Arçelik TKF 8439, TKF 8439, TKF 8439 A, TKF 8439S, TKF 8439 A Service Handbook

...

Arçelik/Blomberg 2009 ARES MLCD

8 kg

Tumble Dryer Service Handbook

1

INDEX

1. Technical Specifications

2. Components and Dryer Principals

3. Control System

4. Service test program

5. Fault algorithms

6. Wiring schematics

7. Exploded views

8. Spare part list

9. Demounting the dryer

Arçelik/Blomberg 2009 ARES MLCD

8 kg

Tumble Dryer Service Handbook

2

Arçelik/Blomberg 2009 ARES MLCD

8 kg

Tumble Dryer Service Handbook

3

1 Technical Specification:

1.1. Product Definition

1.1.1. Manufacturer : Arçelik A.Ş.

Cerkezkoy - Tekirdag / TÜRKĐYE

1.1.2 Model : TKF 8439/8439 A / 8439S

1.1.3 Capacity (kg) : 8

1.1.4 Programs (Qty) : 14 sensor contolled program

1 time program

1 ventilation program

(heater off)

1.2. Dimensions

1.2.1. Height (mm) : 846

1.2.2. Depth (mm) : 598

1.2.3. Width (mm) :595

1.3. Package

1.3.1. Material : PE bag (Shrink-pack)

1.3.2. Supporter : Polystrofoam / Wood

1.3.3. Dimensions :

Height (mm) : 880

Depth (mm) : 660

Width (mm) : 650

1.4. Weight

1.4.1. Unpacked (kg) : 38

1.4.2. Packed (kg) : 40

1.5. Working Condition

1.5.1. Temperautre :

Min. room temperature : 5° C

Max. room temperature : 35° C

1.5.2. Humudity : %95 RH

1.6. Electrical Specification

1.6.1. Voltage (V / Hz) : 220-230 V / 50 Hz

1.6.2. Power (kW) : 2,7 kW

1.6.3. Current (A) : 12

1.7. Power Cord

1.7.1. Type : 3 x 1.5 mm2 Cord Copper wire

Arçelik/Blomberg 2009 ARES MLCD

8 kg

Tumble Dryer Service Handbook

4

1.7.2. Insulation : TS 9760 H05V2V2-F 3G1,5mm2

1.7.3. Plug : Earthed ,PVC injected

1.7.4. Length (mm) : 1605

1.8. Motor

1.8.1. Type : 2 – phase asenkron

1.8.2. Power (W) : max 250

1.8.3. Main Winding (ohm) : 19,5± 5%

1.8.4. Auxillary Winding(ohm) : 19,5± 5%

1.8.5. Motor speed (7 kg (rpm)) : 2750

1.8.6. Drum speed (rpm) : 52 ± 2

1.8.7. Insulation : Sınıfı : F

1.8.8. Run capacitor : 9 mF ± %5

1.9. Heater

1.9.1. Type : Open wire spiral heating element

1.9.2. Nominal Power&Voltage(W) : 230Vac, 1600+900 = 2500 ± %5

1.9.3. Resistance(ohm) : 1600 W 1. level power (57.63 ohm± %5)

: 900 W 2. level power (32.41ohm± %5)

Warning: NTC (regulating thermistor) is damaged, change the heating element

completely. Also check whether the motor or the fan is blocked or the belt is broken.

1.9.4. Manual resetting thermostat : 160°C ±3°C

Rating : 250Vac – 16A

Type : ELTH 261PB

NOTE: If the heater does not work because of manuel resetting thermostat is open curcuit, do

not change heater with the new one. You should do the following operation that described

below.

Arçelik/Blomberg 2009 ARES MLCD

8 kg

Tumble Dryer Service Handbook

5

With the multimeter manual resetting thermostat is checked from the terminals while heater

is on the dryer. If manual resetting thermostat is open curcuit, the button is up and the heater

does not work. If the button is up position,push the button down,and measure the thermostat

and be sure that it is short circuit.

Arçelik/Blomberg 2009 ARES MLCD

8 kg

Tumble Dryer Service Handbook

6

1.9.5. NTC (regulating thermistor) : 19.500 ohm @ 25°C

Type : ELTH 279

1.10. Door NTC

Door NTC (ohm) : 12.000 ohm @ 25°C

1.11. Body :

1.11.1. Material : Sheet metal

1.11.2. Finish : Acyrlic powder paint

1.12. Drum :

1.12.1. Material : Aluzinc/Stainles steel

1.12.2. Volume ( lt ) : 118

1.12.3. Drum speed( rpm ) : 54±2

1.12.4. Front door opening (mm) : 395x320

1.12.5. Proces air flow (m3/h) :190

1.12.6. Maximum loading Capacity:

Cotton(kg) : 8

Delicate, Synthetic (kg) : 4

1.13. Control System Specifications :

1.13.1. On/off Button : 250 V, 16 (4)A

1.13.2. Door Switch : 250 V, 3 (1)A veya 16(4)A

1.13.3. Suppression Fiter : C907C21 0,15 uF(X1) + 1Mohm +

2x0.027uF(Y2)

1.13.4. Program Timer : Elektronic Control Card

220 -240V , 50 Hz

1.14. Pump

1.14.1. Number of turns:2x3250

1.14.2. Wire diameter:0,1 mm

1.14.3. Resistance:956 Ω± %8

1.14.4. PCT C870 Epcos

1.14.5. PA6/66 Grilon TS V0,UL 94V-0,GW-650°C

1.14.6. PA6 Latamid 6H V0, UL 94V-0, GW-650°C

Arçelik/Blomberg 2009 ARES MLCD

8 kg

Tumble Dryer Service Handbook

7

2. Components and Dryer Principals:

Electronic Board:

Mechanical Pats (Dynamic System) :

The main motor is attached to the chassis with four special self threaded screws. In order to

drive drum a polv-y-V belt ise used between the motor pulley and drum There was used a

elastic belt. The drum is made of galvanized sheet steel. The drum group is mounted into the

front bearing house and rear bearing steel bracket, which is located rear panel. The heater is

mounted to the rear panel wtih two screws.

It is advised that the elastic Poly-V belt will be assembled max 3 times. Due to

damage on the belt on assembling, after 3 times please change the Poly-V belt

also.

Temperature Sensor ( NTC ):

Two NTC temperature sensor are used on electronic controlled dryers, one is located after the

door filter in suction canal, other is located in the heater. As the temperature of the surrounding

of NTC increases, its resistance decreases. At fixed temperature NTC will always have a

specified resistance within the tolerance. With the aid of this principle operates until the desired

temperature is reached. In this way, the selected program completes properly each time in

accordance with the program set an auxiliary function neither selected an is nor influenced by

air temperature etc.

Humidity Sensor:

Humidity level will be measured by the resistance of clothes. With this property of the humudity

sensor, its possible to check and control the humudity level precisely. It is driven by macro.

Humidity Sensor

Connector

L

900W Relay

Programming

Connector

Humidity sensor (NTC)

Rotary

Overflow switch connector.

Door Sensing Drain Pump

Motor Direction 1

Motor Direction 2

N

1600W Relay

Arçelik/Blomberg 2009 ARES MLCD

8 kg

Tumble Dryer Service Handbook

8

Heater (Open spiral wire):

A 2500W two circuit open spiral wire type heater is driven by the 2 relays. A manual resettable

thermostat is used on these heater, in order to provide IEC safety rules accordingly. This

manual resettable thermostat cut the heater power at 160°C and can be resetted by the

pressing the button on thermostat, so heater can be used after a failure bacause of thermostat

is open curcuit.

The second temperature regulating element on the heater is NTC. When the desired

temperatures is reached, electronic control card reads the resistance of NTC and if the

prescribed resistance ( and hnce temperature) is reached, the heater is switched off.

This mechanical thermostat operates only;

Locked tumble,

Locked rotor,

Broken fan,

Filter and condenser is full, conditions.

Warning: When NTC is broken down, the heater is changed by the new heater. If

thermostat is open curcuit, the same heater will be used by pressing the button on

thermostat.

Door Lock :

Locking and unlocking mechanism of the door lock used in the dryer is a mechanical type of the

door lock. When the door pushed, the door is locked and the door is closed. When the pull from

the handle of the door, it will be open with a suitable force.

Especially, door lock and hinge sould be checked if there is a locking problem.

Door Switch :

The current is sent to electronic card and motor by the door switch. By this way when door is

opened due to any reason, motor stops automaticlly. However because of EN&IEC safety rules,

when the door is closed again, motor does not start. It is necessary to press start/pause/cancel

button to restart dryer.

Arçelik/Blomberg 2009 ARES MLCD

8 kg

Tumble Dryer Service Handbook

9

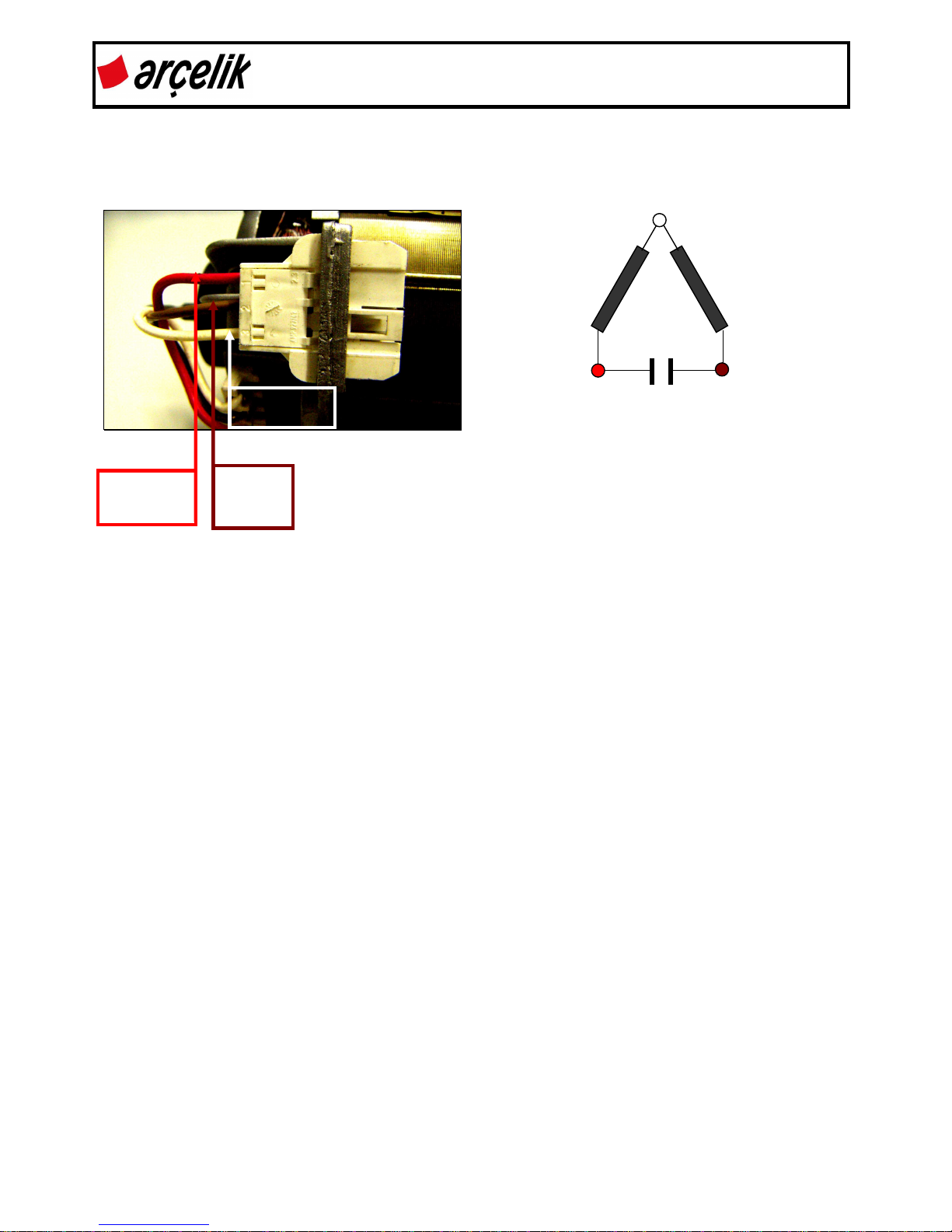

Motor:

Tumble and fan turns via 2 poles asenkron motor. Motor turns 2750 prm ans has a 9 uF

capacitor. Asenkron motor is controled by two Control panel two relays one of them for

direction, other one is for energy that placed in control.

Auxiliary

Winding

Common

Run

Capasitor

Auxiliary

Winding

Main

Winding

Common

Main Winding

Arçelik/Blomberg 2009 ARES MLCD

8 kg

Tumble Dryer Service Handbook

10

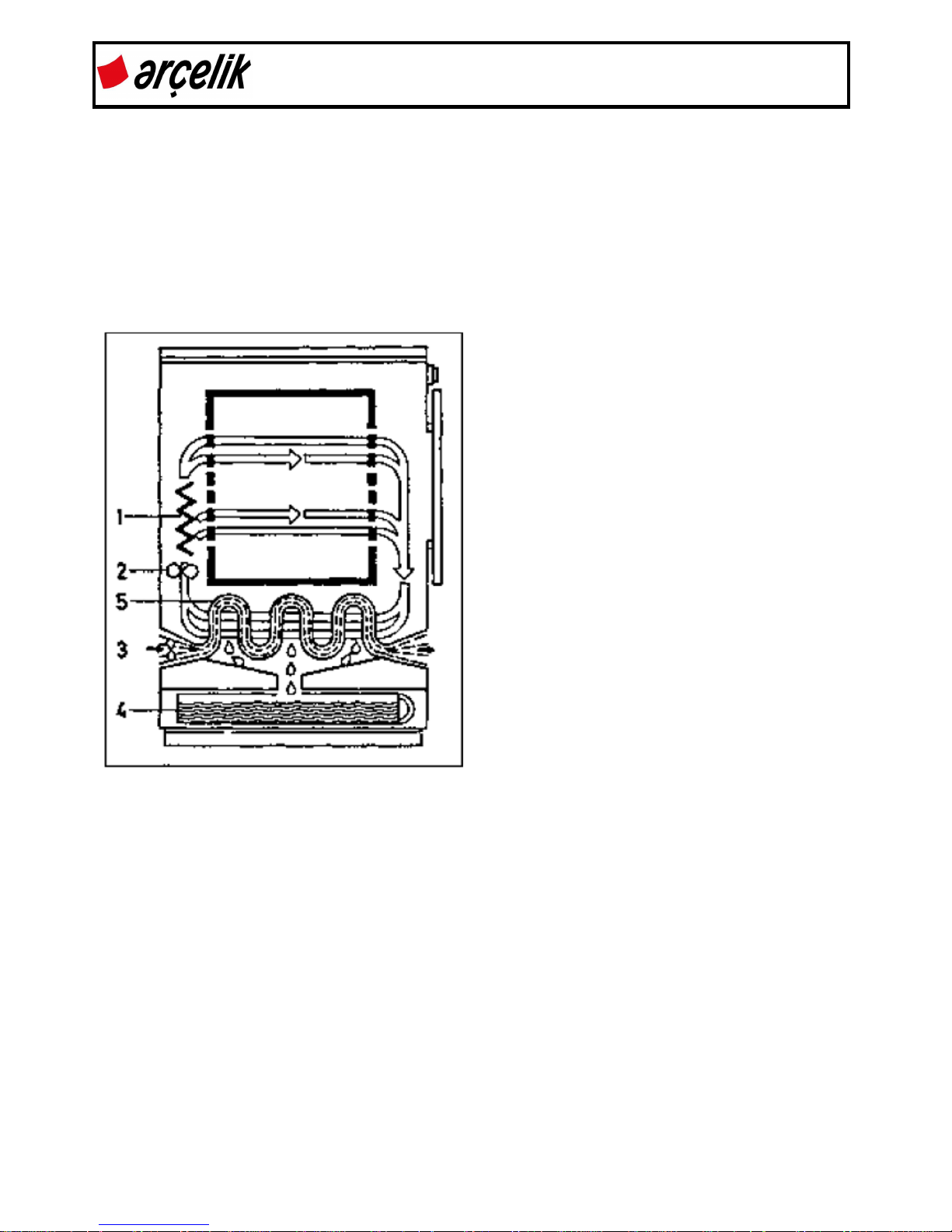

Dryer Principals:

The air heated by the heaters, is directed to the drum and gets moisture of the laundry.

After crossing from the filters, the air pass through the condenser, and condenses.

Then the air is heated again, this circulation continues until the drying process finished.

Condensing occurs by cooling the air. To achieve that, a secondary fan circulates the air in the

condenser. Because of the temperature difference between cooling air and heated air,

condensing process accomplishes.

The condensed water is directed to the water tank by the pump for tank up version.

• Heater

• Process Fan

• Cooling Fan

• Condensed Water

• Condenser

Arçelik/Blomberg 2009 ARES MLCD

8 kg

Tumble Dryer Service Handbook

11

3. Control System:

Arçelik/Blomberg 2009 ARES MLCD

8 kg

Tumble Dryer Service Handbook

12

Symbol Explanations:

Loading...

Loading...