Aseptico ADU-10CF User manual

SERVICE

MANUAL

&

(NSN:

PARTS

ADU-10CF

6520-01-456-7170)

LIST

Part I of

2

P.O.

Box

1548

Woodinville,

1-800-426-5913 * 425-487-3157 * Fax:

email:

info@aseptico.com * Internet:

WA

98072-1548

425-487-2608

www.aseptico.com

12/98

P/N

420218

TABLE

OF

CONTENTS

General

Inspection & Verification

Cleaning & Lubrication

Dis-Assembly

Handpiece

Vacuum

Fiber

TA-97 3-Way

Troubleshooting

System

System

Illustrated

e

Vacuum

Case

HVE & Saliva

NWS-6

TA-97

AA-42

Air

Swivel

KaVo

Service

System/Water

Optic

Schematic;

Schematic;

e

Control

Components

Information

Control/Delivery

System

Syringe

Chart

Handpiece

Vacuum

Parts

List

aç

...

Ejector

Water

System

Autoclavable 3-Way

Standard

Supply

Tray

Fiber

Disc

Line

Assembly

Assembly

Optic

System

...

System

...

..

Assembly

Foot

..

Head . .

Control

Control

Control

MV

Syringe

Control

.

. .

..

.

...

..

.

...

.

le

lc SÜ e e

Specilienil0ns...

TABLE

Handpiece

Vacuum

Fiber

3-Way

System

System

Illustrated

Illustrated

Illustrated

Illustrated

Illustrated

System/Water

Optic

Syringe

Schematic,

Schematic,

Illustrated

Illustrated

Illustrated

Swivel

Tray

KaVo

Fiber

s1...

OF

ILLUSTRATIONS

Control/Delivery

System

.

Parts

List,

Parts

List,

Parts

List,

List,

Parts

List,

Parts

List,

Parts

List,

Parts

List,

Parts

Assembly

Optic

saunaya

System

..

ADU-10CF

ADU10CF

Handpiece

Vacuum

Case

Components

&

HVE

NWS-6

TA-90

AA-42

Supply

Air

System

A

Head

Control

Handpiece

Vacuum

Control

Saliva

Water

Autoclavable

Standard

Control

Control

....

Ejector

System

Disc

Assembly

Line

...

Control

..

3-Way

nes

.

Assembly

..

Syringe

Control

Foot

vie a ara

..

..

.......

dia a а

еее

196

2

Box

P.O.

1-800-426-5913

info@aseptico.com

email:

Woodinville,

1548

425-487-3157

*

*

WA

*

Internet:

www.aseptico.com

98072-1548

425-487-2608

Fax:

Printed

In

The

USA

GENERAL

This

service

Operation

Portable

schematics

coded

listed

that

Use

Field

by

color

in

reverse

can

be

information

the

SERVICE

and

parts

and

Maintenance

Dental

show

components

tone

and

numerical

purchased

in

manual

Unit

line

order

at

retail

Parts

the

INFORMATION

offers

manual.

works,

in

thickness,

hardware

information

thereby

there

actual

in

the

when

List

It

will

and

Parts

stores,

and

help

reducing

places

all

parts

List.

Parts

and

ordering

parts

lists

you

better

service

in

the

are

minimize

replacement

time.

unit

called

marked

service

out

not

available

understand

Exploded

relative

as

parts.

to

one

by

Aseptico

"Commercial"

delays

in

how

parts

another.

part

when

the

ADU-10CF

the

ADU-10CF

drawings

Tubing

number,

are

those

obtained

and

is

then

items

locally.

Inspection

To

verify

that

air

source

pressure

turned

from

three-way

the

to

on

the

While

performance.

Element

Water

require

tube.

container

screen

The

above

not

perform

service.

various

providing

gauge

on,

water

highspeed

the

syringe.

system,

position.

system

should

canister

lubrication

Water

filter

lids

should

describes a basic

as

Use

the

problems.

&

Operation

the

ADU-10CF

60-80

PSI.

and

"On"

indicator

canister

Syringe

the

lift

Vacuum

is

pressurized,

Air

filterAvater

be

replaced

should

or

requires

should

be

inspected

required,

troubleshooting

should

and

line,

should

and

HVE

should

when

be

holding

replacement

replacement

be

sealed

for

inspection & verification

further

Verification

unit

is

functioning

Switch

should

pressurize.

lowspeed

spray

Saliva

inspect

separator

blockage

Ejector

switch

the

pressure

pressure

for a proper

and

holding a vacuum

diagnosis

section

the

master

indicate

Depress

when

line

both

air

valve

vacuum

and

on,

unit

for

drain

should

drop

at

if

it

becomes

and

cleaned

of

settings

as a guide

properly,

On/Off

pressure.

foot

selected.

and

water.

from

air

or

water

be

across

the

lid,

seal.

Inspect

clogged

or

of

and

to

symptoms

connect

toggle

When

control

Depress

With

vacuum

auto

their

generated

leaks

closed,

the

unit

exceeds

and

the

lid

the

and

restricts

when

in

replaced

the

if

ADU-10CF

components

and

the

unit

to

to

the

on

the

water

and

observe

air/water

the

waste

holders

each

at

that

and

gasket

water

operation.

necessary.

appropriate

with

valve.

could

air

filter

10psi

inspected.

filter

water

system.

in

the

a

clean

compressed

position.

system

containers

degrade

element

differential

on

flow.

HVE

If

system

The

is

attached

drive

air

buttons

out

lock

or

Gasket

the

water

Vacuum

solids

the

unit

may

procedures

master

and

pressure

the

on

attached

switch

eliminate

inspected.

pressure.

collector

still

in

may

pick-up

waste

does

require

to

fix

Cleaning

When

thoroughly

cleaner.

finishes

Use a silicone

parts,

o-rings,

assembly

installation

and

servicing

cleaned

Flush

all

and

should

oral

of

parts

easier

Lubrication

the

ADU-10CF

and

parts

with

be

avoided.

base

lubricating

evacuator

that

contain

and

prevent

dental

inspected

clear,

hot

Any

grease

valves,

o-rings

the

o-rings

unit,

before

water.

wiping

such

and

seals

or

seals,

or

the

parts

of

any

component

re-assembly. A hot

Abrasive

should

as

in

seals

cleaners

be

done

with a soft,

Dow

Corning

the

ADU-10CF

apply a light

from

coat

being

have

No.103

damaged.

detergent

the

potential

lint

to

lubricate

unit.

Before

of

silicone

disassembled

solution

free

grease.

is

an

to

damage

cloth.

internal

performing

This

should

will

be

effective

surface

moving

any

re-

make

Page

3

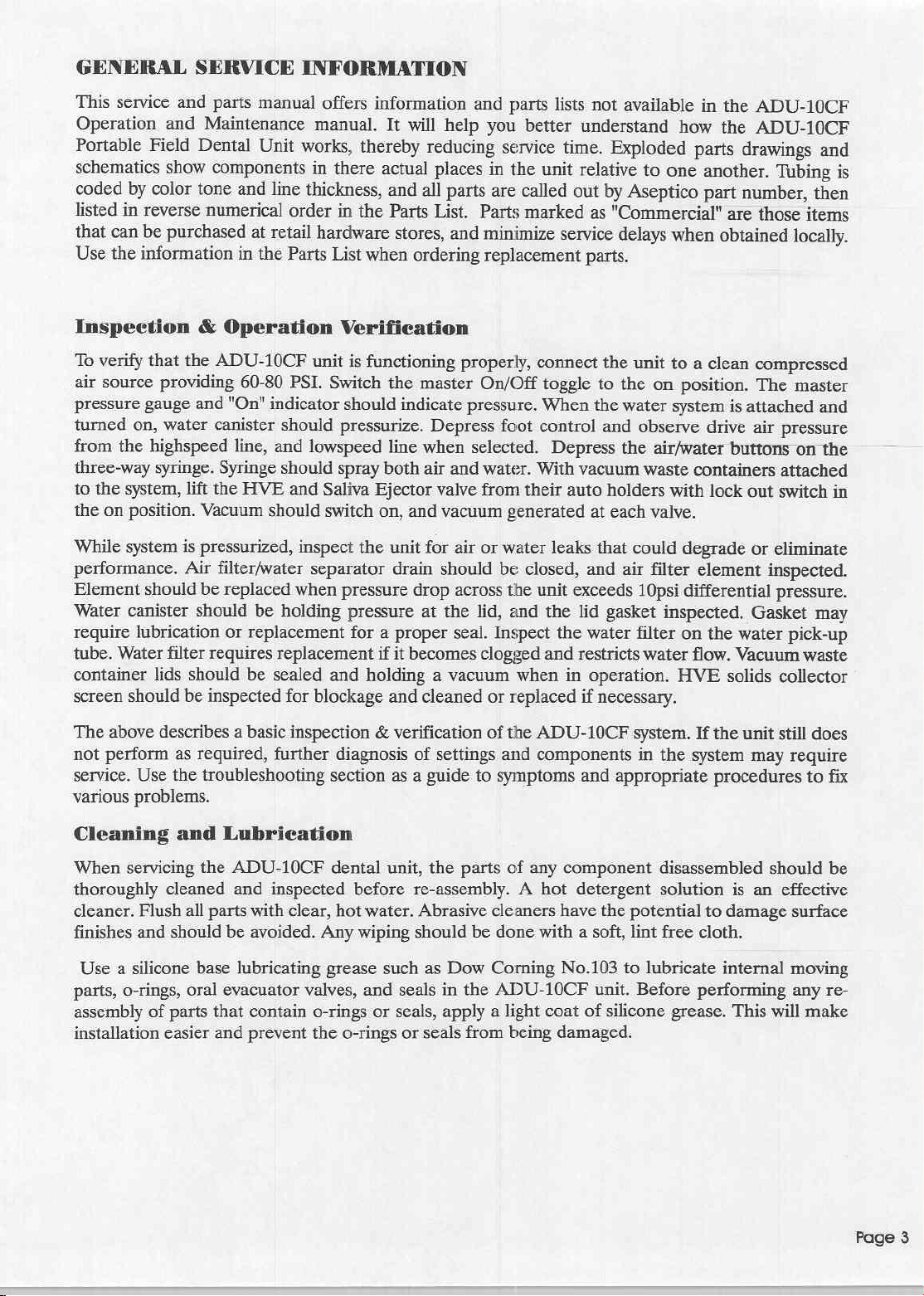

DIS-ASSEMBLY

Handpiece

Most

cover(P/N

6-32x1/4"

Disconnect

If

the

four

remove

the

four

Head

Re-assembly

Control/Delivery

all

service

460311-08).

socket

pressure

entire

Handpiece

mounting

Handpiece

10-32x1/2"

assembly

is

screws

while

Control/Delivery

Vacuum

To gain

from

the

use a 1/8"

washers.

To

vacuum

signal

System/Water

access

its

to

mounting

Vacuum/Water

Hex

Support

completely

remove

pick-up

lines.

(Reference

Head

to

the

Handpiece

To

remove

screws

beneath

gauge

and

Control/Delivery

behind

Control/Delivery

socket screws

removing

done

in

the

reverse

Head

assembly.

System

internal

position

wrench

the

tubes,

parts

in

the

System

Control.

to

loosen

Vacuum/Water

the

Vacuum/Water

the

3/8"

Figure

2A)

(Reference

Control/Delivery

front

cover,

the

front

edge.

On/Off

Indicator

Head

the

Handpiece

Head

assembly,

and

#10

sealing

mounting

screws.

order.

Align

front

Control

of

case.

(Reference

the

Vacuum/Water

Locate

To

remove

and

remove

System

System

air

supply

line,

Figure

1)

Head

use a 5/64"

Pull

front

lines

to

assembly

can

Hex

cover

completely

must

Control/Delivery

use a 1/8"

washers.

Replace

cover

with

Figure

the

four

Handpiece

the

four

Control

Control

the

1/4"

Support

sealing

rear

2)

System

Control,

mounting

Vacuum/Water

10-32x1/2"

assembly

from

handpiece

be

accessed

wrench

to

straight

remove

be

removed

Head

Hex

washers

on

wrench

the

Handpiece

when

alignment

you

screws

on

socket

while

removing

the

case,

air

supply

by

loosen

off

front

from

the

to

mounting

pins

when

must

the

System

screws

you

line,

removing

and

remove

rear

alignment

the

the

cover.

the

case,

locate

back

of

the

case.

loosen

and

remove

Control/Delivery

Handpiece

replacing.

remove

top

mounting

must

the

of

the

case

Control

and

#10

screws.

disconnect

and

the

assembly

assembly,

sealing

air

front

two

pins.

the

To

above

the

pilot

Re-assembly

System

assembly.

is

done

in

the

Reattach

reverse

supply

tubes

order.

per

Replace

vacuum

sealing

control

washers

when

mounting

schematic.(Reference

=

Alignment

Socket

Pins

Screws

Vacuum/Water

Figure

2A)

ige

Figure

Handpiece

4

Control/Delivery

1

Head

Vacuum

Figure

System/Water

2

System

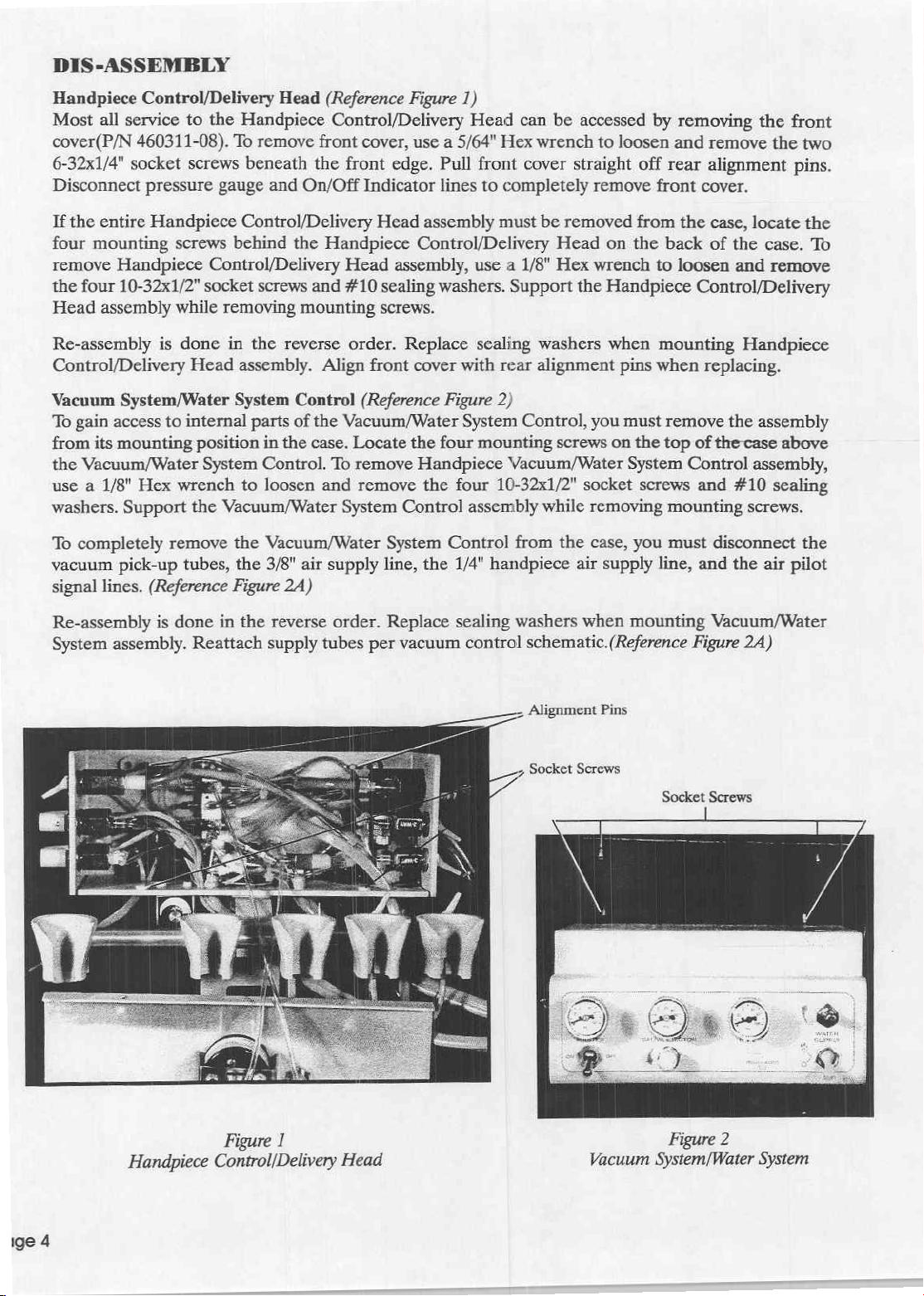

Fiber

Optic

The

ADU-10CF

Control

removal

To

remove

Remote

Control

To

remove

System

is

Module,

for

service

the

Remote

Intensity

cable

from

the

KaVo

Control/Delivery

blade

screwdriver,

the

LCM

control,

handpiece

Handpiece

replacement.

To

remove

and

Remote

Signal

driver,

control,

Hex

Control/Delivery

in

the

tubing

Air

tube

loosen

position

Nuts

holding

reverse

Control/Delivery

Reassembly

the

KaVo

Intensity

from

holding

No.

Head.

order.

(Reference

equipped

Remote

or

Intensity

replacement.

Intensity

Control

the

LCM

LCM

Head

front

loosen

position

Drive

Air,

is

LCM

Control

the

LCM

screws

4(reference

the

LCM

Remove

Figure

with a KaVo

Control,

bracket

control

Handpiece

cover

as

holding

No.

Coolant

screws

4.

Carefully

Head

done

in

Fiber

Optic

cable

control box

for

the

Fig.

control box

LCM

3)

LCM

Control,

and/or

unscrew

underneath

jack

marked

Tubing

described

for

the

slide

Air,

and

Coolant

(reference

the

reverse

Handpiece

from

the

LCM

at

the

low

voltage

12A-Fiber

to

the

mounting

control box

Fiber

Optic

the

KaVo

the

the

delivery

"INT".

from

in

the

first

low

voltage

the

wires

Water

Fig.

1A-System

order.

control

control

position

handpiece

Optic

System

bracket

for

service

Handpiece

LCM

Handpiece

two

4-40x1/4"

head.

Unplug

Reassembly

the

unit,

paragraph

handpiece

out

of

the

tubes

from

Schematic).

box,

first

box.

Disconnect

marked

"HP4".

tubing

Schematic).

in

the

or

replacement.

Lighting

tubing

socket

screws

the

is

done

in

the

first

remove

of this

section.

tubing

wires

delivery head.

their

connections

Remove

unplug

the

the red

With a small

wires

connected

Remove

unit

beneath

Reassembly

System.

The

may

require

holding

Remote

reverse

the

Intensity

order.

Handpiece

With a small

connected

Remove

inside

tubing

transformer

1/8"

Fiber

blade

screw-

to

the

the

two

the

Handpiece

is

LCM

the

to

the

the

for

cable,

Optic

LCM

6-32

done

Remote

Handpiece

Intensity

KaVo

Control

LCM

Tubing

Handpiece

With

HAND + AIR

2)

Figure

Conirol/Delivery

Fiber

3

Optic

System

Head

Low

Voltage

Tubing

Remote

Fiber

KaVo

6-32

Handpiece

Wires

Intensity

Optic

Signal

Box

LCM

Hex

Nut, 2 Pl.

Jack

Air

Page 5

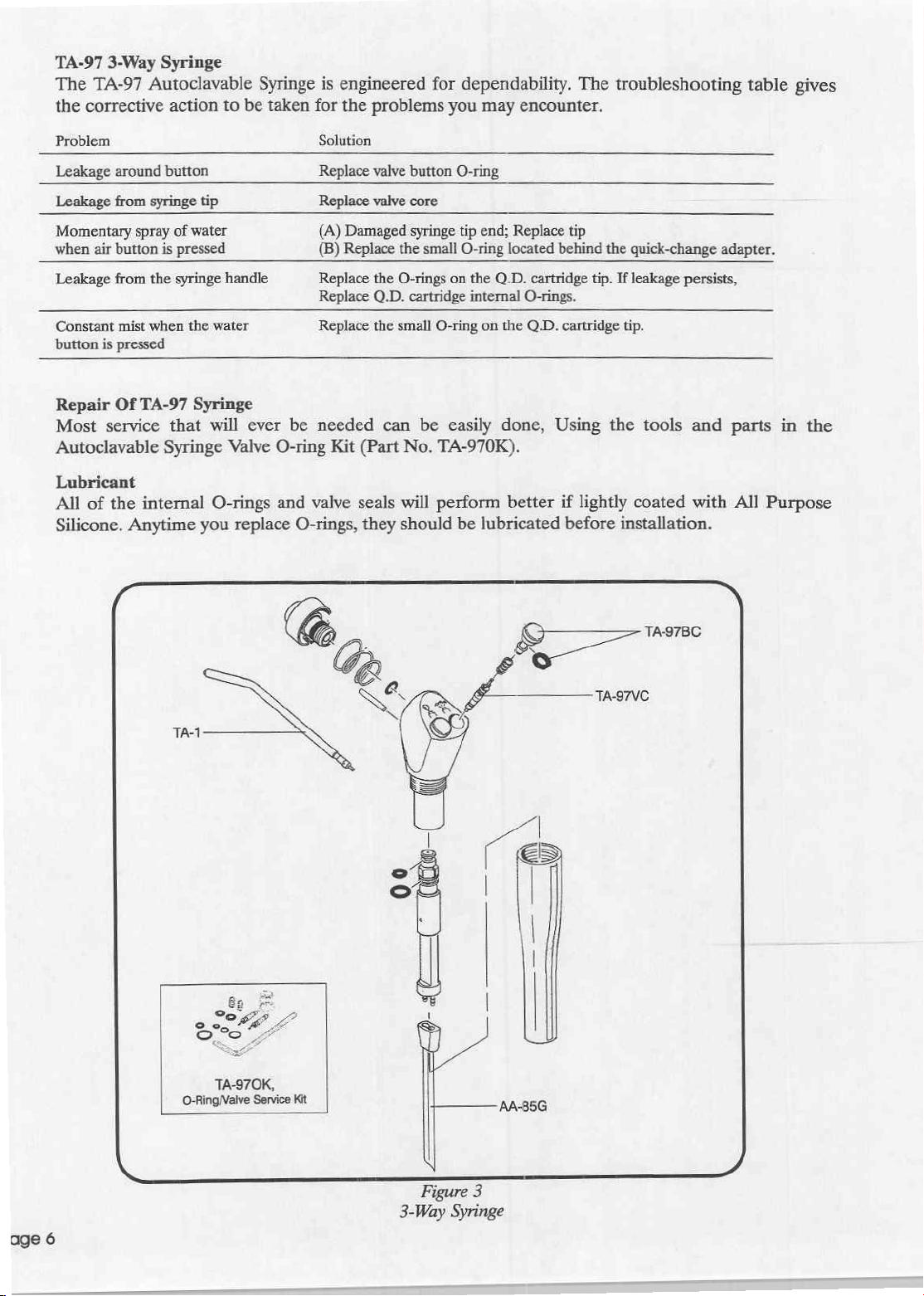

TA-97

The

the

3-Way

TA-97

corrective

Syringe

Autoclavable

action

to

be

Syringe

taken

for

is

engineered

the

problems

for

dependability.

you

may

encounter.

The

troubleshooting

table

gives

Problem

Leakage

Leakage

Momentary

when

Leakage

Constant

button

Repair

Most

Autoclavable

Lubricant

All

Silicone.

around

from

air

button

from

mist

is

pressed

Of

service

of

the

[三

button

syringe

spray

of

is

pressed

the

syringe

when

the

TA-97

that

Syringe

internal

Anytime

tip

water

handle

water

Syringe

will

ever

Valve

O-rings

you replace

Solution

Replace

Replace

(A)

(B)

Replace

Replace

Replace

be

needed

O-ring

and

valve

O-rings,

Damaged

Replace

Kit

(Part

seals

they

valve

button O-ring

valve

core

syringe

the

the

O-rings

Q.D.

cartridge

the

small

can

be

No.

will

should

tip

end;

small

O-ring

on

the

internal

O-ring

on

easily

TA-970K).

perform

be

lubricated

Replace

located

Q.D.

cartridge

O-rings.

the

Q.D.

done,

better

tip

behind

the

quick-change

tip.

If

leakage

cartridge

Using

if

before

tip.

the

lightly

installation.

persists,

tools

coated

adapter.

and

with

a

parts

All

Purpose

in

the

TAA

TA-970K,

O-RingValve

(©

Service

Kit

i

“e

SG

A

TA-97BC

TA-97VC

Massa

Figure

3-Way

3

Syringe

Button

Before

metallic

syringe

Use

installing

Excessive

Do

To

the

Drop

Tip

Remove

Kit

and

Valve

removing

device

body.

the

valve

the

tightening

not

reinstall a used

replace

button

Adapter & Collar

to

the

itself.

the

coil

the

syringe

unscrew

the

such

Be

careful

core

new

valve

O-ring

Push

spring

the

syringe

as a tongue

not

tool

(Part

core,

may

impair

valve

on

the

the

replacement

into

the

tip,

then

tip

adapter.

button,

depressor

to

lose

the

No.

TA-97VT)

do

not

valve

core,

because

syringe

syringe

use

the

Remove

button,

disconnect

or

small

over-tighten

operation.

O-ring

body,

then

hex

key

the

the

Popsicle

coil

to

unscrew

it.

it

will

be

remove

into

carefully

furnished

adapter,

syringe

stick

spring

that

the

It

needs

difficult

the

old

its

groove

with

collar

from

to

is

valve

only

to

O-ring

push

the

and

the

Q.D.

gently

pry

the

located

to

get

on

the

Autoclavable

spring

beneath

core

from

be

snug

it

to

seal

carefully,

the

stem

button

from

cartridge.

button

the

the

syringe

enough

properly.

so as

to

of

the

button.

into

place.

Syringe

the

syringe

Use a non-

valve

out

button.

body.

to

seal

the

avoid

damaging

Valve

body.

of

the

When

bore.

O-ring

Use a dental

syringe

install

into

to

Before

assure

collar

Use

you

the

have

Q.D.

Removing

adapter. A bent

the

the

be

installed

that

with

the

don’t

adapter.

approximately

Cartridge

pick

body.

Be

replacement

bore.

The

with

reinstalling

the

the

pin,

hex

key

have a torque

If

Before

air

and

syringe

the

or a bent

especially

is

to

O-ring

care.

the

adapter

alignment

then

to

you

tighten

performing

water,

O-Rings

paper

pin

push

carefully

measuring

the

right

and

from

clip

paper

clip

careful

slip

around

screw

the

torque.

any

bleed

the

or a dental

not

it

onto

the

and

collar

is

in

place.

the

collar

in

device,

adapter

service

pressure

Q.D.

to

remove

to

nick

the

end

outside

the

as

of

assembly,

With

the

into

the

adapter.

hold

tight

IMPORTANT

on

the

Q.D.

from

the

cartridge

pick

gives

can

the

tiny

O-ring

or

scratch

of a syringe

the

adapter

look

spring

syringe body.

Tighten

the

hex

as

you

cartridge,

system

you

be

used

the

down

in

the

key

can

while

by

access

to

remove

from

the

bottom

sealing

tip,

is

thin

into

place

adapter

by

the

it

is

running a handpiece.

to

surfaces.

lubricate

and

the

in

short

holding

necessary

the

the

the

fragile,

bore

the

collar,

firmly

end, with

the

O-rings

two

O-rings.

O-ring,

so

in

the

align

(35

tool

to

turn

of

the

the

easiest

then

the

new

syringe

the

in-lbs

the

this

way,

off

the

on

bore

in

way

insert

one

body

and

slot

in

torque).

long

end

you

will

the

of

end

the

to

it

has

the

If

in

the

Further

material

disassembly

accumulated

has

of

Q.D.

the

inside

cartridge

upper

the

needed

is

cartridge

body.

only

there

if

There

is

are

reason

no

to

serviceable

believe

parts

foreign

that

inside.

Page

7

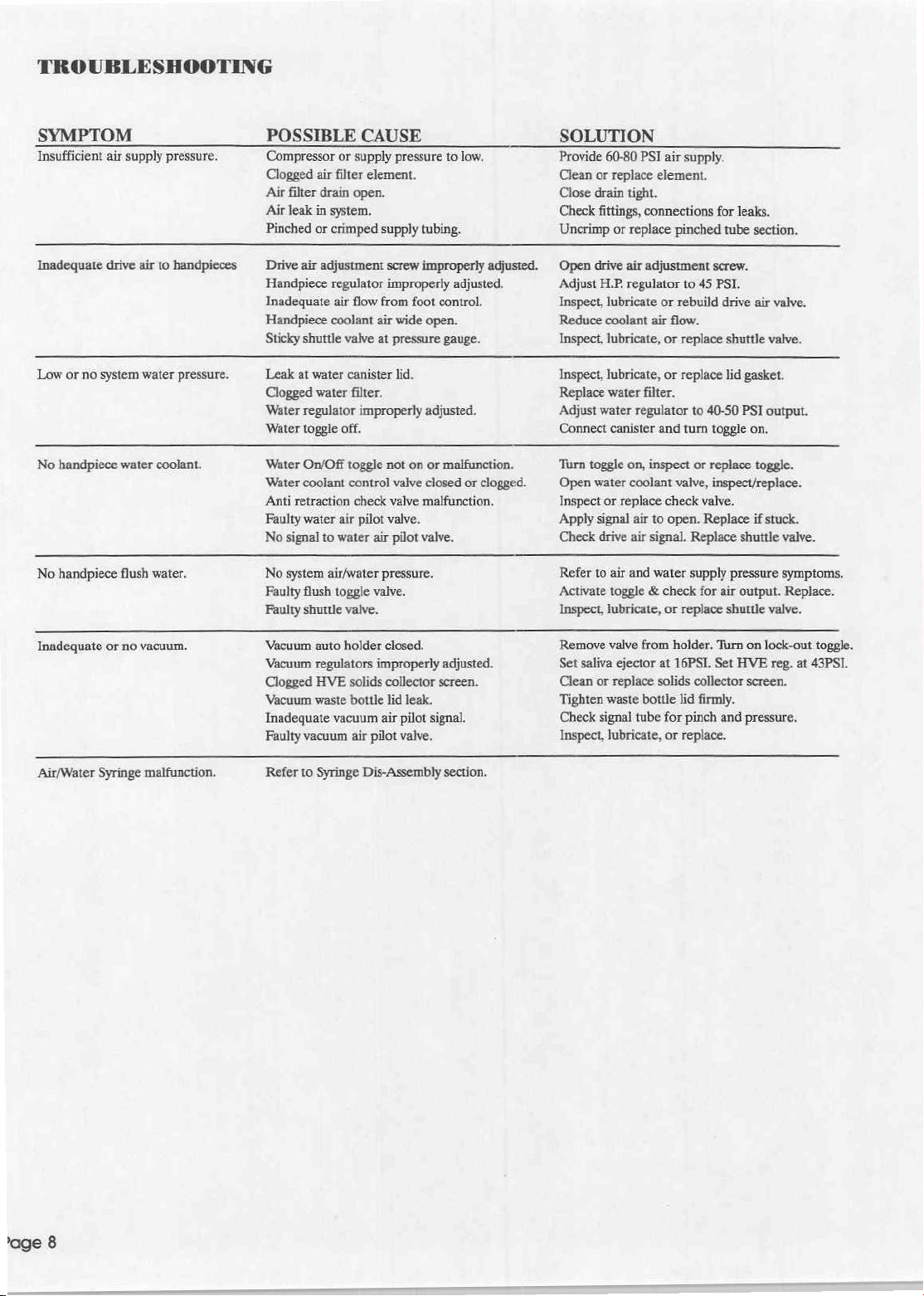

TROUBLESHOOTING

SYMPTOM

Insufficient

Inadequate

Low

No

No

Inadequate

‘Ait/Water

air

supply

drive

air

or

no

system

water

handpiece

handpiece

water

flush

or

no

vacuum.

Syringe

malfunction.

pressure.

to

handpieces

pressure.

coolant.

water.

POSSIBLE

Compressor

Clogged

Air

filter

Air leak

Pinched

Drive

air

Handpiece

Inadequate

Handpiece

Sticky

shuttle

Leak

at

Clogged

Water

regulator

‘Water

toggle

Water

On/Off

Water

coolant

Anti

retraction

Faulty

water

No

signal

No

system

Faulty

flush

Faulty

shuttle

‘Vacuum

‘Vacuum

Clogged

Vacuum

Inadeguate

Faulty

vacuum

Refer

to

CAUSE

or

supply

air

filter

drain

open.

in

system.

or

crimped

adjustment

regulator

air

flow

coolant

valve

water

canister

water

filter.

improperly

off.

toggle

control

check

air

pilot

to

water

air/water pressure.

toggle

valve.

auto

holder

regulators

HVE

solids

waste

bottle

vacuum

air

Syringe

pressure

element.

supply

screw

improperly

from

air

wide

at

pressure

lid.

to

low.

tubing.

improperly

adjusted.

foot

control.

open.

gauge.

adjusted.

not

on

or

malfunction.

valve

closed

or

valve

malfunction.

valve.

air

pilot

valve.

valve.

closed.

improperly

collector

lid

air

pilot

Dis-Assembly

leak.

pilot

signal.

valve.

adjusted.

screen.

section.

SOLUTION

Provide

Clean

Close

Check

Uncrimp

adjusted.

Open

Adjust

Inspect,

Reduce

Inspect,

Inspect,

Replace

Adjust

Connect

Turn

clogged.

Open

Inspect

Apply

Check

Refer

Activate

Inspect,

Remove

Set

Clean

Tighten

60-80

or

replace

drain

tight.

fittings,

or

replace

drive

air

H.P.

regulator

lubricate

coolant

lubricate,

lubricate,

water

water

regulator

canister

toggle

on,

water

coolant

or

replace

signal

air

drive

air

to

air

and

toggle & check

lubricate,

valve

saliva

ejector

or

replace

waste

Check

signal

tube

Inspect,

lubricate,

PSI

air

supply.

element.

connections

adjustment

or

air

or

or

filter.

and

inspect

check

to

open.

signal.

water

or

from

at

solids

bottle

for

or

for

leaks.

pinched

tube

screw.

to

45

PSI.

rebuild

drive

flow.

replace

shuttle

replace

lid

to

40-50

PSI

turn

toggle

or

replace

valve,

inspect/replace.

valve.

Replace

Replace

supply

replace

holder.

16PSI.

pressure

for

air

shuttle

Turn

Set

shuttle

output.

HVE

collector

lid

firmly.

pinch

and

replace.

section.

air

valve.

valve.

gasket.

output.

on.

toggle.

if

stuck.

valve.

symptoms.

Replace.

valve.

on

lock-out

reg.

at

toggle.

43PSI.

screen.

pressure,

‘age

8

ADU-10CF

SCHEMATIC

PARTS

DIAGRAMS

&

LIST

Page

Loading...

Loading...