Page 1

Installation Instructions for

0

1

3

2

4

5

HIGH PRESS.

PORT

PISTON MAGNET

R

OTARY MAGNET

T

EFLON

®

S

EAL

POINTER

S

WITCH

(

OPTIONAL)

RANGE SPRING

L

OW PRESS.

P

ORT

PISTON

ASHCROFT®Model 1130

Differential Pressure Gauge/Switch

For efficient working of your gauge, please read all instructions

carefully before attempting to install.

CAUTION: Do not exceed maximum operating pressure given

on the gauge label. Check fluid compatibility with wetted parts

before use. Minor leakage past the Teflon seal is possible.

“High” and low media must be compatible.

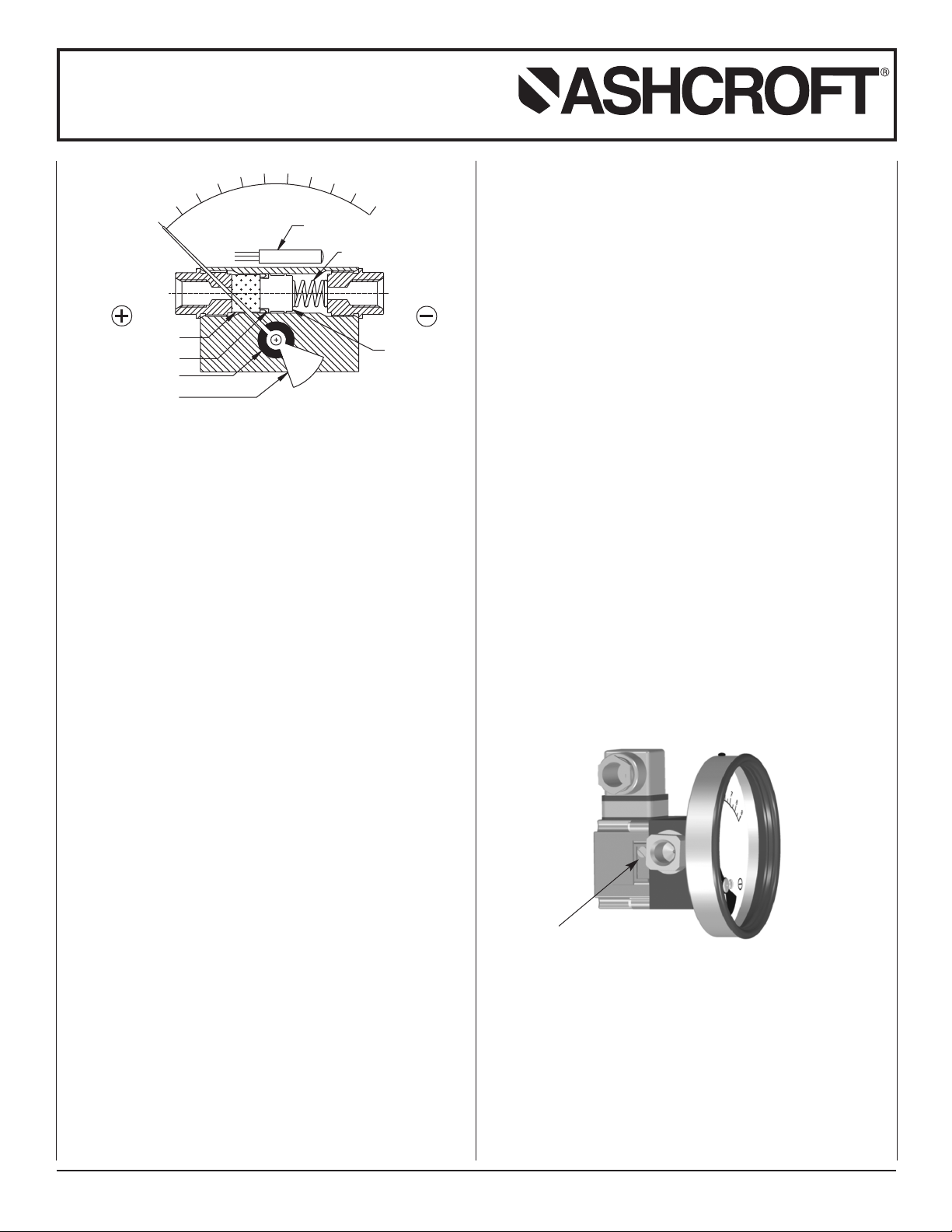

OPERATING PRINCIPLE

High and Low pressures are separated by a sensor assembly

consisting of a magnet, diaphragm and a range spring. The

difference in pressure causes the sensor assembly to move in

proportion to the change against a range spring.

A rotary magnet, located in a separate body compartment and

isolated from the acting pressures is rotated by a magnetic

coupling following the linear movement of the sensor assembly. A pointer attached to the rotary magnet indicates differential pressure on the dial.

SWITCH: Reed switches (optional) are located adjacent to the

pressure chamber and are activated by the magnetic field of

the sensor assembly.

Note: The gauges are calibrated to give ±2% full scale accuracy on ascending readings.

INSTALLATION

For better performance the gauge should be mounted horizontally with the dial vertical. Depressurize the system and connect the high and low pressure lines of your system to the

“High” and “Low”ports of the gauge, respectively.

It is recommended to use “O” rings with male connectors to

avoid excessive tightening and to prevent leakage (for parallel

threads). The gauge is now ready for operation. Apply “High”

and “Low”pressures simultaneously, to avoid damage to the

internal parts.

Model 1130 consists of a piston type mechanism to sense the

pressure difference. It can withstand maximum operating pressure up to 3000 psi for all ranges

rated maximum pressure, “O” rings used on male connectors,

and the Teflon seal inside the pressure chamber, will be damaged. If maximum operating pressure is within the allowable

limit of 3000 psi

© Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0357, www.ashcroft.com

All sales subject to standard terms and conditions of sale. I&M008-10089-12/01 AMR 2C09/09

range, there will be no damage to the gauge. The pointer will

only go to the extreme right end of the scale.

PRECAUTIONS

o not connect “High” and “Low” ports to the wrong pipe ends.

D

Do not subject the gauge to excessive vibration. The gauge is

never to be used in an area where a magnetic field is present.

t may show the wrong readings.

I

s the gauge works on a magnetic coupling principle, use only

A

non-magnetic fittings, parts, etc. in areas closer than 2˝ on all

sides, otherwise calibration will be affected. Panel mounted

gauges should be installed in non-ferrous panel material.

However, gauges with 2˝ and 2.5˝ dials, mounted in steel

panels, may require pointer adjustment. This is done by the

manufacturer, upon request.

Model 1130

Piston

Do not try to open any part of the gauge for any reason, because if not reassembled properly calibration will be affected.

SWITCH SETTING

Please follow these instructions when your differential pressure

gauges are supplied with a switch. The switches are normally

factory set to save time the customer time. However, they are

field adjustable.

CAUTION: Supply voltage should not exceed switch rating. For

higher supply, use of relay circuit is recommended.

SWITCH ADJUSTMENT

The following procedure must be done by putting the gauge on

a test bench or while in actual service. The switch adjustment

screw is located on the plastic cover. Rotate the screw anticlockwise to increase the setpoint and clockwise to decrease

the setpoint. One or two trials may be necessary to attain the

exact setpoint.

(1) 6000 psi for stainless steel

*Teflon TM of duPont

Increase setpoint

anti-clockwise

(1)

, but the differential pressure exceeds gauge

(1)

. If pressure exceeds the

View from high pressure side

Page 2

Load

L

(+)

N

(-)

N

(-)

RRB

B

Switch #1 Switch

#2

L

oad

L

(+)

N

(-)

R

B

S

witch

#

1

6

6

5

5

4

4

3

3

221

1

6

6

5

5

4

4

3

3

221

1

Lor (+)

Lor (+)

Load

N or (-)

N or (-)

N or

(-)

1

3

2

E

B

R

E

1

3

2

SPST

Switch

Load for

Load for

Switch #1

3

2

E

1

3

1

E

R

B

2

B

Switch #2

Switch #1

Switch #2

Installation Instructions for

Load

NC

NO

1

3

2

E

N

(

-)

L

(+)

N

(-)

Load

Load

NC

NO

B

R

Y

6

6

5

5

4

4

3

3

221

1

N

(-)

L

(+)

N

(-)

N

(

-)

Load

Load

Load

Load

N

(-)

NC

NC

NO

NO

B

R

Y

Y

B

6

6

5

5

4

4

3

3

221

1

Lor (+)

N or (-)

N or (-)

Y

R

3

1

2

E

B

SPDT

Switch

Switch #1

Switch #1 Switch #2

ASHCROFT®Model 1130

Differential Pressure Gauge/Switch

SPST SWITCH

Specifications

Contact Rating : 10 VA ac (rms) or dc (max)

Switching Current : 0.5 Amp ac (rms) or dc (max)

Switch Voltage : 100 Vac/Vdc (max)

PDT SWITCH

S

pecifications

S

Contact Rating : 3 VA ac (rms) or dc (max)

Switching Current : 0.3 Amp ac (rms) or dc (max)

witch Voltage : 30 Vac/Vdc (max)

S

ONE SPST SWITCH

Reed Switches and

Terminal Strip Connection

Reed Switches and

DIN Plug Connection

iew of socket for supply connections

V

TWO SPST SWITCHES

Terminal Strip Connection

DIN Plug Connection

iew of socket for supply connections

V

Reed Switches and

Reed Switches and

ONE SPDT SWITCH

Reed Switches and

Terminal Strip Connection

Reed Switches and

DIN Plug Connection

iew of socket for supply connections

V

TWO SPDT SWITCHES

Reed Switches and

Terminal Strip Connection

View of plug after removing the socket View of plug after removing the socket

View of plug after removing the socket

R = Red; B = Black; Y = Yellow; L = Live or + Supply; N = Neutral or – Supply.

© Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0357, www.ashcroft.com

All sales subject to standard terms and conditions of sale. I&M008-10089-12/01 AMR 2C09/09

Body to be suitably grounded while using gauge + switch and only switch.

*

Loading...

Loading...