Asco 8215 Installation & Maintenance Instructions Manual

Installation & Maintenance Instructions

SERIES

2--WAY INTERNAL PILOT--OPERATED SOLENOID VALVES

NORMALLY CLOSED OPERATION -- 3/4I,1I,1--1/4I,1--1/2I OR 2I NPT

Positioning

IMPORTANT: See separate solenoid installation and

maintenance instructions for information on: Wiring,

Solenoid Temperature, Causes of Improper Operation, and

Coil Replacement.

DESCRIPTION

Series 8215 valves are 2--- way normally closed internal

pilot---operated solenoid valves. Valve bodies are made of

rugged aluminum with trim and internal parts made of steel

and sta inless steel. Series 8215 valves may be provided with

a general purpose or explosionproof solenoid enclosure.

OPERATION

Normally Closed: Valve is closed when solenoid is

de ---energized; open when energized.

Note: No minimum operating pressure differential

required.

INSTALLATION

CAUTION: Not all valves are approved for fuel gas

service. Check nameplate for correct catalog number,

pressure,voltage,frequency,andservice.Neverapply

incompatible fluids or exceed pressure rating of the valve.

Installation and valve maintenance to be performed by

qualified personnel.

Future Service Considerations

Provision should be made for performing seat leakage,

external leakage, and operational tests on the valve with a

nonhazardous, noncombustible fluid after disassembly and

reassembly.

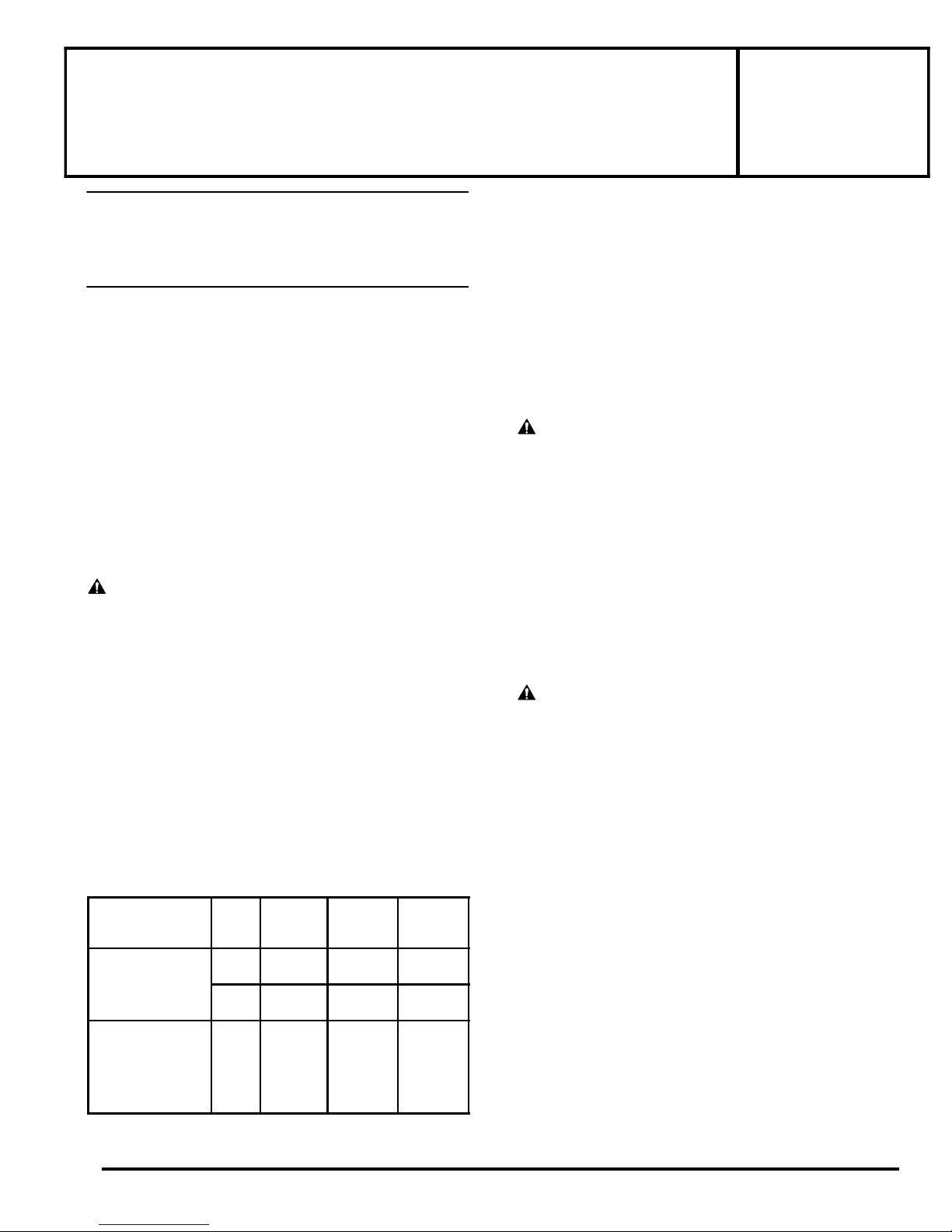

Temperature Limitations

For maximum valve ambient and fluid temperatures, refer

to chart below. Check catalog number prefix on nameplate

to determine maximum temperatures.

Valve must be mounted with solenoid vertical and upright.

Piping

Connect piping to valve according to markings on valve

body. Apply pipe compound sparingly to male pipe threads

only. Ifapplied to valvethreads the compoundmay enter the

valveandcauseoperationaldifficulty.Avoidpipestrainby

properly supporting and aligning piping. When tightening

thepipe,donotusevalveorsolenoidasalever.Locate

wrenches applied to valve body or piping as close as possible

to connection point.

CAUTION: To avoid damage to the valve body, DO NOT

OVERTIGHTEN PIPE CONNECTIONS. If Teflon* tape,

paste, spray or similar lubricant is used, use extra care when

tightening due to reduced friction.

IMPORTANT: To protect the solenoid valve, install a

strainer or filter, suitable forthe serviceinvolved, in the inlet

side as close to the valve as possible. Clean periodically

depending on service conditions. See ASCO Series 8600,

8601 and 8602 for strainers.

WARNING: T o prevent the possibility of

death, serious injury or property damage, turn off

electrical power, depressurize valve, extinguish all

open flames and avoid any type of sparking or

ignition. Vent hazardous or combustible fluid to a

safe area before servicing the valve.

NOTE: It is not necessary to remove the valve from the

pipeline for repairs.

8215

I&M No.V5996R6

MAINTENANCE

Catalog

Construction Coil

Class

AC Construction

DC Construction or or 77 77

ASCO Valves

EASCO Valve, Inc.R 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Number

Prefix

F FT 125 125

H HT 140 140

B None

H HT

R

Max.

Ambient

Tem p _F

Max.

Fluid

Tem p _F

Cleaning

All solenoid valves should be cleaned periodically. The time

between cleanings will vary depending on the medium and

service conditions. In general, if the voltage to the coil is

correct, sluggish valve operation, excessive noise or leakage

will indicate that cleaning is required. In the extreme case,

faulty valve operation will occur and the valve may fail to

open or close. Clean valve strainer or filter when cleaning

the valve.

*Dupont Co. Registered Trademark

Page 1 of 4

E209037--- 04/ 10

All Rights Reserved.

Preventive Maintenance

S Keep the medium flowing through the valve as free from

dirt and foreig n m aterial as possible

Periodic exercise of the valve should be considered if

S

ambient or fluid conditions are such that corrosion,

elastomer degradation, fluid contamination build up, or

other conditions that could impede solenoid valve

shifting are possible. The actual frequency of exercise

necessary will depend on specificoperating conditions. A

successful operating history is the best indication of a

proper interval between exercise cycles.

S Depending on the me dium and service c onditio ns, periodic

inspection of internal valv e parts for damage or excessiv e

wear is rec omm ended. Thoroughly clean all parts. If parts

are worn or damaged, install a complete rebuild kit.

.

Causes of Improper Operation

S Incorrect Pressure: Check valve pressure. Pressure to

valve must be within range specified on nameplate.

S Excessive Leakage: Disassemble valve and clean all

parts. If parts are worn or damaged, install a complete

ASCO Rebuild Kit.

Valve Disassembly

WARNING: To prevent the possibility of

death, serious injury or property damage, turn off

electrical power, depressurize valve, extinguish all

open flames and avoid any type of sparking or

ignition. Vent hazardous or combustible fluid to a

safe area before servicing the valve.

NOTE: Determine valveconstructionAC (Figure1 onpage

3) or DC (Figure 2 on page 4) then proceed as follows:

1. Remove solenoid enclosure, see separate installation

and maintenance instructions.

2. For AC Construction, unscrew solenoid base

sub--- assembly. For DC Construction, unscrew solenoid

base sub---assembly with special wrench adapter

provided in ASCO Rebuild Kit. For wrench adapter

only, order kit No.K218---949. NOTE: For alternate

type open end wrench, order kit No.K168---146---1

which is available for solenoid base sub---assembly

removal or replacement.

3. Remove bonnet screws, valve bonnet, bonnet gasket,

core/diaphragm sub --- assembly and body gasket.

4. All parts are now accessible to clean or replace. If parts

are worn or damaged, install a complete ASCORebuild

kit.

Valve Reassembly

1. Lubricate bonnet gasket and body gasket with a light

coat of DOW CORNINGr 200 Fluid lubricant or an

equivalent high---grade silicone fluid.

2. ApplyalightcoatofTFL50r Dry Lube to:

S Va l ve se at

S Valve body flange where diaphragm assembly

contacts the valve body and body gasket.

S Internal surface of valve bonnet where

diaphragm assembly contacts bonnet when

valve is in the energized (open position).

IMPORTANT: If valve has been disassembled for inspection

and cleaning only and a Rebuild Kit is not being installed,

lubricate the following with TFL 50r Dry Lube:

S Diaphragm assembly on both sides.

S Main disc base of core/diaphragm sub- --assembly.

S Pilotdiscatbaseofcoreassembly.

CAUTION: Do not distort hanger spring between core

assembly and diaphragm assembly when lubricating pilot

disc.

3. Replace body gasket and cor e/ diaph rag m sub--- assembly

with closing spring attached. Locate bleed hole in

core/diaphragm sub---assembly approximately 30_ from

the val v e inlet.

4. Replace valve bonnet and bonnet screws (6). Torque

screws in a crisscross manner to 100 ±10 in --- lbs [11,3

±1,1Nm].

5. For AC construction, replace bonnet gasket and

solenoid base sub---assembly. Torque solenoid base

sub--- assembly to 45 ± 5 ft --- lbs [61,1 ± 6,8 Nm] For DC

construction refer to separate “Solenoid Installation

and Maintenance Instructions” for lubrication

instructions; then install bonnet gasket, housing and

solenoid base sub---assembly. Torque solenoid base

sub--- assembly to 30 ± 5 ft --- lbs [40,7 ± 6,8 Nm].

6. Replace solenoid (see separate instructions) and make

electrical hookup.

WARNING: To prevent the possibility of death,

serious injury or property damage, check valve for

proper operation before returning to service. Also

perfor m internal seat and exte r n al leakage tests

with a nonhazardous, noncombustible fluid.

7. Restore line pressure and electrical power supply to

valve.

8. After maintenance is completed, operate the valve a

few times to be sure of proper operation. A metallic

click signifies the solenoid is operating.

ORDERING INFORMATION

FOR ASCO REBUILD KITS

Parts marked with an asterisk (*) in the

exploded views are supplied in Rebuild Kits.

D When Ordering Rebuild Kits for ASCO Valves,

order the Rebuild Kit number stamped on the valve

nameplate.

+ If the number of the kit is not visible, order by

indicating the number of kits required, and the Catalog

Number and Serial Number of the valve(s) for which they

are intended.

Page 2 of 4

EASCO Valve, Inc.R 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

I&M No.V5996R6

Loading...

Loading...