Page 1

PRESSURE GAUGE

INSTALLATION,

OPERATION AND

MAINTENANCE

I&M008-10098-5/02 (250-1353-L) Rev. 12/15

1

Page 2

2

Page 3

CONTENTS

1.0 Selection and Application

1.1 Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.3 Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.4 Oxidizing media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.5 Pulsation/Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.6 Gauge fills . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.7 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.0 Temperature

2.1 Ambient Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.2 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.3 Steam service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.4 Hot or very cold media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.5 Diaphragm seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.6 Autoclaving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.0 Installation

3.1 Installation Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.2 Gauge reuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.3 Tightening of gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.4 Process isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.5 Surface mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.6 Flush mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4.0 Operation

4.1 Frequency of inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4.2 In-service inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4.3 When to check accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4.4 When to recalibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4.5 Other considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4.6 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

5.0 Gauge Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

6.0 Accuracy: Procedures/Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

6.1 Calibration - Rotary movement gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

7.0 Diaphragm Seals

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7.4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7.5 Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

8.0 Dampening Devices

8.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

8.2 Throttle Screws & Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

8.3 Ashcroft Pulsation Dampener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

8.4 Ashcroft Pressure Snubber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

8.5 Ashcroft Needle Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

8.6 Chemiquip

9.0 Test Equipment & Tool Kits

9.1 Pressure Instrument Testing Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

9.2 Tools & Tool Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

9.3 Kits to Convert a Dry Gauge to a Liquid Filled or . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weather Proof Case Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

9.4

Appendix

Type 1188 Bellows Gauge Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Type 1009 Calibration Procedure (Vacuum-Previous Style) . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Type 1009 Calibration Procedure (Pressure-Previous Style) . . . . . . . . . . . . . . . . . . . . . . . . . .13

Type 1009 Calibration Procedure (Pressure & Vacuum-Current Style) . . . . . . . . . . . . . . . . . .14

Type 1279 & 1379 I&M Liquid Fill Conversion Instruction . . . . . . . . . . . . . . . . . . . . . . . . . .15-16

Type 1082 Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-18

21⁄2 & 31⁄2 1009 Duralife®Gauge Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

®

Pressure Limiting Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Page

Cover photo courtesy of Johnson/Yokogawa Co.

Chemiquip®is a registered trademark of Chemiquip Products Co. Inc.

3

Page 4

1.0 SELECTION & APPLICATION

sers should become familiar with ASME B40.100 (Gauges

U

– Pressure Indicating Dial Type – Elastic Element) before

specifying pressure measuring gauges. That document –

ontaining valuable information regarding gauge construction,

c

accuracy, safety, selection and testing – may be ordered from:

ASME International

Three Park Avenue

New York, N.Y. 10016-5990

800-843-2763 (US/Canada)

001-800-843-2763 (Mexico)

973-882-1170 outside North America

email: infocentral@asme.org

www.asme.org

WARNING:

should be selected considering media and ambient operating

conditions. Improper application can be detrimental to the

gauge, causing failure and possible personal injury, property

damage or death. The information contained in this manual is

offered as a guide in making the proper selection of a pressure

gauge. Additional information is available from Ashcroft Inc.

The following is a highlight of some of the more important considerations:

1.1 Range – The range of the instrument should be approximately twice the maximum operating pressure. Too low a

range may result in (a) low fatigue life of the elastic element

due to high operating stress and (b) susceptibility to overpressure set due to pressure transients that exceed the normal operating pressure. Too high a range may yield insufficient resolution for the application.

1.2 Temperature – Refer to Section 2 of this manual for

important information concerning temperature related limitations of pressure gauges, both dry and liquid filled.

1.3 Media – The material of the process sensing element must

be compatible with the process media. Use of a diaphragm seal

with the gauge is recommended for process media that (a) is

corrosive to the process sensing element; (b) contain heavy

particulates (slurries) or (c) are very viscous including those

that harden at room temperature.

1.4 Oxidizing media – Gauges for direct use on oxidizing

media should be specially cleaned. Gauges for oxygen service should be ordered to variation X6B and will carry the

ASME required dial marking “USE NO OIL” in red letters.

Gauges for direct use on other oxidizing media may be

ordered to variation X6W. They will be cleaned but carry no

dial marking. PLUS!

filled gauge or diaphragm fill is required for use with oxidizing media; order variation XCF.

1.5 Pulsation/Vibration – Pressure pulsation can be dampened by several mechanisms; the patented PLUS! Perfor-

mance gauge will handle the vast majority of applications.

One exception to this is high frequency pulsation which is

difficult to detect. The only indication may be an upscale zero

shift due to movement wear. These applications should be

addressed with a liquid filled gauge, or in extreme cases, a

remotely mounted liquid filled gauge connected with a length

of capillary line. The small diameter of the capillary provides

excellent dampening, but can be plugged. The Ashcroft 1106

pulsation dampener and 1112 snubber are auxiliary devices

which dampen pulsation with less tendency to plug.

1.6 Gauge fills. – Once it has been determined that a liquid

filled gauge is in order, the next step is selecting the type of fill.

To prevent misapplication, pressure gauges

™

Performance gauges or Halocarbon

Glycerin satisfies most applications. While being the least

xpensive fill, its usable temperature range is 20/180°F.

e

Silicone filled gauges have a broader service range: –

40/250°F. Oxidizing media require the use of Halocarbon,

ith a service range of –40/250°F. Pointer motion will be

w

slowed at the low end of the low end of these temperature

ranges.

1.7 Mounting – Users should predetermine how the gauge

will be mounted in service: stem (pipe), wall (surface) or panel

(flush). Ashcroft wall or panel mounting kits should be ordered

the gauge. See Section 3.

with

2.0 TEMPERATURE

2.1 Ambient Temperature – To ensure long life and accura-

cy, pressure gauges should preferably be used at an ambient temperature between –20 and +150°F (–30 to +65°C).

At very low temperatures, standard gauges may exhibit slow

pointer response. Above 150°F, the accuracy will be affected

by approximately 1.5% per 100°F. Other than discoloration of

the dial and hardening of the gasketing and degradation of

accuracy, non-liquid filled Type 1279 (phenolic case) and

1379 (aluminum case) Duragauge

glass windows, can withstand continuous operating temperatures up to 250°F. Unigauge models 2

1008S liquid filled gauges can withstand 200°F but glycerin

fill and the acrylic window of Duragauge

yellow. Silicone fill will have much less tendency to yellow.

Low pressure, liquid filled Types 1008 and 1009 gauges may

have some downscale errors caused by liquid fill expansion.

This can be alleviated by venting the gauge at the top plug

(pullout the blue plug insert). To do this the gauge must be

installed in the vertical position.

Although the gauge may be destroyed and calibration lost,

gauges can withstand short times at the following temperatures: gauges with all welded pressure boundary joints, 750°F

(400°C); gauges with silver brazed joints, 450°F (232°C) and

gauges with soft soldered joints, 250°F (121°C). For expected

long term service below –20°F (–30°C) Duragauge

1009 gauges should be hermetically sealed and specially

lubricated; add “H” to the product code for hermetic sealing.

Add variation XVY for special lubricant. Standard Duralife

gauges may be used to –50°F (–45°C) without modification.

2.2 Accuracy – Heat and cold affect accuracy of indication.

A general rule of thumb for dry gauges is 0.5% of full scale

change for every 40°F change from 75°F. Double that al lowance for gauges with hermetically sealed or liquid filled

cases, except for Duragauge

allowance is required due to the elastomeric, compensating

back. Above 250°F there may exist very significant errors in

indication.

2.3 Steam service – In order to prevent live steam from

entering the Bourdon tube, a siphon filled with water should

be installed between the gauge and the process line.

Siphons can be supplied with ratings up to 4,000 psi. If

freezing of the condensate in the loop of the siphon is a possibility, a diaphragm seal should be used to isolate the

gauge from the process steam. Siphons should also be used

whenever condensing, hot vapors (not just steam) are present. Super heated steam should have enough piping or

capillary line ahead of the siphon to maintain liquid water in

the siphon loop.

2.4 Hot or very cold media – A five foot capillary line assembly will bring most hot or cold process media within the recommended gauge ambient temperature range. For media above

®

gauge, with standard

1

⁄2˝ and 31⁄2˝ 1009 and

®

gauges will tend to

®

gauges where no extra

®

and 41⁄

2˝

®

4

Page 5

750°F (400°C) the customers should use their own small

diameter piping to avoid possible corrosion of the stainless steel.

he five foot capillary will protect the gauges used on the com-

T

mon cryogenic (less than –300°F (200°C) gases, liquid argon,

nitrogen, and oxygen.) The capillary and gauge must be

cleaned for oxygen service. The media must not be corrosive to

stainless steel, and must not plug the small bore of the capillary.

2.5 Diaphragm seals – A diaphragm seal should be used to

protect gauges from corrosive media, or media that will plug

the instrument. Diaphragm seals are offered in a wide variety

of designs and corrosion resistant materials to accommodate almost any application and most connections. Visit

www.ashcroft.com for details.

.6 Autoclaving – Sanitary gauges with clamp type connec-

2

tions are frequently steam sterilized in an autoclave. Gauges

equipped with polysulfone windows will withstand more autoclave cycles than those equipped with polycarbonate windows. Gauges equipped with plain glass or laminated safety

glass should not be autoclaved. Gauge cases should be

vented to atmosphere (removing the rubber fill/safety plug if

necessary) before autoclaving to prevent the plastic window

from cracking or excessively distorting. If the gauge is liquid

filled, the fill should be drained from the case and the front

ring loosened before autoclaving.

3.0 INSTALLATION

3.1 Location – Whenever possible, gauges should be located to minimize the effects of vibration, extreme ambient temperatures and moisture. Dry locations away from very high

thermal sources (ovens, boilers etc.) are preferred. If the

mechanical vibration level is extreme, the gauge should be

remotely located (usually on a wall) and connected to the

pressure source via flexible tubing.

3.2 Gauge reuse – ASME B40.100 recommends that

gauges not be moved indiscriminately

to another. The cumulative number of pressure cycles on an

in-service or previously used gauge is generally unknown, so

it is generally safer to install a new gauge whenever and

wherever possible. This will also minimize the possibility of a

reaction with previous media

3.3 Tightening of gauge – Torque should never be applied

to the gauge case. Instead, an open end or adjustable

wrench should always be used on the wrench flats of the

gauge socket to tighten the gauge into the fitting or pipe.

NPT threads require the use of a suitable thread sealant,

such as pipe dope or teflon tape, and must be tightened very

securely to ensure a leak tight seal.

.

CAUTION: Torque applied to a diaphragm seal or its

attached gauge, that tends to loosen one relative to the

other, can cause loss of fill and subsequent inaccurate readings. Always apply torque only to the wrench flats on the

lower seal housing when installing filled, diaphragm seal

assemblies or removing same from process lines.

3.4 Process isolation – A shut-off valve should be installed

between the gauge and the process in order to be able to

isolate the gauge for inspection or replacement without shutting down the process.

3.5 Surface mounting – Also known as wall mounting.

Gauges should be kept free of piping strains. The gauge case

mounting feet, if applicable, will ensure clearance between the

pressure relieving back and the mounting surface.

3.6 Flush mounting – Also known as panel mounting. The

applicable panel mounting cutout dimensions can be found

at www.ashcroft.com

from one application

4.0 OPERATION

4.1 Frequency of inspection – This is quite subjective and

depends upon the severity of the service and how critical the

accuracy of the indicated pressure is. For example, a monthly inspection frequency may be in order for critical, severe

service applications. Annual inspections, or even less frequent schedules, are often employed in non-critical applications.

.2 In-service inspection – If the accuracy of the gauge

4

cannot be checked in place, the user can at least look for (a)

erratic or random pointer motion; (b) readings that are sus-

ect – especially indications of pressure when the user

p

believes the true pressure is 0 psig. Any gauge which is

obviously not working or indicating erroneously, should be

mmediately valved-off or removed from service to avoid a

i

possible pressure boundary failure.

4.3 When to check accuracy – Any suspicious behavior of

the gauge pointer warrants that a full accuracy check be performed. Even if the gauge is not showing any symptoms of

abnormal performance, the user may want to establish a frequency of bench type inspection.

4.4 When to recalibrate – This depends on the criticality of

the application. If the accuracy of a 3-2-3% commercial type

gauge is only 0.5% beyond specification, the user must

decide whether it’s worth the time and expense to bring the

gauge back into specification. Conversely if the accuracy of

a 0.25% test gauge is found to be 0.1% out of specification

then the gauge should be recalibrated.

4.5 Other considerations – These include (a) bent or unattached pointers due to extreme pressure pulsation; (b) broken windows which should be replaced to keep dirt out of

the internals; (c) leakage of gauge fill; (d) case damage –

dents and/or cracks; (e) any signs of service media leakage

through the gauge including its connection; (f) discoloration

of gauge fill that impedes readability.

4.6 Spare parts – As a general rule it is recommended

that the user maintain in inventory one complete Ashcroft

instrument for every ten (or fraction thereof) of that

instrument type in service.

®

5.0 GAUGE REPLACEMENT

It is recommended that the user stock one complete

Ashcroft

instrument type in service. With regard to gauges having a

service history, consideration should be given to discarding

rather than repairing them. Gauges in this category include

the following:

a. Gauges that exhibit a span shift greater than 10%. It is

b. Gauges that exhibit a zero shift greater than 25%. It is

c. Gauges which have accumulated over 1,000,000 pres-

d. Gauges showing any signs of corrosion and/or leakage

e. Gauges which have been exposed to high temperature

®

instrument for every ten (or fraction thereof) of that

possible the Bourdon tube has suffered thinning of its

walls by corrosion.

likely the Bourdon tube has seen significant overpressure leaving residual stresses that may be detrimental

to the application.

sure cycles with significant pointer excursion.

of the pressure system.

or exhibit signs of having been exposed to high temperature – specifically 250°F or greater for soft soldered

systems; 450°F or greater for brazed systems; and

750°F or greater for welded systems.

5

Page 6

f. Gauges showing significant friction error and/or wear of

he movement and linkage.

t

g. Gauges having damaged sockets, especially damaged

threads.

h. Liquid filled gauges showing loss of case fill.

NOTE: ASME B40.100 does not recommend moving gauges

rom one application to another. This policy is prudent in that

f

it encourages the user to procure a new gauge, properly tailored by specification, to each application that arises

.

6.0 ACCURACY: PROCEDURES/DEFINITIONS

Accuracy inspection – Readings at approximately five

oints equally spaced over the dial should be taken, both

p

upscale and downscale, before and after lightly rapping the

gauge to remove friction. A pressure standard with accuracy

at least four times greater than the accuracy of the gauge

being tested is recommended.

Equipment – A finely regulated pressure supply will be required.

It is critical that the piping system associated with the test setup

be leaktight. The gauge under test should be positioned as it will

be in service to eliminate positional errors due to gravity.

Method – ASME B40.100 recommends that known pres-

ure (based on the reading from the pressure standard used)

s

be applied to the gauge under test. Readings including any

error from the nominal input pressure, are then taken from the

auge under test. The practice of aligning the pointer of the

g

gauge under test with a dial graduation and then reading the

error from the master gauge (“reverse reading”) can result in

nconsistent and misleading data and should NOT be used.

i

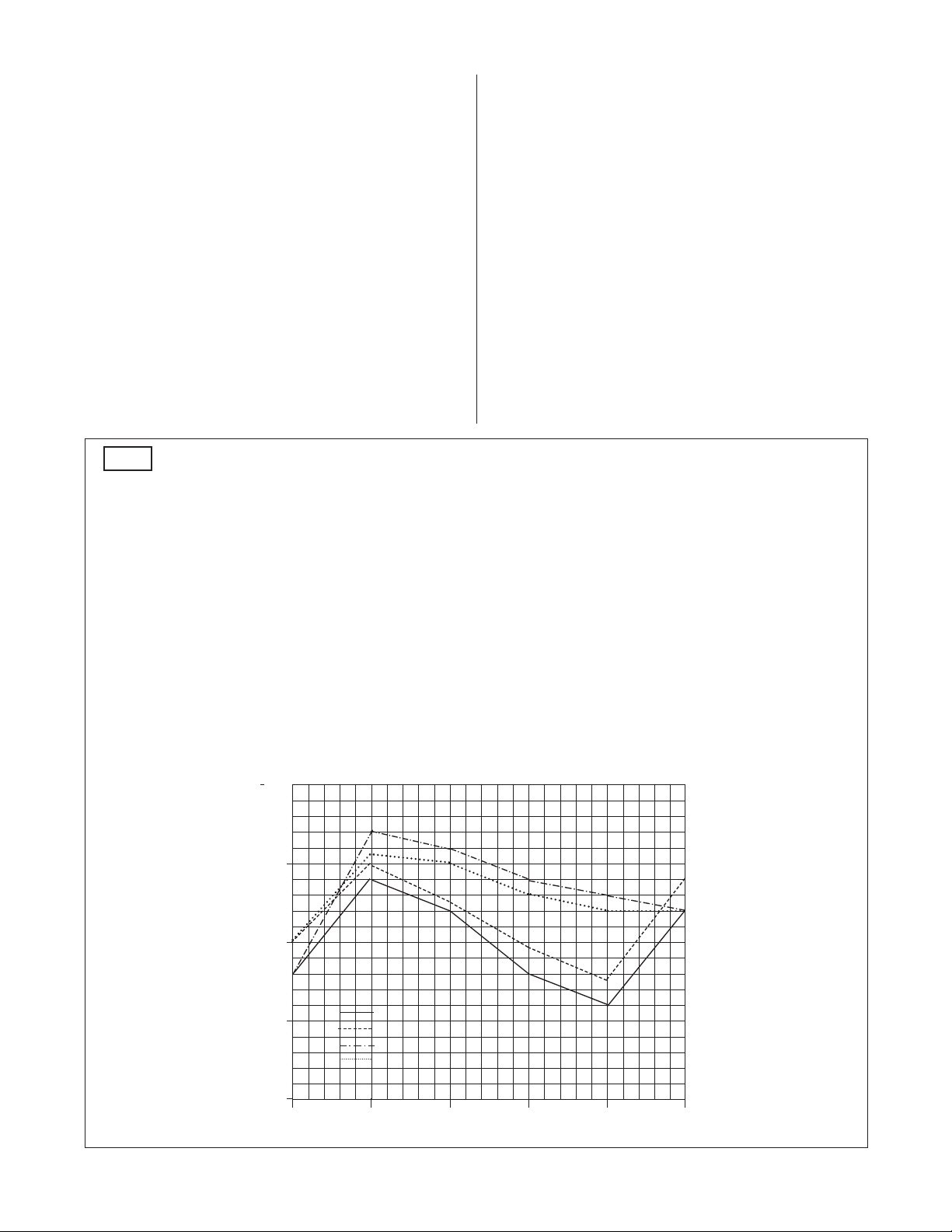

Calibration chart – After recording all of the readings it is

necessary to calculate the errors associated with each test

point using the following formula: ERROR in percent = 100

times (TRUE VALUE minus READING) ÷ RANGE. Plotting

the individual errors (Figure 1) makes it possible to visualize

the total gauge characteristic. The plot should contain all four

curves: upscale – before rap; upscale – after rap; downscale

– before rap; downscale – after rap. “Rap” means lightly tapping the gauge before reading to remove friction as

described in ASME B40.100.

Referring to Figure 1, several classes of error may be seen:

Zero – An error which is approximately equal over the entire

scale. This error can be manifested when either the gauge is

FIG. 1

TYPICAL CALIBRATION CHART

INDICATED VALUE (PSI)

True Value – Increasing – Increasing – Decreasing – Decreasing –

PSI Without RAP With RAP Without RAP With RAP

0 –.4 0 –.4 0

40 +.8 +1.0 +1.4 +1.1

80 +.4 +.5 +1.2 +1.0

120 –.4 –1.0 +.8 +.6

160 –.8 –.5 +.6 +.4

200 +.4 +.8 +.4 +.4

ERROR (% OF FULL SCALE)

True Value – Increasing – Increasing – Decreasing – Decreasing –

% of Range Without RAP With RAP Without RAP With RAP

0 –.20 0 –.20 0

20 +.40 +.50 +.70 +.55

40 +.20 +.25 +.60 +.50

60 –.20 –.05 +.40 +.30

80 –.40 –.25 +.30 +.20

100 +.20 +.40 +.20 +.20

1.0

◆

◆

■

◆

●

▲

■

◆

■

●

▲

0.5

■

●

▲

●

0.0

▲

Error (% of Full Scale)

–0.5

–1.0

▲ ▲ upscale – without rap

● ● upscale – with rap

◆ ◆ downscale – without rap

■ ■ downscale – with rap

0 20 40 60 80 100

% of Range

●

▲

6

●

▲

Page 7

BO UR DO N TU BE

SEGMENT

TIP

LINK

BACKPLATE

SOCKET

ROTARY MOVEMENT

PINION

HAIRSPRING

TIP

LINK

BOURDEN TUBE

MOVEMENT

HAIRSPRING

BACKPLATE

SOCKET

dropped or overpressured and the Bourdon tube takes a

permanent set. This error may often be corrected by simply

epositioning the pointer. Except for test gauges, it is recom-

r

mended that the pointer be set at midscale pressure to “split”

the errors.

Span – A span error exists when the error at full scale pressure is different from the error at zero pressure. This error is

often proportional to the applied pressure. Most Ashcroft

gauges are equipped with an internal, adjusting mechanism

with which the user can correct any span errors which have

developed in service.

Linearity – A gauge that has been properly spanned can

still be out of specification at intermediate points if the

esponse of the gauge as seen in Figure 1 (Typical

r

Calibration Chart) is not linear. The Ashcroft Duragauge

®

pressure gauge is equipped with a rotary movement feature

which permits the user to minimize this class of error. Other

Ashcroft gauge designs (e.g., 1009 Duralife

®

) require that

the dial be moved left or right prior to tightening the dial

screws.

Hysteresis – Some Bourdon tubes have a material property

known as hysteresis. This material characteristic results in

differences between the upscale and downscale curves. This

class of error can not be eliminated by adjusting the gauge

movement or dial position.

Friction – This error is defined as the difference in readings

before and after lightly tapping the gauge case at a check

point. Possible causes of friction are burrs or foreign material

in the movement gearing, “bound” linkages between the

movement and the bourdon tube, or an improperly tensioned

hairspring. If correcting these potential causes of friction

does not eliminate excessive friction error, the movement

should be replaced.

6.1 Calibration – Rotary Movement Gauges and Type

1259 Gauges – Inspect gauge for accuracy. Many times

gauges are simply “off zero” and a simple pointer adjustment

using the micrometer pointer is adequate. If inspection shows

the gauge warrants recalibration to correct span and/or linearity

errors, proceed as follows:

a. Remove ring, window and, if solid front case, the rear

closure assembly.

b. Pressurize the gauge once to full scale and back to zero.

c. Refer to Figure 2 (Ashcroft System Assembly w/Rotary

Gear Movement) for a view of a typical Ashcroft rotary

system assembly with component parts identified. Refer to

FIG. 2 ASHCROFT SYSTEM ASSEMBLY W/ROTARY GEAR MOVEMENT

FIG. 2A ASHCROFT TYPE 1259 SYSTEM ASSEMBLY

Figure 2A for link configuration of Type 1259 gauge.

d. Adjust the micrometer pointer so that it rests at the true

zero position. For open front gauges the pointer and dial

must also be disassembled and the pointer should then

be lightly pressed onto the pinion at the 9:00 o’clock

position.

e. Apply full scale pressure and note the magnitude of the

span error. With open front gauges, ideal span (270

degrees) will exist when at full scale pressure the pointer

rests exactly at the 6:00 o’clock position.

f. If the span has shifted significantly (span error greater

than 10%), the gauge should be replaced because there

may be some partial corrosion inside the Bourdon tube

which could lead to ultimate failure. If the span error

exceeds 0.25%, loosen the lower link screw and move

the lower end of the link toward the movement to

increase span or away to decrease span. An adjustment

of 0.004 inch will change the span by approximately 1%.

This is a repetitive procedure which often requires more

than one adjustment of the link position and the subsequent

rechecking of the errors at zero and full scale pressure.

g. Apply midscale pressure and note error in reading. Even

though the gauge is accurate at zero and full scale, it

may be inaccurate at the midpoint. This is called linearity

error. For corrections to linearity with the Type 1259

FIG. 2B LINEARITY ADJUSTMENT & LINK CONFIGURATION FOR

ASHCROFT TYPE 1259

To increase pointer indication

at mid-scale, use a pliers to

open the link.

To decrease pointer indication

at mid-scale, use a pliers to

close the link.

gauges refer to Figure 2B. For rotary movement gauges,

note the following: if the error is positive, the movement

should be rotated counter clockwise. Rotating the movement one degree will change this error by approximately

0.25%. Rotating the movement often affects span and it

should be subsequently rechecked and readjusted if necessary according to step 6.1e and 6.1f.

h. While recalibrating the gauge, the friction error – differ-

ence in readings taken with and without rap – should be

7

Page 8

noted. This error should not exceed the basic accuracy

of the gauge. If the friction error is excessive, the move-

ent should be replaced. One possible cause of exces-

m

sive friction is improper adjustment of the hairspring. The

hairspring torque,or tension, must be adequate without

being excessive. The hairspring should also be level, unwind

evenly (no turns rubbing) and it should never tangle.

NOTES:

1 For operation of test gauge external zero

reset, refer to page 17.

2 For test gauge calibration procedure,

refer to Figure 2 on page 18.

7.0 DIAPHRAGM SEALS

7.1 General – A diaphragm seal (isolator) is a device which is

attached to the inlet connection of a pressure instrument to

isolate its measuring element from the process media. The

space between the diaphragm and the instrument’s pressure

sensing element is solidly filled with a suitable liquid.

Displacement of the liquid fill in the pressure element, through

movement of the diaphragm, transmits process pressure

changes directly to a gauge, switch or any other pressure

instrument. When diaphragm seals are used with pressure

gauges, an additional 0.5% tolerance must be added to the

gauge accuracy because of the diaphragm spring rate.

Used in a variety of process applications where corrosives,

slurries or viscous fluids may be encountered, the diaphragm

seal affords protection to the instrument where:

• The process fluid being measured would normally clog

the pressure element.

• Pressure element materials capable of withstanding corrosive effects of certain fluids are not available.

• The process fluid might freeze due to changes in ambient

temperature and damage the element.

7.2 Installation – Refer to bulletin OH-1 for information

regarding (a) seal configurations; (b) filling fluids; (c) temperature range of filling fluids; (d) diaphragm material pressure

and temperature limits; (e) bottom housing material pressure

and temperature limits; (f) pressure rating of seal assembly;

(g) accuracy/temperature errors of seal assembly; (h)

diaphragm seal displacement. The volumetric displacement

of the diaphragm must at least equal the volu metric displacement of the measuring element in the pressure instrument to which the seal is to be attached.

It is imperative that the pressure instrument/diaphragm seal

assembly be properly filled prior to being placed in service.

Ashcroft diaphragm seal assemblies should only be filled by

a seal assembler certified by Ashcroft Inc. Refer to section

3.3 for a cautionary note about not applying torque on either

the instrument or seal relative to the other.

7.3 Operation – All Ashcroft

exception of Type 310 mini-seals, are continuous duty.

Should the pressure instrument fail, or be removed accidentally or deliberately, the diaphragm will seat against a match-

ing surface preventing damage to the diaphragm or leakage

of the process fluid.

7.4 Maintenance – Clamp type diaphragm seals – Types

100, 200 and 300 – allow for replacement of the diaphragm

or diaphragm capsule, if that ever becomes necessary. The

Type 200 top housing must also be replaced with the diaphragm. With all three types the clamping arrangement allows

field dis as sem bly to permit cleaning of the seal interior.

®

diaphragm seals, with the

7.5 Failures – Diaphragm failures are generally caused by

ither corrosion, high temperatures or fill leakage. Process

e

media build-up on the process side of the diaphragm can

also require seal cleaning or replacement. Consult Customer

ervice, Stratford CT for advice on seal failures and/or

S

replacement.

WARNING: All seal components should be selected

considering process and ambient operating conditions to

prevent misapplication. Improper application could result in

failure, possible personal injury, property damage or death.

8.0 DAMPENING DEVICES

8.1 General – Some type of dampening device should be

used whenever the pressure gauge may be exposed to

repetitive pressure fluctuations that are fairly rapid, high in

magnitude and especially when transitory pressure spikes

exceeding the gauge range are present (as with starting and

stopping action of valves and pumps). A restricted orifice of

some kind is employed through which pressure fluctuations

must pass before they reach the Bourdon tube. The dampener reduces the magnitude of the pressure pulse thus

extending the life of the Bourdon tube and movement. This

reduction of the pressure pulsation as “seen” by the pressure

gauge is generally evidenced by a reduction in the pointer

travel. If the orifice is very small the pointer may indicate the

average service pressure, with little or no indication of the

time varying component of the process pressure.

Commonly encountered media (e.g. – water and hydraulic

oil) often carry impurities which can plug the orifice over time

thus rendering the gauge inoperative until the dampener is

cleaned or replaced.

Highly viscous media and media that tend to periodically

harden (e.g., asphalt) require a diaphragm seal be fitted to

the gauge. The seal contains an internal orifice which dampens the pressure fluctuation within the fill fluid.

8.2 Throttle Screws & Plugs – These accessories provide

dampening for the least cost. They have the advantage of fitting completely within the gauge socket and come in three

types: (a) a screwed-in type which permits easy removal for

cleaning or replacement; (b) a pressed in, non-threaded

design and (c) a pressed in, threaded design which provides

a highly restrictive, helical flow path. Not all styles are available on all gauge types.

8.3 Ashcroft Pulsation Dampener – Type 1106 Ashcroft

pulsation dampener is a moving pin type in which the

restricted orifice is the clearance between the pin and any

one of five preselected hole diameters. Unlike a simple throttle screw/plug, this device has a self-cleaning action in that

the pin moves up and down under the influence of pressure

fluc tuations.

8.4 Ashcroft Pressure Snubber – The heart of the Type

1112 pressure snubber is a thick porous metal filter disc. The

disc is available in four standard porosity grades.

8.5 Ashcroft Needle Valves – Type 7001 thru 7004 steel

needle valves provide varying degrees of dampening. These

devices, in the event of plugging, can easily be opened to

allow the pressure fluid to clear away the obstruction.

8.6 Chemiquip

255, PLV-2550, PLV-5460, PLV-5500 and PLV-6430, available with and without built-in snubbers, automatically “shut

off” at adjustable preset values of pressure to protect the

gauge from damage to overpressure. They are especially

useful on hydraulic systems wherein hydraulic transients

®

Pressure Limiting Valves – Model PLV-

8

Page 9

(spikes) are common.

9.0 TEST EQUIPMENT & TOOL KITS

See our website www.ashcroft.com for more details

9.1 Pressure Instrument Testing Equipment

Type 1305D Deadweight Tester

Type 1327D Pressure Gauge Comparator

Type 1327CM “Precision” Gauge Comparator

9.2 Tools & Tool Kits For Recalibration of 4

Larger Gauges

Type 2505 universal carrying case for 1082 test gauge

Type 266A132-01 span wrench for 1082 test gauge

Type 1281 socket O-Ring kit for 1279/1379 lower connect

Type 1285 4

1

⁄

2˝ ring wrench for 1279/1379 lower & back

connect

Type 1286 6˝ ring wrench for 1379 lower & back connect

Type 3220 pointer puller (all gauges except 1009

Duralife

®

)

Type 3530 pinion back-up tool for 1009 Duralife

Type 3220 Handjack set

Type 1105 Tool Kit

9.3 Kits to Convert a Dry Gauge to a Liquid Filled or

Weather Proof Case Gauge

Type 1280 conversion kit for 4

1

⁄

2˝ lower connect

1279/1379

1

⁄

Type 1283 conversion kit for 4

2˝ back connect

1279/1379

Type 1284 conversion kit for 6˝ lower & back connect

1

⁄2˝ and

®

TYPE 3 22 0

HAND J AC K SET

TYPE 1 10 5

TOOL KIT

9

Page 10

1

9.4 2

⁄2 & 31⁄2 1009 Duralife®Gauge Tools

Description Part No.

Pointer Puller Screw/Pin

Pointer Puller Body

Pointer Staker

Span Wrench

(2)(4)

(2)(5)

Ring Wrench 31⁄2˝

Ring Wrench 21⁄2˝

Nest 21⁄2˝ & 31⁄2˝

(1)(5)

Ring Removal Tool

Ring Removal Tool

(6)

Nest 21⁄2˝

Nest 31⁄2˝

to hold gauge for ring removal) (25 1009)

(

(6)

to hold gauge for ring removal) (35 1009)

(

Type 1230 throttle plug insertion (

Type 1231 throttle plug insertion (

(2)(3)(4)

112A381-01

(

2)(3)(4)

292A133-01

188A101-01

(to adjust span) 266A137-01

(1)(5)

for ring removal) (35 1009)

(

(1)(5)

(for ring removal) (25 1009) 266B135-01

266B134-01

(to hold gauge for ring removal) (25/35 1009) 266B136-01

(6)

25 1009)

(

(6)

(35 1009) 101B221-01

101B221-02

101B220-02

101B220-01

1

⁄4 NPT) for 1009 Duralife

1

PT) for 1009 Duralife

⁄2 N

)

®

1230

®

body only)

(

1231

Tool to open orifice on push-in throttle plug 101A206-01

(1) Formerly 1206T Tool Kit.

(2) Formerly some par ts in 1205T Tool Kit.

(3) Both parts must be purchased together.

(4) Previous and current design.

(5) Previous design only.

(6) Current design only.

RING W RE NC H

266B134-01

NEST

101B220-02

RING REMOVA L TO OL

101B221-02

NEST

266B136-01

RING REMOVA L TO OL

101B221-01

POINTER STAKER

188A101-01

POINTER PU LLER

SCREW/PIN 112A381-01

and

RING

WRENCH

266B135-01

NEST

101B220-01

POINTER PU LLER BO DY

292A133-01

SPAN WREN CH

266A137-01

10

Page 11

ASHCROFT®Type 1188 Bellows Gauge

1/8

60°

.020 R

E (LINK)

S (SLIDE)

Calibration Procedure

ALIBRATION & TROUBLE

C

CORRECTION DIAGRAM

RANGE SPAN ADJUSTMENT

RANGE TOO SHORT

Adjust slide “S” inward

OTE: After adjusting range span, set both movement stops.

N

RANGE TOO LONG

Adjust slide “S” outward

Set the underload stop so that the pointer will stop at

zero. Set the overload stop so that the pointer will pass

the maximum range approximately 5˝.

NOTE: After adjusting span re-zero pointer by removing from

pinion and re-assembling at the proper dial mark.

NON LINEAR

FIRST 3RD.

ADJ. ANGLE OF PULL

BY INCREASING ANGLE “A”

NOTE: To increase or decrease angle “A,“ bend tip inward or outward as

required. Doing this may run the movement segment off the pinion. This can be corrected by cutting off one end off the link “E”

decreasing its length, or makin a new length from .032 dia. phos.

bronze wire.

Caution: When reproducing link end, follow figure 44 very closely.

this will prevent too much play, or, binding in operation.

NON LINEAR

STICKY PARTS

Clean all bearings

and gear teeth

SLUGGISH MOVEMENT

POINTER JUMPING

LOOSE HAIRSPRING

Remove backlash by

disengaging pinion &

rotate to tighten

COUNTER BALANCE

RUBBING

Bend if necessary to

lear socket in travel

c

TIGHT HAIRSPRING

Loosen by disengaging pinion & rotate

NON LINEAR

LAST 3RD.

ADJ. ANGLE OF PULL

BY DECREASING ANGLE “A”

REF: Replacing System Bellows

After assembling bellows to the gauge socket securely, subject sys-

tem to 30 psi for five minutes, allowing bellows to travel approximately 1/8˝ against the overload stop. After this, heat treat system for

15 hours at 250°F, this procedure is necssary to prevent gauge drift.

SLIDE AND LINK (angle “A”)

Enlarged view of slide and link

© Ashcroft Inc., 250 E. Main St., Stratford, CT 06614-5145, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale.

I&M008-10173-3/10 (1188)

OVERLOAD

STOP

UNDERLOAD

STOP

STOP LOCKING

SCREWS

11

Page 12

ASHCROFT®Previous Type 1009 Duralife

0

25

Span Block

Decrease

7/64 Open

End Wrench

Increase

P

encil Marks on Case Flange

25

15

0

Calibration Procedure – Vacuum Range

®

1. Remove ring, window and gasket pointer.

2. Using a pencil, refer to dial and mark the 0 and

25˝ Hg positions on the case flange.

3. Remove dial.

4. Apply 25˝ Hg vac.

5. Lightly press pointer onto pinion carefully aligning it

with the 25˝ Hg vac. mark on the flange.

6. Release vacuum fully.

7. Note agreement of pointer to zero mark on flange.

8. If span is high or low, turn span block as shown in

Figure 1.

Figure 1 –

15. recheck accuracy at 15 and 25˝ Hg vac. (Figure 2).

16. Reassemble window, gasket and ring.

Figure 2 –

Notes: See page 10 for any tools required to calibrate.

For models produced prior to

September 2008 for 2

December 2008 for 3

1

⁄2˝ version and

1

⁄2˝ version.

Back of gauge will have a date code sticker.

9. Repeat steps 4 through 8 until span is correct.

10. Remove pointer.

11. With 25˝ Hg vac applied, reassemble dial, dial screws

(finger tight) and point.

12. Apply 15˝ Hg vac. and note accuracy of indication.

If required, slide dial left or right to reduce error to 1%

maximum.

13. Firmly tighten dial screws.

14. Firmly tap pointer onto pinion.

© 2010 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale. I&M008-10077 9/01 AMR 05/10

12

Page 13

Dial Screws

Zero Box

Full Scale Mark

Mid Scale Mark

ASHCROFT®Previous Type 1009 Duralife

Span Block

Decrease Increase

Start Point

Span

Calibration Procedure – Pressure Range

®

Step 1. With the dial off, install pointer at 9 o’clock “lightly,”

Figure 3.

igure 3 –

F

Step 2. Go to full scale pressure…rotate span block with

tool until pointer rests at 6 o’clock.

Step 3. Go to zero pressure (9 o’clock)…if pointer has not

moved away from start point, go to Step 4. If pointer

has moved, repeat Step 1 until span is correct.

Step 4. Install dial with screws snug.

Step 5. Install pointer centered in zero box, Figure 4.

tep 6. Go to full scale pressure…check that pointer is

S

within 1% of full scale mark. If not, remove pointer

and dial and return to step 1, Figure 4.

Step 7. Go to mid-scale pressure…rotate dial until mid-

scale mark is aligned with pointer, Figure 4.

Step 8. Tighten dials screws and stake on pointer.

Step 9. Check zero and full scale. Reassemble window,

gasket and ring.

Notes: See page 10 for any tools required to calibrate.

For models produced prior to

September 2008 for 2

December 2008 for 3

1

⁄2˝ version and

1

⁄2˝ version.

Back of gauge will have a date code sticker.

Figure 4 –

© 2010 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale. I&M008-10077 9/01 AMR 05/10

13

Page 14

ASHCROFT®Current Type 1009 Duralife

1

0

0

Mid-scale mark

Full scale mark

Span adjust

Dial screw

Zero box

0

50

15

2

5

0

Zero boxZero adjust

D

ial screw

Calibration Procedure – Pressure and

Vacuum Range

®

Calibration – 1009 Duralife®Gauge –

Inspect gauge for accuracy. At times gauges are simply

“off zero” and opening the ventable plug at the top of the

gauge will relieve internal gauge pressure and correct the

ffset. If this is not adequate and inspection shows that

o

the gauge warrants recalibration to correct zero, span

and/or linearity errors, proceed as follows:

Remove ring, window, and gasket using Ashcroft Ring

Removal Tools P/N 101B220-02 and 101B221-02 for 2½”

gauges and 101B220-01 and 101B221-01 for 3½” gauges.

PRESSURE

Positive Pressure Ranges –

1. Adjust pointer with a slotted screwdriver until it is in the

center of the zero box. This is often all that is required

it correct calibration issues.

2. Apply full scale pressure. If error exceeds 1% rotate

the black span adjustment device with a #0 square

drive bit. Clockwise increases span, counterclockwise

decrease span.

3. Fully exhaust pressure and check that pointer still is

still in the zero box. If not, repeat step 1 and 2

4. Once 0 and full scale are within tolerance, pressurize

gauge to mid-scale.

5. If gauge is within 1%, calibration is complete. If not

loosen the dial screw and rotate dial left or right to

adjust midpoint. Retighten dial screw.

6. If an adjustment was made in step 5, recheck the

gauge at zero and full scale, adjust accordingly until

zero, mid and full scale points are in tolerance.

Vacuum Range –

1. Adjust pointer with a slotted screwdriver until it is in

the center of the zero box. This is often all that is

required it correct calibration issues.

2. Apply 25 inches Hg vacuum. If the error exceeds 1%

adjust pointer with a slotted screwdriver until gauge is

within tolerance.

VACUUM

3. Vent to 0 pressure and check pointer position in the

zero box. If error exceeds 1% rotate the black span

adjustment device with a #0 square drive bit.

Clockwise rotation moves pointer clockwise, counterclockwise rotation moves the pointer counterclockwise.

4. Repeat step 1 and 2 until 0 and 25 inches of Hg are

within gauge tolerance.

5. Apply 15 inches Hg vacuum. If gauge is within 1%,

calibration is complete. If not loosen the dial screw

and rotate dial left or right to adjust midpoint.

Retighten dial screw.

6. If an adjustment was made in step 4, recheck the

gauge at zero and 25 inches of Hg vacuum, adjust

accordingly until zero, 15 and 25 inches Hg are in tolerance.

7. Continue below.

Re-assemble window and ring to gauge:

a. If plastic window is used, push window back into front

of gauge, ensure the o-ring does not roll out of window groove (lubricate if necessary). Align the tabs of

the window with the tabs of the case front. Once window is in place, install ring and tighten with tools referenced above and shown on page 10.

b If safety glass is used, reinstall window, gasket, and

ring. Ensure that the gasket is seated properly under

all four tabs of the ring and does not wrinkle when ring

is tightened.

Note: Tighten ring: Apply 120-200inlb of torque. Rotate

ring clockwise to tighten. Warning: over tightening of safety glass may induce cracking.

Notes: See page 10 for any tools required to calibrate.

For models produced after

September 2008 for 2

December 2008 for 3

1

⁄2˝ version and

1

⁄2˝ version.

Back of gauge will have a date code sticker.

© 2010 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale. I&M008-10081-05/10 AMR 05/10

14

Page 15

TYPE 1279 & 1379 SOLID FRONT DURAGAUGE

®

PRESSURE GAUGE CONVERSION INSTRUCTIONS TO:

• Convert A Standard Dry Gauge To A Liquid Filled Gauge

• Convert A Standard Dry Gauge To A Dry, Weatherproof

I

P66 Gauge

TYPICAL 45-1279_S-04L-100* GAUGE

SHOWN WITH KIT 101A202-01

E

lastomeric Diaphragm

w

“O” Ring Acrylic Window Threaded Ring

ith Integral “O” Ring

1279 1379

4

KIT PART NO. 101A202-01 101A203-01 1280 1283 1284

QUANTITY INCLUDED

1

LOWER 4

⁄

2˝

1

BACK 4

⁄

2˝

1

LOWER 4

⁄

2˝

1

BACK 6˝ LOWER & BACK

⁄

2˝

ACRYLIC WINDOW 1 1 1 1 1

FRONT O-RING 1 1 1 1 1

(

DIAPHRAGM

1)

1 1 1 1 2(1-LC:1-BC)

REAR COVER 1 1 1 1 2(1-LC:1-BC)

COVER SCREWS 4 4 - - THROTTLE SCREWS 2 2 2 2 2

GARTER SPRING – 1 1 1 1

FILL IDENTIFICATION 1 1 1 1 1

THREADED RING – – 1 1 1

TOP FILL PLUG – – 1 1 –

1. When Halocarbon fill is a requirement, rear case diaphragm bladder material is Viton instead of

the standard Buna diaphragm bladder. Consult factory for part number.

TEMPERATURE LIMITS

Ambient Process Storage

Dry –20/200°F –20/250°F

(IP66) (–29/93°C) (–29/121°C) (–40/121°C)

LF 20/150°F 20/200°F 0/150°F

(glycerin) (7/66°C) (7/93°C) (–18/66°C)

–40/150°F –40/200°F –40/150°F

(silicone)

–40/150°F –40/200°F –40/150°F

(–40/66°C) (–40/93°C) (–40/66°C)

(halocarbon)

Note: Other than discoloration of the dial and hardening of the gasketing that may occur

as ambient or process temperatures exceeds 150°F, non-liquid-filled gauges with standard

glass windows, can withstand continuous operating temperatures up to 250°F (121°C).

Liquid-filled gauges can withstand 200°F (93°C) but glycerin fill and acrylic window will

tend to yellow. Accuracy at temperatures above or below the reference ambient temperature of 68°F will be affected by approximately .4% per 25°F. Gauges with welded joints

will withstand 750°F (450°F (232°C) with silver brazed joints) for short times without rupture, although other parts of the gauge will be destroyed and calibration will be lost. For

continuous use and for process or ambient temperatures above 250°F (121°C), a

diaphragm seal or capillary or siphon is recom

(1) Available for temperature below –20°F, see Production Information page ASH-PI-21B

for details

(–40/66°C) (–40/93°C) (–40/66°C)

1

1)

(

–40/250°F

mended.

1. Unscrew front threaded ring (turn CCW).

Remove and discard glass window. For range

spans 60 psi and under, shift pointer down

scale by the amount shown in the table. With

either the glass or plastic window, replace the

O-ring with one furnished in the kit.

2. Remove protective paper from acrylic plastic

window taking care not to scratch window.

Assemble window in gauge.

3. Moisten face of threaded ring with silicone oil

or silicone grease where ring bears up against

window. Replace front threaded ring and tighten firmly hand tight. See instructions on

reverse side for applying proper torque to ring

to establish desired squeeze on O-ring seal.

(Fig. 4).

60 psi and Under

Down Scale Zero

Shift Required

NONE

NONE

.12 psi

.12 psi

It is important to hold gauge rigidly, other-

wise ring lugs may be damaged during

removal or assembly process.

4. From rear of gauge, remove and discard these

parts: rear cover and cover gaskets from case.

Note: Disregard Step Nos. 5a and 5b if converting to hermetically sealed version.

When converting a 45-1379 with the top fill

hole configuration, p/n 256A176-01 fill plug is

required and must be ordered separately.

5. Filling Procedures:

a. Manual Filling Procedure: Place gauge

face down on bench and tip gauge by

blocking up front with a

12 o’clock dial position. Tipping of the

gauge is necessary so fluid will flow into

Rear Cover

3

⁄8 inch block at the

ront cavity of the case. Pour in fill liquid to

f

within about

ubbles stop rising, front cavity is filled.

b

emove

R

until level is about

ng lip.

i

ote: An alternative method of filling is to

N

1

⁄16 inch of rear seal lip. When

3

nch block and pour in liquid

⁄8 i

1

⁄16 inch below rear seal-

fill the front dial cavity, adding the front

window, etc., as in Step No. 3. Then fill the

ear of the gauge. This method eliminates

r

the need to tip the gauge.

b. Vacuum Pump Fill Procedure: (This pro-

edure is recommended when filling a

c

large number of gauges.) Place gauge face

down and insert a

onnected to a vacuum pump, through the

c

2 o’clock position hole in the rear, solid

1

1

⁄8 inch diameter tube,

front portion of the case (see Fig. 5).

Evacuate the air from the front dial cavity

while pouring in the fill fluid through the

case back. The vacuum will displace the air

with fluid. When the dial cavity is solidly

filled, remove the tubing and continue to

pour the fill fluid to within

1

⁄16 inch BELOW

the O -ring channel lip.

Pre-measuring fill amount is not necessary

with above methods. For reference,

amount of fill is approximately

400 ml. or 14 fluid oz. (4

ml. or 16 fluid oz. (6˝ GA.).

c. Note: The liquid fill level should be

1

(±

⁄8) as measured from the inside of the

1

⁄2˝ GA.) and 455

3

⁄8˝

ring at the 12:00 o’clock position.

6. On lower connection gauges, assemble rear

seal dia phragm to case.

For back connection gauges see instructions

on reverse side. (Fig. 2/4).

7. For 1279:

Assemble rear cover and six self tapping

screws in a criss-cross pattern and torque to

12 in lbs. (±2 in lbs.)

For 1379:

- Thread rear ring and torque to 200 in lbs

- Install stainless steel back cover using

two screws. Torque screws to 14 in lbs.

(±2 in lbs.)

8. Assemble throttle screw to threaded hole in

socket.

Note: If system is monel (socket wrench

flat stamped “PHS” or “PH”) use monel throttle screw.

9. Check appropriate box on fill identification

label, and peel off label back, and attach fill

label to gauge case.

10. If gauge is to be repackaged:

a. Include enclosed instruction sheet inside

carton.

b. Change type number on carton label to:

(1) Hermetically Sealed – 1279(*)SH.

(2) Liquid Filled – 1279(*)SL.

*Bourdon Tube System Code

Glycerin or silicone should not be used in applications involving Oxygen, Chlorine, Nitric Acid,

Hydrogen Peroxide or other strong oxidizing

agents, because of danger of spontaneous chemical reaction, ignition or explosion. Halocarbon

should be specified. Products with this fill can be

ordered from factory.

The use of fluids other than those listed in the table

above (for example, Hydrocarbon-based oils) may

result in leakage caused by a reaction between the

fluid and the elastomeric seals. Consult the factory

before filling with any other fluid.

© 2015 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614 USA, Tel: 203-378-8281, Fax 203-385-0402 www.ashcroft.com

All sales subject to standard terms and conditions of sale. All rights reserved. I&M008-10090 (84B276) Rev 10/15

15

Page 16

TYPE 1279 & 1379 SOLID FRONT DURAGAUGE

®

PRESSURE GAUGE CONVERSION INSTRUCTIONS TO:

• Convert A Standard Dry Gauge To A Liquid Filled Gauge

• Convert A Standard Dry Gauge To A Dry, Weatherproof

I

P66 Gauge

INSTRUCTIONS FOR USING CONE

TOOL AND RING WRENCH

Garter Spring & Diaphragm Assembly

(Back Connection Gauge Only)

A

. Place cone tool over socket shank as shown.

B. Moisten lip of socket and outer O-ring surface

with silicone oil or grease.

C

. Place diaphragm with rib side facing upward over

c

one into case grove.

Diaphragm O-ring must be completely in socketshank grove.

D

. Place garter spring over cone as shown and slide

o

nto diaphragm in socket grove

E. Assemble rear cover with screws per step 7.

Front Ring Assembly (All Gauges)

A

. Assemble ring to case by hand to start.

B

. Place ring on wrench as shown

1

C. Use

⁄2˝ drive extension and torque ring to 200 in. lb

Alternate Method

A. Tighten ring snugly by hand

B. Mark case and ring.

C. Turn ring another 100 to 120 degrees (slightly

1

less than

⁄2 turn) using the ring wrench and 1⁄2˝

drive socket wrench or place the blunt end of a

wooden or plastic dowel against a ring lug and

tap with a hammer.

Fig. 2

Fig. 3

B

ACK CONNECTION ASSEMBLED GAUGE

IAPHRAGM

D

Fig. 3

CASE

EAR COVER

R

GARTER SPRING

Fig. 4

INSTRUCTIONS FOR LIQUID FILLING

®

ASHCROFT

SOLID FRONT DURAGAUGE

TYPE 1279 AND 1379

®

PRESSURE GAUGES USING A

VACUUM PUMP

A. Insert a length of

12 o’clock position hole in the rear, solid front

portion of the case, as shown.

B. Evacuate the air from the front dial cavity while

pouring in the fill fluid through the case back.

The vacuum will displace the air with fluid.*

C. When the dial cavity is solidly filled, remove the

tubing and continue to pour the fill fluid to within

1

⁄16 ˝ below the o-ring channel lip, as shown.

D. When converting a 45-1379 with the top fill hole

configuration, p/n 256A176-01 fill plug is

required and must be ordered separately.

*To prevent breakage, reduce vacuum to 15 in.

Hg for plain glass and safety glass.

1

⁄8 ˝ diameter tubing through the

Fig. 5

Ø 1⁄8 TUBING

DIAL

VACUUM

TRAP

VACUUM

PUMP

© 2015 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614 USA, Tel: 203-378-8281, Fax 203-385-0402 www.ashcroft.com

All sales subject to standard terms and conditions of sale. All rights reserved. I&M008-10090 (84B276) Rev 10/15

16

Page 17

ASHCROFT®Type 1082 Test Gauge

Calibration Procedure – Pressure Range

INSTRUCTIONS FOR USE OF EXTERNAL

ASY ZERO™ ADJUST FEATURE*

E

Fig. 1

A

B

RING

. LOOSEN RING-LOCKING SCREW A.

1

2. OBTAIN REQUIRED ADJUSTMENT BY

OTATING KNOB B CLOCKWISE OR

R

OUNTER-CLOCKWISE.

C

. TIGHTEN SCREW A DOWN ON KNOB B.

3

*Applicable only for test gauge with hinged

ring design.

ADDITIONAL

CALIBRATION INSTRUCTIONS

1) “Standards shall have nominal errors no greater than

1

⁄4 of these permitted for the gauge being tested.”

(Ref: ASME B40=100-1998)

2) The instrument used as the calibration standard

should have a maximum range no greater than 2x

that of the gauge being tested. (i.e. Do not use a

400psi standard to test a 15psi gauge.)

3) “Known pressure shall be applied at each test point

on increasing pressure (or vacuum) from one end to

the other end of the scale. At each test point the

gauge shall be . . .

lightly tapped, and then read . . .”

(Ref: ASME B40.1 ¶ 6.2.4.1)

4) To read gauge indication, move eye over red pointer

tip at OD of printed dial until red reflection in mirror

band is no longer visible, and then read the pointer

position in reference to the dial.

© Ashcroft Inc., 250 E. Main St., Stratford, CT 06614-5145, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale.

I&M008-10082 11/01 RevB (250-2917-4) AMR 10/07

17

Page 18

Installation and Maintenance Instructions for

ASHCROFT

®

Type 1082 Test Gauge

Calibration Procedure – Pressure Range

Fig. 2

MICRO

SPAN

MICROMETER

SPAN

>0.2%

THIS TEST GAUGE IS PROVIDED WITH A MICROSPAN™ ADJUSTMENT

TO SIMPLIFY CALIBRATION. THE FLOW CHART BELOW OUTLINES THE

RECOMMENDED CALIBRATION PROCEDURE

CENTER DIAL

O

VER PINION

SET POINTER

AT 0%

GO TO

100%

MICRO

SPAN

SET POINTER

AT 100%

GO TO

0%

CHECK

ACCURACY

<0.2%

>0.2 <1.5%

CHECK

ACCURACY

<0.2%

GO TO

0%

>1.5%

<0.2%

COARSE

SPAN

SET POINTER

AT 100%

GO TO

0%

CHECK

ACCURACY

>0.2<1.5%

COARSE

SPAN

>1.5%

COARSE

SPAN

ROTATE MOVEMENT

COUNTER-CLOCKWISE

TO REDUCE READING

AT MIDSCALE

TEMPERATURE

COMPENSATOR

MICROSPAN

ADJUSTMENT

–TIGHTEN SCREW TO

INCREASE SPAN

1 TURN – APPROX.

1

⁄2%

NOTE

COARSE

LINEARITY

MOVEMENT

screwdriver required.

GO TO

0%

ROTATE

COARSE SPAN

ADJUSTMENT

–LOOSEN TWO SCREWS

–MOVE SLIDE INWARD

TO INCREASE SPAN

(.004 IN. – APPROX. 1%)

–TIGHTEN TWO SCREWS

1.5mm hex

Ball end wrench or

>1.5%

>0.2<1.5%

SET POINTER

AT 0%

GO TO

50%

CHECK

ACCURACY

<0.2%

GO TO

100%

CHECK

ACCURACY

<0.2%

CHECK

ACCURACY

AT 0-25-50-75-100%

>1.5%

< – LESS THAN

> – GREATER THAN

© Ashcroft Inc., 250 E. Main St., Stratford, CT 06614-5145, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale.

I&M008-10082 11/01 Rev C (250-2917-4) 12/15

18

Page 19

19

Page 20

Ashcroft Inc.,

250 East Main Street

Stratford, CT 06614-5145

U.S.A.

Tel: 203-378-8281

Fax: 203-385-0408 (Domestic)

Fax: 203-385-0357 (International)

email: info@ashcroft.com

www.ashcroft.com

I&M008-10098-5/02 (250-1353-L) Rev. 12/15

Visit our web site www.ashcroft.com

20

Loading...

Loading...