Page 1

531

24

2

4

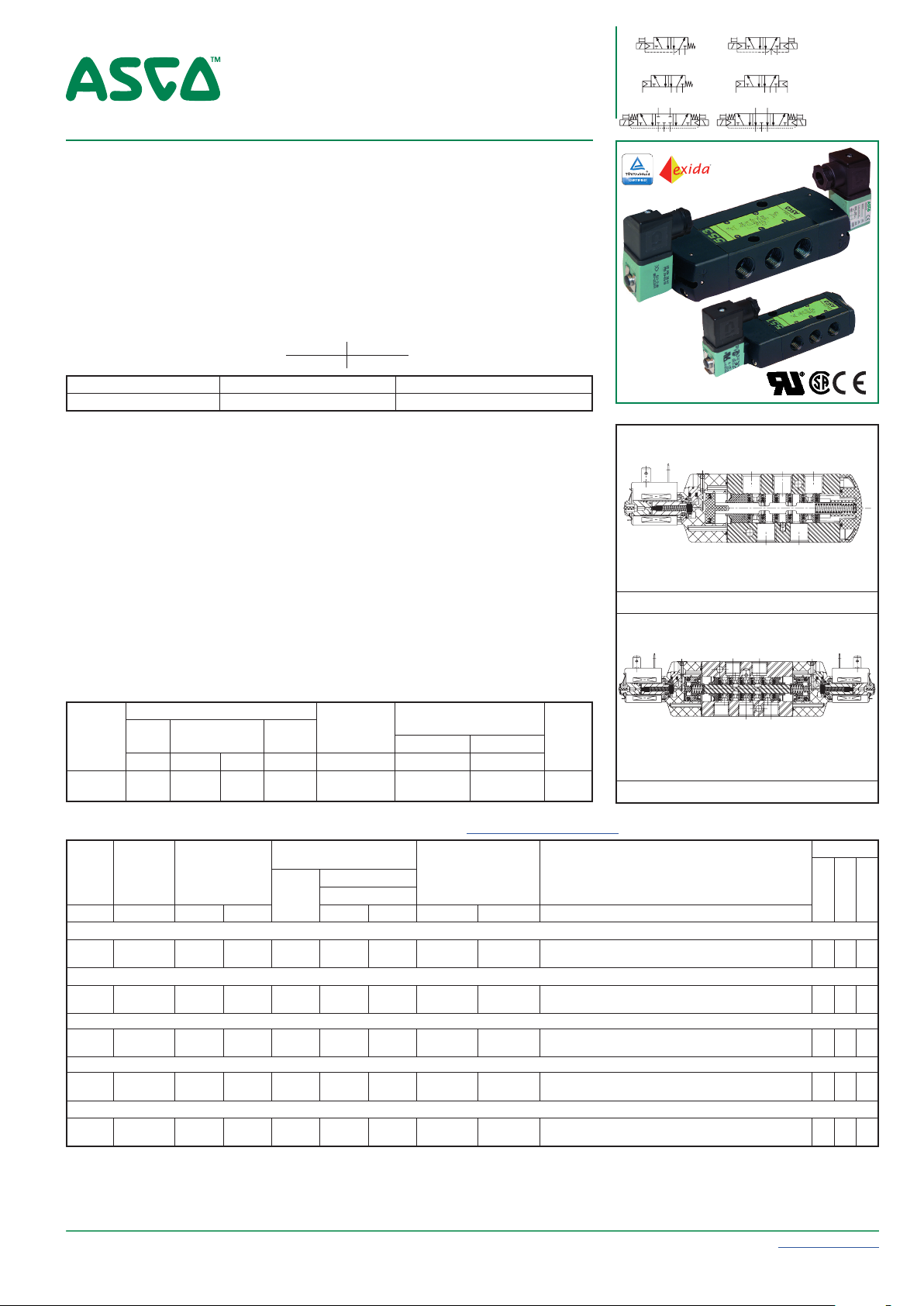

SPOOL VALVES

14

12

24

531

12

24

531

14

14

12

24

531

14

12

24

531

12

531

14

12

531

14

5/2-5/3

pilot operated or air operated, spool type

single/dual solenoid or air

aluminium body, 1/4 - 1/2

24

FEATURES

• All the exhaust ports of the spool valve are connectable, providing better environmental

protection. Particularly recommended for sensitive areas, such as clean rooms, and

applications in the pharmaceutical and food processing sectors

• The valves offer environmental protection against the ingress of liquids, dusts or

other foreign matter (environmentally-protected construction)

• The monostable spool valves in conformity with IEC 61508 Standard (2010 route 2H

version) have TÜV (551 series) and EXIDA (551-553 series) certified with integrity

levels: SIL 2 for HFT = 0 / SIL 3 for HFT = 1

• The solenoid valves satisfy all relevant EU directives

GENERAL

Differential pressure 2 - 10 bar [1 bar = 100 kPa]

Flow (Qv at 6 bar) l/min (ANR)

1/4 1/2

860 3800

fluids () temperature range (TS) seal materials ()

air, inert gas, filtered

-25°C to +60°C NBR (nitrile) + PUR (polyurethane)

MATERIALS IN CONTACT WITH FLUID

()

Ensure that the compatibility of the fluids in contact with the materials is verified

Body, end cover Aluminium, black anodized

End cover (spring return) Glass fibre filled PA

Spool valve internal parts Zamak, stainless steel, POM, aluminium

Seals NBR + PUR

Core tube Brass

Core and plugnut Stainless steel

Shading coil Copper

ELECTRICAL CHARACTERISTICS

Coil insulation class F

Connector Spade plug (cable Ø 6-8 mm or Ø 6-10 mm)

Connector specification

or ISO 4400 / EN 175301-803, form A (

EN 175301-803, 11 mm, industry standard form B (type 01)

type

02)

Electrical safety IEC 335

Electrical enclosure protection

Moulded IP65 (EN 60529)

Standard voltages DC (=) : 24V - 48V

(Other voltages and 60 Hz on request) AC (~) : 24V - 48V - 115V - 230V / 50 Hz

power ratings

prefix

option

inrush

~

holding

~

hot/cold

=

(VA) (VA) (W) (W) (C°)

SC 6 3,5 2,5 2,5 / 3 -25 to +60 400127-097 400904-542 01

SC 15 7 5 4 / 5 -25 to +60 400727-117 400727-185 02

(1)

Refer to the dimensional drawings on the following page

SPECIFICATIONS

pipe

size

orifice

size

G (mm) (m3/h) (l/min) ~ = ~ = ~/=

flow

coefficient

Kv

min.

operator

ambient

temperature

range (TS)

operating pressure

differential (bar)

max. (PS)

air (*)

replacement coil

~ =

230 V/50 Hz 24 V DC

Configurator - CAD Files

power coil

(W)

type

(1)

catalogue

number

5/2 - Solenoid air pilot operated - spring return (monostable)

1/4 6 0,75 12,5 2 10 10 2,5 3 SCG551A017 MS - -

1/2 13 3,15 52,5 2 10 10 5 5 SCG553A017 MS - -

5/2 - Solenoid air pilot operated and return (bistable)

1/4 6 0,75 12,5 2 10 10 2,5 3 SCG551A018 MS - -

1/2 13 3,15 52,5 2 10 10 5 5 SCG553A018 MS - -

5/3 - W1 - pressure held, solenoid air pilot and return

1/4 6 0,75 12,5 2 10 10 2,5 3 SCG551A067 MS - -

1/2 13 3,15 52,5 2 10 10 5 5 SCG553A067 MS - -

5/3 - W3 - pressure released, solenoid air pilot and return

1/4 6 0,75 12,5 2 10 10 2,5 3 SCG551A068 MS - -

1/2 13 3,15 52,5 2 10 10 5 5 SCG553A068 MS - -

5/2 - Solenoid air pilot operated spring return (monostable), certified IEC 61508 Functional Safety data

1/4 6 0,75 12,5 2 10 10 2,5 3 SCG551A017SL - - -

1/2 13 3,15 52,5 2 10 10 5 5 SCG553A017SL - - -

5/2 function

5

5/3 function

24

3

1

maintained

Series

551

553

options

man. operator

00093GB-2017/R01

Availability, design and specifications are subject to change without notice. All rights reserved.

All leaflets are available on: www.asco.com

Pneumatic Valves (5/2 - 5/3) - 5

Page 2

SOLENOID VALVES SERIES 551-553

210

13

13

75

52

M5

59

95

1

24

5

3

B

94,5

161,5

189

31,6 31,8

78,5 43

40,2

==

72,3

=

=

51

=

=

75 31,6

G1/4

5 x 1/2

1 34 25

1 34 25

5

12 10

1

72

125

146

3

45

=

=

27,5

=

=

32

=

=

5x 1/4

G1/8

21,8

==

50,5 32

4 2

A

41

==

AIR OPERATED AND OPTIONS

• Versions (Type 03): - pilot air operated, spring return, catalogue numbers: G551A117 / G551A117SL (1/4);

G553A117 / G553A117SL (1/2)

- pilot air operated and return, catalogue numbers: G551A118 (1/4); G553A118 (1/2)

• Suffix “GD“ (air operated only, ATEX 2GD c)

• Explosionproof enclosures for use in zones 1/21-2/22, categories 2-3 to ATEX Directive 2014/34/EU (www.asco.com)

• Supply rail (www.asco.com)

• Other pipe connections are available on request

• Connector with visual indication and peak voltage suppression or with cable length of 2 m (www.asco.com)

INSTALLATION

• The valves can be mounted in any position without affecting operation

• It is necessary to connect pipes or fittings to the exhaust ports to protect the internal parts of the spool valve and its pneumatic

operator if used outside or in harsh environments (dusts, liquids etc.)

• IEC 61508 Functional Safety (suffix SL). Check temperature range of valve body and solenoid for suitability. For probability of

failure, contact us

• Valves with suffix “SL” are supplied with specific exhaust protectors

• Threaded pipe connection is standard: G = G (ISO 228/1)

• Installation/maintenance instructions are included with each valve

ACCESSORIES

series

pipe

size

551 G 1/4 34600419

553 G 1/2 34600479

551-553 M5 34600484

(1)

Supplied with suffix “SL”

exhaust protector

(stainless steel)

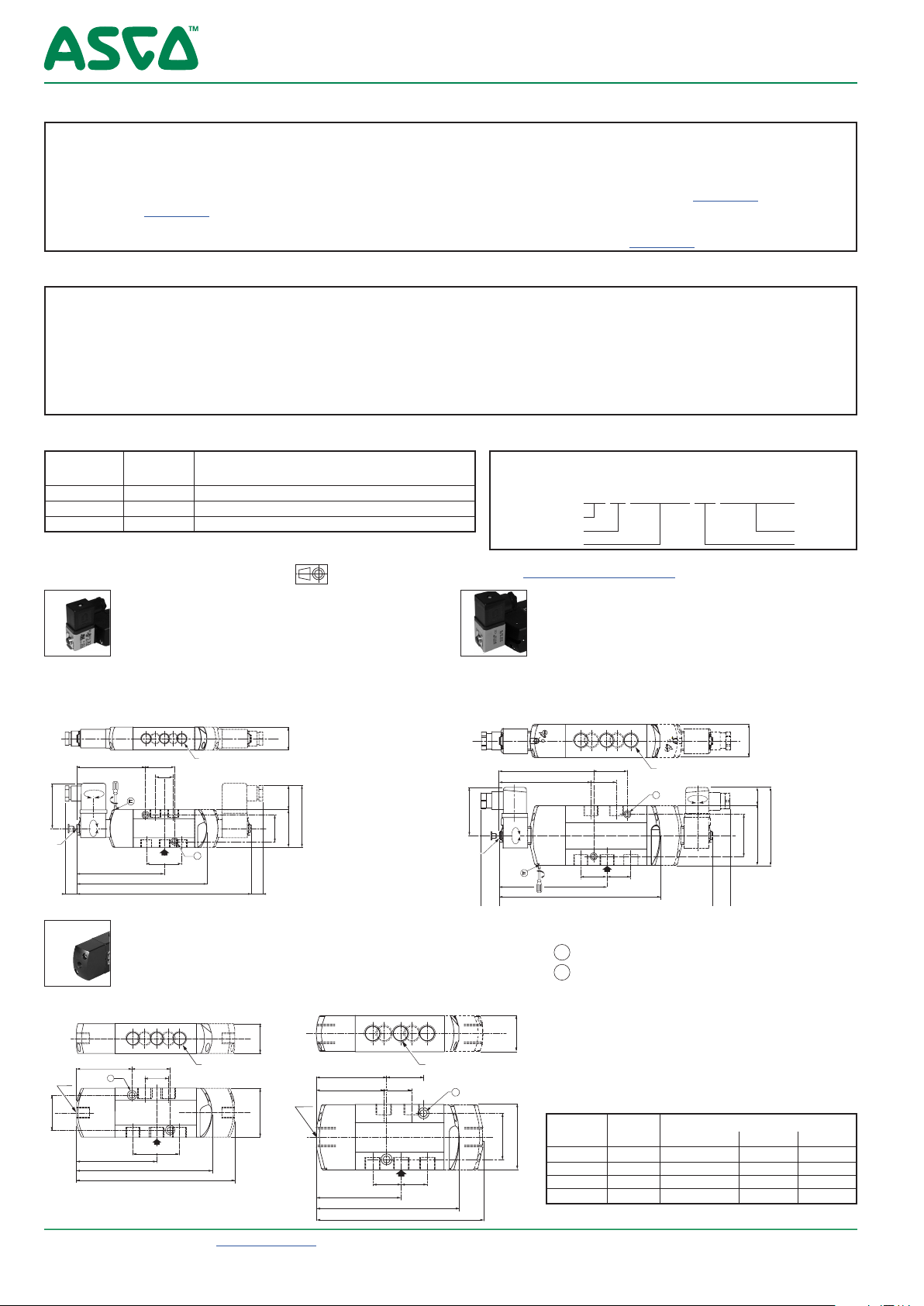

DIMENSIONS (mm), WEIGHT (kg)

TYPE 01

Prefix “SC” Solenoid

Epoxy moulded

IEC 335 / DIN 43650

82,5 32

180°

1

°

360

104,5

IP65

0

4 2

513

==

157

1 34 25

21,8

41

==

5 x 1/4

==

1

27,5

30

=

=

45

32

=

=

551A017 / A017MS / A017SL / A018 / A018MS

551A067 / A067MS / A068 / A068MS

ORDERING EXAMPLES:

SC G 551 A 017 MS 230V / 50 Hz

SC G 551 A 017 SL 24V / DC

(1)

(1)

(1)

pipe thread

basic number

SC G 553 A 018 115V / 50 Hz

G 551 A 117 SL

prefix

voltage

suffix

Configurator - CAD Files

TYPE 02

Prefix “SC” Solenoid

Epoxy moulded

IEC 335 / ISO 4400

553A017 / A017MS / A018 / A018MS / A067 / A067MS / A068 / A068MS

553A017SL

M5

IP65

114,5 43

111

°

360

0

1

130,5

5

197,5

40,2

=

51

=

==

=

72 23

=

1 34 25

31,6

4

1

5 x 1/2

B

2

3

31,8 31,6

90°

TYPE 03

No prefix

Air operated version

551A117 / A117SL / A118

All leaflets are available on: www.asco.com

6 - Pneumatic Valves (5/2 - 5/3)

2 mounting holes:

A 5,3 mm dia. (Spotfacing: 9 mm dia., depth 5 mm)

B 6,5 mm dia. (Spotfacing: 11 mm dia., depth 6 mm)

553A117 / A117SL / A118

type

prefix

option

monostable.

(2)

weight

bistable W1-W3

01 (551) SC 0,48 0,60 0,60

02 (553) SC 0,84 1,14 1,14

03 (551) - 0,32 0,40 0,40

03 (553) - 0,79 1,24 1,24

(2)

Incl. coil(s) and connector(s).

00093GB-2019/R01

Availability, design and specifications are subject to change without notice. All rights reserved.

Page 3

13

5

42

SOLENOID VALVES

14

24

531

12

24

531

14

pilot operated, spool type

single/dual solenoid (mono/bistable function)

aluminium body, 1/4 - 1/2

FEATURES

• All the exhaust ports of the spool valve are connectable, providing better environmental

protection. Particularly recommended for sensitive areas, such as clean rooms, and

applications in the pharmaceutical and food processing sectors

• The valves offer environmental protection against the ingress of liquids, dusts or

other foreign matter (environmentally-protected construction)

• Solenoid pilot valve with spade-plug connector type EN 175301-803, industry

standard form C, with 9,4 mm spacing. Versions with M12 connection

• Solenoid pilot valve, CNOMO size 15 interface, with or without integral LED and

electrical protection. LED indicator visible from 3 sides

• The monostable spool valves in conformity with IEC 61508 Standard (2010 route 2H

version) have TÜV (551 series) and EXIDA (551-553 series) certified with integrity

levels: SIL 2 for HFT = 0 / SIL 3 for HFT = 1

• The solenoid valves satisfy all relevant EU directives

GENERAL

Differential pressure 2 - 10 bar [1 bar = 100 kPa]

Flow (Qv at 6 bar) l/min (ANR)

1/4 1/2

Pilot mounting interface surface

fluids () temperature range (TS) seal materials ()

air, inert gas, filtered -25°C to +40°C NBR (nitrile) + PUR (polyurethane)

ISO 15218 (CNOMO E06.36.120N, size 15)

MATERIALS IN CONTACT WITH FLUID

() Ensure that the compatibility of the fluids in contact with the materials is verified

Body Aluminium, black anodized

End cover (spring) Glass fibre filled PA

Spool valve internal parts Zamak, stainless steel, POM, aluminium

Pilot body PARA

Pilot internal parts POM, PET, stainless steel and brass

Pneumatic interface seal TPE

ELECTRICAL CHARACTERISTICS

Coil insulation class F

Connector (type 05) Spade plug (cable Ø 4-6 mm)

Connector specification

Connection

Electrical safety IEC 335

Electrical enclosure protection Moulded IP65 [05] or IP67 [07] (EN 60529)

Standard voltages DC (=): 24V

(Other voltages and 60 Hz on request)

power ratings

prefix

option

CFSC

CFVT

((1)

Refer to the dimensional drawings on the following page.

(2)

Values with LED indicator and protection, use TPL 20674.

inrush

~

(VA) (VA) (W) (W) (C°)

1,4 1,2 1,1 1/1,2

1,8

2,1 1,6 1,5 - -25 to +60

2,5

(3)

- - -

holding

(2)

(2)

1,6

2

(2)

(2)

AC (~) : 24V-115V-230V / 50 Hz (prefix CFSC)

~

(2)

1,5

(2)

1,9

SPECIFICATIONS

pipe

size

orifice

size

G (mm) (m3/h) (l/min) ~ = ~ = ~/= =

5/2 - Solenoid air pilot operated - spring return (monostable)

1/4 6 0,75 12,5 2 10 10

1/2 13 3,15 52,5 2 10 10

5/2 - Solenoid air pilot operated and return (bistable)

1/4 6 0,75 12,5 2 10 10

1/2 13 3,15 52,5 2 10 10

00093GB-2017/R01

Availability, design and specifications are subject to change without notice. All rights reserved.

flow

coefficient

Kv

860 3800

Type 05:

Type

07: M12 (CNOMO E03.62.520.N)

hot/cold

=

(2)

1,15/1,35

- -25 to +50

1,15/1,35

operating pressure

differential (bar)

min.

DIN 43650, 9,4 mm, form C

operator

ambient

temperature

range (TS)

-25 to +60 24-115 24

-25 to +60 - 24 07

voltage

~ =

(V) (V)

230 -

(3)

Supplied with LED indicator and

protection.

Configurator - CAD Files

power coil

max. (PS)

air (*)

(W)

1,1..1,5 1,2 CFSCG551C517 - MS MO -

- 1,35 - CFVTG551C517 MS MO -

1,1..1,5 1,2 CFSCG553A517 - MS MO -

- 1,35 - CFVTG553A517 MS MO -

1,1..1,5 1,2 CFSCG551C518 - MS MO -

- 1,35 - CFVTG551C518 MS MO -

1,1..1,5 1,2 CFSCG553A518 -

- 1,35 - CFVTG553A518 MS MO -

(1)

type

05

catalogue number options

connector

EN 175301-803 (9,4 mm)

(type 05) (type 07)

All leaflets are available on:www.asco.com

12

551 (prefix CFSC)

4

2

1

5

553 (prefix CFSC)

M12

3

maintained

MS MO -

5/2

Series

551

553

man. operator

impulse

man. operator

Pneumatic Valves (5/2) - 7

Page 4

SOLENOID VALVES SERIES 551-553

45

32

99

45

32

89

==

==

SPECIFICATIONS

operating pressure

differential (bar)

max. (PS)

min.

air (*)

power coil

(W)

connector

EN 175301-803 (9,4 mm)

(type 05) (type 07)

pipe

size

orifice

size

flow

coefficient

Kv

G (mm) (m3/h) (l/min) ~ = ~ = ~/= =

5/2 - Solenoid air pilot operated - spring return (monostable), certified IEC 61508 Functional Safety data

1/4 6 0,75 12,5 2 10 10

1/2 13 3,15 52,5 2 10 10

1,1..1,5 1,2 CFSCG551C517SL - - MO -

- 1,35 - CFVTG551C517SL - MO -

1,1..1,5 1,2 CFSCG553A517SL - - MO -

- 1,35 - CFVTG553A517SL - MO -

OPTIONS

• Explosionproof enclosures for use in zones 0/20-1/21-2/22, categories 1-2-3 to ATEX-Directive 2014/34/EU (www.asco.com)

• LED and protection, prefix CFSC, use TPL number: TPL 20674 (e.g.: TPL 20674 (e.g.: CFSCXG551C505TPL20674)

• Straight M12 connector: with 5 m cable length (catalogue number 88130212 )

• Supply rail (www.asco.com)

• Versions with spade-plug connector type ISO 15217/DIN 43650 form C with 8 mm spacing or with cable ends: contact us

• Other pipe connections are available on request

• Connector with visual indication and peak voltage suppression or with cable length of 2 m (www.asco.com)

INSTALLATION

• The valves can be mounted in any position without affecting operation

• It is necessary to connect pipes or fittings to the exhaust ports to protect the internal parts of the spool valve and its pneumatic

operator if used outside or in harsh environments (dusts, liquids etc.)

• IEC 61508 Functional Safety (suffix SL). Check temperature range of valve body and solenoid for suitability. For probability of

failure, contact us

• Threaded pipe connection is standard: G = G (ISO 228/1)

• Valves with suffix “SL” are supplied with specific exhaust protectors

• Installation/maintenance instructions are included with each valve

ACCESSORIES

series

551 G 1/4 34600419

553 G 1/2 34600479

551-553 M5 34600484

(1)

Supplied with suffix “SL”

pipe

size

DIMENSIONS (mm), WEIGHT (kg)

TYPE 05

Prefix "CFSC"

Polyarilamide

IEC 335 / IP65

DIN 43650, 9,4 mm

551

3

1

120

31,6

94,5

78,5

21,8

161,5

5

A

2

4

41

=

===

173

242

42

5

13

43

4

2

B

513

189

31,8

31,8

5 x 1/4

5 x 1/2

=

=

1

32

=

=

1

553

75

All leaflets are available on: www.asco.com

exhaust protector

(stainless steel)

74,6

27,5 59,8

90,2

40,251

72,3

(1)

(1)

(1)

Configurator - CAD Files

551

=

32

=

prefix

type

option

05 CFSC 0,36 1 0,41 2,08

07 CFVT 0,38 1,02 0,45 2,12

(2)

Prefix CFSC: including connector(s).

monostable bistable

551 553 551 553

ORDERING EXAMPLES:

prefix

pipe thread

basic number

3

1

110

21,8

162

weight

5

A

2

4

41

=

===

5 x 1/4

222

(2)

1

==

CFSC G 551 C 517 230V / 50 Hz

CFSC G 551 C 517 SL 115V / 50 Hz

CFSC G 553 A 517 SLMO 230V / 50 Hz

catalogue number options

CFVT G 553 A 518 MS 24V / DC

TYPE 07

Prefix "CFVT"

Polyarilamide

IEC 335 / IP67

M12

49,3

53,6

27,5

1

Manual operator location

2 mounting holes:

A 5,3 mm dia. (Spotfacing: 9 mm dia.,

depth 5 mm)

B 6,5 mm dia. (Spotfacing: 11 mm dia.,

depth 6 mm)

75

M12

maintained

man. operator

impulse

man. operator

voltage

suffix

553

1

5

31,6

94,5

78,5

4

513

161,5

4

189

2

13

31,8

43

31,8

2

B

5 x 1/2

40,251

79,2

72,3

00093GB-2018/R01

Availability, design and specifications are subject to change without notice. All rights reserved.

8 - Pneumatic Valves (5/2)

Loading...

Loading...