Page 1

Data Sheet

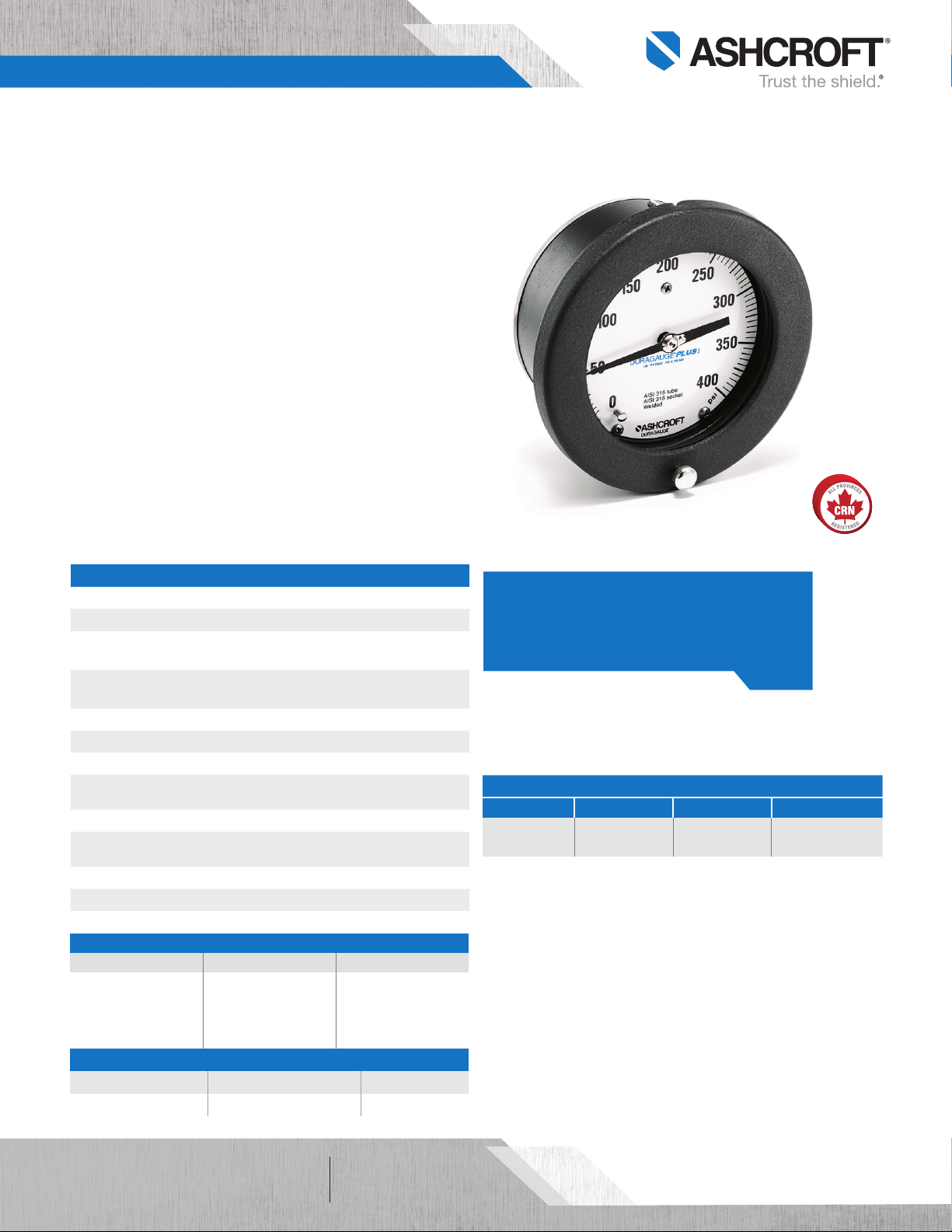

1377 Duragauge® Pressure Gauge

FEATURES

Solid front safety case with pressure relief back

Dial sizes 4½˝, 6˝ and 8½˝

±0.5% of span (ASME B40.100 Grade 2A)

Customizable dial printing options

TYPICAL USES

Refineries

Chemical and petrochemical plants

Offshore oil rigs

Water and wastewater pressure control

Pulp and water

Mining and metals

Equipment skids

Specialized OEM equipment

1377

41⁄2˝ dial size

SPECIFICATIONS

Accuracy: ±0.5% of span (ASME B40.100 Grade 2A)

Dial Sizes: 41⁄2˝, 6˝, 81⁄2˝

Process Connection:1⁄4 NPT, 1⁄2 NPT,

Process Connection

Location:

Ranges: Vacuum, compound to 30,000 psi

Case Style: Solid front with pressure relief back

Movement: Rotary, adjustable, 400 SS, Teflon® coated

Window Material:

Pointer: Micrometer, adjustable, aluminum, maximum

Weather Protection: Dry case: Case not sealed, recommended for

Mounting: Stem, surface, flush or remote

Dampening: PLUS!™ Performance

Approvals: CRN

WETTED COMPONENTS

Bourdon Tube Process Connection Joints

316L SS 316L SS Welded

316L SS Steel Welded

K-Monel® 500 Tube Monel® 400 Welded

C510 Phos. Bronze Brass Silver brazed

NON-WETTED COMPONENTS

Case Ring Back Cover

Aluminum, black epoxy Steel, hinged, black enamel 300 SS

9

⁄16 -18 UNF-2B (high pressure connection)

Lower, back

Glass (STD.), safety glass, acrylic,

non-glare glass (OPT.)

weather protected environment only

KEY BENEFITS

• Ideal for panel mounting

• Available 8½˝ dial size for remote reading

MIN/MAX TEMPERATURE LIMITS

Version Ambient Process Storage

Dry

-20°F to 200°F

(-29°C to 93°C)

-20°F to 250°F

(-29°C to 121°C)

-40°F to 250°F

(-40°C to 121°C)

All specifications are subject to change without notice.

All sales subject to standard terms and conditions.

©2019 Ashcroft Inc. 1377_gauge_ds2.0, Rev E, 06/19

ashcroft.com

of 41

info@ashcroft.com

1.800.328.8258

Page 2

Data Sheet

1377 Duragauge® Pressure Gauge

ORDERING CODE Example:

Dial Size/Model Code

451377 - 41⁄2˝ aluminum case 451377

601377 - 6˝ aluminum case

851377 - 81⁄2˝ aluminum case

System (tube and process connection)

A - Bronze tube, brass process connection, max. pressure connection 1,000 psi

P - K-Monel® 500 tube, Monel® 400 process connection, max. pressure 30,000 psi

R - 316L SS tube, steel process connection, max. pressure 20,000 psi

S - 316 SS tube and 316L SS process connection, max. pressure 20,000 psi S

WW - Inconel® 718 tube and process connection

Case Design

S - Solid front case, dry

Process Connection Sizes

02 - 1⁄4 NPT Male, N/A for ranges over 20,000 psi

04 - 1⁄2 NPT Male, N/A for ranges over 20,000 psi

09 - 9⁄16 18 UNF-2B, high pressure fitting, standard for pressures over 20,000 psi

Process Connection Location

L - Lower

B - Back

D - Side (3 o’clock)

E - Side connection (9 o’clock)

T - Top connection

Options (If choosing an option(s) must include a “X”)

Dampening

LL - PLUS!™ Performance

NZ - PLUS!™ Performance, silicone free

TS - Throttle screw (standard with PLUS!™ Performance)

Dial

DA - Dial marking (text marking on the dial)

D3 - DuraVis™ Retroreflective Dial (4½˝ case only)

Windows/Pointers

PD - Acrylic window

SG - Safety glass

NG - Non-glare glass (4

EP - Maximum pointer (adjustable)

SH - Red set hand stationary

Other

6B - Cleaned for gaseous, oxygen service

NH - Stainless Steel tag wired to case

AB - Gauges calibrated to compensate for absolute pressure

OS - Overload stop

VS - Underload stop

HY - Hydrostatic/pneumatic testing (system pressurized to 150% of rated system pressure for 5 minutes. Overload stop standard.)

C4 - Individual calibration chart (in accordance with ASME B40.100:2013. Accuracy traceable to NIST)

Range (coding examples only, see range table on page 3 for all standard ranges)

Single Scales

15# - 15 psi 15#

1BR - 1 bar

1KG - 1 kg/sm

100KP - 100 kPa

Dual Scales

15#/BR - 15 psi inner scale, 1 bar outer scale

1BR/# - 1 bar inner scale, 15 psi outer scale

1

⁄2˝ and 6˝ cases only)

2

451377

S S 04 L XLL 15#

04

L

X__

LL

All specifications are subject to change without notice.

All sales subject to standard terms and conditions.

©2019 Ashcroft Inc. 1377_gauge_ds2.0, Rev E, 06/19

ashcroft.com

of 42

info@ashcroft.com

1.800.328.8258

Page 3

Data Sheet

1377 Duragauge® Pressure Gauge

STANDARD PRESSURE RANGES

psi bar kPa mPa kg/cm

30IMV N1BR N100KP N1MP N1KG

Vacuum

Compound

Positive Pressure

– N1/0.6BR N100/60KP 0.1/0.06MP N1/0.6KG

V/15# – – – –

– N1/1.5BR N100/150KP N.1/0.15MP N1/1.5KG

V/30# – – – –

– N1/3BR N100/300KP N.1/0.3MP N1/3KG

V/60# – – – –

– N1/5BR N100/500KP N.1/.5MP N1/5KG

V/100# – – – –

– N1/9BR N100/900KP N.1/.9MP N1/9KG

15# 1BR 100KP 0.1MP 1KG

20# – – – –

– 1.6BR 160KP 0.16MP 1.6KG

30# – – – –

– 2.5BR 250KP 0.25MP 2.5KG

60# 4BR 400KP 0.4MP 4KG

– 6BR 600KP 0.6MP 6KG

100# – – – –

120# – – – –

– 10BR 1000KP 1MP 10KG

160# – – – –

200# – – – –

– 16BR 1600KP 1.6MP 16KG

300# – – – –

– 25BR 2500KP 2.5MP 25KG

400# – – – –

500# – – – –

600# 40BR 4000KP 4MP 40KG

800# – – – –

– 60BR 6000KP 6MP 60KG

1000# – – – –

1500# 100BR 10000KP 10MP 100KG

2000# – – – –

– 160BR 16000KP 16MP 160KG

3000# – – – –

– 250BR 25000KP 25MP 250KG

4000# – – – –

5000# – – – –

6000# 400BR 40000KP 40MP 400KG

8000# – – – –

– 600BR 60000KP 60MP 600KG

10000# – – – –

15000# 1000BR 100000KP 100MP 1000KG

20000# - - - -

- 1600BR - 160MP 1600KG

30000# - - - -

2500BR - 250MP 2500KG

50000# - - -

- 4000BR - 400MP 4000KG

80000# - - -

- 6000BR - 600MP 6000KG

100000# - - - -

2

All specifications are subject to change without notice.

All sales subject to standard terms and conditions.

©2019 Ashcroft Inc. 1377_gauge_ds2.0, Rev E, 06/19

ashcroft.com

of 43

info@ashcroft.com

1.800.328.8258

Page 4

Hole in

3 Mounting studs

equally spaced on

S

Data Sheet

1377 Duragauge® Pressure Gauge

DIMENSIONS in [ ] are millimeters

Drawings are for reference only, consult Ashcroft for specific dimensional drawings.

Dial Size

Inches

41⁄2

6

1

8

⁄2

A B C D E F G H K M P S T U CC LL

7

3

1

3

5

15

6

[152]

9

7

[192]

10

[257]

2

⁄8

4

⁄4

1

⁄16

5

⁄8

1

⁄8

[73]

[121]

7

⁄16

2

⁄8

[73]

[121]

7

1

2

⁄8

⁄16

[73]

[121]

3

4

⁄4

3

4

⁄4

[27]

[137]

1

1

⁄16

[27]7[178]

1

1

[27]

5

⁄16

9

[244]

⁄8

3

[41]

[100]

5

1

⁄8

4

[41]

[114]

5

1

⁄8

[41]6[152]

3

⁄16

1

⁄8

1

[35]

[27]

1

3

⁄2

1

⁄8

1

[35]

[27]

3

1

⁄8

1

[35]

[27]9[229]

1377 4½˝ and 6˝ lower connection 1377 4½˝ and 6˝ back connection

A

B

S

U

Nuts & washers

not supplied by

Ashcroft

C

T

M

panel

F

G

H

CC threaded

E dia. Bolt Circle

P

D

K

LL

1

1

1

⁄16

⁄16

⁄16

7

4

[124]

1

6

[165]

Weight

(lbs)

1

5

5

⁄8

2

⁄8

[54]

⁄2

2

[54]

2

[54]

⁄8

[16]

[16]

1

5

⁄8

⁄8

[16]

[16]

1

5

⁄8

⁄8

[16]

[16]

⁄8

5

⁄8

5

⁄8

3

[19]

3

[19]

3

[19]

⁄4

⁄4

⁄4

#10-24

1

⁄4-20

1

⁄4-20

1

⁄8-1⁄2

[3][13]

1

⁄8-1⁄2

[3][13]

1

⁄8-1⁄2

[3][13]

2.5

2.5

4.5

3 Mounting studs CC threaded

equally spaced on E dia. Bolt Circle

All specifications are subject to change without notice.

All sales subject to standard terms and conditions.

©2019 Ashcroft Inc. 1377_gauge_ds2.0, Rev E, 06/19

1377 8½˝ lower connection 1377 8½˝ back connection

Nuts & washers

not supplied by

A

B

G

T

P

D

U

T

H

K

LL

ashcroft.com

info@ashcroft.com

1.800.328.8258

Ashcroft

C

F

M

Hole in

panel

of 44

Loading...

Loading...