Page 1

Advanced Redundant Control

System (ARCS)

Direct Acting Platform

-141 Series

Safety Manual for Safety Integrated system

ASCO Valves

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com Page 1 of 24

®

E290115 - 12/2018

All Rights Reserved.

IM-IND-536661-Rev AA

Page 2

TABLE OF CONTENTS

1 INTRODUCTION ......................................................................................................................... 3

1.1 TERMS AND ABBREVIATIONS ................................................................................................ 3

1.2 ACRONYMS ........................................................................................................................ 3

1.3 PRODUCT SUPPORT............................................................................................................ 4

1.4 RELATED LITERATURE ......................................................................................................... 4

1.5 REFERENCE STANDARDS .................................................................................................... 4

2 ARCS DIRECT ACTING DESCRIPTION ........................................................................................ 4

2.1 REDUNDANT CONFIGURATIONS ............................................................................................ 4

2.2 REDUNDANT FUNCTIONS ..................................................................................................... 4

3 DESIGNING A SAFETY INSTRUMENTED FUNCTION USING AN ASCO ARCS ................................. 5

3.1 SAFETY FUNCTION .............................................................................................................. 5

3.2 ENVIRONMENTAL LIMITS ...................................................................................................... 5

3.3 APPLICATION LIMITS ............................................................................................................ 5

3.4 DESIGN VERIFICATION ........................................................................................................ 5

3.5 SIL CAPABILITY .................................................................................................................. 5

3.5.1 SYSTEMATIC INTEGRITY ................................................................................................ 5

3.5.2 RANDOM INTEGRITY ...................................................................................................... 6

3.5.3 SAFETY PARAMETERS ................................................................................................... 6

3.6 CONNECTION OF THE ARCS TO THE SIS LOGIC-SOLVER ....................................................... 6

3.7 GENERAL REQUIREMENTS ................................................................................................... 6

4 INSTALLATION AND COMMISSIONING .......................................................................................... 7

4.1 INSTALLATION ..................................................................................................................... 7

4.2 PHYSICAL LOCATION AND PLACEMENT ................................................................................. 7

4.3 ELECTRICAL CONNECTIONS ................................................................................................. 7

4.4 PNEUMATIC CONNECTIONS .................................................................................................. 7

5 OPERATION AND MAINTENANCE ................................................................................................ 8

5.1 MODES OF OPERATION ....................................................................................................... 8

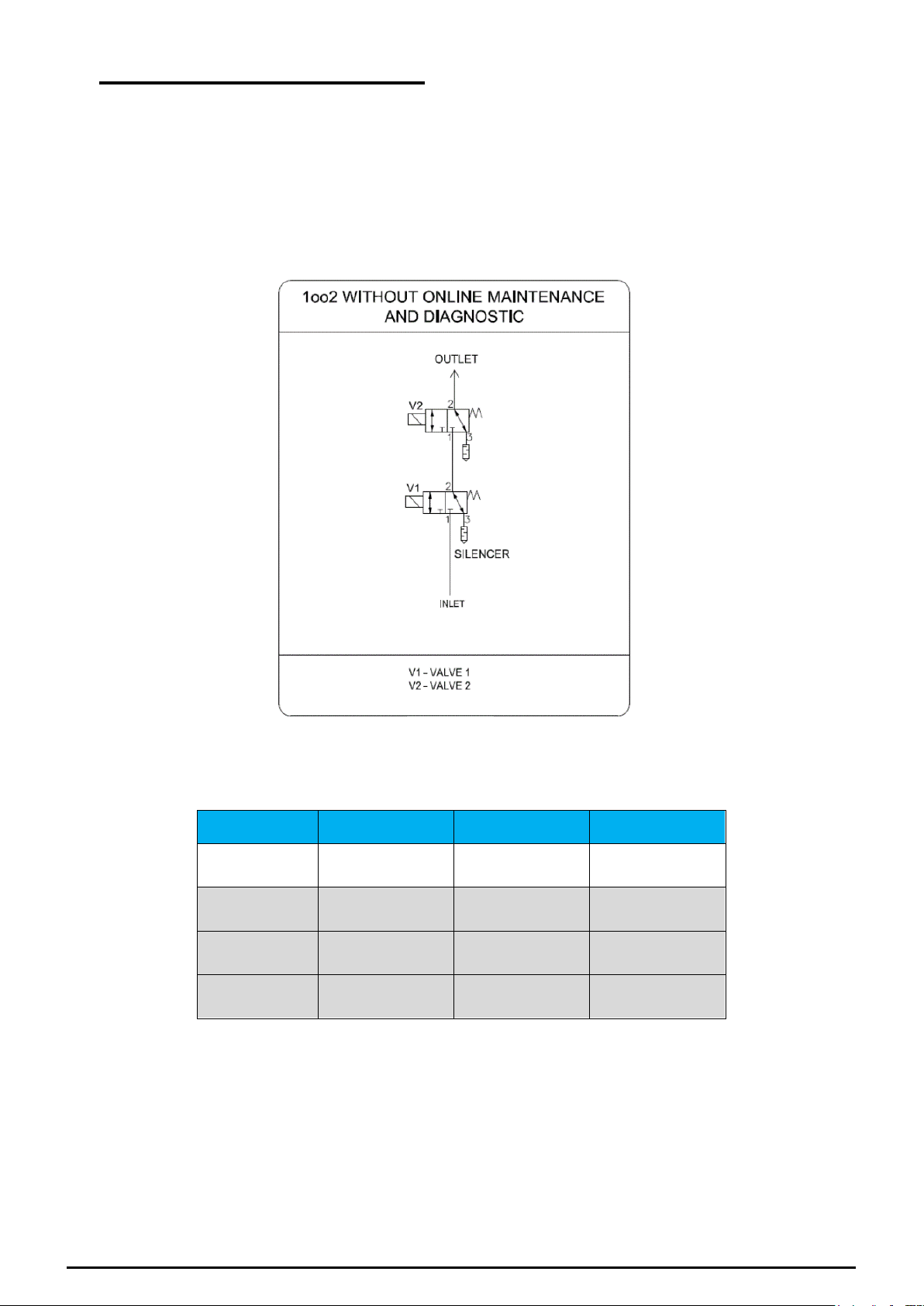

5.1.1 1OO2 WITHOUT ONLINE MAINTENANCE & WITHOUT DIAGNOSTIC ....................................... 8

5.1.2 1OO2 WITH COMMON BYPASS & WITHOUT DIAGNOSTIC .................................................... 8

5.1.3 2OO2 WITHOUT ONLINE MAINTENANCE & WITHOUT DIAGNOSTIC ..................................... 10

5.1.4 2OO2 WITHOUT ONLINE MAINTENANCE & WITH DIAGNOSTIC ........................................... 11

5.1.5 2OO2 WITH COMMON BYPASS AND WITH DIAGNOSTIC ..................................................... 12

5.1.6 2OO2 WITH INDIVIDUAL ISOLATION AND WITH DIAGNOSTIC .............................................. 13

5.1.7 2OO3 WITHOUT ONLINE MAINTENANCE & WITHOUT DIAGNOSTIC ..................................... 14

5.1.8 2OO3 WITHOUT ONLINE MAINTENANCE & WITH DIAGNOSTIC ........................................... 16

5.1.9 2OO3 WITH INDIVIDUAL ISOLATION AND WITH DIAGNOSTIC .............................................. 18

5.1.10 2OO3 WITH COMMON BYPASS AND WITH DIAGNOSTIC ..................................................... 20

5.2 OPERATOR INTERFACE OPTIONS ....................................................................................... 22

5.3 ADT - OPTIONAL .............................................................................................................. 23

5.3.1 STATE VERIFICATION TEST .......................................................................................... 23

5.4 REPAIR AND REPLACEMENT ............................................................................................... 23

5.5 ASCO NOTIFICATION ........................................................................................................ 23

6 STATUS OF THE DOCUMENT ..................................................................................................... 23

6.1 RELEASES ....................................................................................................................... 23

APPENDIX A – SIS CHECKLIST ...................................................................................................... 24

Page 2 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 3

1 Introduction

This Safety Manual provides information necessary to design, install, verify and maintain a Safety Instrumented

Function (SIF) utilizing an ASCO Advanced Redundant Control System, ARCS (141 series). This manual provides

necessary requirements for meeting the IEC 61508 or IEC 61511 functional safety standards.

1.1 Terms and Abbreviations

• Safety - Freedom from unacceptable risk of harm

• Functional Safety - The ability of a system to carry out the actions necessary to achieve or to maintain

defined safe state for the equipment / machinery / plant / apparatus under control of the system

• Basic Safety - The equipment must be designed and manufactured such that it protects against risk of

damage to persons by electrical shock and other hazards and against resulting fire and explosion. The

protection must be effective under all conditions of the nominal operation and under single fault

condition

• Safety Assessment - The investigation to arrive at a judgment - based on evidence - of the safety

achieved by safety-related systems

• Fail-Safe State - State where the solenoid valve is de-energized and spring is extended.

• Fail Safe Failure - Failure which causes the valve to go to the defined fail-safe state without a demand

from the process.

• Fail Dangerous Failure - Failure that does not respond to a demand from the process (i.e. being

unable to go to the defined fail-safe state).

• Fail Dangerous Undetected - Failure that is dangerous and that is not being diagnosed by automatic

stroke testing.

• Fail Dangerous Detected - Failure that is dangerous but is detected by automatic stroke testing.

• Fail Annunciation Undetected - Failure that does not cause a false trip or prevent the safety function

but does cause loss of an automatic diagnostic and is not detected by another diagnostic.

• Fail Annunciation Detected - Failure that does not cause a false trip or prevent the safety function but

does cause loss of an automatic diagnostic or false diagnostic indication.

• Fail No Effect - Failure of a component that is part of the safety function but has no effect on the safety

function.

• Low demand Mode - Mode where the frequency of demands for operation made on a safety related

system is no greater than twice the proof test frequency.

1.2 Acronyms

• FMEDA - Failure Modes, Effects and Diagnostic Analysis

• HFT - Hardware Fault Tolerance

• MOC - Management of Change. These are specific procedures often done when performing any work

activities in compliance with government regulatory authorities.

• MTTFS - Mean Time To Fail Spurious

• PFDavg - Average Probability of Failure on Demand

• SFF - Safe Failure Fraction, the fraction of the overall failure rate of a device that results in either a safe

fault or a diagnosed unsafe fault.

• SIF - Safety Instrumented Function, a set of equipment intended to reduce the risk due to a specific

hazard (a safety loop).

• SIL - Safety Integrity Level, discrete level (one out of a possible four) for specifying the safety integrity

requirements of the safety functions to be allocated to the E/E/PE safety-related systems where Safety

Integrity Level 4 has the highest level of safety integrity and Safety Integrity Level 1 has the lowest.

• SIS - Safety Instrumented System – Implementation of one or more Safety Instrumented Functions. An

SIS is composed of any combination of sensor(s), logic solver(s), and final element(s).

Page 3 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 4

1.3 Product Support

Product support can be obtained from:

ASCO Numatics (India) Pvt. Ltd.,

No.57, Kundrathur Main Road, Gerugambakkam,

Chennai-600128, India

1.4 Related Literature

• Hardware Documents: ASCO ARCS Operation Guide I&M Number 536985

1.5 Reference Standards

• Functional Safety

• IEC 61508: 2000 Functional safety of electrical/electronic/ programmable electronic safety-related

systems

• IEC 61511 Mod. Functional Safety – Safety Instrumented Systems for the Process Industry Sector

2 ARCS Direct Acting Description

The ASCO ARCS (141 series) is designed for emergency shut down valves (ON/OFF vales) with various redundant

configurations (1oo2, 2oo2 & 2oo3) to meet both safety & availability.

The ASCO ARCS (141 series) 2oo3 redundant solenoid valve piloting system combines the advantages of both

1oo2 & 2oo2 systems to achieve a high level of process safety and reliability.

ARCS (141 series) are an electro-mechanical and pneumatic system consisting of solenoid operated valves and

push pull type manually operated spool valves. The valves are interconnected to allow different architectures for the

control of pneumatically actuated block valves. It provides diagnostic components to verify the state of the devices

as well as enabling online testing of the devices. These components are visual indicator or pressure gauges and

pressure switches monitoring the pneumatic pressures at critical points of the ARCS assembly.

2.1 Redundant Configurations

• 1oo2 - Redundancy built to achieve a high level of process safety.

Hardware fault tolerant = 1

SIL3

• 2oo2 - Redundancy built to achieve high availability and prevent nuisance trips.

Hardware fault tolerant = 0

SIL2

• 2oo3 - Redundancy built to achieve a high level of process safety and availability.

Hardware fault tolerant = 1

SIL3

2.2 Redundant Functions

• 1oo2 Manifold Assembly, without Online Maintenance & without Diagnostic

• 1oo2 Manifold Assembly, with Common By-pass & without Diagnostic

• 2oo2 Manifold Assembly, without Online Maintenance & Diagnostic

• 2oo2 Manifold Assembly, without Online Maintenance, with Diagnostic

• 2oo2 Manifold Assembly, with Common By-pass with Diagnostic

• 2oo2 Manifold Assembly, with Individual Isolation with Diagnostic

• 2oo3 Manifold Assembly, without Online Maintenance & Diagnostic

• 2oo3 Manifold Assembly, without Online Maintenance, with Diagnostic

• 2oo3 Manifold Assembly, with Common By-pass with Diagnostic

• 2oo3 Manifold Assembly, with Individual Isolation & with Diagnostic

Page 4 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 5

3 Designing a Safety Instrumented Function using an ASCO

ARCS

3.1 Safety Function

When de-energized, the ASCO ARCS (141 series) moves to its fail-safe position. Depending on the version

specified, 1oo2, 2oo2, 2oo3 the ARCS will supply air and vent air depending on the piping of the installation.

As defined in IEC 61508, the ARCS is intended to be a part of the final element subsystem and the designer must

verify the achieved SIL level of the designed function.

3.2 Environmental limits

The designer of a SIF must check that the product is rated for use within the expected environmental

limits.

Temperature: The ARCS shall be mounted either plate or inside enclosure. The temperature does not exceed the

specified temperature limits for standard or low temperature mentioned in catalogues.

3.3 Application limits

The application limits of an ASCO ARCS (141 series) are specified in the user manual. I&M Number 536985 It is

especially important that the designer checks for material compatibility considering on-site chemical contaminants

and air supply conditions. If the ARCS is used outside of the application limits or with incompatible materials, the

reliability data provided becomes invalid.

3.4 Design Verification

A detailed Failure Mode, Effects, and Diagnostics Analysis (FMEDA) report is available from ASCO. This report

details all failure rates and failure modes as well as the expected lifetime.

The achieved Safety Integrity Level (SIL) of an entire Safety Instrumented Function (SIF) design must be verified

by the designer via a calculation of PFDavg considering redundant architectures, proof test interval, proof test

effectiveness, any automatic diagnostics, average repair time and the specific failure rates of all products included

in the SIF. Each subsystem must be checked to assure compliance with minimum hardware fault tolerance (HFT)

requirements. The Exida exSILentia® tool is recommended for this purpose as it contains accurate models for the

ARCS and its failure rates.

When using an ASCO ARCS (141 series) in a redundant configuration, a common cause factor of 5% should be

included in safety integrity calculations.

The failure rate data listed in the FMEDA report is only valid for the useful lifetime of an ASCO Solenoid.

The failure rates will increase sometime after this time period. Reliability calculations based on the data

listed in the FMEDA report for mission times beyond the lifetime may yield results that are too optimistic,

i.e. the calculated Safety Integrity Level will not be achieved.

3.5 SIL Capability

3.5.1 Systematic Integrity

Page 5 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 6

This product has met manufacturer design process requirements for Safety Integrity Level (SIL) 3. These are

intended to achieve sufficient integrity against systematic errors of design by the manufacturer. A Safety

Instrumented Function (SIF) designed with this product must not be used at a SIL level higher than the statement

without “prior use” justification by end user or diverse technology redundancy in the design.

3.5.2 Random Integrity

The ARCS (141 series) is a Type A Device. Therefore, depending on redundant architecture, the design can

meet SIL 3 requirements @ HFT=1. the design can meet SIL 2 @ HFT = 0.

When the final element assembly consists of many components (ARCS, quick exhaust valve, actuator, isolation

valve, etc.) the SIL must be verified for the entire assembly using failure rates from all components. This analysis

must account for any hardware fault tolerance and architecture constraints.

3.5.3 Safety Parameters

For detailed failure rate information refer to the Failure Modes, Effects and Diagnostic Analysis Report for the

ARCS.

3.6 Connection of the ARCS to the SIS Logic-solver

The ARCS (141 series) is connected to the safety rated logic solver which is actively performing the safety function

as well as automatic diagnostics designed to diagnose potentially dangerous failures within the ARCS. The

isolating valves solenoid control power shall be supplied by the safety logic solver via the safety function output.

Connections must be made according the instructions supplied by the safety rated logic solver.

The output rating of the I/O module shall meet or exceed the electrical specifications of the valve solenoid. Refer

catalogue for detailed solenoid specifications.

If the safety rated logic solver output module provides line-integrity testing by pulse tests or other means, the

impedance range applicable for this test shall be within the ARCS solenoid impedance.

If connected to a passive input module (a module that provides only the switching but not the switching energy),

the external power supply shall meet all pertinent electrical safety requirements specified by the safety rated logic

solver (i.e. IEC 61010).

The input rating of the Digital Input module shall meet the electrical specifications of the pressure switch:

If the safety rated logic solver input module requires line-end devices for open wire / short circuit wire protection,

these devices shall be mounted at the terminal block of the ARCS according to the logic-solver manufacturer’s

instructions.

If the logic-solver input module provides line-integrity testing by pulse tests or other means the impedance range

applicable for this test shall be within the ARCS pressure switch impedance.

3.7 General Requirements

• The system’s response time shall be less than process safety time. The ARCS will switch between two

states in less than 105 ms.

• All SIS components including the ARCS must be operational before process start-up.

• The user shall verify that the ARCS is suitable for use in safety applications by confirming that the

ARCS nameplate is properly marked.

• Personnel performing maintenance and testing on the ARCS shall be competent to do so.

• The useful life of the ARCS is discussed in the Failure Modes, Effects and Diagnostic Analysis Report

for the ARCS.

Page 6 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 7

4 Installation and Commissioning

4.1 Installation

• The ASCO Solenoid valve must be installed per standard installation practices outlined in the

Installation Manual.

• The environment must be checked to verify that environmental conditions do not exceed the ratings.

• The ASCO Solenoid must be accessible for physical inspection.

4.2 Physical Location and Placement

• The ARCS shall be accessible with sufficient room for cabling and pneumatic connections and shall

allow manual proof testing of the bypass function.

• Pneumatic piping to the block valve shall be kept as short and straight as possible to minimize the

airflow restrictions and potential clogging of the exhaust line. Long or kinked pneumatic tubes may also

increase the block valve closure time.

• The Breather/Vent valve shall be accessible and should be inspected for obstruction during manual

proof testing.

• The ARCS shall be mounted in a low vibration environment. If excessive vibration is expected, special

precautions shall be taken to ensure the integrity of electrical and pneumatic connectors or the vibration

should be reduced using appropriate damping mounts.

4.3 Electrical Connections

• The device requires external electrical connections. The ARCS device is available in the following

control signal configurations: 12 VDC, 24 VDC, 48VDC, 120 VDC, 120/60-110/60 VAC or 230/50240/50 VAC.

• All wirings shall provide sufficient electrical isolation between adjacent signal lines and between signal

lines and ground.

• Stranded 16 to 18 AWG (or equivalent gauge and flexibility) shall be used.

• It is recommended that conduit sealant be used to prevent condensation from entering the enclosure

and, as per IEC standard conditions will prevent hazardous gasses and vapours from migrating through

the conduit to the control room or open ignition source.

• The terminal clamps are designed for one wire only; DO NOT attempt to terminate multiple wires into

one terminal.

• Strip the wires to the recommended length appropriate for the termination block.

• Ensure all wire strands are fully inserted into the terminal block and no shorts between adjacent wires

on the terminal block are possible.

• Use care when running signal wiring near to, or crossing conduit or wiring that supplies power to motors,

solenoids, lighting, horns, bells, etc. Sufficient electrical isolation and shielding against electro-magnetic

interference from items in the vicinity of the cable run shall be provided.

• AC power wiring should be run in a separate conduit from DC power. All power wiring to and from the

ARCS should be in a grounded conduit. Outdoor cable runs shall be protected against lightning strike.

• The ARCS shall be connected to a high-quality instrument grade ground with #14 AWG or heavier wire.

A grounding stud is provided on the inside and outside of the enclosure.

4.4 Pneumatic Connections

• Recommended piping for the inlet and outlet pneumatic connections to the ARCS is ¼” or ½” stainless

steel tubing. The length of tubing between the ARCS and the block valve shall be kept as short as

possible and free of kinks.

• Only dry instrument air filtered to 25-micron level or better shall be used.

• The process air pressure shall be 1or 2 – 10 BAR

Page 7 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 8

5 Operation and Maintenance

State

V1

V2

Outlet

1

(Normal)

Energized

Energized

Air Supply

2

(Safe)

De-Energized

De-Energized

Vented

3

(Safe)

Energized

De-Energized

Vented

4

(Safe)

De-Energized

Energized

Vented

Figure 1

5.1 Modes of Operation

5.1.1 1oo2 without Online Maintenance & without Diagnostic

Figure 1 shows circuit diagram of 1oo2 without online maintenance & without diagnostic (safety state action). In

this condition, the ARCS is blocking the inlet air supply and venting the valve actuator (Normally closed

operation). This configuration is mostly used in safety applications since a loss of electrical or pneumatic energy

will result in the safe state of the actuator. V1 & V2 are solenoid operated valves. Both valves are energized then

only outlet will gets air supply. Online maintenance not applicable in this configuration.

The truth table for all possible device states is shown in Table 1.

Table 1

If the logic solver responds to a safety demand, it de-energizes SOV1 and SOV2 and causes the inlet air supply

to be blocked off and venting the block valve actuator.

5.1.2 1oo2 with common bypass & without Diagnostic

Figure 2 shows circuit diagram of 1oo2 with common bypass and without diagnostic (safety state action). In this

condition, the ARCS is blocking the inlet air supply and venting the valve actuator (Normally closed operation).

This configuration is mostly used in safety applications since a loss of electrical or pneumatic energy will result in

the safe state of the actuator. V1 & V2 are solenoid operated valves. Both valves are energized then only outlet

will gets air supply. B1 is manual operated bypass valve with LOTO protection. A, B and C are visual indicators,

Page 8 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 9

A & B will show green when air is available and will show red when air is not available at particular valve zone.

State

Bypass Valve

in

Normal

V1

V2

Bypass

Visual

Indicator

A

Visual

Indicator

B

Visual

Indicator

C

Outlet

1

(Normal)

Both SOV's

Energized

Energized

Energized

Normal

Green

Green

Red

Air Supply

2

(Safe)

Both SOV's

De-Energized

De-

Energized

De-

Energized

Normal

Red

Red

Red

Vented

3

(Safe)

V1

De-Energized

only

De-

Energized

Energized

Normal

Red

Red

Red

Vented

4

(Safe)

V2

De-energized

Only

Energized

De-

Energized

Normal

Green

Red

Red

Vented

State

Bypass Valve

in

Bypass

V1

V2

Bypass

Visual

Indicator

A

Visual

Indicator

B

Visual

Indicator

C

Outlet

5

(Bypass)

Valve bypassed

for

repair

De-

Energized

De-

Energized

Bypass

Red

Red

Green

Air Supply

6

Illegal state

Energized

Energized

Bypass

Red

Red

Green

Air Supply

7

Illegal state

De-

Energized

Energized

Bypass

Red

Red

Green

Air Supply

8

Illegal state

Energized

De-

Energized

Bypass

Red

Red

Green

Air Supply

Figure 2

Table 2

Indicator C will be in red when bypass valve mode in normal.

Before switching to bypass mode, remove LOTO and lock pin from bypass valve and pull the knob downwards

and again put the lock pin and LOTO and make it secured. Bypass valve indicator will show green when bypass

mode is activated. To put in normal mode, do the above-mentioned process as reverse. Can do the repair of

SOV and Visual indicator after bypass mode is activated and without disturbing the outlet air supply.

The truth table for all possible device states is shown in Table 2.

• Highlighted in light gray is the state when the ARCS unit is in a legal mode other than the standard

running conditions.

• Dark gray indicates an illegal state.

Page 9 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 10

If the logic solver responds to a safety demand, it de-energizes SOV1 and SOV2 and causes the inlet air supply

State

V1

V2

Outlet

1

(Normal)

Energized

Energized

Air Supply

2

(Normal)

Energized

De-Energized

Air Supply

3

(Normal)

De-Energized

Energized

Air Supply

4

(Safe)

De-Energized

De-Energized

Vented

Figure 3

to be blocked off and venting the block valve actuator.

5.1.3 2oo2 without Online Maintenance & without Diagnostic

Figure 3 shows circuit diagram of 2oo2 without online maintenance and diagnostic (safety state action). In this

condition, the ARCS is blocking the inlet air supply and venting the valve actuator (Normally closed operation).

This configuration is mostly used in availability applications since a loss of electrical or pneumatic energy of any

one valve also outlet will supply air to the actuator. V1 & V2 are solenoid operated valves. Online maintenance

not applicable in this configuration.

Page 10 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

The truth table for all possible device states is shown in Table 3.

Table 3

If the logic solver responds to a safety demand, it de-energizes SOV1 and SOV2 and causes the inlet air supply

to be blocked off and venting the block valve actuator.

IM-IND-536661-Rev AA

Page 11

5.1.4 2oo2 without Online Maintenance & with Diagnostic

State

V1

V2

Visual Indicator A/

Pressure Switch P1

Visual Indicator B/

Pressure Switch P2

Outlet

1

(Normal)

Energized

Energized

Green

(Close)

Green

(Close)

Air Supply

2

(Normal)

Energized

De-Energized

Green

(Close)

Red

(Open)

Air Supply

3

(Normal)

De-Energized

Energized

Red

(Open)

Green

(Close)

Air Supply

4

(Safe)

De-Energized

De-Energized

Red

(Open)

Red

(Open)

Vented

Figure 4

Figure 4 shows circuit diagram of 2oo2 without online maintenance and with diagnostic (safety state action). In

this condition, the ARCS is blocking the inlet air supply and venting the valve actuator (Normally closed

operation). This configuration is mostly used in availability applications since a loss of electrical or pneumatic

energy of any one valve also outlet will supply air to the actuator. V1 & V2 are solenoid operated valves. A and B

are visual indicators, P1 and P2 are pressure switches. Indicators will show green when air is available and will

show red when air is not available at particular valve zone. Pressure switches will give signal of each valve zone

which is open or close. Online maintenance not applicable in this configuration.

The truth table for all possible device states is shown in Table 4

If the logic solver responds to a safety demand, it de-energizes SOV1 and SOV2 and causes the inlet air supply

to be blocked off and venting the block valve actuator.

Page 11 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

Table 4

IM-IND-536661-Rev AA

Page 12

5.1.5 2oo2 with common bypass and with Diagnostic

Figure 5

Figure 5 shows circuit diagram of 2oo2 with common bypass and with diagnostic (safety state action). In this

condition, the ARCS is blocking the inlet air supply and venting the valve actuator (Normally closed operation).

This configuration is mostly used in availability applications since a loss of electrical or pneumatic energy of any

one valve also outlet will supply air to the actuator. V1 & V2 are solenoid operated valves. B1 is manual operated

bypass valve with LOTO protection. A, B and C are visual indicators, A & B will show green when air is available

and will show red when air is not available at particular valve zone. Indicator C will be in red when bypass valve

mode in normal. P1 and P2 are Pressure Switches, pressure switches will give signal of each of the valve zone

which is open or close.

Before switching to bypass mode, remove LOTO and lock pin from bypass valve and pull the knob downwards

and again put the lock pin and LOTO and make it secured. Bypass valve indicator will show green when bypass

mode is activated. Can do the repair of SOV, Visual indicator and pressure switches after bypass mode is

activated and without disturbing the outlet air supply.

To put in normal mode, do the above-mentioned process as reverse.

The truth table for all possible device states is shown in Table 5

Page 12 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 13

Table 5

State

Bypass

valve in

Normal

V1

V2

Bypass

Visual

Indicator

A/

Pressure

Switch P1

Visual

Indicator

B/

Pressure

Switch

P2

Visual

Indicator

C

Outlet

1

(Normal)

Both SOV's

Energized

Energized

Energized

Normal

Green

(Close)

Green

(Close)

Red

Air

Supply

2

(Safe)

Both SOV's

De-

Energized

De-

Energized

De-

Energized

Normal

Red

(Open)

Red

(Open)

Red

Vented

3

(Normal)

V1

De-

Energized

only

De-

Energized

Energized

Normal

Red

(Open)

Green

(Close)

Red

Air

Supply

4

(Normal)

V2

De-

energized

Only

Energized

De-

Energized

Normal

Green

(Close)

Red

(Open)

Red

Air

Supply

State

Bypass

valve in

Bypass

V1

V2

Bypass

Visual

Indicator

A/

Pressure

Switch P1

Visual

Indicator

B/

Pressure

Switch

P2

Visual

Indicator

C

Outlet

5

(Bypass)

Valve

bypassed

for

repair

De-

Energized

De-

Energized

Bypass

Red

(Open)

Red

(Open)

Green

Air

Supply

6

Illegal state

Energized

Energized

Bypass

Red

(Open)

Red

(Open)

Green

Air

Supply

7

Illegal state

De-

Energized

Energized

Bypass

Red

(Open)

Red

(Open)

Green

Air

Supply

8

Illegal state

Energized

De-

Energized

Bypass

Red

(Open)

Red

(Open)

Green

Air

Supply

Page 13 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

If the logic solver responds to a safety demand, it de-energizes SOV1 and SOV2 and causes the inlet air supply

to be blocked off and venting the block valve actuator.

5.1.6 2oo2 with individual isolation and with Diagnostic

Figure 6 shows circuit diagram of 2oo2 with individual isolation and with diagnostic (safety state action). In this

condition, the ARCS is blocking the inlet air supply and venting the valve actuator (Normally closed operation).

This configuration is mostly used in availability applications since a loss of electrical or pneumatic energy of any

one valve also outlet will supply air to the actuator. V1 & V2 are solenoid operated valves. I1 & I2 are manual

operated isolation valves with LOTO protection. A & B are visual indicators, P1 and P2 are pressure switches.

Indicators will show green when air is available and will show red when air is not available at particular valve

zone. Pressure switches will give signal of each valve zone which is open or close.

Before switching to isolation mode, remove LOTO and lock pin from isolation valve and pull the knob downwards

and again put the lock pin and LOTO and make it secured. Corresponding SOV, visual indicator and pressure

switch are isolated from the main line. Corresponding Indicator will show red when isolation valve is activated.

Can do maintenance of SOV, Indicator and pressure switch without disturbing outlet air supply.

To put in normal mode, do the above-mentioned process as reverse.

IM-IND-536661-Rev AA

Page 14

State

V1

V2

Visual Indicator A/

Pressure Switch P1

Visual Indicator B/

Pressure Switch P2

Outlet

1

(Normal)

Energized

Energized

Green

(Close)

Green

(Close)

Air Supply

2

(Normal)

Energized

De-Energized

Green

(Close)

Red

(Open)

Air Supply

3

(Normal)

De-Energized

Energized

Red

(Open)

Green

(Close)

Air Supply

4

(Safe)

De-Energized

De-Energized

Red

(Open)

Red

(Open)

Vented

Figure 6

The truth table for all possible device states is shown in Table 6

Table 6

If the logic solver responds to a safety demand, it de-energizes SOV1 and SOV2 and causes the inlet air supply

to be blocked off and venting the block valve actuator.

5.1.7 2oo3 without Online Maintenance & without Diagnostic

Figure 7 shows circuit diagram of 2oo3 without online maintenance and diagnostic (safety state action). In this

condition, the ARCS is blocking the inlet air supply and venting the valve actuator (Normally closed operation).

This configuration is mostly used in safety and availability applications. V1, V2, V3 & V4 are solenoid operated

valves. Online maintenance not applicable in this configuration.

Page 14 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 15

The truth table for all possible device states is shown in Table 7

Figure 7

Page 15 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 16

Table 7

State

Channel - 1

Channel - 2

Channel - 3

Outlet

V1

V2

V3

V4

1

Energized

De-Energized

De-Energized

De-Energized

Vented

2

Energized

Energized

De-Energized

De-Energized

Vented

3

Energized

Energized

Energized

De-Energized

Air Supply

4

Energized

Energized

Energized

Energized

Air Supply

5

De-Energized

Energized

De-Energized

De-Energized

Vented

6

De-Energized

Energized

Energized

De-Energized

Vented

7

De-Energized

Energized

Energized

Energized

Air Supply

8

De-Energized

Energized

De-Energized

Energized

Air Supply

9

De-Energized

De-Energized

Energized

De-Energized

Vented

10

De-Energized

De-Energized

Energized

Energized

Vented

11

Energized

De-Energized

Energized

Energized

Air Supply

12

Energized

De-Energized

Energized

De-Energized

Air Supply

13

De-Energized

De-Energized

De-Energized

Energized

Vented

14

Energized

De-Energized

De-Energized

Energized

Air Supply

15

Energized

Energized

De-Energized

Energized

Air Supply

16

De-Energized

De-Energized

De-Energized

De-Energized

Vented

If the logic solver responds to a safety demand, it de-energizes SOV1, SOV2, SOV3 and SOV4 and causes the

inlet air supply to be blocked off and venting the block valve actuator.

5.1.8 2oo3 without Online Maintenance & with Diagnostic

Figure 8 shows circuit diagram of 2oo3 without online maintenance, with diagnostic (safety state action). In this

condition, the ARCS is blocking the inlet air supply and venting the valve actuator (Normally closed operation).

This configuration is mostly used in safety and availability applications. V1, V2, V3 & V4 are solenoid operated

valves. A, B, C and D are visual indicators, P1, P2, P3 and P4 are pressure switches. Indicators will show green

when air is available and will show red when air is not available at particular valve zone. Pressure switches will

give signal of each valve zone which is open or close. Online maintenance not applicable in this configuration.

Page 16 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 17

The truth table for all possible device states is shown in Table 8.

Figure 8

Page 17 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 18

Table 8

State

Channel -1

Channel -

2

Channel -

3

Visual

Indicator

A/

Pressure

Switch

P1

Visual

Indicator

D/

Pressure

Switch

P4

Visual

Indicator

B/

Pressure

Switch

P2

Visual

Indicator

C/

Pressure

Switch

P3

Outlet

V1

V4

V2

V3

1

Energized

De-

Energized

De-

Energized

De-

Energized

Green

(Close)

Red

(Open)

Red

(Open)

Red

(Open)

Vented

2

Energized

De-

Energized

Energized

De-

Energized

Green

(Close)

Red

(Open)

Green

(Close)

Red

(Open)

Vented

3

Energized

De-

Energized

Energized

Energized

Green

(Close)

Red

(Open)

Green

(Close)

Green

(Close)

Air

Supply

4

Energized

Energized

Energized

Energized

Green

(Close)

Green

(Close)

Green

(Close)

Green

(Close)

Air

Supply

5

De-

Energized

De-

Energized

Energized

De-

Energized

Red

(Open)

Red

(Open)

Green

(Close)

Red

(Open)

Vented

6

De-

Energized

De-

Energized

Energized

Energized

Red

(Open)

Red

(Open)

Green

(Close)

Green

(Close)

Air

Supply

7

De-

Energized

Energized

Energized

Energized

Red

(Open)

Green

(Close)

Green

(Close)

Green

(Close)

Air

Supply

8

De-

Energized

Energized

Energized

De-

Energized

Red

(Open)

Green

(Close)

Green

(Close)

Red

(Open)

Air

Supply

9

De-

Energized

De-

Energized

De-

Energized

Energized

Red

(Open)

Red

(Open)

Red

(Open)

Red*

(Open)

Vented

10

De-

Energized

Energized

De-

Energized

Energized

Red

(Open)

Red*

(Open)

Red

(Open)

Red*

(Open)

Vented

11

Energized

Energized

De-

Energized

Energized

Green

(Close)

Red*

(Open)

Red

(Open)

Green

(Close)

Air

Supply

12

Energized

De-

Energized

De-

Energized

Energized

Green

(Close)

Red

(Open)

Red

(Open)

Green

(Close)

Air

Supply

13

De-

Energized

Energized

De-

Energized

De-

Energized

Red

(Open)

Red*

(Open)

Red

(Open)

Red

(Open)

Vented

14

Energized

Energized

De-

Energized

De-

Energized

Green

(Close)

Red*

(Open)

Red

(Open)

Red

(Open)

Vented

15

Energized

Energized

Energized

De-

Energized

Green

(Close)

Green

(Close)

Green

(Close)

Red

(Open)

Air

Supply

16

De-

Energized

De-

Energized

De-

Energized

De-

Energized

Red

(Open)

Red

(Open)

Red

(Open)

Red

(Open)

Vented

* Indicators show Red which is "False" state, due to unavailability of Pneumatic air since the valves are

connected in series (Refer Circuit).

If the logic solver responds to a safety demand, it de-energizes SOV1, SOV2, SOV3 and SOV4 and causes the

inlet air supply to be blocked off and venting the block valve actuator.

5.1.9 2oo3 with individual isolation and with Diagnostic

Figure 9 shows circuit diagram of 2oo3 with individual isolation and with diagnostic (safety state action). In this

condition, the ARCS is blocking the inlet air supply and venting the valve actuator (Normally closed operation).

This configuration is mostly used in safety and availability applications. V1, V2, V3 & V4 are solenoid operated

valves. I1, I2, I3 & I4 are manual operated isolation valve with LOTO protection. A, B, C & D are visual indicators,

P1, P2, P3 and P4 are pressure switches. Indicators will show green when air is available and will show red

when air is not available at particular valve zone. Pressure switches will give signal of each valve zone which is

open or close. Before switching to isolation mode, remove LOTO and lock pin from isolation valve and pull the

knob downwards and again put the lock pin and LOTO and make it secured. Corresponding SOV, visual

indicator and pressure switch are isolated from the main line. Corresponding Indicator will show red when

isolation valve is activated. Can do maintenance of SOV, Indicator and pressure switch without disturbing outlet

air supply. To put in normal mode, do the above-mentioned process as reverse.

Page 18 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 19

Figure 9

The truth table for all possible device states is shown in Table 9.

Page 19 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 20

State

Channel -1

Channel -

2

Channel -

3

Visual

Indicator

A/

Pressure

Switch P1

Visual

Indicator

D/

Pressure

Switch P4

Visual

Indicator

B/

Pressure

Switch P2

Visual

Indicator

C/

Pressure

Switch P3

Outlet

V1

V4

V2

V3

1

Energized

De-

Energized

De-

Energized

De-

Energized

Green

(Close)

Red

(Open)

Red

(Open)

Red

(Open)

Vented

2

Energized

De-

Energized

Energized

De-

Energized

Green

(Close)

Red

(Open)

Green

(Close)

Red

(Open)

Vented

3

Energized

De-

Energized

Energized

Energized

Green

(Close)

Red

(Open)

Green

(Close)

Green

(Close)

Air

Supply

4

Energized

Energized

Energized

Energized

Green

(Close)

Green

(Close)

Green

(Close)

Green

(Close)

Air

Supply

5

De-

Energized

De-

Energized

Energized

De-

Energized

Red

(Open)

Red

(Open)

Green

(Close)

Red

(Open)

Vented

6

De-

Energized

De-

Energized

Energized

Energized

Red

(Open)

Red

(Open)

Green

(Close)

Green

(Close)

Air

Supply

7

De-

Energized

Energized

Energized

Energized

Red

(Open)

Green

(Close)

Green

(Close)

Green

(Close)

Air

Supply

8

De-

Energized

Energized

Energized

De-

Energized

Red

(Open)

Green

(Close)

Green

(Close)

Red

(Open)

Air

Supply

9

De-

Energized

De-

Energized

De-

Energized

Energized

Red

(Open)

Red

(Open)

Red

(Open)

Red*

(Open)

Vented

10

De-

Energized

Energized

De-

Energized

Energized

Red

(Open)

Red*

(Open)

Red

(Open)

Red*

(Open)

Vented

11

Energized

Energized

De-

Energized

Energized

Green

(Close)

Red*

(Open)

Red

(Open)

Green

(Close)

Air

Supply

12

Energized

De-

Energized

De-

Energized

Energized

Green

(Close)

Red

(Open)

Red

(Open)

Green

(Close)

Air

Supply

13

De-

Energized

Energized

De-

Energized

De-

Energized

Red

(Open)

Red*

(Open)

Red

(Open)

Red

(Open)

Vented

14

Energized

Energized

De-

Energized

De-

Energized

Green

(Close)

Red*

(Open)

Red

(Open)

Red

(Open)

Vented

15

Energized

Energized

Energized

De-

Energized

Green

(Close)

Green

(Close)

Green

(Close)

Red

(Open)

Air

Supply

16

De-

Energized

De-

Energized

De-

Energized

De-

Energized

Red

(Open)

Red

(Open)

Red

(Open)

Red

(Open)

Vented

Table 9

* Indicators show Red which is "False" state, due to unavailability of Pneumatic air since the valves are

connected in series (Refer Circuit).

If the logic solver responds to a safety demand, it de-energizes SOV1, SOV2, SOV3 and SOV4 and causes the

inlet air supply to be blocked off and venting the block valve actuator.

5.1.10 2oo3 with common bypass and with Diagnostic

Figure 10 shows circuit diagram of 2oo3 with common bypass and with diagnostic (safety state action). In this

condition, the ARCS is blocking the inlet air supply and venting the valve actuator (Normally closed operation).

This configuration is mostly used in safety and availability applications. V1, V2, V3 & V4 are solenoid operated

valves. B1 is manual operated bypass valve with LOTO protection. A, B, C, D and E are visual indicators, A, B, C

& D will show green when air is available and will show red when air is not available at particular valve zone.

Page 20 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 21

Indicator E will be in red when bypass valve mode in normal. P1, P2, P3 and P4 are Pressure Switches,

Figure 10

pressure switches will give signal of each of the valve zone which is open or close.

Before switching to bypass mode, remove LOTO and lock pin from bypass valve and pull the knob downwards

and again put the lock pin and LOTO and make it secured. Bypass valve indicator E will show green when

bypass mode is activated. Can do the repair of SOV, Visual indicator and pressure switches after bypass mode

is activated and without disturbing the outlet air supply.

To put in normal mode, do the above-mentioned process as reverse.

Page 21 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

The truth table for all possible device states is shown in Table 10.

IM-IND-536661-Rev AA

Page 22

Bypass valve in Normal Mode

State

Channel -1

Channel -

2

Channel -

3

Visual

Indicator

A/

Pressure

Switch

P1

Visual

Indicator

D/

Pressure

Switch

P4

Visual

Indicator

B/

Pressure

Switch

P2

Visual

Indicator

C/

Pressure

Switch

P3

Visual

Indicator

E

Outlet

V1

V4

V2

V3

1

Energized

De-

Energized

De-

Energized

De-

Energized

Green

(Close)

Red

(Open)

Red

(Open)

Red

(Open)

Red

Vented

2

Energized

De-

Energized

Energized

De-

Energized

Green

(Close)

Red

(Open)

Green

(Close)

Red

(Open)

Red

Vented

3

Energized

De-

Energized

Energized

Energized

Green

(Close)

Red

(Open)

Green

(Close)

Green

(Close)

Red

Air Supply

4

Energized

Energized

Energized

Energized

Green

(Close)

Green

(Close)

Green

(Close)

Green

(Close)

Red

Air Supply

5

De-

Energized

De-

Energized

Energized

De-

Energized

Red

(Open)

Red

(Open)

Green

(Close)

Red

(Open)

Red

Vented

6

De-

Energized

De-

Energized

Energized

Energized

Red

(Open)

Red

(Open)

Green

(Close)

Green

(Close)

Red

Air Supply

7

De-

Energized

Energized

Energized

Energized

Red

(Open)

Green

(Close)

Green

(Close)

Green

(Close)

Red

Air Supply

8

De-

Energized

Energized

Energized

De-

Energized

Red

(Open)

Green

(Close)

Green

(Close)

Red

(Open)

Red

Air Supply

9

De-

Energized

De-

Energized

De-

Energized

Energized

Red

(Open)

Red

(Open)

Red

(Open)

Red*

(Open)

Red

Vented

10

De-

Energized

Energized

De-

Energized

Energized

Red

(Open)

Red*

(Open)

Red

(Open)

Red*

(Open)

Red

Vented

11

Energized

Energized

De-

Energized

Energized

Green

(Close)

Red*

(Open)

Red

(Open)

Green

(Close)

Red

Air Supply

12

Energized

De-

Energized

De-

Energized

Energized

Green

(Close)

Red

(Open)

Red

(Open)

Green

(Close)

Red

Air Supply

13

De-

Energized

Energized

De-

Energized

De-

Energized

Red

(Open)

Red*

(Open)

Red

(Open)

Red

(Open)

Red

Vented

14

Energized

Energized

De-

Energized

De-

Energized

Green

(Close)

Red*

(Open)

Red

(Open)

Red

(Open)

Red

Vented

15

Energized

Energized

Energized

De-

Energized

Green

(Close)

Green

(Close)

Green

(Close)

Red

(Open)

Red

Air Supply

16

De-

Energized

De-

Energized

De-

Energized

De-

Energized

Red

(Open)

Red

(Open)

Red

(Open)

Red

(Open)

Red

Vented

State

Bypass

valve in

bypass

Channel -1

Channel -

2

Channel -

3

Visual

Indicator

A/

Pressure

Switch

P1

Visual

Indicator

D/

Pressure

Switch

P4

Visual

Indicator

B/

Pressure

Switch

P2

Visual

Indicator

C/

Pressure

Switch

P3

Visual

Indicator

E

Outlet

V1

V4

V2

V3

1

(Bypass)

Valve

bypassed

for

repair

De-

Energized

De-

Energized

De-

Energized

De-

Energized

Red

(Open)

Red

(Open)

Red

(Open)

Red

(Open)

Green

Air

Supply

Table 10

* Indicators show Red which is "False" state, due to unavailability of Pneumatic air, since the valves are connected in

series (Refer Circuit).

Bypass valve in bypass Mode

Remaining states are illegal state when bypass mode is activated.

5.2 Operator Interface Options

The ARCS (141 series) is available with various interface and visual indication options. These options provide

local indication and feedback for plant personnel. There are several constraints related to these options.

• Any operator interface shall be implemented in a manner that has a predictable effect on the ARCS and

does not interfere with its safety function.

• Field modifications shall not be made to the internal wiring or pneumatic connections of the ARCS.

Page 22 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 23

5.3 ADT - Optional

ARCS (141 series) has redundant architecture which is sufficient to meet safety integrity level. However, ARCS

facilitate Automated diagnostic testing for individual solenoid valve in 2oo2 and 2oo3 configurations. Pressure or

Proximity switches shall be provided as optional for individual solenoid valves which facilitates online testing of

solenoid valves through safety systems or DCS.

In addition to the static detection of the system state and to enable the logic-solver to verify correct system state

transition, the sensor information is used to implement a safety-critical test of the ARCS function.

For functional testing, all solenoids are brought on-line depending on redundant configuration. Each solenoid is

then de-energized individually with pressure switch confirmation of successful venting. No bypass/isolation is

required for functional testing. This means that the system is sequenced through the truth table and the correct

assertion of these states is verified by reading the pressure switch transition. The safe state can be achieved at

any time during the function test by de-energizing the digital outputs on the safety rated logic solver.

The functional testing is performed to detect potential undetected dangerous component failure within the device

such as:

• SOV is stuck in energized position

• Pressure switch stuck in open or closed position

The position of the bypass / isolation valve is safety critical, are provided with LOTO protection which can be

secured with a lock. The bypass / isolation valve should be locked position at any state normal operation or

Bypass / isolation.

Any failure detected by the ADT shall be annunciated by the safety rated logic solver.

5.3.1 State Verification Test

The correct state of all valves shall be verified and compared against the commanded state. The state table in

section 5.1 of this manual can be used as a guide. This verification shall be performed periodically with a cycle

time of ½ of the process safety time or less.

If any illegal states are detected, they shall be immediately annunciated. These states are excluded by design

and the root cause for these faults cannot be determined or be contributed to a specific component. The ARCS

shall be repaired within 72 hours.

5.4 Repair and replacement

Repair procedures in I&M Number 536985 must be followed.

5.5 ASCO Notification

Any failures that are detected and that compromise functional safety should be reported to ASCO

Please contact ASCO Technical Support.

6 Status of the document

6.1 Releases

Version: V0

Revision: R0

Release status: ECN 290115 Released on December 12, 2018

Page 23 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Page 24

Appendix A – SIS Checklist

#

Activity

Result

Verified

By

Date

Design

Target Safety Integrity Level and PFDavg determined

Correct valve mode chosen (NC)

Design decision documented

Electrical compatibility and suitability verified

Pneumatic compatibility and suitability verified

SIS logic solver requirements for valve tests defined and

documented

Line monitoring requirements for SIS logic solver connection

determined

Routing of electric and pneumatic connections determined

Design formally reviewed, and suitability formally assessed

Implementation

Physical location appropriate

Electrical connections appropriate and according to applicable

codes

Pneumatic connections appropriate and according to applicable

codes

SIS logic solver state verification test implemented

SIS logic solver valve actuation test implemented

Maintenance instructions for proof test released (Optional)

Verification and test plan released

Implementation formally reviewed, and suitability formally

assessed

Verification and Testing

Electrical connections verified and tested

Pneumatic connection verified and tested

SIS logic solver state verification test verified

SIS logic solver valve actuation test verified

Safety loop function verified

Safety loop timing measured

Bypass function tested

Verification and test results formally reviewed, and suitability

formally assessed

Maintenance

Tubing blockage / partial blockage tested

Enclosure vent inspected

Electrical connection inspected

Bypass function and pressure sensors tested

Safety loop function tested

The following checklist may be used as a guide to employ the RCS device in a safety critical SIF compliant to

IEC61508.tivit

y

Page 24 of 24

No. 57, Kundrathur Main Rd., Gerugambakkam, Chennai -6000128, India www.asco.com

IM-IND-536661-Rev AA

Loading...

Loading...