P

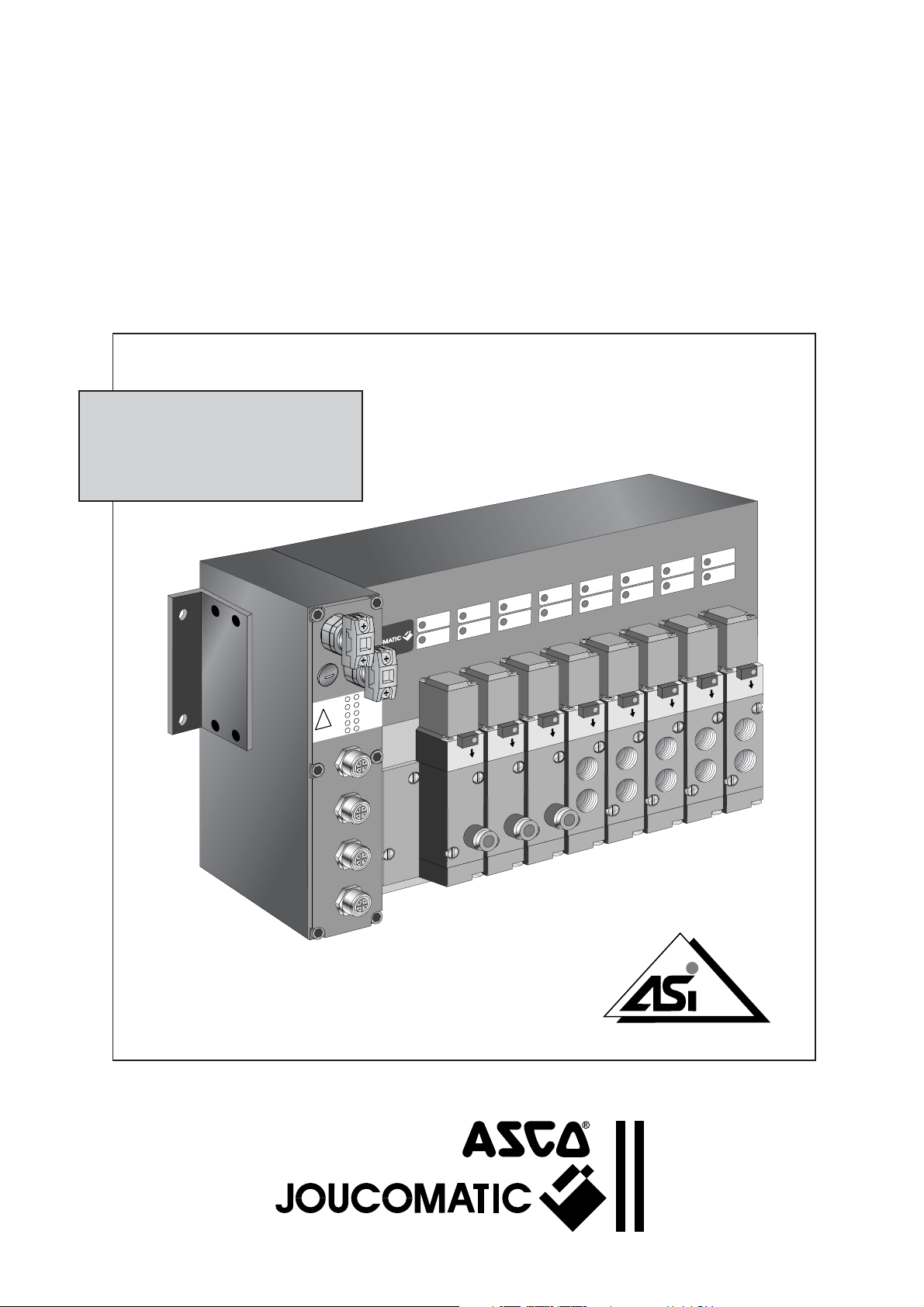

NEUMATIC SPOOL VALVE ISLANDS

ØM5 - G1/8 - G1/4 or instant fittings

designed for connection to a PLC by field bus and

AS-Interface protocol

BUSLINK-Generation C

Installation manual

R

W

P

I

S

A

-2

1

IN

-1

1

-4

1

IN

IN

-3

1

-2

2

IN

IN

-1

2

-4

2

IN

IN

-3

2

IN

5

1

3

NTERFACE

N˚ 21401

MS-P586-5.GB.R2a

BUSLINK - AS-Interface INSTALLATION

CONTENTS Page

1. The BUSLINK system - Generation C - with AS-Interface protocol _________________________________ 3

2. System components _______________________________________________________________________ 5

2.1 Functional description ______________________________________________________________ 5

2.2 Component assembly _______________________________________________________________ 5

2.3 Dimensions - Mounting ______________________________________________________________ 6

2.4 Ordering information for a BUSLINK valve island - Generation C - with AS-Interface ______________ 7

2.5 Manual override ___________________________________________________________________ 8

2.6 Spool valves series 569 - 570 - 571 ____________________________________________________ 9

3. Assembly of BUSLINK Generation C with AS-Interface __________________________________________ 10

3.1 Mounting _________________________________________________________________________ 10

3.2 Pneumatic connection ______________________________________________________________ 10

4. Electrical connection ______________________________________________________________________ 12

4.1 General __________________________________________________________________________ 12

4.2 Voltage supply ____________________________________________________________________ 12

4.3 Calculation of power draw ___________________________________________________________ 12

4.4 Connection of inputs ________________________________________________________________ 13

4.5 Addressing of inputs/outputs _________________________________________________________ 14

4.6 Control signals ____________________________________________________________________ 16

5. AS-Interface network ______________________________________________________________________ 18

5.1 Connection of AS-Interface bus (yellow cable) ___________________________________________ 18

5.2 Programming instructions ____________________________________________________________ 18

5.3 Connection of supply voltage (black cable) ______________________________________________ 19

5.4 Startup of AS-Interface network _______________________________________________________ 19

5.5 Diagnostics _______________________________________________________________________ 19

5.6 Fuses ___________________________________________________________________________ 19

5.7 Accessories for AS-Interface _________________________________________________________ 20

5.8 Dimensions of the accessories for AS-Interface __________________________________________ 20

CAUTION

To avoid malfunction of the bus system, please check on any valve island

• for correct addressing parameters.

• all installation, adjustment and maintenance operations must be carried out by qualified personnel.

A separate Declaration of Incorporation relating to EEC-Directive 89/392/EEC Annex II B is available on request.

Please provide acknowledgement number and serial numbers of products concerned.

This product complies with the essential requirements of the EMC-Directive 89/336/EEC and amendments. A

separate Declaration of Conformity is available on request.

NOTICE

The information in this manual is subject to change without notice.

In no event shall ASCO/JOUCOMATIC be liable for technical or editorial errors or omissions. Neither is any liability assumed

for accidental or consequential damages arising out of or in connection with the supply or use of the informaton contained

herein.

THIS MANUAL CONTAINS INFORMATION PROTECTED BY COPYRIGHT. NO PART OF THIS DOCUMENT MAY BE

PHOTOCOPIED OR REPRODUCED IN ANY FORM OR MANNER WHATSOEVER WITHOUT PRIOR WRITTEN PERMISSION

FROM JOUCOMATIC.

COPYRIGHT © 1999 - 2000 - ASCO/JOUCOMATIC - All rights reserved.

2

INSTALLATION BUSLINK - AS-Interface

42

513

14

12

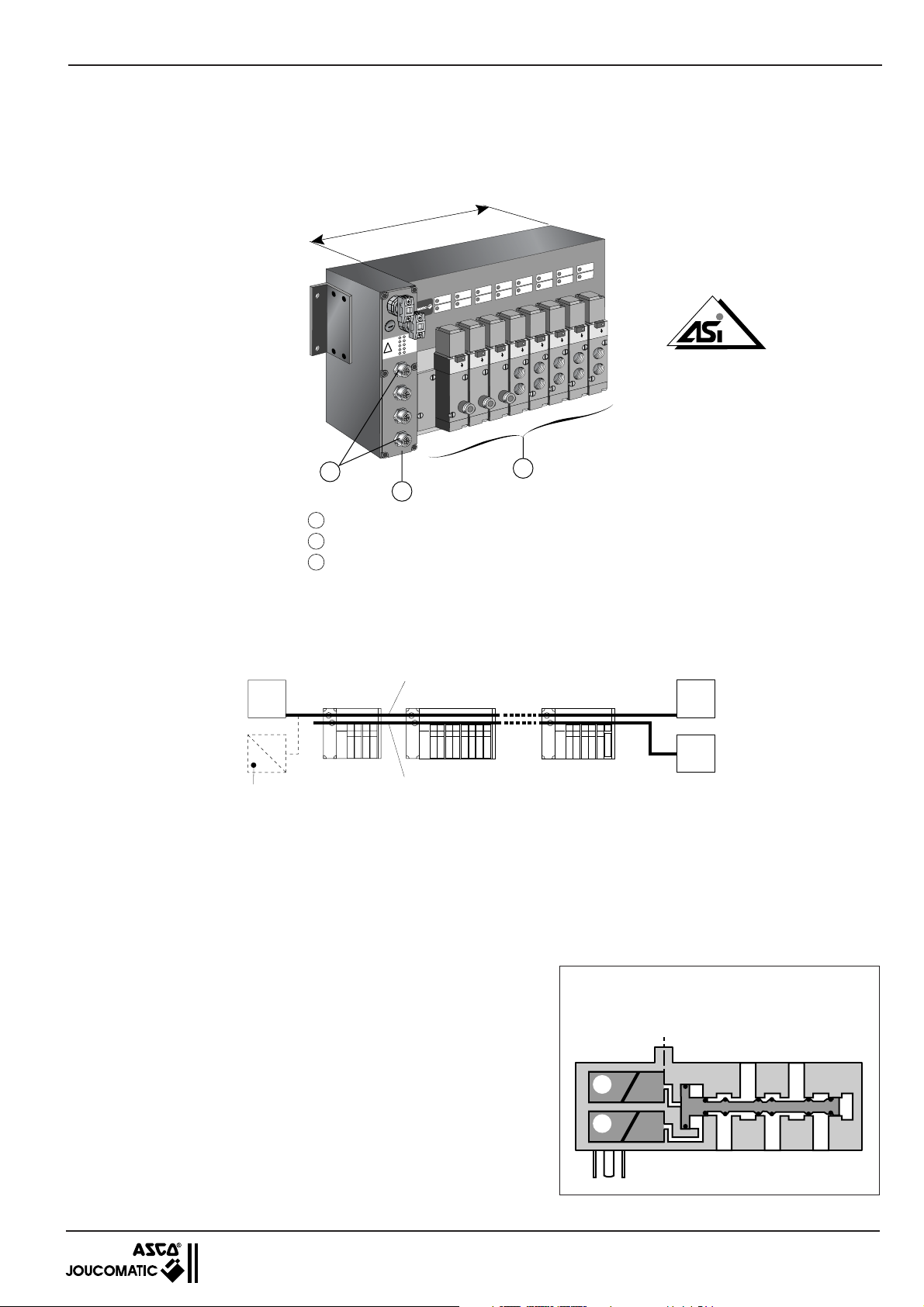

1. The BUSLINK system - generation C - with AS-Interface protocol

Pneumatic islands of 4 to 8 monostable or bistable spool valves, ØM5 - G1/8 - G1/4, with integrated connections for data

exchange with a control system (PLC) by means of a field bus and standardized AS-Interface protocol.

Max. 8 outputs (valves)

R

W

P

I

S

A

-2

1

IN

1

1-

-4

1

IN

IN

-3

1

-2

2

IN

IN

-1

2

-4

2

IN

IN

-3

2

IN

5

1

3

N˚ 21401

NTERFACE

3

1

2

1

Spool valves ( 8 monostable or 4 bistable valves at maximum )

2

Module for AS-Interface connection

3

4 or 8 inputs at option

NOTE - No additional input or output modules available

CONNECTION DIAGRAM

AS-Interface

master

ASi

yellow cable

black cable

AS-Interface bridge to

other protocols

(Profibus-DP, FIPIO,

Device NET, . . .)

ADVANTAGES

With the many advantages it offers, the Buslink system meets modern needs for automated installations.

• No bulky and difficult wiring.

• Time and money saved due to direct electric cabling and common air supply.

• Unit tested and equipped with spool valves at delivery.

• Easy maintenance.

COMBINATIONS

Buslink units can be grouped as follows:

•

Islands of 4, 6 or 8 monostable 3/2, 5/2 or 5/3 spool valves or 4 bistable spool

valves or 4 double 3/2 NC.

•

Differently sized islands for spool valve series 569 - 570 - 571 (only one valve

size per island

• Upon request, each island can be equipped with four 5-pin female panel

connectors M12 to connect 4 inputs (1 node configuration) or 8 outputs (2

node configuration).

• Monostable and bistable spool valves with integrated push/pull pilot valves

(

), all functions available on one island.

*

• Any configuration possible upon request.

).

(*) Bistable spool valves series 569 - 570 - 571

integrated push/pull pilot valves (pilots placed on

one side of the island offering a compact solution).

AS-Interface

supply

24V =

with

3

BUSLINK - AS-Interface INSTALLATION

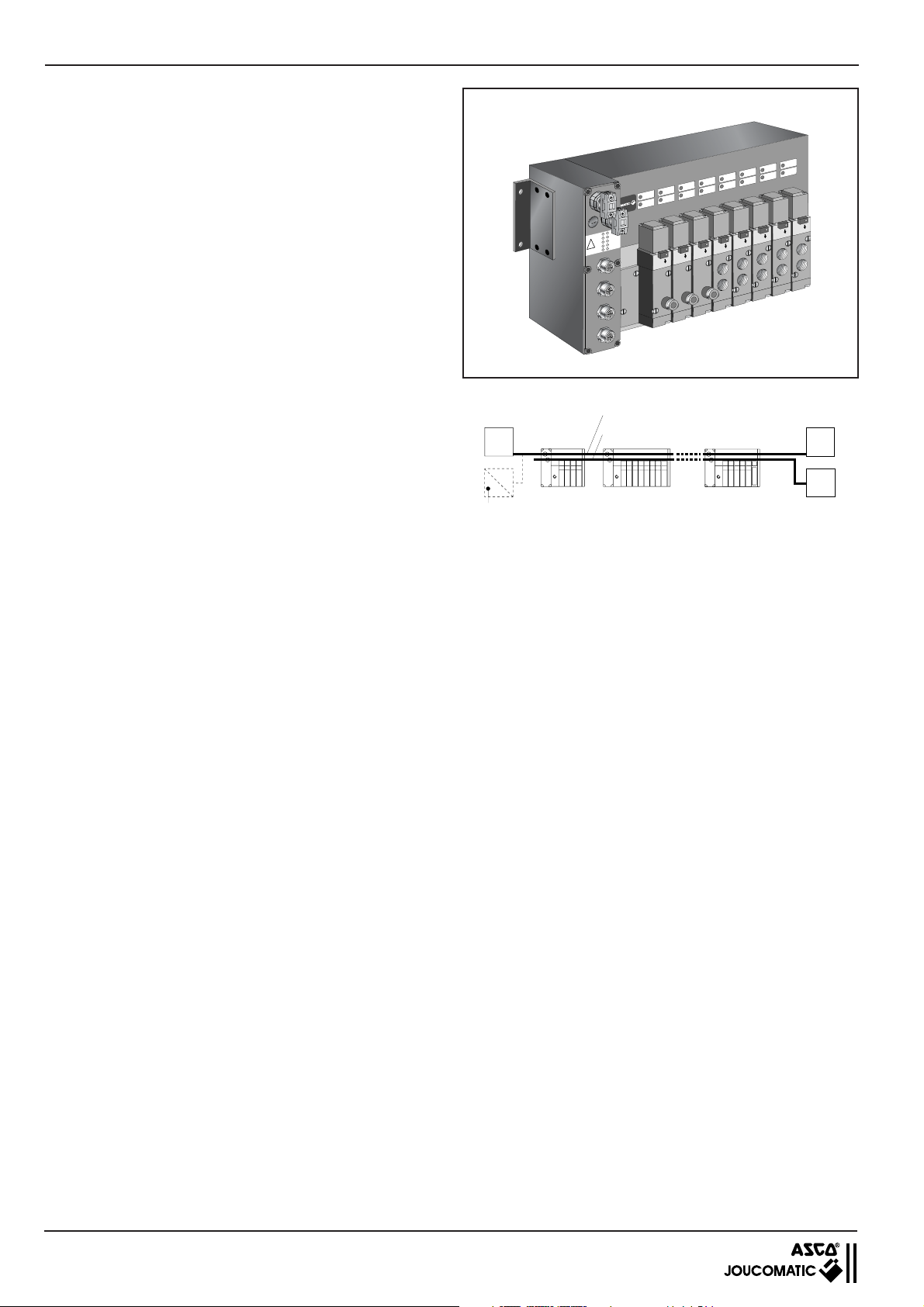

AS-INTERFACE (AS-Interface)

Pneumatic spool valve island for data exchange via field bus

and standardized AS-Interface protocol.

The connection between a control system (PLC) and several spool

valve islands by means of a field bus allows the transmission of data

with a standard AS-Interface cable :

• control signals to the spool valves,

• information signals from the sensor inputs.

ADVANTAGES

With the many advantages it offers, the Buslink system meets

modern needs for automated installations.

• No bulky and difficult wiring.

• Time and money saved due to direct electric cabling and common

air supply.

• Visual display and quick disconnection for easy maintenance.

• Unit tested and equipped with spool valves at delivery.

R

W

P

I

S

A

-2

1

IN

-1

1

-4

1

IN

IN

-3

1

-2

2

IN

IN

-1

2

-4

2

IN

IN

-3

2

IN

5

1

3

COMBINATIONS

Buslink units can be grouped as follows:

• Modules for 3/2, 2x3/2, 5/2 or 5/3 spool valves series 569 (ØM5 or

AS-Interface

master

yellow cable

black cable

instant fittings) - 570 (G1/8 or instant fittings) - 571 (G1/4).

ASi

OPTIONS

• Island with air supplied at two different pressure rates.

• Island with external air supply for pilot pressure.

AS-Interface bridge to other protocols

(Profibus-DP, FIPIO, Device NET etc.)

COMMUNICATION CHARACTERISTICS

Communication protocol : AS-Interface (bidirectional mode)

Transmission : flat AS-Interface cable (yellow, 2 wires)

Bus structure : any structure according to AS-Interface standards

Max. number of spool valve islands : 31 nodes (1 valve island can have 2 nodes)

Number of valves per island : 4 to 8

Number of inputs/outputs : 0, 4 or 8 inputs

Max. bus cable length : 100 m (300 m with repeaters)

Island addressing (participants) : AS-Interface master

Compatibility with control system : no modification of current programmes

Compatible equipment : various options

ELECTRICAL CHARACTERISTICS

Supply voltage : 24 V DC, ±10% at the island.

Supply to the valves with an additional flat AS-Interface cable (black, 2 wires).

Max. ripple ratio : 10 %

Consumption : 79 mA per valve and 9 mA per input

Coil insulation class : F

Protection : IP65

Electrical insulation of the inputs : optocouplers

Peak voltage suppression : integrated in the island for each coil

Additional 24 V supply connection : vampire-type panel connector for AS-Interface cable (black cable)

Bus connection (IN/OUT) : vampire-type panel connector for AS-Interface cable (yellow cable)

Input connection : 5-pin female panel connector M12

Earth connection : earthing screw on the pneumatic subbase

Electromagnetic compatibility : in accordance with the EU directive EMC 89/336/EEC

CE identification

AS-Interface

supply

24V =

PNEUMATIC CHARACTERISTICS

Fluid : air or neutral gas, filtered at 30 µm, lubricated or not

Operating pressure : 1.5 to 8 bar (2.5 to 8 bar with 3/2 NO spool valves and series 569 functions 5/3)

Flow rate (Qv at 6 bar) series 569 : 175 l/min

series 570 : 600 l/min (3/2: 400 l/min - 2x3/2 : 550 l/min)

series 571 : 1050 l/min

Allowable temperature : +5 °C to +50 °C

ACCESSORIES: see following page

4

INSTALLATION BUSLINK - AS-Interface

2. SYSTEM COMPONENTS

2.1 FUNCTIONAL DESCRIPTION

The spool valve islands are connected to a PLC with a (yellow) AS-Interface bus cable to pilot the spool valves and detect the sensor

status if the island is provided with inputs. A second adapter is used to supply the valves with power (black cable).

The pressure supply and exhaust are collected in the pneumatic subbase. The spool valves ensure the pressure supply and exhaust

of the pneumatic actuators. The pneumatic connection of the actuators is made on the top side of the spool valves. The island can be

equipped with inputs upon request. The electrical sensors are connected to the input modules with male connectors ØM12.

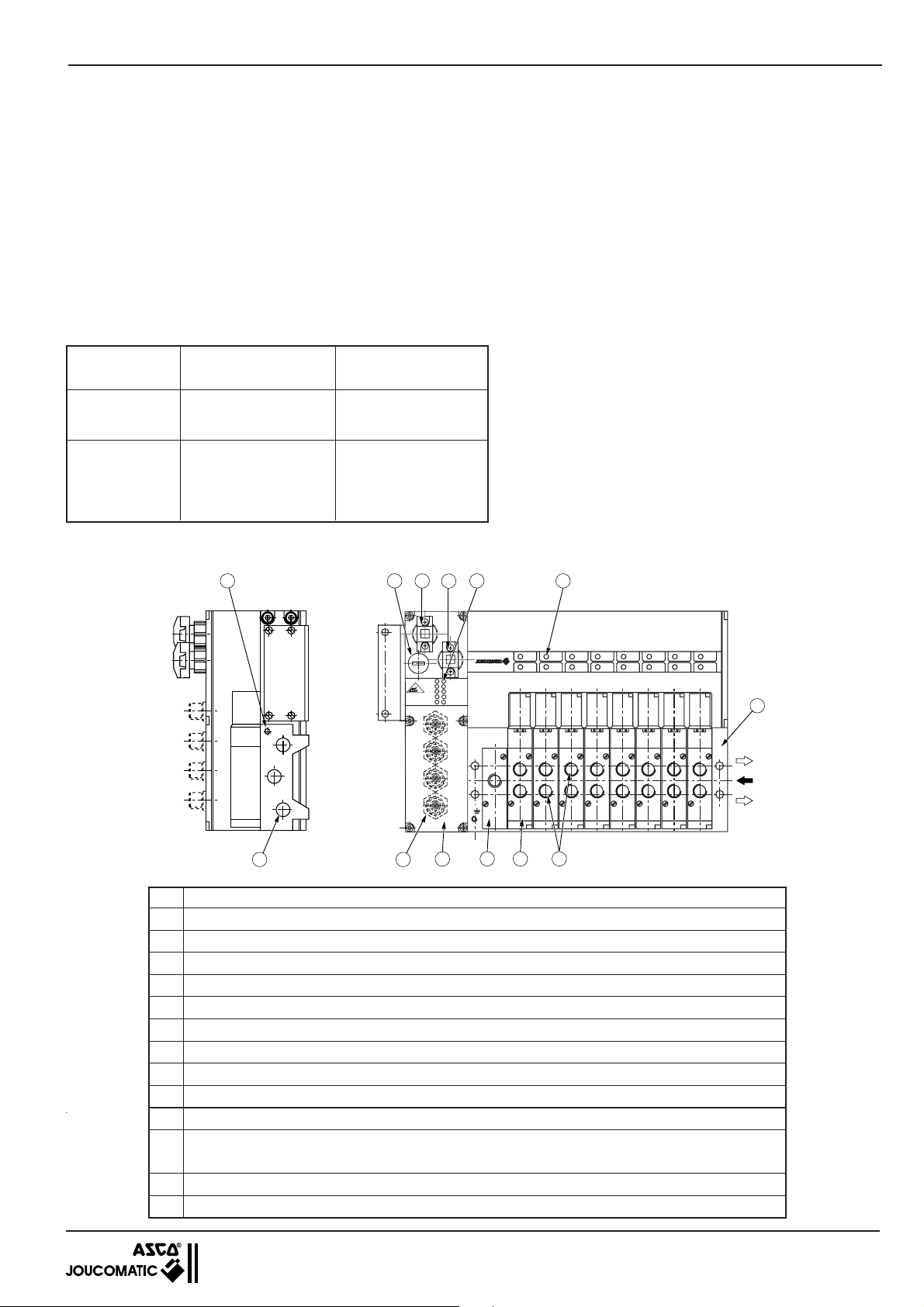

MAXIMUM CAPACITY OF THE SPOOL VALVE ISLAND

According to the configuration you choose, the islands can be equipped with a maximum of 8 inputs and 8 outputs (1 output = 1 spool

valve pilot).

The maximum capacity of the island depends on the number of nodes (see table below).

Example for maximum configuration:

Number

of nodes

1

2

Max. number

of valves

4 monostable

or 2 bistable

or 2 double 3/2 NC

8 monostable

or 4 bistable

or 4 double 3/2 NC

or 4 monostable +

2 bistable (1)

Max. number

of inputs

4

8

NOTE:

- Maximum configuration for 1 node

: 4 outputs / 4 inputs

- Maximum configuration for 2 nodes: 8 outputs / 8 inputs

- 1 output = 1 monostable spool valve

- 2 outputs = 2 monostable spool valves or 1 bistable spool

valve

(1) In this configuration, the bistable spool valves are

always to be placed on the right-hand side of the island.

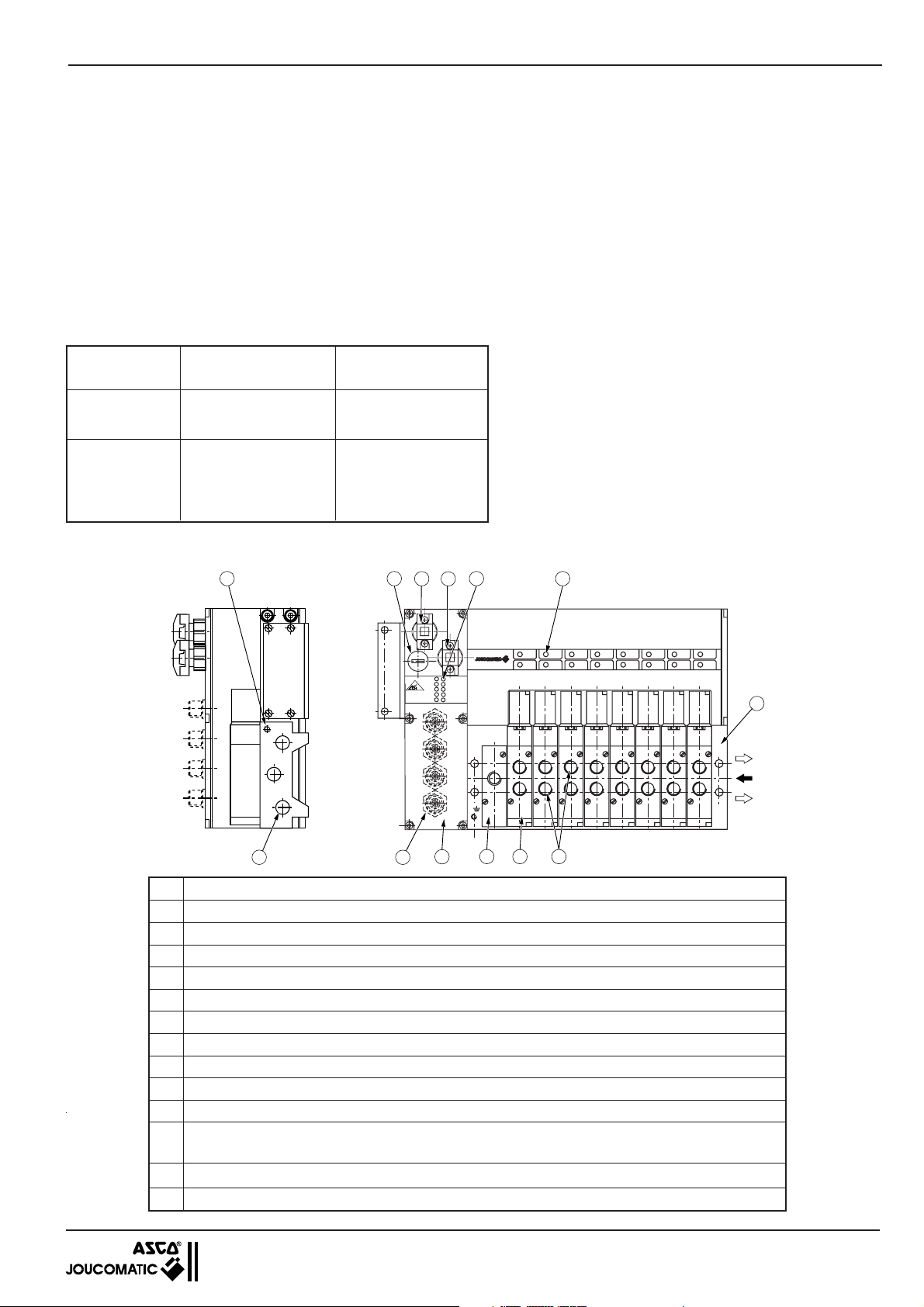

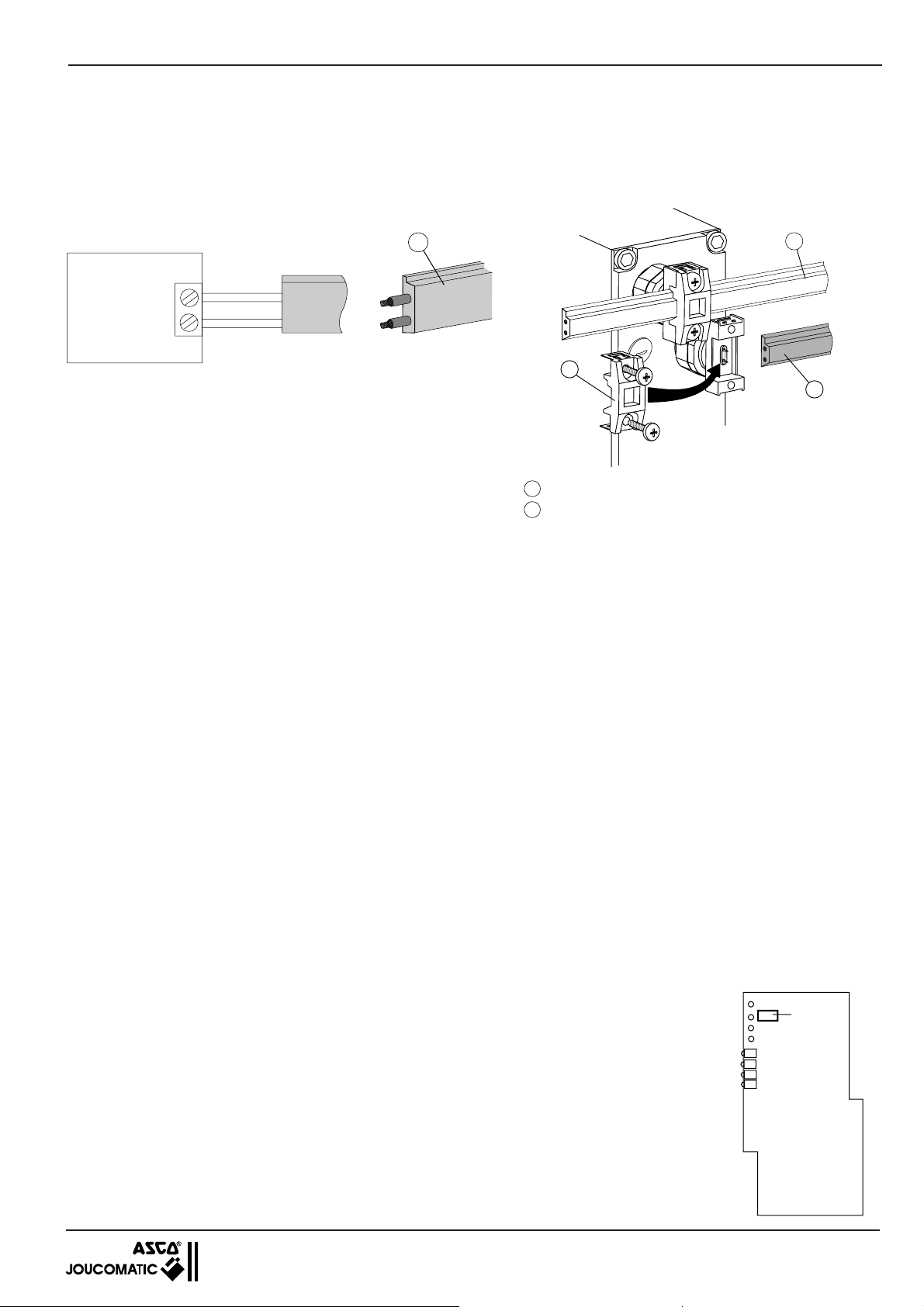

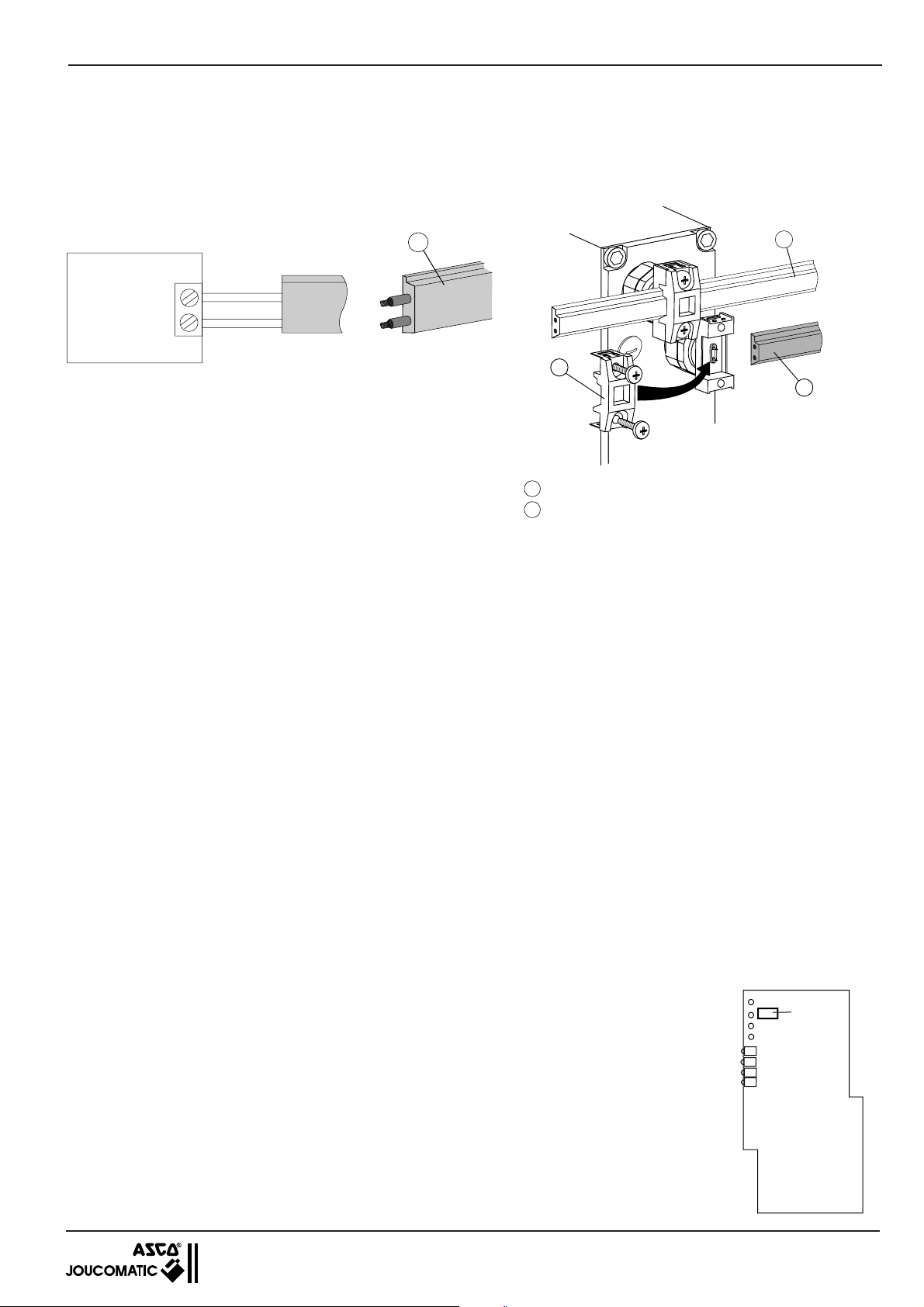

2.2 COMPONENT ASSEMBLY

13

5

No. Description

1 Subbase for pneumatic connection of the Buslink valve island

2 AS-Interface bus connection

3 Monostable or bistable 3/2-2x3/2-5/2-5/3 spool valves (max. 8)

4 Operating ports "2-4" with threaded connection or instant fittings (top side ports)

5 Pressure supply "1" and exhausts "3-5" with threaded connections

6 Connecting flange for pressure supply (for island with 8 valves) (see page 11)

7 LED visual indicator for pilot valves

8 AS-Interface; adapter for AS-Interface bus cable (yellow)

9 AS-Interface; adapter for additional AS-Interface power supply cable (black)

10 Island addressing

2 LEDs for AS-Interface and supply

11

8 LEDs for inputs

12 Input connection with female panel connectors ØM12 (upon request)

13 Common exhaust of pilots 82-84 (ØM5)

10 11

8

9

PWR

ASI

IN1-1 IN1-2

NTERFACE

IN1-3 IN1-4

IN2-1

IN2-2

IN2-3 IN2-4

2

12

7

1

5

1

3

6

3 4

5

BUSLINK - AS-Interface INSTALLATION

2.3 DIMENSIONS - MOUNTING

The island is provided with four mounting holes in the

spool valve subbase and two mounting holes on the

left side for input/output modules. The centre distance

L2 is dependent on the number and size of the spool

valves.

Total length of spool valve island: L2 + 77

Make sure to provide for enough room on the right

side for pressure supply and optional exhaust

silencers.

P1

2 Ø5,5

PWR

ASI

IN1-1 IN1-2

NTERFACE

IN1-3 IN1-4

IN2-1

IN2-2

IN2-3 IN2-4

n2

P3 (1) (2)

P2K2

B

Valve

series

569 (M5)

570 (G1/8)

571 (G1/4)

CK1D

28,5

5 5,5

66,5 L2

L2

n2: number of valves

B C D ØF K1 K2 4 6 8 P1 P2 (1) (2)

163 23 47.5 4.5 60.4 15 91.5 123.5 155.5 3 35 120

163.5 28.3 59 5.5 60.4 21 105 143 181 3 33 130 190

181.5 34.7 70.5 5.5 60.4 26 126.5 172.5 218.5 3 31 170

C

4 ØF

P3

mm

(1) BUSLINK AS-Interface without input : height required for pneumatic cabling with rilsan hoses (the AS-Interface cables are

connected horizontally).

(2) BUSLINK AS-Interface with inputs : height required for electric connection with M12 connectors and cables.

WEIGHTS

Weight of a Buslink island without bus module (kg)

Valve

series

n2: number of valves

468

Weight of one bus module

- without input : 0.550 kg

- with inputs : 0.600 kg

569

570 (3/2)

570 (5/2-5/3)

571

0.9 1.32 1.73

1.14 1.6 2.06

1.18 1.66 2.14

1.61 2.31 3.01

Total weight of a BUSLINK spool valve island - generation C: define the weight of the pneumatic components from the spool valve series

and number of valves required (see above table) + the weight of the bus connection module (with or without inputs).

6

INSTALLATION BUSLINK - AS-Interface

24

3

5

14

12

1

24

3

5

14

12

1

24

3

5

14

12

1

2.4

ORDERING INFORMATION FOR A BUSLINK VALVE ISLAND - GENERATION C - WITH AS-Interface

When ordering please specify the electrical compontents (1), the pneumatic components (2), and the optional accessories

separately.

1

■■

■

Electrical components

■■

Generation C

E Electrical components

BI BUSLINK-AS-Interface

OPTION

00 without option

- -

other options

}

99

Input/Output number

A1 1 node - 4 outputs

A2 1 node - 4 outputs / 4 inputs

A3 2 node - 8 outputs

A4 2 node - 8 outputs / 8 inputs

2

■■

■

Pneumatic components

■■

Generation C

P Pneumatic components

GR

2 569 (ØM5 or instant fittings)

3 570 (G1/8 or instant fittings)

4 571 (G1/4)

Spool valve

series and size

OPTIONS

00 without

- -

other options

}

99

Connection

G Gaz thread

N NPT thread

Q instant fittings (metric)

Ports : 2 - 4

Position

0 top side

Connection

G Gaz thread

N NPT thread

Position

Ports: 1 - 3 - 5

1 lateral

▲

TYPE

C

▼

B

E

▼

▲

GR

OPTION

C

P

▲

▲

▲

OPTION

I

▲▲▲

▲

▼

-

▼

An island can be equipped with two or

four M12 connectors (A) for connection of

four or eight input/sensors as shown in

the table opposite.

No. of

places

1234 5678

-

▲

Number of positions : - 4 bistable valves or

Type

Blanking plates for electr./pneum. mounting surface

A

Z

2

3

1

K

2

4

141214

M

J

5

3

1

2

4

14 1214

5

3

1

G

B

E

4

- 4 to 8 monostable valves (1)

Spool valve functions

3/2 NC- Solenoid air operated pilot

2 x 3/2 NC

5/2 - Solenoid air operated pilot

5/2 - Solenoid air operated

5/3 - Pressure held (W1)

5/3 - Pressure applied (W2)

5/3 - Exhaust released (W3)

R

PW

SI

A

-2

1

IN

1-1

-4

1

IN

IN

-3

1

-2

2

IN

N

I

2-1

-4

2

IN

IN

3

2IN

A

6

8

Spring/Differential return

Solenoid air operated pilot

Differential return

Differential return

pilot and return

Solenoid air operated pilot

Solenoid air operated pilot

Solenoid air operated pilot

04

Number of spool valve

06

08

places

on the island

(1)

(1) For detailed information on spool valves see chapter 2.1.

ORDERING EXAMPLE:

Reference : CEBI00A4

CP300Q0G106-KKMMJJ

BUSLINK valve island - Generation C, AS-Interface protocol, with 2 nodes, 8 outputs and 8 inputs over 4 ØM12 connectors.Island for 6 spool

valves series 570 with outputs and instant fitting for flexible hose OD 6 mm,

equipped as follows:

- Positions nos. 1 and 2 : 2 monostable 3/2 spool valves NC, type K

- Positions nos. 3 and 4 : 2 monostable 5/2 spool valves, type M

- Positions nos. 5 and 6 : 2 bistable 5/2 spool valves, type J

NOTE : In this configuration, the bistable spool valves are always to be placed on the right-hand side of the island.

ACCESSORIES (see page 20)

7

BUSLINK - AS-Interface INSTALLATION

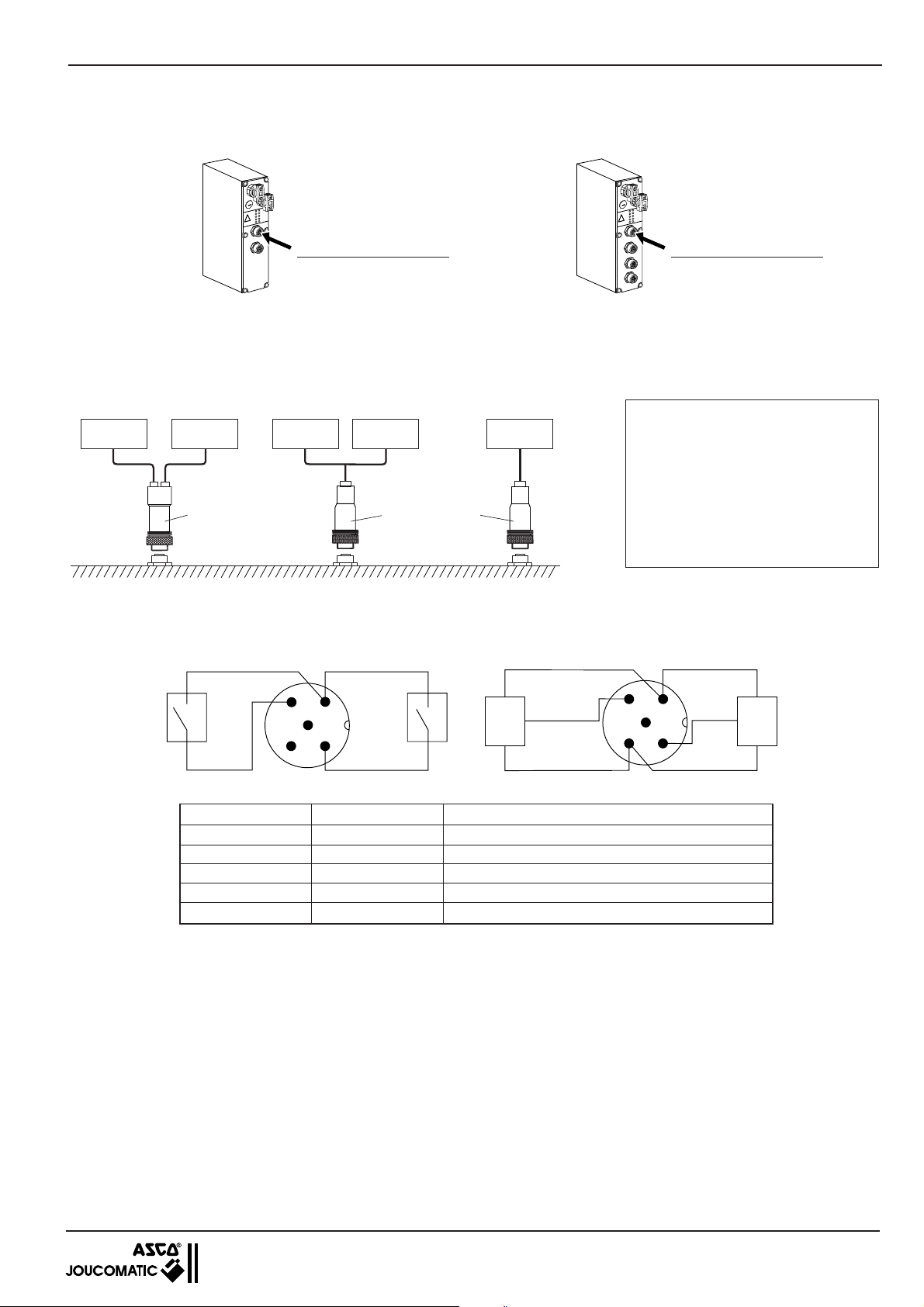

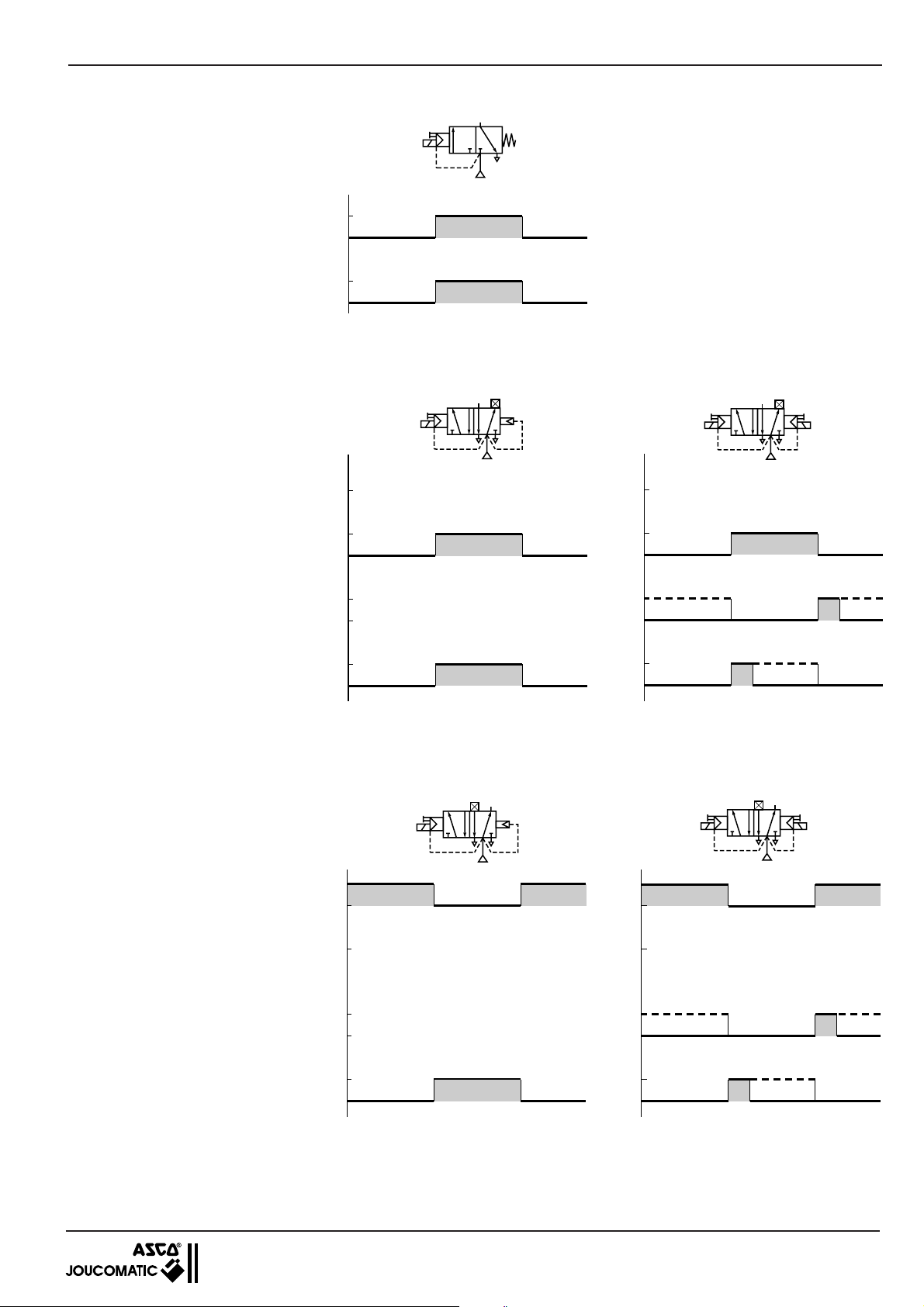

2.5 MANUAL OVERRIDE

Spool valves series 569 - 570 - 571 are equipped with manual

override by impulse (A).

monostable spool valve bistable spool valve

(A)

Valve type

(A)

Procedure Valve function

3/2 - 5/2

monostable

(A)

(bistable spool valve)

14

12

The valve is activated as long as the manual override is

pressed in (

Reset when the manual override is released

)

*

42

513

5/2

bistable

or

5/3

with neutral position

5/2

5/3

5/2

5/3

5/2

5/3

5/2

5/3

The valve is activated (

Permanently activated position is maintained

Reset to central neutral position

Reset (*) (identical to return 12)

Reset position is maintained

Reset to central neutral position

) (identical to pilot 14)

*

) These changes can only be made if the valve is under pressure.

(

*

Supply pressure at port 1 (min. 1.5 bar).

8

INSTALLATION BUSLINK - AS-Interface

2.6

SPOOL VALVE SERIES 569 (ØM5) - 570 (G1/8) - 571 (G1/4)

SPECIFICATIONS

FLUID : air or neutral gas, filtered 30µm, lubricated or not

OPERATING PRESSURE : 1.5 to 8 bar (2.5 to 8 bar series 569 functions 5/3)

ALLOWABLE TEMPERATURE : +5 °C to +50 °C

FUNCTION : 3/2 - 2x3/2 - 5/2 - 5/3, monostable or bistable

OPERATORS : solenoid air operated with internal supply

SPECIAL FEATURE : in the push/pull version both pilots are integrated in

the operator placed on one side = compact solution

(see P586-2).

CONSTRUCTION

SPOOL VALVE

Body in light alloy, cover in thermoplastic (PA-Ar)

Internal parts in stainless steel, light alloy and acetal resin (POM)

Sealings in nitrile (NBR)

PILOT VALVE

Sealings in nitrile (NBR)

Electrical equipment in compliance with standard NF C79300

Coil and iron circuit encapsulated in epoxy resin

Impulse manual override (A)

ELECTRICAL SPECIFICATIONS

VOLTAGE : 24V DC ±10%

max. ripple ratio: 10%

CONSUMPTION : 1.7 W (per coil)

INSULATION CLASS : F

PROTECTION : IP 65

Monostable

spool valve

(A)

Bistable

spool valve

(A)

1 = Pressure 12 = Return

2-4 = Operating ports 14 = Pilot

3-5 = Exhausts

570 spool valve (2 x 3/2)

570 spool valve (5/2)

CHOICE OF EQUIPMENT

(1)

2

TYPE

Symbols

Functions

3/2

Z

NC

1

2x

3/2

K

M

J

G

B

E

NC

5/2

5/2

14

5/3

14

5/3

14

5/3

4

141214

5

1

4

14 1214

5

1

24

5

3

1

24

5

3

1

24

5

3

1

Operators

Pilot

(14)

Solenoid

3

2

3

2

3

12

12

12

air

Solenoid

air

Solenoid

air

Solenoid

air

Pressure held

solenoid air

Pressure applied

solenoid air

Exhaust released

solenoid air

Return

(12)

Spring/

Differential

Differential

Differential

Solenoid

air

W1

W2

W3

GR

3 (570)

(570)

3

2 (569)

3 (570)

4 (571)

2 (569)

3 (570)

4 (571)

2 (569)

3 (570)

4 (571)

2 (569)

3 (570)

4 (571)

2 (569)

3 (570)

4 (571)

Instant fitting for flexible

Ø

Ports

2 - 4

hose O.D.6 mm

G1/8

G1/8

M5

G1/8

G1/4

M5

G1/8

G1/4

M5

G1/8

G1/4

M5

G1/8

G1/4

M5

G1/8

G1/4

Ori-

fice

(mm)

2,5

2,5

2,5

2,5

2,5

Flow

at 6 bar

(l/min.)

5

5

4

6

4

6

4

6

4

6

400

550

175

600

1050

175

4

6

600

1050

175

600

1050

175

600

1050

175

600

1050

VALVE

CODES

(24 VDC)

570 00 053

570 00 051

570 00 103

569 00 012

570 00 012

571 00 012

569 00 014

570 00 014

571 00 014

569 00 016

570 00 016

571 00 016

569 00 018

570 00 018

571 00 018

569 00 020

570 00 020

571 00 020

The 5/2 spool valves can be used in function 3/2 NC (by plugging port 2) or 3/2 NO (by plugging port 4).

(1) The function of push/pull pilot valves corresponds to the function of conventional valves. Marking to ISO 1219-1.

NOTE - Only one valve size per island.

9

BUSLINK - AS-Interface INSTALLATION

3 ASSEMBLY OF BUSLINK Generation C with AS-Interface

3.1 MOUNTING

Mount the island as described in chapter 2.3.

Make sure to provide for enough room for the cables, connectors and optional exhaust silencers. Proceed with pneumatic and

electrical connection.

A

Pressure supply 1

and exhausts 3 - 5

B

Operating ports 2 - 4

C

Bus connection (yellow cable)

D

24VDC power supply to valves (black cable)

E

Sensor inputs (upon request)

C

C

D

V

4

2

I

S

A

2

N

I

1

1

N

I

4

1

N

I

1

3

N

I

2

1

N

I

2

1

N

I

4

2

N

I

2

3

N

I

2

5

D

1

3

E

3.2 PNEUMATIC CONNECTION

3.2.1 GENERAL

■■

■ To subbase

■■

The lines for the following common pneumatic signals are collected in the subbase: supply pressure (1), exhausts (3) and (5),

exhaust. The connecting ports are either on the right side or - in some versions - on the left side of the subbase (see below).

82-84

5

1

A

3

B

and pilot valve

■■

■ To spool valves

■■

Two connection possibilities for operating ports (2 - 4) on top side:

- Threaded connection directly on the spool valve body.

- With instant fittings for flexible hose (for valve series 569 and 570).

■■

■ Connecting instructions

■■

- Remove all protective plastic caps.

- Insert the gasket which generally comes with the ØM5 connectors or banjo-type screw-fittings.

- Screw down the connectors and screw-fittings correctly.

- Screw in the exhaust silencers.

- Connect the pneumatic piping. Gather the tubes in order to have neat and accessible piping.

■ Recommendation for pressure supply connection (see following page)

■ Connections

Series

Pressure supply

Exhausts

Pilot valve exhausts

Operating ports

(82/84)

(1)

(3) (5)

(2) (4)

569 G 1/8 G 1/8 M 5 M 5 (❇)

570 (3/2-2x3/2) G 1/4 G 1/4 M 5

instant fittings

G1/8

570 (5/2-5/3) G 1/4 G 1/4 M 5 G 1/8 (❇)

571 G 3/8 G 3/8 M 5 G 1/4

(❇) or with connecting flange and instant fittings for flexible hose:

• OD 4 mm (569)

• OD 6 mm (570)

Version with threaded connection Version with instant fitting

10

2

4

2

4

INSTALLATION BUSLINK - AS-Interface

3.2.2 CONNECTION OF PNEUMATIC SUPPLY

■ SUPPLY WITH 1 PRESSURE (P1)

- Island with 4 to 6 spool valves: pressure supply on right side.

PWR

ASI

IN1-1 IN1-2

NTERFACE

IN1-3 IN1-4

IN2-1

IN2-2

IN2-3 IN2-4

+

+

5

P1

1

3

A maximum of five spool valves can be operated at the same time without pneumatic malfunction.

- Island with 8 spool valves

The pressure on an island with more than 6 spool valves must be supplied from both sides.

For this purpose, all islands for 8 to 16 spool valves are equipped with a connecting flange.

PWR

ASI

IN1-1 IN1-2

NTERFACE

IN1-3 IN1-4

IN2-1

IN2-2

IN2-3 IN2-4

5

5

1

P1

1

I

S

A

1

-

1

N

I

3

-

1

N

I

1

-

2

N

I

3I

-

2

N

I

R

W

P

2

-

1

N

I

4

-

1

N

I

2

-

2

N

I

4

-

2

N

5

1

3

3

P1

3

Valve

series

Ports

1 - 3 - 5

569 G1/8

570 G1/4

571 G3/8

P1

■ Supply with 2 different pressures (P1 - P2)

Possibility of supplying 1 to 4 spool valves with pressure P2 (consult us).

■ External pressure supply of pilot valves (consult us)

11

BUSLINK - AS-Interface INSTALLATION

1

3

5

4 ELECTRICAL CONNECTION

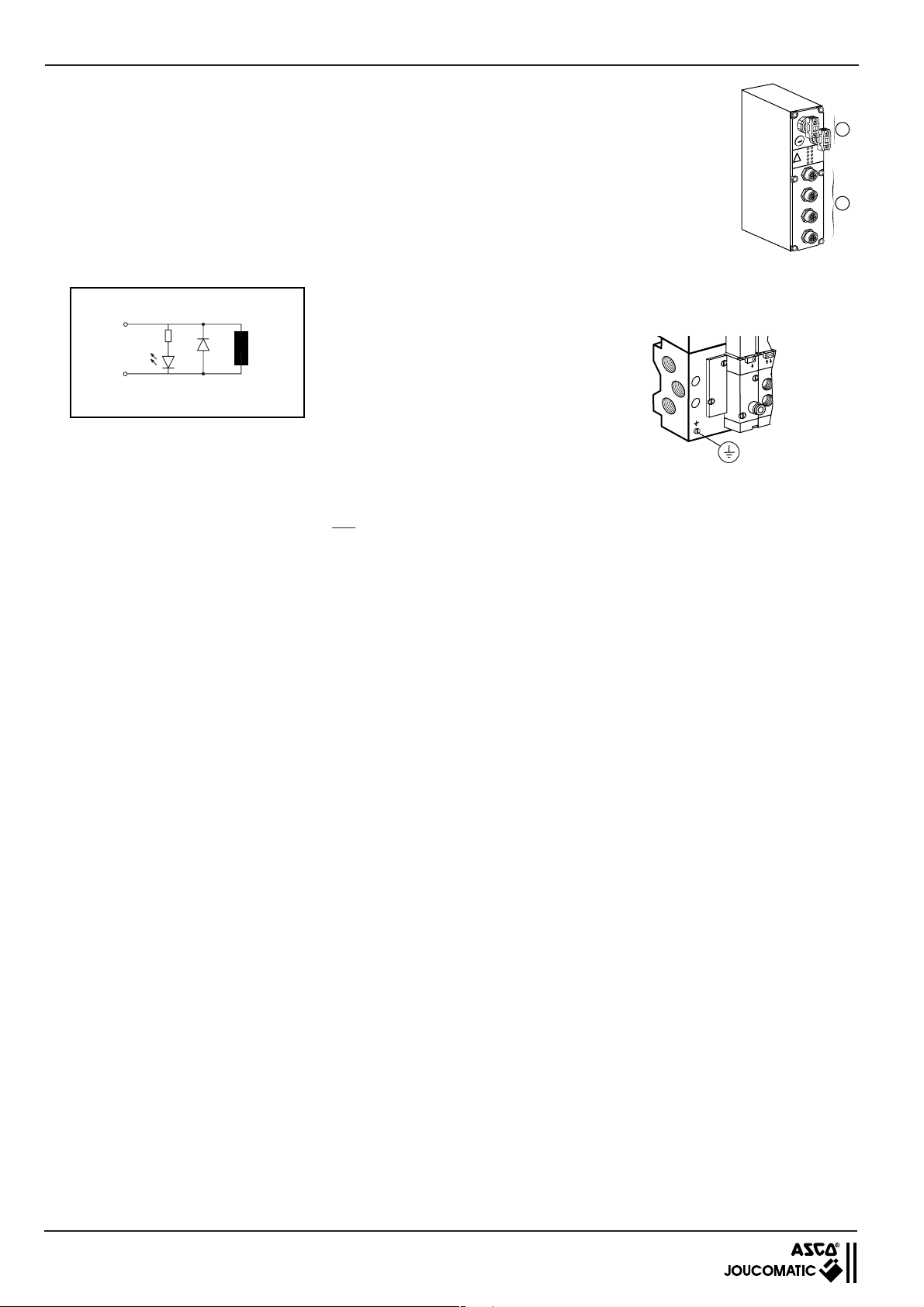

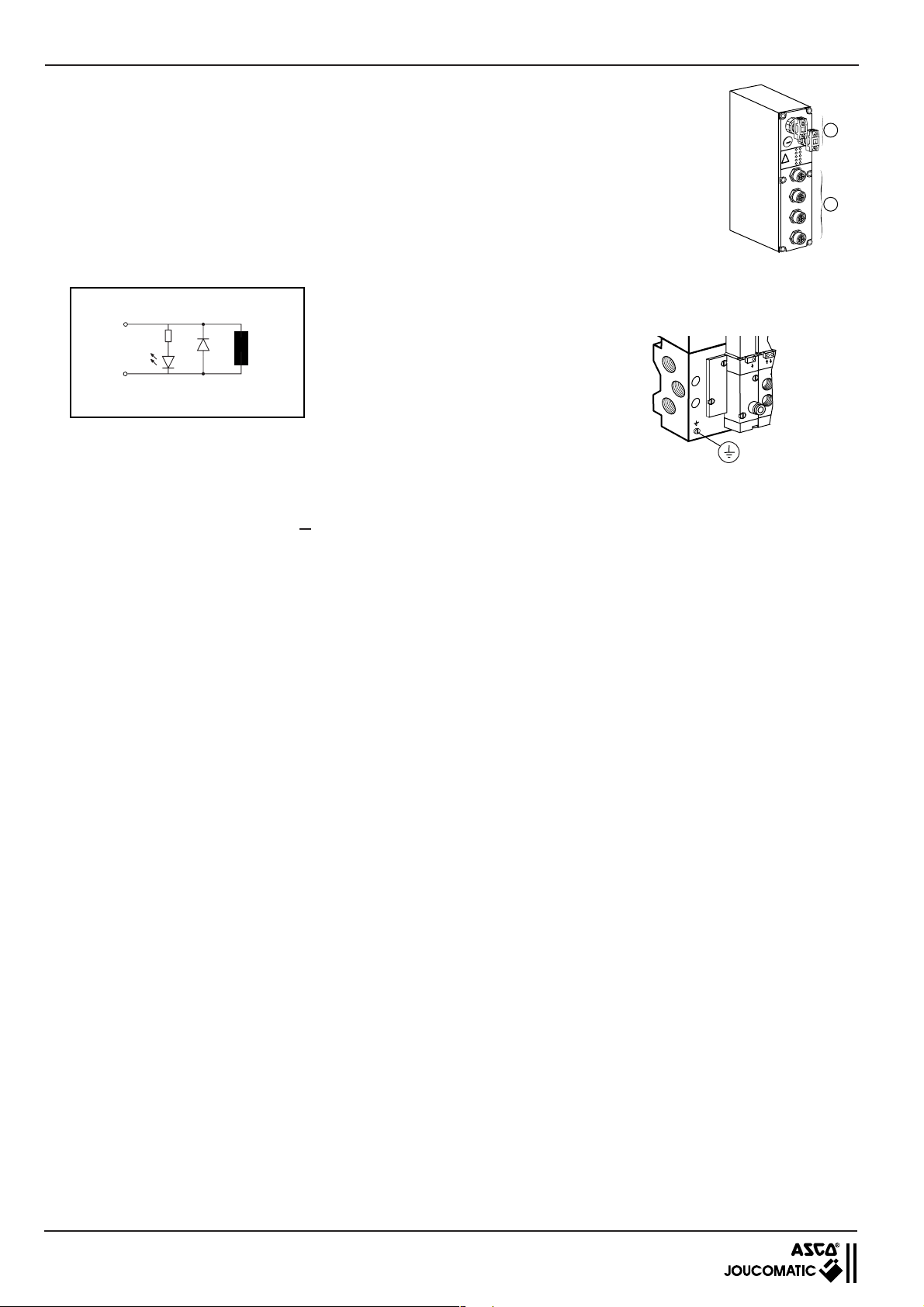

4.1 GENERAL

The islands are equipped with 2 vampire-type AS-Interface connectors to connect the bus network and power supply (B).

Upon request, the subbases can also be provided with two or four 5-pin female panel connectors M12 for the inputs (A).

Cables and M12 connectors must be supplied separately.

Integrated protection circuit for each coil.

Grounding

Grounding for personal protection is

V N.N

effected directly on the island with the

ground screw.

Bobine

Coil

Spule

GND

4.2 VOLTAGE SUPPLY

- The yellow cable is used to supply the AS-Interface.

- The black cable is used to supply the valves and inputs.

Supply voltage : 24 VDC, ±10%

Max. ripple ratio : ±10 %

Consumption : 1.7 per coil, + 0.2 W per LED

max. 5 W / bus electronics

Inputs: total value < 0.5 A

Calculation of power draw (see below).

Check the supply voltage during operation and make sure the admissible tolerance (±10%) is observed.

B

R

W

P

ASI

-2

IN1

1-1

1-4

IN

IN

1-3

2-2

IN

IN

2-1

2-4

IN

IN

2-3

IN

A

4.3 CALCULATION OF POWER DRAW

The island's power draw depends on its configuration.

Calculating this power draw will allow the user to provide for optimal 24 V power supply.

Consumption of the different elements:

- Consumption of bus electronics : 40 mA

- Consumption of one input : 9 mA

- Consumption of one valve + LED : 79 mA

12

INSTALLATION BUSLINK - AS-Interface

1

2

4

3

5

+

-

+

-

4.4 CONNECTION OF INPUTS (inputs upon request)

Connection with detachable M12 connectors with protection to IP65.

Possibility of connecting sensors with 2 or 3 wires

Island provided with

two M12 panel connectors

R

W

P

for 4 inputs

I

S

A

2

-

1

N

I

1

-

1

4

-

N

1

I

N

I

3

2

1

-

N

2

I

N

I

1

-

2

4

-

N

I

2

N

I

3

-

2

N

I

(2 inputs for each connector)

Input addressing:

x : IN1-1, IN1-3

X + 1 : IN1-2, IN1-4

(see chapter 4.5)

CONNECTION WITH M12 CONNECTOR

The two following M12 connector types are recommended:

- Straight duo connector (A) for the connection of 2 separate cables (one for each sensor)

- Straight mono connector (B) for the connection of a sensor or cable bundle.

Sensor Sensor Sensor Sensor Sensor

(A) 881 00 253

● Sensors with 2 wires ● Sensors with 3 wires (magnetoresistive example)

24V 24V

(B) 881 00 330

Wiring diagram of inputs

View from screw side of male connector

24V 24V

Island provided with

four M12 panel connectors

R

W

P

for 8 inputs

I

S

A

2

-

1

N

I

1

-

1

4

-

N

1

I

N

I

3

2

1

-

N

2

I

N

I

1

-

2

4

-

N

I

2

N

I

3

-

2

N

I

(2 inputs for each connector)

Input addressing:

x : IN1-1, IN1-3, IN2-1, IN2-3

X + 1: IN1-2, IN1-4, IN2-2, IN2-4

(see chapter 4.5)

Connectors to be supplied separately:

(A) Straight 5-pin male duo connector

M12, cable feed-throughs of 3 to

5 mm dia. for each cable

code: 881 00 253

(B) Straight 5-pin male mono connector

M12 for 1 cable feed-through of 4 to

6 mm dia.

code : 881 00 330

1

Sensor

5

x+1

IN x+1

2

Sensor

x

IN x

IN x+1

GND GND

Sensor

x+1

Sensor x

IN x

4

3

Pin Name Description

1 24V DC Supply of inputs

2 IN x +1 Input: positive logic x + 1

3 0 V Common ground (sensors with 3 wires)

4 IN x Input: positive logic x

5 PE Protection earth

NOTE:

The status of the connected sensors can be sampled over the inputs. The inputs have positive logic, they can be operated together

with sensors with pnp outputs. The inputs are "LOW" and must be switched to + 24 V (HIGH) in order to be activated.

Typical input current: 9 mA at 24 VDC.

● Logical status "LOW" : < 8 V ● Logical status "HIGH" : > 14 V

Max. input voltage for external power supply of inputs: 40 V.

When 2-wires sensors are connected, the max. residual current must be < 1 mA.

In "LOW" status, the max. residual current at the input must be < 1 mA.

13

BUSLINK - AS-Interface INSTALLATION

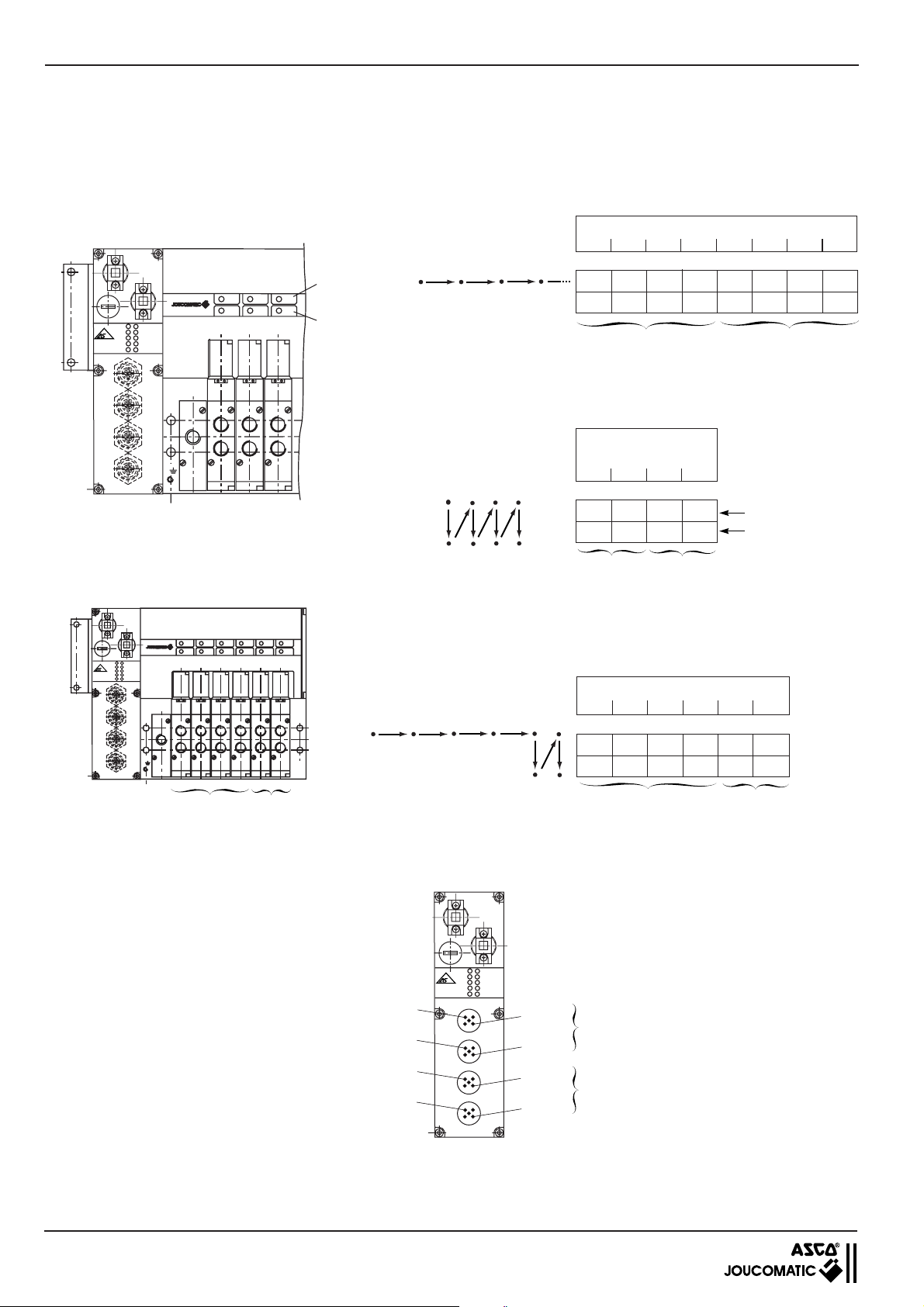

4.5 ADDRESSING

4.5.1 ADDRESSING OF VALVES

Control signals for the valves (see chapter 4.6)

Valve are addressed according to the type of valve used (monostable or bistable valve).

■ Monostable valves (max. = 8)

Horizontal addressing:

Valve position

12345678

Addressing:

V0.0 V0.2 V0.4 V0.6 V1.0 V1.2 V1.4 V1.6

__ ______

1st node 2nd node

Valve

position

1234

Addressing :

V0.0 V0.2 V0.4 V0.6

V0.1 V0.3 V0.5 V0.7

Pilot signals (14)

Return signals

(12)

1st node 2nd node

ASI

IN1-1 IN1-2

IN1-3 IN1-4

IN2-1

IN2-3 IN2-4

Pilot

signals

PWR

IN2-2

Return

signals

■ Bistable valves (max. = 4)

Addressing priority is from top to bottom and from left to right.

PWR

ASI

IN1-1 IN1-2

IN1-3 IN1-4

IN2-1

IN2-2

IN2-3 IN2-4

4 monostable

valves

2 bistable valves

(2nd node)

(1st node)

4.5.2 INPUT ADDRESSING

■ NOTE: In 2-node configuration it is possible to mix monostable and

bistable valves (max. configuration = 4 monostable valves and 2 bistable

valves). These are always placed as shown opposite.

In this case, the addressing priority is as follows:

Adressing:

AS-Interface island with inputs

PWR

ASI

IN1-1 IN1-2

IN1-3 IN1-4

IN2-1

IN2-2

IN1-1

IN1-3

IN2-1

IN2-3

IN2-3 IN2-4

IN1-2

IN1-4

IN2-2

IN2-4

Valve position

123456

V0.0 V0.2 V0.4 V0.6 V1.0 V1.2

__ __

V1.1 V1.3

1st node 2nd node

1st node

2nd node

Connect 2 sensors (2 inputs) for each M12 connector (see previous page).

14

INSTALLATION BUSLINK - AS-Interface

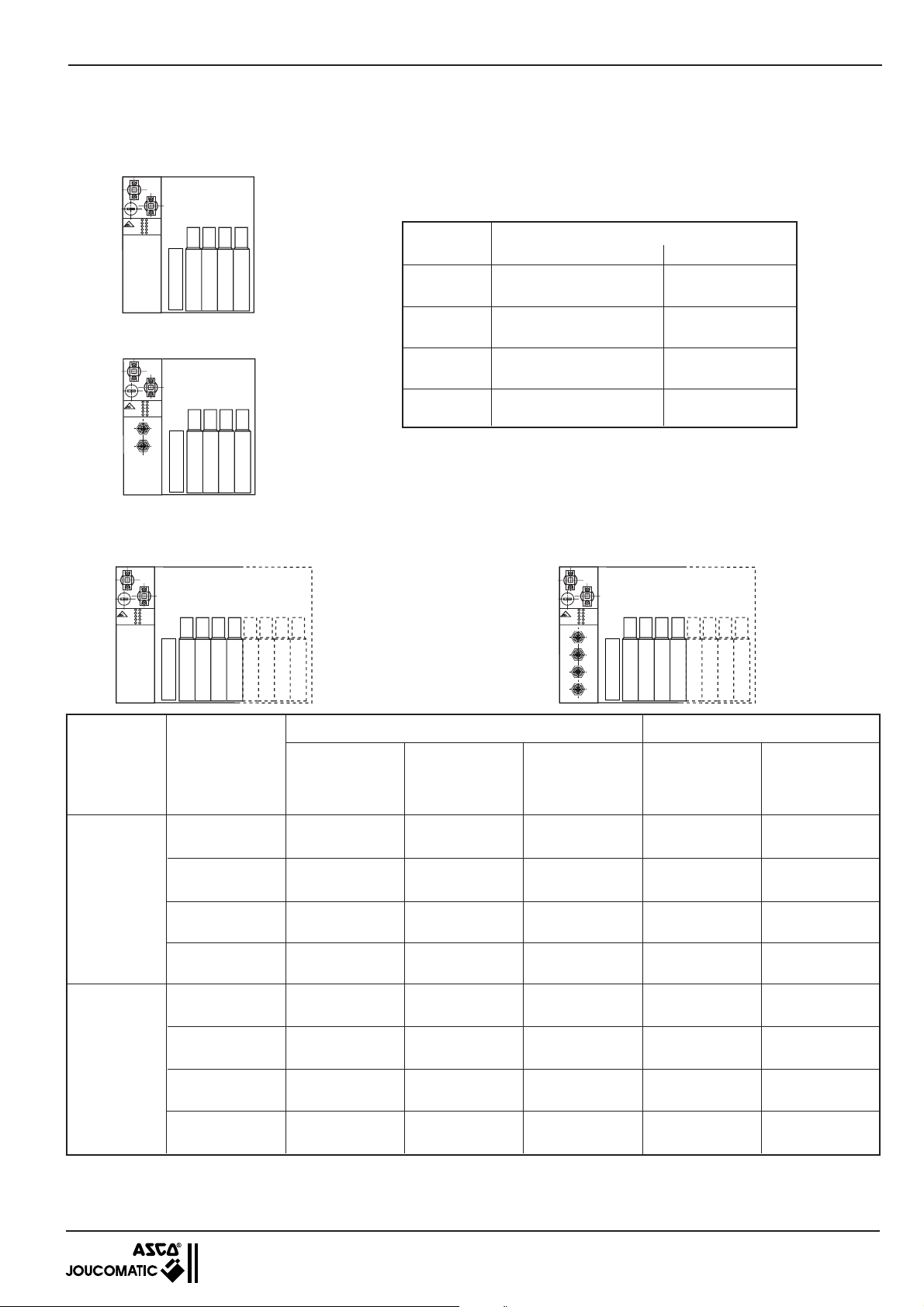

4.5.3 ADDRESSING SUMMARY

■ AS-Interface island with 1 node

4 monostable valves

(Island reference : A1)

PWR

ASI

IN1-1 IN1-2

NTERFACE

IN1-3 IN1-4

IN2-1

IN2-2

IN2-3 IN2-4

+

234

1

+

4 monostable valves and 4 inputs

(Island reference : A2)

PWR

ASI

IN1-1 IN1-2

NTERFACE

IN1-3 IN1-4

IN2-1

IN2-2

IN2-3 IN2-4

+

234

1

+

Data bit

D0

D1

D2

D3

Valves Inputs

Valve no.1 / 14 Input 1

Valve no. 2 / 14 Input 2

Valve no. 3 / 14 Input 3

Valve no. 4 / 14 Input 4

■ AS-Interface island with 2 nodes

8 monostable valves or 4 bistable valves 8 monostable valves or 4 bistable valves and 8 inputs

(Island reference : A3) (Island reference : A4)

Addressing

V0.0 IN1-1

V0.2 IN1-2

V0.4 IN1-3

V0.6 IN1-4

NTERFACE

ASI

IN1-1 IN1-2

IN1-3 IN1-4

IN2-1

IN2-3 IN2-4

PWR

IN2-2

+

678

234

1

+

5

IN1-1 IN1-2

NTERFACE

IN1-3 IN1-4

IN2-1

IN2-3 IN2-4

PWR

ASI

IN2-2

+

234

1

+

678

5

Valve addressing Input addressing

4 monostable

Node number Data bit 8 monostable

valves

4 bistable

valves

valves

and

4 inputs 8 inputs

2 bistable valves

D0

D1

1

D2

D3

D0

D1

2

D2

D3

Valve X/14 = voltage supply to "pilot" coil 14

Valve 1/14 Valve 1/14 Valve 1/14 Input 1 Input 1

V0.0 V0.0 V0.0 IN1-1 IN1-1

Valve 2/14 Valve 1/12 Valve 2/14 Input 2 Input 2

V0.2 V0.1 V0.2 IN1-2 IN1-2

Valve 3/14 Valve 2/14 Valve 3/14 Input 3 Input 3

V0.4 V0.2 V0.4 IN1-3 IN1-3

Valve 4/14 Valve 2/12 Valve 4/14 Input 4 Input 4

V0.6 V0.3 V0.6 IN1-4 IN1-4

Valve 5/14 Valve 3/14 Valve 5/14

V1.0 V0.4 V1.0 IN2-1

Valve 6/14 Valve 3/12 Valve 5/12

V1.2 V0.5 V1.1 IN2-2

Valve 7/14 Valve 4/14 Valve 6/14

V1.4 V0.6 V1.2 IN2-3

Valve 8/14 Valve 4/12 Valve 6/12

V1.6 V0.7 V1.3 IN2-4

(1)

: port 4 under pressure

_

_

_

_

Input 5

Input 6

Input 7

Input 8

Valve X/12 = voltage supply to "return" coil 12 : port 2 under pressure

(1)Except for monostable 3/2 valves series 570 where the pilot is 12 (port 2 under pressure). Return by cutting supply voltage to coil

12 (for pilot signals see chapter 4.6 and following pages).

15

BUSLINK - AS-Interface INSTALLATION

141214

2

3

5

4

1

1

14 1214

2

3

5

4

1

P

0

P

0

24 V

0 V

24 V

0 V

2

2

W2 (B) W3 (E) W1 (G)

24

3

5

14

12

1

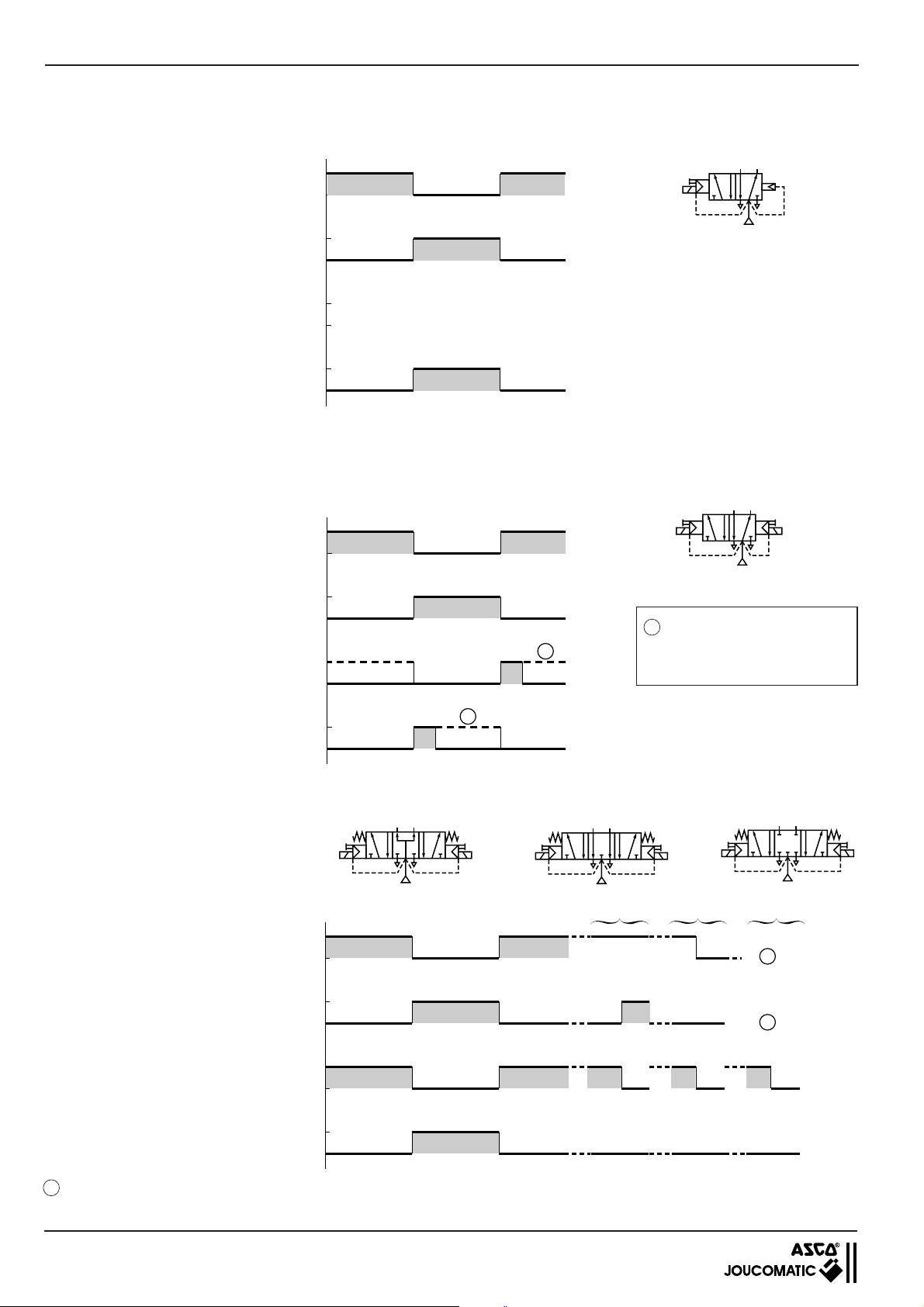

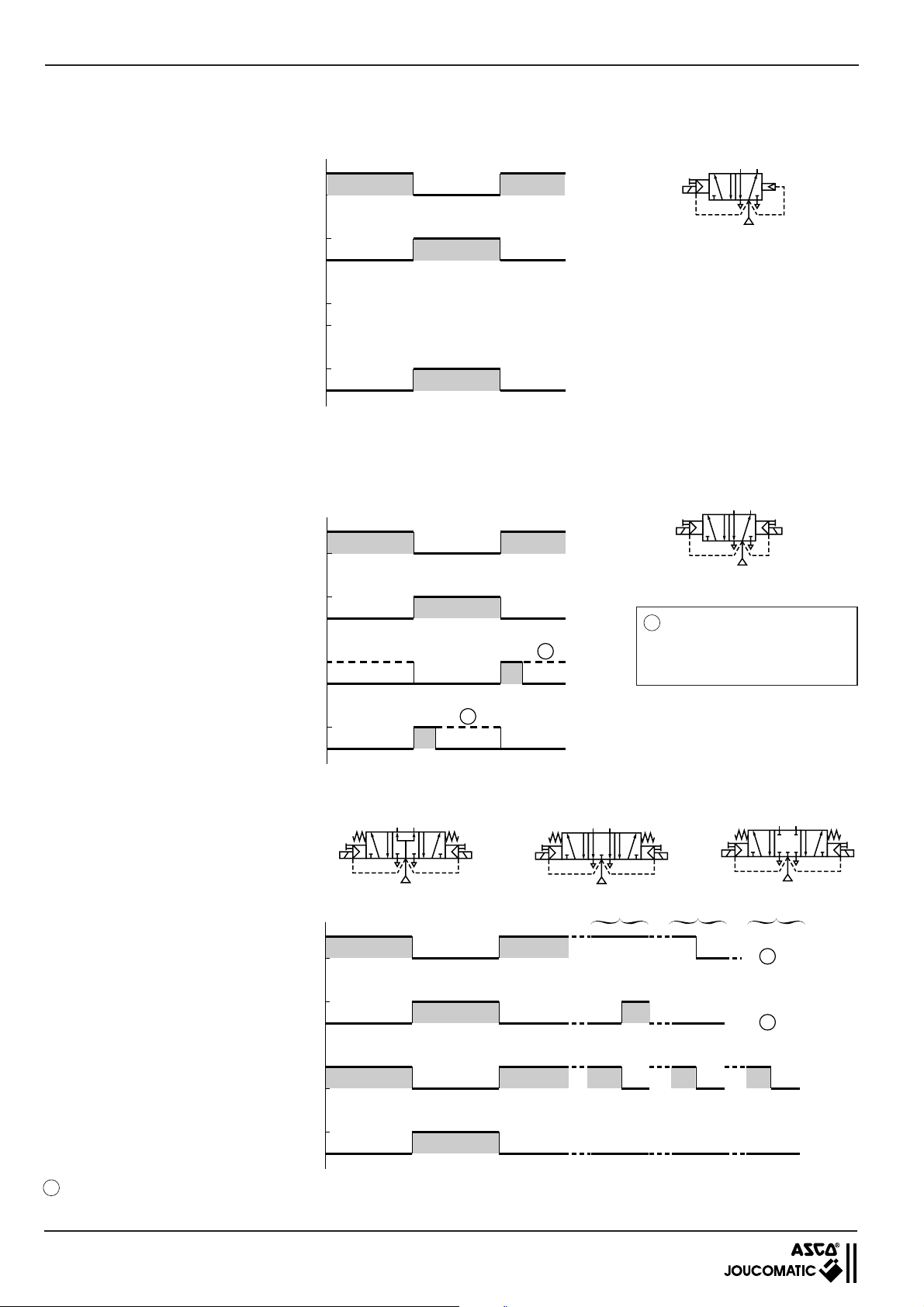

4.6 CONTROL SIGNALS

■ MONOSTABLE 5/2 SPOOL VALVES (differential pneumatic return) - Type: M

Port 2

0

P

P

Port 4

0

24 V

Signal to coil 12

0 V

24 V

Signal to coil 14 (pilot)

0 V

■ BISTABLE 5/2 SPOOL VALVE - Type: J

Port 2

Port 4

Signal to coil 12 (return)

P

0

P

0

24 V

0 V

not necessary (no coil 12, differential return)

1

P = Pressure

These signals can be pulsed

or maintained until change of

status.

Signal to coil 14 (pilot)

24 V

■ 5/3 SPOOL VALVES - Types: B - E - G

Port 2

Port 4

Signal to coil 12

Signal to coil14

1

0 V

14

24

5

1

12

3

24

14

5

1

12

3

2

In the 5/3 pressure held version type W1, the pressure at ports 2 and 4 is that which existed when coils 12 and 14 were deenergized.

16

INSTALLATION BUSLINK - AS-Interface

P

0

P

0

24 V

0 V

24 V

0 V

P

0

P

0

24 V

0 V

24 V

0 V

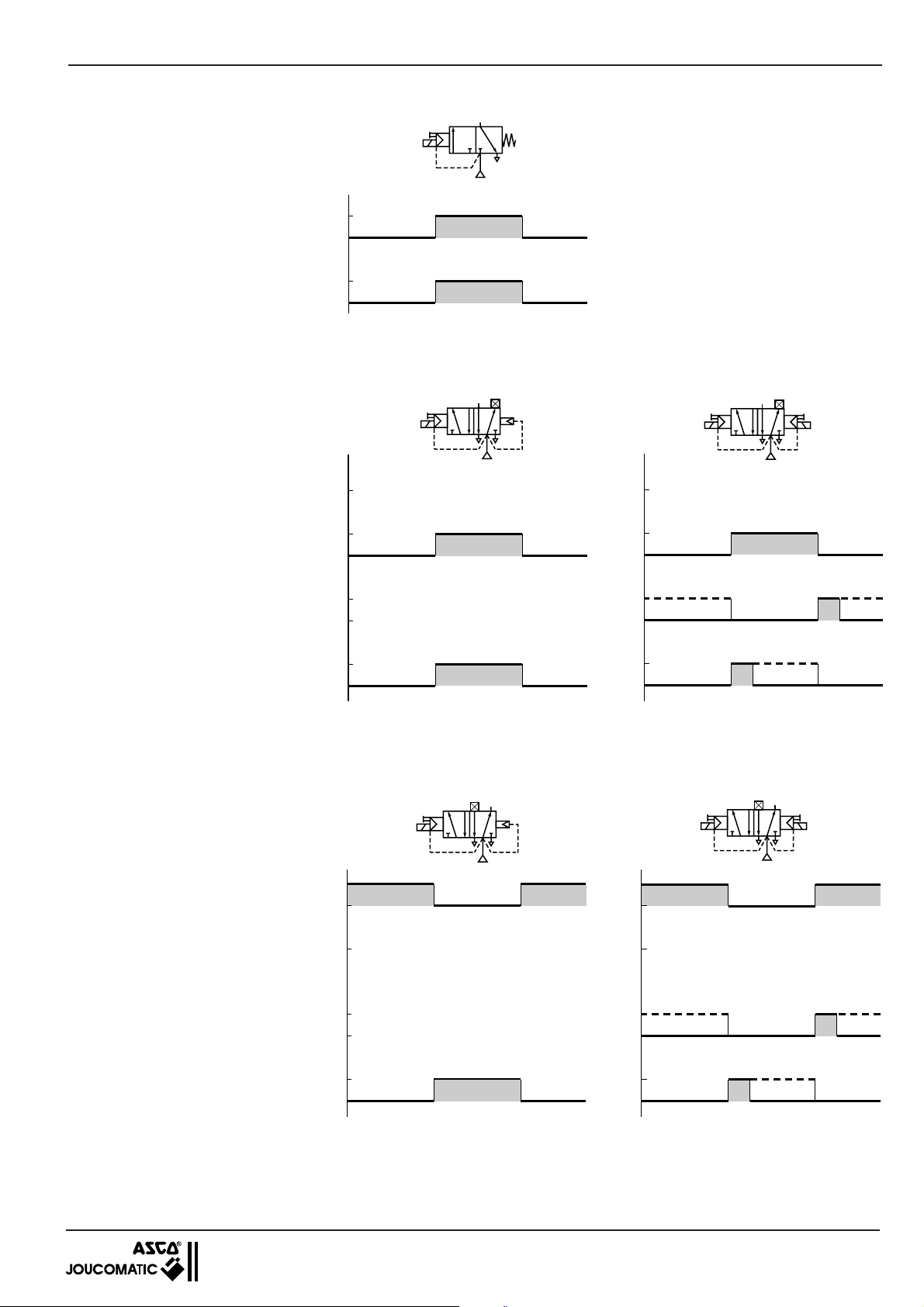

■ MONOSTABLE 3/2 SPOOL VALVE SERIES 570 NC - Type: Z

12

2

3

1

Port 2

P

0

) Take signal 14 for the addressing and

(

*

Coil 12 (

MONOSTABLE OR BISTABLE 5/2 SPOOL VALVE OPERATED IN 3/2 NC FUNCTION (block port 2)

■

)

0 V

*

24 V

pilot connection of the 3/2-spool valves

NC into account.

MONOSTABLE

2

4

Port 2

Blocked

141214

5

3

1

14 1214

Blocked

Port 4

Signal to coil 12

not necessary (differential return)

BISTABLE

4

5

1

2

3

Signal to coil 14

■ MONOSTABLE OR BISTABLE 5/2 SPOOL VALVE OPERATED IN 3/2 NO FUNCTION (block port 4)

MONOSTABLE

2

4

141214

5

3

1

Port 2

P

0

24 V

P

0

Blocked

Port 4

Signal to coil 12 not necessary (differential return)

0 V

Signal to coil 14

24 V

0 V

24 V

0 V

24 V

0 V

P

0

P

0

Blocked

BISTABLE

14 1214

2

4

5

3

1

17

BUSLINK - AS-Interface INSTALLATION

X

5 AS-INTERFACE NETWORK

5.1 CONNECTION OF AS-Interface BUS

The front panel of the pneumatic spool valve island for AS-Interface is equipped with vampire-type panel connectors for instant

connection. The yellow flat profiled AS-Interface bus cable is screwless and unstripped. It is used to transmit control signals and

supply the sensor inputs.

■■

■ Connection of the AS-Interface bus

■■

Bridge

AS-

Interface

AS-

PC

Interface

master

24V =

■■

■ Connection to AS-Interface master

■■

AS-Interface

brown

+

_

Master

NOTE - Carry out all programming instructions prior

to connecting the black power supply cable.

blue

C

C

NOTE: When connecting the cable to the island, please

observe the mounting direction of the cable and adapter

(mounting direction of adapter secured by differently sized

side pieces).

■■

■ AS-Interface connection to island

■■

X

Yellow AS-Interface cable

Adapter for AS-Interface connector

This adapter is supplied with the island.

C

5.2 PROGRAMMING INSTRUCTIONS

See AS-Interface manufacturer's manual.

5.2.1 ADDRESS SELECTION

1 -

Unscrew the threaded plug to access the addressing

switch.

2 - Set the switch into position 1 and connect the island

to the master or the hand-held programmer.

1

2

3

NTERFACE

ASI

IN1-1 IN1-2

IN1-3 IN1-4

IN2-1

IN2-3 IN2-4

Switch

position

PWR

IN2-2

1

2

3

1

2

3

1

2

3

Node

number

Addressing

1

Addressing

2

1+2 RUN

node 1

node 2

3 - Program the address for the 1st node, or

increment

or decrement with the hand-held programmer and

press "write".

4 - Set the switch into position 3.

5 - Set the address for the 2nd node, or

increment or

decrement with the hand-held programmer and press

"write".

6 - Set the switch into position 2.

7 - The 2 addresses are saved in the island memory.

Remount the threaded plug.

5.2.2 SETTING OF THE TRANSMISSION SPEED

The transmission speed is fixed and preset by the AS-Interface master.

5.2.3 CONTROLLER CARD CONFIGURATION WITH THE ISLANDS

In case the AS-Interface network is configured with the AS-Interface coupler which is integrated in the PLC, the identification codes

for a JOUCOMATIC AS-Interface island are as follows:

Code

inputs/outputs

Identificator code of JOUCOMATIC island 7 F

ID code

18

INSTALLATION BUSLINK - AS-Interface

5.3 CONNECTION OF SUPPLY VOLTAGE

The supply voltage is connected after having carried out all programming instructions (see preceding chapters).

The operating voltage is connected to the front of the island with the black profiled AS-Interface cable and the vampire-type

connector provided for instant connection of the cable to the island with a clip-on adapter (see below). No screw or stripping of

cable ends is required).

■■

■ Connection to supply unit ■ Connection of supply voltage to island

■■

D

brown

+

24V =

Power supply

5.4 STARTUP OF AS-Interface NETWORK

1 - Connect the yellow cable.

2 - Connect the black cable.

3 - Power-on the AS-Interface master.

_

blue

C

X

D

Black AS-Interface cable

D

Adapter for AS-Interface connector

X

This adapter is supplied with the island.

NOTE: When connecting the cable to the island, please

observe the mounting direction of the cable and adapter

(mounting direction of adapter secured by differently sized

side pieces).

5.5 DIAGNOSTICS

5.5.1 LED INDICATIONS

ON THE BUSLINK MODULE:

The Buslink AS-Interface module is provided with 2, 6 or 10 diagnostic LEDS (according to the version).

• AS-Interface (green) lights up as soon as data exchange is possible.

• POWER (green) lights up to indicate correct 24 V power supply through the black cable to the valves.

• IN1-1 .... IN1-4 4 LEDs (1-node island with 4 inputs) light up as soon as the sensors are activated.

• IN1-1 .... IN2-4 8 LEDs (2-node island with 8 inputs) light up as soon as the sensors are activated.

5.5.2 DIAGNOSTICS REGISTER

See AS-Interface information.

5.5.3 RESET POSITION

AS-Interface islands are provided with a reset into zero position.

5.6 FUSES

The power supply by the black cable is protected with a fuse enclosed in the bus module housing.

Replace the fuse by unscrewing the lid of the module housing. Remove the fuse with a thin pair of tweezers.

Only fuses of the same type and value may be used for replacement.

(A) Fuse type: 20 mm × 5 mm - 250V/2A

(A)

19

BUSLINK - AS-Interface INSTALLATION

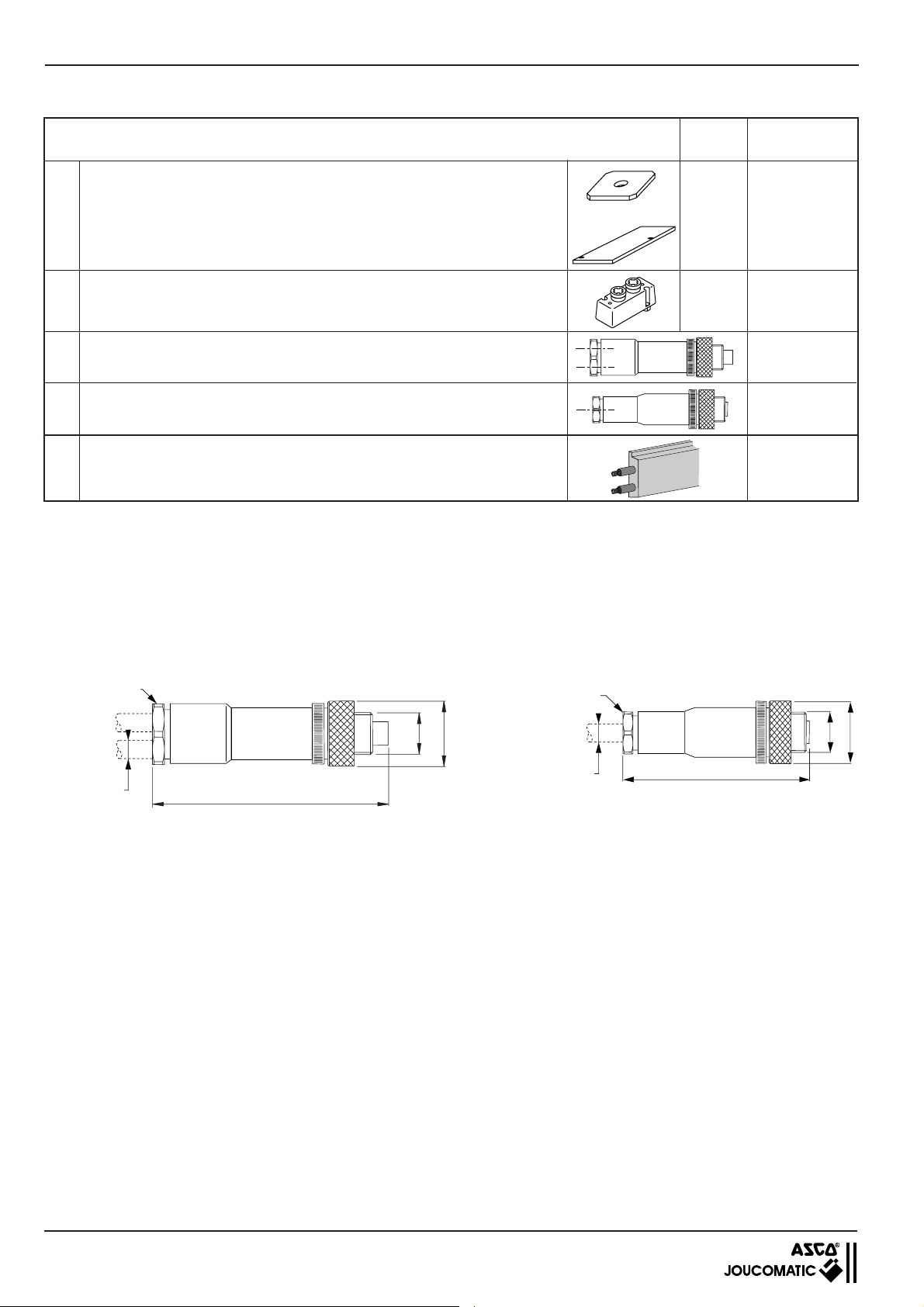

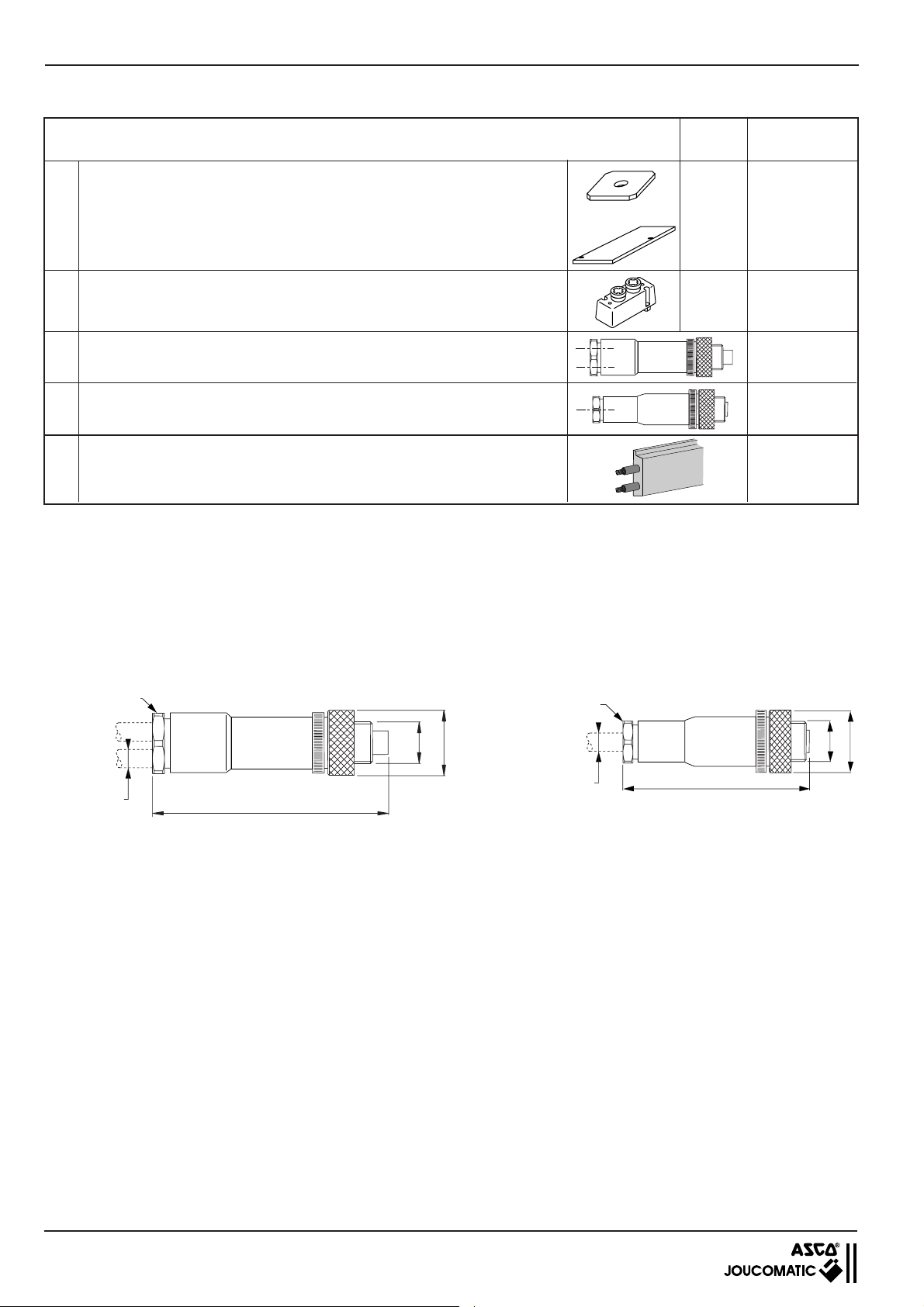

5.7 ACCESSORIES FOR AS-Interface

Description

Valve

series

Codes

A Electrical

Connecting flange for operating ports 2 and 4 with

pressure indicators and instant fittings for flexible hose

Straight 5-pin male duo connector M12 for 2 inputs/outputs (2 cables Ø3 - 5 mm)

Straight 5-pin male mono connector M12 (1 cable Ø 4-6 mm) for 1 input

D Black profiled cable for 24V power supply

(1) (2) These plates can be adapted to islands to block the electrical and pneumatic mounting surfaces of an unused valve place

(removable for further extension).

(3) Length to be specified in metres: max. 100 m (please consult us for longer cables).

(1)

and pneumatic

(2)

blanking plates

+

569

570

571

569

570

881 66 905

881 67 001

881 67 101

881 35 525

881 35 532

881 00 253

881 00 330

881 00 302

(3)

5.8 DIMENSIONS OF THE ACCESSORIES FOR THE AS-Interface

INPUTS (ØM12)

Straight duo connector: 881 00 253

Straight mono connector: 881 00 330

INPUTS (ØM12)

PG11

Ø 3 - 5 mm

PG7

M12

Ø 20

Ø 4 - 6 mm

63

60

M12

Ø 20

20

ILOTS DE DISTRIBUTEURS PNEUMATIQUES

ØM5 - G1/8 - G1/4 ou à coupleurs

à

commande par Bus de terrain avec protocole

AS-Interface

BUSLINK-Génération C

Manuel d'installation

R

W

P

I

S

A

-2

1

IN

-1

1

-4

1

IN

IN

-3

1

-2

2

IN

IN

-1

2

-4

2

IN

IN

-3

2

IN

5

1

3

NTERFACE

N˚ 21401

MS-P586-5.FR.R2a

BUSLINK - AS-Interface INSTALLATION

SOMMAIRE Page

1. Le Système BUSLINK Génération C avec protocole AS-Interface _________________________________ 3

2. Composants du système ___________________________________________________________________ 5

2.1 Description fonctionnelle ____________________________________________________________ 5

2.2 Implantation des composants _________________________________________________________ 5

2.3 Encombrements - Fixation ___________________________________________________________ 6

2.4 Référence d'un îlot BUSLINK Génération C avec AS-Interface _______________________________ 7

2.5 Commande manuelle auxiliaire _______________________________________________________ 8

2.6 Distributeurs séries 569 - 570 - 571 ____________________________________________________ 9

3. Montage du BUSLINK Génération C __________________________________________________________ 10

3.1 Fixation ________________________________________________________________________ 10

3.2 Raccordement pneumatique _________________________________________________________ 10

4. Raccordement électrique ___________________________________________________________________ 12

4.1 Généralités _______________________________________________________________________ 12

4.2 Alimentation en tension _____________________________________________________________ 12

4.3 Calcul de la puissance absorbée ______________________________________________________ 12

4.4 Raccordement des entrées __________________________________________________________ 13

4.5 Adressage des entrées/sorties ________________________________________________________ 14

4.6 Signaux de commande ______________________________________________________________ 16

5. Réseau AS-Interface _______________________________________________________________________

18

5.1 Raccordement du bus AS-Interface (câble jaune) _________________________________________ 18

5.2 Instructions de programmation ________________________________________________________ 18

5.3 Raccordement de la tension d'alimentation (câble noir) ____________________________________ 19

5.4 Mise en service du réseau AS-Interface ________________________________________________ 19

5.5 Diagnostic ________________________________________________________________________ 19

5.6 Fusibles ________________________________________________________________________ 19

5.7 Accessoires pour AS-Interface ________________________________________________________ 20

5.8 Encombrements des accessoires pour AS-Interface _______________________________________ 20

AVERTISSEMENT

Pour le bon fonctionnement des îlots de distributeurs pneumatiques veillez à ce que :

• l'adressage soit correctement paramétré

• toutes interventions d'installation, de réglage et de maintenance doivent être réalisées par un personnel

compétent

Conformément à la directive CEE 89/392/CEE Annexe II B, une Déclaration d’incorporation peut être fournie sur

demande. Veuillez nous indiquer le numéro d’accusé de réception (AR) et les références ou codes des produits

concernés.

Ce produit est conforme aux exigences essentielles de la Directive 89/336/CEE sur la Compatibilité

et amendements. Une déclaration de conformité peut être fournie sur simple demande.

Electromagnétique,

NOTE

Les informations contenues dans le présent manuel sont susceptibles d'être modifiées sans préavis.

ASCO/JOUCOMATIC ne peut être tenu responsable des omissions techniques ou rédactionnelles, ni des dommages

accidentels ou consécutifs à la fourniture ou l'utilisation du présent document.

LE PRESENT MANUEL CONTIENT DES INFORMATIONS PROTEGEES PAR COPYRIGHT, AUCUNE PARTIE DU

PRESENT DOCUMENT NE PEUT ETRE PHOTOCOPIEE OU REPRODUITE SOUS QUELQUE FORME QUE CE SOIT

SANS AUTORISATION ECRITE PREALABLE DE JOUCOMATIC

COPYRIGHT © 1999 - 2000 - ASCO/JOUCOMATIC - Tous droits réservés

2

INSTALLATION BUSLINK - AS-Interface

42

513

14

12

1. LE SYSTEME BUSLINK Génération C avec protocole AS-Interface

Ensemble constitué d'îlots de 4 à 8 distributeurs pneumatiques à commande monostable ou bistable, ØM5 - G1/8 - G1/4, à

connectique intégrée prévue pour raccordement avec automate programmable (API) par liaison série - bus de terrain - via le

protocole de communication normalisé AS-Interface.

Maximum 8 sorties

R

W

P

I

S

A

-2

1

IN

1

1-

-4

1

IN

IN

-3

1

-2

2

IN

IN

-1

2

-4

2

IN

IN

-3

2

IN

5

1

3

N˚ 21401

NTERFACE

3

1

2

1

Distributeurs (nombre maxi : 8 monostables ou 4 bistables)

2

Module boitier de connexion AS-Interface

3

Sur demande - 4 ou 8 entrées

NOTA - Pas de modules d'entrées ou sorties supplémentaires

SCHEMA -TYPE

Maitre

AS-Interface

ASi

Passerelle AS-Interface

vers d'autres protocoles

(Profibus-DP, FIPIO,

Device NET, . . .)

Câble jaune

Câble noir

Alimentation

AS-Interface

AVANTAGES

Par l'étendue de ses possibilités, le système BUSLINK répond aux besoins modernes d'installations automatisées :

• Suppression des faisceaux de fils encombrants

• Economie de temps et de coût des câblages électrique et pneumatique

• Ensemble livré testé, équipé des distributeurs

• Maintenance facilitée

ENSEMBLES REALISABLES

Possibilité de constituer des ensembles Buslink composés :

•

D'îlots de 4, 6 ou 8 distributeurs monostables 3/2 ou 5/2 ou 4 distributeurs

bistables (5/2 - 5/3) ou 4 distributeurs 2x3/2

D'îlots de tailles différentes pour distributeurs séries 569 - 570 - 571 (un îlot ne

•

reçoit qu'une même taille de distributeur)

• Sur demande chaque îlot peut être équipé de 4 embases de connexion M12

à 5 broches femelles pour raccordement de 4 entrées (configuration 1 noeud)

8 entrées (configuration 2 noeuds)

• Distributeurs monostables et bistables à double pilote intégré (

fonctions adaptables sur un même îlot

• Toute configuration réalisable à la demande

), toutes

*

(*) Distributeurs bistables séries 569 - 570 - 571

double pilote intégré (pilotes placés du même

coté pour une solution plus compacte)

ou

24V =

à

3

BUSLINK - AS-Interface INSTALLATION

AS-Interface

Ensemble de distribution pneumatique prévu pour communication

d'informations par bus de terrain via le protocole normalisé ASInterface.

La liaison par bus de terrain entre un système de commande (API)

et un ensemble de modules d'électrodistributeurs pneumatiques

permet de transmettre, par un câble standard AS-Interface, tous les

signaux :

• de commande aux distributeurs

• d'information en provenance des entrées des capteurs

AVANTAGES

Le système Buslink répond aux besoins modernes d'installations

automatisées:

• Suppression des faisceaux de fils encombrants.

• Economie de temps et de coût par câblage électrique directe et

alimentation pneumatique commune.

Visualisation et déconnexion rapide pour une maintenance aisée.

•

• Ensemble livré testé, équipé des distributeurs.

ENSEMBLES REALISABLES

Possibilité de constituer des ensembles Buslink composés de:

•

Distributeurs 3/2, 2x3/2, 5/2 ou 5/3 séries 569 (Ø M5 ou à coupleurs)

570 (G1/8 ou à coupleurs) - 571 (G1/4).

OPTIONS (nous consulter)

• Alimentation pneumatique par 2 pressions différentes.

• Alimentation pneumatique externe des pilotes.

Maitre

AS-Interface

ASi

-

Passerelle AS-Interface vers d'autres protocoles

(Profibus-DP, FIPIO, Device NET, . . .)

R

W

P

I

S

A

-2

1

IN

-1

1

-4

1

IN

IN

-3

1

-2

2

IN

IN

-1

2

-4

2

IN

IN

-3

2

IN

5

1

3

Câble jaune

Câble noir

Alimentation

AS-Interface

24V =

CARACTERISTIQUES DE COMMUNICATION

Protocole : AS-Interface (mode bidirectionnel)

Support de transmission : câble plat AS-Interface (jaune 2 fils)

Structure du bus : optionnelle suivant les recommandations AS-Interface

Nombre maxi d'ensembles : 31 noeuds (1 îlot peut comprendre 2 noeuds)

Nombre de distributeurs par ensemble : 4 à 8 distributeurs

Nombre maxi d'entrées : 8 entrées

Longueur maxi du câble bus : 100 m (300 m avec répéteur)

Adressage des ensembles (abonnés) : par maître AS-Interface

Harmonisation optimale avec automates : pas de modification des programmes existants

Automates compatibles : divers

CARACTERISTIQUES ELECTRIQUES

Tension d'alimentation : 24 V=, ±10% sur l'îlot;

alimentation des distributeurs par câble plat AS-Interface supplémentaire (noir 2 fils)

Taux d'ondulation maxi : 10 %

Consommation : 79 mA par distributeur et 9 mA par entrée

Classe d'isolation (bobines) : F

Degré de protection : IP65

Isolement électrique des entrées : par optocouplage

Protection électrique : intégrée pour chaque bobine

Raccordement supplémentaire de l'alimentation 24V:connecteur intégré à prise vampire pour câble AS-Interface (câble noir)

Raccordement du bus (IN/OUT) : connecteur intégré à prise vampire pour câble AS-Interface (câble jaune)

Raccordement des entrées : par connecteur M12 à 5 broches femelles

Prise de terre : par la vis de mise à la terre sur l'embase pneumatique

Compatibilité électromagnétique : Ces produits sont conformes à la directive européenne CEM 89/336/CEE.

Ils sont certifiés CE

CARACTERISTIQUES PNEUMATIQUES

Fluide distribué : air ou gaz neutre, filtré à 30 µm, lubrifié ou non

Pression d'utilisation : 1,5 à 8 bar (2,5 à 8 bar avec distributeurs 3/2 NO et série 569 fonctions 5/3)

Débit (Qv à 6 bar) série 569 : 175 l/min (ANR)

série 570 : 600 l/min (ANR) (3/2 : 400 l/min - 2x3/2 : 550 l/min)

série 571 : 1050 l/min (ANR)

Température admissible : +5 °C à +50 °C

4

INSTALLATION BUSLINK - AS-Interface

2. COMPOSANTS DU SYSTEME

2.1 DESCRIPTION FONCTIONNELLE

Les ensembles et le système de commande (API) sont liés par 1 câble bus AS-Interface (jaune) pour piloter les distributeurs et relever

les états des capteurs si l'îlot comprend des entrées. Un 2

des distributeurs (câble noir).

L’alimentation en pression et l’échappement sont raccordés sur les embases pneumatiques par canalisations communes. Les

distributeurs établissent l’alimentation en pression et l’échappement des actionneurs pneumatiques. Le raccordement pneumatique

des actionneurs s'effectue sur la face supérieure des distributeurs. Sur demande, l'îlot peut être équipé d’entrées. Les capteurs

électriques sont ainsi raccordables au moyen de connecteurs enfichables ØM12.

CAPACITE MAXIMALE DE L'ILOT

Suivant la configuration choisie, les îlots peuvent recevoir, au maximum, 8 entrées et 8 sorties (1 sortie = 1 pilote de distributeur)

La capacité maximale de l'îlot dépend du nombre de noeuds (voir tableau ci-dessous).

Exemple de configurations maximales :

Nombre de

noeud(s)

Nombre maxi de distri-

buteurs

Nombre maxi

d'entrées

4 monostables

1

ou 2 bistables

ou 2 doubles 3/2 NF

8 monostables

ou 4 bistables

2

ou 4 doubles 3/2 NF

ou 4 monostables +

2 bistables (1)

ème

adaptateur de connexion est utilisé pour l’alimentation en puissance

NOTA :

- Pour 1 noeud , la configuration maximale de l'îlot

est de 4 sorties / 4 entrées

- Pour 2 noeuds, la configuration maximale de

4

l'îlot est de 8 sorties / 8 entrées

- 1 sortie = 1 distributeur monostable

- 2 sorties = 2 distributeurs monostables ou 1 bistable

8

(1) Dans cette configuration les distributeurs bistables sont

toujours à placer à droite sur l'îlot.

2.2 IMPLANTATION DES COMPOSANTS

13

5

Rep. Description

1 Embase de raccordement pneumatique de l'îlot Buslink

2 Module de connexion du Bus AS-Interface

3 Distributeurs 3/2-2x3/2-5/2-5/3 monostables ou bistables (8 maxi)

4 Raccordement taraudé ou à coupleurs des orifices d'utilisation "2-4" (partie supérieure)

5 Raccordement taraudé d'alimentation pneumatique "1" et des échappements "3-5"

6 Bride de raccordement d'alimentation (pour îlot de 8 distributeurs) (voir page 11)

7 LED de visualisation de la mise sous tension des pilotes

8 AS-Interface; adaptateur pour câble du bus AS-Interface (jaune)

9 AS-Interface; adaptateur pour câble d'alimentation AS-Interface supplémentaire (noir)

10 Réglage de l'adresse

2 LED de visualisation de AS-Interface et alimentation

11

8 LED de visualisation des entrées

12 Raccordement des entrées par connecteurs ØM12 (sur demande)

13 Echappement des pilotes 82-84 collecté et raccordable (ØM5)

10 11

8

ASI

IN1-1 IN1-2

NTERFACE

IN1-3 IN1-4

IN2-1

IN2-3 IN2-4

12

9

PWR

IN2-2

7

1

5

1

3

6

2

3 4

5

BUSLINK - AS-Interface INSTALLATION

2.3 ENCOMBREMENTS-FIXATION

L'îlot de distribution comprend 4 trous de fixation

principale sur l'embase des distributeurs complétée

d'une éventuelle fixation de maintien du module de

connexion à l'aide de 2 trous dans l'équerre latérale

gauche. L'entraxe de fixation L2 évolue en fonction

du nombre et de la taille des distributeurs.

Longueur totale de l'îlot : L2 + 77

S'assurer lors du montage qu'il y ait suffisamment de

place à droite pour le raccordement pneumatique et

les éventuels silencieux d'échappement

P1

2 Ø5,5

PWR

ASI

IN1-1 IN1-2

NTERFACE

IN1-3 IN1-4

IN2-1

IN2-2

IN2-3 IN2-4

n2

P3 (1) (2)

P2K2

B

Série

distributeurs

569 (M5)

570 (G1/8)

571 (G1/4)

CK1D

28,5

5 5,5

66,5 L2

L2

n2 : nombre de distributeurs

B C D ØF K1 K2 4 6 8 P1 P2 (1) (2)

163 23 47,5 4,5 60,4 15 91,5 123,5 155,5 3 35 120

163,5 28,3 59 5,5 60,4 21 105 143 181 3 33 130 190

181,5 34,7 70,5 5,5 60,4 26 126,5 172,5 218,5 3 31 170

C

4 ØF

P3

mm

(1) BUSLINK AS-Interface sans entrée :

hauteur nécessaire au câblage pneumatique par tubes rilsan

(les câbles AS-Interface étant placés horizontalement)

(2) BUSLINK AS-Interface avec entrées : hauteur nécessaire au raccordement électrique par connecteurs M12 et câbles de liaison

MASSES

Masse Buslink sans module bus (kg)

Série

distributeurs

n2 : nombre de distributeurs

468

Masse du module de connexion du bus

- sans entrée : 0,550 kg

- avec entrées : 0,600 kg

569

570 (3/2)

570 (5/2-5/3)

571

0,9 1,32 1,73

1,14 1,6 2,06

1,18 1,66 2,14

1,61 2,31 3,01

Masse totale d'un îlot BUSLINK Génération C : définir la masse de la partie électropneumatique en fonction de la série et du nombre

de distributeurs (voir tableau ci-dessus) + la masse du module de connexion du bus (avec ou sans entrées)

6

INSTALLATION BUSLINK - AS-Interface

24

3

5

14

12

1

24

3

5

14

12

1

24

3

5

14

12

1

2.4 REFERENCE D'UN ILOT BUSLINK GENERATION C AVEC AS-Interface

Pour votre commande, nous préciser la référence de la partie électrique 1 ainsi que la référence de la partie pneumatique 2

et les éventuels accessoires

1

■■

■

Partie électrique

■■

TYPE

OPTION

Génération C

E partie Electrique

BI BUSLINK-AS-Interface

OPTION

00 sans option

- -

options ultérieures

}

99

Nombre d'E/S

A1 1 noeud - 4 sorties

A2 1 noeud - 4 sorties / 4 entrées

A3 2 noeuds - 8 sorties

A4 2 noeuds - 8 sorties / 8 entrées

2

■■

■

Partie pneumatique

■■

Génération C

P partie Pneumatique

GR

2 569 (ØM5 ou coupleurs)

3 570 (G1/8 ou coupleurs)

4 571 (G1/4)

Série et taille

des distributeurs

OPTION

00 sans option

- -

options ultérieures

}

99

Type de raccordement

G Orifices taraudés Gaz

N Orifices taraudés NPT

Q à coupleurs (métrique)

Emplacement

ORIFICES : 2 - 4

0 Sur le dessus

Type de raccordement

G Orifices taraudés Gaz

N Orifices taraudés NPT

Emplacement

1 latéral

ORIFICES : 1 - 3 - 5

04

Nombre d'emplacements

06

de distributeurs par îlot

08

(1)

▲

C

E

▼

▼

I

B

▲

▼

-

▼

R

W

P

I

AS

1-2

IN

-1

1

-4

1

IN

IN

-3

1

-2

2

IN

IN

1

2-

-4

2

IN

IN

2-3

IN

A

Possibilité d'équiper l'îlot de 2 ou 4 connecteurs M12 (A) pour raccordement de 4 ou 8

entrées/capteurs suivant le tableau ci-contre.

GR

OPTION

C

P

▲

▲

▲

▲▲▲

Nb places

▲

▲

1234 5678

-

4

6

8

Nombre d'emplacements : - 4 distributeurs bistables ou

- 4 à 8 distributeurs monostables (1)

type

Plaques d'obturations/plans de pose pneu. et élec.

A

Z

K

141214

M

14 1214

J

G

B

E

Fonction des distributeurs

2

1

4

5

4

5

3/2 NF- Cde électropneumatique

3

2

3

1

2

3

1

Rappel ressort/différentiel

2 x

- C

3/2 NF

Rappel différentiel

5/2 - C

Rappel différentiel

5/2 - C

électropneumatiques

5/3 - Centre fermé (W1)

C

5/3 -Centre ouvert à la pression (W2)

C

5/3 -

Centre ouvert à l'échappement (W3)

des

C

de

électropneumatique

de

électropneumatique

de

et rappel

des

électropneumatiques

des

électropneumatiques

électropneumatiques

(1) A définir en fonction des distributeurs, des entrées

et sorties suppplémentaires (voir chapitre 2.1)

EXEMPLE DE COMMANDE :

Référence : CEBI00A4

CP300Q0G106-KKMMJJ

Ilot BUSLINK - Génération C, protocole AS-Interface, avec 2 noeuds, 8 sorties et 8 entrées par 4 connecteurs ØM12. Ensemble prévu

pour 6 emplacements de distributeurs série 570 à sorties par coupleurs pour tubes souples Ø6 mm extr ,

avec les modèles suivants :

- Positions no1 et 2 : 2 distributeurs 3/2 NF monostables, type K

- Positions no3 et 4 : 2 distributeurs 5/2 monostables, type M

- Positions no5 et 6 : 2 distributeurs 5/2 bistables, type J

NOTA : Dans cette configuration les distributeurs bistables sont toujours à placer à droite sur l'îlot.

ACCESSOIRES (voir page 20)

7

BUSLINK - AS-Interface INSTALLATION

2.5 COMMANDE MANUELLE AUXILIAIRE

Les distributeurs séries 569 - 570 - 571 sont équipés de commande(s)

manuelle(s) auxiliaire(s) à impulsion (A).

Distributeur monostable Distributeur bistable

(A)

Type de distributeur

Actions sur

la/les commande(s)

manuelle(s)

(A)

Le distributeur est actionné en position travail tant que la

commande manuelle est maintenue enfoncée (

3/2 - 5/2

monostables

Passage en position rappel lors du relâchement de la

commande manuelle

(A)

(distributeur bistable)

14

12

Fonction du distributeur

42

513

)

*

5/2

bistable

ou

5/3

à position

neutre

5/2

5/3

5/2

5/3

5/2

5/3

5/2

5/3

Le distributeur est actionné en position travail (

(identique à commande 14 actionnée)

Maintien en position travail

Retour à la position neutre centrale

Le distributeur est actionné en position rappel (*)

(identique à fonction rappel 12)

Maintien en position rappel

Retour à la position neutre centrale

*

)

) Ces changements d'état ne sont réalisés que lorsque le distributeur est sous pression.

(

*

Pression d'alimentation sur orifice 1 (1,5 bar mini).

8

INSTALLATION BUSLINK - AS-Interface

2.6

DISTRIBUTEURS SERIES 569 (ØM5) - 570 (G1/8) - 571 (G1/4)

SPECIFICATIONS

FLUIDE DISTRIBUE : Air ou gaz neutre, filtré 30µm, lubrifié ou non

PRESSION D'UTILISATION : 1,5 à 8 bar (2,5 à 8 bar série 569 fonctions 5/3)

TEMPERATURE ADMISSIBLE : +5 °C à +50 °C

FONCTIONS : 3/2 - 2 x 3/2 - 5/2 - 5/3, monostables ou bistables

ORGANES DE PILOTAGE : électropneumatique à alimentation interne

PARTICULARITE : En version double pilote, les 2 pilotes sont intégrés

dans une même tête magnétique monobloc placée

d'un seul côté = solution plus compacte (voir page 5)

CONSTRUCTION

DISTRIBUTEUR

Corps en alliage d'aluminium et

couvercle en thermoplastique (PA-Ar)

Pièces internes en acier inoxydable, alliage d'aluminium,

et résine acétal (POM)

Joints d'étanchéité en nitrile (NBR)

PILOTE

Etanchéité par garniture en nitrile (NBR)

Appareillage électrique conforme à la norme NF C79300

Bobinage et circuit magnétique monobloc surmoulés

Commande(s) manuelle(s) à impulsion

CARACTERISTIQUES ELECTRIQUES

TENSION D'ALIMENTATION : 24V CC ±10%,

ondulation maxi 10%

PUISSANCE ABSORBEE : 1,7 W (par bobine)

CLASSE D'ISOLATION : F

DEGRE DE PROTECTION : IP 65

Distributeur

monostable

(A)

Distributeur

bistable

(A)

1 = Pression 12 = Rappel

2 - 4 = Utilisations 14 = Commande

3 - 5 = Echappements

Distributeur 570 (2 x 3/2)

Distributeur 570 (5/2)

SELECTION DU MATERIEL

Symboles

Fonctions

TYPE

(1)

2

3/2

Z

NF

3

1

2 x

K

3/2

2

4

141214

5/2

M

5/2

J

14

5/3

G

14

5/3

B

14

5/3

E

Possibilité d'utiliser les distributeurs 5/2 en fonction 3/2 NF, (en obturant l'orifice 2) ou 3/2 NO (en obturant l'orifice 4).

(1) Les fonctions de la nouvelle construction à double pilotes intégrés restent identiques à la version classique.

La symbolisation reste conforme à ISO 1219-1

NOTA - Toutes les versions ci-dessus peuvent être montées et combinées sur le même îlot, dans une même taille.

5

3

1

2

4

14 1214

5

3

1

24

5

1

24

5

3

1

24

5

1

12

3

12

12

3

Organes de pîlotage

Commande

(14)

Electro-

pneumatique

Electro-

pneumatique

Electro-

pneumatique

Electro-

pneumatique

Centre fermé

commandes

électropneumatiques

Centre ouvert

à la pression

commandes

électropneumatiques

Centre ouvert

à l'échappement

commandes

électropneumatiques

Différentiel

Différentiel

Différentiel

pneumatique

W1

W2

W3

Rappel

(12)

Ressort/

Electro-

GR

3 (570)

(570)

3

2 (569)

3 (570)

4 (571)

2 (569)

3 (570)

4 (571)

2 (569)

3 (570)

4 (571)

2 (569)

3 (570)

4 (571)

(569)

2

3 (570)

4 (571)

à coupleur pour tube

souple Ø6 mm ext

Ø

raccordement

orifices

d'utilisations

G1/8

G1/8

M5

G1/8

G1/4

M5

G1/8

G1/4

M5

G1/8

G1/4

M5

G1/8

G1/4

M5

G1/8

G1/4

Ø

pas-

sage

(mm)

r

5

5

2,5

4

6

2,5

4

6

2,5

4

6

2,5

4

6

2,5

4

6

Débit

à 6 bar

(l/min)

ANR

400

550

175

600

1050

175

600

1050

175

600

1050

175

600

1050

175

600

1050

CODES

DISTRIBUTEURS

(24 V =)

570 00 053

570 00 051

570 00 103

569 00 012

570 00 012

571 00 012

569 00 014

570 00 014

571 00 014

569 00 016

570 00 016

571 00 016

569 00 018

570 00 018

571 00 018

569 00 020

570 00 020

571 00 020

9

BUSLINK - AS-Interface INSTALLATION

3 MONTAGE DU BUSLINK Génération C avec AS-Interface

3.1 FIXATION

Effectuer la fixation de l'îlot (voir chapitre 2.3)

S'assurer lors du montage qu'il y ait suffisamment de place pour le câblage, les connecteurs et les éventuels silencieux d'échappement. Puis procéder au raccordement pneumatique et électrique.

A

Alimentation pression 1

et échappements 3 - 5

B

Utilisations 2 - 4

C

Raccordement du bus (câble jaune)

D

Alimentation des distributeurs 24 V CC (câble noir)

E

Entrées détecteurs (sur demande)

C

C

D

V

4

2

I

S

A

2

N

I

1

1

N

I

4

1

N

I

1

3

N

I

2

1

N

I

2

1

N

I

4

2

N

I

2

3

N

I

2

5

D

1

3

E

3.2 RACCORDEMENT PNEUMATIQUE

3.2.1 GENERALITES

■■

■ Sur l’embase

■■

L' embase comporte les canaux pour collecter les signaux pneumatiques communs : pression d'alimentation (1), Echappements (3) et (5),

et échappement des électrovannes pilotes. Les orifices de raccordement sont disposés sur le coté droit de l'embase, ou pour certaines

versions d'îlots les orifices de raccordement se trouvent aussi à gauche des distributeurs (voir ci-contre)

82-84

5

1

A

3

B

■■

■ Sur les distributeurs

■■

Deux possibilités de raccordement des orifices d’utilisations (2 - 4) sur la face supérieure:

- raccords taraudés directement sur le corps du distributeur

- raccords instantanés par coupleurs tubes souples (sur distributeurs séries 569 et 570).

■■

■ Procédure de raccordement

■■

- Enlever tous les bouchons de protection en plastique.

- Pour les ØM5 ou raccords orientables type banjo, placer le joint (généralement fourni avec le raccord)

- Visser correctement les raccords

- Visser les silencieux d'échappement.

- Raccorder les canalisations pneumatiques. Lier les tubes afin d’obtenir un câblage propre et accessible.

■ Recommandation de raccordement de l'alimentation de pression (voir page suivante)

■ Raccordements

Série

Orifice d'alimentation

Orifices d'échappement

Orifices d'échappement

Orifices d'utilisations

des pilotes

(1)

(3) (5)

(82/84)

(2) (4)

569 G 1/8 G 1/8 M 5 M 5 (❇)

(3/2-2x3/2)

570

G 1/4 G 1/4 M 5

à coupleur

G1/8

570 (5/2-5/3) G 1/4 G 1/4 M 5 G 1/8 (❇)

571 G 3/8 G 3/8 M 5 G 1/4

(❇) ou par bride à coupleurs rapides pour tubes souples :

• Ø 4 mm extérieur (569)

• Ø 6 mm extérieur (570)

Version taraudée Version à bride à coupleurs

10

2

4

2

4

INSTALLATION BUSLINK - AS-Interface

3.2.2 RACCORDEMENT DE L'ALIMENTATION DE PRESSION

■ Alimentation par 1 pression (P1)

- Ilot de 4 à 6 distributeurs; raccordement de l'alimentation coté droit

Série

NTERFACE

ASI

IN1-1 IN1-2

IN1-3 IN1-4

IN2-1

IN2-3 IN2-4

PWR

IN2-2

+

+

5

P1

1

3

distributeurs

569 G1/8

570 G1/4

571 G3/8

Recommandation de montage

Cinq distributeurs peuvent fonctionner simultanément, au maximum sans perturbation pneumatique.

- Ilot de 8 distributeurs

Au-delà de 6 distributeurs il faut alimenter l'ensemble des 2 cotés, à cet effet les îlots de 8 distributeurs sont toujours

fournis avec une bride de connexion.

PWR

ASI