Page 1

IntraChassis 9000

Ethernet Switch

User’s Manual

Page 2

Copyright Notice

All rights reserved. No part of this manual, or any associated artwork, software, product, design or design

concept, may be copied, reproduced or stored, in whole or in part, in any form or by any means mechanical, electronic, optical, photocopying, recording or any other wise, including translation to another language or format, without the express written consent of Asanté Technologies, Inc.

Trademarks

Asanté Technologies and NetStacker are trademarks of Asanté Technologies, Inc. Ethernet is a registered

trademark of the Xerox Corporation. A ll brand names and products are trademarks or registered trademarks of their respective holders.

FCC Information

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Operation of this equipment in a residential area is likely to cause interference, in which case, the user, at

his or her own risk and expense, will be required to correct the interference.

LIMITED FIVE YEAR WARRANTY

Subject to the limitations and exclusions below, Asanté warrants to the original end user purchaser that the

covered products will be free from defects in title, materials and manufacturing workmanship for a period

of five years from the date of purchase. This warranty excludes fans, power supplies, non-integrated software and accessories. Asanté warrants that the fans and power supplies will be free from defects in title,

materials and manufacturing workmanship for one year from date of purchase. Asanté warrants that nonintegrated software included with its products will be free from defects in title, materials, and workmanship

for a period of 90 days from date of purchase, and the Company will support such software for the purpose

for which it was intended for a period of 90 days from the date of purchase. This warranty expressly

excludes problems arising due to compatibility with other vendors products, or future compatibility due to

third party software or driver updates.

To take advantage of this warranty, you must contact Asanté for a return materials authorization (RMA)

number. The RMA number must be clearly written on the outside of the returned package. Product must

be sent to Asanté postage paid. In the event of a defect, Asanté will repair or replace defective product or

components with new, refurbished or equivalent product or components as deemed appropriate by Asanté.

The foregoing is your sole remedy, and Asanté's only obligation, with respect to any defect or non-conformity. Asanté makes no warranty with respect to accessories (including but not limited to cables, brackets

and fasteners) included with the covered product, nor to any discontinued product, i.e., product purchased

more than thirty days after Asanté has removed such product from its price list or discontinued shipments

of such product.

This warranty is exclusive and is limited to the original end user purchaser only. This warranty shall not

apply to secondhand products or to products that have been subjected to abuse, misuse, abnormal electrical

or environmental conditions, or any condition other than what can be considered normal use.

ASANTÉ MAKES NO OTHER WARRANTIES, EXPRESS, IMPLIED OR OTHERWISE, REGARDING THE

ASANTÉ PRODUCTS, EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW, ALL WARRANTIES OR

CONDITIONS OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. ASANTÉ’S LIABILITY ARISING FROM OR RELATING TO THE PURCHASE, USE OR INABILITY

TO USE THE PRODUCTS IS LIMITED TO A REFUND OF THE PURCHASE PRICE PAID. IN NO EVENT WILL

ASANTÉ BE LIABLE FOR INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES FOR THE

BREACH OF ANY EXPRESS OR IMPLIED WARRANTY, INCLUDING ECONOMIC LOSS, DAMAGE TO PROPERTY AND, TO THE EXTENT PERMITTED BY LAW, DAMAGES FOR PERSONAL INJURY, HOWEVER

CAUSED AND ON ANY THEORY OF LIABILITY (INCLUDING NEGLIGENCE). THESE LIMITATIONS SHALL

APPLY EVEN IF ASANTE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES OR IF THIS WARRANTY IS FOUND TO FAIL OF ITS ESSENTIAL PURPOSE.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an implied warranty lasts, so the above limitations or exclusions may not apply to you.

This warranty gives you specific legal rights, and you may have other rights, which vary from jurisdiction

to jurisdiction.

Page 3

Contents

1 Introduction ....................................................... 1-1

IntraCore Architecture Overview .................... 1-1

The Core Switching Engine ...................... 1-1

Infrastructure Connectivity ........................ 1-2

Network Management, Security, Performance, and

Control ...................................................... 1-2

The IntraCore Product Family ........................ 1-4

The IntraChassis 9000 ................................... 1-4

Modules ......................................................... 1-5

Network Management Module .................. 1-5

24-port 10/100 Switch Module .................. 1-6

2-port Gigabit Ethernet Switch Module ..... 1-6

Power Supply ........................................... 1-7

Features ......................................................... 1-8

Defaults and Specifications .......................... 1-10

LEDs ............................................................ 1-11

2 Installation and Set-up ..................................... 2-1

Installation Guidelines .................................... 2-1

Safety Information .................................... 2-1

Power Requirements ................................ 2-4

Environmental Requirements ................... 2-4

Cooling and Airflow ................................... 2-4

Installation Overview ...................................... 2-5

Rack Mounting/Desktop Placement ............... 2-5

Equipment Rack Installation of the Chassis 2-6

Free-Standing/Desktop Installation of the Chassis

2-8

Cable Guide Installation ........................... 2-8

Installing Modules .......................................... 2-9

Installing GBIC Interfaces ....................... 2-11

Page -iii

Page 4

Installing Second Power Supply ................... 2-11

Connecting Power ........................................ 2-11

Connecting to the Network ........................... 2-12

10/100BaseX Ports Cabling Procedures 2-12

1000BaseX Ports Cabling Procedures ...2-13

Configuring for Management ........................ 2-13

BootP Configuration ................................ 2-14

Connecting To a Console .......................2-15

Management Options ................................... 2-16

Out-of-Band Management ......................2-16

In-Band Management .............................2-17

Management Interface .................................2-18

Accessing a Submenu ............................ 2-19

Exiting a Submenu .................................. 2-19

General Information Screen ......................... 2-19

Accessing General Information ............... 2-19

Configuration Menu ...................................... 2-20

Logging into the Configuration Menu ...... 2-20

Configuration Menu Options ................... 2-21

3 Basic Configuration ........................................... 3-1

Basic Configuration Overview ........................ 3-1

System Administration Configuration ............. 3-2

Current Settings ........................................ 3-2

Changing System Administration Info ....... 3-3

System IP Configuration ................................. 3-3

Current Settings ........................................ 3-4

Changing System IP Information .............. 3-4

Bootstrap Configuration .................................. 3-5

Loading Software Locally .......................... 3-7

Loading Software Remotely ...................... 3-7

Current Settings ........................................ 3-9

SNMP Configuration ..................................... 3-11

Page iv

Page 5

Current Settings ...................................... 3-12

Changing Community Strings ................. 3-12

Enabling Authentication Traps ................ 3-13

Adding or Updating a Trap Receiver ...... 3-13

Deleting a Trap Receiver ........................ 3-13

Port Configuration ........................................ 3-14

Viewing Legends for Configuration Settings 3-16

Current Port Settings .............................. 3-17

Enabling or Disabling a Port ................... 3-17

Configuring Auto-negotiation .................. 3-18

Configuring a Port Manually ................... 3-19

Configuration of 1000BaseX ports ......... 3-20

Enabling or Disabling a Port ................... 3-20

Advanced Port Configuration ....................... 3-22

Advanced 10/100BaseTX Port Configuration 3-22

Current Settings ...................................... 3-22

Setting the Maximum Broadcast or Multicast Rate

3-23

Enabling or Disabling 802.3x Flow Control 3-24

Setting Port Default Priority .................... 3-24

Advanced 1000BaseX Port Configuration 3-26

Global Port Configuration ............................. 3-26

Unicast Forwarding Database Configuration 3-28

Current Settings ...................................... 3-30

Displaying the Forwarding Database ...... 3-30

Searching for a MAC Address ................ 3-36

Setting the MAC Address Age-Out Time 3-37

Image File Downloading Configuration ........ 3-37

Image Downloading Through TFTP ....... 3-38

Serial Downloading Configuration .......... 3-41

System Reset Configuration ........................ 3-44

Current Options ...................................... 3-44

Resetting the IntraChassis 9000 ............ 3-45

Scheduling a Reset ................................ 3-45

Page -v

Page 6

Viewing the System Log ............................... 3-46

Clearing the System Log ......................... 3-47

Viewing Current Operating Information ........ 3-48

User Interface Configuration ........................3-50

Current Settings ...................................... 3-50

Setting Console Idle Time-out Period ..... 3-51

Setting Telnet Idle Time-out Period ........3-51

Changing the Password .......................... 3-52

..................................................................... 3-52

4 Statistics ...........................................................4-1

Viewing Statistics ...........................................4-1

5 Advanced Management .................................... 5-1

Spanning Tree Protocol .................................. 5-1

Overview ................................................... 5-1

How It Works ............................................. 5-2

Enabling and Disabling STP ..................... 5-2

Configuring Spanning Tree Parameters ...5-2

Current STP Settings ................................ 5-5

Spanning Tree Port Configuration ............5-5

Setting Port Priority and Path Cost ........... 5-6

SNMP and RMON Management .................... 5-7

RMON Management ................................. 5-7

Security .......................................................... 5-8

Enabling and Disabling Duplicated-IP Detection 510

Enabling and Disabling Duplicated-IP Trap 5-10

Enabling and Disabling Station Movement Trap 510

Viewing a List of Duplicated-IP Addresses 5-11

Resetting Security to Defaults ................. 5-11

VLAN Management ...................................... 5-11

Page vi

Page 7

VLAN Specifications for the IntraChassis 9000 5-

12

Other VLAN Features in IntraChassis 9000 5-14

Abbreviations .......................................... 5-14

Default VLAN .......................................... 5-15

Port VLAN ID .......................................... 5-15

Port Admit Frame Type .......................... 5-16

Port Ingress Filtering .............................. 5-16

VLAN Port Membership and Untagging . 5-16

6 Web Browser Management .............................. 6-1

Accessing with a Web Browser ...................... 6-1

Management Buttons ..................................... 6-2

Front Panel Button ......................................... 6-3

Genl Info (General Information) Button .......... 6-5

Statistics Button ............................................. 6-6

Port Config (Port Configuration) Button ......... 6-9

Span Tree (Spanning Tree) Button .............. 6-10

SNMP Button ............................................... 6-11

Addr (Address) Table Button ....................... 6-12

VLAN Button ................................................ 6-13

Duplicate IP Button ...................................... 6-17

Contacting Technical Support ..................A-1

MIB Object Definitions for Counters ......... B-1

App. A Technical Support .................................. A-1

App. B MIB Statistics .......................................... B-1

Page -vii

Page 8

Page viii

Page 9

1

Introduction

This chapter introduces the IntraChassis 9000 architecture, then gives a

description of the chassis and the various modules that can be installed in it.

There are also tables of the key features, default settings, and specifications of

the IntraChassis 9000, and explanations of the different LED indicators used by

the various modules.

IntraCore Architecture Overview

Asanté has developed the IntraCore™ Architecture to meet the needs of multiservice networks that support all applications and data types. The architecture is

standards-based and provides

❑

multi-vendor inter operability

❑

a migration path from current systems

❑

investment protection

With the IntraCore Architecture, Asanté has found innovative ways of

embracing industry standards and technology advances to create products

capable of meeting real world requirements for converged, multi-service

networks.

The overall design incorporates a family of tightly integrated ASICs, designed as

system building blocks. These building blocks enable the rapid development of

advanced networking systems that are timed to meet market requirements. The

architecture ensures consistent high performance as systems scale their capacity

and feature capability. This approach extends the useful life of the system and

protects customer investments.

The Core Switching Engine

The Core Switching Engine is the centerpiece for all IntraCore products. Based

on advanced silicon ASICs, the Core Switching Engine is a high performance,

non-blocking, multi-gigabit switching fabric with scalable bandwidth capacity.

The Core Switching Engine is data format independent and can support either

frame or cell based interfaces. This capability is becoming increasingly

Page 1-1

Page 10

Introduction

important as enterprise (primarily frame-based) and service provider (primarily

cell-based) networks move closer together.

Infrastructure Connectivity

The second key element of the architecture is Infrastructure Connectivity.

IntraCore specifies standards based, high performance, cost effective

technologies for connectivity among devices in the network.

In the LAN –

At the network edge, Layer 2 switched 10/100/1000 Ethernet meets the

requirements for high-speed connectivity of desktop computers and scalable,

cost effective data transmission for trunks to the network core.

In the network core, Layer 2/3+-switched 10/100/1000 Ethernet meets the

requirements for high speed, scalable, cost effective data transmission and

support for all multi-service data types. High performance servers can be

centrally located for added physical security.

Throughout the LAN, advanced queuing techniques combined with multiple

priority levels and support for industry standard 802.1Q and 802.1p enable

Quality of Service within the network.

In the MAN/WAN –

Long haul Gigabit Ethernet, ATM, and Packet over SONET meet the

requirements for all of the following:

❑

scalable, cost effective data transmission

❑

support for all multi-service data types

❑

service provider inter operability

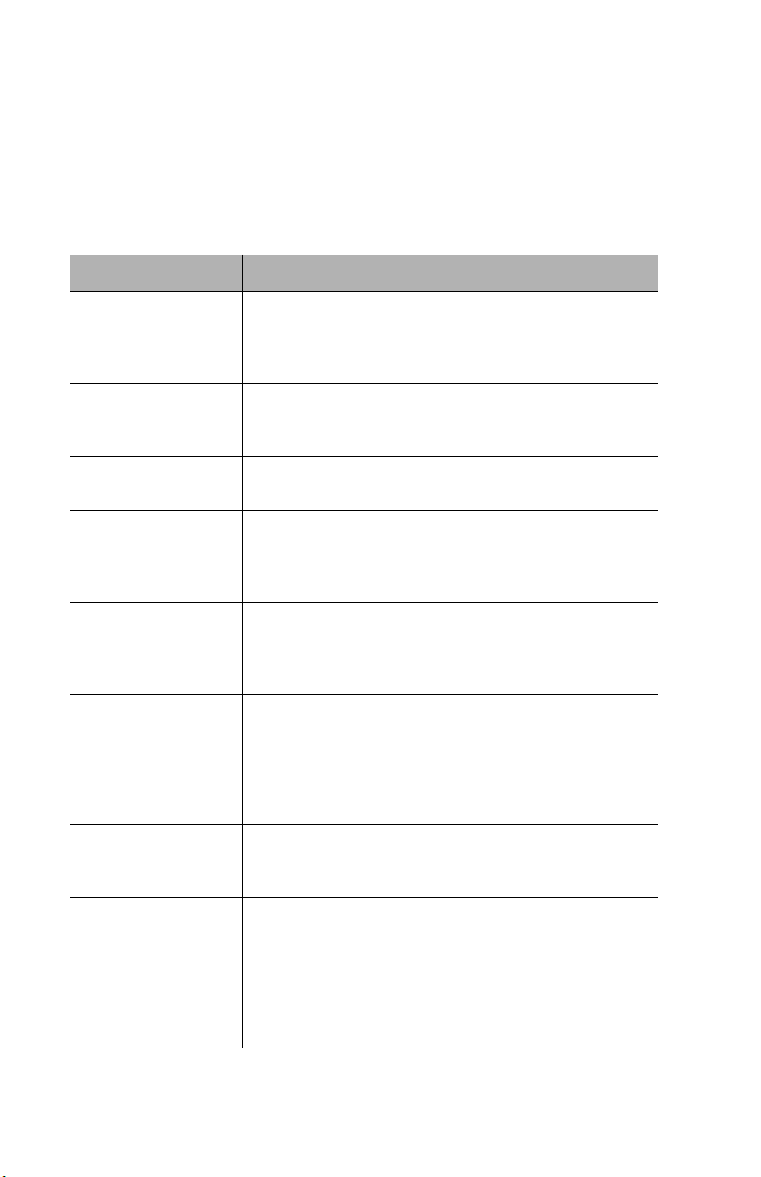

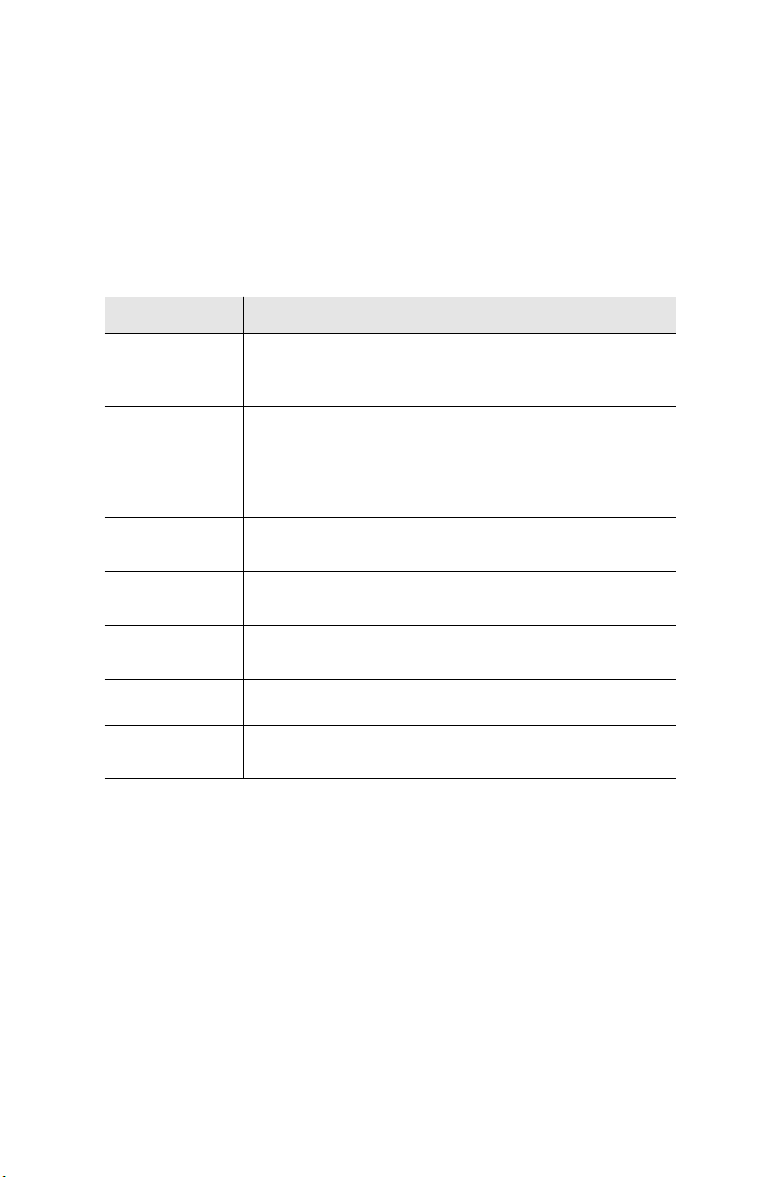

Network Management, Security, Performance, and Control

IntraCore includes a rich suite of features required for the effective

management, security, performance and control of the network. The following

table illustrates the features and standards supported as part of this section of

the overall architecture.

Page 1-2

Page 11

IntraCore Architecture Overview

Feature

Web Browser Management

SNMP, RMON

Standard MIsS

802.1P Priority

802.1Q VLAN Tagging

802.1D – Spanning Tree

IGMP V1, V2 Snooping

RSVP Snooping

GARP Multicast Registration

Duplicate IP addr. detection

Station movement notification

IP to MAC address binding

Controlled management

access

GVRP (Group VLAN Registration Protocol)

Advanced Port Configuration: Broadcast & Multicast

rate limit & port priority

Manage-

ment

Supported

Supported Supported Supported

Supported Supported Supported

Supported Supported Supported

Supported Supported

Supported Supported

Supported Supported

Supported Supported Supported

Supported Supported Supported

Security

Supported Supported Supported

Supported

Performance

Supported Supported

Supported Supported

Supported Supported

Supported Supported

Control

Policy management: IntServ

(RSVP), DiffServ, COPS

Directory services: DNS,

DHCP, LDAP

Table 1-1 Summary of IntraCore’s supported features

Supported Supported Supported Supported

Supported Supported Supported Supported

Page 1-3

Page 12

Introduction

The IntraCore Product Family

The Asanté IntraCore architecture is the basis for a family of switching system

products in fixed, stackable and chassis form factors that allow customers to

integrate telephony, video and data applications. Initially two systems will be

offered that provide high performance, high port count Layer 2 switching.

Additional configurations will be introduced to offer advanced Layer 3 and

above routing, traffic classification, advanced QoS, higher bandwidth and port

capacity. All systems will be consistent in their operation and management

allowing customers to seamlessly deploy any model in their network.

Edge Switches

Providing the first point of connectivity to the network are the Edge Switches.

These connect to an Enterprise switch in the network core and provide

aggregation of traffic from desktop computers over high capacity trunks. The

initial product introduced in the Edge Switch category is the IntraStack 8000.

The IntraStack 8000 is a stackable, high performance solution for enterprise

edge applications. Each stack supports up to 192 10/100Mbps switched

Ethernet connections for cost-effective high-density connectivity in wiring

closets. The system can operate as a stand-alone network or be used in

combination with IntraChassis 9000 in the backbone.

Enterprise Switches

In the network core, Enterprise Switches are deployed to aggregate traffic from

wiring closets and provide high-speed connectivity to network servers. Typically

these switches are modular in form factor, and can be easily upgraded or

reconfigured. This flexibility provides for customized configurations to meet a

wide variety of requirements. The initial product introduced in this category is

the IntraChassis 9000.

The IntraChassis 9000

The IntraChassis 9000 is a chassis based modular Gigabit Ethernet enterprise

switch designed for either high density wiring closets or as the core of the

network backbone. The system can support up to 192 10/100Mbps switched

Ethernet or 16 switched Gigabit Ethernet connections. System modules offer

choice in media and connector types to best suit existing wiring infrastructure

systems.

Page 1-4

Page 13

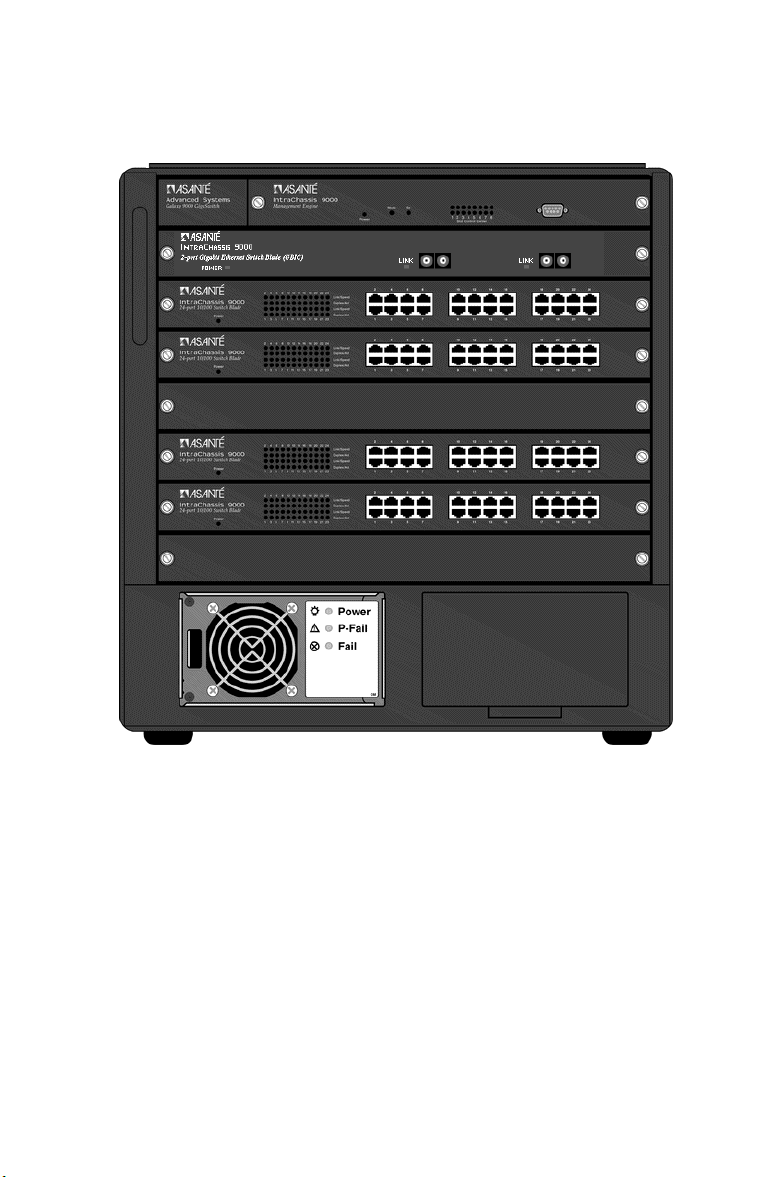

Modules

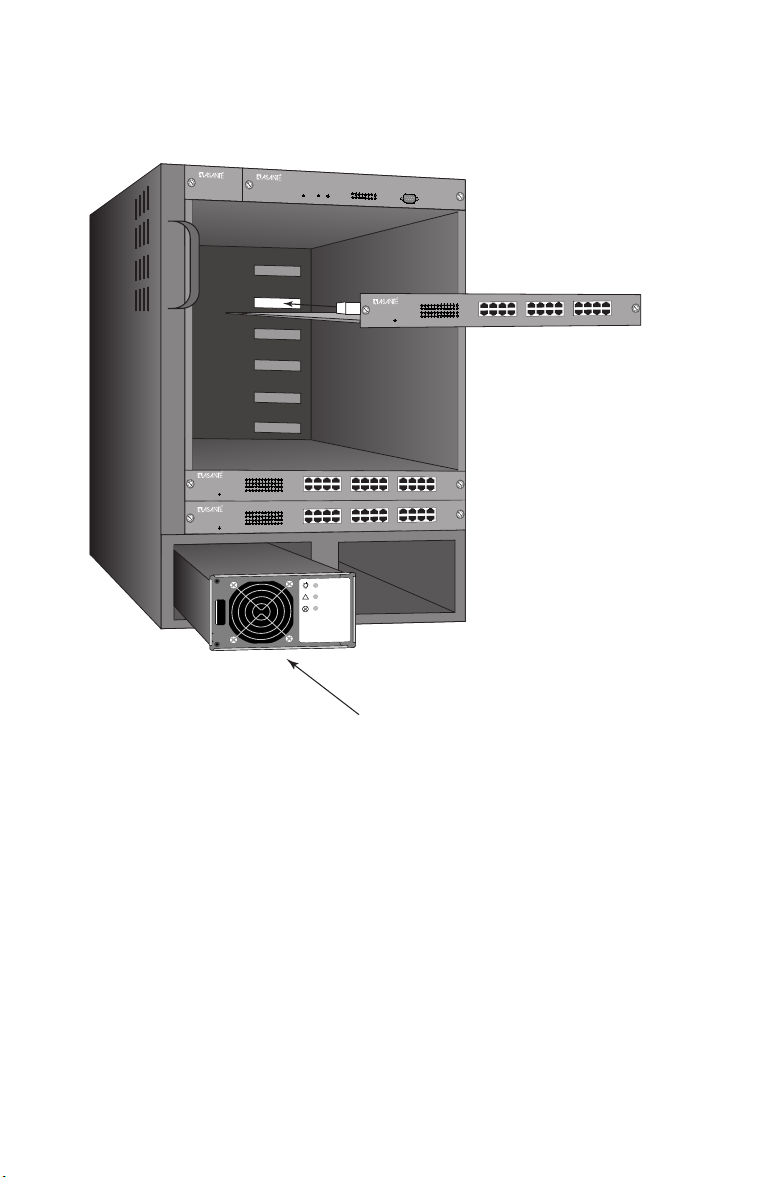

Figure 1-1 IntraChassis 9000 Front Panels

Modules

The following modules can be installed in the IntraChassis 9000 chassis.

Network Management Module

This module is included with the IntraChassis 9000 chassis, and provides

management for it and all other modules you install. It occupies one slot, and

has a single DB-9 port for the console. The module supports Telnet and Web

Page 1-5

Page 14

Introduction

Browser management via industry standard SNMP with support for MIB II,

RMON (four groups), Bridge MIB, and Asanté private MIBs.

Figure 1-2 Management Module

24-port 10/100 Switch Module

This module provides 24 ports supporting switched 100BaseTX or 10BaseT

per port. Each module occupies a single slot and has either 24 RJ-45

connectors, or 2 RJ-21 connectors.

Figure 1-3 24-port 10/100 Switch Module

2-port Gigabit Ethernet Switch Module

This module provides slots for two switched Gigabit Ethernet ports. Each

module occupies a single slot and has 2 GBIC interfaces, which accept Asanté

or third party GBIC interfaces. The following subsections describe the possible

GBIC interfaces.

Figure 1-4 2-port Gigabit Ethernet Switch Module

1000Base SX GBIC

This module provides a GBIC interface with SC-type fiber connectors. The

interface supports 62.5 and 50 micron multimode fiber media. The 62.5

micron multimode fiber can be up to 260 meters long, and the 50 micron

multimode fiber can be up to 525 meters long.

Page 1-6

Page 15

Modules

1000BaseLX Long Haul GBIC

This module provides a GBIC interface for SC-type fiber connectors. The

interface supports 10 micron single mode fiber for distances up to 100

kilometers.

1000BaseLX GBIC

This module provides a GBIC interface for SC-type fiber connectors. The

interface supports 10 micron single mode fiber for distances up to 3 kilometers.

Power Supply

One Power Supply is provided with the IntraChassis 9000. A second Power

Supply can be added to provide additional power and redundancy for the other

modules.

Figure 1-5 Power Supply

Page 1-7

Page 16

Introduction

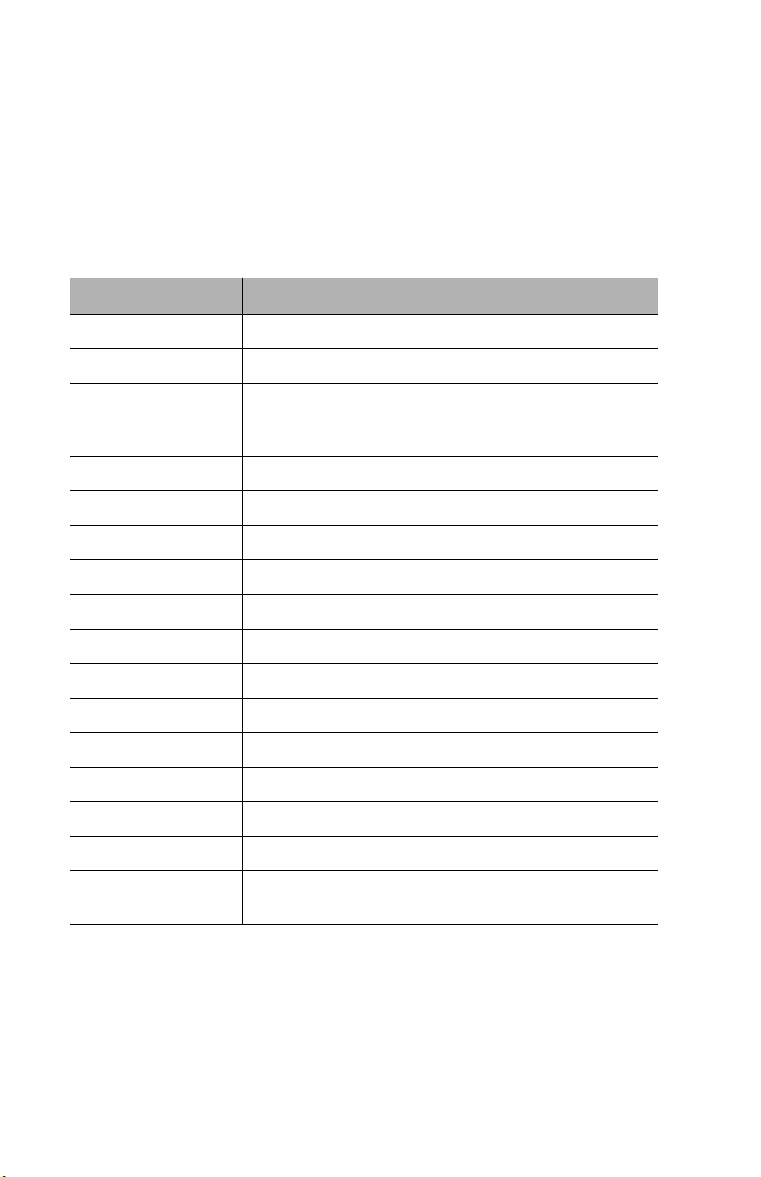

Features

The following table lists the major features of the IntraChassis 9000 switch.

Feature

Media Flexibility Expansion module options include 24-port 10/100 Base-TX

High Density Supports up to 192 10/100 switched Ethernet ports or up to 16

ASIC-Based Architecture ASIC-based packet processing provides wire speed performance

High Performance

16Gbps Backplane

Multiple Priority Queues The “application aware” system ensures that mission critical appli-

Chassis Based Form Factor

Configuration Flexibility and Growth

switched Ethernet modules, 2-port Gigabit Ethernet modules

with GBIC slots, and 24-port 10/100 Base-TX switched Ethernet

RJ-21 modules for compatibility with existing wiring.

switched Gigabit Ethernet ports in a single chassis. This saves

space in crowded equipment rooms.

on all interfaces.

The system supports current requirements for multi-service voice,

video, and data applications with bandwidth to spare. The highcapacity backplane is designed so that it may be scaled up to

128Gbps, extending the useful life of the chassis.

cations get the bandwidth and priority they need, even under

heavy traffic conditions. Low latency requirements are managed

by the system when network congestion occurs.

The nine slot modular chassis allows configuration flexibility and

cost effective network expansion. A wide variety of switched 10/

100/1000 Ethernet interfaces are supported, with flexible media

options to meet all network requirements. The IntraChassis 9000

can be configured as a high-density switch for campus wiring closets, or a high-capacity switch for Gigabit Ethernet backbones.

Expansion modules can be mixed and matched in any configuration and quantity to meet design requirements. You can add

capacity only when your business requires it.

Description

GBIC Modules for Gigabit Ethernet Media Flexibility

Page 1-8

The two GBIC Gigabit Ethernet modules can be configured with

any combination of 1000SX, 1000LX or 1000LX (Long Haul)

GBIC interfaces. Either Asanté or third party GBIC interfaces can

be used, and the interfaces can be “hot swapped.” This means that

GBIC interfaces can be re-deployed if equipment is retired.

Page 17

Feature (Cont.) Definition (Continued)

Features

Reliability and Redundancy

Installation Options The system can be rack-mounted to save space.

Security Node summary tracks MAC and IP addresses per device, for mul-

Web Based Management Built-in Web-based interface is provided for chassis management,

VLANs Supports up to 64 port-based VLANs (IEEE 802.1Q compliant)

Multicast Control The IntraChassis 9000 supports standards based IGMP snooping

RMON The administrator can use a RMON probe for in-depth traffic

For maximum uptime and minimum network disruption, the

interface and management modules are hot-swappable. Configuration options include support for up to two load-sharing, hotswappable power supplies.

tiple devices on each port. The New Node Detection feature provides per-port security, allowing the network manager to specify

which MAC is authorized on each port. Only the device with that

MAC address is allowed to connect to that specific port.

module management, port-level control, and monitoring. The

IntraChassis 9000 can also be managed via Telnet, Console, or

third party SNMP console.

for security, logical network design, and the control of broadcast

traffic. The 802.1Q standard specifies VLAN tagging for trunking

VLANs from switch to switch, or switch to router. Compatible

with all 802.1Q equipment for easy integration into existing networks.

and GMRP for control of multicast traffic generated by bandwidth-hungry applications like video, ensuring maximum application and network performance.

analysis, with support for four groups of RMON.

Spanning Tree Protocol Spanning Tree Protocol (STP) detects and eliminates data loops to

Y2K compliance All IntraChassis 9000 modules are Y2K compliant.

prevent broadcast storms from overwhelming your network.

Table 1-2 IntraChassis 9000 Features

Page 1-9

Page 18

Introduction

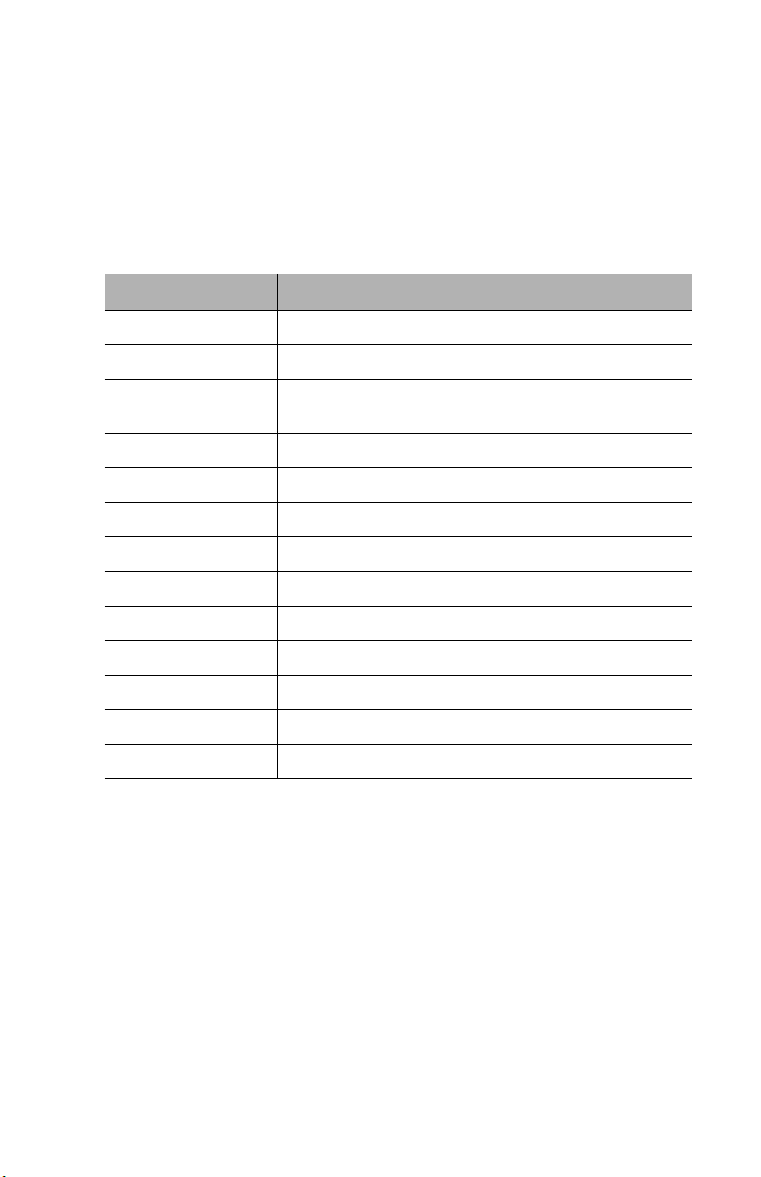

Defaults and Specifications

The IntraChassis 9000 is shipped with the following factory default settings

and specifications:

Configuration

Backplane Speed 32Gbps.

Switching Method Store-and-forward

Forwarding Rates:

(64 byte packets)

Buffer Size 4MB

MAC Address Table 8K

Full-Duplex Standards based Auto-negotiation enabled

VLAN 64 port based VLANs, GVRP support, 802.1Q VLAN Tagging

Spanning Tree Protocol 802.1D, enabled

Flood Rate Limiting Broadcast traffic

Priority 802.1Q, 8 levels mapped to 4 Queues

RMON Groups 1-3, 9

SNMP MIB-II, Bridge MIB, RMON MIB, Asanté private MIBs

Console Baud Rate 9600

Password Asanté

Power Requirements 90 - 224 V, 50 - 60 Hz

Switched 10Mbps = 14,880 pps

Switched 100Mbps = 148,810 pps

Switched 1000Mbps = 1,488,100 pps

Default Setting

Environmental Operating Range

Page 1-10

Temperature: 0° - 45° C (Storage: -40° - 85° C)

Relative Humidity: 5% - 95% non-condensing

Table 1-3 Defaults and Specifications

Page 19

LEDs

The following indicator lights are used on the various modules of the

IntraChassis 9000.

LEDs

LED

Management Module

Power Green - Power is on when lit

Slot Control Center Green - upper row - For future functionality

Green - lower row - Module is installed in this slot.

Gigabit Switch (GBIC)

Power Green - Power is on when lit

Link Green - connection and link has been made.

24-port 10/100 Switch

Link/Speed Green - Link at 100Mbps Amber - Link at 10Mbps

Duplex/Activity Green -Full Duplex Amber - Half Duplex Blinking - Active

Power Module

Power Green - Power is available to IntraChassis 9000

P-Fail Amber - Power is not available to module

Fail Amber - Power module is not delivering power

Color and Meaning

Table 1-4 LEDs and their meanings

Page 1-11

Page 20

Introduction

Page 1-12

Page 21

2

Installation and Set-up

This chapter explains how to install, connect, and configure the IntraChassis

9000 chassis and modules to work with your network. It also explains how to

set up your IntraChassis 9000 for management, either from a console, via

telnet, via SNMP, or by using a Web browser.

Installation Guidelines

The following guidelines will help you prepare to install your IntraChassis 9000

in such a way that it has the proper power supply and environment.

Safety Information

The following sections provide guidelines and procedures to help you install

and use the IntraChassis 9000 safely.

Safety First

Use the following guidelines to ensure your safety and protect the equipment.

This list is not inclusive of all potentially hazardous situations that you may be

exposed to as you install the switch, so

❑

Never try to lift an IntraChassis 9000 chassis by yourself; two people

are required to lift these switches.

❑

Always unplug all power cords before installing or removing a chassis

or removing the chassis front panel.

❑

Keep the chassis area clear and free of dust during and after installation.

❑

Keep tools and chassis components off the floor and away from foot

traffic.

❑

Avoid wearing jewelry (including rings and chains) or other items

that could get caught in the chassis. Avoid wearing any loose clothing

or securely fasten items such as ties, scarves, or sleeves.

❑

Install the system in compliance with the following local and national

electrical codes:

be alert

.

Page 2-1

Page 22

Installation and Set-up

❑

United States—National Fire Protection Association

(NFPA 70); United States National Electrical Code

❑

Canada—Canadian Electrical Code, Part I, CSA C22.1

❑

Other countries—International Electrotechnical Com-

mission (IEC) 364, Part 1 through Part 7

▲

Important:

Take the following precautions when installing

the IntraChassis 9000:

Only trained and qualified personnel should be allowed to

install or replace this equipment.

This equipment is to be installed and maintained by service

personnel only as defined by AS/NZS 3260 Clause 1.2.14.3

Service Personnel.

Before working on equipment that is connected to power

lines, remove jewelry (including rings, necklaces, and

watches). Metal objects will heat up when connected to

power and ground and can cause serious burns or weld the

metal object to the terminals.

Unplug the power cord before you work on a system that

does not have an on/off switch.

Before installing the IntraChassis 9000, unplug the power

cord.

Do not work on the system or connect or disconnect cables

during periods of lightning activity.

Do not touch the power supply when the power cord is

connected. Line voltages are present within the power supply when the power cord is connected.

Read the installation instructions before you connect the

system to its power source.

This unit might have more than one power cord. To reduce

the risk of electric shock, disconnect the two power supply

cords before servicing the unit.

Do not stack the chassis on any other equipment. If the

chassis falls, it can cause severe bodily injury and equipment

damage.

Page 2-2

Page 23

Installation Guidelines

Lifting the Chassis Safely

The IntraChassis 9000 is not intended to be moved frequently. Before you

install the switch, ensure that your site is properly prepared so that you can

avoid moving the chassis later to accommodate power sources and network

connections.

Two people are required to lift the IntraChassis 9000. Whenever you lift the

chassis or any heavy object, follow these guidelines:

❑

Never attempt to lift a chassis by yourself. The size and weight of a

chassis requires two people to safely lift and move it without causing

injury or damaging the equipment.

❑

Ensure that your footing is solid, and balance the weight of the chassis between your feet.

❑

Lift the IntraChassis 9000 slowly; never move suddenly or twist your

body as you lift.

❑

Keep your back straight and lift with your legs, not your back. If you

must bend down to lift the chassis, bend at the knees, not at the

waist, to reduce the strain on your lower back muscles.

❑

Leave all switch and power modules in place once they are properly

installed.

❑ Always disconnect all external cables before lifting or moving the

chassis.

Safety With Electricity

The secondary power supply is designed to be removed and replaced while the

system is operating without presenting an electrical hazard or damage to the

system. Before removing a redundant power supply, ensure that the other power

supply is turned on.

Follow these basic guidelines when working with any electrical equipment:

❑ Before beginning any procedures requiring access to the chassis inte-

rior, locate the emergency power-off switch for the room in which

you are working.

❑ Disconnect all power and external cables before installing or remov-

ing a chassis.

❑ Do not work alone when potentially hazardous conditions exist.

❑ Never assume that power has been disconnected from a circuit;

Page 2-3

Page 24

Installation and Set-up

always check.

❑ Do not perform any action that creates a potential hazard to people

or makes the equipment unsafe.

❑ Carefully examine your work area for possible hazards such as moist

floors, ungrounded power extension cables, and missing safety

grounds.

❑ Never install telephone jacks in wet locations unless the jack is specif-

ically designed for wet locations.

❑ Never touch uninsulated telephone wires or terminals unless the tele-

phone line has been disconnected at the network interface.

❑ Never touch uninsulated telephone wires or terminals unless the tele-

phone line has been disconnected at the network interface.

Power Requirements

The source electrical outlet should be installed near the IntraChassis 9000 and

easily accessible. It must also be properly grounded.

Make sure the power source adheres to the following guidelines:

❑ Voltage range: 100 to 240 VAC

❑ Frequency range: 60/50 Hz

❑ Maximum current: 10 A per power supply at 110 volts

Environmental Requirements

The IntraChassis 9000 must be installed in a clean, dry, dust-free area with

adequate air circulation to maintain the following environmental limits:

❑ Temperature: 0° to 40° C (32° to 104° F)104°

❑ Relative Humidity: 5% to 85% non-condensing

Avoid direct sunlight, heat sources, or areas with high levels of electromagnetic

interference.

Cooling and Airflow

Do not restrict air flow by covering or obstructing air vents on the sides of the

chassis.

Page 2-4

Page 25

Installation Overview

Installation Overview

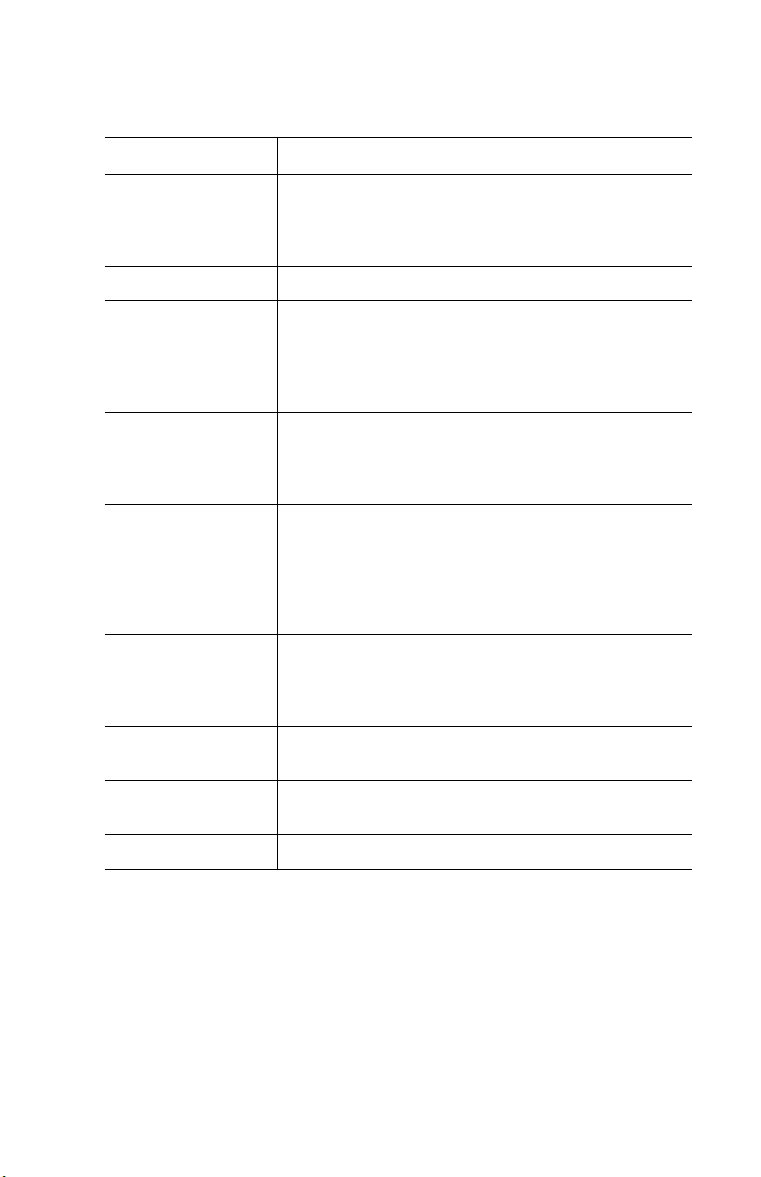

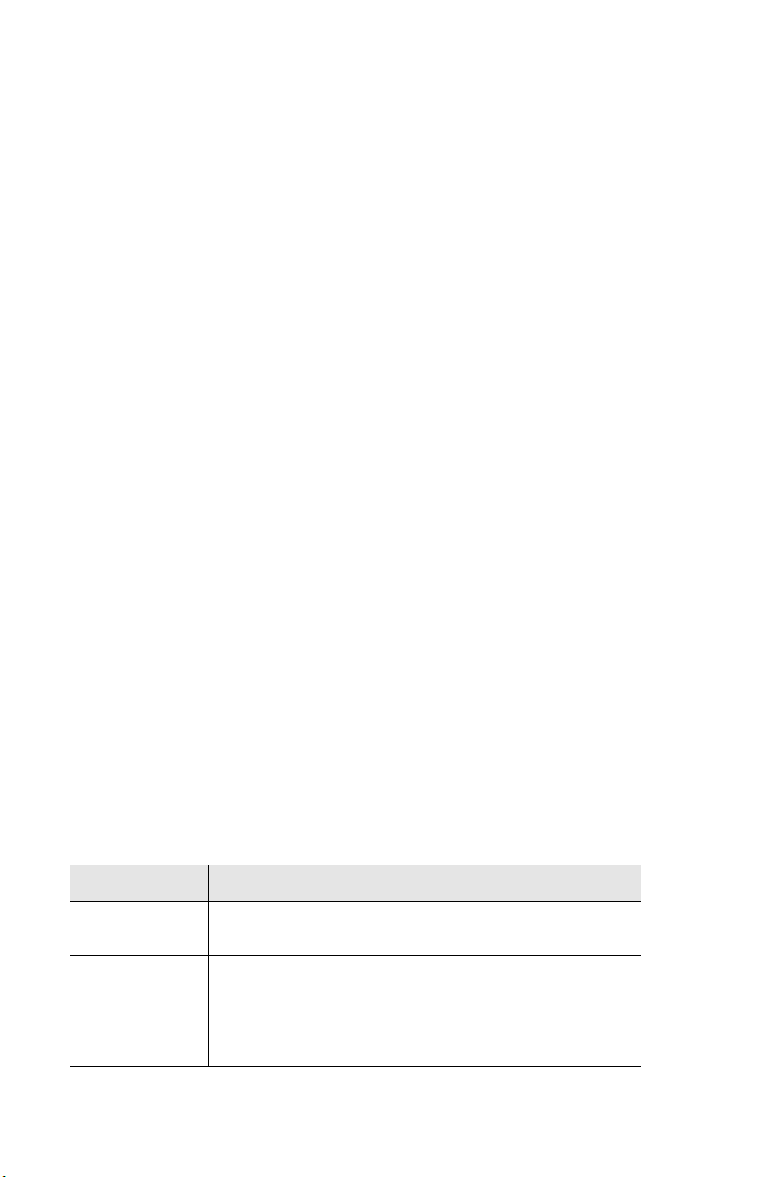

The table below describes the steps needed to install the IntraChassis 9000. The

steps that are optional are labeled “optional” and the steps that are required are

labeled “required.” The sections that follow explain each step in detail.

Step Action to Be Taken

1(Required)

2(Required)

3(Required)

4(Optional)

5(Required)

6(Required)

7(Required)

Open the box and check the contents.

See the Package Contents sheet for a complete list of the items

included with your IntraChassis 9000.

Install the IntraChassis 9000 chassis in an equipment rack or wall

rack, or prepare it for desktop placement. See page 2-5.

Important! When fully loaded, the IntraChassis 9000 can weigh

over 100 lbs (45 Kg). Use proper lifting equipment and techniques to prevent back and other injuries.

Install the modules you have purchased for your IntraChassis 9000

and ensure each is properly seated and locked in place. See page 2-9.

Install a second power supply module and make sure it is properly

seated in the chassis. See page 2-11.

Connect the power supply or power supplies.

See page 2-11.

Connect the modules to your network cables. See page 2-12.

Configure the IntraChassis 9000 for management capabilities.

See page 2-13.

Table 2-1 Installation Overview

Rack Mounting/Desktop Placement

The IntraChassis 9000 chassis can be installed in a standard 19-inch equipment

rack. It can also be placed on a stable horizontal surface with support

capabilities of 150 pounds (68.2 kilograms).

▲ Important: The equipment rack or desk on which you

install your IntraChassis 9000 must be secure and stable.

Equipment racks must be fastened to the floor; desks must

be resting on a flat, stable surface.

Page 2-5

Page 26

Installation and Set-up

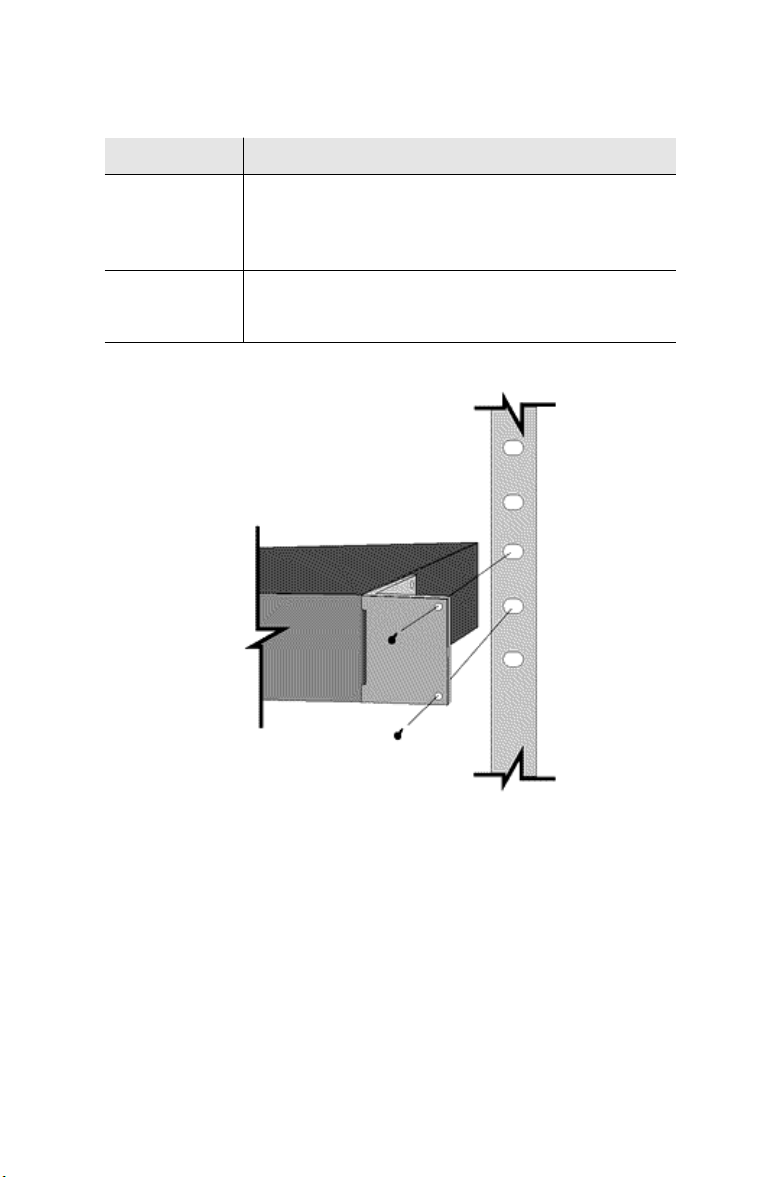

Equipment Rack Installation of the Chassis

To install the unit in an equipment rack, use the following procedure. Refer to

Figure 2-1 below.

Safety Precautions for Rack Installation

▲ Important! Disconnect all cables from the IntraChassis

9000 before continuing. Also, do not install the modules

you have purchased until the chassis has been installed in

the rack. This will reduce the weight of the chassis during

rack installation.

▲ Important! Before installing the chassis in a rack, read the

“Safety Information” section earlier in this chapter to familiarize yourself with the proper site and environmental conditions. Failure to read and follow these guidelines could

lead to an unsuccessful installation and possible damage to

the system and components.

▲ Important! To prevent bodily injury when mounting or

servicing this unit in a rack, you must take special precautions to ensure that the system remains stable. The following guidelines are provided to ensure your safety:

❑ This unit should be mounted at the bottom of the rack

if it is the only unit in the rack.

❑ When mounting this unit in a partially filled rack, load

the rack from the bottom to the top with the heaviest

component at the bottom of the rack.

Rack Guidelines

Guideline Specification

Size Width; 17.75 inches (45.09 cm).

Stability Rack must be bolted to the floor. Mount heavier units at the bottom

Page 2-6

Depth: 19.25 inches (48.9 cm) to 32 inches (81.3 cm).

of the rack, and mount the IntraChassis 9000 at the bottom of the

rack if it is the only unit mounted; this will ensure that the rack does

not become top-heavy. If the rack has stabilizing devices, make sure

they are installed before mounting the IntraChassis 9000.

Page 27

Rack Mounting/Desktop Placement

Guideline Specification

Ventilation Ensure that the rack is installed in a room where the temperature

remains below 40

obstructions, such as other equipment or cables, blocking airflow to

or from the IntraChassis 9000 vents.

° C (104° F). Ensure also that there are no

Clearance In addition to providing clearance for ventilation, ensure that there is

Figure 2-1 Mounting rack bracket on the IntraChassis 9000 chassis

adequate clearance for servicing the modules of the IntraChassis 9000

from the front.

1 Place the IntraChassis 9000 chassis on a flat, stable surface.

2 Locate a rack-mounting bracket (supplied) and place it over

the mounting holes on one side of the unit.

3 Insert five screws (supplied) into the holes and tighten with

a Phillips screwdriver. Do not use less than six screws for

this mounting.

4 Repeat the two previous steps for the unit’s other side.

Page 2-7

Page 28

Installation and Set-up

5 Place the unit in the equipment rack.

▲ Important! When fully loaded, the IntraChassis 9000

can weigh over 100 lbs. Use proper lifting equipment

and techniques, as described in “Lifting the Chassis

Safely” earlier in this chapter, to prevent back and other

injuries.

6 Secure the unit by screwing its mounting brackets to the

equipment rack. Use a minimum of six {right?} screws for

this purpose.

▲ Important! Make sure the unit is supported until all

the mounting screws for each bracket are secured to the

equipment rack. Failure to do so could cause the unit to

fall, resulting in personal injury or damage to the unit,

or both.

7 Proceed to the “Cable Guide Installation” section.

Free-Standing/Desktop Installation of the Chassis

The IntraChassis 9000 chassis has four rubber feet on the bottom of the chassis

that allow for free-standing installation of the unit.

For free-standing/desktop placement:

1 Attach the four rubber pads (supplied) to the bottom of

each corner of the IntraChassis 9000 chassis.

2 Place the unit on a flat surface with a minimum area of

17.1” x 13.5” (434.3 mm x 342.9 mm) and support capacity of 150 lbs (68.2 kg).

3 Make sure there is enough ventilation space between the

IntraChassis 9000 and surrounding objects.

4 Proceed to “Cable Guide Installation” below.

Cable Guide Installation

Before installing any of the modules in your IntraChassis 9000, place the cable

guide hook units on each side of the front panel and attach them with the

screws provided. Make sure you install the guides in such a way that the hooks

open upward.

Page 2-8

Page 29

Installing Modules

Installing Modules

Up to eight IntraChassis modules can be installed in the IntraChassis 9000

chassis, in addition to the Management Engine module, which is pre-installed

in the factory.

Before installing any modules, make sure the cable guides have been installed, as

explained in the previous section of this chapter.

To install any combination of 2-port Gigabit Ethernet Switch (GBIC) modules

and 24-port 10/100 Switch modules, use the following procedure.

▲ Important: Make sure the IntraChassis 9000 chassis is

properly installed in an equipment rack or resting on a flat,

stable surface capable of supporting 150 pounds (68.2kg).

Also make sure the power cord for the power module is disconnected for initial installation.

1 Pull the small ejector lever on each end of the module’s face

plate out, away from the face plate.

2 Align the bottom of the module with the rails on the inside

of the chassis slot where you want to install the module, as

shown in Figure 2-2.

3 Slide the module into the slot until it stops, then push the

module in gently until it seats with the connector.

Page 2-9

Page 30

Installation and Set-up

Advanced Systems

G

alax

y

9

0

0

0 G

ig

aSw

itch

IntraChassis 9000

2

4

-p

o

rt 10

/10

0

S

w

itch

B

lad

e

P

o

w

e

r

IntraChassis 9000

24-port 10/100 Switch Blade

Power

IntraChassis 9000

M

a

2

4

68

1

0

1

357

9

10

8

6

4

2

7911

35

1

n

age

m

e

n

t E

ng

ine

M

od

e

S

et

Power

12

3

4

5678

S

lot Contro

l Cen

ter

24

222018

161412

10

8

64

2

22 24

16 18 20

14

12

810

6

4

2

Link/Speed

IntraChassis 9000

24-port 10/100 Switch Blade

Power

2

64

8

1

0

1

2

1

4

1

6

5

Power

P-Fail

Fail

6

753

9

1

1

1

3

1

5

16

1412

10

8

15

13

11

9

7

M

C

1

2

1

41

6

1

8

2

0

2

2

2

4

L

in

k

/

S

p

e

e

d

D

u

p

l

e

x

/

A

c

t

L

i

n

k

/

S

p

e

e

d

D

u

p

le

x

/

A

c

t

1

1

1

31

5

1

7

1

9

2

1

2

3

1

42

22 24

20

16 18

14

12

Link/Speed

Duplex/Act

Link/Speed

Duplex/Act

31

19 21 23

17

15

13

!

Duplex/Act

Link/Speed

Duplex/Act

21 23

17 19

15

13

11

9

57

3

1

1

8

2

0

2

2

2

4

1

7

1

9

2

1

2

3

24

22

2018

23

21

1917

119

753

1

2321

1917

15

13

Figure 2-2 Installing module and power supply

4 Press both ejector levers in, toward the module’s face plate,

simultaneously. This will lock the module in place and

insure proper contact of all connecting surfaces.

5 Tighten the thumbscrews at the ends of the module’s face

plate, next to the ejector levers. Use a straight-bladed screwdriver, so the thumbscrews cannot be loosened by hand.

Installation of the module is complete. Repeat this procedure for each module

you have purchased, then proceed to “Connecting Power”.

▲ Important: Modules are not to be removed from the Intra-

Chassis 9000 except by a qualified System Administrator.

Page 2-10

Page 31

Installing Second Power Supply

Installing GBIC Interfaces

If you have installed modules for GBIC interfaces, install each interface itself by

sliding it into the port, until the locking tabs on either side of the GBIC

interface unit click into the locked position. You can then connect the SC-type

fiber media.

To remove a GBIC interface, squeeze the locking tabs against the sides of the

unit until they release it, then slide the interface out of the port.

Installing Second Power Supply

To install a power supply module in your IntraChassis 9000, first loosen and

undo the thumbscrew holding the cover plate, then remove the plate and slide

the second power supply into the chassis from the front, as shown in Figure 2-2.

Tighten the thumbscrew to hold the power supply firmly in place.

Connecting Power

To connect power to the IntraChassis 9000, use the following procedure.

▲ Important: Carefully review the power requirements on

page 2-4 before connecting power to the IntraChassis 9000.

1 If you have purchased a second power supply, insert it in the

bay provided at the bottom of the IntraChassis 9000 chassis, as shown in Figure 2-2.

2 Plug one end of the supplied power cord into the power

connector on the back of the unit.

3 Plug the other end into a grounded AC outlet.

▲ Important: If the power does not come on, refer to

Appendix A, “Troubleshooting.”

The IntraChassis 9000 is ready for connection to the network.

Page 2-11

Page 32

Installation and Set-up

Connecting to the Network

The IntraChassis 9000 unit may be connected to an Ethernet network, with the

unit powered either on or off. Use the following procedure to make your

network connections.

1 Connect network devices to the IntraChassis 9000, follow-

ing the cable guidelines outlined below.

2 Route the cables through the cable supports at the ends of

each module, to keep cables from the different modules

from interfering with each other.

3 After the unit is connected to the network, it can be config-

ured for management capabilities. See “Configuring for

Management” later in this chapter.

10/100BaseX Ports Cabling Procedures

The 24 fixed ports on each 10/100 module allow for the connection of 10BaseT or 100Base-TX network devices. The ports are compatible with IEEE 802.3

and 802.3u standards.

▲ Important: The IntraChassis 9000 must be located

within 100 meters of its attached 10Base-T or 100Base-TX

devices.

Connecting To Cable Required

Network Station Category 5 UTP (Unshielded Twisted-Pair) straight-through cable

Repeater/Hub Category 5, UTP cross-over cable (100 meters maximum) with RJ-

Repeater/Hub’s Uplink

port

Table 2-2 10/100BaseTX cabling requirements

Page 2-12

(100 meters maximum) with RJ-45 connectors.

45 connectors.

Category 5, UTP straight-through cable (100 meters maximum)

with RJ-45 connectors.

Page 33

Configuring for Management

1000BaseX Ports Cabling Procedures

Cabling requirements for the 2-port Gigabit Ethernet modules depend on

which type of GBIC interface has been installed. Use the following chart to

determine the cabling requirements for your GBIC.

Connecting To Cable Required

1000BaseSX GBIC Cables with SC-type fiber connectors: 62.5 micron multimode

1000BaseLX Long

Haul GBIC

1000BaseLX GBIC Cables with SC-type fiber connectors: 10 micron single mode fiber

fiber media up to 260 meters long, or 50 micron multimode fiber

media up to 525 meters long.

Cables with SC-type fiber connectors: 10 micron single mode fiber

media up to 100 kilometers long.

media up to 3 kilometers long.

Table 2-3 1000BaseX cabling requirements

Configuring for Management

To use the IntraChassis 9000 as a managed switch, it must be configured with

an IP address. This can be accomplished in one of two ways:

❑ automatically using BootP (default)

❑ manually via the unit’s Console port

Page 2-13

Page 34

Installation and Set-up

BootP Configuration

The IntraChassis 9000 is shipped with BootP support. BootP allows the

IntraChassis 9000 to be automatically configured with an IP address when it is

connected to the network and is powered on, if your network contains a BootP

server configured with available, valid IP addresses. Use the following procedure

to set up BootP.

▲ Important: BootP configuration only works if the

IntraChassis 9000 does not have an IP address assigned to

it.

1 Make sure your network has a BootP server configured with

a valid IP address entry for the IntraChassis 9000.

2 When the IntraChassis 9000 is connected to the network

and is powered on, it automatically transmits a BootP

request across the network (up to 10 times) until it receives

a valid IP address from the BootP server.

3 After an IP address is received, the IntraChassis 9000 can be

managed via in-band access. See Chapter 3, “Basic Configuration” for more information.

To verify that a valid IP address was received, try to ‘ping’ the IntraChassis

9000; if you can access the IntraChassis 9000, it is properly configured with an

IP address.

See “Bootstrap Configuration” in Chapter 3 for more information on using

BootP.

Page 2-14

Page 35

Configuring for Management

Connecting To a Console

Use the following procedure to make the cable connection from a terminal to

the console port on the Management Engine of the IntraChassis 9000.

1 Using a straight-through RS-232 cable with a 9-pin male

D-subminiature plug at one end, connect a terminal or

workstation (PC or Macintosh) running a terminal emulator to the Console port on the front of the IntraChassis

9000.

2 Make sure both units are powered on.

If using a PC with a terminal emulator, make sure it is configured with the following terminal settings:

❑ Baud: 9600

❑ Data Bits: 8

❑ Parity: None

❑ Stop Bits: 1

❑ Flow Control: None

3 Once connected, the Local Management Main Menu

appears on the terminal screen.

For further information on setting an IP address for configuration of a terminal,

or a PC running a VT100 terminal or emulator (such as HyperTerminal,

ProComm, or ZTerm), see “System IP Configuration” in Chapter 3.

Page 2-15

Page 36

Installation and Set-up

Management Options

The IntraChassis 9000 can be managed using any of the following methods:

Method Type Description

Console Out-of-band man-

Telnet

(four sessions maximum)

HTTP Server In-band manage-

SNMP-Based Network

Management Software

agement

In-band management

ment

In-band management

Table 2-4 Management Methods

The remaining sections of this chapter describe how to connect to the

IntraChassis 9000 using either out-of-band or in-band management.

Out-of-Band Management

Out-of-band network management allows you to configure, manage, and

monitor the IntraChassis 9000 and all of the installed modules. You can

perform these functions by attaching a terminal (or a terminal emulator) to the

Console port on the management engine and using the menu-driven Local

Management Interface.

Out-of-band network management is guaranteed even when the in-band

Ethernet network is down.

To access the IntraChassis 9000 Local Management Interface using out-of-band

management, first follow the procedure in “Connecting To a Console” and then

go on to the “Management Interface” section, later in this chapter.

Local connection to the IntraChassis 9000 via the

Console port

Remote connection over the network to the

IntraChassis 9000 via Telnet session

Remote connection to the IntraChassis 9000 via

a Web browser

Remote connection to the IntraChassis 9000 via

any SNMP-based network management application

Page 2-16

Page 37

Management Options

In-Band Management

In-band network management allows you to manage, control, and monitor the

IntraChassis 9000 over the Ethernet network.

You can perform these functions by accessing the IntraChassis 9000 via any of

the following methods:

❑ By connecting with a Telnet program and using the Local Manage-

ment Interface.

❑ By connecting with any World Wide Web browser, and using the

Web Management Interface.

❑ By connecting with any SNMP-based network management applica-

tion and using its interface.

To manage the IntraChassis 9000 via in-band management, use the following

procedure.

1 Make sure the network to which the IntraChassis 9000 is

connected is functioning.

2 Make sure the IntraChassis 9000 is configured with valid IP

information.

See “Configuring for Management” earlier in this chapter.

3 Connect to the IntraChassis 9000 via Telnet, with a Web

browser, or with any SNMP-based network management

application.

Telnet

Use a network connection to any PC and enter the telnet command to

access the IntraChassis 9000. The Main Menu of the Management Interface

will appear. Go on to the “Management Interface” section below.

◆ Note: Almost all management screens using a Telnet con-

nection are identical to those of the out-of-band Console

Interface. On the Main Menu, however, there will be a q

option for closing the connection to the IntraChassis 9000.

Web Browser

Refer to Chapter 6, “Web Browser Management”, for information on managing

the IntraChassis 9000 with a Web browser.

Page 2-17

Page 38

Installation and Set-up

SNMP-Based Management

Refer to Chapter 5, “Advanced Management” and your SNMP Software

Manual for information on managing the IntraChassis 9000 with SNMP-based

management software.

The Asanté private MIB for the IntraChassis 9000 is available from the Asanté

ftp site, ftp.asante.com, or you can copy it from the Installation CD-ROM.

Access to Remote Network Monitoring (RMON) features is available only by

using an SNMP manager. See “SNMP and RMON Management” in Chapter 5

for details.

Management Interface

After you connect to the Local Management Interface using either an out-ofband Console connection or an in-band Telnet connection as described in

“Configuring for Management”, the Main Menu appears, as in Figure 2-3.

=================================================================

IntraChassis 9000 Local Management System Version 1.000

Compiled Date: May 7 1999 15:33:24

Asante Technologies, Inc.

Copyright (c) 1999 Asante Technologies, Inc.

=================================================================

Main Menu

<Cmd> <Description>

g G

c C

s S

Command>

eneral Information

onfiguration

tatistics

Figure 2-3 Local Management Main menu

From the Main Menu, you can access three submenus:

❑ General Information — 2-19

❑ Configuration — 2-20

❑ Statistics — 4-1

If you are using Telnet, a fourth option, for closing the connection, will also be

available.

Page 2-18

Page 39

General Information Screen

Accessing a Submenu

To access a submenu, type the command letter of the corresponding option

(e.g., type g for General Information).

Exiting a Submenu

To exit a submenu, type q. To exit a command line without changing the

configuration setting (e.g., the “Set Password” option in the User Interface

Configuration Menu), press ctrl-c.

General Information Screen

The General Information Screen displays the current operating information of

the IntraChassis 9000, such as its name, IP address, and boot information.

◆ Note: The information displayed on this screen is read-only.

Accessing General Information

To view General Information for your IntraChassis 9000, type g in the Local

Management Main menu. A screen similar to Figure 2-4 appears.

IntraChassis 9000 General Information

System up for: 000days, 21hrs, 45mins, 45secs

Software Version

Bank 1 Image Version/Date: 1.10/Dec 7 1999 12:14:38 (Running)

Bank 2 Image Version/Date: 1.10/Dec 7 1999 11:54:14

System Information

Prom Image Ver/Date: 1.01/Sep 8 1999 15:59:14

DRAM Size: 4MB Flash Size: 2.0MB

EEPROM Size: 32KB Console Baud Rate: 9600 bps

Administration Information

System Name: Asante IntraChassis Switch

System Location: ZLabs Head Office

System Contact: CLB

System MAC Address, IP Address, Subnet Mask and Router

MAC Address: 00:00:94:8E:F3:7B

IP Address: 192.168.54.240

Subnet Mask: 255.255.255.0

Router: 192.168.54.2

Bootstrap Configuration

Boot Load Mode: LOCAL

Press any key to continue...

Figure 2-4 General Information Screen

Page 2-19

Page 40

Installation and Set-up

◆ Note: For a description of each parameter on the General

Information Screen, see “Viewing Current Operating Information” on page 3-48.

To exit the General Information Screen, press any key on your keyboard.

Configuration Menu

The Configuration Menu allows you to manage and configure the IntraChassis

9000 and each of its ports.

Logging into the Configuration Menu

1 Type c from the Local Management Interface Main Menu.

2 Enter your password at the “Enter Password” prompt, then

press Return.

▲ Important: The default password is Asante. The pass-

word is case-sensitive; enter it exactly as shown. For

information on changing the password, see “Changing

the Password” in Chapter 3.

The Configuration Menu appears, as shown in Figure 2-5.

IntraChassis 9000 Configuration Menu

<Cmd> <Description>

a System A

i System I

b B

n SN

p P

d Unicast Forwarding D

f F

r System R

l System L

u U

s S

t S

v V

q Return to previous Menu

Command>

Page 2-20

dministration Configuration

P Configuration

ootstrap Configuration

MP Configuration

ort Configuration

ile Downloading Configuration

eset Options

og

ser Interface Configuration

panning Tree Configuration

ecurity Management

LAN Management

Figure 2-5 Configuration Menu

atabase Configuration

Page 41

Configuration Menu

3 Type the command letter of the configuration option you

need to use. For example, type a for the System Administration Configuration menu.

Configuration Menu Options

Table 2-5 on the next page describes each of the options in the Configuration

menu.

Menu Item Description

System Administration Configuration

System IP Configuration

Bootstrap Configuration

SNMP Configuration

Port Configuration Allows you to configure manually each of the switch’s ports for speed,

Unicast Forwarding Database Configuration

Image File Downloading Configuration

System Reset Configuration

System Log Allows you to view a record of any major system events or errors that

Displays and allows you to change the name, location, and contact

information for the IntraChassis 9000. See page 3-2.

Displays and allows changing the IP Address of the IntraChassis

9000. This address is for network access to the switch. See page 3-3.

Allows you to change boot bank and method for loading switch software, or change downloading parameters. See page 3-5.

Displays and allows you to change the SNMP (Simple Network

Management Protocol) parameters of the IntraChassis 9000; such as

read/write community strings. See page 3-11.

connection, link mode, and auto-negotiation. Also displays overall

port status. See page 3-14.

Allows you to display all of the forwarding database, or display it by

port or VLAN, either with or without showing IP addresses. Also lets

you search for MAC or IP addresses and lets you set the age-out time

for MAC addresses. See page 3-28.

Allows you to download an Image file for the purpose of upgrading

the IntraChassis 9000 software. See page 3-37.

Allows you to reset the switch by a “warm” reboot, or arrange for an

automatic reset (up to 24 hours) in advance. See page 3-44.

have occurred on the IntraChassis 9000. See page 3-46

User Interface

Configuration

Allows you to set the idle time-out period and password when using

Console or Telnet access. See page 3-50.

Page 2-21

Page 42

Installation and Set-up

Menu Item Description

Spanning Tree

Configuration

Security Management

VLAN Management

Return to Previous

Menu

Displays and allows you to change Spanning Tree parameters, to

make sure you prevent loops in network paths. See page 5-2.

Allows you to use various features such as Duplicate IP traps, for port

security. See page 5-8.

Allows you to set up virtual networks. See page 5-11

Allows you to Exit the Configuration menu to the Local Management Interface menu.

Table 2-5 Configuration Menu Options

The first ten options for configuration are described in detail in Chapter 3,

“Basic Configuration” and the more advanced options are discussed in Chapter

5, the “Advanced Management” chapter.

Page 2-22

Page 43

Basic Configuration

This chapter describes how to manage the IntraChassis 9000 using the out-ofband Console or in-band Telnet interface.

This chapter contains the following sections:

❑ Overview

❑ System Administration Configuration

❑ System IP Configuration

❑ Bootstrap Configuration

❑ SNMP Configuration

❑ Port Configuration

❑ Advanced Port Configuration

❑ Global Port Configuration

❑ Unicast Forwarding Database Configuration

❑ Image File Downloading Configuration

❑ System Reset Configuration

❑ Viewing the System Log

❑ Viewing Current Operating Information

❑ User Interface Configuration

3

Basic Configuration Overview

The IntraChassis 9000 Local Management Interface is a menu-driven

application which provides management and configuration support for the

IntraChassis 9000 and each of the ports in its different modules.

The Local Management Interface can be accessed via two methods:

❑ Out-of-band connection to the Console port

❑ In-band connection via Telnet (four sessions maximum).

Page 3-1

Page 44

Basic Configuration

For details on accessing the Local Management Interface, see Chapter 2,

“Installation and Set-up”.

System Administration Configuration

This menu displays and allows you to change the IntraChassis 9000’s name,

location, and contact information.

To access the System Administration Configuration Menu, type a in the

Configuration Menu. A screen similar to Figure 3-1 appears.

IntraChassis 9000 System Admin. Configuration Menu

System Name: Asante IntraChassis Switch

System Location: ZLabs Main Office

System Contact: CLB

<Cmd> <Description>

n Set System N

l Set System L

c Set System C

q Return to Previous Menu

Command>

Figure 3-1 System Administration Configuration Menu

ame

ocation

ontact Information

Current Settings

The following table describes each setting on the System Administration

Configuration Menu.

Setting Description

System Name The name of the IntraChassis 9000 (up to 64 characters, includ-

System Location Place where you have installed the IntraChassis 9000 (up to 64

System Contact The name of the person or entity responsible for the IntraChassis

Page 3-2

ing spaces).

characters, including spaces).

9000 (up to 64 characters, including spaces).

Table 3-1 System Administration settings

Page 45

System IP Configuration

Changing System Administration Info

To change the name, location, or contact information for the IntraChassis

9000, use the following procedure.

1 Open the System Administration Configuration Menu by

typing a in the Configuration Menu.

2 Type the command letter of the item to be changed in the

System Administration Configuration Menu.

3 Type the information at the prompt.

See Table 3-1 for a description of each parameter.

◆ Note: Each parameter is limited to 64 characters,

including spaces.

To cancel a selected option, press ctrl-c at the command

prompt.

4 Press Return.

The IntraChassis 9000 system administration information

changes take effect.

5 Type q to quit and return to the Configuration menu.

System IP Configuration

This menu displays and allows you to change the information needed to access

the IntraChassis 9000 over the network via in-band management.

To access the System IP Configuration Menu, type i in the Configuration

Menu. A screen similar to Figure 3-2 appears.

Page 3-3

Page 46

Basic Configuration

IntraChassis 9000 System IP Configuration Menu

System MAC Address: 00:00:92:CC:BB:AA

System IP Address: 192.168.54.240 (intrach.asante.com)

System Subnet Mask: 255.255.255.0

System Default Router: 192.168.54.2

<Cmd> <Description>

i Set I

m Set Subnet M

r Set Default R

n Set Domain N

q Return to Previous Menu

Command>

P Address

ask

outer

ame Server

Figure 3-2 System IP Configuration Menu

▲ Important: By default, each address is set to 0.0.0.0.

Current Settings

Table 3-2 describes each setting on the System IP Configuration menu.

Setting Description

System IP Address The IP (Internet Protocol) address of the IntraChassis 9000.

System Subnet Mask The filter which determines how the IntraChassis 9000 IP address

System Default Router The IP address of the default router for the IntraChassis 9000.

is split into network and host portions.

Table 3-2 System IP settings

Changing System IP Information

To change the IP address, subnet mask, or default router of the IntraChassis

9000, use the following procedure.

1 Open the System IP Configuration Menu by typing i in the

Configuration Menu.

2 Type the command letter of the option you want to change.

Page 3-4

Page 47

Bootstrap Configuration

3 Type the new address at the prompt.

See Table 3-2 for a description of each address.

▲ Important: follow the format:

number.number.number.number

To cancel a change, press ctrl-c at the command prompt.

4 Press Return.

The IP setting change for the IntraChassis 9000 takes effect.

5 Type q to quit and return to the Configuration Menu.

Bootstrap Configuration

This menu displays (and allows you to change) the bootstrap parameters used

for loading the software for the IntraChassis 9000 at startup, and for

downloading a new version of software when one is issued.To access the

Bootstrap Configuration Menu, type b in the Configuration Menu. If the

Load Mode is set to LOCAL, a screen similar to Figure 3-3 appears.

IntraChassis 9000 Bootstrap Configuration Menu

Bank 1 Image Version/Date: 1.00B/May 3 1999 10:00:07 (Running)

Bank 2 Image Version/Date: 1.00G/May 5 1999 17:32:18

Load Mode: Local

Boot Bank: 2

<Cmd> <Description>

r Set Load Mode to R

a Toggle Boot Ba

q Return to previous menu

Command>

nk

EMOTE

Figure 3-3 Local Bootstrap Configuration Menu

When the IntraChassis 9000 is powered on, it loads its software via one of two

methods: locally (via its internal flash memory which is the default setting) or

remotely over the network.

▲ Important: The default Load Mode setting for the IntraC-

hassis 9000 is Local.

Page 3-5

Page 48

Basic Configuration

Image Banks

The IntraChassis 9000 has two banks to store its runtime software. The banks

are referred to as bank 1 and bank 2.

Either of these banks may be the Boot Bank, which is the bank from which the

runtime code will be loaded the next time the IntraChassis 9000 is booted.

When downloading new runtime image codes, you may specify either of the

two banks as the Destination Bank in which the new code will be loaded.

Page 3-6

Page 49

Bootstrap Configuration

Loading Software Locally

The IntraChassis 9000 will always boot locally unless you set it to boot load

remotely. It would then download the new image code and reset to load locally.

1 Open the Bootstrap Configuration Menu by typing b in the

Configuration Menu.

2 Type a in the Bootstrap Configuration Menu if you need to

toggle the Boot Bank setting for the next boot. Typically,

you will want to set the boot bank to be the one on which

the latest version of the Image resides.

The IntraChassis 9000 is set to load software locally from its flash memory. This

occurs whenever the unit is powered on or reset.

Loading Software Remotely

To set the IntraChassis 9000 to download its software over the network from a

remote server, use the following procedure.

1 Open the Local Bootstrap Configuration Menu by typing b

in Configuration Menu.

2 Open the Remote Bootstrap Configuration Menu by typing

r in the Local Bootstrap Configuration Menu. The menu

appears, as shown in Figure 3-4.

Page 3-7

Page 50

Basic Configuration

IntraChassis 9000 Bootstrap Configuration Menu

Bank 1 Image Version/Date: 1.10J/Dec 7 1999 12:14:38 (Running)

Bank 2 Image Version/Date: 1.00G/May 5 1999 17:32:18

Load Mode: Remote

Boot Mode: TFTP only

Boot Server IP: 192.168.54.150

Boot File Name: c:\base\newcrc.ima

Retry Count: 5

Boot Bank: 1

<Cmd> <Description>

b Set Boot Mode to B

t Set Boot Mode to T

l Set Load Mode to L

s Set Boot S

f Set Boot F

c Set Remote Boot Retry C

a Toggle Boot Ba

q Return to Previous Menu

Command>

erver IP Address

ile Name

nk

OOTP-TFTP

FTP only

OCAL

ount

Figure 3-4 Remote Bootstrap Configuration Menu

Page 3-8

Page 51

Bootstrap Configuration

Current Settings

Table 3-3 explains each setting on the Remote Bootstrap Configuration Menu.

Setting Description

Running Image Version/

Date

Load Mode The current method for loading software for the IntraChassis

Boot Mode The method for requesting the image file from the network. This

The version and compilation date of runtime code that is currently running on the IntraChassis 9000.

9000.

Remote — Loads the image file from a server on the network.

Local — Executes the software image file from the IntraChassis

9000’s internal flash memory (default setting; the IntraChassis

9000 automatically reverts to this setting after downloading a new

software file).

option is available only if you have selected Remote Load Mode.

BootP-TFTP — Sets the IntraChassis 9000 to request an IP

address from a BootP server AND to download the software’s

image file through TFTP (Trivial File Transfer Protocol).

▲ Important: To use this option, the IntraChas-

sis 9000 IP address must be set to 0.0.0.0.

TFTP ONLY — Sets the IntraChassis 9000 to only download the

software image file through TFTP.

▲ Important: To use this option, the switch must

already have an assigned IP address and the Load

Mode must be set to Remote.

Boot Server IP The Internet Protocol (IP) address of the TFTP server providing

the TFTP capabilities on your network. Not Available if Boot

Mode is BootP-TFTP.

Boot File Name The name of the file you are going to request for download. Not

Retry Count Number of attempts the IntraChassis 9000 makes to download

Boot Bank Number of the destination bank for the image file you are down-

available if boot mode is BootP/TFTP.

the image file if errors occur. The default is 5.

loading (1 or 2).

Table 3-3 Bootstrap Settings

Page 3-9

Page 52

Basic Configuration

3 Type b to set the Boot Mode to BootP-TFTP, or type t to

set Boot Mode to TFTP only. If you choose BootP-TFTP

mode, the options for setting the IP Address of the TFTP

server and the Boot File Name become unavailable; in this

case, skip Steps 4-7 and go on to Step 8.

4 Type s in the Bootstrap Configuration Menu, to select the

option Set Boot Server IP Address.

5 At the prompt, type the IP address of the remote boot server

which contains the switch’s software image file. Then press

Return. The Bootstrap Configuration Menu appears.