ASCO Instruction Manual: Series 308 Tamperproof High-Shock Manual Reset Solenoid Valves I&M No. V 9602 R2 | ASCO Manuals & Guides

I&M V_9602_R2

Installation & Maintenance Instructions

3-WAY MANUAL RESET PNEUMATIC/SOLENOID OPERATED VALVES

NORMALLY CLOSED OPERATION

NO-VOLTAGE RELEASE & ELECTRICALLY TRIPPED

1/2” AND 1/4” NPT - 5/8” AND 5/16” ORIFICE - STAINLESS STEEL CONSTRUCTION

For No-Voltage Release Operation

WARNING: Do not disassemble this valve

except as required to replace solenoid.

AVERTISSEMENT: Ne démonter pas cette

vanne sauf si il faut remplacer la bobine.

NOTICE: See separate solenoid installation and

maintenance instructions for information on: Wiring,

Solenoid Temperature, Causes of Improper Operation, and

Solenoid Replacement.

DESCRIPTION

EV8308G360 & EV8308G361 valves are 3-way, normally

closed, no-voltage release, manual reset pneumatic/solenoid

operated valves. EV8310G361 valve is a 3-way, normally

closed, electrically tripped (TSO), manual reset pneumatic/

solenoid operated valve. (Please see Flow Diagram for

Electrically Tripped Operation). Valves bodies are made of CF8M stainless steel with internal parts of stainless steel; elastomers

are Fluorocarbon, Fluorosilicone and Nitrile. The manual reset

assembly is anodized aluminum.

OPERATION

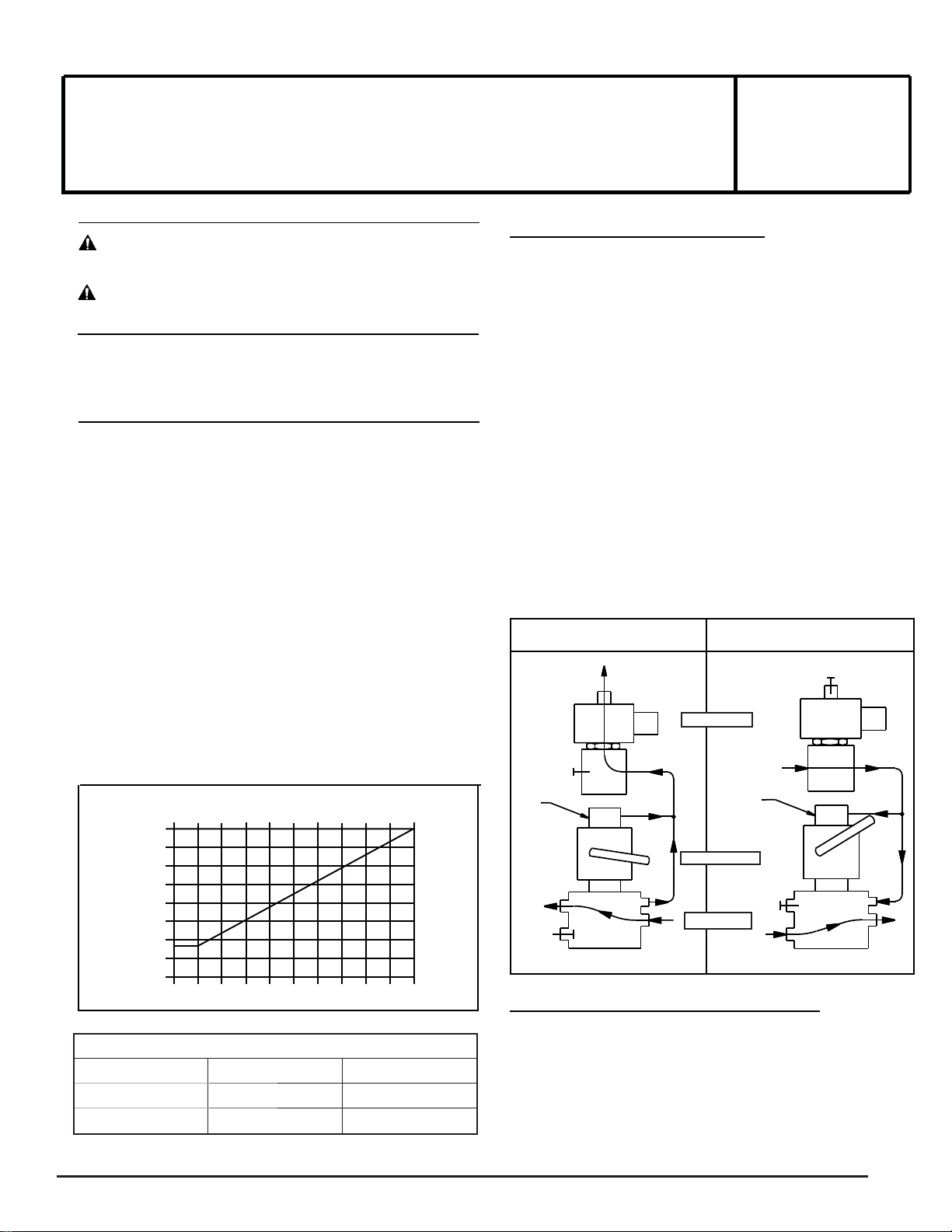

Auxiliary Piloting allows a zero minimum main line pressure

with the application of proper auxiliary air pressure. Refer

to Table 1, Operating Pressure Differential, and the graph

Auxiliary Pilot Pressure vs Main Line Pressure. Use this graph

to determine the minimum auxiliary air pressure required for a

given main line pressure.

Auxiliary Line Pressure vs Main Line Pressure

(Minimum Auxiliary Air 25 psi)

120

105

90

75

60

45

30

15

Auxiliary Line Pressure PSI

0

0 15 30 45 60 75 90 105 120 135 150

Table 1. Operating Pressure Differential

Valve Minimum Maximum

Main valve 0 150 psig

Pilot valve 25 125 psig

Main Line Pressure PSI

Unlatched - Solenoid De-energized: With valve unlatched and

the solenoid de-energized, main valve fl ow will be from cylinder

to exhaust. The pressure port is closed, whether or not auxiliary

pressure is present.

Latched - Solenoid Energized with Auxiliary Pressure

Applied: With solenoid energized and auxiliary pilot pressure

present, the valve may be manually operated (shifted) by raising

the handle until it latches the operator in the (up) latched position.

In the latched position, main valve fl ow will be from pressure to

cylinder. Exhaust will be closed. When solenoid is de-energized,

valve will return (trip) to the (down) unlatched position. Valve

can not be latched, until solenoid is energized, auxiliary pressure

applied, and handle is raised to the (up) latched position.

NOTE: Upon solenoid de-energization or loss of auxiliary pilot

valve pressure, valve will return (trip) to the unlatched position.

Valve can not be latched until auxiliary pilot pressure is restored,

solenoid is energized and lever handle is raised. The valve is now

latched.

Flow Diagrams for No-Voltage Release

UNLATCHED

DE-ENERGIZED

PILOT

EXH

‘3’

PILOT VALVE

PILOT

PRESSURE

PILOT

PISTON

CYLINDER

EXH

PRESS

For Electrically Tripped (TSO) Operation

Apply proper auxiliary pressure to port 3 of the pilot valve. Port 2

is now the auxiliary exhaust port - DO NOT BLOCK OFF.

Latched - Solenoid De-energized: With solenoid de-energized,

raise the handle until it latches in the (up) latched position. Main

valve fl ow is now from the pressure to the cylinder port. The

exhaust port of the main valve is closed.

‘2’ ‘1’

MANUAL RESET

AUX

MAIN VALVE

CYL

CATALOG

EV8308G360

EV8308G361

EV8310G361

Low Power

LATCHED

ENERGIZED

PILOT

PRESSURE

PILOT

PISTON

CYLINDER

EXH

PRESS

PILOT

EXH

‘3’

‘2’ ‘1’

AUX

CYL

ASCO Valves

©

ASCO Valve, Inc. 160 Park Avenue, Florham Park, New Jersey 07932 www.ascovalve.com Page 1 of 4

®

E269586 - 04/2017 All Rights Reserved. I&M V_9602_R2

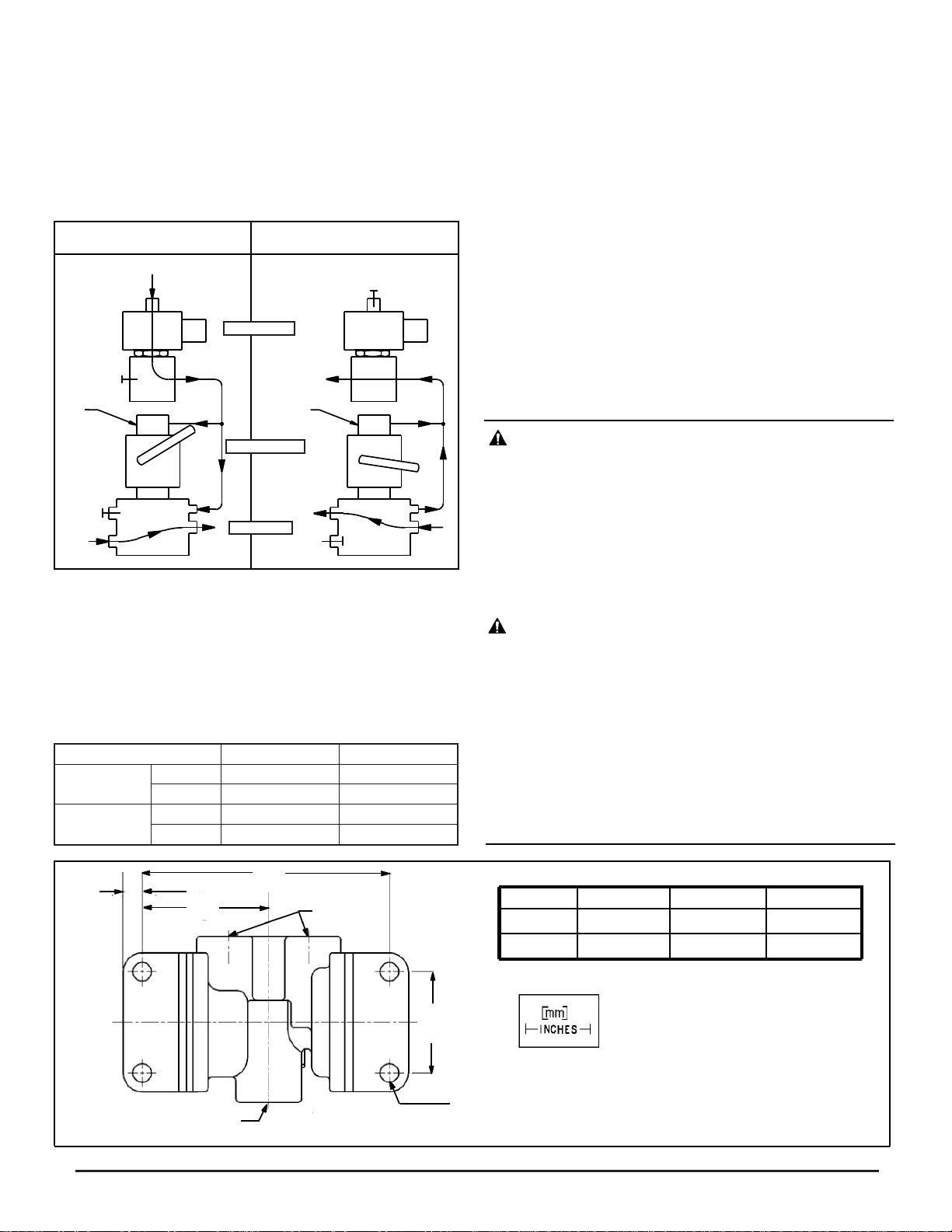

Unlatched - Solenoid Energized: With solenoid energized, the

handle will now return to the (down) unlatched position. The

pressure port of the main valve will close and fl ow in the main

valve will be from cylinder to exhaust.

NOTE: When piped in the electrically tripped (TSO) mode,

loss of auxiliary pressure will cause the operator to return to the

unlatched position - Main valve pressure will close and exhaust

will open.

Flow Diagrams for Electrically Tripped

DE-ENERGIZED

PILOT

PRESSURE

PILOT

EXH

PILOT

PISTON

CYLINDER

EXH

PRESS

LATCHED

‘3’ ‘3’

PILOT VALVE

‘2’ ‘1’

MANUAL RESET

AUX

MAIN VALVE

CYL

UNLATCHED

ENERGIZED

PILOT

PRESSURE

PILOT

EXH

PILOT

PISTON

CYLINDER

EXH

PRESS

‘2’ ‘1’

AUX

CYL

INSTALLATION

Check nameplate for correct catalog number, pressure, voltage,

frequency, and service. Never apply incompatible fl uids or exceed

pressure rating of the valve. Installation and valve maintenance

to be performed by qualifi ed personnel only.

Temperature Limitations

Please refer to chart below, or as limited by solenoid approvals.

See solenoid installation and maintenance instructions.

Temperatures Pilot Valve Main valve

Fluid

Ambient

Min. -4°F (-20°C) -4°F (-20°C)

Max. 140°F (60°C) 140°F (60°C)

Min. -4°F (-20°C) -4°F (-20°C)

Max. 140°F (60°C) 140°F (60°C)

Positioning

Valve may be mounted in any position. For optimum performance

mount with operator vertical and upright.

Mounting

For valve body mounting refer to Figure 1.

Piping

There are three exhaust fl ow modes: pilot valve, auxiliary pilot

and main valve exhaust. For pilot valve and auxiliary pilot exhaust

use a muffl er to vent to atmosphere or connect to main exhaust

system if the air or inert gas cannot be exhausted directly to the

atmosphere.

Connect piping or tubing to valve according to markings on valve

body. Refer to fl ow diagrams in OPERATION section and Figure

2 Valve Port Connections. Apply pipe compound sparingly to

male pipe threads only. If applied to valve threads, the compound

may enter the valve and cause operational diffi culty. Avoid

pipe strain by properly supporting and aligning piping. When

tightening the pipe, do not use valve or solenoid as a lever. Locate

wrenches applied to valve body or piping as close as possible to

connection point.

CAUTION: These solenoid valves are intended for

use on clean dry air, inert gas or natural gas, fi ltered to 40

micrometres or better. The dew point of the media should

be at least 10°C (18°F) below the minimum temperature

to which any portion of the clean air/inert gas system

could be exposed to prevent freezing. If lubricated air is

used, the lubricants must be compatible with FKM and/

or Nitrile elastomers. Diester oils may cause operational

problems. Instrument air in compliance with ANSI/ISA

Standard 7.0.01-1996 exceeds the above requirements

and is, therefore, an acceptable media for these valves.

ATTENTION : Ces électrovannes doivent être

utilisées avec de l’air sec, du gaz inerte ou gaz naturel

propre, fi ltré jusqu’à 40 micromètres ou plus. Le point

de rosée du fl uide doit être d’au moins 10ºC inférieur

à la température minimale à laquelle toute partie du

système d’air/gaz inerte propre pourrait être exposée,

afi n d’éviter le gel. En cas d’utilisation d’air lubrifi é,

les lubrifi ants doivent être compatibles avec le FKM

et/ou élastomères nitrile. Les huiles diester peuvent

engendrer des problèmes de fonctionnement. L’air

d’instrumentation conforme à la norme ANSI/ISA 7.0.011996 dépasse les exigences ci-dessus et constitue, par

conséquent, un média acceptable pour ces vannes.

.31 [8]

”D”

PRESS EXH

ANPT

”F”

CYL

ANPT

ANPT

1/4”

1/2”

”E”

Ø.28 [7]

4 MOUNTING HOLES

Figure 1. Mounting dimensions (partial view)

D

2.09 [53]

2.18 [55]

E

1.25 [32]

1.66 [42]

F

4.05 [103]

4.26 [108]

Page 2 of 4 I&M No. V_9602_R2

©ASCO Valve, Inc. 160 Park Avenue, Florham Park, New Jersey 07932 www.ascovalve.com

Loading...

Loading...