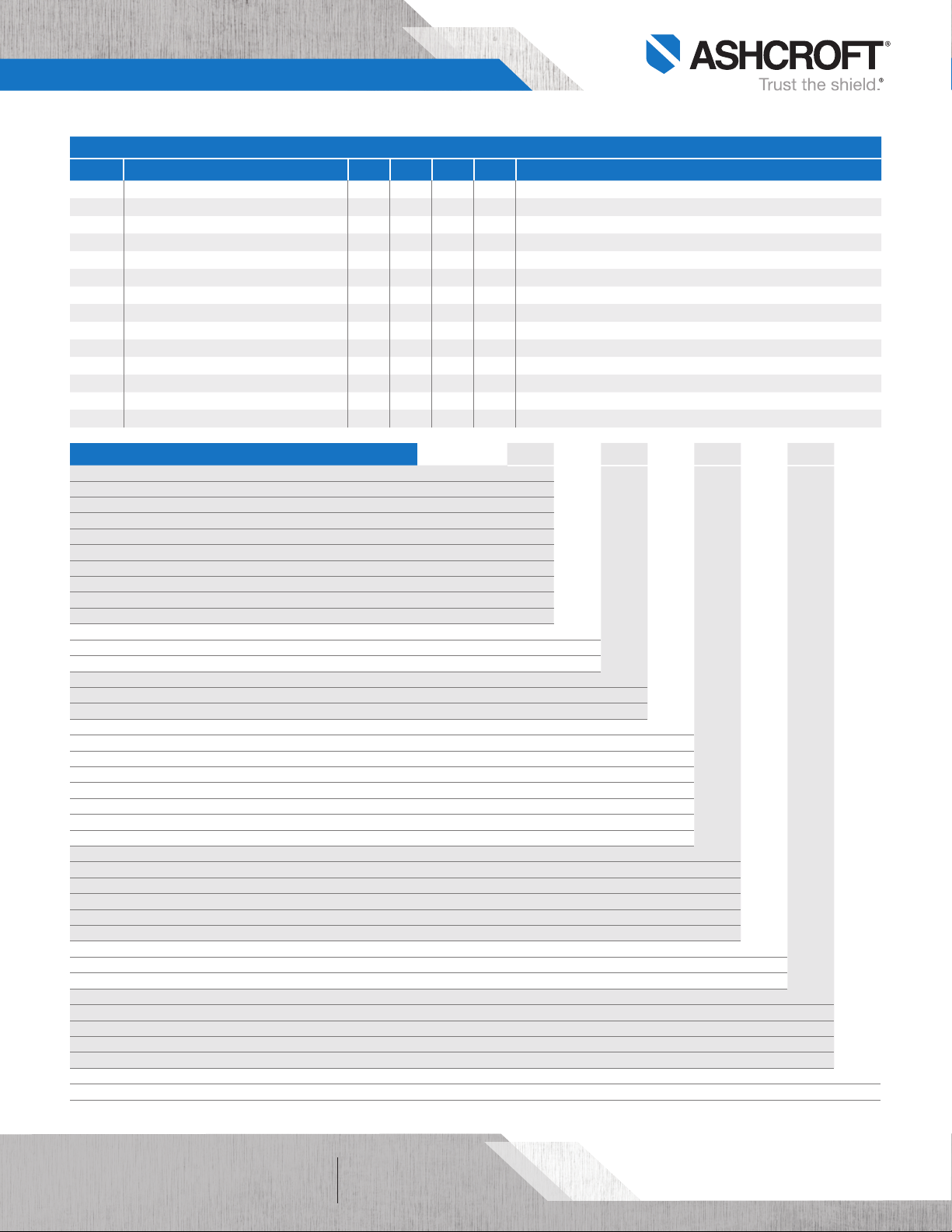

TABLE 1 - OPTIONS

Code Option 400 401 500 501 Notes

LD SS locking device • •

PU Pipe plug for flushing connection • • Plug will match bottom housing material

HB Hastelloy® C-276 upper housing • • • •

SE SS rings and bolts • • 1,500 psi Max., 5,000 psi Max. with XHP

HP High-pressure clamp rings • • 9,000 psi Max., 5,000 psi Max. with SE

6B Cleaned for oxygen service • • • •

AW Single ½ NPT flushing connection • • ¾ NPT Female or smaller process connection

DB Dual ½ NPT flushing connections • • ¾ NPT Female or smaller process connection

DK Dual ¼ NPT flushing connections • •

DU Instrument welded to seal • • • •

MQ Positive material identification • • • •

W1 Dye penetrant testing • • • •

CD-5 NACE compliance certificate • • • • Stainless, Hastelloy®, or Monel® wetted materials

CD-6 Typical material certification • • • •

ORDERING CODE Example:

Process Connection Size

02 - ¼ NPT Male (400, 500 only) 02

04 - ½ NPT Male (400, 500 only)

06 - ¾ NPT Male (400, 500 only)

08 - 1 NPT Male (400, 500 only)

25 - ¼ NPT Female

50 - ½ NPT Female

75 - ¾ NPT Female

10 - 1 NPT Female

15 - 1½ NPT Female

Diaphragm Seal Type

4 - 400 Series All-welded clamped seal, threaded process connection 4

5 - 500 Series All-welded seal without clamps, threaded process connection

Flushing Port

00 - No flushing port 00

01 - With flushing port

Diaphragm Material

S - 316L SS S

H - Hastelloy® C-276

J - Hastelloy® C-22

U - Tantalum (only available with Monel® top and lower housing)

G - Hastelloy® B

P - K-Monel® (only available with Monel® top and lower housing)

Ti - Titanium (only available with a Titanium top and lower housing)

Bottom Housing Material

S - 316L SS S

H - Hastelloy® C-276

J - Hastelloy® C-22

M - Monel® (includes Monel® top housing standard)

TI - Titanium (includes Titanium top and housing standard)

Instrument Connection Size

02T - ¼ NPT Female 02T

04T - ½ NPT Female

Options (if choosing an option(s) must include an “X”)

Fill Fluid (see table 2 on page 3 for more available fill fluids)

CG - Glycerin

CK - Silicone SF-96 CK

CF - Halocarbon

Optional Features (see Table 1 above for option list)

HP - High-pressure clamp rings HP

®

02 4 00 S S 02T XCK HP

X__

All speci fications are subject to change without notice.

All sales subject to standard terms and conditions.

©2018 Ashcroft Inc. 400-500_ds1_seal _LR , Rev D, 04/18

of 42

ashcroft.com

info@ashcroft.com

1.800.328.8258

Loading...

Loading...