Page 1

Digital Industrial Gauge

Operating Instructions

I&M008-10109 Rev. F 10/13

Page 2

Congratulations on your purchase of the Ashcroft

®

digital industrial gauge. This feature-packed gauge

offers a menu-driven display for easy customization.

User selectable features include 12 units of measure-

ment, password protected calibration and disable

functions, adjustable bar graph and update rate.

A five digit display for maximum resolution is standard.

Optional 4-20mA output, switching and line- power

add to the versatility of the gauge. With the range

printed on the keypad, Ashcroft digital gauges meet

ASME B40.7 specification. See a complete listing of

product features and specifications on pages 16.

Ashcroft Inc.

250 East Main Street | Stratford, CT 06614-5145

Tel: 203-378-8281 | Fax: 203-385-0602

e-mail: info@ashcroft.com | www.ashcroft.com

– 2–

Page 3

TABLE OF CONTENTS

Quick Reference ............................................4-5

Keypad Functions ..........................................6-8

• ON/OFF KEY

• ZERO/CLEAR KEY

• MIN/MAX KEY

(down arrow key)

• MENU KEY

• BACKLITE KEY

(up arrow key)

• ENTER KEY

MENU Functions (MENU Mode) ................................8-15

• Engineering Units

• CONFIG Mode

• Set Password

• Recalibration of Gauge

• Zero Key Adjustment

• Disabling Menu Options

• Bar Graph Options

• Auto Off Options

• Update Options for Displayed Pressure

• Dampening Options

• Backlite Options (Backlite Optional)

• Set Switch(es) Option(s) (Switches Optional)

Specifications ................................................16

Ranges ........................................................17

Display Messages ..........................................17

Wiring Diagrams ........................................18-29

Gauge Installation & Maintenance ....................30-32

• Mounting

• Battery Replacement & Installation

– 3–

Page 4

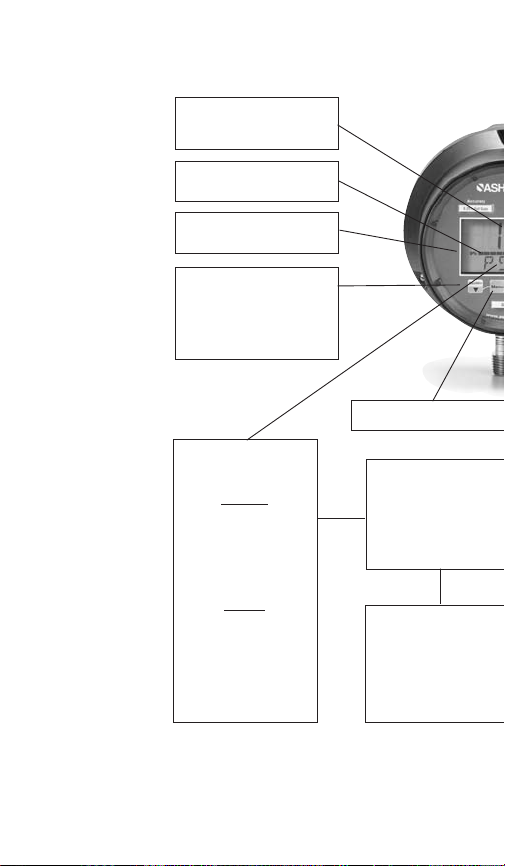

.88˝ high digital display (41⁄2˝ case)

.60 high digital display(3˝ case)

Bar graph

% of full scale

Flashing display when unit

pressured below zero

Press to indicate minimum

or maximum pressure

gauge has measured

Press again to return to

pressure units

UNITS (Pressure)

ENGLISH

INHG

PSI*

INH2O

@ 4°C, 20°C, 60°F

FTW

FTSW

METRIC

BAR

MBAR

KPA

CMH2O

KG/CM2

QUICK REFE

Press to read menu

UPDATE RATE

(Pressure measurement

per second)

10x (100 MS)*

5x (200 MS)

2x (500 MS)

1x (1 Sec)

BACKLITE

(Off options)

Never

2 SEC

5 SEC*

15 MIN

30 MIN

– 4–

Page 5

While in unit of measurement mode (eg: psi),

press the ZERO CLEAR button to rezero the

gauge. This feature functions when displayed

pressure is within ±5% or 10% of zero value

pressurized beyond full-scale

This bar graph indicates battery level;

the more segments, the closer the

battery is to full charge (only dis-

played on units with battery

Press to turn backlite on or off

Range on keypad;

complies with ASME B40.7

AUTO OFF

(Turns unit off after

option selected)

Never*

2 minutes

5 minutes

15 minutes

30 minutes

DAMPENING

(Takes pressure reading

and averages

process pressure

None*

Avg 2

Avg 4

Avg 6

Avg 8

Press to turn unit on or off

Flashing display when unit

(backlite optional)

CALIBRATE

Zero and span

adjustments,

password

protected

DISABLE

Allows for

“lockout” of

MENU

options

*Indicates Default

– 5–

Page 6

KEYPAD FUNCTIONS

Turns the gauge on and off. When pressing the

ON/OFF

ON/OFF key while in the off position, gauge startup display first indicates the software version

followed by the model number and gauge pressure range. The gauge will then display indicated

pressure and be ready for use.

Press this key for one second prior to gauge

ZERO

usage to rezero any initial zero shift. If zero shift

CLR

is greater than programmed zero allowance, the

gauge will display OFSET (blinking) for 1 second, then return to the measure mode. To clear

minimum and maximum values, press

ZERO/CLR button (when min/max values are

indicated). Gauge will auto advance once zeroed.

MAX/MIN

The Max/Min key allows review of minimum and

maximum pressure values since unit start-up or

last push of the clear key. Press key to:

1) Indicate maximum pressure.

2) Indicate minimum pressure.

3) Exit MAX/MIN mode and return the unit to

pressure measurement mode. To clear minimum and maximum values press ZERO/CLR

key (must be in MAX/MIN mode).

(down arrow key) is used in the MENU

The

mode, see following MENU key section.

– 6–

Page 7

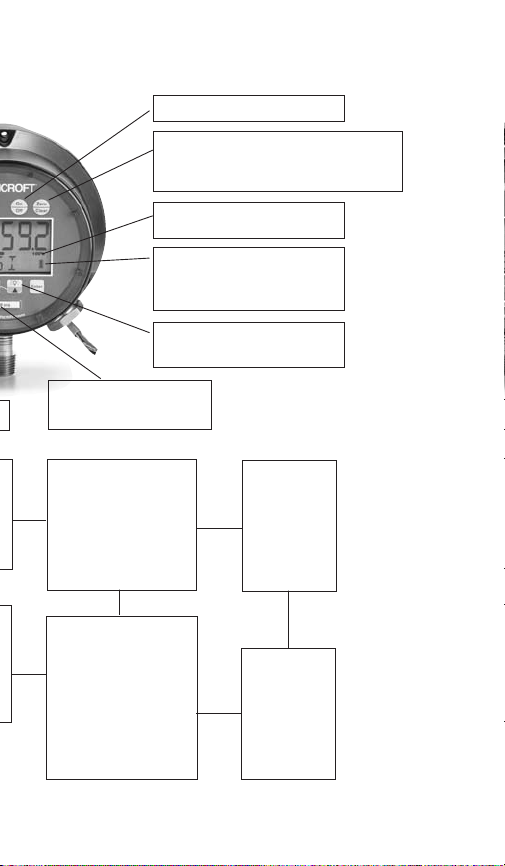

MENU

Key for gauge

with Backlite

Key for gauge

without Backlite

displayed with

(up arrow

icon only)

KEYPAD FUNCTIONS

This key allows for customization of the gauge.

Pressing the MENU key allows cycling through

the main MENU items; UNITS, CONFIG, GRAPH,

OFF, UPDAT & DAMP. Any item changed in the

Menu become the new default setting(s).

Revised settings are saved in the event of power

loss.

The

(up arrow key) or (down arrow key)

on the keypad allows for scrolling through the

MENU options to increase or decrease numeric

values as required. If in the menu mode, gauge

will automatically advance to measure mode

once selected MENU item has been set.

This key manually turns the backlite on or off.

Five options are available. They include NEVER,

10 sec, 30, sec, 1 min, 5 min*. With the NEVER

option, the gauge BACKLITE will remain lit

whenever the gauge is in the ON mode or until

the BACKLITE button is pushed again. Options,

10 sec, 30 sec, 1 min, 5 min*. allow the BACKLITE to automatically turn-off after a selected

period of time.

To use the BACKLITE option:

Step 1: Press the MENU key.

Step 2: Press the

(up arrow key) or (down

arrow key) until the word LITE appears.

Step 3: Press ENTER.

Step 4: Press the

(up arrow key) or (down

arrow key) to select the BACKLITE option.

Step 5: Press the ENTER key to finalize your

choice of LITE options.

– 7–

Page 8

KEYPAD FUNCTIONS

This key allows for selecting gauge features in the

ENTER

menu finalizing selection. Use of the enter key is

described throughout operating instructions.

MENU OPTIONS

UNITS: 12 units of measurement are available: psi, mmHG,

inH

O with three temperature options: 20°C, 60°F, 4°C*,

2

mBar, inHg, ftH

O, mPa, kPa, kg/cm2and bar.

2

Step 1: Press the MENU key until the word UNITS appears.

Step 2: Press ENTER.

Step 3: Press the

(up arrow key) or (down arrow

key) to select the required unit of measure.

Step 4: Press ENTER to finalize the UNIT selection.

Note: For inH

press the

0 range with three temperature options,

2

(up arrow key) and (down arrow key) to

select the desired temperature, then press ENTER to finalize the UNIT selection.

CONFIG: This option allows access to additional Menu

options. Options include:

• ENTPW or enter password (this appears as a sub-menu

in the CONFIG mode if a user password has been set).

• RECAL (allows for zero, span and mid-scale calibra-

tion of the gauge).

• 0bUTN or zero key (allows for adjustment of % of

range that can be zeroed),

• dISAb, allows for disabling MENU options.

• SETPW: This feature allows for a user defined numer-

ic password. If a user password is not set, all features

in the CONFIG mode will be accessible without a

password. If a user password is set, all items in the

CONFIG menu options are accessible with or without

a user password. If a user password is programmed,

it will be required to access the CONFIG menu options.

Default user password is 12045 or 12*45.

– 8–

*Indicates default.

Page 9

MENU FUNCTIONS

How to Use Your Menu Functions

To set a user password (SETPW):

Step 1: Press the MENU key on the keypad

Step 2: Press the

(up arrow key) or (down arrow

key) until the word CONFIG appears.

Step 3: Press ENTER. The word SETPW appears on the

gauge display

Step 4: Press ENTER. A five digit numeric password is

now required.

Step 5: Press the

(up arrow key) or (down arrow

key) on the keypad to select the first digit of the password.

Step 6: Press ENTER.

Step 7: Repeat until the five-digit password is shown on

the gauge display.

Step 8: Press ENTER.

Note: to erase password at any time while in the SETPW

(set password) mode, press the ZERO/CLEAR key. The

user will be prompted to reprogram the password once the

five-digit password is entered. The gauge will display SAVE.

Step 9: Press ENTER to save the password setting.

ENTPW: Once a user password has been established and

entry into the CONFIG mode is required, the user will be

prompted to ENTPW or enter password.

Follow setup steps 4-8 above.

RECAL: or recalibrate allows for zero, mid-scale, full-scale

and factory default calibration of the gauge. The RECAL

feature also allows for recalibration of gauges with

4-20mA output.

– 9–

*Indicates default.

Page 10

MENU FUNCTIONS

To use RECAL option:

Step 1: Press the MENU key on the keypad

Step 2: Press the

(up arrow key) or (down arrow

key) on the keypad until the word CONFIG appears.

Step 3: Press ENTER.

Step 4: Enter user password if it has been programmed.

Step 5: Press

(up arrow key) or (down arrow key)

until the word RECAL appears.

Step 6: Press ENTER.

Step 7: The gauge will now flash between INPUT and unit

of measure on the lower line and .00 on the top line. Apply

zero pressure to the gauge.

Step 8: Press ENTER. Zero pressure is now set.

Step 9: The gauge will display full-scale pressure. Apply

full-scale pressure to the gauge.

Step 10: Press ENTER. Full-scale pressure is now set.

Step 11: The gauge will now display mid-scale pressure.

Apply mid-scale pressure to the gauge.

Step 12: Press ENTER. Mid-scale pressure is now set.

Step 13: After zero, full-scale and/or mid-scale or factory

default calibration have been set, the word SAVE appears

on the gauge display.

Step 14: Press ENTER to finalize calibration.

(Note: For compound ranges this recalibration is zero,

full-scale, mid-scale and full-vac.)

FOR FACTORY CALIBRATED SETTINGS:

To reinstate factory settings for zero, full-scale and midscale follow RECAL steps 1-6

Step 7: When the word INPUT appears press

(up arrow

key) until the word FACT appears.

Step 8: Press ENTER to finalize calibration.

– 10 –

*Indicates default.

Page 11

MENU FUNCTIONS

Note: Calibration of Zero, mid-scale or span can be set independently of each other. For instance, if only full-scale calibration is required, press the

(down arrow key) until the

gauge display indicates full-scale pressure. Press Enter and

proceed as indicated above. Calibration of zero, midscale

and full-scale is recommended when recalibrating the gauge.

ZERO KEY (0bUTN): This feature allows the user to select

percent of full-scale at which the gauge can be rezeroed

using the Zero/Clear key on the keypad. Options include 5%

full-scale*, 10% full-scale or DISAB (disable of the zero key).

To use ZERO option:

Step 1: Press the MENU key on the keypad.

Step 2: Press the

(up arrow key) or (down arrow

key) until the word CONFIG appears.

Step 3: Press ENTER.

Step 4: Enter user password, if it has been programmed.

Step 5: Press the

(up arrow key) or (down arrow

key) until the word 0bUTN (zero key) appears.

Step 6: Press ENTER.

Step 7: Press the

(up arrow key) or (down arrow

key) to select 5PCT (5% full-scale), dISAb (disable zero

key) or 10PCT (10% full-scale).

Step 8: Press ENTER to finalize the selection.

DISAB: or disable: This feature allows the user to dISAb

(or disable) or ENAb (enable) items in the MENU. Some

keypad keys can also be enabled or disabled. Any or all

MENU items can be enabled or disabled.

To use DISAB option:

Step 1: Press the MENU key on the keypad.

Step 2: Press the

(up arrow key) or (down arrow

key) until the word dISAb appears.

– 11 –

*Indicates default.

Page 12

MENU FUNCTIONS

Step 3: press ENTER. The current setting (ENAB or dISAB)

will be displayed.

Step 4: Press the

(up arrow key) or (down arrow

key) on the keypad to select a setting.

Step 5: Press ENTER To finalize the setting.

GRAPH: This option allows the user to change the BAR

graph on the gauge display to correspond to any desired

pressure within the pressure limits of the gauge. This

option is useful when identifying a select portion of the

full-scale range of the gauge. The default setting for the

GRAPH is zero and full-scale pressure. For compound

gauges, the default setting for zero is set at full-scale vacuum. Full-scale pressure is set at the positive pressure as

displayed on the gauge keypad.

For gauges supplied with the 4-20mA output option, the

default is 4mA equals 0% of the bar graph and 20 mA

equals 100% of the bar graph.

Changing the bar graph to a pressure other than 0 and

100% of range will also change the 4-20mA output to correspond with the new bar graph pressures for 0 and 100%.

To use GRAPH option:

Step 1: Press the MENU key.

Step 2: Press the

(up arrow key) or (down arrow key)

on the keypad until the word until the word GRAPH appears.

Step 3: Press ENTER . The gauge display will indicate the

set full scale pressure range setting on the top line. The

middle line indicates the bar graph at 100% of full-scale.

The bottom line of the display will indicate SETFS to set

the full-scale range as displayed by the bar graph and 420mA.

Step 4: Press the

(up arrow key) or (down arrow key)

on the keypad to increase or decrease gauge value at

100% of range.

– 12 –

*Indicates default.

Page 13

MENU FUNCTIONS

Step 5: Press the ENTER key to finalize your choice. The

gauge display will now display SET. After two seconds the

screen will display the pressure value for 0% on the top

line. The middle line indicates the bar graph at 100% of

fullscale. The bottom line will display SET 0.

Step 6: Press the

(up arrow key) or (down arrow

key) on the keypad to increase or decrease gauge value at

0% of range.

Step 7: Press the ENTER key to finalize your choice. The

new values for the bar graph and 4/20mA settings have

now been saved.

OFF: This option sets the amount of time before the gauge will

turn itself off. Offerings are Never*, 30MIN,10MIN, 5MIN, 2

MIN.

To use the OFF option:

Step 1: Press the MENU key.

Step 2: Press the

(up arrow key) or (down arrow

key) until the word OFF appears.

Step 3: Press ENTER.

Step 4: Press the

(up arrow key) or (down arrow

key) to select the desired OFF time.

Step 5: Press the ENTER key to finalize the OFF setting.

UPDATE: This option allows for changing the rate at which

pressure is updated on the display screen. This feature is

useful with rapid changes in process pressure that may

cause flutter of the display. Options are 100ms*, 1 sec,

500ms and 200ms, updates per second or 100ms*.

Since customer processes vary, update rates should be

selected based on the application.

To use the UPDATE option:

Step 1: Press the MENU key.

– 13 –

*Indicates default.

Page 14

MENU FUNCTIONS

Step 2: Press the (up arrow key) or (down arrow

key) until the word UPDATE appears.

Step 3: Press ENTER.

Step 4: Press the

(up arrow key) or (down arrow

key) to select an update rate.

Step 5: Press ENTER to finalize the selection.

DAMP or dampening: with five different options, this mode

allows for taking process pressure readings and averaging

them. This option is particularly useful to stabilize minor

process fluctuations. The options are NONE*, AVG 8, AVG

6, AVG 4, AVG 2.

Step 1: Press the MENU key until the word dAMP appears.

Step 2: Press ENTER.

Step 3: Press the

(up arrow key) or (down arrow

key) to select a dampening option.

Step 4: Press the ENTER key to finalize your Damp option.

(This Menu item is only seen on units with the switch option)

SWSET: Allows for setting switch setpoints. The gauge is

offered with (1) or (2) SPDT switches. If (1) SPDT switch

is ordered the menu option is SW1. If (2) SPDT switches

are ordered, the MENU options are SW1 and SW2.

Step 1: Press the MENU key.

Step 2: Press the

(up arrow key) or (down arrow

key) on the keypad to select the switch to be set. (If two

switches are present.)

Step 3: Press ENTER. The top line of the gauge display will

indicate pressure at 60% of the full-scale gauge range* or

the most recent switch setpoint. The middle line of the display will indicate a bar graph that displays the pressure

– 14 –

*Indicates default.

Page 15

MENU FUNCTIONS

position within the pressure range. The bottom line will

display SETPT (blinking). SETPT is switch setpoint on

rising pressure.

Note: Setpoints are limited to the full-scale pressure range

of the gauge.

Step 4: Press the

(up arrow key) or (down arrow key)

on the keypad to increase or decrease switch set-point

Step 5: Press the ENTER key to finalize switch setpoint. The

gauge will display SET. After two seconds, the top line will

indicate RETRP pressure. The bottom line will read SET.

RETRP is switch setpoint on falling pressure.

Step 6: Repeat above to set RETRP (retrip value) If the

gauge is supplied with (1) setpoint, the screen will advance

to the measurement mode. If (2) switches are supplied the

display will advance to SW2.

Repeat the aforementioned if the gauge is supplied with

(2) switches.

Notes: The bar graph will increase or decrease as any

setpoint pressure is adjusted. The bar graph indicates

switch setpoint position within the full-scale pressure

range of the gauge.

The switch setpoint unit of pressure measurement corresponds with the current set unit of measure of the gauge.

If gauge unit of measurement is changed after switch(es)

is set, switch setpoint(s) will automatically be updated to

correspond with revised unit of measurement. Switch

deadband is the difference between the SETPT (setpoint)

and the RETRP (retrip) pressure.

– 15 –

Page 16

DIGITAL INDUSTRIAL GAUGE SPECIFICATIONS

Type: 2074 (battery), 2174 (loop), 2274 (line)

Accuracy: .25% Full Scale, terminal point

Case Size: 3˝, 41⁄2˝

Case Material: 3˝ SS, 4

Case Encl. Rating: Weatherproof, IP65

Wetted Materials: 17-4 SS (sensor), 316SS (socket)

Socket Size:

Socket Location: Lower, 3, 9 and 12 o’clock

Ranges: Vac. thru 20,000 psi (see engineering units below for other

Operating Temp.: 14/140°F (10/60°C)

Storage Temp.: –4/158°F (-20/70°C)

DISPLAY

Type: LCD

Display Digits: Five (5)

Character Height: 3˝ .60˝, 41⁄2˝ .88˝

Backlite: Optional

Bar Graph: Yes

Battery Life: 3˝ >1000 hrs., 41⁄2˝ >3600 hrs.

Agency Approvals: CE, FM* (Intrinsically Safe Class1, Div 1), CSA *FM is not

KEYPAD FUNCTIONS

On/Off: Manually turns unit on and off (auto off options in menu)

Zero/Clear: Zeros display or clears min. and max. values when displayed

(down) Stores min and max values, arrow key allows for

Min/Max

Arrow Key: scrolling thru menu items

Menu Key: Provides access to menu options

(up) Manually turns backlite on and off (auto off options in

Backlite

Arrow Key: menu), arrow key allows for five menu options.

(Backlite optional) arrow key allows for scrolling thru menu options

Enter: Selects items in the menu

MENU MODE

Engineering Units: 10 units of measurement are available; psi, In. H

Configuration Mode Allows for changes to default settings of gauge

(Config): Including zero disable feaure

Bar Graph (Graph): Allows for adjustment of bargraph and 4-20

Auto Off (Off): Allows for changes to auto off of gauge, five options:

Update Rate

(Update): Four options: 100 ms, 200 ms, 500 ms, 1 sec

Dampening (Damp): Six options: None, average, 2, 4, 6, 8 times per 100ms

Backlite: Five options: Never, 10 sec., 30 sec., 1 min., 5 min.

Field Recalibration: Allows for recalibration of zero, midscale and span

OPTIONS

4-20mA Display: 12-36 Vdc, mA with unlimited turndown (within gauge range)

Line Powered: 12-36 Vdc, 2VA max.

Switching*: (1) or (2) SPDT switches,(max. contact 30Vdc, 1 amp,

1

⁄2˝ fiberglass reinforced thermoplastic or

black epoxy coated aluminum

1

⁄4 or 1⁄2 NPT, JIS, DIN, SAE, (1⁄2 NPT only with 41⁄2˝ case,

others on application)

units)

1

available with the following: 4

switch option(s) (XU1, U2) or Backlite (XBL) option)

three temp. options: 20°C, 60°F, 4°C*), Ft. H

kPa, kg/cm2, Bar, inHg and mmHg

⁄2˝ polypropylene case, SPDT

O (with

2

O, mPa, mBar,

2

(optional feature)

Never, 2 min., 5 min., 15 min., 30 min.

(password protected)

125Vac .5 Amp, Switches adjustable to 100% of range

(up)

– 16 –

Page 17

DIGITAL INDUSTRIAL GAUGE RANGES

Note: Rows listed are not the equivalent of each other.

in.Hg Comp. mmHg in.Hg in. ft. Bar/

psi

(vacuum) (psi) (pressure)(pressure) H

15 30

–15/0/15

30

60

100

160 5000 200 4000 400 6 600 6

200 10,000 300 5000 600 10 1000 10

300 400 6000 1000 16 1600 16

600 600 10,000 25 2500 25

800 800 15,000 40 4000 40

1000 20,000 60 6000 60

1500 100 10,000 100

2000 140 16,000 160

3000 25,000 250

5000 40,000 400

8000 60,000 600

10,000 100,000 1000

15,000 140,000 1400

20,000

800 30 400 1000 60 1 100 1

–15/0/30

1000 60 800 1500 160 1.6 160 1.6

–15/0/60

2000 100 1000 2000 200 2.5 250 2.5

–15/0/100

3000 160 2500 300 4 400 4

mBar

O

2

mPa kPa

H2O

DISPLAY MESSAGES:

Display/Problem Description Action

No Battery Icon

Display (applicable to

gauges with batteries

OFSET (blinking)

Menu button disabled

Unit of measure

selected in Menu

displays N/A

I can’t set the

password I want

I can’t access items in

the main Menu

Gauge has <10%

battery life left

Zero/Clear button

pushed when pressure

displayed is beyond set

rezero pressure limit

Gauge is in

Max/Min mode

Resolution at full scale

pressure range

exceeds 50,000 counts

00000 is not a valid

password

Items that cannot be

accessed have been

disabled

Replace batteries

Only rezero the gauge within

limits of setting in Menu

Push Max/Min button until

unit of measure is displayed

on keypad

Choose another unit of

measure

Select a different password

Enable item(s) in the Menu.

See Menu/CONFIG and

diSAb or DISABLE

KSC

– 17 –

Page 18

WIRING DIAGRAM

Loop Powered 4-20mA (Type 2174)

2 conductor, 20 AWG shielded

Red (+ exec.) A

Black (– exec.) B

R19

LOOP–

ECND

R21

V6

T9

D10

C14

T8

Q3

U5

V1

C2

FID5

FID4

D11

V2

U7

C15

R18

D5

R9

R10

R11

R12

R13

D8

Red

J5

FID3

T11

321CO21–

EGND

(+)

(A)

D6

D15

D3

T12

GND

Battery Input

J1

1

1

J6

J3

1

J7

POWER

SUPPL Y

–

T7

D9

R2

R22

R20 C17

R14R16

Q4

D16

D12

LOOP+

D7

Y1

F1D1

C3

C7

R7

D14

D1

R24

R23

D13

T10

+24V

+

(–)

(B) (–)

Black

METER

PLC

SCADA

+

–

Installation Procedure for 2174:

Shield

FID2

FID6

C1

R8

R5

FO7

R1

C10

Q1

Q2

J3

C4

J2

U4

L1

C9

R6

C5

C8

DQ/TB 2003

C6

R4

Sensor Input

Y2

Keypad Input

V+

GAUGE

V–

ESD precautions should be taken. See page 31 for details.

1. Ensure all power is off/disconnected from the circuit.

2. Connect the red wire (A) to the positive power terminal.

3. Connect the black wire (B) to the positive terminal on the

meter.

4. Connect the negative side of the meter to the negative

power terminal.

Note: Meter should be installed on the black wire only.

– 18 –

Page 19

1000

Load Limitations 4-20mA Output Only

RL-Loop Resistance in Ohms

750

500

OPERATING

250

REGION

0

Loop Supply Voltage (Vdc)

Vdc MIN = 12V + [0.022A X (RL) ]

= RS+ R

R

L

W

RL= Loop Resistance (ohms)

= Sense Resistance (ohms)

R

S

= Wiring Resistance (ohms)

R

w

30

620100

– 19 –

Page 20

WIRING DIAGRAM

POWER

Line Powered (Type 2274)

2 conductor, 20 AWG shielded

Y1

F1D1

V1

C3

J1

Battery Input

SUPPL Y

–

1

R2

1

J6

R22

R14R16

J3

1

J7

Q4

D16

R20 C17

D12

C2

D15

D3

D11

U7

R18

D5

D6

T12

GND

Red (C)

FID5

FID4

V2

C15

R9

R10

R11

D8

FID3

T11

321CO21–

EGND

(+)

C7

R7

D14

D1

R24

R23

D13

T10

+24V

+

Black (D)

R12

( – )

Q1

R13

J5

FID6

C1

R8

FO7

R1

C10

C9

R6

Q2

J3

C4

V+

V–

R5

L1

C5

C8

DQ/TB 2003

C6

R4

Keypad Input

Shield

Black (–exec.) D

Red (+exec.) C

FID2

J2

U4

Y2

GAUGE

Sensor Input

Installation Procedure for 2274:

ESD precautions should be taken. See page 31 for details.

1. Ensure all power is off/disconnected from the circuit.

2. Connect the red wire (C) to the positive power terminal.

3. Connect the black wire (D) to the negative power terminal.

– 20 –

Page 21

WIRING DIAGRAM

Line Powered with (1) SPDT switch (Type 2274 XU1)

5 conductor, 22 AWG shielded

(–exec.) F

(+exec.) E

POWER

SUPPL Y

+

–

Red (E)

Black (F)

White (NO)

Brown (Common)

Green (NC)

(+)

V+

(–)

GAUGE

V–

•

Installation Procedure for 2274 XU1:

ESD precautions should be taken. See page 31 for details.

1. Ensure all power is off/disconnected from the circuit.

2. Connect the red wire (E) to the positive power terminal.

3. Connect the black wire (F) to the negative power terminal.

Wiring the Switch:

Normally Open: Use the white and brown wires.

Normally Closed: Use the green and brown wires.

– 21 –

Page 22

SWITCH 1

WIRING DIAGRAM

Line Powered with (2) SPDT switches (Type 2274 XU2)

8 conductor, 22 AWG shielded

(N.O .) W hi t e

(N. C. ) Green

(COM) Brown

FID2

SWITCH 2

T5

(N.C.) Yell ow

T6

(N.O.)

Blue

(COM) Orang e

T4

J2

Sensor Input

Y2

Battery Input

Y1

C3

J1

1

R2

C7

1

R7

J6

R22

R20 C17

D14

D1

R14 R16

R24

J3

R23

1

D13

J7

Q4

D16

D12

T10

+24V

T2

T3

FID6

C1

R8

FO7

Q1

Q2

J3

C4

D2

C11

C13

C12

R5

R1

C10

C9

R6

C6

R4

T1

K1

K2

K2

U4

L1

C5

C8

DQ/TB 2003

Ke ypad Input

Shiel d

Blac k (–exec.) G

Red (+exec.) H

F1D1

V1

U7

D5

D6

D15

D3

T12

GND

ISO 1

R15

ISO 2

R17

C2

FID5

FID4

D11

V2

C15

R1 8

R9

R10

R11

R12

R13

D8

J5

FID3

T11

321CO21–

EGND

POWER

SUPPLY

–

Switch 1

Switch 2

Red (G)

+

Black (H)

White (NO)

Brown (Common)

Green (NC)

Blue (NO)

Orange (Common)

Yellow (NC)

(+)

(–)

– 22 –

V+

V–

GAUGE

•

•

Page 23

Installation Procedure for 2274 XU2:

ESD precautions should be taken. See page 31 for details.

1. Ensure all power is off/disconnected from the circuit.

2. Connect the red wire (G) to the positive power terminal.

3. Connect the black wire (H) to the positive meter terminal.

Wiring Switch 1:

Normally Open: Use the white and brown wires.

Normally Closed: Use the green and brown wires.

Wiring Switch 2:

Normally Open: Use the blue and orange wires.

Normally Closed: Use the yellow and orange wires.

– 23 –

Page 24

WIRING DIAGRAM

Line Powered/Loop Powered 4-20mA (Type 2274 XAO)

4 conductor, 20 AWG shielded

Red (I)

Black (J)

LOOP–

D10

C14

V1

U7

D5

D6

D15

D3

T12

GND

Black (J)

+

ECND

T9

U5

C2

D11

C15

R18

T11

EGND

Red (I)

White (K)

Green (L)

R19

R21

V6

T8

Q3

FID5

FID6

C1

FID4

R8

V2

FO7

R1

C10

Q1

R9

R10

R11

R12

R13

D8

Q2

J5

J3

FID3

C4

321CO21–

FID2

R5

J2

U4

L1

C9

R6

C5

C8

DQ/TB 2003

C6

R4

Sensor Input

Y2

Keypad Input

Shield

Green (L)

White (K)

(+)

V+

(+)

(–)

(–)

GAUGE

V–

Battery Input

–

–

METER

PLC

SCADA

LOOP+

T7

D9

Y1

J1

1

R2

1

J6

R22

R20 C17

R14R16

J3

1

J7

Q4

D16

D12

POWER

SUPPLY

D7

F1D1

C3

C7

R7

D14

D1

R24

R23

D13

T10

+24V

+

– 24 –

Page 25

Installation Procedure for 2274 XAO:

ESD precautions should be taken. See page 31 for details.

1. Ensure all power is off/disconnected from the circuit.

2. Connect the white wire (K) to the positive power terminal.

3. Connect the green wire (L) to the negative power terminal.

4. Connect the red wire (I) to the positive power terminal.

5. Connect the black wire (J) to the positive meter terminal.

6. Connect the negative power terminal with the negative

meter terminal.

Note: Meter should be installed on the black wire only.

If red/black wires are connected prior to the green/white

and power is connected, output may be damaged due to

overloading.

Warning: Using multiple power sources for line and loop

power is not recommended as it may cause damage to

the unit.

– 25 –

Page 26

WIRING DIAGRAM

Line Powered/Loop Powered 4-20mA with (1) SPDT switch

(Type 2274 XAOU1) 7 conductor, 22 AWG shielded

Red M

Blac k N

(N.O.) Bl ue

(N.C.) Or ang e

(COM) Brown

FID2

J2

Sensor Input

Y2

Battery Input

–

–

LOOP+

T7

D9

D7

Y1

J1

1

R2

1

J6

R22

R20 C17

R14R16

J3

1

J7

Q4

D16

D12

+24V

POWER

SUPPLY

METER

PLC

SCADA

Switch

LOOP–

T9

D10

C14

F1D1

V1

C3

C7

R7

D11

D14

D1

U7

C15

R24

R18

D5

R23

D13

D6

D15

D3

T12

T10

GND

Red (M)

+

White (P)

Green (O)

Black (N)

+

Blue (NO)

Brown (Common)

Orange (NC)

R19

ECND

T8

Q3

U5

C2

FID5

R9

D8

T11

321CO21–

EGND

T2

T3

FID6

C1

R8

FO7

Q1

Q2

J5

C11

R5

R1

C10

C9

R6

J3

C4

R4

V+

V–

T1

D2

K1

K2

U4

L1

C5

C8

DQ/TB 2003

C6

Keypad Input

Shield

Green (–ex ec.) O

White (+e xec.) P

GAUGE

R21

V6

ISO1

R15

ISO2

R17

FID4

V2

R10

R11

R12

R13

FID3

(+)

(+)

(–)

(–)

•

– 26 –

Page 27

Installation Procedure for 2274 XAOU1:

ESD precautions should be taken. See page 31 for details.

1. Ensure all power is off/disconnected from the circuit.

2. Connect the white wire (P) to the positive power terminal.

3. Connect the green wire (O) to the negative power terminal.

4. Connect the red wire (M) to the positive power terminal.

5. Connect the black wire (N) to the positive meter terminal.

6. Connect the negative power terminal with the negative

meter terminal.

Note: Meter should be installed on the black wire only.

If red/black wires are connected prior to the green/white

and power is connected, output may be damaged due to

overloading.

Wiring the Switch:

Normally Open: Use the blue and brown wires.

Normally Closed: Use the orange and brown wires.

– 27 –

Page 28

Whit e

WIRING DIAGRAM

Line Powered/Loop Powered 4-20mA with (2) SPDT switches

(Type 2274 XAOU2) 10 conductor, 22 AWG shielded

Red Q

Black R

SWITCH 1

(N.O .) Bl ue

(N.C .) O ra ng e

FID2

T5

T6

T4

J2

Y2

(-exec.) S

(+exec.) T

V+

V–

(COM) Br ow n

SWITCH 2

(N.C.) V i o le t

(N.O .) Ye ll o w

(COM) G re y

Sensor Input

GAUGE

•

•

Battery Input

LOOP+

T7

D9

D7

Y1

C3

J1

1

R2

C7

1

R7

J6

R22

R20 C17

D14

D1

R14 R16

R24

J3

R23

1

D13

J7

Q4

D16

D12

T10

+24V

–

METER

PLC SCADA

LOOP–

D10

C14

F1D1

V1

U7

D5

D6

D15

D3

T12

GND

POWER

SUPPLY

–

Switch 1

Switch 2

ECND

T9

T8

U5

C2

D11

C15

R18

D8

T11

EGN D

+

+

R19

T2

T3

R21

V6

D2

ISO1

Q3

R15

C11

ISO2

R17

FID5

FID6

C13

C1

C12

FID4

R8

V2

R5

FO7

R1

C10

Q1

R9

R1 0

R1 1

R1 2

R1 3

C9

R6

Q2

J5

J3

FID3

C4

321CO21–

C6

R4

Red (Q)

White (T)

Green (S)

Black (R)

Blue (NO)

Brown (Common)

Orange (NC)

Yellow (NO)

Grey (Common)

Violet (NC)

T1

K1

K2

K2

U4

L1

C5

C8

DQ/TB 2003

Ke ypad Input

Shiel d

Green

(+)

(+)

(–)

(–)

– 28 –

Page 29

Installation Procedure for 2274 XAOU2:

ESD precautions should be taken. See page 31 for details.

1. Ensure all power is off/disconnected from the circuit.

2. Connect the white wire (T) to the positive power terminal.

3. Connect the green wire (S) to the negative power terminal.

4. Connect the red wire (Q) to the positive power terminal.

5. Connect the black wire (R) to the positive meter terminal.

6. Connect the negative power terminal with the negative

meter terminal.

Note: Meter should be installed on the black wire only.

Wiring Switch 1:

Normally Open: Use the blue and brown wires.

Normally Closed: Use the orange and brown wires.

Wiring Switch 2:

Normally Open: Use the yellow and grey wires.

Normally Closed: Use the violet and grey wires.

If red/black wired are connected prior to green/white wires

and power is connected, output may be damaged due to

overloading.

– 29 –

Page 30

GAUGE INSTALLATION:

The Ashcroft digital industrial gauge comes standard with

1

⁄4 or 1⁄2 NPT connection. Good piping practices rec-

either

ommend using teflon tape or a pipe sealant on the gauge

threads. Utilize a

9

⁄16˝ (3˝ case), 5⁄8˝ (41⁄2˝ case) wrench on

the wrench flat of the gauge to tighten the gauge to the

process.

NEVER TIGHTEN GAUGE THREADS BY HOLDING THE

BODY OF THE GAUGE. DOING SO MAY DAMAGE THE

GAUGE AND MAKE THE GAUGE INOPERABLE.

Battery Installation and Replacement:

The 3˝ Type 2074 comes with two AA alkaline batteries

installed. For battery replacement use;

• Duracell AA alkaline, MN1500 LR06 1.5V

1

The 4

⁄2˝ Type 2074 comes with two C alkaline batteries

installed. For battery replacement use one or the other;

• Energizer C alkaline, E93 or EN93 alkaline LR14 AM2 1.5V

• Duracell C alkaline, MN1400 LR14 1.5V

Do not mix ages or brands of batteries. Do not replace

batteries in hazardous areas.

Batteries have a life of approximately 450 hours (3˝ case).

2500 hours (4

1

⁄2˝ case). Battery life is dependent on gauge

usage, backlite settings and power off settings. When the

lower bar of the battery icon of the gauge display flashes,

the gauge has approximately 7 hours of life remaining.

To replace the batteries (3˝ case):

1) Remove the single screw on the back of the gauge case.

2) Hold the keypad in the palm of hand.

3) Carefully remove the two batteries from the holder and

replace batteries.

1

To replace the batteries (4

⁄2˝ case):

1) Remove the ring on the front of the gauge case.

2) Looking at the gauge case, carefully pull the front face

out of the case.

3) Lay the gauge, face down on a flat surface.

4) Carefully remove the two batteries from the holder and

replace the batteries.

– 30 –

Page 31

ESD PRECAUTIONS

Care should be taken to minimize exposure to ESD.

Proper proto-call should be followed as outlined in:

ANSI/ESD S20.20-2007

ESD ADV1.0-2009

ANSI/ESD S541-2008

Additional ESD Precautions on Proper Handling:

Avoid carpets in cool, dry areas as well as other static

generating materials such as plastic, cellophane, paper, or

cardboard.

Leave digital gauges in their anti-static packaging until

ready to be installed.

Dissipate static electricity before handling the digital

gauge or using keypad by touching a well-grounded metal

object, such as the system unit unpainted metal chassis.

If possible, use antistatic devices, such as wrist straps and

floor mats.

When installing batteries, avoid touching (including clothing) the contacts and components.

When making wiring connection to digital gauge terminals, place digital gauge on grounded mat prior to making

connection, and take care to avoid touching (including

clothing) any components.

Take care when connecting or disconnecting cables. A

damaged cable can cause a short in the electrical circuit.

When disconnecting a cable, always pull on the cable connector, case, or strain-relief loop, not on the cable itself.

– 31 –

Page 32

Notes:

1) Do not mix ages or brands of batteries.

2) Do not replace batteries in hazardous areas.

3) To provide maximum battery life, replace both batteries

4) To provide maximum battery life, replace both batteries.

Pipe to which gauge is attached must be properly

grounded.

PANEL MOUNTING DIMENSIONS:

.17

4.00

MOUNTING

RING

HOLE

CUTOUT

DIAMETER

3.406

13

⁄32±1⁄32)

(3

CLAMPING RING (1278G ONLY)

WASHER

SPACER POST

(3 REQ’D)

1.860

3˝ CASE

6˝ RING

DIA.

5.65˝

PANEL

OPENING

“B” (3 REQ’D)

5/16˝ MAX PANEL

THICKNESS

PANEL

41⁄2˝ CASE

Ashcroft Inc.

250 East Main Street | Stratford, CT 06614-5145

Tel: 203-378-8281 | Fax: 203-385-0602

e-mail: info@ashcroft.com | www.ashcroft.com

I&M008-10109 Rev. F 10/13

– 32 –

– 32 –

Loading...

Loading...