Page 1

I&M No. V_9512_R9

Operation & Maintenance Guide

THIS DOCUMENT CONTROLLED BY

RCS Ex CERTIFICATION

ASCO Valves

©

ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com Page 1 of 18

®

E258615 - 09/2015 All Rights Reserved. I&M No. V_9512_R9

Page 2

Operation & Maintenance Guide

Redundant Control System

Table of Contents

Product Description 3

ATEX Environmental Ratings 4

General Specications 4

Nameplate Information (ATEX Versions Only) 5

Section 1-Normally Closed 7

1. General Operation 7

2. Testing and Maintenance 9

Section 2-Normally Open 10

1. General Operation 10

2. Testing and Maintenance 11

Section 3-Double Acting 12

1. General Operation 12

2. Testing and Maintenance 13

Section 4 14

1. Functional Test Certication 14

2. Spare Parts 14

3. Packaging 14

4. Limited Warranty 14

5. Tools Required for Routine Service 14

RCS Base Unit Wiring Diagram (A) 15

RCS Base Unit with PLC Wiring Diagram (B) 16

RCS N.C. Piping Diagrams 17

RCS N.O. Piping Diagrams 18

Page 2 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Page 3

Documentation Conventions

This guide uses the following typographic conventions:

EXAMPLE

NOTE

Notes containing supplementary information.

This symbol precedes information about

potential equipment damage.

This symbol precedes information about

potential personnel hazards.

Description

User Experience Prerequisites

To effectively use the Pneumatic RCS, users should have some

experience with pneumatic systems.

Warnings!

READ THIS ENTIRE MANUAL AND ALL RELATED

PUBLICATIONS PERTAINING TO THE WORK TO BE

PERFORMED BEFORE INSTALLING, OPERATING OR

SERVICING THIS EQUIPMENT.

• Follow all appropriate safety codes and standards.

• Failure to follow instructions may result in personal injury

and/or property damage.

• Use extreme caution when working around power-input

cables. These cables may have potentially lethal or dangerous

voltages.

• Prior to energizing the equipment, have qualied personnel

verify all wiring and connections against vendor drawings.

Incorrect wiring and/or connections can result in equipment

damage or serious system failure. If you have questions or

need more information on installing and operating ASCO

equipment, contact ASCO.

OPERATIONAL ATMOSPHERE CONSIDERATIONS:

The ATEX version of the Redundant Control System (hereafter

referred to as RCS) is designed in accordance with Annex II of

the European Directive 94/EC and European standards EN 60079-

0, EN 60079-1, EN 60079-7, and EN 600079-18. Classication : II

2G Ex d e mb IIC Gb IP-56.

MODELS COVERED BY ATEX APPROVAL:

ATEX Approval applies to RCS products having an ASCO Part

Number beginning with “5RC”, and that contain any combination

of the following features:

Manifold Architecture: Normally Closed, Normally Open, or

Double Acting.

Enclosure Material: 304 SS, 316 SS

System Voltage: 12 VDC, 24 VDC, 48 VDC, 120 VDC, 110/50-

120/60, 230/50-240/50

Operational Mode: Energized to trip or De-energized to trip

Optional Features: Common Alarm, Local Initiation of SOV test,

Local Initiation of Partial Stroke test, Bypass indication, Silver

Contact for relay logic or Lever type bypass switch.

User dened lights and push buttons: Any combination of standard

catalog lights and push buttons.

Options not covered by ATEX Approval:

• RCS products having an ASCO Part Number beginning with “5RC”

that include Local Manual Reset or a Composite Enclosure

• RCS units containing a PLC

PRODUCT DESCRIPTION

The RCS is a two-out-of-two (2oo2) or one-out-of-one hot standby

(1oo1 HS) voting, solenoid-operated valve system designed for

use as a component in safety instrumented systems. It functions

as a redundant pneumatic tripping device to control the pilot air

signal to a process valve actuator. The RCS uses 2oo2 or 1oo1

HS voting solenoids to enhance the reliability of the circuit. The

RCS consists of two electrically actuated solenoid valves (SOV1,

SOV2) and a pneumatically operated (Manually Controlled) bypass

valve, and three pressure switches. The pressure switches provide

solenoid state feedback and are used during on-line testing of the

RCS unit. The bypass valve allows for maintenance of the solenoid

valves without having to shut down the process valve. The use of

the Maintenance Bypass Valve is not required for functional testing

of the RCS unit. The RCS is available as a base unit (5R) and base

unit with on-board PLC (5L). The 5L unit with on-board PLC is

programmed with the logic required for proper operation. The type

of operation (2oo2 NC, 2oo2 NO, 2oo2 DA, 1oo1HS NC, 1oo1HS

NO) must be specied by the customer at the time of order. During

normal operation of a 5L construction power is routed through the

PLC to SOV1 and SOV2. Pressure switches (PS1, PS2 and PS3)

are monitored by the PLC. In the event of a PLC failure, SOV1 and

SOV2 will be connected directly to the Diagnostic Control System

(hereafter referred to as DCS) output, allowing the DCS to have

supervisory control of SOV1 and SOV2. Normal operation of the

processed valve unit will not be effected during this event. The RCS

unit will continue to function with restricted capabilities.

Under normal operating conditions:

The RCS allows for periodic testing of the solenoids by cycling one

solenoid valve and then the other either manually or automatically

therefore attaining the desired safety availability. This testing is

performed online without the need for bypassing of the safety

action and without interruption of the process.

For all constructions, three pressure switches are included to

provide indication of each solenoid-operated valve and bypass valve

position.

Normally Closed Construction: the RCS supplies air to the

process valve actuator through the “Process” port when energized.

Page 3 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Normally Open Construction: the RCS blocks the incoming

pneumatic signal and connects the “Process” port to the “Exhaust”

port when energized.

Double Acting Construction: the incoming pneumatic control

signal passes through the RCS to one side (C2) of the process valve

actuator while the other side (C1) of the process valve actuator

is vented through the RCS when energized. The 1oo1 HS mode

cannot be used with the double acting construction.

When a trip occurs:

Normally Closed Construction: the RCS blocks the incoming

pneumatic signal and connects the “Process” port to the “Exhaust”

port. This vents the air signal from the process valve actuator and

allows the actuator return spring to move the process to its failsafe position.

Normally Open Construction: the RCS supplies air to the process

valve actuator through the “Process” port. This allows the actuator

to move the process to its fail-safe position.

Double Acting Construction: (C2) of the process valve actuator is

vented through the RCS while the pneumatic control signal is applied

to (C1) of the process valve actuator. This causes the process valve

actuator to move from its normal operating position to its fail-safe

position.

HARDWARE

For proper operation, a pneumatic pressure of 3-150 PSI must be

supplied to the RCS [process connection] while a pressure of 40-150

PSI must be supplied to the [pilot connection]. It is housed in a 20”

x 16” x 8” enclosure. The primary components include:

• Hard anodized aluminum manifold body

• Two low power solenoid-operated ISO-3 valves

• A key-actuated bypass valve.

• Three pressure switches (ATEX rated Ex d IIC).

• An electrical terminal block for wiring termination (ATEX

rated Ex e IIC)

• Associated wiring.

• An on-board digital processor (RCS-L only)

Page 4

3

-150 PSI

must

pressure

is

components

valves

(meets

A

key

-actuated bypass

valve.

Three p

ressure

switches

(meets UL Class I, Div. 2 and

ATEX rated Ex

d

IIC)

.

An electrical terminal block for wiring

termination

(ATEX rated Ex e

II)

Associated

wiring.

An

on

-board digital processor

(RCS-L only).

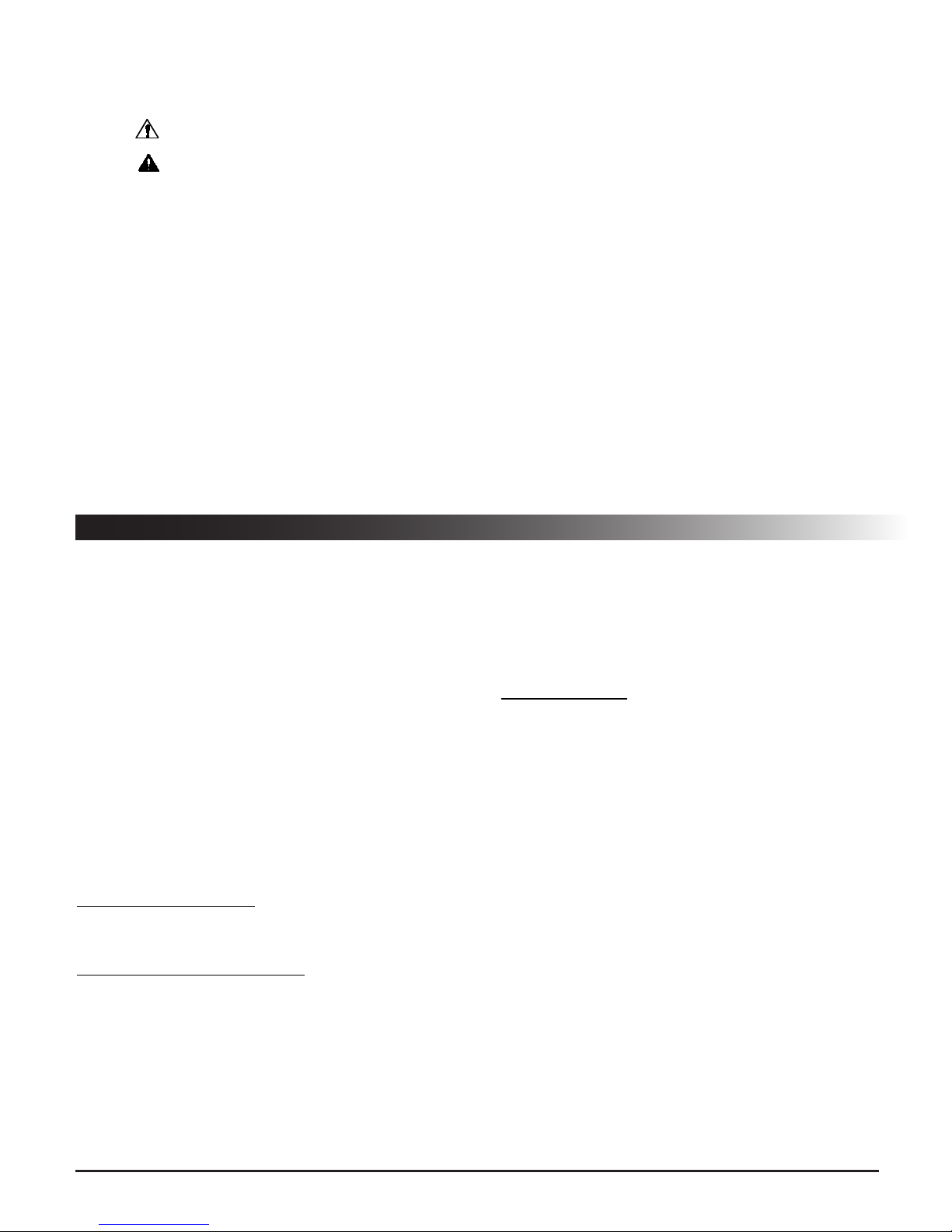

RCS-5R

eld wiring termination block

RCS-5L With Onboard PLC

Figure 1. General Appreance of the RCS

mounting brackets (2 on top)

on-board digital processor (RCS-L only)

pneumatic manifold

solenoid valves (2)

bypass valve

internal grounding/earthing connection

breather/vent

external grounding/earthing connection

Figure 2. RCS Components (Normally Closed shown)

ATEX ENVIRONMENTAL RATINGS

CE 0344 II 2G

Ex d e mb IIC T* Gb

• Ex : Explosion Protection Marking

• II: Equipment Group Other than Mines

• 2G: Category 2; Gas Atmosphere

• Ex : Explosion Protected

• d : Flameproof Protection Method

GENERAL SPECIFICATIONS

Solenoid Operator:

12, 24, 48 or 120 Volt DC Low Power,

Class F coil-1.4 watts and 1.7 watts

(1.7 watts does not apply to ATEX

versions)

120/60-110/50 or 230/50-240/50 AC

10.1 Watts

Pneumatic Valve:

ISO-3; 5/2 air-spring valve; solenoid

operated/Requires external pilot air

supply.

Bypass Valve:

ISO-3; 5/2 air-spring valve; manually

operated/Requires external pilot air

supply.

Manifold:

3- station ISO base; unique pneumatic

circuit design

• e : Increased Safety Protection Method

• mb : Encapsulation safety method (solenoid only)

• IIC : Atmosphere Group: Acetylene & Hydrogen

• *T180°C : Temperature Class 180°C-120/60-110/50 or 230/50-240/50 Applications

• *T6 : Temperature Class 85°C-12/DC, 24/DC, 48/DC or 120/DC Applications

• Gb : Equipment Protection level (“High” Level)

Pressure Switches:

3 each (ATEX rated Ex II 2G D Ex IIC T6)

Pressure Switch Type:

SPDT switches, hermetically sealed,

Anodized Aluminum

Switch Contact Rating:

Gold contacts (std) 1 amp suppressed

resistive load; .5 amps inductive load @

28 VDC.

Silver contacts (opt) 5 amps suppressed

resistive load; 3 amps inductive load @ 28

VDC.

Connection & Setting:

¼” NPTF; 3 psi increasing/ 1 psi decreasing;

non-adjustable.

Electrical:

Digital Processor (PLC):

RCS-L only, 14 inputs, 10 outputs

manually actuated bypass valve

pressure switches (3)

pneumatic connections

mounting brackets (2 on bottom)

Pneumatic Connections:

Pilot:

1/8” NPTF

Pilot Pressure:

40-150 psi

Inlet & Process:

1/2” NPTF

Exhaust Port:

1/2” NPTF

Process Pressure Range:

3 psi to 150 psi

Air Quality:

Instrument air per ANSI/ISA 7.0.01-1996

Particle size ≤ 40 microns.

Materials:

Enclosure:

Stainless Steel (304 SS, 316SS) or Fiberglass

(Fiberglass does not apply to ATEX versions)

Page 4 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Page 5

Size:

24”x 16”x 8”

Weight:

Approximately 75 lbs.

Mounting Panel

Painted Steel

Manifold:

Anodized aluminum.

Valves:

Body – Die-cast Aluminum alloy, SealingNitrile (NBR) and Polyurethane (PUR),

Solenoid Coil:

Epoxy encapsulated.

Pressure Switches:

316 Stainless Steel Wetted Surfaces

Environmental:

Ambient temperature range:

Consult panel nameplate to verify.

• RCS-R = -40°F to 140°F (-40°C to 60°C)

• RCS-R with local manual reset option

= -4°F to 140°F (-20°C to 60°C)

• RCS-L = -4°F to 131°F (-20°C to 55°C)

Approvals:

Exida

Certied SIL 3 capable (Standard

Normally Open and Normally Closed

constructions, see SIL certicate for

special constructions).

Spool and Stainless Steel.

NAMEPLATE INFORMATION (ATEX VERSIONS ONLY)

name of manufacturer

CE marking and number of

notied body responsible for

quality system (CE 0344)

ambient temperature rating

certicate number

serial number

including date code

120/60 - 110/50 or 230/50 - 240/50 Volt AC Applications

name of manufacturer

CE marking and number of

notied body responsible for

quality system (CE 0344)

™

ENCLOSURE TYPE 4, 4X, IP-66

Ex d e mb IIC T180°C Gb

Tamb -40°C to +60°C

ITS 07ATEX15746

MAX. AMBIENT TEMP

MODEL NO.

SERIAL NO./DATE

FLORHAM PARK, NEW JERSEY, USA

™

ENCLOSURE TYPE 4, 4X, IP-66

explosion protection marking

equipment group II category 2

type of explosive atmosphere

G=gas, vapor or mist

POWER MAX.

VOLTAGE AIR.

electrical parameters

INLET (PSI) AIR.

PILOT (PSI)

address of manufacturer

explosion protection marking

equipment group II category 2

type of explosive atmosphere

G=gas, vapor or mist

temperature T code T6=85°C/185°F

12/DC, 24/DC, 48/DC or 120/DC

applications

ambient temperature rating

certicate number

serial number

including date code

Page 5 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Ex d e mb IIC T6 Gb

Tamb -40°C to +60°C

ITS 07ATEX15746

POWER MAX.

MAX. AMBIENT TEMP

MODEL NO.

SERIAL NO./DATE

FLORHAM PARK, NEW JERSEY, USA

VOLTAGE AIR.

INLET (PSI) AIR.

PILOT (PSI)

12, 24, 48 or 120 Volt DC Applications

electrical parameters

address of manufacturer

Page 6

INSTALLATION

This section provides the information needed to install the RCS.

Unpacking:

Upon receipt of the RCS, unpack it carefully and visually check

for damage. The packing list shows the complete model number and

describes the features of the unit.

1. If the unit is damaged, immediately contact ASCO.

2. If everything is in order, proceed to the instructions in the

following sections.

Mounting Location Considerations:

The RCS is designed to be eld mounted near the process valve

to be actuated. The following factors should be considered when

selecting a mounting location:

• Accessibility: Allow ample space for door operation, and for

wiring and tubing runs.

• Temperature: Consider the amount of heat generated by equipment

in the mounting area. The RCS is intended for operation in ambient

temperatures from - 40°C to 60°C (RCS-R), -20°C to 60°C (RCS-R

with local manual reset option), from -20°C to 55°C (RCS-L).

WARNING: Explosion Hazard! Do not remove

or replace any component while circuit is live

unless the area is known to be nonhazardous.

ASCO components are intended to be used only within the

technical characteristics as specied on the nameplate. Changes to

the equipment are only allowed after consulting the manufacturer

or its representative. The Redundant Control System with ATEX

certication is intended for installation in potentially explosive

atmospheres, ATEX category 2G, gas Group IIC. The surface

temperature classication depends on the voltage, wattage and

ambient temperature which are stated on the nameplate. Depending

on the ambient/operation temperature heat resistant cabling capable

for the temperature as indicated on the nameplate must be used.

Mounting:

The RCS is designed to be mounted using the four mounting brackets

provided on the enclosure corners as shown in the gure below. It is

recommended that four 3/8” or 10 mm diameter bolts be used.

Field Connections:

Pneumatic Connections (Figure 5 A)

WARNING: Explosion Hazard! Do not remove

or replace any component while circuit is live

unless the area is known to be nonhazardous.

The RCS should be mounted as closely to the process valve as

possible. In order to insure proper operation of the process valve,

tubing runs should be as straight and short as possible. Recommended

piping for the inlet and outlet pneumatic connections to the RCS

is ½” stainless steel tubing. Recommended piping for pilot supply

is 1/8” stainless steel tubing.

process

1/2” NPT

inlet (supply)

1/2” NPT

inlet (supply)

1/2” NPT

Normally Closed

exhaust

1/2” NPT

pilot (supply)

1/8” NPT

exhaust

1/2” NPT

254 mm

406 mm

Figure 4. Mounting Dimensions

541 mm

241 mm

process

1/2” NPT

inlet (supply)

1/2” NPT

C2 process

1/2” NPT

Normally Open

Double Acting

Figure 5A. Pneumatic Connections

Page 6 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

pilot (supply)

1/8” NPT

exhaust

1/2” NPT

C1 process

1/2” NPT

pilot (supply)

1/8” NPT

Page 7

• The RCS should be connected to a high quality instrument

grade ground with #14 AWG or heavier wire. A grounding

stud is provided both inside and outside the enclosure.

Electrical Connection (Customer Responsibility):

General (Figure 5 B)

1. In all cases follow local and national electrical codes and

conrm compliance with Zone 1 ATEX requirements.

2. Placement of the conduit connection is up to the customer,

in compliance with Zone 1, ATEX requirements, based on

location and ease of installation. The upper or lower left side

of the box will give the shortest run to the wire terminal.

3. Cable/conduit connections can be added in location as shown

on Figure 5 B. Entry of external conductors and cables must

be through properly installed and suitable certied ameproof

cable entry devices and in accordance with ATEX Zone 1

increased safety requirements. Assemble and install cable

glands per manufacturer’s instructions. Connect cable ground

connections to the grounding/earthing terminal blocks or

grounding / earth studs provided internally and externally.

4. It is recommended that standard industry practices are followed

to prevent condensation from entering the enclosure and, in

some cases of Class I, Div 2 or ATEX Zone 1 conditions, to

prevent hazardous gasses and vapors from migrating through

the conduit to the control room or open ignition source.

Grounding and Earthing. (Figure 5 C)

Internal and external grounding studs are provided on the RCS

product. Ground/earth the product in accordance with local and

national electric codes as well as ATEX Zone 1 requirements.

mm

mm

mm

470

mm

25

483

25

25

mm

178 mm

left side

127

mm

Enclosure openings are

permitted in shaded

areas. Multiple openings

must have a minimum

of 102 mm. spacing.

Maximum number of

enclosure openings is 4

per side.

Stainless Steel

Enclosures

Entry of external

conductors and cable

must be thru properly

installed and suitable

ameproof cable entry

devices and conform to

local and national wiring

codes and zone 1 ATEX

requirements.

Composite

Enclosures

178 mm

rightside

127

mm

165

mm

165

mm

25

mm

483

mm

25

mm

470

mm

Green earthing terminal blocks are provided for easy installation of

25

mm

left side

Figure 5B. Enclosure Openings

rightside

conductor up to 4 mm sq.

Only insert one conductor per terminal block. Grounding studs are

provided inside and outside of the enclosure for additional grounding/

earthing requirements. (see Figure 5 C)

RCS-R Base Unit (without on-board PLC)

1. Connect the power source to the designated terminals

(SOV1, SOV2) as per wiring diagram provided with the RCS

unit. Wiring diagrams are available on the Internet at: www.

ascovalve.com/rcscongurator

2. Wire the three pressure switches (PS1, PS2 & PS3) as per

wiring diagram.

3. Wire optional accessories.

RCS-L Base Unit (with on-board PLC)

1. Connect to the PLC as per wiring diagram provided with the

RCS unit. Wiring diagrams are available on the Internet at:

www.ascovalve.com/rcscongurator (SOV1, SOV2, PS1,

PS2 and PS3 are pre- wired to PLC by ASCO)

internal grounding/

earthing locations

(stud not visible)

external grounding/

earthing location

Figure 5C. Grounding Connections

Wiring Guidelines

The following general guidelines apply to all wiring discussed

in this document.

WARNING: Circuit power must be removed from

the device prior to disconnecting the wiring on

either the eld or internal side of the terminal strip.

• Wiring shall be according to the National Electrical Code

(ANSI-NFPA 70), Zone 1 ATEX requirements or other

applicable codes.

• Wire size: stranded 16 and 18 AWG.

• The terminal clamps are designed for one wire only; DO NOT

attempt to terminate multiple wires into one terminal.

• Use care when running signal wiring near to or crossing

conduit or wiring that supplies power to motors, solenoids,

lighting, horns, bells, etc.

• AC power wiring should be run in a separate conduit from

DC power. All power wiring to and from the RCS should be in

grounded conduit.

Page 7 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

2. Use care when running signal wiring near to or crossing

conduit or wiring that supplies power to motors, solenoids,

lighting, horns, bells, etc.

3. AC power wiring should be run in a separate conduit from

DC power. All power wiring to and from the RCS should be

in grounded conduit.

4. The RCS should be connected to a high quality instrument

grade ground with #14 AWG or heavier wire. A grounding

stud is provided both inside and outside the enclosure.

5. Torque wire connection screw on PLC to 0.56Nm (5 inch-

pound).

Section 1. - Normally Closed

1. General Operation

The RCS is a two-out-of-two (2oo2) or one-out-of-one hot standby

(1oo1 HS) voting, solenoid-operated valve system designed for

use as a component in safety instrumented systems. It functions

as a redundant pneumatic tripping device to control the pilot air

signal to a process valve actuator. Both solenoids must be deenergized (De-Energize-To-Trip Version) or energized (EnergizeTo-Trip Version) prior to moving the process to its fail-safe position.

Three pressure switches are included to provide indication of each

solenoid-operated valve and bypass valve position.

The RCS allows for periodic testing of the solenoids by cycling one

Page 8

solenoid valve and then the other either manually (when ordered

with a local initiation of SOV test option) or automatically (by

the system DCS or the onboard diagnostic processor) therefore

maintaining the desired safety availability. This testing is performed

online without the need for bypassing of the safety action and without

interruption of the system process.

Under normal operating conditions, the RCS supplies pilot air to

the process valve actuator through the “process” port. When a trip

occurs, the RCS blocks the incoming pneumatic signal and connects

the “process” port to the “exhaust” port. This vents the air signal

from the process valve actuator and allows the actuator return spring

to move the process to its fail-safe position.

The pressure switches report solenoid valve positions as follows:

RUN MODE:

• De-Energize-To-Trip:(Figure3a)

If solenoid valve #1 (resp. #2) is in the energized position, the

contact of pressure switch #1 (resp. #2) is open. Pressure

vents from pressure switch #1 (resp #2). Pressure is applied to

pressure switch #3 and contact closed.

• Energize-To-Trip:(Figure 3b)

If solenoid valve #1 (resp. #2) is in the de-energized position,

the contact of pressure switch #1 (resp. #2) is open. Pressure

vents from pressure switch #1 (resp. #2). Pressure is applied to

pressure switch #3 and contact closed.

BYPASS MODE:

• The manually operated maintenance bypass valve is used to

isolate and depressurize the solenoid valves and pressure

switches during maintenance. The maintenance bypass valve

position is indicated by pressure switch #3.

• In the Bypass mode, the RCS “inlet” port is directly connected

to the “process” port. The solenoid valves and pressure switches

are vented to “exhaust”.

• In the Bypass mode, the contacts of pressure switches #1, #2

and #3 are open which indicates that no pressure is on the valves

or pressure switches.

Manually-Actuated maintenance bypass valve operation:

The manually-actuated bypass valve has two positions: NORMAL

for system run and MAINTENANCE BYPASS for maintenance

of the solenoid valves and pressure switches. To change positions

simply rotate the key (a lever option is available in place of the key)

to the desired position indicated on the valve.

Pressure Switches:

The pressure switches are factory set to actuate at 3 psig -increasing and 1 psig decreasing pressure. The pressure switches are xed and not

adjustable.

Status of SOVs Pressure Switches indicate as shown

Solenoid Valves

Both SOVs Energized O O CL

Both SOVs De-Energized CL CL CL

SOV 1 De-Energized Only CL O CL

SOV 2 De-Energized Only O CL CL

Bypass Mode O O O

Pressure

Switch 1

Pressure

Switch 2

Pressure

Switch 3

CL = Pressure switch Normally Open contact is Closed

O = Pressure switch Normally Open contact is Open

Figure 3a. Test Table of Solenoid Valve Status

(Normally Closed, De-Energize-To-Trip)

Status of SOVs Pressure Switches indicate as shown

Solenoid Valves

Both SOVs Energized CL CL CL

Both SOVs De-Energized O O CL

SOV 1 Energized Only CL O CL

SOV 2 Energized Only O CL CL

Bypass Mode O O O

Pressure

Switch 1

Pressure

Switch 2

Pressure

Switch 3

CL = Pressure switch Normally Open contact is Closed

O = Pressure switch Normally Open contact is Open

Figure 3b. Test Table of Solenoid Valve Status

(Normally Closed, Energize-To-Trip)

PS1 PS2 PS3

SOV1 SOV2

Energized Energized

PS1 PS2 PS3

Air Supply

B/P

Normal De-Energized De-Energized Normal

Exhaust

SOV1

SOV2

B/P

Air Supply

Exhaust

PS1

De-Energized Normal

SOV1

PS2 PS3

SOV2

B/P

Energized

Air Supply

Exhaust

Process Valve Open Process Valve Closed (TRIP) Process Valve Open

PS1 PS2 PS3

SOV1

SOV2

Energized

De-Energized Normal

B/P

Process Valve Open

Air Supply

Exhaust

PS1 PS2

SOV1

Energized

Energized Maintenance

PS3

SOV2

B/P

Bypass

Air Supply

Exhaust EXHAUST

Process Valve Open (BYPASS MODE)

PRESSURE

Figure 3c. RCS System Status (Normally Closed, De-Energize -To-Trip)

Page 8 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Page 9

PS1 PS2 PS3

SOV1

Energized Energized

SOV2

B/P

Normal

Air Supply

Exhaust

PS1

De-Energized De-Energized Normal

PS2 PS3

B/P

Air Supply

Exhaust

PS1 PS2 PS3

SOV2

SOV1

De-Energized Normal

B/P

Energized

Air Supply

Exhaust

Process Valve Closed (TRIP) Process Valve Open

PS1 PS2 PS3

SOV1

SOV2

B/P

Energized

De-Energized Normal

Air Supply

Exhaust

PS1 PS2 PS3

SOV2

SOV1

De-Energized

De-Energized

B/P

Bypass

Air Supply

Exhaust

Process Valve Open

PRESSURE

EXHAUST

Process Valve Open Process Valve Open (BYPASS MODE)

Figure 3d. RCS System Status (Normally Closed, Energize-To-Trip)

2. Testing and Maintenance:

Testing:

Solenoid-operated valve testing

The solenoid-operated valves and their associated pressure switches

can be tested online without interruption of the process. This

testing is implemented by cycling each solenoid-operated valve and

comparing the associated pressure switch contact reading to the test

table (see Figure 3a and 3b).

Partial Stroke testing

A partial stroke of the process valve can be performed online

without interruption of the process. This testing is implemented

by performing solenoid-operated valve testing, then moving the

process valve toward the safe state for a predetermined time. At

the end of the predetermined time, the process valve is returned to

the normal position.

Testing can be automated using a programmable logic controller

(PLC), a distributed control system (DCS) or an on-board digital

processor (RCS-L only).

CAUTION: (De - Energize - To - Trip Version) De-

energizing two solenoid valves at the same time will

initiate a shutdown.

(Energize - To - Trip Version) Energizing two solenoid

valves at the same time will initiate a shutdown.

1. At all times during testing, one out of the two solenoid-operated

valves must be in the energized position (De-Energize-To-Trip

Version) or de-energized (Energize-To-Trip Version).

2. IF, during the test process, the pressure switches do not

indicate what is expected according to the test table (see Figure

3a and 3b), the second solenoid-operated valve must not be

de-energized (De-Energize-To-Trip Version) or energized

(Energize-To-Trip Version).

Maintenance:

WARNING: Potential Electrostatic Charging

Hazard. Use wet or damp cloth when cleaning

any non-metallic/painted surfaces.

The Pneumatic RCS requires no routine maintenance except

periodic inspections for loose wires and ttings. The enclosure

should be opened occasionally and the components checked to

make sure they are tight, clean, and dry. The Breather/Vent valve

shall be inspected for obstruction and that it is free of debris during

routine maintenance cycles and during manual proof testing.

Manually-Actuated Bypass Valve

If it is necessary to replace a solenoid- operated valve or pressure

switch during normal operation, the manually- operated bypass

valve is used.

This valve is used to isolate and depressurize the solenoid valves

and pressure switches for maintenance only.

When the switch is rotated to the bypass position, the RCS

manifold channels the inlet pressure directly to the process port.

Pressure to the solenoid valves and pressure switches are vented to

“exhaust”. Contacts to pressure switches #1, #2, and #3 are open

which signals the PLC/DCS that the RCS is in bypass and not in

shut down.

Manual Bypass Valve Operation

(for maintenance only)

WARNING: Explosion Hazard. Do not open the

enclosure unless area is known to be nonhazardous.

1. Turn the key clockwise from “Normal” to “Maintenance

Bypass”. The system pressure is now bypassed directly

from “inlet” to “process” so that the process valve position is

maintained.

2. Verify that all 3 pressure switch contacts are open, indicating

the RCS is in Bypass.

WARNING: Remove the maintenance bypass

key from the switch and place the key in the

bottom of the enclosure until maintenance has

been completed.

WARNING: Explosion Hazard. Do not remove

or replace any component while circuit is live

unless area is known to be non - hazardous.

3. Turn off power to the RCS; disconnect appropriate wires from

terminal block.

4. Remove device (coil, solenoid valve, or pressure switch) and

install the new device following instructions supplied. If

replacing a solenoid valve, apply a small amount of anti-seize

to the bolt threads and torque to 160-175 in-lbs in a crisscross

pattern. Reconnect wires to appropriate terminal, (see wiring

diagrams).

5. Turn on power to the RCS. Verify that each device has power

and is in the correct state. (see Figure 3a and 3b).

6. Replace key in the Maintenance Bypass and rotate counter-

clockwise to the “Normal” position.

7. Have the control room run through the programmed test to be

sure the system is operating properly.

Page 9 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Page 10

Section 2. - Normally Open

1. General Operation

The RCS is a two-out-of-two (2oo2) or one-out-of-one hot

standby (1oo1 HS) voting, solenoid-operated valve system

designed for use as a component in safety instrumented systems.

It functions as a redundant pneumatic tripping device to control

the air signal to a process valve actuator. Both solenoids must be

de-energized (De-Energize-To-Trip ) or energized (EnergizeTo-Trip) prior to moving the process to its fail-safe position.

Three pressure switches are included to provide indication of

each solenoid-operated valve and bypass valve position. The

RCS allows for periodic testing of the solenoids by cycling one

solenoid valve and then the other either manually (when ordered

with a local initiation of SOV test option) or automatically (by

the system DCS or the onboard diagnostic processor in the case

of a 5L unit) therefore attaining the desired safety availability.

This testing is performed online without the need for bypassing

of the safety action and without interruption of the system

process.

Under normal operating conditions, the RCS blocks the pilot air

supply from the process valve and connects the “process” port

to the “exhaust” port. When a trip occurs, the RCS supplies

pilot air to the process valve actuator through the “process”

port. This allows the actuator to move the process valve actuator

to its fail-safe position.

The pressure switches report solenoid valve positions as follows:

RUN MODE:

• De-Energize-To-Trip: (Figure 6a & 6c)

If solenoid valve #1 (resp. #2) is in the energized position, the contact of

pressure switch #1 (resp. #2) is closed. Pressure is applied to pressure

switch #1 (resp #2). Pressure is applied to pressure switch #3 and

contact closed.

• Energize-To-Trip: (Figure 6b & 6d)

If solenoid valve #1 (resp. #2) is in the de-energized position, the

contact of pressure switch #1 (resp. #2) is closed. Pressure is applied to

pressure switch #1 (resp. #2). Pressure is applied to pressure switch

#3 and contact closed.

BYPASS MODE:

• The manually operated bypass valve is used to isolate and depressurize

the solenoid valves and pressure switches during maintenance. The

maintenance bypass valve position is indicated by pressure switch #3.

• In the Bypass mode the “inlet” air to the RCS is blocked, the “process”

port is connected to the “exhaust”. In addition, the solenoid valves and

pressure switches, including pressure switch #3, are vented to “exhaust”.

• In the Bypass mode, the contacts of pressure switches #1, #2 and #3

are open which indicates that no pressure is on the valves or pressure

switches.

Manually-Actuated Bypass Valve Operation:

The manually-actuated bypass valve has two positions: NORMAL for

system run and MAINTENANCE BYPASS for maintenance of the

solenoid valves and pressure switches. To change positions simply rotate

the key (a lever option is available in place of the key) to the desired

position indicated on the valve.

Pressure Switches:

The pressure switches are factory set to actuate at 3 psig-increasing and 1 psig decreasing pressure. The pressure switches are xed and not

adjustable.

Status of SOVs Pressure Switches indicate as shown

Solenoid Valves

Both SOVs Energized CL CL CL

Both SOVs De-Energized O O CL

SOV 1 De-Energized Only O CL CL

SOV 2 De-Energized Only CL O CL

Bypass Mode O O O

Pressure

Switch 1

Pressure

Switch 2

Pressure

Switch 3

CL = Pressure switch Normally Open contact is Closed

O = Pressure switch Normally Open contact is Open

Figure 6a. Test Table of Solenoid Valve Status

(Normally Open, De-Energize-To-Trip)

PS1 PS2 PS3

SOV1 SOV2

Energized Energized

Air Supply

B/P

Normal De-Energized De-Energized Normal

Exhaust

PS1 PS2 PS3

SOV1

SOV2

Status of SOVs Pressure Switches indicate as shown

Solenoid Valves

Both SOVs Energized O O CL

Both SOVs De-Energized CL CL CL

SOV 1 Energized Only O CL CL

SOV 2 Energized Only CL O CL

Bypass Mode O O O

Pressure

Switch 1

Pressure

Switch 2

CL = Pressure switch Normally Open contact is Closed

O = Pressure switch Normally Open contact is Open

Figure 6b. Test Table of Solenoid Valve Status

(Normally Open, Energize-To-Trip)

B/P

PS1

Air Supply

Exhaust

De-Energized Normal

SOV1

PS2 PS3

SOV2

B/P

Energized

Air Supply

Exhaust

Pressure

Switch 3

Process Valve Open Process Valve Closed (TRIP) Process Valve Open

PS1 PS2 PS3

SOV1

SOV2

Energized

De-Energized Normal

Air Supply

B/P

Exhaust

PS1 PS2

SOV1

Energized

Maintenance

SOV2

Energized

PS3

B/P

Bypass

Air Supply

(Blocked) PRESSURE

Exhaust EXHAUST

Process Valve Open

Figure 6c. RCS System Status (Normally Open, De-Energize -To-Trip)

Page 10 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Process Valve Open (BYPASS MODE)

Page 11

PS1 PS2 PS3

SOV1

Energized Energized

SOV2

B/P

Normal

Air Supply

Exhaust

PS2 PS3

PS1

B/P

De-Energized De-Energized Normal

Air Supply

Exhaust

PS1 PS2 PS3

SOV2

SOV1

De-Energized Normal

B/P

Energized

Air Supply

Exhaust

Process Valve Closed (TRIP) Process Valve Open

PS1 PS2 PS3

SOV1

SOV2

B/P

Energized

De-Energized Normal

Air Supply

Exhaust

PS1 PS2 PS3

SOV1

SOV2

De-Energized

De-Energized

B/P

Bypass

Air Supply

Exhaust

Process Valve Open

PRESSURE

EXHAUST

Process Valve Open Process Valve Open (BYPASS MODE)

Figure 6d. RCS System Status (Normally Open, Energize-To-Trip)

2. Testing and Maintenance:

Testing:

Solenoid-operated valve testing

The solenoid-operated valves and their associated pressure switches

can be tested online without interruption of the process. This

testing is implemented by cycling each solenoid-operated valve and

comparing the associated pressure switch contact to the test table (see

Figure 6a and 6b).

Partial Stroke testing

A partial stroke of the process valve can be performed online

without interruption of the process. This testing is implemented

by performing a solenoid-operated valve testing, then moving the

process valve toward the safe state for a predetermined time. At the

end of the predetermined time, the process valve is returned to the

normal position. Testing can be automated using a programmable

logic controller (PLC), a distributed control system (DCS) or an onboard digital processor (RCS-L only).

CAUTION: (De - Energize - To - Trip Version) De

- energizing two solenoid valves at the same time will

initiate a shutdown.

(Energize - To - Trip Version) Energizing two solenoid

valves at the same time will initiate a shutdown.

1. At all times during testing, one out of the two solenoid-operated

valves must be in the energized position (De-Energize-To-Trip

Version) or de-energized (Energize-To-Trip Version).

2. IF, during the test process, the pressure switches do not indicate

what is expected according to the test table (see Figure 6a and

6b), a second solenoid-operated valve must not be de-energized

(De-Energize-To-Trip Version) or energized (Energize-To-Trip

Version).

Maintenance:

WARNING: Potential Electrostatic Charging

Hazard. Use wet or damp cloth when cleaning any

non-metallic/painted surfaces.

The Pneumatic RCS requires no routine maintenance except periodic

inspections for loose wires and ttings. The enclosure should be

opened occasionally and the components checked to make sure they

are tight, clean, and dry.

Manually-Actuated Bypass Valve

If it is necessary to replace a solenoid-operated valve or pressure

switch during normal operation, the manually operated bypass valve

This valve is used to isolate and depressurize the solenoid valves and

pressure switches for maintenance only.

When the switch is rotated to the bypass position, the “inlet” air to the

RCS is blocked. The “process” port is connected to the “exhaust”.

Pressure to the solenoid valves and pressure switches are vented

to “exhaust”. Contacts to pressure switches #1, #2, and #3 are open

which signals the PLC/DCS that the RCS is in bypass and not in shut

down.

Manual Bypass Valve Operation

(for maintenance only)

WARNING: Explosion Hazard. Do not open the

enclosure unless area is known to be nonhazardous.

1. Turn the key clockwise from “Normal” to “Bypass”. The system

pressure is now blocked by the RCS, “process” is connected to

“exhaust”.

2. Verify that all 3 pressure switch contacts are open, indicating

the RCS is in Bypass.

WARNING: Remove the maintenance bypass

key from the switch and place the key in the

bottom of the enclosure until maintenance has

been completed.

WARNING: Explosion Hazard. Do not remove

or replace any component while circuit is live

unless area is known to be non - hazardous.

3. Turn off power to the RCS; disconnect appropriate wires from

terminal block.

4. Remove device (coil, solenoid valve, or pressure switch) and

install the new device following instructions supplied. If

replacing a solenoid valve, apply a small amount of anti-seize

to the bolt threads and torque to 160-175 in-lbs in a crisscross

pattern. Reconnect wires to appropriate terminal (see wiring

diagrams provided with unit). Wiring diagrams are available on

the internet at: www.ascovalve.com/rcscongurator.

5. Turn on power to the RCS. Verify that each device has power

and is in the correct state. (see Figure 6a and 6b).

6. Replace key in the Bypass and rotate counter-clockwise to the

“Normal” position.

7. Have the control room run through the programmed test to be

sure the system is operating properly.

is used.

Page 11 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Page 12

Section 3. - Double Acting

NOTE: One-out-of-one hot standby (1oo1HS) mode cannot be used with the Double Acting RCS- L.

1. General Operation

The RCS is a two-out-of-two (2oo2) or one-out-of-one hot

standby (1oo1 HS) voting, solenoid-operated valve system

designed for use as a component in safety instrumented systems.

Double acting RCS units are only available in 2oo2. It functions

as a redundant pneumatic tripping device to control the air signal

to a process valve actuator. Both solenoids must be de-energized

(De-Energize-To-Trip) or energized (Energize-To-Trip) prior to

moving the process to its fail-safe position.

Three pressure switches are included to provide indication of

each solenoid-operated valve and bypass valve position. The

RCS allows for periodic testing of the solenoids by cycling one

solenoid valve and then the other either manually (when ordered

with a local initiation of SOV test option) or automatically (by

the system DCS or the onboard diagnostic processor in the case

of the 5L unit) therefore attaining the desired safety availability.

This testing is performed online without the need for bypassing

of the safety action and without interruption of the system

process.

Under normal operating conditions, the incoming pilot air

supply for the process valve actuator passes through the RCS to

one side (C2) of the process valve actuator while the other side

(C1) of the process valve actuator is vented through the RCS.

When a trip occurs, (C2) of the process valve actuator is vented

through the RCS while the pneumatic control signal is applied

to (C1) of the process valve actuator. This forces the process

valve actuator to move from its normal operating position to its fail-safe

position.

The pressure switches report solenoid valve positions as follows:

RUN MODE:

• De-Energize-To-Trip: (Figure9a&9c)

If solenoid valve #1 (resp. #2) is in the energized position, the contact

of pressure switch #1 (resp. #2) is open. Pressure vents from pressure

switch #2. Pressure is applied to pressure switch #1 and #3.

• Energize-To-Trip: (Figure9b & 9d)

If solenoid valve #1 (resp. #2) is in the de- energized position, the

contact of pressure switch #1 (resp. #2) is open. Pressure vents from

pressure switch #2. Pressure is applied to pressure switch #1 and #3.

BYPASS MODE:

• The manually operated maintenance bypass valve is used to isolate

and depressurize the solenoid valves and pressure switches during

maintenance. The maintenance bypass valve position is indicated by

pressure switch #3.

• In the Bypass mode, the RCS “inlet” port is directly connected to

the “process” port (C2), “process” port (C1) is directly connected to

“exhaust”. In addition, the solenoid valves and pressure switches are

vented to “exhaust”.

• In the Bypass mode, the contacts of pressure switches #2 and #3 are

open, and #1 is closed, which indicates that no pressure is on the valves

or pressure switches.

Manually-Actuated Bypass Valve Operation:

The manually-actuated bypass valve has two positions: NORMAL for

system run and MAINTENANCE BYPASS for maintenance of the

solenoid valves and pressure switches. To change positions simply rotate

the key (a lever option is available in place of the key) to the desired

position indicated on the valve.

Pressure Switches:

The pressure switches are factory set to actuate at 3 psig-increasing and 1 psig decreasing pressure. The pressure switches are xed and not

adjustable.

Status of SOVs Pressure Switches indicate as shown

Solenoid Valves

Both SOVs Energized O O CL

Both SOVs De-Energized CL CL CL

SOV 1 De-Energized Only CL O CL

SOV 2 De-Energized Only O CL CL

Bypass Mode CL O O

Pressure

Switch 1

Pressure

Switch 2

Pressure

Switch 3

CL = Pressure switch contact is Closed

O = Pressure switch contact is Open

Figure 9a. Test Table of Solenoid Valve Status

(Double Acting, De-Energize-To-Trip)

Status of SOVs Pressure Switches indicate as shown

Solenoid Valves

Both SOVs Energized CL CL CL

Both SOVs De-Energized O O CL

SOV 1 Energized Only CL O CL

SOV 2 Energized Only O CL CL

Bypass Mode CL O O

Pressure

Switch 1

Pressure

Switch 2

Pressure

Switch 3

CL = Pressure switch contact is Closed

O = Pressure switch contact is Open

Figure 9b. Test Table of Solenoid Valve Status

(Double Acting, Energize-To-Trip)

PS1 PS2 PS3

SOV1 SOV2

Energized Energized

ACTUATOR

C2

C1

PS1 PS2 PS3

SOV2

SOV1

Energized

De-Energized

ACTUATOR

Normal

C2

C1

Normal De-Energized De-Energized Normal

Process

Valve Open

Air Supply

B/P

Exhaust

Process Valve

Open

Air Supply

B/P

Exhaust

Figure 9c. RCS System Status (Double Acting, De-Energize -To-Trip)

Page 12 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

PS1 PS2 PS3

SOV1

ACTUATOR

SOV2

C2

C1

B/P

Process

Valve Closed

(TRIP)

PS1 PS2

SOV1

Energized Energized

Maintenance

ACTUATOR

SOV2

C2

C1

PS3

B/P

Bypass

Process Valve

Open (BYPASS

MODE)

PS1

Air Supply

Exhaust

De-Energized Normal

Air Supply

(Blocked) PRESSURE

Exhaust EXHAUST

SOV1

Energized

ACTUATOR

PS2 PS3

B/P

SOV2

C2

Process

C1

Valve Open

Air Supply

Exhaust

Page 13

PS1 PS2 PS3

SOV1

Energized Energized

SOV2

ACTUATOR

C2

C1

PS1 PS2 PS3

SOV1

B/P

Energized

De-Energized

ACTUATOR

C2

C1

Air Supply

B/P

Normal

Process Valve

Closed (TRIP)

Exhaust

Air Supply

Exhaust

Normal

Process

Valve Open

Figure 9d. RCS System Status (Normally Open, Energize-To-Trip)

PS2 PS3

PS1

B/P

De-Energized De-Energized Normal

ACTUATOR

C2

C1

Process Valve

Open

PS1 PS2 PS3

SOV1

SOV2

B/P

De-Energized

ACTUATOR

De-Energized

Maintenance

Bypass

C2

C1

Process Valve Open

(BYPASS MODE)

Air Supply

Exhaust

Air Supply

Exhaust

PS1 PS2 PS3

SOV1

Energized

SOV2

De-Energized

ACTUATOR

C2

C1

B/P

PRESSURE

EXHAUST

Air Supply

Exhaust

Normal

Process Valve

Open

2. Testing and Maintenance:

Testing:

Solenoid-operated valve testing

The solenoid-operated valves and their associated pressure switches

can be tested online without interruption to the process. This

testing is implemented by cycling each solenoid-operated valve and

comparing the associated pressure switch contact to the test table

(see Figure 9a and 9b).

Partial Stroke testing

A partial stroke of the process valve can be performed online

without interruption to the process. This testing is implemented

by performing a solenoid-operated valve testing, then moving the

process valve toward the safe state for a predetermined time. At the

end of the predetermined time, the process valve is returned to the

normal position. Testing can be automated using a programmable

logic controller (PLC), a distributed control system (DCS) or an

on-board digital processor (RCS - L only).

CAUTION: (De - Energize - To - Trip Version) De

- energizing two solenoid valves at the same time will

initiate a shutdown.

(Energize - To - Trip Version) Energizing two solenoid

valves at the same time will initiate a shutdown.

1. At all times during testing, one out of the two solenoid-operated

valves must be in the energized position (De-Energize-To-Trip

Version) or de-energized (Energize-To-Trip Version).

2. IF, during the test process, the pressure switches do not indicate

what is expected according to the test table (see Figure 9a and

9b), a second solenoid-operated valve must not be de-energized

(DE-Energize-To-Trip Version) or energized (Energize-To-Trip

Version).

Maintenance:

WARNING: Potential Electrostatic Charging

Hazard. Use wet or damp cloth when cleaning any

non-metallic/painted surfaces.

The Pneumatic RCS requires no routine maintenance except periodic

inspections for loose wires and ttings. The enclosure should be

opened occasionally and the components checked to make sure they

are tight, clean, and dry.

Manually-Actuated Bypass Valve

If it is necessary to replace a solenoid valve or pressure switch during

normal operation, the manually operated bypass is used. The valve

is used to isolate and depressurize the solenoid valves and pressure

switches for maintenance only.

When the maintenance bypass valve is in its maintenance bypass

position, the RCS “inlet” port is directly connected to the “process”

port (C2) allowing the process to continue. In addition, the solenoid

valves and pressure switches, including (C1) and pressure switch

#3, are vented to “exhaust”. In the Maintenance Bypass Mode, the

contacts of pressure switches #2 and #3 are open, and #1 is closed,

which indicates that no pressure is on the valves or pressure switches.

Manual Bypass Valve Operation

(for maintenance only)

WARNING: Explosion Hazard. Do not open the

enclosure unless area is known to be nonhazardous.

1. Turn the key clockwise from “Normal” to “Maintenance

Bypass”. The system pressure is now bypassed directly from

“inlet” to “process” port (C2) so that the process valve position

is maintained (a lever option is available in place of the key).

2. Verify pressure switch #1 is closed and #2 and #3 are open,

indicating the RCS is in bypass.

WARNING: Remove the maintenance bypass

key from the switch and place the key in the

bottom of the enclosure until maintenance has

been completed.

WARNING: Explosion Hazard. Do not remove

or replace any component while circuit is live

unless area is known to be non - hazardous.

3. Turn off power to the RCS; disconnect appropriate wires from

terminal block.

4. Remove device (coil, solenoid valve, or pressure switch) and

install the new device following instructions supplied. If

replacing a solenoid valve, apply a small amount of anti-seize

to the bolt threads and torque to 160-175 in-lbs in a crisscross

pattern. Reconnect wires to appropriate terminal, (see wiring

diagrams provided with the RCS unit).

5. Turn on power to the RCS. Verify that each device has power

and is in the correct state. (see Figure 9a and 9b).

6. Replace key in the Maintenance Bypass and rotate counter-

clockwise to the “Normal” position.

7. Have the control room run through the programmed test to be

sure the system is operating properly.

Page 13 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Page 14

Section 4.

1. Functional Test Certication

Once assembled and inspected the RCS is cycled through a generic

program to validate two-out-of-two (2oo2) or one-out-of-one hot

standby (1oo1 HS); shut down function; partial stroke function;

solenoid valve status and pressure switch indication table; manual

bypass function.

2. Spare Parts

WARNING: Replacement parts are only to be

obtained from ASCO or an authorized distributor

or the certications may be invalidated or there

may be a risk of explosion.

VALVES AND COILS

APPLICATION VOLTAGE VALVE COIL

De-Energize-To-Trip 24/DC 323406 238714-902-D

Energize-To-Trip 24/DC 323407 238714-902-D

De-Energize-To-Trip 120/60-110/50 323404 238814-032-D

Energize-To-Trip 120/60-110/50 323405 238814-032-D

De-Energize-To-Trip 12/DC 323531 238714-903-D

Energize-To-Trip 12/DC 323530 238714-903-D

De-Energize-To-Trip 48/DC 323533 238714-912-D

Energize-To-Trip 48/DC 323532 238714-912-D

De-Energize-To-Trip 120/DC 323535 238714-904-D

Energize-To-Trip 120/DC 323534 238714-904-D

De-Energize-To-Trip 230/50-240/50 323537 238814-059-D

Energize-To-Trip 230/50-240/50 323536 238814-059-D

Bypass ALL 323408

PRESSURE SWITCHES

Pressure Switch SPDT Silver Contacts 323401

Pressure Switch SPDT Gold Contacts 323400

Pressure Switch DPDT Silver Contacts 323378

NO OTHER REPRESENTATION, GUARANTEES OR

WARRANTIES, EXPRESSED OR IMPLIED, ARE MADE BY

THE MANUFACTURE AND THE FOREGOING WARRANTY

IS IN LIEU OF ALL OTHER REPRESENTATIONS AND

WARRANTIES, EXPRESSED OR IMPLIED, WHICH ARE

HEREBY EXPRESSLY DISCLAIMED AND WA I V E D

BY BUYER, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR OF FITNESS FOR PARTICULAR

PURPOSE, WHETHER OR NOT THE PURPOSE OR USE

HAS BEEN DISCLOSED TO SELLER IN SPECIFICATION,

DRAWING OR OTHERWISE, AND WHETHER OR NOT

THE PRODUCT IS SPECIFICALLY DESIGNED AND/OR

MANUFACTURED FOR BUYERS USE OF PURPOSE.

Disclaimer

Because of the variety of uses for the ASCO Redundant Control

System (RCS), the user and those responsible for applying this

equipment must satisfy themselves as to the acceptability of the RCS

for each application.

The illustrations in this manual are solely intended to illustrate the

text of this manual. Because of the many variables and requirements

associated with this particular installation, ASCO cannot assume

responsibility or liability for actual use based upon the illustrative

uses and applications.

In no event will ASCO be responsible or liable for indirect or

consequential damages resulting from the use or application

of this equipment. ASCO disclaims any implied warranties of

merchantability or tness for a particular purpose.

ASCO DISCLAIMS ANY IMPLIED WARRANTY OR

FITNESS FOR A PARTICULAR PURPOSE.

No patent or copyright liability is assumed by ASCO with respect

to use of information, circuits, equipment or software described in

this text.

Reproduction of the content of this manual, in whole or in part,

without written permission from ASCO is prohibited.

5. Tools Required for Routine Service of RCS

Multi-meter

6 mm hex key

3. Packaging

While the package for RCS is designed to handle 2x the weight of the

unit, there are always hazards in shipping. Upon receipt of product,

unpack and check the product against the packing slip. If there is

damage to the product, immediately contact the Authorized ASCO

sales representative.

4. Limited Warranty

WARRANTIES: The manufacturer warrants its products and

equipment to be free from defects in material and workmanship for a

period of one year from the date of shipment from its factory.

The Manufacturer is not responsible for damage to its products

through normal wear and tear, improper installation, maintenance,

use, repairs or adjustment, or attempts to operate it above its rated

capacity or voltage, intentional or otherwise, or for unauthorized

repairs. To the extent the Manufacturer has relied upon specications,

information, representation of operating conditions or other are

supplied by Buyer or its agents to Seller in the selection or design of

the goods, and the operation conditions or other conditions differ

from those represented by the Buyer and relied upon by Manufacture,

and warranties or other provisions contained herein which are

affected by such conditions shall be null and void.

Page 14 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

1/4” hex key

3/16” hex key

Large slotted screwdriver

small slotted screwdriver

wire cutter/stripper

1 1/2” open end wrench

Page 15

RCS Base Unit Wiring Diagram (A)

Page 15 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Page 16

RCS Base Unit wit PLC Wiring Diagrams (B)

Page 16 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Page 17

RCS Normally Closed Piping Diagrams

Page 17 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Page 18

RCS Normally Open Piping Diagrams

Page 18 of 18 I&M No. V_9512_R9

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Loading...

Loading...