Page 1

Type 200 Series Welded or Bonded

Diaphragm Seal

Welded

or Bonded

Capsule

왘

TYPE 200 SHOWN

When isolation of the process from an

nstrument is required, Ashcroft offers a

i

comprehensive line of diaphragm seals.

Seal types include threaded, flanged,

in-line threaded, in-line flanged, in-line

socket weld, in-line butt weld, saddle

and sanitary seals. Also available is a

complete offering of isolation or iso-rings

and isolation or iso-spools.

APPLICATIONS

• Elevated process temperatures

• Corrosive service

• Isolation of the process for safety

• Suspended solids in the process

• Sanitary connections

• Replacement of process dead leg

• Ease of cleaning between batches

FEATURES

• A metal diaphragm is welded to the top

housing. Elastomeric diaphragms are

bonded to the top housing. Either provides

a double positive seal.

• A fill/bleed connection is standard, which

permits filling the seal and instrument

simultaneously after evacuation and allows

the fill to flow into the completed unit.

• A thin Teflon PTFE gasket between the

diaphragm and bottom housing ensures

a leak-tight corrosion resistant seal even

at high pressure.

• Top housing and pressure instrument are

removable.

• Continuous-duty design will prevent loss

of process fluid if pressure instrument is

removed or fails.

SPECIFICATIONS

Model Number: Type 200, 201, 202, 203, 204,

205, 206, 207, 208

Process

Connection

Size: See Table A

Instrument

Connection

Size: 1⁄

Diaphragm

Material: See Table B

Bottom Housing

Materials: See Table C

Filling Fluid: See Table E

OPTIONS Code

316 stainless steel YT

top housing

Stainless steel clamp SE

rings and flanged ring

– includes 300 stainless

steel clamping bolts

(1500 psi max)

300 series stainless SB

steel clamping bolts

(max pres is 1500 psi)

Pipe plugs for flushing PU

connections – pipe

plugs are available

in the same materials

as bottom housings

per Table C

5000 psi pressure rating HP

Threaded inlet and metal

diaphragm only

Welded instrument to DU

diaphragm seal

Dual flushing connections DB

(1⁄2 NPT) (Limited to 2˝

thru 3˝ flanged seals

Ring joint (Flanged seal only) RJ

Flat face (Flanged seal only) FF

Clean for gaseous oxygen 6B

or strong oxidizing agent

applications.

1

4,

⁄

2

NPT

BULLETIN DS-200

HOW TO ORDER:

1. From Table A...select TYPE NUMBER based on process connection, process connection size and diaphragm

2. From Table B...select DIAPHRAGM MATERIAL. (e.g., 316L stainless steel–code S)

3. From Table C...select BOTTOM HOUSING MATERIAL. (e.g., 316 stainless steel–code S)

4. From Table D...select INSTRUMENT CONNECTION size. (e.g., 1⁄4 NPT–code 02T)

5. From Table E...select FILLING FLUID, if diaphragm seal will be attached to instrument. (e.g., Glycerin–code CG)

All specifica tions are subject to change without notice.

All sales subject to standard ter ms and conditions.

© Ashcroft Inc. 2017 Rev. 05/17

type/construction. (e.g., Threaded/1˝/capsule–code-10-200)

Tylpical Code: 10–200SS–02T–CG

Ashcroft Inc., 250 East Main Street, Stratford, CT 06614 USA

Tel: 203-378-8281 • Fax: 203-385-0408

email: info@ashcroft.com • www.ashcroft.com

Page 2

Type 200 Series Welded or Bonded

Diaphragm Seal

TYPE 200 SERIES WELDED

OR BONDED SEAL TYPES

Type 200 –Threaded

1

⁄4, 1⁄2, 3⁄4, 1 NPT

Type 201 –Threaded

with flushing connection

1

⁄4, 1⁄2, 3⁄4, 1 NPT

Type 202 – Raised Face Flanged

1

⁄2,˝ 3⁄4,˝ 1,˝ 11⁄2,˝ 2,˝ 3˝

Type 203 – Raised Face Flanged

with flushing connection

1

⁄2,˝ 3⁄4,˝ 1,˝ 11⁄2,˝ 2,˝ 3˝

(raised face only)

1 piece with flushing conection

Type 204 – In-line Threaded

1

⁄4, 1⁄2, 3⁄4, 1 NPT

Type 205 – Saddle

3,˝ 4˝ pipe only

Type 206 – In-line Flanged

1

⁄2,˝ 3⁄4,˝ 1,˝ 11⁄2,˝ 2,˝ 3,˝ 4,˝ 6,˝ 8˝

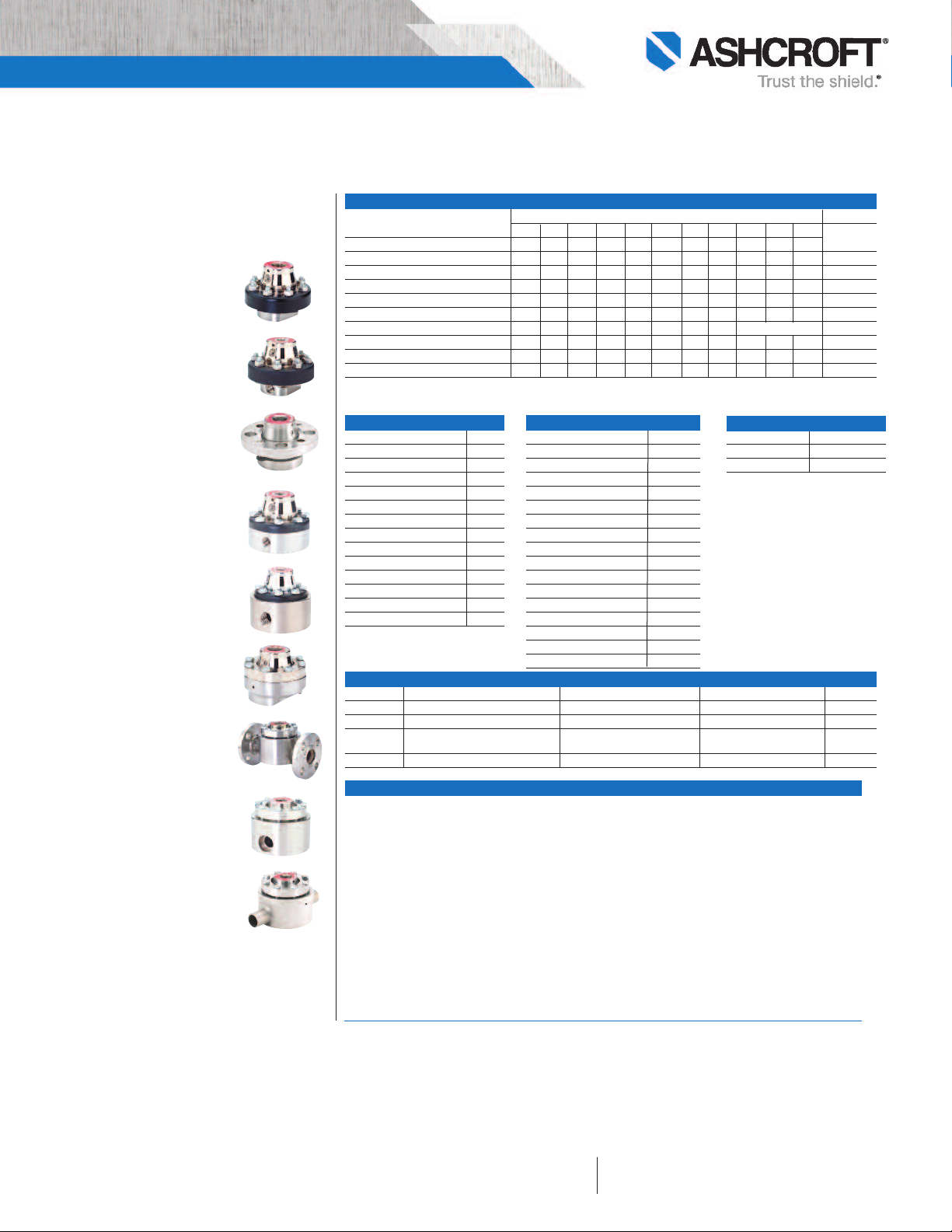

able A – Process Connection/Type Number

T

Process Connection Size/Code—Inches Type Number

Size 1⁄

Process Connection Code 25 50 75 10 15 20 30 40 60 80 Capsule

Threaded–female NPT • • • • • 200

Threaded–female NPT (with flushing conn.) • • • • • 201

1)

(

Flanged

• • • • • • 202

Flanged (with flushing conn.) • • • • • • 203

In-line—threaded NPT • • • • 204

Saddle • AND LARGER 205

In-line—butt weld • • • • • • 208

In-line—flanged

In-line—socket weld • • • • • • 207

Pressure Ratings—All 2500 psi except flanged seals are per ASME B 16.5, temperature limit determined by

iaphragm, bottom housing and/or filling fluid.

d

Table B – Diaphragm Material

2)

(

• • • • • • • • • 206

Table C – Housing Materials

Material Code

316L stainless steel S

304 stainless steel C

Monel 400 P

ickel N

N

arpenter 20 D

C

antalum U

T

Hastelloy B G

Hastelloy C 22

Hastelloy C 276

Teflon

Viton

Kalrez

Titanium

(6)

J

6)

(

(4)

(5)

(12)

H

(14)

TI

316L stainless steel S

T

Y

K

1

4

⁄

2

3

⁄

4 1 1

1

⁄

2 2 3 4 6 8

Material Code

Steel B

304L stainless steel C

astelloy B G

H

astelloy C 22

H

astelloy C 276

H

(6)

J

(6)

H

Carpenter 20 D

Monel “400” M

Inconel “600” W

Nickel N

(7)

(15)

PVC

V

Tantalum clad SS

Halar coated Monel

Teflon flanged steel

13)(15)

(

Kynar

(8)

SU

(8)(9)

BH

(10)

T

KY

able D – Instrument Connection

T

Size – NPT Code

1⁄

4 02T

1

04T

⁄

2

Titanium TI

Table E – Filling Fluid

Filling Service Connection to Instrument Temperature Range °F Code

Glycerin Pressure Direct Only 0/400 CG

Silicone Pressure/Vacuum Direct or Flexible Line –40/500 CK, DJ

Halocarbon Pressure/Vacuum in presence Direct or Flexible Line –70/300 CF

of strong oxidizing agent

(16)

Syltherm Pressure/Vacuum Direct or Flexible Line –40/750 HA

Type 207 – In-line Socket Weld

1

⁄2,˝ 3⁄4,˝ 1,˝ 11⁄2,˝ 2˝

Type 208 – In-line Butt Weld

1

⁄4,˝ 1⁄2,˝ 3⁄4,˝ 1,˝ 11⁄2,˝ 2˝

BULLETIN DS-200

Notes:

(1) 150, 300, 600, 900, 1500 & 2500 class flanges.

(2) 1˝ 150 thru 8˝ 300 class flanges only.

(3) Metal diaphragms welded; Teflon, Kalrez & Viton diaphragms bonded.

(4) Temp limits:−40/400°F.

(5) Max. pressure: 500 psi, Temp. limits:−40/350°F.

(6) Use on applications where NACE standard MR-01-75 2003 is standard.

(7) Maximum press./temp. Threaded: 200 psi/74°F, 125 psi/125°F, 80 psi/150°F. Flanged: 75 psi/100°F.

(8) Type 202 only.

(9) Temp. Limits: –40/300°F.

(10) Only available in 1˝, 1

Consult factory for conditions beyond these limits.

1

⁄

2˝, & 2˝ 150 class, Types 202 max. press./temp. – 270 psi and 150°F.

(11) Max. pressure: 500 psi, Temp. limits:30/212°F.

(12) Maximum pressure/temp.: 200 psi and 180°F.

(13) Type 200:

(14) Includes Titanium top housing.

1

1

⁄

4 or

⁄

2 NPT only. Larger sizes offered with solvent weld joint. N/A in 201 or 203 design.

(15) Type 200 only available in 1/4 NPT or 1/2 NPT. 3/4˝ & 1˝ size avalable as solvent welded joint only.

(16) CK for 50cSt, DJ for 10 cSt

All specifica tions are subject to change without notice.

All sales subject to stadard term s and conditions.

© Ashcroft Inc. 2017 Rev. 05/17

Ashcroft Inc., 250 East Main Street, Stratford, CT 06614 USA

Tel: 203-378-8281 • Fax: 203-385-0408

email: info@ashcroft.com • www.ashcroft.com

Page 3

Type 200 Series Welded or Bonded

A

B

C

3

3

⁄4

(95) 2

7

⁄8

(73) 1

13

⁄16

(46)

A

B

C

(wrench flats)

1

⁄4 NPT for 1⁄4, 1⁄2 & 3⁄4

process connections,

1

⁄8 NPT for 1.0 NPT

process connections

A B C

3

⁄4 (95) 27⁄8 (73) 1

1

3

⁄16 (46)

A

B

N

uts & flange by user

Flange A B

Size Rating # in mm in mm

150 3

1

⁄2 (89) 215⁄16 (75)

1

⁄2˝ 300 or 600 33⁄4 (95) 3 (76)

900 or 1500 4

3

⁄4 (121) 33⁄16 (81)

150 3

7

⁄8 (98) 213⁄16 (71)

3

⁄4˝ 300 or 600 45⁄8 (117) 3 (76)

900 or 1500 5

1

⁄8 (130) 33⁄16 (81)

“E”

BOTTOM OF HOUSING

TO C OF 1/8 NPT

FLUSHING PORT

TYPES 103 & 203 ONLY

)

B

C

D

A

L

Flange A B C

Size Rating # in. mm in. mm in. mm

1 150 4-1/4 (100)

300 or 600 5 (127)

2-9/16 (65) 1-23/32 (69)

103 & 203 only

Flange D E

Size Rating # in. mm in. mm

1 150

300 or 600

1-5/8 (41)

3/8 (9)

“E”

A

D

B

C

BOTTOM OF HOUSING

TO C OF 1/8 NPT

FLUSHING PORT

TYPES 103 & 203 ONLY

)

L

Flange A B C

Size Rating # in . mm in. mm in. mm

1 900 or 1500 5-7/8 (149)

2500 6-1/4 (159)

2-7/8 (73) 2-1/4 (57)

103 & 203 only

Flange D E

Size Rating # in . mm in. mm

1 900 or 1500

2500

3-3/8 (86)

3/8 (9)

B

A

C

N

uts, bolts & flange by user

Flange A B C

Size Rating # in mm in mm in mm

150 5 (127) 1

1

⁄2 (38)

1

1

/2˝ 300 or 600 61⁄

4

(159) 23⁄8 (61) 11⁄2 (38)

900 or 1500 7

(178) 11⁄2 (38)

150 6 (152) 1

3

⁄8 (35)

2˝ 300 or 600 6

1

⁄

2

(165) 115⁄

1

6

(49) 11⁄2 (38)

900 or 1500 8

1

⁄2 (216) 21⁄8 (54)

150 7

1

⁄2 (191) 2 (51) 15⁄8 (41)

3˝ 300 or 600 8

1

⁄

4

(206) 21⁄

1

6

(52) 17⁄8 (47)

900 or 1500 10

1

⁄2 (267) 211⁄16 (68) 31⁄4 (82)

A

B

C

Nuts, bolts & flange by user

Flange A B C

Size Rating # in mm in mm in mm

1

1

⁄2˝ 150 5 (127) 25⁄

1

6

(59) 1

1

3

⁄

3

2

(39)

2˝ 150 6

(152) 21⁄8 (54) 19⁄16 (40)

A

B

Nuts & flange by user

1

⁄4 NPT

flushing

connection

Flange A B

Size Rating # in mm in mm

150 3

1

⁄2 (89) 215⁄16 (75)

1

⁄2˝ 300 or 600 33⁄4 (95) 3 (76)

900 or 1500 4

3

⁄4 (121) 33⁄16 (81)

150 3

7

⁄8 (98) 213⁄16 (71)

3

⁄4˝ 300 or 600 45⁄8 (117) 3 (76)

Diaphragm Seal

DIMENSIONS

Type 200 – Threaded

1

⁄4, 1⁄2, 3⁄4, 1 NPT

Type 201 –Threaded

1

⁄4, 1⁄2, 3⁄4, 1 NPT (with flushing connection)

Type 202 – Flanged 1˝ (raised face only)

two piece bottom housing, 11⁄2,˝ 2,˝ - PVC, Teflon

and Kynar

Type 202 – Flanged (raised face only)

11⁄2,˝ 2,˝ 3˝ one piece bottom housing -

all materials except PVC, Teflon and Kynar

Type 202/203 – Flanged 1˝ (raised face only)

one piece bottom housing, with and without

flushing connection. Class 150, 300, 600

Type 202/203 – Flanged 1˝ (raised face only)

one piece bottom housing, with and without

flushing connection. Class 900, 1500, 2000

Type 202 – Flanged

1

⁄2,˝ 3⁄4,˝

BULLETIN DS-200

Type 203 – Flanged

1

⁄2,˝ 3⁄4˝ (with flushing connection)

All specifica tions are subject to change without notice.

All sales subject to standard ter ms and conditions.

© Ashcroft Inc. 2017 Rev. 05/17

Ashcroft Inc., 250 East Main Street, Stratford, CT 06614 USA

Tel: 203-378-8281 • Fax: 203-385-0408

email: info@ashcroft.com • www.ashcroft.com

Page 4

A

B

C

Nuts, bolts & flange by user

Flushing connection

1

⁄8 NPT for 11⁄2"

1

⁄4 NPT for 2" & 3"

Flange A B C

Size Rating # in mm in mm in mm

150 5 (127)

1

1

⁄2˝

300 or 600 6

1

⁄4 (

159) 3 (76) 2

1

⁄16

(52)

900 or 1500 7

(178)

150 6 (152)

2˝ 300 or 600 6

1

⁄2 (

165) 3

1

1

⁄32

(84) 2

3

⁄8

(60)

900 or 1500 8

1

⁄2 (

215)

150 7

1

⁄2

(191) 3

3

⁄

3

2

(79) 2

7

⁄

3

2

(56)

3˝ 300 or 600 8

1

⁄

4

(210) 33⁄

1

6

(81) 27⁄

3

2

(57)

900 9

1

⁄2 (241)

3

2

3

⁄32 (94) 23⁄4 (70)

1500 10

1

⁄2 (267)

Type 200 Series Welded or Bonded

A

B

C

Process A B C

Connection in mm in mm in mm

1

⁄4 NPT

25⁄8 (67) 21⁄8 (54)

1

⁄2 NPT

4 (102)

35⁄8 (92) 23⁄4 (70)

3

⁄4 NPT 37⁄8 (98) 3 (76)

1 NPT 3

7

⁄8 (98) 3 (76)

A

B

C

E

D

Top of pipe

A B C D E

in mm in mm in mm in mm in mm

3

1

⁄2 (89) 21⁄4 (57) 17⁄8 (48) 13⁄4 (44) 21⁄8 (54)

A

C

E

Top of pipe

D

B

A B C D E

in mm in mm in mm in mm in mm

3

1

⁄2 (89) 115⁄

16

(50) 13⁄16 (31) 3 (76) 231⁄32 (75)

Flange A B C

Size Rating # in mm in mm in mm

150 7 (178) 3

1

⁄2 (89)

1

⁄2˝

300 7 (178)

2

7

⁄16 (62)

3

7

⁄8 (98)

150 7 (178) 4

1

⁄4 (108)

1˝ 300 8

(203)

2

7

⁄16 (62)

4

7

⁄8 (123)

150 8 (203) 5 (127)

1

1

⁄2 ˝

300 9 (229)

211⁄16 (68)

61⁄8 (155)

150 9 (229) 6 (152)

2˝ 300 10

(254)

2

15

⁄16 (75)

6

1

⁄2 (165)

150 11 (279) 7

1

⁄2 (229)

3˝ 300 12

(305)

3

5

⁄8 (92)

8

1

⁄4 (254)

A

C

B

Flange A B C

Size Rating # in mm in mm in mm

150 13 (330) 9

(

229)

4˝ 300 14

(356)

3

3

⁄8 (86)

10 (254)

150 16 (406) 11 (279)

6˝

300 17

(

432)

4

7

⁄16 (113)

12

1

⁄2

(318)

8˝ 150 16 (406) 5

7

⁄

1

6

(138) 13

1

⁄2

(343)

A

C

B

Pipe A B

Size in mm in mm

1

⁄4˝ 211⁄

3

2

(60)

1

⁄2˝, 3⁄4˝ 211⁄32 (60)

1˝ 2

15

⁄32 (63)

1

1

⁄2˝

4

(102)

2

23

⁄32 (69)

2˝ 2

31

⁄32 (75)

A

B

PIPE & WELD BY USER

Diaphragm Seal

DIMENSIONS

Type 203 – Flanged 11⁄2,˝ 2,˝ 3˝ (raised face only)

one piece bottom housing with flushing connection

Type 204 – In-Line Threaded

1

⁄4, 1⁄2, 3⁄4, 1 NPT

Type 205 – Saddle

4˝ Pipe only

Type 205 – Saddle

3˝ Pipe only

Type 206 – In-Line Flanged

4,˝ 6,˝ 8˝

Type 207 – In-Line Welded

1

⁄4,˝ 1⁄2,˝ 3⁄4,˝ 1,˝ 11⁄2,˝ 2˝

BULLETIN DS-200

Type 206 – In-Line Flanged

1

⁄2,˝ 1,˝ 11⁄2,˝ 2,˝ 3˝

All specifica tions are subject to change without notice.

All sales subject to standard ter ms and conditions.

© Ashcroft Inc. 2017 Rev. 05/17

Ashcroft Inc., 250 East Main Street, Stratford, CT 06614 USA

Tel: 203-378-8281 • Fax: 203-385-0408

email: info@ashcroft.com • www.ashcroft.com

Loading...

Loading...