Page 1

Sentronic

Electronic Pressure Regulator

Installation Manual

PLUS

IO-Link CLASS A

Page 2

Sentronic

PLUS

INSTALLATION

MANUAL

ELECTRONIC

PRESSURE REGULATOR

ASCO NUMATICS™

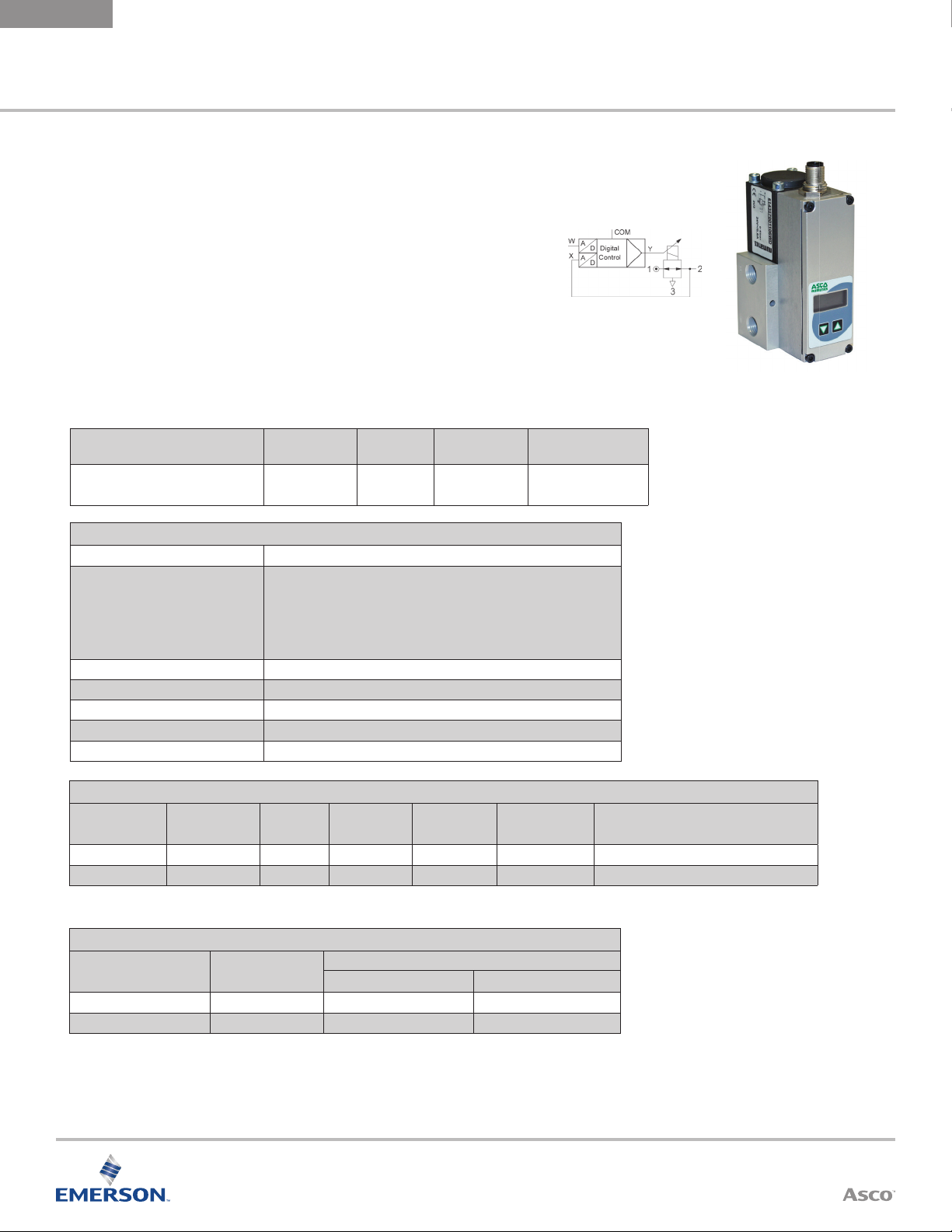

Sentronic

Sentronic

•

Direct operated valve

•

Dynamic behavior (high speed)

•

IO - Link CLASS A Version

•

RoHS, REACH compliant

Air or neutral gas, ltered at 50 µm,

condensate-free, lubricated or

PLUS

Electronic Pressure Regulator

PLUS

is a 3-way proportional valve with digital control.

Fluids

unlubricated

Ambient

Temperature

0 °C to 60 °C

(32 ºF to 140 ºF)

Aluminum

General Valve Information

Fluid Temperature 0 ºC to 60 ºC (32 °F to 140 °F)

PSI Pressure Ranges:

PA & PB (50 & 100 psi ranges): in digital steps of 0.01 psi

PC (150 psi range): in digital steps of 0.1 psi

Command Signal- IO-Link

Ports 1/8, 1/4 (NPT or GTap)

Construction Direct-operated Poppet Valve

Hysteresis 0.5% of span

Linearity/ pressure measurement ± 0.5% of span

Repeatability ± 0.5% of span

Bar Pressure Ranges:

40, 50, 60, V1, V2 & V3 (100mbar, 500mbar, 1bar & all vacuum): in digital

steps of 0.00 01 bar

All others: in digital steps of 0.001 bar

Body

Internal

Parts

Stainless steel

and brass

Seals

NBR (nitrile) and

FPM ( uoroelastomer)

2

Electrical Characteristics

Nominal

Diameter DN

(mm)

3 24 VDC = ± 10% 12 500 F IP65 5-pin M12 connector or 7-pin DIN connector

6 24 VDC = ± 10% 24

* Max. ripple: 10%

1

For DN6, b rass version G o r H/1.8A, 44W

Volt age *

Max.

Power (W)

1

Max. Current

(mA)

1

1000

Insulation

Class

F IP65 5-pin M12 connector or 7-pin DIN connector

Degree of

Protection

Electrical Connection

Specifi cations

Ø

Ports

1/8 NPT or GTap 3 0.21 (0.18) 210

1/4 NPT or GTap 6 0.70 (0.60) 700

Ø

Orifi ce DN

(mm)

Cv Flow Fac tor (K

Visit our website at ASCO.com or contact us at (800) 972-2726

Flow

Nm3/h) at 6 Bar ( l/min - A NR)

v

Page 3

ASCO NUMATICS™

How to Order

6 1 4 3 5 7 E 9 0 1 1 PB

Control Panel

B = IO-LINK with display

C = IO-Link without display

ELECTRONIC

PRESSURE REGULATOR

Options

A00 = Dual loop control

018 = Oxygen clean

Sentronic

PLUS

INSTALLATION

MANUAL

Version

0 = DN6 (G 1/4), ALU

4 = DN6 (NPT 1/4), ALU

7 = DN3 (G 1/8), Brass

8 = DN6 (G 1/4), Brass

9 = DN3 (NPT 1/8), Brass

A = DN6 (NPT 1/4), Brass

C = DN6 (G 1/4), Stainless Steel

Command Signal

B = IO-LINK CLASS A

Feedback

B = IO-LINK CLASS A

(ports)

, Body

Pressure Range

Output Pressure

(psi)

40 = 0 – 0.1 bar (1.5)

50 = 0 – 0.5 bar (7.3)

60 = 0 – 1 bar (14.5)

02 = 0 – 2 bar (29)

03 = 0 – 3 bar (44)

PA = 0 – 3.4 bar (50)

05 = 0 – 5 bar (73)

06 = 0 – 6 bar (87)

PB = 0 – 6.9 bar (100)

10 = 0 – 10 bar (145)

PC = 0 – 10.3 bar (150)

12 = 0 – 12 bar (174)

Digital Output

1 = Standard

Max. Inlet

Pressure

(psi)

2 (29)

2 (29)

2 (29)

3 (44)

8 (116)

8 (116)

8 (116)

12 (174)

12 (174)

12 (174)

12 (174)

14 (203)

Vacuum

(relative)

V1 = 0 to -1 bar

Shut-off valve,

connects to

vacuum on loss

of power

V2 = 0 to -1 bar

Bypass valve

V3 = 0 to -1 bar

Shut-off valve,

connects to

atmosphere on

loss of power

Absolute Pressure

Ranges Available

on Request

Operating Modes

Shut-o:

If the setpoint falls below 0.5 %, the coil current is switched o and the valve is fully exhausted.

Overtemperature:

If the temperature of the internal control electronics exceeds 100°C, the operating mode is switched to AUTOSAFE.

Undervoltage / overvoltage:

If the supply voltage is less than 18 V or more than 30 V, the coil current is switched o and the valve is fully

exhausted.

Autosafe:

If the coil current exceeds a certain value, dependent on the mechanics, for more than 20 seconds, the output

current is limited to max. 70% to prevent the valve from overheating.

Visit our website at ASCO.com or contact us at (800) 972-2726

3

Page 4

Sentronic

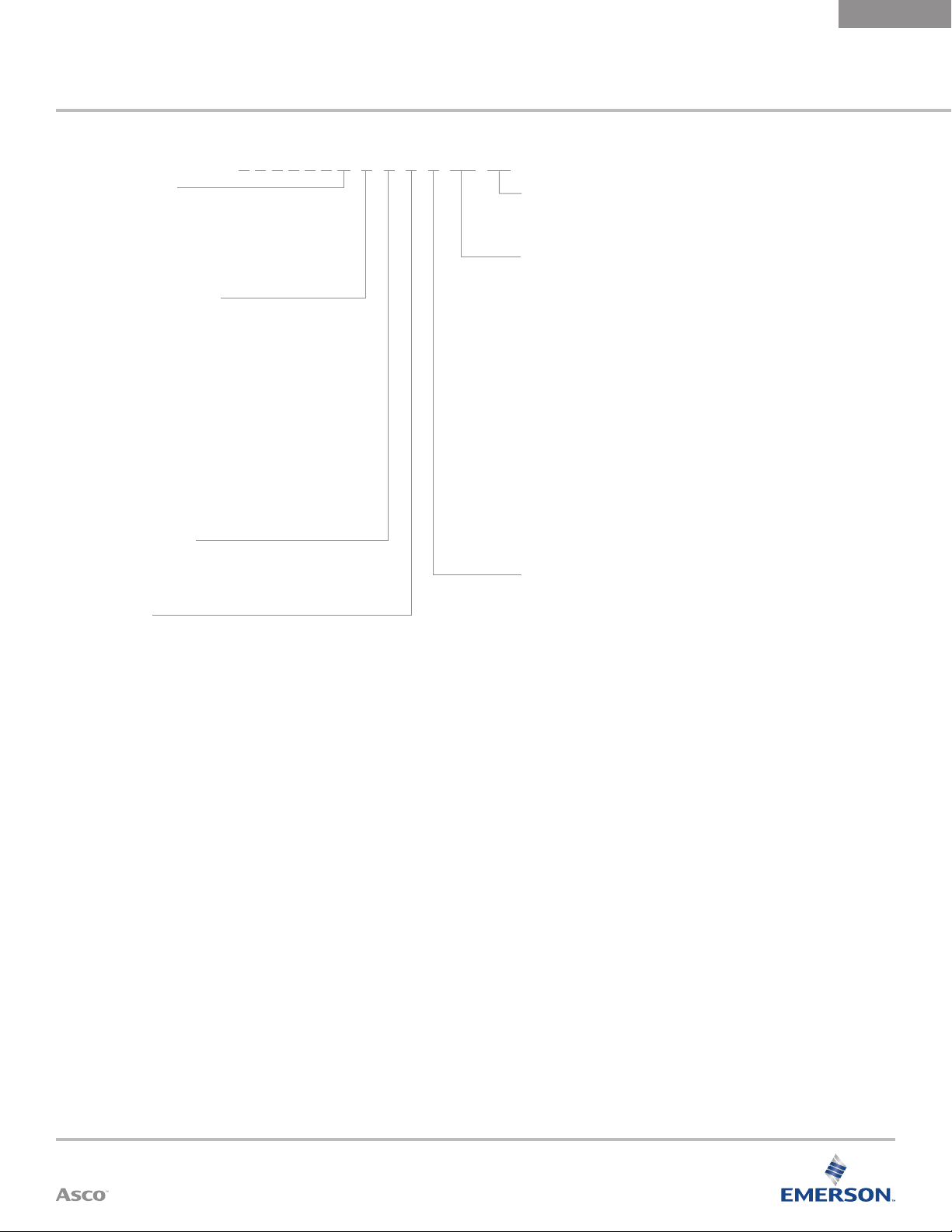

0.98 (25)

1.14 (29)

1.38 (35)

3.75 (95.2)

3.17 (80.5)

1.02 (26)

0.39 (10)

0.71 (18)

0.98 (25)

2xM4-10 deep

3.75 (95.2)

PLUS

INSTALLATION

MANUAL

Dimensions: Inches (mm), Weight in lbs. (kg)

1/8 NPT or GTap (DN3)

Weight: 1.21 (0.55)

ELECTRONIC

PRESSURE REGULATOR

PE (4-8 deep)

ASCO NUMATICS™

1/4 NPT or GTap

Weight: 1.87 (0.85)

3.17 (80.5)

4.52 (114.7)

4.15 (105.3)

2.18 (55.3)

1.02 (26)

0.39 (10)

1.78 (45.3)

0.43 (11)

0.98 (25)

1.14 (29)

1.38 (35)

1.38 (35)

1.69 (43)

2.05 (52)

2 x M4-10 deep

0.98 (25)

0.71 (18)

1.18 (30)

0.39 (10)

3 x 1/8"-8 deep

0.59 (15)

0.98 (25)

2.68 (68)

2.24 (57)

1.42 (36)

PE(4-8 deep)

1.02 (26)

3x1/4"-12 deep

A) Thread M5 - depth 10

(on opposite side);

tapped through-hole

for M4 screw.

4

Visit our website at ASCO.com or contact us at (800) 972-2726

Page 5

ASCO NUMATICS™

ELECTRONIC

PRESSURE REGULATOR

Connector Pin Out

Pin Description

1

2

4

5

3

M12 Class A & B Compatible Cables* and Accessories

1 +24 VDC Supply

2 not connected

3 +0 VDC Common (Supply)

4 C/Q

5 not connected

Body EMC shield

M12 Straight 5 Pin Female Single Ended Cable - Unshielded

TC0505MIE000071P – 5 Meter

TC0 510M IE 000 071P – 10 Mete r

Sentronic

PLUS

INSTALLATION

MANUAL

M12 Straight 5 Pin Female to Male Double Ended Cable - Unshielded

TC0505MIETA0571P – 5 Meter

TC0 510M IE TA0571P – 10 Mete r

M12 90° 5 Pin Female Single Ended Cable - Unshielded

TD0505MIE000071P – 5 Meter

TD 0510MIE0 00 071P – 10 Mete r

M12 90° 5 Pin Female to Male Double Ended Cable - Unshielded

TD0505MIETA0571P – 5 Meter

TD 0510MIETA0571P – 10 Meter

*Reference our G3 Fieldbus catalog for M12 4 pin cables if the selected IO-Link® Master does not

accept 5 pin cables. Maximum IO -Link c able length is 20 m.

Visit our website at ASCO.com or contact us at (800) 972-2726

5

Page 6

Sentronic

INSTALLATION

MANUAL

PLUS

ELECTRONIC

PRESSURE REGULATOR

ASCO NUMATICS™

Installation and Operating Instructions

1. Before putting into operation carefully check all electrical connections and the supply voltage (24 VDC ±10 %).

Overload can destroy the electronics. Recommended pre-fuse T2.0 A.

2. The electrical connection is made with a round connector M12x1. The connector must meet the requirements of

DIN 60079-15.

WARNING:

Do not disconnect the plug while under voltage!

When disconnected from power, use supplied protection cover to ensure IP protection.

3. Use unshielded or shielded cables for the electrical connection of the valve. The shield, connector and control

cabinet must be EMC compliant. The valve body must be electrically connected to ground (PE, machine ground).

Do not run control cables parallel to high-voltage lines or servo-motor control cables.

4. The cable length between the IO-Link master and the valve must not exceed 20m.

5. Make sure that the valve is under pressure when a setpoint signal is applied to the valve (applying a setpoint

signal with no pressure on the valve will cause it to overheat).

6. The valve is factory adjusted.

7. The product must be returned to the factory for repair.

Warning

These products are intended for use in industrial compressed air systems only. Do not use these products where

pressures and temperatures can exceed those listed under SPECIFICATIONS.

Before using these products with uids other than those specied, for non-industrial applications, life-support systems,

or other applications not within published specications, consult ASCO Numatics.

Through misuse, age, or malfunction, components used in uid power systems can fail in various modes.

The system designer is warned to consider the failure modes of all component parts used in uid power

systems and to provide adequate safeguards to prevent personal injury or damage to equipment in the

event of such failure.

System designers must provide a warning to end users in the operating manual if protection against a failure mode

cannot be adequately ensured.

System designers and end users are cautioned to review specic warnings found in instruction sheets packed and

shipped with these products.

6

Visit our website at ASCO.com or contact us at (800) 972-2726

Page 7

Global Contacts

Australia

(61) 2-9-4 51-7077

Brazil

(55) 11-4208-1700

Canada

(1) 519-758-2700

China

(86) 21-3395-0000

Czech Republic

Dubai - UAE

(420) 235-090-061

(971) 4-811-8200

ASCO (USA) | Tel (1) 888-686-2842 | an.insidesales@emerson.com | www.ASCO.com

France

(33) 2-37-24-42-24

Germany

India

Italy

Japan

Mexico

(49) 7237-9960

(91) 44-3919730 0

(39) 02-356931

(81) 798-65-6361

(52) 55-5809-5640

Netherlands

Singapore

South Korea

Spain

United Kingdom

(31) 33-277-7911

(65) 6556-1100

(82) 2-3483-1570

(34) 942-87-6100

(44) 1695-7136 00

4/19

Loading...

Loading...