Page 1

Data Sheet

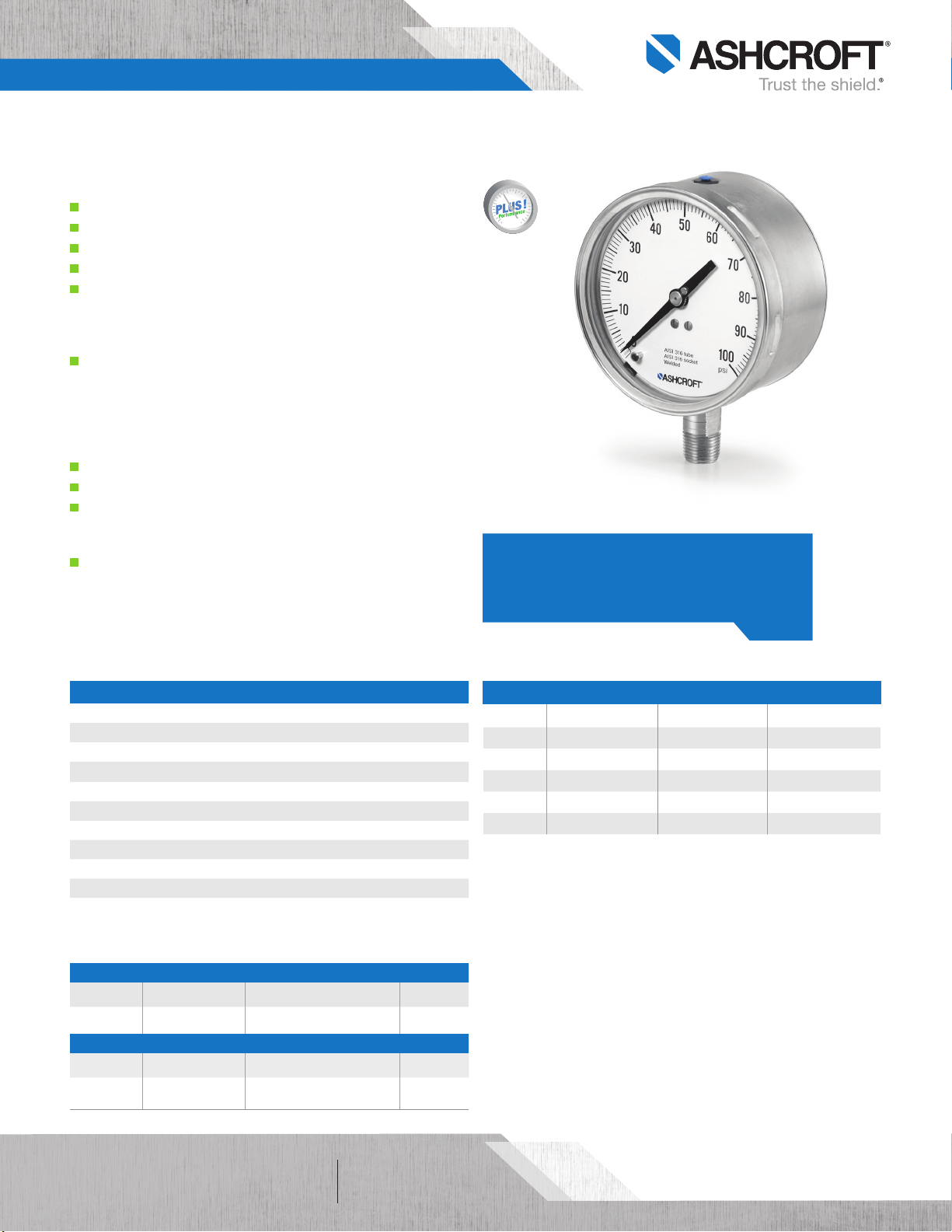

1209 4½˝ SS Process Gauge

FEATURES

Solid front case design with full pressure relief back

4½˝ Dial size

Accuracy: ±0.50% of span (ASME B40.100 Grade 2A)

316L stainless steel case and ring

Patented PLUS!

™

Performance

Dampens vibration, shock and pulsation effects

TYPICAL USES

Oil & Gas Industry

Upstream: Onshore/offshore production

Midstream: Transport, storage and natural

gas compression

Downstream: Refineries and petrochemical

industries

Chemical Industry

Injection Molding Equipment

Power Plants

Conventional power plants

Flue gas desulfurization plants

Other Industries

Waste incineration plants

Seawater desalination plants

Steel mills

Cement plants

TM

1209

41⁄2˝ Dial size

KEY BENEFITS

• Full pressure relief back for safety

• Socket welded to case for superior leak integrity

SPECIFICATIONS

Accuracy: ±0.5% of span (ASME B40.100 Grade 2A)

Dial Size: 4½˝

Range: Vacuum, compound to 20,000 PSI

Process Connection:

1⁄4 NPT Male, 1⁄2 NPT Male

Case Style: Solid front with full pressure relief back

Movement: 304 stainless steel, adjustable

Window Material: Acrylic (STD.), safety glass (OPT.)

Pointer: Micrometer adjustable, aluminum

Weather Protection: IP65 hermetically sealed

Mounting: Stem, surface (STD.), flush, pipe, remote (OPT.)

Dampening:

Liquid fill,

™

PLUS!

Performance, throttle screw,

dampeners, capillary, diaphragm seals and snubbers

WETTED COMPONENTS

Model

1209

Bourdon Tube Process Connection Joints

316L SS 316L SS Welded

NON-WETTED COMPONENTS

Model

1209

Case Ring Back Cover

316L SS 316L SS 316L SS

MIN./MAX. TEMPERATURE LIMITS

Ambient Process Storage

Dry

PLUS

Glycerin

Silicone

Halocarbon®-40 to 150°F (-40 to 66°C) -40 to 150°F (-40 to 66°C) -40 to150°F (-40 to 66°C)

Note: Other than discoloration of the dial and hardening of the gasketing that may occur as ambient or process temperatures exceeds 150°F, non-liquid-filled gauges with standard glass windows, can withstand continuous operating temperatures up to 250°F (121°C). Liquid-filled gauges

can withstand 200°F (93°C) but glycerin fill and acrylic window will tend to yellow. Accuracy at

temperatures above or below the reference ambient temperature of 68°F (20°C) will be affected

by approximately 0.4% per 25°F. Gauges with welded joints will withstand 750°F (400°C), 450°F

(232°C) with silver brazed joints for short times without rupture, although other parts of the gauge

will be destroyed and calibration will be lost. For continuous use and for process or ambient temperatures above 250°F (121°C), a diaphragm seal or capillary or siphon is recommended.

-40 to 200°F (-40 to 93°C) -40 to 200°F (-40 to 93°C) -40 to 200°F (-40 to 93°C)

™

-40 to 200°F (-40 to 93°C) -40 to 200°F (-40 to 93°C) -40 to 200°F (-40 to 93°C)

20 to 150°F (-7 to 66°C) 20 to 150°F (-7 to 66°C) 20 to 150°F (-7 to 66°C)

-40 to 150°F (-40 to 66°C) -40 to 150°F (-40 to 66°C) -40 to 150°F (-40 to 66°C)

All specifications are subject to change without notice.

All sales subject to standard terms and conditions.

©2019 Ashcroft Inc. 1209_gauge_ds _RevE_Ltr_03-19

ashcroft.com

info@ashcroft.com

1.800.328.8258

1 of 3

Page 2

Data Sheet

1209 4½˝ SS Process Gauge

ORDERING CODE Example:

Dial Size/Model Code

451209 - 41⁄2˝ SS, solid front process gauge per ASME B40.100 451209

System (tube and process connection)

S - SS system S

Case Fill

D - Dry Case D

L - Liquid filled case, glycerin (STD.)

Process Connection Sizes

02 - 1⁄4 NPT Male (up to 20,000 psi)

04 - 1⁄2 NPT Male (up to 20,000 psi) 04

Process Connection Location

L - Lower connection only L

Range (coding examples only, see range table on next page for all standard ranges)

Single Scales

15# - 15 psi 15#

1KSC - 1 kg/cm

100KP - 100 kPa

Options (if choosing an option(s) must include an “X”) -X_ _

EP - Maximum pointer, adjustable

GV - Silicone case fill

GX - Halocarbon case fill

LL -

PLUS!

NH - SS tag wired to case

OS - Overload stop

SG - Safety glass

VS - Underload stop

C3 - Material test report to EN 10204.3.1

C4 - Individual calibration chart (in accordance with ASME B40.100:2013. Accuracy traceable to NIST)

D3 - DuraVis™ Retroreflective Dial (4½˝ and dry case only)

6B - Cleaned for oxygen service

2

™

Performance

4512 09

S D 04 L 15# -XLL

LL

All specifications are subject to change without notice.

All sales subject to standard terms and conditions.

©2019 Ashcroft Inc. 1209_gauge_ds _RevE_Ltr_03-19

ashcroft.com

info@ashcroft.com

1.800.328.8258

2 of 3

Page 3

Data Sheet

2.52 [64]

0.74 [15.8]

1209 4½˝ SS Process Gauge

1209 STANDARD RANGES

psi bar kPa mPa kg/cm

30IMV N1BR N100KP N1MP N1KG

Vacuum

– N1/0.6BR N100/60KP 0.1/.06MP N1/0.6KG

V/15# – – – –

– N1/1.5BR N100/150KP N0.1/0.15MP N1/1.5KG

V/30# – – – –

– N1/3BR N100/300KP N0.1/0.3MP N1/3KG

V/60# – – – –

Compound

– N1/5BR N100/500KP N0.1/.5MP N1/5KG

V/100# – – – –

– N1/9BR N100/900KP N0.1/0.9MP N1/9KG

15# 1BR 100KP 0.1MP 1KG

20# – – – –

– 1.6BR 160KP 0.16MP 1.6KG

30# – – – –

– 2.5BR 250KP 0.25MP 2.5KG

60# 4BR 400KP 0.4MP 4KG

– 6BR 600KP 0.6MP 6KG

100# – – – –

120# – – – –

– 10BR 1000KP 1MP 10KG

160# – – – –

200# – – – –

– 16BR 1600KP 1.6MP 16KG

300# – – – –

– 25BR 2500KP 2.5MP 25KG

400# – – – –

500# – – – –

600# 40BR 4000KP 4MP 40KG

800# – – – –

Positive Pressure

– 60BR 6000KP 6MP 60KG

1000# – – – –

1500# 100BR 10000KP 10MP 100KG

2000# – – – –

– 160BR 16000KP 16MP 160KG

3000# – – – –

– 250BR 25000KP 25MP 250KG

4000# – – – –

5000# – – – –

6000# 400BR 40000KP 40MP 400KG

8000# – – – –

– 600BR 60000KP 60MP 600KG

10000# – – – –

15000# 1000BR 100000KP 100MP 1000KG

20000# 1600BR - 160MP 1600KG

DIMENSIONS in [ ] are millimeters

2

For reference only, consult Ashcroft for specific dimensional drawings

4.88 [124]

Ø

6.30 [160]

1.34 [34]

½˝ NPT THREAD ACCD.

ANSI B1.20.1

4.96 [126]

Ø

All specifications are subject to change without notice.

All sales subject to standard terms and conditions.

©2019 Ashcroft Inc. 1209_gauge_ds _RevE_Ltr_03-19

ashcroft.com

info@ashcroft.com

1.800.328.8258

3 of 3

Loading...

Loading...