Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 1

e33

DIGITAL ELECTRONIC

TEMPERATURE CONTROLLER

WITH DEFROSTING FUNCTION

OPERATING INSTRUCTIONS

Vr 01 (ENG) - 17/06 - cod.: ISTR-Me33ENG01

ASCON TECNOLOGIC S.r.l.

Viale Indipendenza 56, 27029 - VIGEVANO (PV) ITALY

Tel.: +39 0381 69871 - Fax: +39 0381 698730

http:\\www.ascontecnologic.com

info@ascontecnologic.com

PREFACE

This manual contains the information necessary for

the product to be installed correctly and also instructions for its maintenance and use; we therefore recommend that the utmost attention is paid to the following

instructions and to save it

This document is the exclusive property of Ascon Tecnologic

S.r.l. which forbids any reproduction and divulgation, even

partially, of the document, unless expressly authorized.

Ascon Tecnologic

S.r.l. reserves the right to make any formal

or functional changes at any moment and without any notice.

Ascon Tecnologic S.r.l. and its legal representatives do not

assume any responsibility for any damage to people, things

or animals deriving from violation, wrong or improper use or

in any case not in compliance with the instrument features.

Whenever a failure or a malfunction of the device

may cause dangerous situations for persons, thing

or animals, please remember that the plant has to be

equipped with additional electromechanical devices

which will guarantee safety.

1. INSTRUMENT DESCRIPTION

1.1 General description

The model e33 is a microprocessor based digital electronic

temperature controller that is typically used in cooling applications with ON/OFF temperature control and defrost

control at time intervals, by arrival at temperature or by

length of time of continuous compressor operation through

stopping the compressor, electric heating or hot gas/cycle

inversion.

The instrument has up to 3 relay outputs and up to 3 NTC

temperature probes inputs one of which can be configured as digital input; it can also be equipped with a built-in

buzzer for alarms acoustic report.

Index

1. Instrument description ............................................... 1

1.1 General description ........................................................... 1

1.2 Front panel pescription .....................................................2

2. Programming ............................................................... 2

2.1 Fast Set Point programming ..............................................2

2.2 Standard mode parameters programming ........................ 2

2.3 Parameter protection using the password ......................... 3

2.4 Customized mode parameter programming (parameters

programming level) ...........................................................3

2.5 Reset parameters to default value ....................................3

2.6 Keyboard lock function ...................................................... 3

3. Usage warnings ........................................................... 3

3.1 Admitted use ..................................................................... 3

4. Installation warnings ................................................... 4

4.1 Mechanical mounting ........................................................ 4

4.2 Electrical connections ....................................................... 4

5. Functions ..................................................................... 5

5.1 ON/Stand-by function ........................................................5

5.2 Normal, Economic and Turbo operation ............................ 5

5.3 Measure and display configuration ...................................5

5.4 Digital input configuration .................................................. 6

5.5 Outputs and buzzer configuration ..................................... 6

5.6 Temperature control .......................................................... 7

5.7 Compressor protection function and power-on delay ........ 8

5.8 Defrost control ................................................................... 8

5.9 Evaporator fans control ...................................................10

5.10 Alarm functions ............................................................... 10

5.11 Function of keys / and /Aux ................................ 12

6. Accessories ............................................................... 12

6.1 Parameters configuration by “A01” ..................................12

7. Programmable parameters table .............................. 13

8. Problems, maintenance and warranty ..................... 16

8.1 Notifications .................................................................... 16

8.2 Cleaning .......................................................................... 16

8.3 Warranty and Repairs .....................................................16

8.4 Disposal .......................................................................... 16

9. Technical data ............................................................ 16

9.1 Electrical characteristics ................................................. 16

9.2 Mechanical characteristics .............................................. 16

9.3 Functional features .........................................................17

10. Instrument ordering code ......................................... 17

Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 2

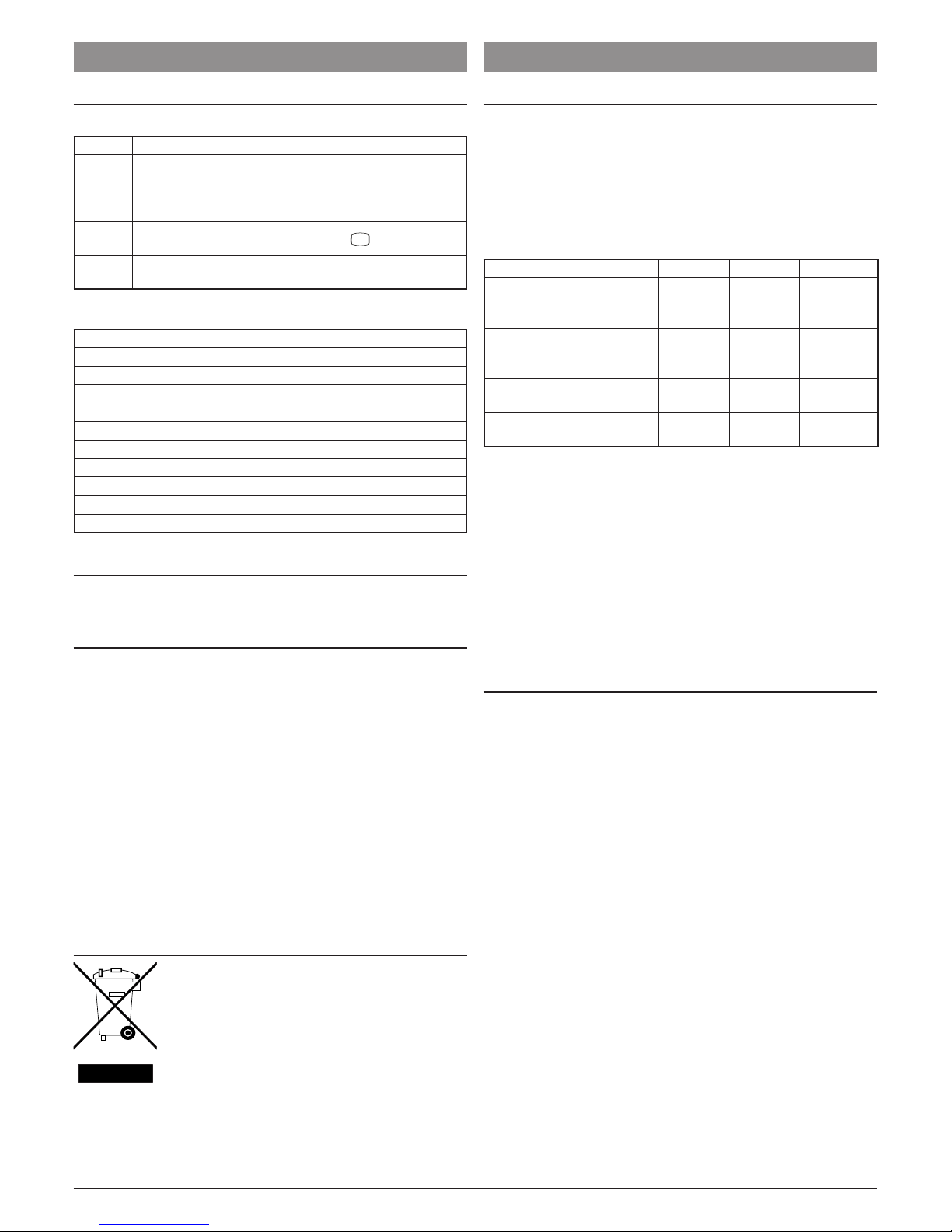

1.2 Front panel pescription

e33

P

U

Aux

1

2

3

4

5

9

7

8

10

6

1 : Used for setting the Set Point (short press) and for

programming the function parameters (pressed for 5 s).

In programming mode is used to enter in parameters edit

mode and confirm the values. In programming mode

can be used together with the key to change the programming level of the parameters. When the keyboard is

locked, the keys and used together (hold pressed

for 5 s), unlock the keyboard.

2 /Aux: In programming mode is used for decreasing

the values to be set and for selecting the parameters. If

programmed using the tFb parameter, when it is pressed

for 1 s during normal operation mode, it can perform other

functions such as Eco mode selectionf, Aux output control

etc. (see “Functions of keys

/

and /Aux”).

3 / : In normal mode (pressed for 5 s) can be used

to start/stop manual defrosting ( ). In programming

mode is used for increasing the values to be set and for

selecting the parameters. In programming mode can be

used together with key to change parameters level.

Pressed together with the key for 5 s allows the keyboard unlock.

4 / : Used (short press) for displaying the instrument

variables (measured temperatures etc.). In programming

mode can be used to return in normal mode (hold for 2 s).

If programmed using the tUf parameter, when it is

pressed for 1 s during normal operation mode allows

to turn ON/OFF (Stand by) the control action or other

functions like the Aux input control etc. (see “

Functions of

keys

/

and /Aux

”).

5 LED dp: Decimal Point, when the instrument is placed in

Stand by mode, this is the only lighted LED. During the

normal operation is the decimal point. In programming

mode, while the parameter code is displayed, the dot

indicates the parameter protection level: not protected

(lit up), protected (flashing) and hidden (turned OFF).

6 LED : Indicates the output status (compressor or

temperature control device) when the instrument

is programmed for cooling operation; ON (lit up),

OFF (turned OFF) or inhibited (flashing).

7 LED : Indicates the output status (compressor or temper-

ature control device) when the instrument is programmed

for heating operation; ON (lit), OFF (turned OFF) or inhib-

ited (flashing).

8 LED : Indicates the alarm status: ON (lit),

OFF (turned OFF) or silenced or stored (flashing).

9 LED : Indicates that the defrost is in progress (on) or

drainage time in progress (flashing).

10 LED : Indicates fan output status ON (on), OFF (off)

or inhibited (flashing).

2. PROGRAMMING

2.1 Fast Set Point programming

The normal mode to program the setpoint is done by momentarily pressing the key, the display shows SP (or SPE)

alternated to the programmed value.

To change it press the key to increase the value or to

decrease it.

These keys increase or decrease the value one digit at a time,

but if the button is pressed for more than one second the value

increase or decreases rapidly and after two seconds the speed

increases even more in order to quickly reach the desired value.

However, through ted parameter you can determine if and

which Set Point can be set with the key rapid procedure.

The parameter can have the following values:

oF The Set Points cannot be changed with the key rapid

procedure (pressing/releasing the key, nothing happens);

1

Only SP can be set with this procedure (Normal Set Point);

2 Only SPE can be set with this procedure (Eco Set Point);

3 Both SP and SPE can be set with this procedure;

4 To select the Active Set Point (SP or SPE);

5 Both SP and SPH can be set with this procedure (SPH:

Set Point Turbo or independent Heating Set Point);

6 All the 3 Set Points (SP/SPE/SPH) can be set with this

procedure.

For example, in case the parameter TEd = 1 or 3, the procedure is the following:

Press and release the key, the display shows SP alternated to the Set Point value. To change the Set Point, press

the key to increase the value or to decrease it

If only Set Point 1 is present (TEd = 1), once the desired value

is set, press the button to exit the fast programming mode.

If also the Eco Set Point (TEd = 3) can be set, pressing and

releasing again the button the display shows SPE alternated to its programmed value. To change the value use

the and keys as for the SP Set Point value. Once the

desired value is correctly set, press the button to exit the

fast Set Point change.

For SPH (TEd = 5 or 6) the procedure is the same of the one

used for SPE.

To exit the fast Setpoint programming mode push the

key after the last Set Point has been displayed or pressing

no buttons for about 10 s, after which the display returns to

normal operation.

2.2 Standard mode parameters programming

To access the instrument function parameters when password protection is disabled, press the key and keep it

pressed for about 5 seconds, after which the display shows

the code that identifies the first programmable parameter

The desired parameter can be selected using the / keys,

then, pressing the key, the display shows the parameter

code alternated to its value that can be changed with the

and keys.

Once the desired value has been set, press the key

again: the new value is stored and the display shows only

the code of the selected parameter

Pressing the and keys, it is possible to select another

parameter and change it as described.

Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 3

To exit the programming mode, press no keys for about 30 s

or keep the key pressed for 2 s.

Previous

Param.

Normal

mode

Parameter select

(Program mode)

Parameters set

Next

Param.

2 s

5 s

Increase

value

Decrease

value

-25.5

sLs -30.0

2.3 Parameter protection using the password

The instrument has a parameter protection function using a

password that can be personalised through the tPP parameter

To protect the parameters, set the desired password number

in the parameter tPP.

When the protection is active, press the key to access

the parameters and keep it pressed for about 5 s, after which

the display shows r.p.

Press the key, the display shows 0, using the / keys,

insert the programmed password number and press the key

again.

If the password is correct the instrument displays the code of

the first parameter and it will be possible to program the instrument in the same way described in the previous section.

The password protection can be disabled by setting tPP = oF.

Normal

mode

2 s

5 s

Increase

value

Decrease

value

-25.5

rp 0

sls

Note: If the Password gets lost, just switch OFF and ON the

instrument, push key during the initial test keeping

it pressed for 5 s. In this way it is possible to access all

the parameters, verify and modify the parameter tPP.

2.4 Customized mode parameter programming

(parameters programming level)

The password hides all the configuration parameters behind a

factory set password to avoid unwanted changes to the controller parameters.

To make a parameter accessible without

having to enter the password when tPP password protection

is activate, use the procedure that follows:

Enter the program mode using the tPP Password and select the

parameter that must be accessible (no password protection).

Once a parameter is selected, if the dp LED flashes the

parameter is programmable by entering the password (is

“protected”). If the dp LED is steady ON the parameter is

programmable without password (is “unprotected”).

To change the parameter visibility, press the key and

keeping it pressed also press the button.

The dp LED changes its state indicating the new level of

parameter accessibility (ON = not protected;

flashing = password protected).

In case some parameters are not protected, accessing

the the programming mode the display first shows the not

protected parameters, then the r.p parameter (through which

will be possible to access the “protected” parameters).

Normal

mode

2 s

5 s

Increase

value

Decrease

value

-25.5

r.p

Previous

Param.

Not protected

parameter

Parameters set

Password

request

Insert

password

Password OK,

Program Mode

Next

Param.

Increase

value

Decrease

value

AHA 35.0

0 sls

2.5 Reset parameters to default value

The instrument allows the reset of the parameters to values

programmed in factory as default

To restore the default parameters value set value -48 at r.p

password request Therefore, to make the reset to the default

parameters, enable the Password using the tPP parameter

so that the r.p setting is requested, at this point insert -48

instead of the programmed access password.

Once confirmed the password with the key the display

shows “---” for 2 s therefore the instrument resets all the

parameters to factory default setting.

2.6 Keyboard lock function

On the instrument it is possible to completely lock the keyboard.

This function is useful when the controller is in an accessible

area and the changes must be avoided.

To activate the keyboard lock it is enough program the pa-

rameter tLo to a value different from oF.

The

tLo

value is the keys inactivity time after which the key-

board will be automatically locked.

Therefore, pressing no buttons for the time set at tLo, the in-

strument automatically disable the normal functions of the keys.

When the keyboard is locked, if any of the key is pressed,

the display showss Ln to indicate that the lock is active.

To unlock the keyboard it is enough to contemporarily push

+ keys and keep them pushed for 5 s, after which the

label LF appears on the display and all the key functions will

be available again.

3. USAGE WARNINGS

3.1 Admitted use

The instrument has been projected and manufactured

as a measuring and control device to be used according to EN60730-1 at altitudes operation below 2000 m.

Using the instrument for applications not expressly permitted

by the above mentioned rule must adopt all the necessary

protective measures.

The instrument MUST NOT BE USED in dangerous environments (flammable or explosive) without adequate protections.

The instrument used with NTC 103AT11 probe (identifiable

by the printed code “103AT-11” visible on the sensor part)

is compliant with standard EN 13485 (“Thermometers for

measuring the air and product temperature for the transport,

storage and distribution of chilled, frozen, deep-frozen/quickfrozen food and ice cream”) with the following classification:

Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 4

[EN13485 air, S, A, 2, -50°C +90°C]

Remember that the end user must periodically check and veri-

fy the thermometers in compliance with standard EN 13486.

The installer must ensure that the EMC rules are respected,

also after the instrument installation, if necessary using

proper filters.

4. INSTALLATION WARNINGS

4.1 Mechanical mounting

The instrument, in case 78 x 35 mm, is designed for flushin panel mounting. Make a 71 x 29 mm hole and insert the

instrument, fixing it with the provided special brackets.

In order to obtain the declared front protection degree, mount

the gasket and use the screw type bracket (both optional).

Avoid placing the instrument in environments with very high

humidity levels or dirt that may create condensation or introduction of conductive substances into the instrument

Ensure adequate ventilation to the instrument and avoid

installation in containers that house devices which may

overheat or which may cause the instrument to function at a

higher temperature than the one permitted and declared.

Connect the instrument as far away as possible from sources

of electromagnetic disturbances such as motors, power relays, relays, solenoid valves, etc..

4.1.1 Mechanical dimensions, panel cut-out and

mounting [mm]

35

28

12.2

14.5

8

6

6478

e33

P

U

Aux

29

+0.6

71

+0.6

mm

RECOMMENDED

PANEL CUTOUT

min. 12 mm

min. 15 mm

Panel + Gasket max. 12 mm

Brackets

34

4.2 Electrical connections

Carry out the electrical wiring by connecting only one wire to

each terminal, according to the following diagram, checking

that the power supply is the same as that indicated on the

instrument and that the load current absorption is no higher

than the maximum electricity current permitted.

As the instrument is built-in equipment with permanent connection inside housing, it is not equipped with either switches

or internal devices to protect against current overloads: the

installation will include an overload protection and a twophase circuit-breaker, placed as near as possible to the instrument and located in a position that can easily be reached

by the user and marked as instrument disconnecting device

which interrupts the power supply to the equipment

It is also recommended that the supply of all the electrical circuits connected to the instrument must be protect properly, using devices (ex. fuses) proportionate to the circulating currents.

It is strongly recommended that cables with proper insulation,

according to the working voltages and temperatures, be used.

Furthermore, the input cable of the probe has to be kept separate from line voltage wiring. If the input cable of the probe is

screened, it has to be connected to the ground at only one side.

Whether the instrument is a 12 V version (Power supply code

F) it is recommended to use an external TCTR transformer, or

with equivalent features (class II insulation) and to use only one

transformer for each instrument because there is no insulation

between supply and input

We recommend that a check should be made that the

parameters are those desired and that the application

functions correctly before connecting the outputs to

the actuators so as to avoid malfunctioning that may

cause irregularities in the plant that could cause damage to people, things or animals.

4.2.1 Electrical wiring diagram

Internal

Buzzer

Pr1 Pr3Pr2

Digital

Input

Power

supply

INPUTS

NO

NO

NONC

C

Out2

Out1

Out3

OUTPUTS

(12 A max. for removable connectors models)

16 FLA

96 LRA

15 A Res.

EN

30 (15) A

61810

Out 1 (H):

15 (15) A

5 FLA

30 LRA

12 A Res.16 (9) AOut 1 (R): 10 (4) A

10 A Res.8 (3) AOut 2: 8 (4) A

2 A Gen. Use5 (1) AOut 3: 2 (1) A

60730

EN UL

Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 5

5. FUNCTIONS

5.1 ON/Stand-by function

Once powered the instrument can assume 2 different conditions:

ON: Means that the controller uses the control functions.

STAND-BY:

Means that the controller uses no control function and

the display is turned off except for the Stand-by LED.

The transition between Standby and ON is equivalent to

power ON the instrument providing the electrical power

In case of power failure, the system always sets itself in the

condition it was in before the black-out

The ON/Stand-by function can be selected:

– With the key / pressed for 1 s if tUF = 3;

– With the key /Aux pressed for 1 s if tfb = 3;

– Using the Digital Input if parameter iFi = 7;

5.2 Normal, Economic and Turbo operation

This tool allows to pre-set 3 different Setpoints, Normal - SP,

Economic (or Eco) - SPE and Turbo SPH.

Associated with each Setpoint there is the relative differential

(hysteresis): Normal - rd, Eco - rEd and Turbo - rHe. Switch-

ing between the various modes can be automatic or manual.

5.2.1 Normal/Eco operation selection

This function can be used when you need to switch two functional temperatures (eg. Day/Night or week-day/week-end).

SPE

SP

Door

rd

rEd

iEt

time“Norm.”

DAY (Shop open) DAY (Shop open)NIGHT (Shop closed)

“Norm.” “ECO”

The Normal/Eco operation can be selected in manual mode:

– Using the / key if parameter tUF = 2;

– Using the /Aux key if parameter tFb = 2;

– Using the Digital Input if parameter iFi = 6.

The Normal/Eco operation can be selected in automatic mode:

– Elapsed the iEt time after the door has been closed

(Normal/Eco switching).

– At door opening if the SPE Setpoint is activated by iEt

parameter (Eco/Normal switching).

– Elapsed the itt time after the door has been closed and

from the activation of SPE Setpoint by iEt parameter

(Eco/Normal switching).

To use this function, it is necessary to set the Digital Input as:

iFi = 1, 2 or 3.

If iEt = oF the selection of Eco/Normal modes via the digital

input is disabled.

If itt = oF the time-out switching from Eco to Normal mode

is disabled.

Switching to Economic mode is indicated by the label Eco.

When idS = Ec the Economic mode is pointed out with a

fixed Eco label otherwise the label Eco appears every 10 s

alternated to the display set with parameter idS.

When used as a shop widow light (oFo = 3), Eco mode

selection is always associated with the Auxiliary Output turn

OFF function.

5.2.2 Turbo/Normal/Eco operation selection

Turbo mode can be selected manually:

– Pressing the / key if parameter tUF = 4;

– Pressing the /Aux key if parameter tFb = 4;

– From digital input if parameter i.Fi = 8;

Turbo mode can be selected automatically:

– Leaving Eco mode (only if rHC = C3)

– Every time the instrument is switched ON (only if rHC = C3

and Pr1 > SPE + rEd)

The instrument quits Turbo mode and returns to normal mode

automatically at the end of rtC time or manually using the

programmed command (key or digital input).

Setting rHC = C3 gives the following operating cycle:

At power ON, the instrument starts in the mode it was in

when it was switched OFF (Normal or “Eco”) unless the temperature at power ON is > SPE + rEd. In this case (see fig.)

a Turbo cycle is automatically initiated.

After time rtC the instrument automatically swiyches to Nor-

mal mode. If the door is opened frequently, the instrument

remains in Normal mode. If however the door is not opened

for time set at iEt parameter, it automatically switches to

Eco mode.

The instrument remains in Eco mode until the door is

opened again or, if set, until the time-out itt.

On leaving Eco mode the instrument therefore runs a Turbo

cycle to allow product temperature to be restored, after

which it reverts to Normal mode and so on.

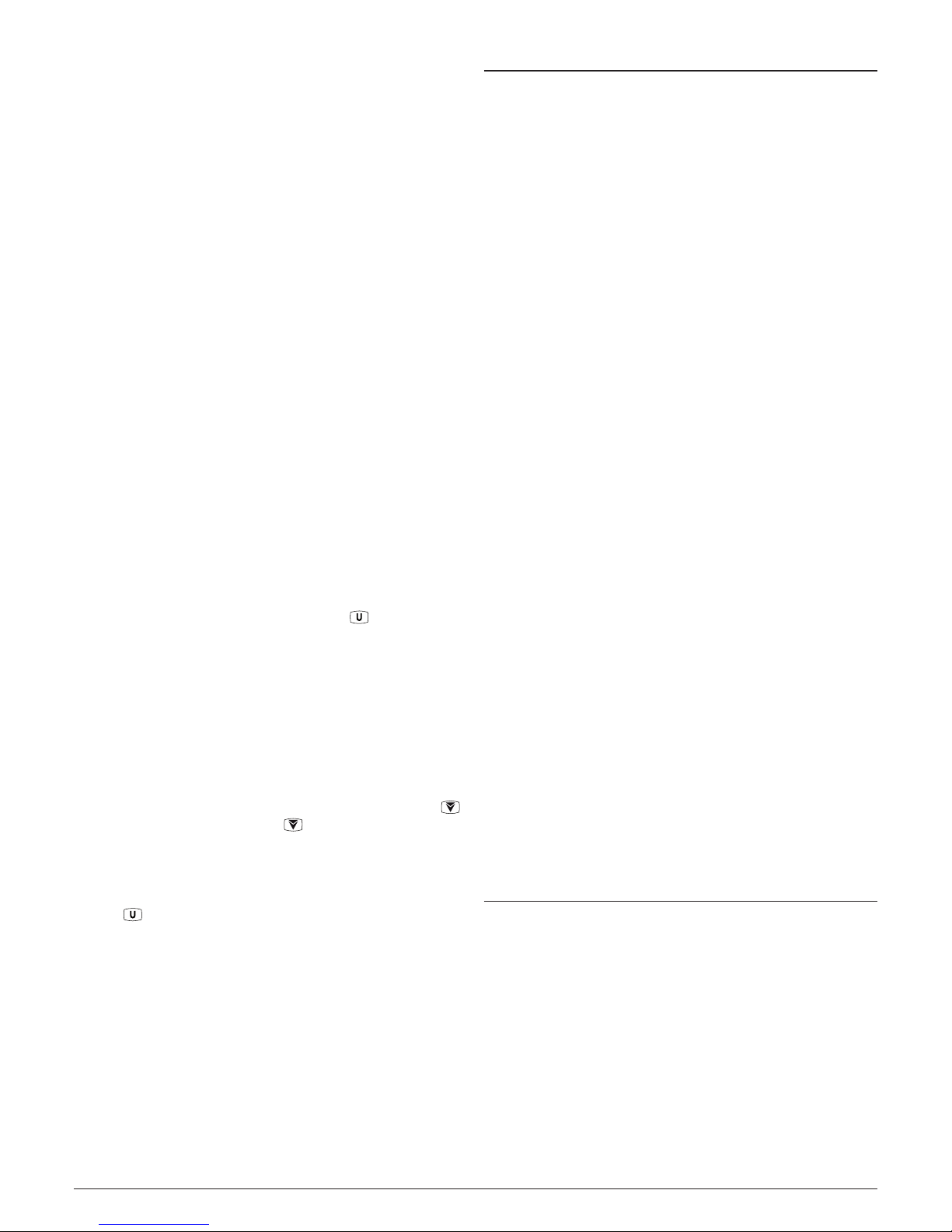

Temp.

SPE

Eco

SP

SPH

Turbo

rHd

rEd

itt (2)

rtCrtC

time

Normal TurboECOTurbo

iEt (1)

rd

Pr1

1 The time iEt is reset every time the door is opened and

in the case shown the door is always closed.

2 The time itt stops when the door is opened and the

instrument immediately switches to Turbo mode. In the

case shown, the door is always closed.

When in Turbo mode, the instrument shows the characters

trb alternated to the normal display indication.

The normal Set Point SP can be set to a value between the

one set with parameter SLS and the one set with parameter

SHS while the Economic Set Point SPE can be set to a value

between the one set with parameter SP and the one set with

parameter SHS; the Turbo Set point (SHP) can be set to a

value between the one set with parameter SLS and the one

set with parameter Sp.

Note: In the following examples the Set Point is generally

indicated as SP and the differential as rd however the

instrument will act according to the Set Point and the

differential selected as active.

5.3 Measure and display configuration

With parameter iuP it is possible to select the temperature engineering unit and the desired measure resolution

(C0 = °C/1°; C1 = °C/0.1°; F0 = °F/1°; F1 = °F/0.1°).

The instrument allows the measure calibration, which can

be used to recalibrate the instrument according to applica-

Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 6

tion needs, the calibration is made by using parameters iC1

(input Pr1), iC2 (Pr2 input) and iC3 (Pr3 input).

Parameters iP2 and/or iP2 allows to select the instrument

usage of Pr2/Pr3 measure as:

EP Evaporator probe: used to managing the defrost and

the evaporator fans (see relative functions).

Au Auxiliary probe;

DG Digital Input (see the Digital input functions).

If Pr2/Pr3 input is not used, set iP2/ip3 = oF.

Two inputs cannot set to perform the same function.

If two inputs are set to do the same function, this is done

only by the P2 input.

Using iFt parameter can be set a software filter for measuring the input values in order to decrease the sensibility to rapid

temperature changes (increasing the sampling time).

Through the idS parameter is possible to set the variable

normally displayed:

P1 Pr1 probe measurement;

P2 Pr2 probe measurement;

P3 Pr3 probe measurement;

SP Active Set Point;

EC

Pr1 probe measure if the instrument is in Normal mode,

the label Eco if the instrument is in (Eco mode);

OFF If the numerical display must be switched off (oF).

When one of the measures is displayed (idS = P1/P2/Ec)

the iCU parameter allows to set an offset that is to be applied

only to the displayed variable (all controls will always made

according to the correct temperature value, changed only by

the calibration parameters).

Regardless of what is set at idS parameter, all the measurement variables can be shown pressing the key.

The display alternately shows the code that identifies the

variable and its value. The variables are:

Pr1 Probe 1 measurement;

Pr2

Probe 2 measurement (on/oFF if Pr2 is a Digital input);

Pr3

Probe 3 measurement (on/oFF if Pr3 is a Digital input);

Lt Minimum stored Pr1 temperature;

Ht Maximum stored Pr1 temperature.

The Peak (min./max.) temperature values of Pr1 probe are

NOT stored in case of power failure. While the controller is

showing the peak values, these can be reset pressing the

key for 3 s. At the end of the key pressure, the display

shows “---” for an instant to indicate that the min./max. values have been erased and the new peak is the temperature

read in that moment.

The system exits the variable dosplay mode after 15 s from

the last

key pressure.

It is also noted that the Pr1 probe display can also be changed

by “Defrost display lock” function via the ddL parameter

(see the Defrost function).

5.4 Digital input configuration

The digital input function (available on terminal 12 or instead

of Pr2 input if ip2 = dg) is defined using the iFi parameter

and the action is delayed for the time programmed with parameter iti. The iFi parameter can be configured for the

following functions:

0 Digital input not active;

1 Cell door opening with NO contact: at input closure (and

after the iti) the instrument displays alternately oP and

the variable set at idS parameter. With this mode of

operation of the digital input activates also the time set

with parameter AoA elapsed which the alarm is activated

to warn that the door has been left open. In addition, at

door opening, the instrument returns to Normal operation if it was in Eco mode and the Eco mode activation

was enabled through parameter iEt;

2 Cell door opening with NO contact: Similar to iFi = 1

but with evaporator fans stop. In addition, at open door

alarm intervention (AoA), the fans are restarted;

3 Cell door opening with compressor and fan outputs lock

and NO contact: similar to iFi = 2 but with compressor

and fans lock. At open door alarm intervention (AoA)

both the fans and the compressor are re-activated.

4 External alarm signal with NO contact: at input closing

(and after the iti time) the alarm is activated and the

instrument alternately shows on the display: AL and the

variable set with parameter idS;

5 External alarm signal withall control outputs disabled and

NO contact: at input closing (and after the iti time) all

the control outputs are disabled, the alarm is activated

and the instrument alternately shows on the display: AL

and the variable set with parameter idS;

6 Normal/Eco mode selection with NO contact: at input

closing (and after the iti time) the instrument switches to

Economic operation mode. Opening the digital input, the

instrument returns in Normal operation mode.

7 Instrument On/Off (stand-by) selection with NO contact:

at input closing (and after the iti time) the instrument

is switched ON while it is placed in Stand-by mode when

the digital input is open;

8 Turbo cycle activation command with NO contact: at in-

put closing (and after the iti time) the instrument starts

a Turbo cycle;

-1, -2, -3, etc. - Features identical to the above but obtained

through a NC contact and a reversed logic operation.

5.5 Outputs and buzzer configuration

The instrument outputs can be configured by the relative

parameters oo1, oo2 and oo3.

The outputs can be configured for the following functions:

ot To control

the temperature control device (e.g. Compressor). To manage the cooling control device for neutral

zone control or Cooling/Heating (rHC = nr or HC);

df To control the defrosting device;

Fn To control the evaporator fans;

Au To control the auxiliary device;

At To control a silenceable alarm device through a contact

that is NO in normal operation then closed when the

alarm sounds;

AL To control an alarm that cannot be silenced through

a contact that is NO in normal operation then closed

Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 7

when the alarm sounds;

An To control an alarm with a memory function through

a contact that is NO in normal operation then closed

when the alarm sounds (see alarm memory);

-t To control a silenceable alarm device through a con-

tact that is NC in normal operation then closed when

the alarm sounds;

-L Control an alarm that cannot be silenced through a

contact that is NC in normal operation then closed

when the alarm sounds;

-n To control an alarm with a memory function through

a contact that is NC in normal operation then closed

when the alarm sounds;

on To command a device that must be turned ON when

the instrument is ON. The output is therefore deactivated when the instrument is not powered or is in

standby mode. This mode of operation can be used

as a control of the shop window lighting, anti-fogging

resistors or other utilities;

HE To control a heating device in neutral zone or Cooling/

Heating control mode (rHC = nr or HC);

oF Output disabled.

If one of the outputs is configured as auxiliary output (oo1/oo2/

oo3 = Au), its function is set by parameter oFo and its operation can be conditioned by the time set to at parameter otu.

Parameter oFo can be configured for the following functions:

oF Auxiliary output not active;

1 Temperature control output delayed with NA contact:

the auxiliary output is activated with a delay that

can be set with parameter otu applied to the output

configured as ot. The output is then turned OFF at

the same time as the ot output is disabled. This function mode can be used as a command for a second

compressor or for all other working utilities according

to the same ot output conditions, but which must be

delayed after the start up of the compressor to avoid

excess electricity absorption;

2 Activation by front key ( or ): the output is ac-

tivated by pressing the keys or suitably configured (tUF or tFb = 1). These commands have a

bi-stable (toggle) function (at first pression the output is

activated, at the second is disabled). In this mode, the

Aux output can be turned OFF automatically after the

time set at parameter otu. When otu = oF the output

is activated and deactivated only manually, using the

or keys or via the digital input. Differently, the

output, once activated, is turned OFF automatically after the otu time. This mode of operation can be used

as a control of the shop window lighting, anti-fogging

resistors or other utilities;

3 Shop window light managed by Normal/Eco mode.

This output will be ON in Normal mode and OFF when

in Eco mode operation.

4 Internal Light output managed by digital input. This

output will be ON when door is opened (iFi = 1, 2, 3).

If present, the internal buzzer can be configured by parameter obu for the following functions:

oF Buzzer always disabled;

1 The Buzzer sounds when an alarm is active;

2 The Buzzer sounds when a key pressed (no alarm);

3 The Buzzer sounds when a key pressed and when an

alarm is active.

5.6 Temperature control

The instrument controls the temperature with an ON/OFF

action and operates on the outputs configured as ot and

HE depending on the PR1 probe measuring, the acive Set

Point/s SP/SPE/SPH, the Hysteresis rd/rEd/rHd and the

function mode set with rHC parameter. Using the rHC parameter can be obtained the functions that follow.

C Cooling;

H Heating.

SP

Temp.

rd

time

offoff

SP

rd

time

ON

rHC =

C

rHC =

H

offoffON ON ON ON ON

output

ot

output

ot

Pr1

Temp.

Pr1

Depending on the function mode programmed with parameter

rHC the differential is automatically considered by the controller with positive values for a Refrigeration control (rHC = C)

or negative values for a Heating control (rHC = H).

nr Neutral Zone

SP

off off

ON

Temp.

time

rd

rd

offoff

rHC

= nr

ON

ON

HE

ot

Outputs

Pr1

When rHC = nr, the output configured as ot operates with a

cooling action (like rHC = C) while the output configured as HE

operates with a heating action both with the active Set Point

(SP/SPE/SPH). The intervention differential (rd/rEd/rHd) is automatically assumed by the controller to have positive values for

the cooling action and negative values for the heating action.

HC

Cooling and Heating with independent Set Points

SP

SPH

off off off

Temp.

time

rd

rd

offoff

off

RHC = HC

ON ON ON

ONON

HE

ot

Pr1

Outputs

As in the previous case, when rHC = HC the output configured as ot operates with cooling action (like rHC = C) while

the output configured as HE operates with heating action.

In this case, however, the Set Point for the ot output is the

active one between SP, SPE or SPH, while for the HE output

the Set Point is SPH.

The intervention differential for the ot

output is the active between rd, rEd or rHd and is automatically assumed by the controller to have positive values for the

cooling action while for the output HE the differential is RHd

considered with negative values as for the Heating actions.

In this mode, the activation of the Turbo cycle causes the

instrument to operate with Neutral Zone and SPH set point.

The time protections described in the next paragraph (PP1/

PP2/PP3) always work on the output configured as ot and

have no effect on the HE output.

In the event of a probe error, it is possible to set the instru-

Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 8

ment so that that the output continues to work in cycles

according to the times programmed with parameter rt1

(activation time) and rt2 (deactivation time).

If a Pr1 probe error occurs, the instrument can continue to

activate the ot output for rt1 time, then disables it for rt2

time and so on until the error persists.

By programming rt1 = oF the output, in probe error condition, will always be OFF. On the contrary, programming rt1

to any value and rt2 = oF the output, in probe error conditions, will always be on.

Remember that the operation of the temperature controller

can be conditioned by the following functions: Compressor

protection function and power-on delay, Defrost, Open door

and External alarm with output block from digital input.

5.7 Compressor protection function and

power-on delay

The “Compressor Protection” function aims to avoid repeated

compressor start-ups controlled by the instrument in cooling

applications or otherwise can be used to add a timed control

on the actuator control output

This function foresees 3 time controls on the switching ON of

the output configured as ot.

The protection consists of preventing the ot output being switched ON during the times set

with parameters PP1, pP2 and PP3 and therefore that any

activation occurs only after all times are elapsed.

1 First control (parameter PP1) foresees a delay to ot out-

put activation (switching-ON delay).

SP

Temp.

time

offoff off off

ON

ON

r.d

P.P1

P.P1

ot

ON

Pr1

Output

P.P1 P.P1

2 Second control (parameter PP2) foresees an inhibition to

the activation of the output by a time delay that starts when

the output is turning OFF (delay after switching-OFF).

offoff off

ON

SP

time

rd

PP2

ON ON

Temp.

ot

Pr1

Output

PP2 PP2 PP2

3 Third control (parameter PP3) foresees an inhibition to

the activation of the output by a time delay that starts

when the output was turned ON last time (delay between

two switching-ON).

offoffoff

ON

SP

time

rd

PP3

PP3 PP3

PP3

ON ON

Temp.

ot

Pr1

Output

During the output inhibition the LED OUT (Cool or Heat )

blinks. It is also possible to prevent activation of all the outputs

after the instrument is turned ON, for the time set in the parameter Pod.

During the power ON delay phase, the display shows the

indication od alternated with the normal visualization.

All these functions are disabled if the relative parameters are

set to OFF (oF).

5.8 Defrost control

The defrost control acts on the outputs configured as ot and dF.

The type of defrost is set by the parameter ddt:

EL With electrical heating (or By stopping compres-

sor): while defrosting, the output ot is deactivated

while the output dF is enabled. The defrost will be by

Stopping compressor if not using the dF output;

in With hot gas or Cycle inversion: while defrosting

both the ot and dF outputs are enabled:

no Without compressor output conditioning: while de-

frosting, the output ot continuous to operate in order to

control thetemperature, also the output dF is enabled;

Et With electrical heating and defrosting temperature

control: during defrosting, the output ot is deactivated

while the output dF operate as evaporator temperature

control. In this mode the defrost lenght is by time-out

(time ddE). During the defrost, the dF output behaves

as an heating mode control with Set Point = dtE, differential fixed at 1°C and operates with the values of

the EP evaporator probe.

5.8.1 Starting automatic defrosts

The automatic control of defrost occours:

– By interval times (regular or dynamic);

– By Evaporator temperature;

– By continuous compressor running time.

In order to avoid unnecessary defrosting when the evaporator temperature is high the dtS parameter allows to set the

temperature related to the evaporator probe (probe configured as EP) under which defrosts are possible.

Defrost by regular interval time

As an alternative to programmable defrosts, the instrument

allows to execute the defrosts at programmed interval time.

Through the ddC parameter, can be set the defrost interval

counting mode:

rt At real-time power-ON intervals. The ddi interval is

counted as the total ignition time of the instrument.

This mode is the one currently used in the refrigeration systems.

ct At time intervals of the compressor operation. The

ddi interval is counted as the sum of the operating

times of the ot output (ot output activated). This mode

is usually used in refrigeration systems with compressor stop defrosting.

cS Defrost cycle at each compressor stop. The instrument

starts a defrost cycle every time the ot output is deactivated, when the Set Point is reached or at the expiration of the interval set with ddi paramreter. If ddi =

oF the defrost happens only at compressor stop.

This mode is used only on particular refrigerating ma-

chines in which is required the maximum evaporator

efficiency at each compressor cycle.

To enable automatic defrost at intervals, after setting the ddC

parameter as desired between rt, ct or cS, with the ddi parameter select the time interval between the end of a defrost

and the beginning of the next.

The time that the instrument must wait to perform the first

defrost after power ON can be set with parameter dSd. This

allows to perform the first defrost to a different interval from

ddi time.

To force the instrument to perform a defrost cycle at each

Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 9

power ON (as long as the conditions set with parameters

dtS and dtE are satisfied) set parameter dSd = oF.

This allows the evaporator to be permanently defrosted,

even when frequent interruptions to power supply occur that

may cause the cancellation of the various defrosting cycles.

If instead it is desired that all the defrosts are performed at

the same interval time, set dSd = ddi.

Setting ddi = oF the Automatic defrost function by interval

is totally disabled (including the first, regardless of the time

set to the dsd parameter).

Dynamic Defrost Intervals System

If ddd = 0 the Dynamic defrost is disabled.

Note: For this function is necessary to use the evaporator

probe.

To enable the Dynamic Defrost Intervals System, program

ddC = rt, ct or cS and set ddd = any value.

Setting ddd = 0, the defrost intervals are those set by the user

and the Dynamic Defrost Intervals System is disabled.

This mode allows to dynamically reduce the defrost interval

counting (ddi or dSd if is the first defrost), anticipating, when

necessary, the defrost execution, all based on an algorithm that

detects a drop in the refrigerator thermal exchange performance.

The algorithm estimates a reduction in thermal exchange

based on the increase in temperature difference between

Pr1 (cell control) and evaporator probe (probe configured as

EP). The result is stored by the instrument when the tem-

perature is close to the Set Point setting.

The advantage of the Dynamic Defrost Interval is the possi-

bility to program a defrost interval time longer than normal.

In this way, when necessary, the instrument has the pos-

sibility to anticipate the defrost or to start the cycle after the

programmed time.

If the system results correctly set, it is possible to avoid

many unnecessary defrosting cycles (and therefore to obtain

aconsistent energy saving) that may occur with normal operation when, to ensure more system efficiency, the defrosting interval is programmed with a time that is often too short.

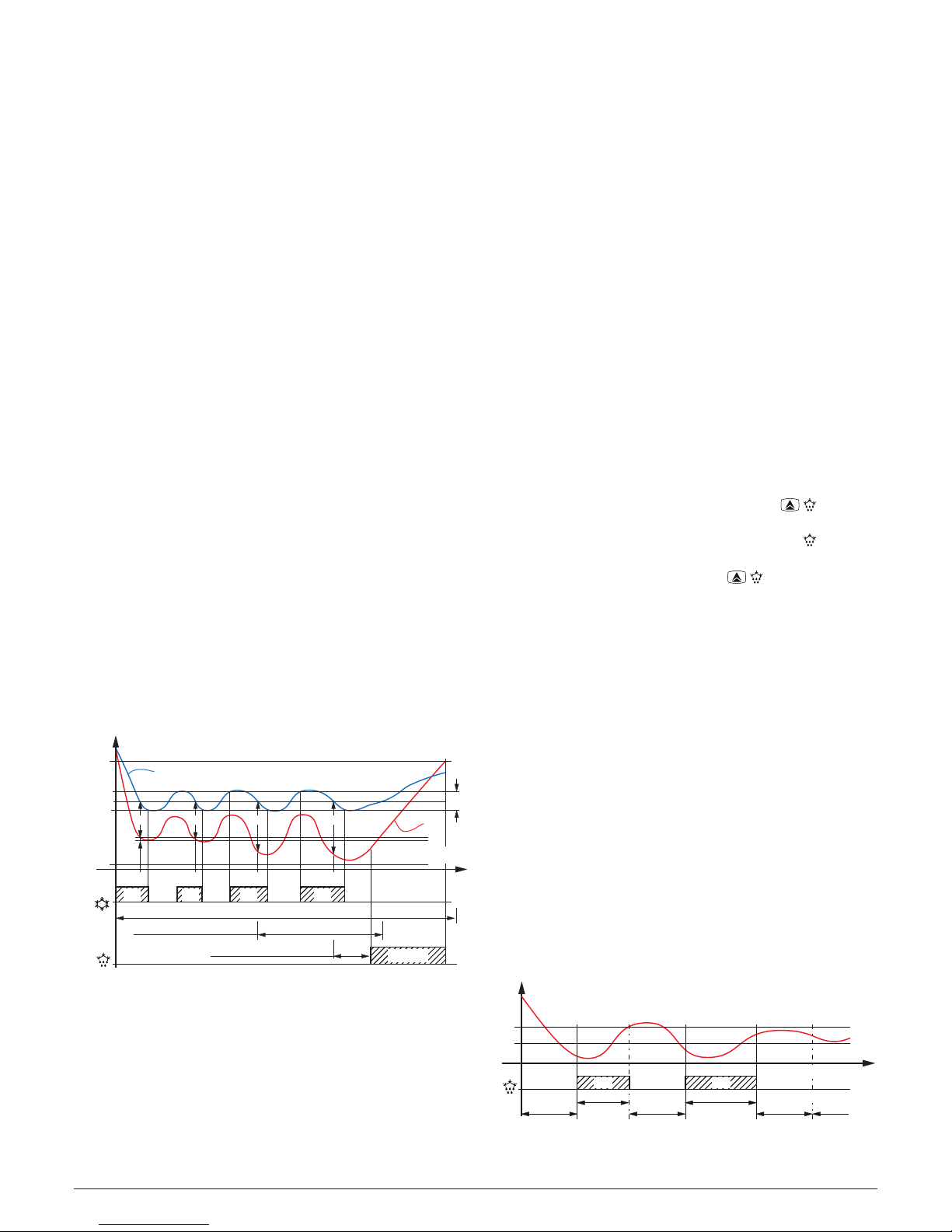

Phase

off off

ON

01 2 3

Temp.

ddi/dSd time to defrost Phases 0, 1

Defrost

off off

DT0

dtE

dtS

Cool

ot

Defrost

dF

SP + rd

SP

Pr1

rd

EP

1°

DT1 DT2 DT3

time to defrost Phase 2

time to defrost Phase 3

time

ON ON ON

Example “dynamic defrost intervals system” with a reduction

ddd = 40% and end defrost by temperature.

With the parameter ddd - Defrost interval percentage reduc-

tion is possible to establish the percentage of reduction of

the remaining time to start defrost when the conditions for

the reduction happen.

If parameter ddd = 100% at the first increase of the stored

difference of temperature (> 1°) between cell (Pr1) and

evaporator (EP) probes a defrost starts immediately.

For correct functioning the instrument needs a first reference

value of the temperature difference between cell and evaporator, in this way all variations to the Active Set Point value, to

the differential rd, the start of a continuous cycle or a defrost

execution deletes this reference value and any reduction cannot be performed until the acquisition of a new reference value.

Defrost by evaporator temperature

The instrument starts a defrost cycle when the evaporator

temperature (EP probe) goes below the dtF programmed

temperature for dSt programmed time.

This system can be used to guarantee a defrost if the evaporator reaches very low temperatures that normally result

symptomatic of a bad thermal exchange in comparison to

the normal working conditions.

When dtF = -99.9 the function is disabled.

Defrost by continuous compressor running time

The instrument start a defrost cycle when the compressor is

turned ON continuously for the time dcd.

This function is used because the continuous operation for an

extended period of the compressor is usually symptomatic of

a bad thermal exchange in comparison to the normal working conditions.

When dcd = oF the function is disabled.

5.8.2 Manual defrost

To start a manual defrost cycle, press the key / when

in Normal operation mode and keep it pressed for about 5 s

after which, if the conditions are correct, the LED lights up

and the instrument performs a defrost cycle.

To stop a defrost cycle, press the key / during the defrost and keep it pressed for about 5 seconds.

5.8.3 End of defrosts

The defrost cycle duration can be time based, or, using the

evaporator probe (configured as EP) when a specific temperature is reached.

If the evaporator probe is not used or the thermostated

defrost mode is used (ddy = Et), the cycle length is set by

parameter dde.

If the Evaporator Probe (EP) is used and the thermostated

electric defrost is not selected (ddy = EL, in, no), the defrost

time occurs when the temperature measured by EP probe

exceeds the temperature at parameter DtE.

If this temperature is not reached in the time set in the parameter ddE, defrost cycle is interrupted.

To avoid unnecessary defrosting when the evaporator temperature is high in modes ddC = rt, ct, cS parameter DtS

allows to set the temperature related to the EP probe under

which defrosts are possible.

Therefore, in the indicated modes, if the temperature measured by the EP probe is higher than the one set at parameters dtS and also dtE the defrosting is inhibited.

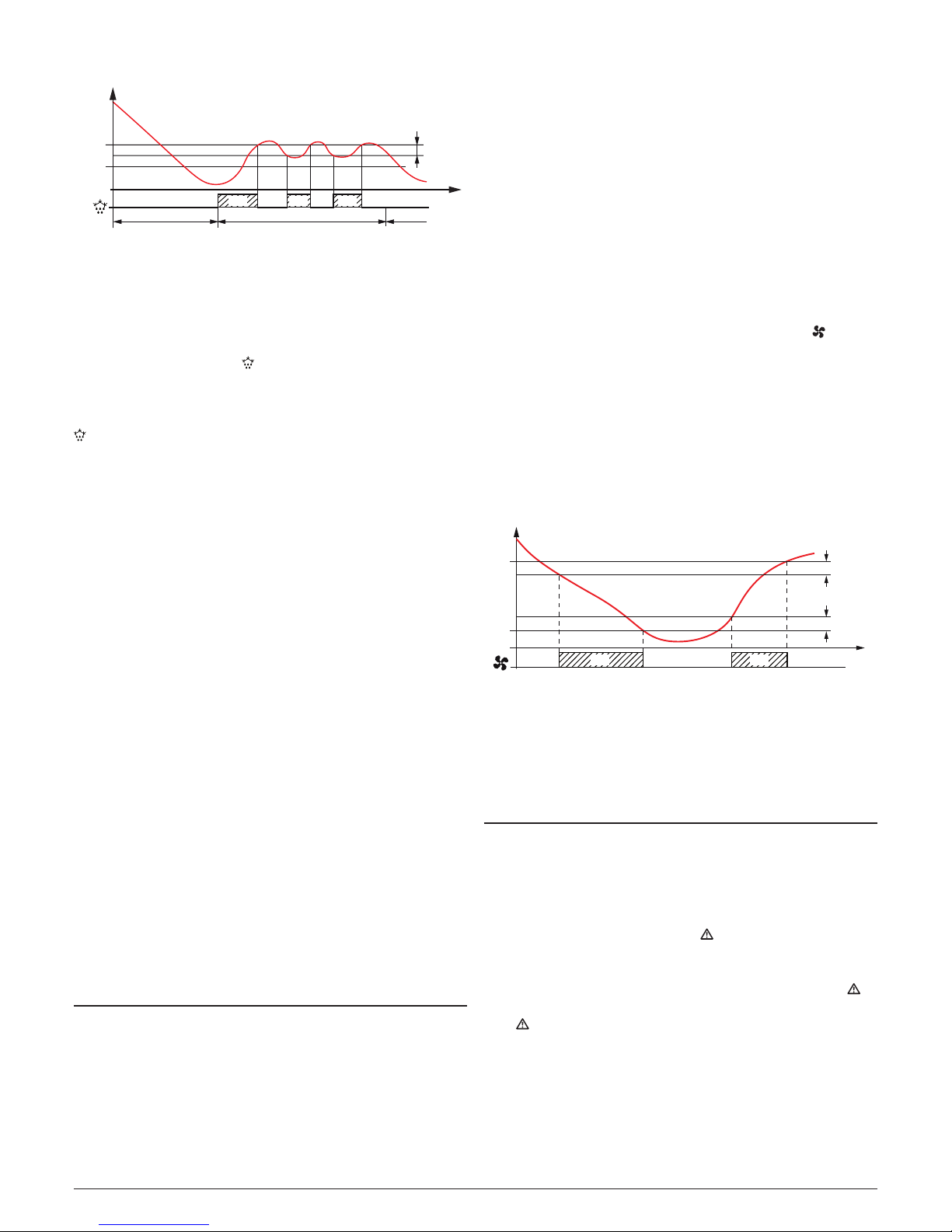

dtE

dts

Defrost

dF

offoffoff

ON ON

AB

Temp.

time

C

(NO defrost)

dde

ddi/dSd

(Defrost)

ddi/dSd

ddi/dSd ddi

(Defrost)

EP

Example: Defrost A ends due to reaching of temperature

dtE, defrost B ends at the end of the ddE time as the

Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 10

temperature dtE is not reached, defrosting C does not take

place as the temperature is higher than dts.

dtE

dts

offoffoff off

ddi/dSd

ON ON ON

time

ddi

(Defrost)

dde

1°

Defrost

dF

Temp.

EP

Example of electric defrost with evaporator temperature

control: the defrost end after ddE programmed time. During

defrost the dF output switch ON/OFF to control evaporator

temperature in heating mode with set point dtE and 1° differential (Hysteresis).

The active defrost is shown on the instrument display with

the lighting up of the LED .

At the end of defrosting, it is possible to delay the new compressor start up (output ot) at the time set in parameter dtd

to allow the evaporator to drain. During this delay, the LED

flashes to indicate the draining state.

5.8.4 Intervals and defrosts duration in case of

evaporator probe error

In event of evaporator probe error the defrosts occur at intervals dEi and duration dEE.

In case an error occurs when the time remaining to the start

or the end of defrost is lower than the one normally set with

the parameters related to error probe conditions, the start or

the end takes place with the shortest time.

These functions are provided because when the EP evaporator probe is used, the set defrost endurance time is usually

longer than necessary (the time ddE is a security time-out)

and in case is used the “Dynamic Intervals Defrost System”

the interval is usually set more longer than what is normally

programmed into instruments that do not have the function.

5.8.5 Display lock during Defrost

Through parameters ddL and AdA it is possible to define the

display behaviour during defrost:

on The ddL parameter locks the display at the last tem-

perature reading during all the defrost cycle until, at

the end of defrost, the temperature has not reached

the lock value or the value [SP + rd] or is elapsed the

time set at parameter AdA

Lb Shows the label dEF during the defrost cycle and PdF

after the defrost until, at the end of defrost, the temperature has not reached the lock value or the value

[SP + rd] or is elapsed the time set on parameter AdA

oF The display continues showing the temperature meas-

ured by the Pr1 probe during the defrost cycle.

5.9 Evaporator fans control

The control of the evaporator fans on the output configured as

Fn depends on some specific control statuses of the instrument

and the temperature measured by the evaporator probe (EP).

In the case that the evaporator probe is not used or in error,

the Fn output is activated only depending on parameters

Ftn, FtF and FFE.

Parameters Ftn and FtF can be used to determine the behavior

of the evaporator fans when the ot outupt (compressor) is OFF.

When ot output is OFF, it is possible to set the instrument so

that that the Fn output continues working in cycles according

to the times programmed at parameters Ftn (fan activation

time) and FtF (fan deactivation time).

When output ot is switched OFF the instrument activates the

output Fn for the time Ftn, then deactivates it for the time

FtF and so on whilst the otuput ot remains OFF.

Programming Ftn = oF the output Fn in ot OFF condition

remains switched OFF.

Programming instead Ftn to any value and FtF = oF the

output Fn when ot in OFF condition remains switched ON.

The parameter FFE decides whether the fans must always

be switched ON independently of the defrosting status

(FFE = on) or switched OFF during defrosting (FFE = oF).

In this later case, it is possible to delay the start up of the

fans even after the end of the defrosting of the time set in the

parameter FFd. When this delay is active the LED flashing to point out that the delay is in progress.

When the evaporator probe is used the fans, as well as being conditioned by the parameters Ftn, FtF and FFE, are

also conditioned by a temperature control.

It is possible to determine whether the fans should be disabled

when the temperature measured by the evaporator probe is

higher than the FFL parameter (too hot) or even when it is

lower than the FLF parameter (too cold).

The relative differential that can be set in parameter FdF is

also associated with these parameters.

FLF

FFL

Temp.

FdF

FdF

time

offoff offON ON

Ep

Fan

Note: It is necessary to pay attention to the correct use of

this fans temperature control functions because in

the typical application of refrigeration the stop of the

evaporator fans stops also the thermal exchange.

Remember that the fans functioning can be conditioned by

the Door open function by the digital input.

5.10 Alarm functions

The alarm conditions of the instrument are:

– Probe errors E1, -E1, E2, -E2 and E3, -E3;

– Temperature alarms Hi and Lo;

– External alarm AL;

– Door open oP.

The alarm functions acts on LED , on the internal buzzer,

if present and configured by the obu parameter and on the

desired output if configured by parameters oo1, oo2 or oo3.

Any active alarm condition is signaled lighting up the LED ,

while the acknowledged alarm status is shown by flashing the

LED .

The buzzer (if present) can be configured to point out the alarms

by programming parameter obu = 1 or 3 and always acts to

signal the acknowlegeable alarms. This means that, when

activated, it can be switched OFF by briefly pressing any key.

The possible selections of output parameters for the alarm

signalling function are:

At

When the output is to be activated in alarm condition

Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 11

and can be deactivated manually by pressing any key of

the instrument (typical application for an acoustic signal);

AL When the output is to be activated in alarm condition

but cannot be deactivated manually; it is then deactivated only when the alarm status ceases (typical

application for a light signal);

An When the output is to be activated in alarm condi-

tion and that remains active even when the alarm

status has ceased. The disabling action (recognition

of stored alarm) can only be carried out manually by

pressing any key when the alarm status has removed

(typical application for light signal).

-t when one wants the function described as At but with

an inverse function (output activated in normal condition and disabled in alarm status).

-L This alarm function is similar to AL but with inverse

logic (output active in normal conditions and disabled

in alarm status).

-n This alarm function is similar to An but with inverse

working logic (output active in normal conditions and

disabled in alarm status).

The instrument offers the possibility to have the alarm

memory function activated via the parameter AtA.

If AtA = oF, the instrument cancels the alarm signal when

the alarm status ends, if instead AtA = on, the instrument

maintains the alarm signal also when the alarm status ends.

To cancel the alarm memory signal, press any key.

It must be remembered that if an output function is desired

with an alarm memory (oo1/oo2/oo3 = An/-An) it is

necessary to set the parameter AtA = on.

5.10.1 Temperature alarms

The temperature alarm works according to Pr1 or AU probes

measurement, the type of alarm set in the parameter AAy the

alarm thresholds set in parameters AHA (maximum alarm)

and ALA (minimum alarm) and the relative differential AAd.

Through parameter AAy it is possible to set the alarm thresholds AHA and ALA as absolute or relative to the active Set

Point, must be related to Pr1 or Au probes and if the message

Hi (High alarm) and Lo (Low Alarm) are to be displayed at

alarm intervention.

Depending on the desired alarm operating mode, parameter

AAy

can be set as:

1 Absolute alarms referred to probe Pr1, displays Hi/Lo;

2 Relative Alarms referred to probe Pr1, displays Hi/Lo;

3 Absolute alarms referred to probe Au, displays Hi/Lo;

4 Relative Alarms referred to probe Au, displays Hi/Lo;

5

Absolute alarm referred to probe Pr1, displays no labels;

6

Relative alarm referred to probe Pr1, displays no labels;

7

Absolute alarm referred to probe Au, displays no labels;

8

Relative alarm referred to probe Au, displays no labels

.

Using some parameters it is also possible to delay the enabling and the intervention of these alarms.

These parameters are:

APA

Temperature alarm exclusion time on switching ON the

instrument if the instrument is in alarm status when it

is switched ON. If the instrument is not in alarm status

when it is switched on the time APA it is not considered.

AdA Temperature alarm exclusion time at the end of de-

frost cycle (and, if programmed, after the draining) or

after a continuous cycle.

AAt Temperature alarms delay activation time. Tempera-

ture alarms are enabled at the end of the exclusion

times and are activated after the AAt time when the

temperature measured by the probe exceeds or goes

below the respective maximum and minimum alarm

thresholds. The alarm thresholds are those set at

parameters AHA and ALA when the alarms are set as

absolute (AAy = 1, 3, 5, 7).

Temp.

AHA

AAd

time

AL

ALA

AAd

offoffoff

ON ON

Hi Lo

Pr1

or they assume the values [SP + AHA] and [SP + ALA]

if the alarms are relative (AAy = 2, 4, 6, 8).

AHA

SP

ALA

offoffoff

ON ON

Hi Lo

AL

AAd

AAd

Temp.

time

Pr1

The maximum and minimum temperature alarms can be disabled by setting the related parameters AHA and ALA = oF.

The temperature alarms are signalled lighting up the alarm

LED ( ) and, if configured, also with the buzzer

5.10.2 External alarm from digital input

The instrument can signal an alarm external to the instrument

using the digital input setting iFi = 4 or 5. The instrument

signals the alarm turning ON the

alarm LED ( )

and display-

ing AL label alternated to the variable set with parameter Ids.

Mode iFi = 4 operates no action on the control output, while

iFi = 5 deactivates the control output at digital input inter-

vention.

5.10.3 Open door alarm

The instrument can signal the open door alarm coondition using

the digital input setting iFi = 1, 2 and 3. As the digital input is

activated, the instrument signals that the door is open showing

on the display the oP label alternated to the variable set with

parameter ids.

After the delay set with parameter AoA the instrument signals

the Open Door alarm with the configured devices (buzzer and/

or Output), lighting up the LED while showing the oP label.

At the open door alarm intervention are also re-activated the

inhibited outputs (compressor).

Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 12

5.11 Function of keys / and /Aux

Two of the instrument keys, in addition to their normal functions, can be configured to operate other commands. The

/ key function can be defined using the tUF parameter

while the /Aux key via parameter TFb. Both parameters

have the same possibilities and can be configured to perform

the following functions:

oF The key carries out no function;

1 Pressing the key for at least 1 s, it is possible to enable/

disable, if configured, the auxiliary output (oFo = 2);

2 Pressing the key for at least 1 s, can be sequentially

select a normal or eco operating mode (SP/SPE).

A selection has been made the display shows for about

1 s the active Set Point code (SP or SPE);

3 Pressing the key for at least 1 s is possible to switch the

instrument from ON to Stand-by state and vice-versa;

4 Pressing the key for at least 1 s activates/deactivates a

Turbo cycle.

6. ACCESSORIES

6.1 Parameters configuration by “A01”

The instrument is equipped with a connector that allows the

transfer from and toward the instrument of the functioning parameters through the device A01 with 5 poles connector.

This device it is mainly usable for the serial programming of

some instruments which need to have the same parameters

configuration or to keep a copy of the parameters setting of an

instrument and allow its rapid retransmission.

The same device allows to connect a PC via USB with which,

through the appropriate configuration software for “AT UniversalConf tools”, the operating parameters can be configured.

To use the device A01 it is necessary that the device or instrument are being supplied directly or through the key.

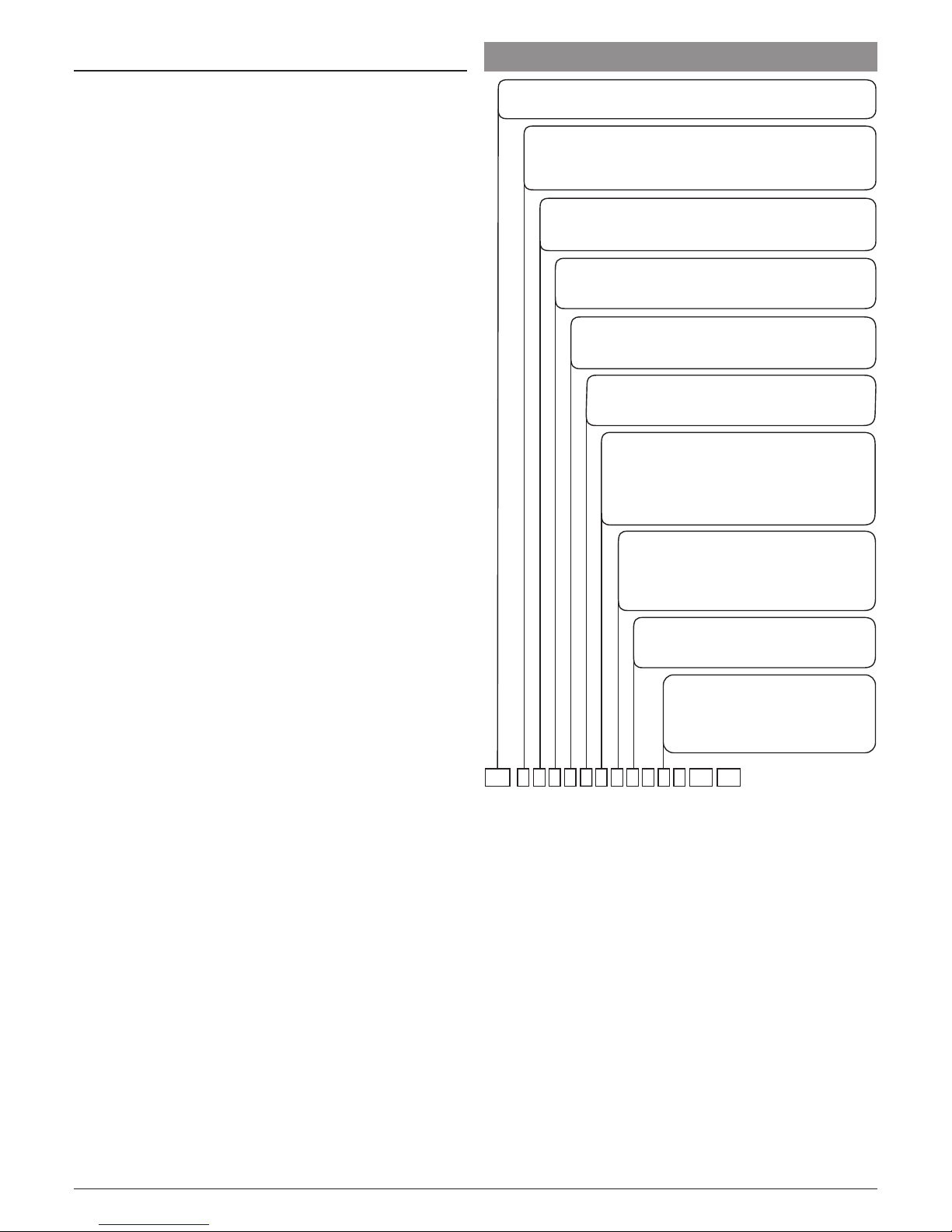

AC supply

Supply adapter

12 VDC

Power supply

Enter

PWS

12 V

A B C

TTL

+-

USB

to PC

USB

Enter

PWS

12 V

A B C

TTL

+-

USB

to PC

USB

For additional info, please have a look at the A01 instruction

manual.

Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 13

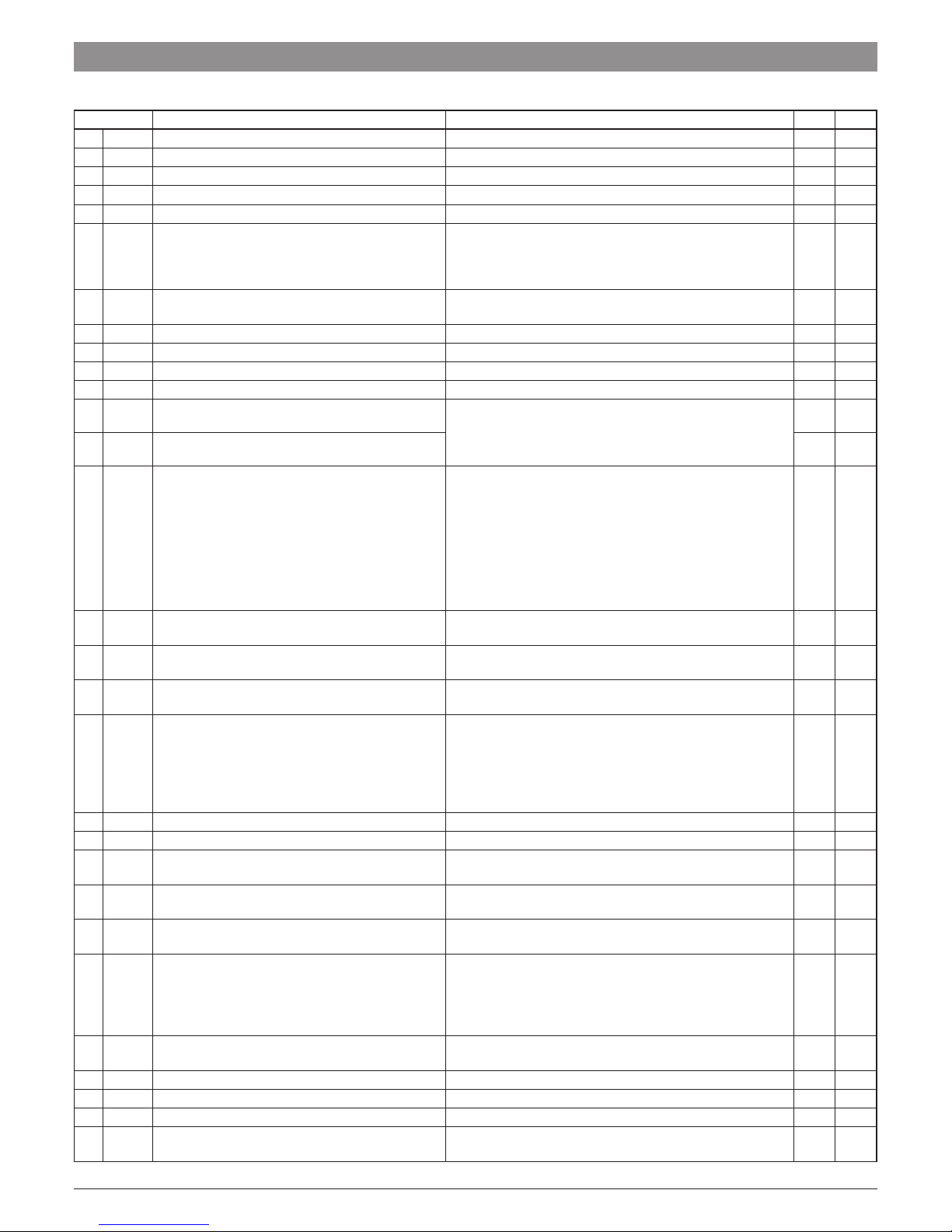

7. PROGRAMMABLE PARAMETERS TABLE

Here below is a description of all the parameters available on the instrument. Some of them may not be present, either due

to the fact they depend on the type of instrument or because they are automatically disabled as unnecessary.

Parameter Description Range Def. Note

1

SLS

Minimum Set Point -99.9... HS -50.0

2

SHS

Maximum Set Point LS... 999 99.9

3

SP

Set Point LS ÷ HS 0.0

4

SPE

Set Point Eco SP ÷ SHS 0.0

5

SPH

Turbo Set Point (or indep. Heating Set Point, HC mode) SLS ÷ SP 0.0

6

iuP

Unit of measurement and resolution (decimal point)

C0 °C, resolution 1°;

F0 °F, resolution 1°;

C1 °C, resolution 0.1°;

F1 °F, resolution 0.1°.

C1

7

iFt

Measurement filter

oF Not used;

0.1 ÷ 20.0 s

2.0

8

iC1

Pr1 Probe Calibration -30.0 ÷ +30.0°C/°F 0.0

9

iC2

Pr2 Probe Calibration -30.0 ÷ +30.0°C/°F 0.0

10

iC3

Pr3 Probe Calibration -30.0 ÷ +30.0°C/°F 0.0

11

iCU

Display offset -30.0 ÷ +30.0°C/°F 0.0

12

iP2

Input Pr2 usage

oF Unused;

EP Evaporator probe;

Au Auxliary probe;

dG Digital Input.

dG

13

iP3

Input Pr3 usage dG

14

iFi

Function and logic functioning of the Digital Input

(adding the “-” minus sign the logic is inverted)

0 No function;

1 Open Door;

2 Open Door with Fan Lock;

3 Open Door with Fan and Output Lock;

4 External Alarm;

5 External alarm with control output disabling;

6 Normal/Eco select;

7 On/Stand by select;

8 Start a Turbo cycle.

0

15

iti

Digital Input Delay

oF Disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min).

oF

16

iEt

Eco Mode activation delay at Door closed

oF Disabled;

-1 ÷ -59 (min) ÷ 1 ÷ 99 (h).

oF

17

itt

Max. time functioning in Eco Mode

oF Disabled;

-1 ÷ -59 (min) ÷ 1 ÷ 99 (h).

oF

18

idS

Variable normally displayed

oF Display not lit;

P1 Probe Pr1 measure;

P2 Probe Pr2 measure;

P3 Probe Pr3 measure;

Ec Measure Pr1 in Normal mode + ECO label when in ECO mode;

SP Active Set Point.

P1

19

rd

Differential (Hysteresis) 0.0 ÷ 30.0°C/°F 2.0

20

rEd

Differential (Hysteresis) in ECO mode

0.0 ÷ 30.0°C/°F

2.0

21

rHd

Differential (Hysteresis) in Turbo mode or Heating in

HC mode

0.0 ÷ 30.0°C/°F

2.0

22

rt1

Output activation time for Pr1 probe error

oF Disabled;

-1 ÷ -59 (s) 1 ÷ 99 (min).

oF

23

rt2

Output deactivation time for Pr1 probe error

oF Disabled;

-1 ÷ -59 (s) 1 ÷ 99 (min).

oF

24

rHC

Output operating mode

H Heating;

C Cooling;

nr Neutral zone;

HC Neutral Zone with indep. Set Point;

C3

Cooling with3 autom. switch modes.

C

25

rtC

Lengh of Turbo cycle

oF Function disabled;

-1 ÷ -59 (min) 1 ÷ 99 (h).

oF

26

dtE

Defrost stop temperature -99.9 ÷ +999°C/°F 8.0

27

dtS

Defrost enable temperature -99.9 ÷ +999°C/°F 10.0

28

dtF

Defrost start temperature -99.9 ÷ +999°C/°F -99.9

29

dSt

Delay start Defrost by dtF start temperature

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min)

1

Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 14

Parameter Description Range Def. Note

30

ddL

Display Lock during defrost

oF Not active;

on Active at last measure;

Lb Active with label (dEF during defrost and PdF at defrost).

oF

31

dcd

Defrost activation time for continuous compressor

operating

oF Disabled;

-1 ÷ -59 (min) ÷ 1 ÷ 99 (h)

oF

32

dde

Max. defrost duration

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min).

oF

33

dtd

Compressor delay after defrost (drainage time)

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min)

20

34

ddt

Defrosting Type

EL Electrical heating/stop compressor;

in Hot gas/reverse cycle;

no Without compressor output condictioning;

Et Electrical heating with evaporator temperature control.

EL

35

ddC

Defrosting starting mode

rt Real time intervals;

ct “ot” output on time intervals;

cS defrost every “ot” switching off (+ rt intervals);

cL Do not use.

rt

36

ddi

Defrosting interval

oF Function disabled;

-1 ÷ -59 (min) ÷ 1 ÷ 99 (h).

oF

37

dSd

Delay first defrost after power-on

oF Defrost at power-on;

-1 ÷ -59 (min) ÷ 1 ÷ 99 (h).

oF

38

ddd

Dynamic Defrost Percentage reduction

0 ÷ 100% 0

39

dEi

Defrosting interval for evaporator probe error

oF Function disabled;

-1 ÷ -59 (min) ÷ 1 ÷ 99 (h)

6

40

dEE

Lengh of defrost cycle for evaporator probe error

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min).

10

41

Ftn

Fan time activation with ot output (compressor) OFF

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min).

5

42

FtF

Fan time deactivation with ot output (compressor) OFF

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min).

oF

43

FFL

High temperature fan deactivation - 99.9 ÷ 999 °C/°F 10.0

44

FLF

Low temperature fan deactivation - 99.9 ÷ 999°C/°F -99.9

45

FdF

Differential fan control 0.0 ÷ 30.0°C/°F 1.0

46

FFE

Fan status during defrost oF - on oF

47

FFd

Fan delay after defrost

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min).

oF

48

PP1

ot output delay at switching ON

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min).

oF

49

PP2

ot output delay after switching OFF

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min).

oF

50

PP3

Min. time between two ot output switching ON

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min).

oF

51

Pod

Outputs delay at power ON

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min).

oF

52

AAy

Temperature Alarm 1 type

1

Absolute for Pr1 with label Hi or Lo;

2

Relative to Pr1 with

label Hi or Lo;

3

Absolute for Au with label Hi or Lo;

4

Relative to Au with

label Hi or Lo;

5 Absolute for Pr1 with no label;

6 Relative to Pr1

with no label;

7

Absolute for Au with no label;

8 Relative to Au

with no label.

1

53

AHA

High temperature Alarm threshold

oF Function disabled;

-99.9 ÷ +999°C/°F.

oF

54

ALA

Low temperature Alarm threshold

oF Function disabled;

-99.9 ÷ +999°C/°F

oF

55

AAd

Temperature Alarms Differential 0.0 ÷ 30.0°C/°F 1.0

56

AAt

Temperature Alarms Delay

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min).

oF

57

AtA

Alarms memory

oF Alarm memory disabled;

on Alarm memory enabled;

oF

58

APA

Temperature Alarms delay at power ON

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min).

2.00

Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 15

Parameter Description Range Def. Note

59

AdA

Temperature Alarms delay and

unlock display delay after defrost

oF Function disabled;

-1 ÷ -59 (min) ÷ 1 ÷ 99 (h).

1.00

60

AoA

Open Door Alarm Delay

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min).

3.00

61

oo1

OUT1 function

oF No function;

ot

Temperature control (compr.);

dF Defrost;

Fn Fans;

Au Auxiliary;

At/-t Silenceable alarm;

AL/-L Not silenceable Alarm;

An/-n Stored Alarm;

on ON when the instrument is ON;

HE Heating (Neutral zone control).

ot

62

oo2

OUT2 function dF

63

oo3

OUT3 function Fn

64

obu

Buzzer function mode

oF Function disabled;

1 Active for alarms only;

2

Active for key pressed only

;

3

Active for alarms and key pressed

.

oF

65

oFo

Auxiliary output function

oF Function disabled;

1 Control output ot delayed;

2 Manual activation by key or digital inpu;

3 Shop window light with Eco mode (ON with SP, OFF with SPE);

4 Internal light (OFF with door closed and ON with door opened).

oF

66

otu

Time relative to auxiliary output

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 99 (min).

oF

67

tUF

/ Key Function

oF No function;

1 Auxiliary output command;

2 Normal/Eco Mode selection;

3 Switch ON/Switch OFF (Stand-by);

4 Turbo cycle command.

oF

68

tFb

/Aux Key Function oF

69

tLo

Keyboard lock function delay

oF Function disabled;

-1 ÷ -59 (s) ÷ 1 ÷ 30 (min).

oF

70

tEd

Set Point visibility with key fast procedure

0 None;

1 SP;

2 SPE;

3 SP and SPE;

4 Active SP;

5 SP and SPH;

6 SP, SPE and SPH.

4

71

tPP

Password to Access Parameter functions

oF Function disabled;

001 ÷ 999.

oF

Ascon Tecnologic - e33 - OPERATING INSTRUCTIONS - PAG. 16

8. PROBLEMS, MAINTENANCE AND WARRANTY

8.1 Notifications

8.1.1 Error messages

Error Reason Action

E1 -E1

E2 -E2

E3 -E3

The probe may be interrupted

(E) or in short circuit (-E) or

may measure a value outside

the range allowed

Check the probe connection with the instrument

and check that the probe

works correctly

epr

Internal EEPROM memory

error

Press P key

err

Fatal memory error

Replace the instrument or

ship to factory for repair

8.1.2 Other messages

Message Reason

od

Delay at power-on in progress

Ln

Keyboard locked

Hi

Maximum temperature alarm in progress

Lo

Minimum temperature alarm in progress

AL

Digital Input alarm in progress

oP

Door Open

dEF

Defrost in progress with ddL = Lb

PdF

Post-defrosting in progress with ddL = Lb

Eco

Eco Mode in progress

trb

Turbo Mode in progress

8.2 Cleaning

We recommend cleaning of the instrument only with a slightly

wet cloth using water and not abrasive cleaners or solvents.

8.3 Warranty and Repairs

The instrument is under warranty against manufacturing flaws

or faulty material, that are found within 18 months from delivery date. The warranty is limited to repairs or to the replacement of the instrument.

The eventual opening of the housing, the violation of the instrument or the improper use and installation of the product will

bring about the immediate withdrawal of the warranty effects.

In the event of a faulty instrument, either within the period

of warranty, or further to its expiry, please contact our sales

department to obtain authorisation for sending the instrument

to our company.

The faulty product must be shipped to Ascon Tecnologic with

a detailed description of the faults found, without any fees or

charge for Ascon Tecnologic, except in the event of alternative

agreements.

8.4 Disposal

The appliance (or the product) must be

disposed of separately in compliance

with the local standards in force on

waste disposal.

9. TECHNICAL DATA

9.1 Electrical characteristics

Power supply: 230 VAC, 115 VAC, 12 VAC/VDC ±10%;

AC frequency: 50/60 Hz;

Power consumption: about 3.5 VA;

Inputs: 3 inputs for temperature probes:

NTC (103AT-2, 10 kW @ 25°C);

1 free of voltage digital input as an alternative

to input probe Pr3;

Output: Up to 3 relay outputs: