Page 1

Installation and

Installation and

Maintenance

Maintenance

Manual for the

Manual for the

®

ASHCROFT

ASHCROFT

1305D Deadweight

1305D Deadweight

Tester and Type

Tester and Type

1327D Portable

1327D Portable

Pump

Pump

®

Type

Type

I&M002-10095 4/02 (250-1526) Rev. 7/05

Page 2

Page 3

®

shcroft

A

or the Ashcroft

f

nd Type 1327D Portable Pump

a

nstallation and Maintenance Manual

I

®

ype 1305D Deadweight Tester

T

INDEX

Section Description

.

1

.

2

cope of Manual Safety Precautions

S

roduct Description 1305

P

heory of Operation

T

Construction

Specifications

roduct Description 1327

P

heory of Operation

T

onstruction

C

Specifications

3. Inspection

Installation 1305

Operation 1305

Installation 1327

Operation 1327

4. Factors Affecting Operation of Deadweight

Testers

5. Maintenance Instructions

6. Warranty

Shipping Instructions

List of Illustrations

Figure 1-1

Figure 1-2

Figure 2-1

Figure 2-2

Figure 5-1

.0 PURPOSE AND SCOPE OF MANUAL

1

his manual is provided to guide users of Model 1305D

T

nd 1327D pressure testing devices in:

a

(1) installing the equipment

(2) Routine operations

he instructions in this manual are designed to be per-

T

ormed by qualified instrument maintenance personnel.

f

Ashcroft Inc. does not recommend troubleshoot ing or

repairs beyond the scope of this manual. Problems that

cannot be remedied by following the instructions in this

anual should be referred to the manuf acturer. Immediate

m

ssistance can often be supplied by telephone. Defectiv e

a

omponents will be repaired or replaced by the manufac-

c

turer at his discretion and will be returned to the user by

the same mode of shipment. Airmail or air express is recommended for urgent shipments. Returned goods should

be accompanied by information requested in Section 6.

Contact Customer Service at:

Ashcroft Inc.

250 East Main Street

Stratford, CT 06614

Phone: (203) 378-8281

Fax: (203) 385-0402

www.ashcroft.com

email: info@ashcroft.com

1.1 Safety Precautions

Pressure Testing Equipment must be selected and used in

accordance with recognized industry codes and safety

practices to avoid the possibility of misuse or misapplication which could result in personal injury or property damage. Personnel responsib le for selection and installation

should also be familiar with the safety recommendations of

ASME B40.1 that apply to elastic pressure elements and

their application in general and specific services. ASME

B40.1 is availab le from:

ANSI or ASME

1430 Broadway 345 47th Street

New York, NY 10018 New York, NY 10017

1. Pressure – Select a range so that the maximum

applied pressure will never exceed the upper range limit.

2. Vibration – Excessive vibration could cause a loosening of components and abnormal wear resulting in loss of

ument accuracy or failure to provide v alid data.

instr

3. Temperature – Operation of the instrument in an environment where temperatures are in excess of design ratings may result in loss of accuracy and failure .

ust be resis-

4. Process – Pressure boundary mater

ials m

tant to the process media. Failure to assure compatibility

may result in pressure boundary deterioration or failure.

Instruments operated at high pressure or with potentially

hazardous service, such as oxygen, should be carefully

selected in accordance with recognized industry codes

and the recommendations of ASME B40.1.

2.0 PRODUCT DESCRIPTION –

THEORY OF OPERATION – CONSTRUCTION

2.1.2 Product Description

2.1.3 Construction

The Ashcroft Type 1305D Dual Range Deadweight testers

imary pressure standards, used for

are precision b

uilt pr

testing, setting, calibrating or repairing pressure measuring devices within the test points 15 psi (100kPa) to

10,000 psi (70,000kP

a).

Page 4

he deadweight tester consists of a two stage hydraulic

T

ump containing a manifold which is pressurized during

p

peration. Integral to the pump is a shuttle valv e that

o

allows the operator to regulate the speed of pressure

increase. One connection to the manifold includes a cylinder and a free-floating precision machined piston with a

plate for holding calibrated weights. A second connection

to the manifold accommodates a gauge or other pressure

measuring device to be calibrated or checked.

ncorporated into the manifold is a hand operated dis-

I

lacement valve that allows small adjustments in fluid v ol-

p

me to be made without further operation of the pump

u

handle or release valve.

The tester is dual range having two interchangeable piston

nd cylinder assemblies. One is a low pressure piston

a

aving an effective area five times larger than that of the

h

high pressure piston. The low pressure piston is used for

making measurements below 2,000 psi (14,000 kPa). The

high pressure piston, with an area 1/5 that of the low pressure piston, is used to measure pressure through 10,000

psi (70,000 kPa). The weight masses are pre-measured

and identified with the pressure values they produce when

operated with the interchangeable piston and cylinder

assemblies.

Pressure calibration points produced by the deadweight

tester are accurate to within ± 0.1% of the reading certified

traceable to the N.I.S.T. The tester provides consistent,

repeatable accuracy, maintaining its pressure for an appreciable length of time regardless of temperature changes,

slight leaks in the pressure system, or changes in volume

of the pressurized system due to movement of a Bourdon

tube or other device.

A hand jack set, three wrenches, spare O-rings, and a

special adapter for making connections to pressure outlets

that do not accommodate cone pipe seating, are included

with each unit.

All deadweight testers are supplied with lower and back

connection offset pipe assemblies, with pipe adapters for

1

⁄

4 NPT or

1

⁄

2 NPT connections.

An all metal, double-latched, top handle carrying case is

supplied with the complete tester for all fittings and attachments. Deadweights are packed in metal, double-latched

storage-carrying boxes.

2.1.2 Theory of Operation – 1305D

The theory behind a deadweight tester can be expressed

as simply as force acting upon a known area. Pressure

y the manifold, to the

produced b

y the pump is distrib

base of a precision machined piston and to a de

uted b

vice being

calibrated or checked. Pre-selected weights loaded onto

the piston platfor

m are acted upon b

y g

a

r

vity and de

velop

a force that is to be equally opposed by the fluid pressure

from the pump. When equilibrium is achieved, the pressure value is known, it being a direct result of the sum of

the forces from the weights, piston platf orm and the piston

divided by the effective area of the piston and cylinder

assemb

ly.

With the 1305D two piston and cylinder assemblies are

supplied, one having an effective area 1/5 of the other.

When using the smaller piston and cylinder assembly, five

times more pressure is required to oppose the force of a

ravity. For this rea-

constant mass being acted upon b

y g

son the masses supplied with the tester are stamped with

two pressure values, the value being contingent on the

e area of the piston and cylinder assemb

ectiv

eff

ly selected

.

.1.3 Specifications – 1305D

2

ccuracy:

A

ylinder assemblies within 0.1% of reading. Weight toler-

c

ombined tolerance of weights and piston and

C

ance within 0.05% of mass. Piston and cylinder is within

0.05% of rated mean effective area.

Deadweight: Non-magnetic die cast zinc alloy. Total

weight to produce maximum pressure of 10,000 psi

(70,000kPa) is 125 lbs. (56.7 kg).

Piston & Cylinder Assemblies: High strength stainless

teel piston and cylinder with brass collar and aluminum

s

eight platform.

w

ump:Two stage, lev er operated gener ates 10,000 psi

P

(70,000 kPa) with 28 pounds (12.7 kg) of force on lever

handle.

Pump Body: Aluminum, corrosion inhibited and coated

with baked blue epoxy finish.

Shuttle Valve: Stainless steel bypass valv e that controls

rate of pressure increase and reduces operator effort

when working at high pressure.

Displacement Valve: A fine pitched threaded valve rod

permitting vernier adjustments to fluid volume and provide

precise pressure changes or adjustment of piston travel.

Limit stops prevent rod removal during normal operation.

Mounting: Four bench mounting holes located in base for

positive mounting to any level surface.

Instrument Connections: Tw o coned pipe assemb lies

provide vertical calibration capability for back and low er

connected gauges. Standard

1

⁄4 inch internal NPT and 1⁄2

inch inter NPT fitting adapters are supplied.

Operating Fluid: 1305D – Light grade machine oils, automotive petroleum base SAE 20 oils or other equivalent fluids suitable for use with Buna N O-ring materials. 1.5 pints

required (.7 liters).

1305DH – Most hydraulic oils of phosphate ester base,

brake fluids, skydrol, pydraul etc., suitable for use with

Butyl or Ethylene-Propylene O-ring materials. 1.5 pints

required (.7 liters).

2.1.4 Certification:

Standard (CD-3)

– Certificate of NIST traceability

(accuracy/traceability statement only).

Optional (CD-5) – Certification document includes actual

(as left) weight values for each weight and piston, piston

diameter values, environmental data and NIST test

numbers. Set includes numbered weights.

2.2 Product Description 1327D

2.2.1 Construction

The Ashcroft T

ype 1327D Portable Test Pumps are

rugged, versatile pressure transfer standards, used for

testing, setting, calibrating or repair

ing pressure measur

ing devices with ranges up to 10,000 psi (70,000kP a). A

selection of high accuracy test gauges, with a precision of

±0.25% of span, are supplied as the standard to which the

device under test is compared.

aulic

The main component to the tester is a tw

o stage h

ydr

pump containing a manifold which is pressurized during

operation. Integral to the pump is a shuttle valv e that

allows the operator to regulate the speed of pressure

increase. One connection to the manifold has a straight

pipe with a precision test gauge attached serving as the

erence standard. A second connection to the manif

ref

old

accommodates a gauge or other pressure measuring

device to be calibrated or check ed. Incorporated into the

e that

old is a hand oper

manif

ated displacement v

alv

allows small adjustments in fluid volume to be made without further operation of the pump handle or release valve.

Page 5

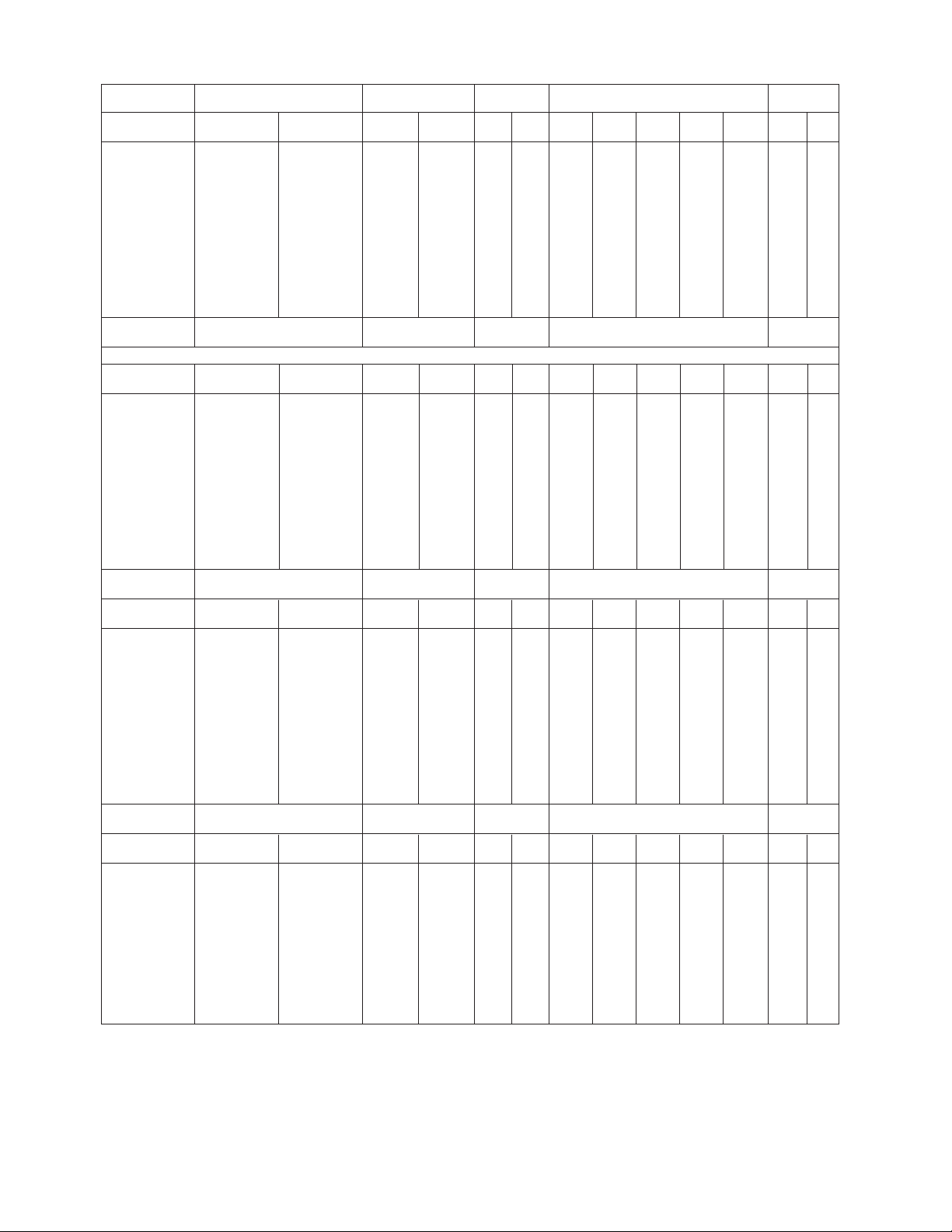

Model Piston Assembly Piston Net

Number Pressure Range Piston Area Value Number of Weights by Value Weight

L-5 L-10 L-20 L-40 L-100

psi Type Low High Low High Low

High

H-25 H-50 H-100 H-200 H-500

lbs. kg.

1305D-10

1305DH-10 15/200 75/1000 5 25 1 3 2 3 -- 60 27

1305D-20

1305DH-20 15/400 75/2000 5 25 1 3 2 3 2 70 32

1305D-30 .

0625 in.2.0125 in.

2

1305DH-30 15/600 75/3000 (.4032) (.0806) 5 25 1 3 2 3 4 85 39

305D-50

1

1305DH-50 15/1000 75/5000 5 25 1 3 2 3 8 105 48

1305D-100

1305DH-100 15/2000 75/10000 5 25 1 3 2 3 18 175 80

Model Piston Assembly Piston Net

Number Pressure Range Piston Area Value Number of Weights by Value Weight

M

kg/cm2Type Low High Low High Low High

METRIC RANGES ARE NO LONGER AVAILABLE – INFORMATION FOR REFERENCE ONLY

L-.5 L-1 L-2 L-4 L-5

H-2.5 H-5 H-10 H-20 H-25

lbs. kg.

1305DM-20

1305DMH-20 1/20 -- .5 2.5 1 1 2 1 2 63 29

1305DM-100

1305DMH-100 1/20 5/100 .5 2.5 1 1 2 1 2 65 30

1305DM-150 .

0625 in.2.0125 in.

2

1305DMh-150 1/30 5/150 (.4032) (.0806) .5 2.5 1 1 2 1 4 75 34

1305DM-350

1305DMH-350 1/70 5/350 .5 2.5 1 1 2 1 12 105 48

1305DM-700

1305DMH-700 1/140 5/700 .5 2.5 2 1 2 1 26 175 80

Model Piston Assembly Piston Net

Number Pressure Range Piston Area Value Number of Weights by Value Weight

bar Type Low High Low High Low High

L-.5 L-1 L-2 L-4 L-5

H-2.5 H-5 H-10 H-20 H-25

lbs. kg.

1305DB-20

1305DBH-20 1/20 -- .5 2.5 1 1 2 1 2 63 29

1305DB-100

1305DBH-100 1/20 5/100 .5 2.5 1 1 2 1 2 65 30

1305DB-150 .

0613 in.2.0123 in.

2

1305DBH-150 1/30 5/150 (.3954) (.0791) .5 2.5 1 1 2 1 4 75 34

1305DB-350

1305DBH-350 1/70 5/350 .5 2.5 1 1 2 1 12 105 48

1305DB-700

1305DBH-700 1/140 5/700 .5 2.5 2 1 2 1 26 175 80

Model Piston Assembly Piston Net

Number Pressure Range Piston Area Value Number of Weights by Value Weight

Pascal T

ype

Low

High

Low

High

Low High

L-50 L-100 L-200 L-400 L-500

H-250 H-500 H-1000 H-2000 H-2500

lbs.

1305DA-2000

1305DAH-2000

100/2000

--

50 250

1

2126329

1

1305DA-10000

1305DAH-10000

1305DA-15000

1305-DAH-15000

100/2000 500/10000 50 250 1 1 2 1 2 65 30

.

0613 in.2.0123 in.

2

100/3000 500/15000 (.3954) (.0791) 50 250 1 1 2 1 4 75 34

1305DA-35000

1305DAH-35000

100/700 500/35000

50 250 1 1 2 1 12 105 48

1305DA-70000

1305DAH-70000

Dimensions in ( ) are square centimeters

100/14000 500/70000 50 250 2 1 2 1 26 175 80

kg

.

TABLE 2-1

Page 6

ressure values produced by the pump are able to be

P

learly read to within ±0.25% accuracy of the span of the

c

recision test gauge selected for testing. Certification of

p

test gauge accuracy traceable to the N.I.S.T., is a v ailab le

upon request. A hand jack set, three wrenches, spare Orings, and special adapter for making connections to pressure outlets that do not accommodate cone pipe seating,

are included with each unit.

Test pump accessories include lower and back connection

offset pipe assemblies, with pipe adapters for

1

⁄

4 and

1

⁄

2

NPT connections.

n all metal, double-latched, top handle carrying case is

A

upplied with the complete tester to hold all fittings and

s

attachments.

2.2.2 Theory of Operation – 1327D

The operating principle behind the 1327D Test Pump is a

simple form of comparison. Pressure produced by the

pump is equally distributed by the manifold to a test gauge

and to a device being calibrated or check ed. The reading

of the test gauge serves as the reference to which other

device readings are compared against.

Selection of the test gauge range is the determining factor

in establishing the precision to which a comparison check

is to be made. Test gauge accuracy is expressed as a percentage of its span.

Proper selection of the test gauge range must be made to

minimize the amount of the unit error. If a 5,000 psi

(35,000kPa) range test gauge were used to test de vices

whose span values were less than a fourth of the test

gauge range, the unit error of 12.5 psi (87kPa) would be

greater than 1% of the test pressure. Therefore, it is important to select a test gauge that has a full scale range equal

to or only slightly in excess of the pressure value to be

measured.

2.2.3 Specifications – 1327D

Accuracy:

Test Gauges: Ashcroft solid front type 45-1082-02L-XAZ,

1

4

⁄

2˝ dial size (120mm case). Bourdon tube materials for

1

⁄

4% of 1% of test gauge span.

1327D and DH are bronze and Monel. Bourdon tube

materials for 1327DO are bronze and Monel.

Pump: T

wo stage, lev er operated gener ates 10,000 psi

(70,000kPa) with 28 pounds (12.7kg) of force on lever

handle.

Pump Body:Alumin

with bak

ed blue epoxy finish.

um, corrosion inhibited and coated

Shuttle Valve: Stainless steel bypass valv e that controls

rate of pressure increase and reduces operator effort

when working at high pressure.

Displacement Valve: A fine pitched threaded valve road

permitting vernier adjustments to fluid volume to provide

precise changes. Limit stops prevent road remo v al during

normal operation.

Mounting: F

our bench mounting holes located in base f

or

positive mounting to any level surface.

o coned pipe assemblies

Instrument Connections: T

provide vertical calibration capability for back and low er

connected gauges. Standard

inch inter

nal NPT fitting adapters are supplied.

w

1

⁄

4 inch internal NPT and

1

⁄

2

Operating Fluid: 1327D – Light grade machine oils, auto-

e petroleum base SAE 20 oils or other equiv

motiv

alent fluids suitable for use with Buna N O-ring materials. 1.5 pints

required (.7 liters).

327DH –Most hydraulic oils of phosphate ester base,

1

rake fluids, skydrol, pydr aul etc., suitab le for use with

b

utyl or Ethylene-Propylene O-ring materials. 1.5 pints

B

required (.7 liters).

1327DO – Distilled water with compatible corrosion

nhibitor. A .1% solution of sodium dichromate is a suitable

i

nhibitor. 1.5 pints required (.7 liters).

i

2.2.4 Certification:

Standard –

Master gauges are calibrated on NIST trace-

able standards, no certification documentation provided.

Optional (CD-4) – Individual certified calibration chart

(NIST traceable) for each master gauge.

.0 SETTING UP THE TESTER

3

3.1 Inspection

3.1.1 Component Check 1305D

The deadweight tester, as shipped from the f actory, contains all of the components necessary for operation except

pump fluid. Depending upon the model and pressure

range selected, the total number of weights, weight bo xes

and piston and cylinder assemblies will vary. Refer to

Specifications, Section 2.1, Table 2-1 for model clarification.

3.1.2 Component Check 1327D

The portable test pump, as shipped from the factory, contains all of the components necessary for operation except

pump fluid. Depending upon the model and pressure

range selected, the total number and their ranges will vary.

Refer to Specifications , Section 2.2, Table 2-3 f or model

clarification.

3.1.3 Claim for Missing or Damaged Goods

In the event it is determined that an item is missing or

damaged, contact Customer Service immediately at the

address indicated in Section 1.0. Damaged merchandise

and the packaging materials must be held for inspection

by authorized Ashcroft Inc. personnel or the responsible

carrier. Disposition of damaged or missing goods will be

determined after inspection has been performed on location, or at the discretion of the manufacturer ,at the factory.

Inspection may be waived if circumstances, as judged by

the manufacturer , preclude its necessity.

3.2 Installation Type 1305D

3.2.1 Set-up Pr

ocedure (See Figure 2-1)

To remove the tester from the case, release the spring clip,

depressing the clip by hand, grasp the pump reservoir and

lift up the back end of the pump assembly.

ving removed the pump assembly from its carrying

Ha

case, remove the two plastic shipping plugs .

Select a lower connection (64) or back connection (66) offset pipe and connect to inner pump body outlet as shown

in Fig. 2-1.

Remove the reservoir filler plug (35) and fill reservoir with

operating fluid.

3.2.2 Bench Space Required (See Figure 1-1)

w a space:

Allo

10 inches (25.4 cm) width

27 inches (68.6 cm) depth

22 inches (55.9 cm) height – allows for maximum load of

deadweights

e Space Required

3.2.3 Stora

One Tester Bo x:

101⁄

g

2 inch (2.6 cm); 22

1

⁄

2 inch (57 cm) depth; 10 inch (25

cm) height

Page 7

nit Of Model Tools & Net Weight

U

easure Number Case Access. Gauge Range(s) Included lbs. kg

M

1327*

1327H* – – – – – – 12 5

1327O

1327D

327DH X X – – – – 34 15

1

327DO

1

1327DG-2

1327DGH-2 X X 0/150 – – – 36 16

1327DGO-2

327DG-6

1

327DGH-6 X X 0/150 0/600 – – 38 17

1

327DGO-6

psig

1

1327DG-50

1327DGH-50 X X 0/150 0/600 0/5000 – 40 18

1327DGO-50

1327DG-100

1327DGH-100 X X 0/150 0/600 0/5000 0/10000 42 19

1327DGO-100

1327DMG-10

1327DMGH-10 X X 0/10 – – – 36 16

1327DMGO-10

1327DMG-40

1327DMGH-40 X X 0/10 0/40 – – 38 17

kg/cm2

1327DMGO-40

1327DMG-250

1327DMGH-250

X X 0/10 0/40 0/250 – 40 18

1327DMGO-250

1327DMG-600

1327DMGH-600 X X 0/10 0/40 0/250 0/600 42 19

1327DMGO-600

1327DBG-10

1327DBGH-10 X X 0/10 – – – 36 16

1327DBGO-10

1327DBG-40

1327DBGH-40 X X 0/10 0/40 – – 38 17

bar

1327DBGO-40

1327DBG-250

1327DBGH-250 X X 0/10 0/40 0/250 – 40 18

1327DBGO-250

1327DBG-600

1327DBGH-600 X

X

0/10 0/40 0/250 0/600 42 19

1327DBGO-600

1327DAG-1000

1327DAGH-1000 X X 0/1000 – – – 36 16

GO-1000

A

1327D

1327DA

1327D

G-4000

GH-4000

A

X X 0/1000 0/4000 – – 38 17

Pascal 1327DAGO-4000

(kPa) 1327DAG-25000

AGH-25000 X X 0/1000 0/4000 0/25000 – 40 18

1327D

1327DAGO-25000

G-60000

A

1327D

1327DAGH-60000 X X 0/1000 0/4000 0/25000 0/60000 42 19

1327DAGO-60000

*Includes Test Pump Only

T ABLE 2-2

Page 8

One Weight Box:

10 inch (25 cm) width; 10 inch (25 cm); 10 inch (25 cm)

height

Storage space dimensions are larger than actual size of

ester carrying case and deadweight carrying case by

t

approximately _ inch, (1.3 cm), in order to facilitate ease of

handling in storage.

Note: For catalog numbers 1305D, DH-100, 1305DM,

DMH-150, 1305DB, DBH-700 and 1305DA, DAH-

00 allow storage space for two weight boxes.

7

3.3 Operation 1305D

3.3.1 Piston and Cylinder Selection

The 1305D Tester is a dual range device in that most

-models utilize two interchangeable piston and cylinder

assemblies for measurement of pressure throughout the

entire range. Each piston and cylinder assembly has a

minimum and maximum operating range. First, determine

what pressure points need to be measured and select the

appropriate assembly. The pressure range of the assemblies is shown in Table 2-1. When priming the pump the

high pressure piston and cylinder assembly should be used.

3.3.2 Priming the Pump

The offset pipe (64 or 66 Figure 2-1) should already be

secured in place and the reservoir should contain the

operating fluid (refer to Installation Section 3.2).

Close the release valve (37) by turning it clockwise and

open the air vent by loosening the filler plug (35) a few

turns. The shuttle valve (51) should be pulled outward

from the pump body, the end of the knob approximately

even with the edge of drip pan. In this position the high

volume displacement mode is selected and the pump is

self-priming. Operate the pump handle several times using

full strokes, until you see fluid appear in the outer pump

body outlet.

The cone seat (82) is located in the base of the outerpump body outlet and serves as the sealing surface

between the bottom of the piston and cylinder assembly

and the pump body. Confirm the coned end of the seat is

facing up and the cylindrical end of it is facing down.

Thread the high pressure piston and cylinder assembly

(79) or (67) into the outer body outlet as shown, using the

wrenches provided.

Operate the pump handle a few more times until fluid is

ed at the end of the offset pipe. Connect the gauge

v

obser

or other device to be tested to the offset pipe. For purposes of priming, the device must be designed to withstand

the full operating pressure of 10,000 psi (70,000kPa). If a

lower range device must be used, extreme care must be

exercised to a v oid o verpressuring its pressure element.

Seal the connection to the device by tightening nut adapter

(62) and adapter (60) until the coned end of the pipe is

, rotate the device for view-

orced into its inlet. If necessar

f

y loosening nut adapter (62), set it to the proper posi-

ing b

y

tion and retighten nut adapter.

Again, operate the pump handle a few more times. After a

few strokes positive pressure will develop and the pump

handle will begin to resist pumping action. Raise the pump

handle to its upper

most travel position. Loosen the bleed

screw (30) a half turn counter clockwise and slowly operate the pump handle through a do

ent. Close the b

ws steadily from the b

flo

leed v

wnw

ard strok

e until fluid

leed scre

w

just prior to completing the downward handle motion.

Repeat this action until no air bubbles are observed in the

fluid flow. (Note – the bleed screw must be closed when

he handle is being raised). Push the shuttle valve in

t

owards the pump body and continue pumping to the

t

esired test pressure. Open the release valve (37) to v ent

d

the pressure. To check operation pull the shuttle valve outward, close the release valve and operate the pump handle several times . When handle resistance is f elt, push the

shuttle valve inward and continue pumping within the

range of the test device.

Entrapped air will prevent the pump from operating in the

high pressure valve position or cause it to achie v e only

partial pressure. Repeat the above bleed procedure as

necessary to assure all air is removed. Once air is

removed the pump will continue to operate without further

attention providing the reservoir level is maintained.

3.3.3 Weights

The weight set consists of a selection of various masses

that will produce desired pressure increments when operated with the appropriate piston and cylinder assembly.

Each weight is stamped with two pressure values. When

applied to the high pressure piston and cylinder assembly

the equivalent pressure value is indicated ne xt to the letter

“H”. Conversely, when applied to the low pressure piston

and cylinder assembly the equivalent pressure value is

indicated next to the letter “L”. The piston and piston platform also contribute to the total mass. Their equivalent

pressure value is stamped on the top of the platform.

During normal operation, selected weights are added to

the plate and piston assembly to equal the desired pressure value.

3.3.4 Levelness

The deadweight tester must be level to function properly.

The unit may be leveled byplacing a bubble type level on

top of the piston plate and revolving it slowly. Shims ma y

be used between drip pan and bench to level the piston

plate. The unit is level when the position of the bubble

does not change within the glass as it is rotated on top of

the piston assembly.

3.3.5 Making the Test

Add weight to the piston plate to give desired calibrating

pressure.

Pull the shuttle valve (51) outward from the body and close

the pressure release valve (37). Operate the pump handle

until the fluid pressure forces the piston to raise the

weights. When pumping, the weights should be rotated

slowly to decrease cylinder wall friction. If pump handle

resistance is difficult and the weights have not risen, push

the shuttle v

shuttle v

alve pushed in, the fluid displacement of each

alve inw

ard and contin

ue pumping. With the

stroke is reduced, thereby requiring less effort to continue

pumping.

The piston assembly has a maximum lift of

cm). It is recommended that readings be tak

point, or

3

⁄

8 inch (1 cm) lift. Small adjustments to the piston

3

⁄

4 inch (1.9

en at mid-

lift can be made with the pump handle or the displacement

e (41).

alv

v

Improper readings will result if the piston plate is so low

that it rests on the b

ushing, or so high that the inter

nal

stop on the piston assembly is touching the underside of

the bushing.

Spin the weights by hand and take readings only when the

weights are spinning. Speed of rotation is unimportant,

although a slo

w speed is more con

venient and

recommended.

To release pressure, turn valve (37) counterclockwise slo wly.

Page 9

igure 2-1Ashcroft Portable Deadweight Tester 1305D

F

Page 10

.3.6 T o Dismantle

3

o replace the tester in its case, remove the gauge offset

T

ipe assembly (64 or 66) and the piston and cylinder

p

assembly (67 or 79). Install shipping plugs in body outlet

holes. Screw in the displacement valv e (41) until it stops .

Close the vent plug (35). Open the release valve (37)

approximately _ turn. Replace the tester in its case, reservoir last. Engage the spring clip catch.

3.3.7 General Precautions

It is important that the deadweight tester be connected to

a leak tight system.

he deadweight tester should be set-up so that the axis of

T

he located piston is vertical, the weights carefully cen-

t

tered on that axis, and the piston rotated during use. The

purpose of the rotation is to spread the lubricant over the

entire surface between piston and cylinder , so that there

will be no metal-to-metal contact. If rotation is not maintained, the lubricant film will not cover the surface properly,

and readings will be in error.

The high and low pressure piston assemblies hav e an

internal overload stop, which prev ents the piston and cylinder from being forced apart if weights are accidentally

removed.

3.3.8 Operating Fluids

Standard T ester:

Any medium weight oil may be used (including automotive

oils S.A.E. 10, 20 or 30) S.A.E. 20-W recommended.

Hydraulic Tester:

Any hydraulic fluid (silicate or phosphate base). Skydrol or

Pydraul is suitable.

For normal operation, it is not necessary to change the

weight of oil for various pressures. A lighter oil may be

used where low pressures are being checked, and a heavier oil where higher pressures are being tested.

The reservoir can be refilled while the tester is operating

under pressure.

3.3.9 Caution

Standard testers designed for oil service may not be used

with water for oxygen service.

3.3.10

Hydraulic service testers should not be filled with water or

any oil other than hydraulic fluid. Serious pump failure may

occur due to O-ring damage.

3.4. Installation Type 1327

3.4.1 Set up Pr

o remove the test pump from the case, release the spring

T

ocedure (See Figures 2-2)

clip, depressing the clip by hand, grasp the pump reser-

, and lift up the bac

oir

v

k end of the pump assembly

.

Remove the two plastic shipping plugs from the outlet connections

v

. Remov

oir filling hole. Remove the offset pipe (64) or (66) from

e the threaded filler plug (35) from reser-

the carrying case and connect to the inner pump body out-

e the straight pipe

let as sho

wn in Figure 2-2. Remo

v

extension (58), and assemble to outer vertical pump body

outlet as shown in Figure 2-2.

3.4.2 Connecting The Gauge (See Figure 2-2)

Select a test gauge that is adequate for the pressure

ange desired. Assemb

r

le the test gauge to the str

aight

pipe extension, using adapter nut (62), collar (61), adapter

(60) and reducer bushing (59).

Seal the connection by tightening nut adapter (62) and

adapter (60) until the coned end of the pipe is forced into

he gauge socket. Rotate the gauge for vie wing b y loosen-

t

ng nut adapter (62), setting the gauge to the desired posi-

i

ion, and re-tightening nut adapter.

t

Repeat the above procedure to connect the gauge being

tested to the offset pipe assembly (64) or (66).

3.4.3 Bench Space Required

Allow a space:

10 inch (2.5 cm) width

23 inch (5.8 cm) depth

22 inch (5.6 cm) height allows for testing gauges up to 8.5

nch (250 mm) size

i

3.4.4 Storage Space Required

101⁄

2 inch (27 cm) width

1

⁄

2 in (57 cm) depth

22

10 inch (25 cm) height

Storage space dimensions are larger than actual size of

test pump carrying case by approximately 0.5 inch (1.3

cm), in order to facilitate ease of handling in storage.

3.5 Operation 1327D

3.5.1 Test Gauge Selection

The portable test pump is used for calibrating instruments

such as pressure gauges, pressure switches or other

pressure devices rated up to 10,000 psi (70,000kP a).

First, select the proper test gauge, depending upon the

pressure range desired. When priming the pump a test

gauge rated to 10,000 psi (70,000kPa) should be used.

3.5.2 Priming The Pump

The offset pipe (64 or 66 Figure 2-2) and straight pipe

extension (58) should already be secured in place and the

reservoir should contain the operating fluid (refer to installation Section 3.4).

Close the release valve (37) by turning it clockwise and

open the air vent by loosening the filler plug (35) a few

turns. The shuttle valve (30) should be pulled outward

from the pump body, the end of the knob approximately

even with the edge of the drip pan. In this position the high

volume displacement mode is selected and the pump is

self-priming. Operate the pump handle several times using

full strokes, until you see fluid appear at the top of the

straight pipe extension. Connect the test gauge to it (refer

to Installation Section 3.4 for proper gauge connection).

ate the pump handle a few more times until fluid is

Oper

observed at the end of the offset pipe. Connect the gauge

or other device to be tested to the offset pipe. For purposes of priming, the device must be designed to withstand

the full operating pressure of 10,000 psi (70,000kPa). If a

lower range device must be used, extreme care must be

exercised to a v oid o verpressuring its pressure element.

Seal the connection to the de

vice by tightening n

ut adapter

(62) and adapter (60) until the coned end of the pipe is

forced into its inlet. If necessary, rotate the device for view-

y loosening n

ing b

ut adapter (62), set it to the proper posi

tion and retighten nut adapter.

Again, oper

ate the pump handle a fe

w more times. After a

few strokes positive pressure will develop and the pump

handle will begin to resist pumping action. Raise the pump

handle to its uppermost tra

el position. Loosen the b

v

leed

screw (51) a half turn counter clockwise and slowly operate the pump handle through a downward stroke until fluid

flows steadily from the bleed vent. Close the b leed scre w

just prior to completing the downward handle motion.

Repeat this action until no air bubbles are observed in the

. (Note – the bleed screw must be closed when

w

fluid flo

the handle is being raised). Push the shuttle valve in

-

Page 11

owards the pump body and continue pumping to the

t

esired test pressure. Open the release valve (37) to v ent

d

he pressure. To check operation pull the shuttle valve out-

t

ward, close the release valve and operate the pump handle several times . When handle resistance is f elt, push the

shuttle valve inward and continue pumping within the

range of the test device.

ntrapped air will prevent the pump from operating in the

E

high pressure valve position or cause it to achie v e only

partial pressure. Repeat the above bleeding procedure as

necessary to assure all air is removed. Once air is

removed the pump will continue to operate without further

attention providing the reservoir level is maintained.

3.5.3 Making The Test

Turn displacement piston handle (41) to mid-position, so

that it may be used for setting an e xact pressure on the

gauge. The displacement piston has internal stops which

prevent unscrewing or accidental loss of pressure .

Clockwise rotation of displacement piston will produce an

increase in pressure; counterclockwise will decrease

pressure.

Prior to taking readings, both gauges should be fingertapped lightly at the center of the gauge face, to eliminate

any movement friction. Note the pressure readings on the

test gauge and the gauge under test. If the pressure indicated on the gauge under test is not equal (within the tolerance of the gauge) to the pressures of the master test

gauge, the gauge being tested requires calibration.

CAUTION:

Do not pump handle to pressures greater than the pressure range of the gauges connected to the test pump, as

this may damage the gauges.

3.5.4 T o Release Pressure

Open release valve slowly (37), until pressure returns to

zero. Do not loosen any connections until pressure in the

gauge tester has reached zero, as indicated on the test

gauge.

If additional gauges are to be tested, close the release

valve when the pressure reaches zero. This will prevent

complete drainage of oil in the tester back to the reservoir.

Unseal the gauge that has been tested by unscrewing

adapter nut (62) from connector (60) several turns.

Unscrew the gauge from bushing (59) if used, or connector (60), and remove.

ve the test gauge in the same manner as the gauge

Remo

under test.

3.5.5 T o Dismantle

To replace test pump in case, remove gauges and both

tube assemb

Close filler plug (35).

3.5.6 Operating Fluids

Standard T est Pump:

Any medium weight oil may be used (including automotiv e

oils S

Hydraulic Test Pump:

Any hydraulic fluid (silicate or phosphate base). Skydrol or

Pydraul is suitable.

Oxyg

Distilled or demineralized water with a compatible corrosion inhibitor added. A .1% solution of sodium dichromate

is a suitable inhibitor.

For normal operation it is not necessary to change the

lies. Put shipping plugs into pump and tighten.

.A.E 10, 20 or 30) S.A.E. 20-W recommended.

est Pump:

en T

eight of oil for various pressures. A lighter oil ma y be

w

sed where low pressures are being checked, a heavier oil

u

here higher pressures are being tested.

w

The reservoir can be refilled while the test pump is operat-

ing under pressure.

3.5.7 Caution

Standard testers designed for oil service may not be used

with water for oxygen service.

.5.8

3

Hydraulic service testers should not be filled with water or

any oil other than hydraulic fluid. Serious pump failure may

occur due to O-ring damage.

.0 F ACTORS AFFECTING OPERATION OF

4

EADWEIGHT TESTERS

D

4.1 Deadweight Tester Accurac y

Excellent accuracy is possible using the deadweight tester

through analysis and control of certain factors. If the

tester’s rated accuracy of 1/10th of 1% is adequate , then

the nominal pressure (sum of the denominations of the

weights loading the piston) may be assumed to be correct.

The pressure normally developed is determined by this

formula: Deadweight Tester Pressure =

Mass of weights plus piston mass

Effective area of piston and cylinder

P = (M-ph) g

P =pressure

M = mass of the load on the piston

A =effectiv e area of the piston in sq. inches , or sq. cm

g/gs =ratio of the v alue (g) of g ravity at the point of use to

the standard value of gravity (gs)

P =density of liquid used in test

h = difference in level between gauge being tested, and

the bottom of the piston

The deadweight tester is capable of measuring pressures

to proper corrections after analyzing these factors.

4.2 Gravity , Calibrated Weights

eights furnished are calibrated at standard gravity of

W

980.665 gals. If precise accuracy is required, the error

introduced by change of weight due to change in gravity at

the locality should be calculated and included in results.

The mechanism of an Ashcroft Pressure Gauge includes

a Bourdon tube and geared movement, which is unaffected by variations in gravity. Conversely, the pressure developed by a deadweight tester is proportional to the value of

gravity. Readings of this type pressure gauge will correspond to those of a deadweight tester when the tester is

subjected to standard gravity (gs = 980.665 gals. in the

International System). In southern sections of the United

, the value of g

States

less than the standard v

vation above sea level (a) for an area are known, the

ximate v

appro

this formula:

Ø = Latitude (Degrees)

a = Elevation abo v e sea level (ft)

ective Measured Area: Chamber

Eff

4.3

The effective area of the deadweight tester may be determined by the average of the cross sectional area of the

piston and the area of the cylinder bore. This effective area

A gs

ravity may be se veral thousandths

alue, if the latitude (Ø) and the ele-

alue of (g) in gals

g = 980.632-2.586 COS 2Ø

+.003 COS 4Ø - .000094a

. may be calculated from

Page 12

s affected somewhat by temperature, and by the elastic

i

istortion of the piston and cylinder when pressure is

d

eing applied. The effective area of a stainless steel piston

b

and cylinder increases approximately .068% with a 50

degree F (28 degree C) change in temperature. The

pressure will, therefore be less than indicated at high

temperatures.

.4 Mass, Height, and Buoyancy

4

The density of air at room temperature and sea level pressure is about 0.0012 grams/c.c., and the mass of the piston assembly and weights under these conditions will be

reduced by about one part in 7,000 or .014%. When the

submerged part of the piston has a uniform cross section,

as with the 1305D Deadweight Tester, a b uoyancy correc-

ion is not necessary. In other designs , the piston is some-

t

imes enlarged to provide a stop for its upward motion or

t

for increased strength. If these enlargements are submerged in liquid, a buoyancy correction is necessary.

4.5 Absence of Friction

By rotating the weights and piston, friction effects are

greatly reduced.

4.6 Head of T ransmitting Fluid

Oftentimes, the gauge being tested, or the point at which

pressure is being measured, is not at the same level as

the lower end of the piston. A correction, therefore, should

be made for the pressure distance between these points;

the height is considered positive when the gauge is above

the piston. When oil is used in the gauge tester, the correction will be approximately 0.03 psi (.2 kPa) for each

inch (2.54 cm) difference in level.

4.7 Method of Operation

It is important that the piston be kept floating in mid-position, either spinning or oscillating.

4.8 Levelness

The piston assembly should be vertical to within ±1

degree. A 3 degree tilt to piston axis may cause a .13% of

1% error. The deadweight tester is manufactured and tested to 1/10th of 1% accuracy, to this degree of levelness. A

tilt piston/cylinder axis causes excessive friction, due to

side loading of the piston against the cylinder.

4.9 Cleanliness

The weights have been manufactured and tested to a precision of 0.05%. A buildup of dirt and grease may cause

the weight value to exceed its original tolerance and

produce erroneous pressure readings.

Periodically clean the weights to assure proper

performance.

5.0 MAINTENANCE INSTR

UCTION

5.1 General Maintenance

The Deadweight tester and test pump are designed to

serve as precise pressure measuring standards. They are

precision built units and should be cared for in the same

manner as other sensitiv

e laborator

y equipment. General

maintenance is limited to cleaning and replacement of Oring packings, which can be done with tools supplied with

the equipment and requires only limited disassemb

ly of

the gauge tester.

The piston suppor

ting the w

eight platf

orm has been manufactured to very close tolerances. It has an area accuracy

of 1/20th of 1% and a weight accuracy of 1/20th of 1%.

The deadw

eights ha

e been cer

v

tified tr

le to N.I.S.T.

aceab

with the accuracy of the finished weights better than

1/20th of 1%. To maintain deadweight tester accuracy,

andle the weights with care and keep the piston and

h

ylinder in clean condition.

c

The tester should be flushed with a solvent occasionally,

preferably e very six months, so that operating fluid is

always clean. This will prolong component life , and pro vide

rotection against possible sticky action between the pis-

p

on and cylinder. After cleaning, always lubricate parts

t

efore assembly.

b

If a deadweight tester is not used for long periods of time,

or if a piston and cylinder assembly is being replaced, the

iston should be removed from the cylinder and coated

p

ith the hydraulic fluid, so that it never operates in a dry

w

tate. When removing or replacing the piston, it should be

s

rotated back and forth.

Should a piston or cylinder wear excessively, the tester will

leak oil at a high rate, and will not be operable. A ne w piston and cylinder assembly should be installed.

Piston wear will result from improper or contaminated

lubrication, excessive dirt, or from several y ears of

continuous use.

5.2 Cleaning

Both the Tester and Test Pump should be cleaned thoroughly whenever the operating fluid is seriously contaminated with dirt, grit, or chemicals. A good practice is to

clean the test unit prior to anticipated periods when the

unit will not be in use.

5.3 T o Disassemble for Cleaning

(See Figure 2-1, Figure 2-2 and Figure 5-1)

It is necessary to disassemble only those components

which come in contact with the operating fluid. Complete

disassembly is rarely necessary.

a.Remove pipe e xtension assemb ly (58) or piston and

cylinder assembly(67) and (79).

b.Then remove low er or bac k connection pipe assemb ly

(64, 66).

5.4 Removing Pump Handle and Piston

a.Remove f our retaining rings (8).

b.Slide out twoclevis pins (9).

c. Remove clevis (10).

d.Lift hand assembly (4) with piston pin (7) piston (20)

O-ring packing (12, 19) and back-up ring (11)

attached to it, out of piston sleeve (6).

. Remove back-up washers (18, 11) and O-ring pac king

e

(12, 19).

f. Unscre w piston (20)

g.Remove piston slee v e (6) and O-ring pac king (45, 16)

and back-up washers (46, 17)

oir and Fill T ube

Removing Reser

5.5

Unscrew filler plug (35) from reservoir.

a.

v

b.Remove gasket (36).

c. Remo

e reserv

v

oir (5) by remo

ving three screws (24).

d.Twist reservoir to free O-ring packing (21) seat.

e. Remove O-ring packing (21) from body (2).

f. Remove fill tube assemb ly (23) and O-ring pac king (27).

g.Remove plug (22).

5.6

Remo

ving Shuttle V

alve, Shuttle V

alve Plug

and Check V alve

a.Remove set screw (33) and spring (32).

b.Slide shuttle valve piston (31) out of body (2). Operate

back and forth as necessary to dislodge pin (31)

engagement.

c.

valve piston cavity using a plastic shaft less than

1

⁄

8

ve shuttle pin (31) by pushing it into the shuttle

Remo

inch (3mm) in diameter.

Page 13

.Unscrew shuttle valv e plug (43) and remo v e O-ring

d

acking (27).

p

. Remove check v alv e spring (14) and chec k v alve (44).

e

f. Remove O-ring packing (15) from check valve (44).

5.7 Removing Bleeder Valve and Check V alve Assembly

.Unscrew bleeder v alv e (51)

a

. Unscrew bleed plug (50) and remove O-ring packing

b

27).

(

c. Remove valve spacer (29) check v alve spring (14)

and check valve (44).

d.Remove O-ring (15) from check v alv e (44).

.8 Removing High Pressure Check V alve

5

.Unscrew plug (28) and remove O-ring pac king (27).

a

b.Unscrew adjusting screw (26).

c. Remove guide rod (13), check valve spring (14), and

check valve (44).

d.Remove O-ring packing (15) from chec k v alv e (44).

5.9 Removing Release Valve

a.Remove release v alv e assemb ly (37) and O-ring

packing (27)

b.Disassemble valv e assemb ly b y rotating handle

counter-clockwise until valve stem is free from valve

body.

c. Remove O-ring packing from valve stem.

d.Remove screw (38) and seal (39) b y turning counter-

clockwise.

e.Remove O-ring packing (40).

5.10 Removing Displacement V alve

a.Remove displacement v alv e assemb ly (41).

b.Remove O-ring packing (27).

c. Remove handle from stem by rotating handle counter-

clockwise. This is not required for normal cleaning.

d.Rotate the stem clockwise (using screwdriver in the

slot at the top of the stem) until it is free from body.

e.Remov e n ut bac k-up w ashers and ring packing from

stem.

5.11 Stem Body from Drip Pan

a.Take out three bolts (25). This is not required for

normal cleaning.

b.Remove body assemb ly (2) from drip pan (3). This is

not required for normal cleaning.

5.12 Inspection

Visually inspect these parts for wear, damage, chips ,

cracks and stripped threads:

Body Assembly Threads

Piston

Piston Slee

Displacement Stem and Mating Surf

Back-up Washers

Moving O-r

Dead Weights

Piston and Cylinder Assembly – 1305D

Test Gauges – 1327D

Back-up washers must fit snugly into piston slee v e and

into displacement v

ing) packing for pinch marks, tearing or extrusion. Check

all valve seats f or scratches and roughness .

Replace all worn or damaged parts. Replace all O-ring

packings at each overhaul. Coat O-ring packings with suitab

tearing during assembly and tightening of connections.

5.13 Reassemb

When reassembling, use where possible the wrenches

supplied with the equipment. These wrenches permit

le lubr

icant bef

e (6)

v

ackings

ing P

. Then check static (non-mo

e body

alv

ore replacing, to pre

y

l

ace in Body

ent stic

v

king and

nough leverage to seal all connections . Excessiv e tight-

e

ning of parts with tools other than those supplied may

e

ause distortion and eventual failure of threaded portions

c

of the tester body assembly casting. When replacing Oring packings, coat them with suitable lubricant to prev ent

sticking and tearing during assembly and tightening of

connection.

.14 T o Reassemble

5

Body assembly on drip pans.

Replace body assembly (2) on drip pan (3) using bolts (25).

.15 Replacing Displacement Valve

5

.Place O-ring packing between back-up washers .

a

. Attach back-up washers and O-ring packing to dis

b

placement valve stem with nut.

c. Thread stem into body from the bottom – use screw

driver in the slot at top of stem.

d.Screw stem through body until the back-up washers ,

and O-ring packing are fully enclosed in the body.

CAUTION: Do not damage O-ring packing when

threading stem through body.

e.Screw handle onto stem.

f. Replace displacement v alv e assembly (41) with

O-ring packing (27) in body assembly (2).

5.16 Replacing Release Valve

a.Place O-ring packing (40) in body casting (2) hole.

b.Insert seat (39) into body casting hole.

c. Thread & tighten screw (38) into body casting hole.

CAUTION: Be sure that stem of seat (39) fits into

screw hole.

d.Place O-ring packing on valve stem.

e.Screw handle onto valv e stem.

f. Scre w v alve stem into body until end of stem does not

extend beyond valve body.

CAUTION: Do not damage O-ring packing when

threading valve stem through valve body .

g.Replace O-ring packing (27).

h.Replace release valve assemb ly (37) in body

assembly (2).

5.17 Replacing High Pressure Check Valve

a.Place O-ring packing (15) on check valv e (44).

b.Slide check valve (44), check valve spring (14), and

guide rod (13) into body assembly (2).

c. Replace adjusting screw (26) and screw it in until it

stops.

d. Then turn (26) back two complete revolutions.

Replace plug (28) with O-r

.

e

assemb

5.18 Replacing Bleeder Valve and Chec k

a.Replace O-ring packing (15) on check valv e (44).

Slide chec

.

b

v

c. Replace bleed plug (50) with O-ring packing (27) into

body assemb

5.19 Replacing Shuttle Valve, Shuttle Valve Plug and

-

v

a.Insert shuttle valve piston (3) into body (2).

b.Slide shuttle pin (31) into 1/8 inch (3mm) diameter

opening adjacent to fill tube (23) port. Apply slight

inserting pressure to shuttle pin (31) with plastic shaft

and operating shuttle valve (30) to insure proper

pin engagement.

c. Replace spring (32) directly behind shuttle pin (31)

and secure with set screw (33). Set screw must be

recessed b

d. Replace O-ring packing (15) on check valve (44).

ly (2).

Valve Assembl y

k valve (44), check valve spring (14) and

alve space (29) into body assembly (2).

ly (2).

alve

k V

Chec

y .050 inch (12mm) minim

ing packing (27) in body

um.

Page 14

igure 2-2Ashcroft Portable Test Pump – Type 1327D

F

Page 15

. Slide check valve (44) and check valve spring (14)

e

nto body assembly (2).

i

5.20 Replacing Reservoir and Fill Tube

a.Replace plug (22).

b. Replace fill tube assembly (21) and O-ring packing (27).

. Replace O-ring packing (21) on body assembly (2).

c

.Replace reservoir (5) using three screws (24).

d

. Replace filler plug (35) and gasket (36) on body.

e

5.21 Replacing Pump Handle and Piston

a.Replace piston sleeve (6) and O-ring packing (45, 16)

nd back-up washers (46, 17) in body assembly (2).

a

. Place O-ring packing (12, 19) between back-up

b

ashers (18, 11)

w

c. Attach back-up washers (18,11) and O-ring packing

(12, 19) to piston (20).

d.Lubricate piston and sleeve.

e.Attach assembled piston to handle assembly (4).

CAUTION: Do not damage O-ring packing (12, 19)

when sliding assembled piston into piston sleeve (6).

f. Attach cle vis (10) to handle assemb ly and to body

assembly (2), using clevis pins (9) and retaining

rings (8).

5.22 Replacing Piston/Cylinder Assemblies

The piston/cylinder assembly for a deadweight tester

should be replaced when excessive wear is detected on

any component part. Worn piston assemblies are usually

noted by:

1.Excessive leakage of operating fluid through piston

assembly when under pressure.

2.Seizure of piston in cylinder.

3.Damaged piston plate, damaged cylinder threads, or

damage to any component part that results in inferior

performance, or malfunctioning of the unit.

The piston/cylinder assembly is availab le as a unit only.

This assures the user of maximum accuracy in his

Ashcroft Deadweight Tester and maintains certified traceability to the N.I.S.T.

6.0 WARRANTY – SHIPPING INSTR UCTIONS –

HOW T O ORDER

6.1 Warranty and Limitation of Liability

All products and parts carry a warranty against defectiv e

material and workmanship for period of one (1) year from

date of shipment.

A complete w

made on the standard quotation form at the time of sale.

6.2 Shipping Instructions For Return T o F actory

Pack securely to pre vent possible damage in shipment.

SHIP T

arranty and limitation of liability statement is

O:

Ashcroft Inc.

250 East Main Street

Stratford, CT 06614

Phone: (203) 378-8281

Fax: (203) 385-0402

www.ashcroft.com

email: info@ashcroft.com

IMPORTANT – Obtain written authorization to return

uments that ha

instr

hazardous materials such as mercury and radioactive

solutions.

Please furnish the following information with return of

instrument:

e been in contact with corrosive or

v

HIPPING INSTRUCTIONS

S

Company Name

Phone Number

AX Number – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

F

Person to Contact

Address

–––––––––––––––––––––––––––––––––––––––––––

–

–––––––––––––––––––––––––––––––––––––––––––

–

–––––––––––––––––––––––––––––––––––––––––––

–

email Address

Model

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Serial Number

Symptoms

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Page 16

.4 T r oub leshooting Chart

5

Corrective

Symptom Case Action

Pressure does

not build up when

Insufficient fluid

level in reservoir.

Add fluid.

pumping handle.

iston O-rings

P

orn or ruptured.

w

Inspect O-rings

and replace as

ecessary. If

n

-rings are new,

O

erify their fluid

v

compatibility.

Bleed port check

valve or shuttle

check valve

Inspect O-rings

and replace as

necessary.

inoperative.

Fill tube assembly

and filter plugged.

Remove and clean

fill tube assembly.

Refill reservoir

with clean fluid.

Shuttle valve

pushed in for

small fluid dis-

Pull shuttle valve

outward from

body.

placement when

large fluid displacement is

required.

High pressure

does not increase

when pumping

handle while

shuttle valve is

pushed in.

Air trapped in

pump piston.

Rapid pump handle strokes which

lessen fluid flow

through the pump

Reprime pump.

Operate pump

handle with

smooth moderate

action.

piston.

Pressure builds up

when pumping

handle, but

decreases when

pumping is

stopped.

Leakage at outlet

or gauge connections(s).

High pressure

check valve O-ring

worn or ruptured.

Defective pressure

release valve.

Inspect connec-

tions and tighten

as necessary.

Inspect O-ring and

replace as neces-

sary.

Hand tighten

release valve.

Inspect release

valve seating sur-

aces

f

necessary.

Remove release

valve seat and

inspect O-ring

underneath.

Replace as

necessary.

. Replace as

Corrective

Symptom Case Action

Pump handle rises

after pumping.

Piston plate (with

eadweights)

d

drops rapidly.*

Unable to hold

High pressure

check valve O-ring

worn or ruptured.

Worn piston and

ylinder assembly.

c

Inspect O-ring

and replace as

necessary.

Use a heavy oil

emporarily.

t

Replace piston &

cylinder.

constant pressure.

Stacked dead-

weights wobble

when spinning piston plate.*

Damaged deadweights.

Check deadweights for visible

damage (bends,

dents, nicks, etc.)

and alignment.

Piston plate

assembly will not

spin.*

Too heavy an oil

grade being used.

Flush & fill unit

with proper grade

of oil (SAE 20 or

SAE 10).

Replace piston &

cylinder assembly.

Disassemble and

flush complete test

unit with kerosene

or alcohol.

Reassemble unit.

*These symptoms apply only to the 1305D Deadweight Testers.

Page 17

4A

Page 18

REPLACEMENT PARTS – D SERIES – BLUE COLOR

PORTABLE DEADWEIGHT TESTER – TYPE 1305D

PORTABLE TEST PUMP – TYPE 1327D

Qty.

Item Per

No. Asmy. Part No. Description

1 603D001-01 Body Only, Pump

2

1 LB285A Drip Pan

3

1 603X010-01 Handle

4

A 1 636X003-01 Grip

4

1 LF341A Reservoir

5

1 610C001-01 Sleeve, Piston

6

1 LA810A Pin, Piston

7

4 BA221L Retaining Ring

8

2 LB810A Pin, Clevis

9

0 1 LD278A Clevis

1

11 1 607A002-02 Backup Ring

12 1 607A001-02 “O” Ring

1 LB802 Guide Rod

13

14 3 LA242 Spring, Valve

15 4 SSSS882 “O” Ring

1 607A001-03 “O” Ring

16

17 1 607A002-03 Backup Ring

8 1 6

1

19 2 607A001-01 “O” Ring

0 1 614C001-01 Piston, Dual Diameter

2

21 1 BA122R “O” Ring 2.90

22 1 604A003-01 Plug 15.40

23 1 615B001-01 Fill Tube Assembly 92.70

24 3 605A002-06 Screw, Round Head 1.70

25 3 SAFH37 Screw, Allen Socket Head 1.70

26 1 LK260A Adjusting Screw 8.90

27 6 BA122V “O” Ring 1.70

28 1 LK696A Plug 19.40

29 1 — Spacer, Valve, Use Item 50

30 1 614B002-01 Piston, Shuttle 68.10

31 1 609A001-01 Pin, Shuttle 15.80

32 1 612B001-01 Spring, Shuttle Pin 1.70

33 1 605A001-01 Set Screw 162.00

34 2 LP696 Plug, Shipping 4.40

35 1 604B002-01 Plug, Fill 13.70

36 1 607A003-01 Gasket, Fill Plug 2.60

37 1 LAH292C Valve Assembly, Release 165.00

37a 1 328A105-01 Knob 14.10

37b 1

37c

38 1 LD83A Scew, Seat 13.70

39 1 LD911A Seat 5.50

40 2 BA122U “O” Ring 1.70

41 1 LAG292C Valve Assembly, Displacement 187.00

41a

41 b 1 LE83 Nut 13.40

41c 2 LB122 Backup Washer 1.70

41d

41e

42 1 LA521A Sleeve 19.70

43 1 604B001-01 Plug, Shuttle Valve 59.30

44 3 609B003-01 Check Valve 49.60

45 1 BA122W “O” Ring 1.70

46

50 1 604B004-01 Plug, Bleed 36.70

51 1 609B004-01 Bleed Valve 27.70

52

58

07A002-01 Back

LD870B V

LAH292A Body

1

328A105-02 Knob 14.10

1

LB870A

1

1

1 607A002-04 Backup Ring 2.30

1

1

G292A Body, Displacement Valve 111.00

LA

LEE236

LK227 Pipe Extension Assembly 180.00

up Ring

e Stem 50.20

alv

, Release Valve 88.20

Stem

Nameplate

41.70

4.70

Qty. Unit

Item Per List

No. Asmy. Part No. DescriptionPrice

59 2 LD227A Bushing2 9.50

0 2 LN141 Adapter 25.40

6

61 4 LD186 Collar 9.50

2 4 LD117 Nut, Adapter 25.20

6

3 1 LH227A Extension Pipe 67.00

6

4 1 LJ227 Lower Connection Pipe Assembly

6

5 1 LF227A Lower Connection Pipe 104.00

6

6 1 LG227A Back Connection Pipe 104.00

6

7 — Low Pressure Piston Assembly

6

9 – High Pressure Piston Assembly

7

82 1 LF217 Disc Seat 12.30

83 1 LM141 Adapter 37.10

*Piston and bushing can only be replaced as a complete assembly, the

part number for this assembly is for:

1305DH – part no. 617B001-01 List Price $155.04

1305DH – part no. 617B001-02 List Price $163.83

LM869 psig 528.00

1

LN869 psig 552.00

1

1 617C002-01 “O” Ring Kit, Oil 26.70

1 617A003-01 Overhaul Kit, Oil (see note 1) 180.00

1 LH244A Wrench (1 x 11⁄8) 67.60

1 LH244 Wrench (7⁄8 x 1) 63.30

1 LG244 Wrench (

5

⁄8) 33.30

PARTS IN THE SECTION BELOW ARE USED IN

HYDRAULIC SERVICE UNITS. THESE UNITS CAN BE

RECOGNIZED BY THE INCLUSION OF THE LETTER “H”

IN THE MODEL DESIGNATION.

12 1 607A004-02 “O” Ring 2.10

15 4 BA122H “O” Ring 2.60

16 1 607A004-03 “O” Ring 2.10

19 2 607A004-01 “O” Ring 2.60

21 1 BA122E “O” Ring 4.20

27 6 BA122D “O” Ring 2.50

37 1 LAH292D Valve Assembly, Release 165.00

40 2 BA122G “O” Ring 2.10

41 1 LAG292D Valve Assembly, Displacement 191.00

45 1

1 Overhaul kit includes all O-rings required to overhaul pump as

well as piston and bushing assembly.

BA122F “O” Ring 5.00

1 LGG236A Nameplate, Hydraulic 7.50

1 617C002-02 “O” Ring Kit, Hydraulic 41.10

617A003-02

1

Overhaul Kit, Hydraulic (see note 1)

PARTS IN THE SECTION BELOW ARE USED IN OXYGEN

(DISTILLED

W

A TER) SERVICE UNITS WHICH ARE IDENTIFIED BY THE INCLUSION OF THE LETTER “O” IN THE

MODEL DESIGNATION.

ning Label 2.40

47

58

59 3 LD227B Bushing 36.40

60 3 LN141A Adapter 35.30

61 6 LD186A Collar 12.50

62 6 LD117A Nut, Adapter 34.70

64

83 1 LM141A Adapter 75.90

LK227A

1

1 LJ227A Lower Connection, Pipe Assembly

LKK236

1

Oxygen W

Pipe Extension Assembly 252.00

ar

Page 19

AVAILABLE WEIGHTS & WEIGHT SETS

INDIVIDUAL WEIGHTS

Part

N

umber Units Low High

LF199D psig 1 5

LPF462 psig 2 10

LAZ199D psig 5 25

LAZ199 psig 10 50

LAZ199A psig 20 100

LAZ199B psig 40 200

LAZ199C psig 100 500

PSI WEIGHT SETS

Weight Set

Part Carrying 25 50 100 200 500

Number Case psi psi psi psi psi

LBH199C 1000 psi 1 3 2 3 –

LBH199B 2000 psi 13232

LBH199A 3000 psi 1 3 2 3 4

LBH199* 5000 psi 1 3 2 3 8

LBH199D

*For complete 10,000 psi weight set, order both part no. LBH199 and LBH199D.

with

5000 to

10000 psi

– –

Pressure Range

Number of Weights

by High Pressure Value

– –10

Page 20

Ashcroft Inc. Sales and Customer Service Locations

World Headquarters

U.S.A.

A

shcroft Inc.250 East Main Street

Stratford, CT 06614-5145 U.S.A.

Tel: (203) 378-8281

Fax: (203) 385-0408 (Domestic)

Fax: (203) 385-0357 (International)

email: info@heise.com

www.ashcroft.com

International Operations

Brazil (Willy Plant)

Willy Instrumentos de Medicao e

Controle Ltda.

An Ashcroft Inc. Company

Rua Senador Vergueiro No. 433

09521-320 Sao Caetano Do Sul

Sao Paulo, Brazil

Tel: 55-11-4224-7400

Fax: 55-11-4229-8710

Fax: 55-11-4221-9712

Fax: 55-11-4224-7477

Alexandre Nakashato B14 #

Contact: 55-11-4224-7412

email: alexandre.nakashato@ashcroft.com

Commercial Gauge Plant

Willy Instrumentos de Medicao e

Controle Ltda.

Divisao Commercial Gauge

Rua Joao Pessoa, 620

CEP. 09520-000

Sao Caetano Do Sul, Sao Paulo, Brazil

Tel: 55-11-4223-3900

Fax: 55-11-4227-5163

Contact: Alexandre Nakashato-Sales

email: alexandre.nakashato@ashcroft.com

Canada

Ashcroft Instruments Canada Inc.

151 Steeles Ave. East, Upper Level

Milton, Ontario L9T 1Y1

T

el: 905-864-4989 Ext. 610

Fax: 905-864-7383

email: lloyd.clarke@ashcroft.com

China

Ashcroft China Representative Office

Room 203, First Shanghai Center,

No. 39 Liang Ma Qiao Road

B

eijing, China 100016

Tel: 86-10-8453-5127

86-10-8453-5259

Fax: 86-10-8453-5259

Contact: Mr . Wei Dong (Sales Manager)

(C) 86-13901216821

Mr. Peter W ei (Sales Application Engineer)

(C) 86-13911185210

email: sales@ashcroft.com.cn

wei.dong@ashcrofrt.com.cn

peter.wei@ashcrofrt.com.cn

France

Ashcroft GmbH Sales Office

Division Instrumentation

206 Rue des Campanules, Le Mandinet

F77185 Lognes

France

Tel: 33-1-60-3725-30

Fax: 33-1-60-3725-39

Contact: Jackier Lacamus

email: ashcroft.europe@wanadoo.fr

Germany

Ashcroft Instruments GmbH

Postfach 11 20

Max-Planck-Strasse 1

D-52499 Baesweiler, Germany

Tel: 49-24-01-8080

Fax: 49-24-01-7027

Contact: Mr . Joerg Muller49-24-01-808-134 or

Mr. Dietmar Heinen49-24-01-808-165

email: sales@ashcrofteurope.com

.heinen@ashcrofteurope. com

dietmar

Mexico

A

shcroft Instruments Mexico,

S.A. de C.V .

Henry Ford No. 114

Esq. Foulton

Fracc. Industrial San Nicolas

54030 Tlalnepantla, Edo De Mexico

Tel: 525-55-310-7217

525-55-310-8983

5

25-55-311-2829

525-55-311-2875

Fax: 525-55-310-2608

Contact: Mr . Javier Mendieta or

Ms. Elliette Rovira

email: jmendieta@ashcroft.com.

mxerovira@ashcroft.com.mx

Saudi Arabia

Joint Venture with

Al-Rushaid -Investment Co., Ltd.

P.O. Box 10145, Support Industry Park

Section E, Lot 1, Block 5K

Saudi Arabia 31981

Tel: 966-3-341-0278

Fax: 966-3-341-7624

Contact: D. R. Pai

(P) 966-3-341-0278 x 13 or

(F) 966-3-341-0696Rahul V J

email: drpai@darvico.com

rahul@darvico.com

Singapore

Ashcroft Instruments Singapore Pte. Ltd.

Block 1004 Toa Payoh North

#07-15/17

Singapore 318995

Tel: 65-6252-6602

Fax: 65-6252-6603

Mr.John Wong(Director,Asia Pacific) or

Contact:

Mr.Joseph Tan(Area Sales Manager)

email: Sales@ashcroft.com.

sgJohn.Wong@ashcroft.com.

an@ashcroft.com.sg

sgJoe.T

United Kingdom/Sales Office

Ashcroft Instruments GmbH Sales Office

Cambridge Office

Unit 5 William James House

Cowley Road

Cambridge CB4 0WX

Tel: 44-01223-395500

Fax: 44-01223-395501

Contact: Selwyn Hammond,Territory

Sales Manager, South

email: sales@ashcrofteurope.net

Visit our web site www.heise.com

All specifications are subject to change without notice.

All sales subject to standard terms and conditions.

Ashcroft Inc. I&M002-10095 4/02 (250-1526) 1P10/92 8P5/07

©

Venezuela

Manufacturas Petroleras Venezolanas

KM 7 Carretera A

El Mojan Calle 18

#15B355 ZONA

Ind. Norte Sector Canchancha

Maracaibo Edo Zulia Venezuela

Tel: 58-261-757-9070/9762

Fax: 58-261-757-9461

email: contactenos@mapvensa.com

www.mapvensa.com

Loading...

Loading...