Artisan 880 OPERATORS and SPARTS PARTS Manual

MODEL

880

Pin

Point

(Saddle

Sewing

2 Needle

OPERATORS

and

Stitch)

Machine,

Chainstitch

SPARTS PARTS

Manual

-----

CONT

ENTS -----

1. Prec

auti

ons bef

1) Sa fety

2)

Pr

ecaution before St

3)

Pr

ecaution for Op

ore

pr

ecautions

starting operation···········..·..·· ·..······.· , , 1

arting

erating

~

Operation

·· ·..·· · ··..·..··..····..· · · ·..········· 1

Conditions··..·..·..· ·..· ····..·..·..···..·· ·..·..········ ·..····..··· 1

·······..· ··.· · 1

2. How to use the sewing machine ··..· ·..·..· ·..· · ·..·..·······..· · · · · ·..· · ·:·· 1

1) How to set the needle ·..· · ·..· · 1

2) How to

3)

Adjustment

4) Pressing for sewn goods··..·····..···· ·· · ······..·· ····..···..·..··..·..············· ····· ···..··..··..·..·2

5) Sewing condition 2

6) Upper

3. C

auti

1) Oilin g ·..······..···· · ·..··..· · · ·..·····..·· ···..··· ··..· · ····..·..· · · ·..3

2) Clean periodically in

4. Outline of machine

I) Timing

2)

Height

3) How to fit needle

4) Adjustment of needle guide 6

5)

Adjustment

6)

Adjustment

5.

Parts

catalog ····..·..··..··..·..· ······· · · · ·..· ··8

threading

· ·..·..··..··..·..·· ·..·..· · ········..···..·..·..·······..··········..···..··..·· ···· ·..··..·.. 1

of stitch length ···..· ·..···· ·..·2

thr

ead

tension ·..· ·..·..· · ·2

on f

or

use to use the sewing machin e ·· ·..· · ·····..·..·..· ·..·..· ·· ·..· ·· ·..3

of

of

needle

needle

of

thread

of

thread

accordanc

adju

stment

and

feed dog·..· ·..·..· • · · ·..·..···..·· ··..··..· 4

bar·

· ····..···..·· ·..·..······..·..· · · ·..· ········..·..·..· ···· ·..·..· ·..4

and

looper · · ·..·..·..· ··..·· ·· ··..· · ·..· · · ·· ···· 5

tension

tightening..· ·..·· ··..· • ·..·..····..· ·· ··..·..·· ·..·· ·· ··7

e with using frequ ency..····..·..·..······..·..···..· · ·..·· ··..· ··4

..··· ·..·· · ·..·..·· ·· ·..· ·· ·..· · ··..·· 4

sprin

g· · ·· ·····..· ·..·..·· ··..··· · · · · ···..··6

A)

Arm

bed & Its accessories ..· ·..·..·· ·..· · ·· · · ·..· · ·..· ·8

B) Sewing mechanism ······..··· ·· ·..····..···..··············· 10

C) Feeding

D) Stitch

Presser

E)

F) Oil

and

feed lifting &

regulator

mechanism : ·..·..·..··..·· 16

Lower

shaft

mechanism ..· ·..·..· · · · · · ·....·..···..13

foot mechanism ·..··..·..· · · ·..··18

lubrication

mechanism · ·..·· · ·..····· ··..·..·..· ··· · ··..·· ·· ·..·..·..·..··..· ·•·..···..20

G) Accessories..··..· ·..··..··..· ·..· ·..· ·..·· · · ···..·..·..·..··· ·· ·..·..·..· ·22

1. Precautions before

1) Safety precautions:

staring

operation

() When turning the power on, keep

and the area around the pulley.

(2) Power must be turned

(3) Power must be turned

the mach ine, or when replacing.

(4) Avoid placing fingers, hairs, bars etc., near the pulley,

the machine is in operation.

(5) Do not insert fingers into the thread take -up cover, under/around the needle, or pulley when the machine

is in operation.

(6) If a belt cover, fin

devices.

2) Precautions before

(I)

If the machine's oil pan has an oil sump, never operate the machine before filling it.

(2) If the machine is lubricated by a drop oiler, never operate the machine before lubricating.

(3) When a new sewing machine is first turned on, verify the rotational direction

off

when the machine is not in use, or when the operator leaves the seat.

off

when tilting the machine head, installing or removing the

ger

guard, eye guard are installed, do not operate the machine without these safety

starting

your

operation:

hands and finger s away from the area around/under the needle

"V"

belt, adjusting

"V

" belt, bobbin winder pulley, or motor when

of

the pulle y with the

power on. (The pulley should rotate counterclockwise when viewed from the pulley)

(4) Verify the voltage and (single or three) phase with those given on the machine nameplate.

3) Precautions for

I) Avoid using the machine at abnormally high temperatures C35·C or

lower) .

2) Avoid using the machine in dusty conditions.

operating

conditions:

higher)

or low temperatures ( 5·C or

2. How to use the sewing machine

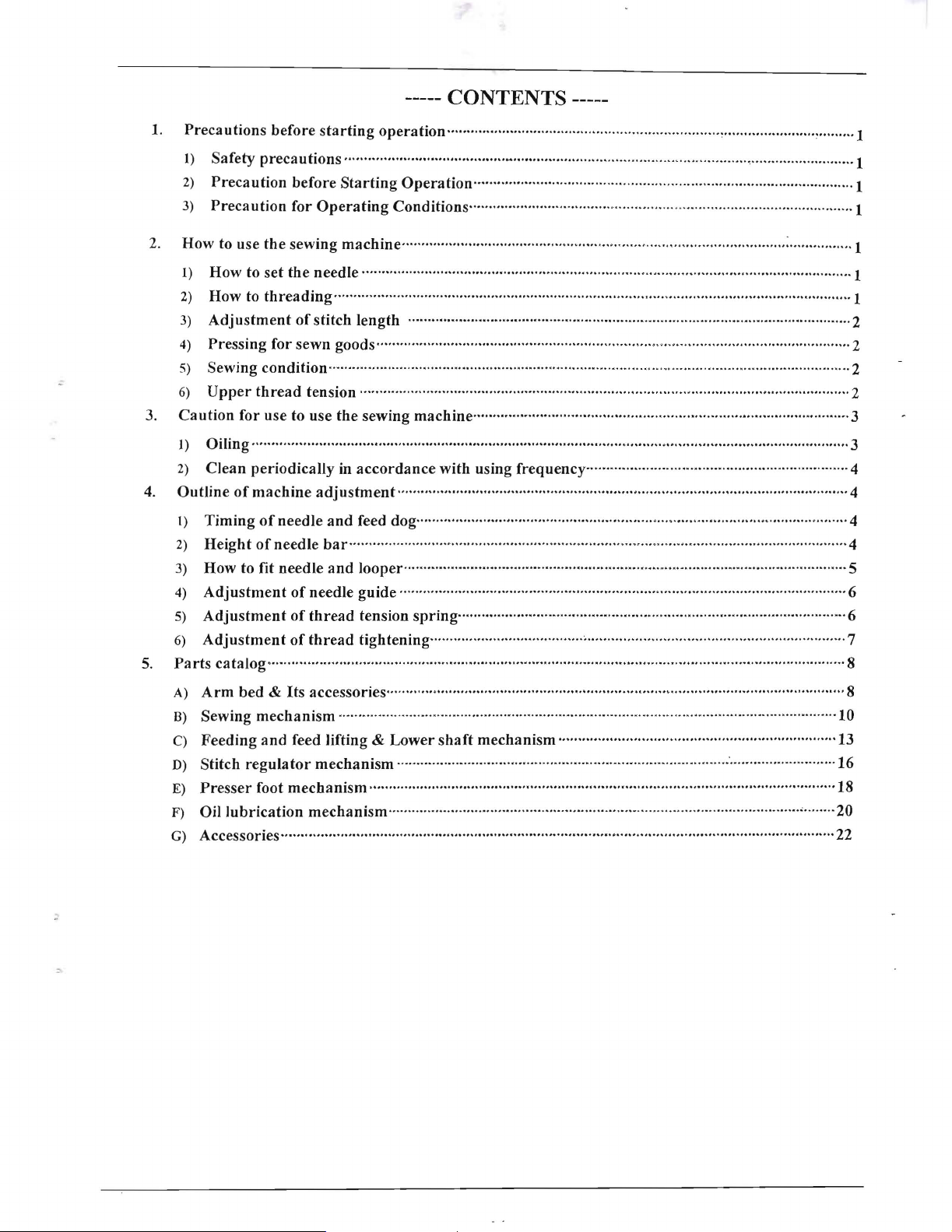

1) How to set the needle

Put in the needle as far as it comes to the end, keep the groove on the left side and tighten

the screw.

of

Note: When fitting the needl e, tighten the right side screw softly and tighten the

2) How to

Keep the thread take-up lever at its highest position thread in numerical order.

threading

this side.

-1-

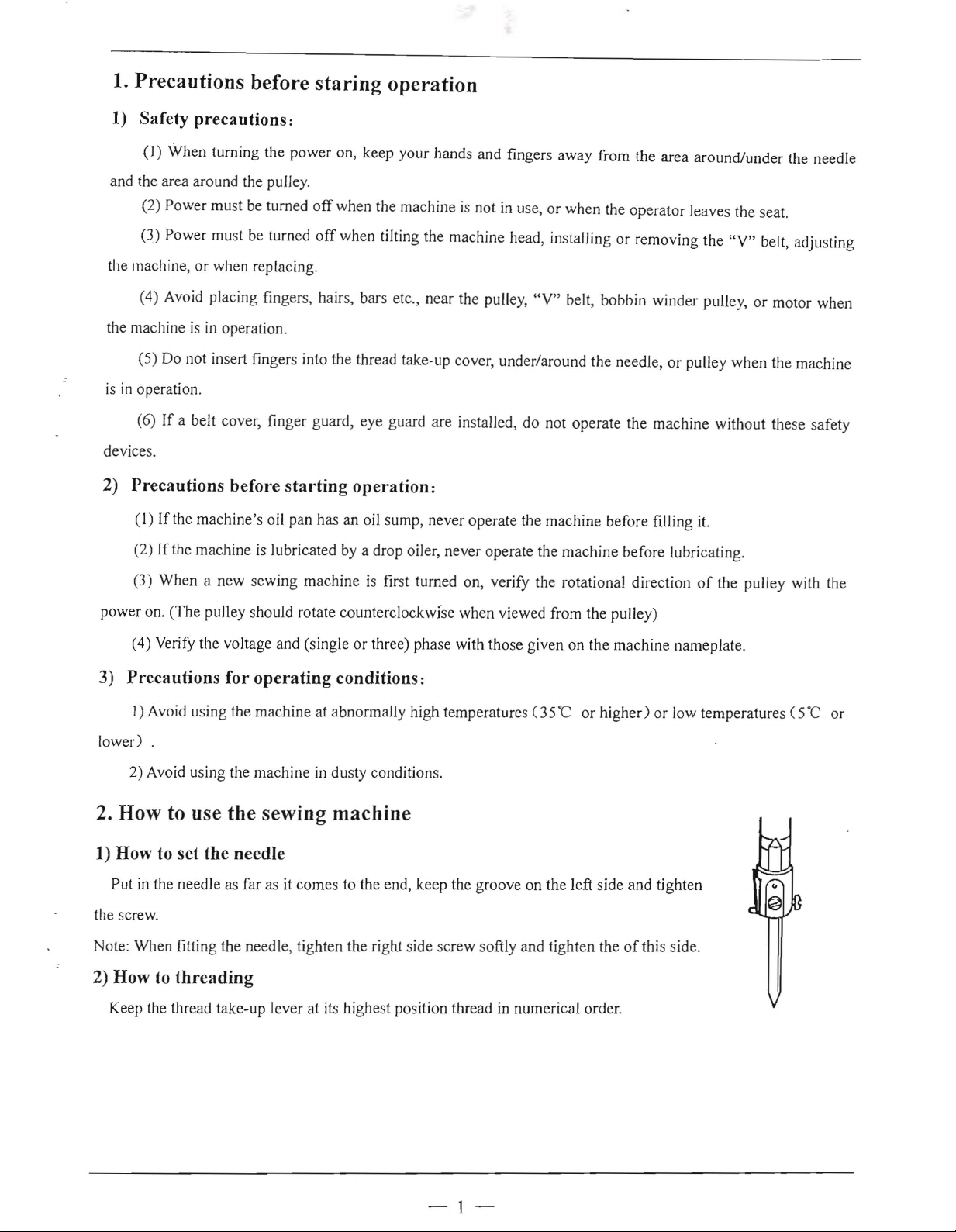

3) Adjustment of stitch length

Note: When you make the stitch length small, turn the stitch length

dial.

4) Pressing for sewn goods

Standard pressure of the feed dog is obtained when the

upper surface of the presser regulating thumb screw is in the

position approximately 20mm above the arm surface.

Jncrease the pressure by turning the pressure regulating

thumb screw, if the sewing cloth is skipped stitch due to the

hook needle catching a fiber of the cloth, or other reasons

Presser

thumb

.

regulating

scren

-

depending on the state

of

the sewing cloth.

S) Sewing condition

Well-balanced good stitch.

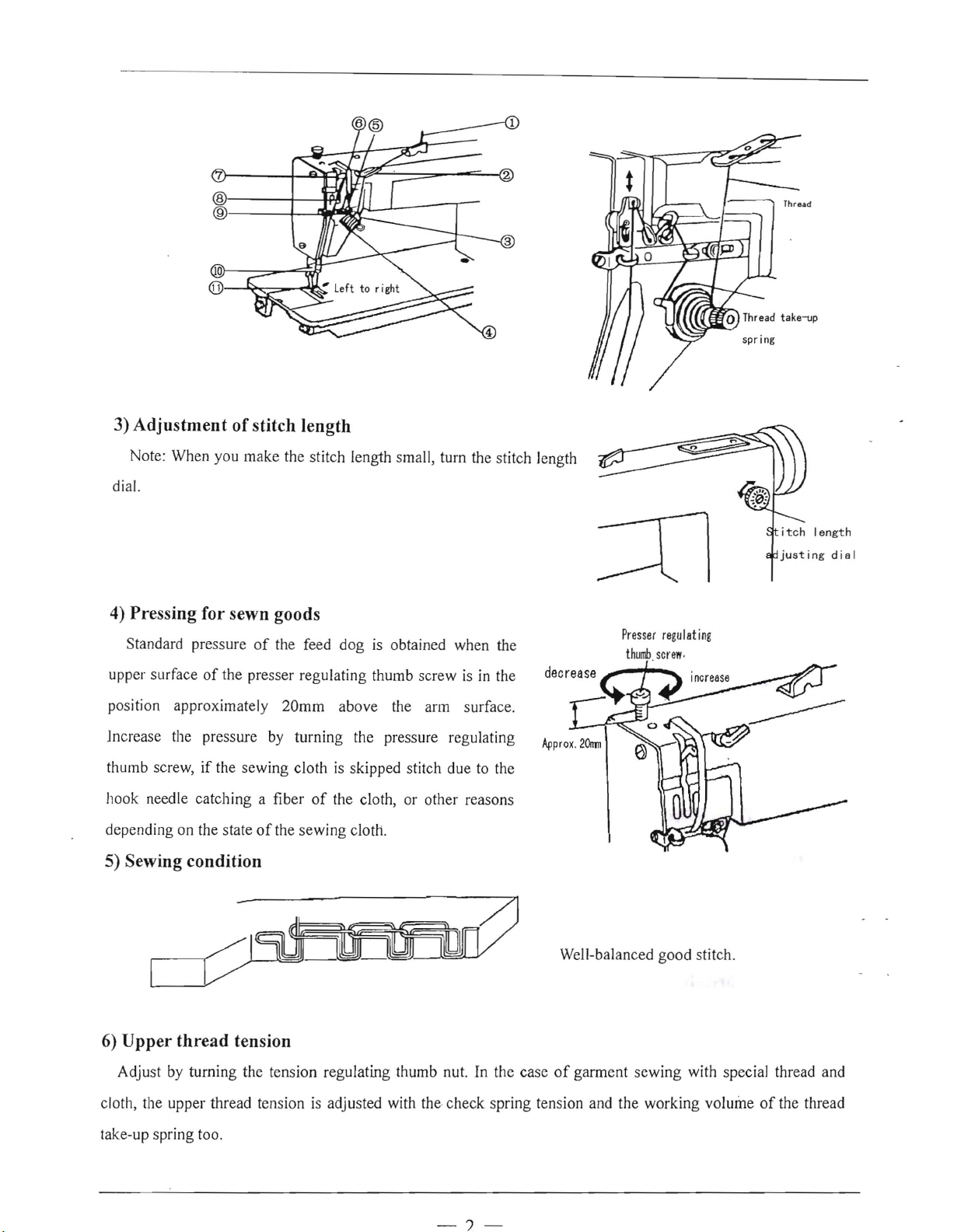

6)

Upper

Adjust by turning the tension regulating thumb nut. In the case

cloth, the upper thread tension is adjusted with the check spring tension and the working volume of the thread

take-up spring too.

thread

tension

-?

of

garment sewing with special thread and

-

loose

Tens ion: r

t humb nut

egulating

3. Caution for use

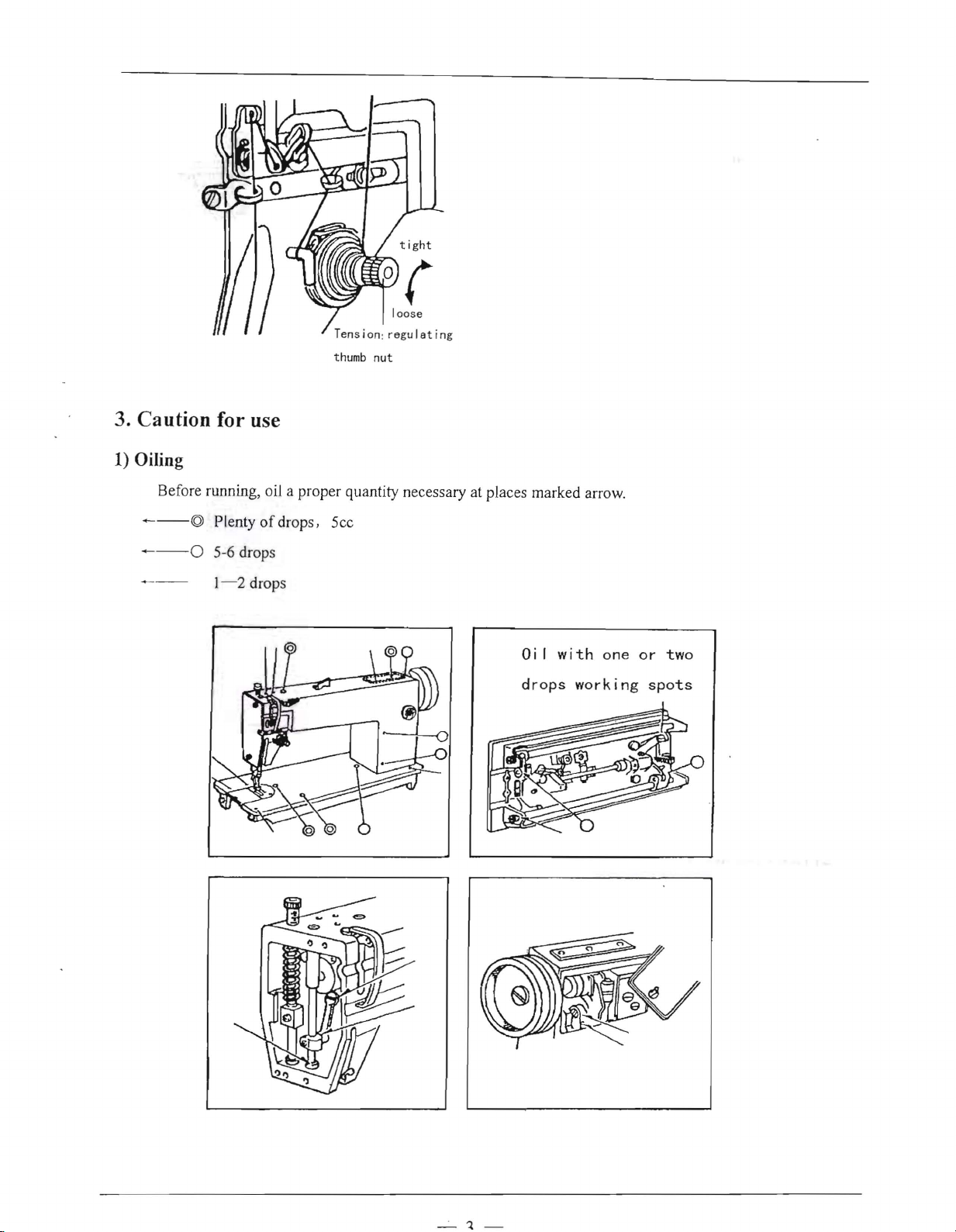

1) Oiling

Before running, oil a proper quantity necessary at places marked arrow.

- -

-©

Plenty of drops , Scc

---0

5-6 drops

]

-2

drops

Oi I

drops

with

working

one or two

spots

-

·1

-

2) Clean periodically in accordance with using frequency

Remove the needle plate. Take

for assembling

hand and tighten it evenly with a long screwdriver.

Note: When fitting the needle plate, fit so that the needle might

the center

4. Outline

1) Timing

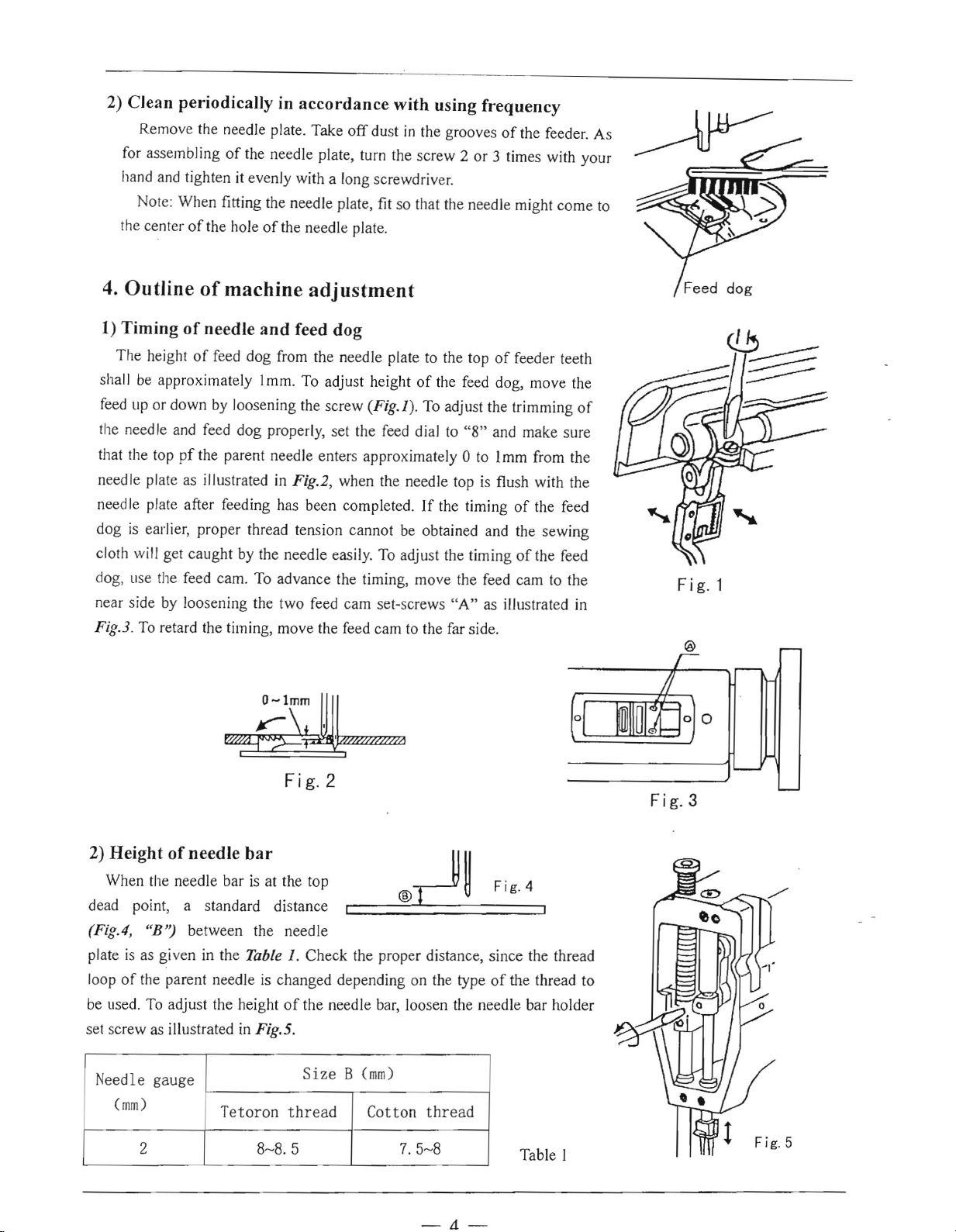

The height

shall be approximately Imm. To adjust height

LIp

feed

the needle and feed dog properly, set the feed dial to

that the top

needle plate as illustrated in

need Ie plate after feeding has been completed.

dog is earl ier, proper thread tension cannot be obtained and the sewing

cloth will get caught by the needle easily. To adjust the timing

dog,

near side by loosening the two feed cam set-screws

or down by loosening the screw (Fig. I). To adjust the trimming

LI

se the feed cam . To advance the timing, move the feed cam to the

of

the needle plate , turn the screw 2 or 3 times with

of

the hole

of

of

needle and feed dog

of

feed dog from the needle plate to the top

pf

the parent needle enters approximately 0 to

of

the needle plate .

machine adjustment

Fig.2, when the needle top is flush with the

off

dust in the grooves

of

the feed dog, move the

If

the timing

of

of

"8"

and make sure

lmm

"A"

as illustrated in

the feeder. As

come

feeder teeth

from the

of

the feed

of

the feed

Fig.3. To retard the timing, move the feed cam to the far side.

your

to

of

Fi g. 1

@

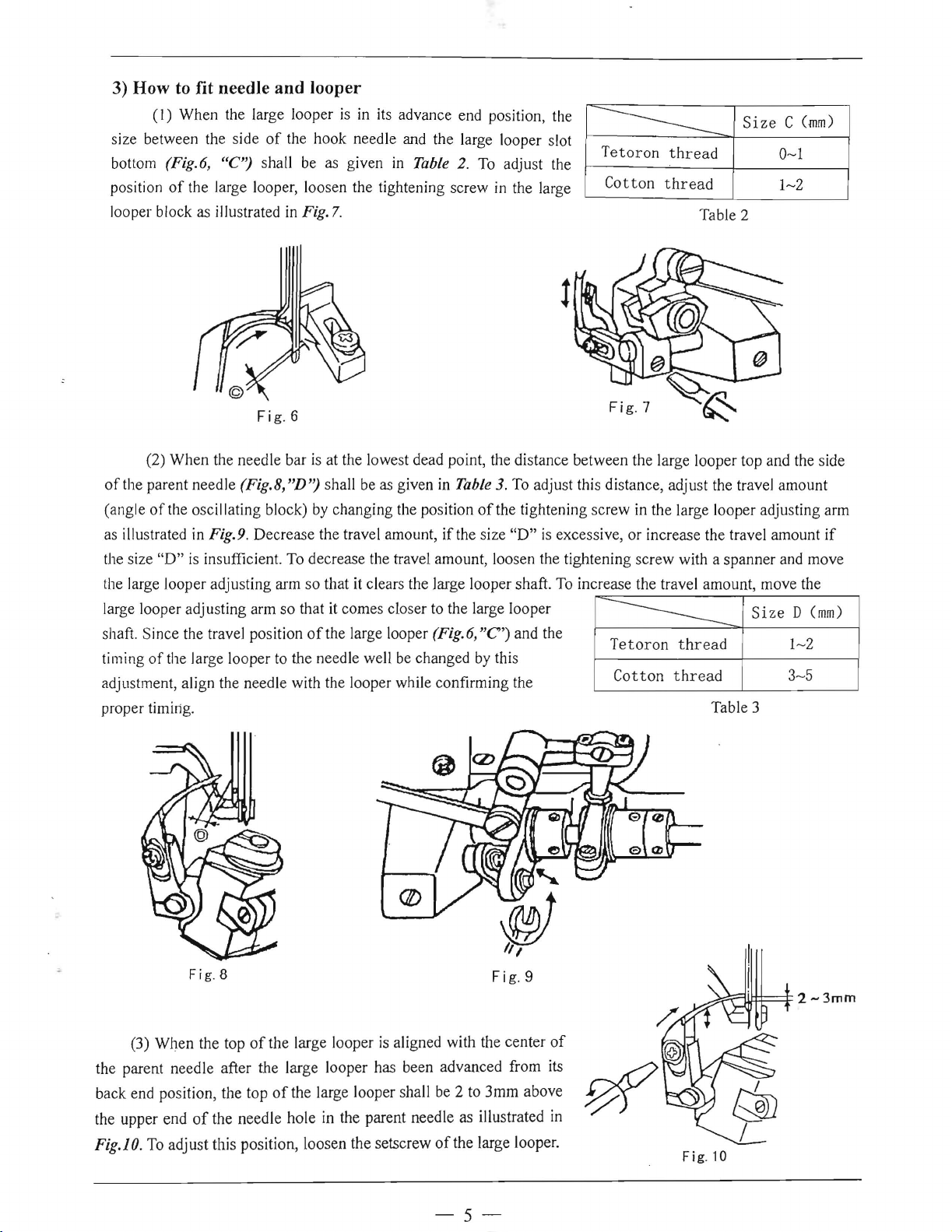

2) Height

When the needle bar is at the top

dead point, a standard distance

of

needle bar

(Fig.d, "B'') between the needle

plate is as given in the

loop

of

the parent needle is changed depending on the type

be used. To adjust the height

set screw as illustrated in

N

eed

le

gauge

(m

m)

2

Table 1. Check the proper distance, since the thread

of

the needle bar, loosen the needle bar holder

Fig.5.

Size B

Tetoron

8~8

thread

.

5

(mm

)

Cotton

thre

7.5-8

-

ad

L1-

Fig.4

of

the thread to

Table I

Fig.3

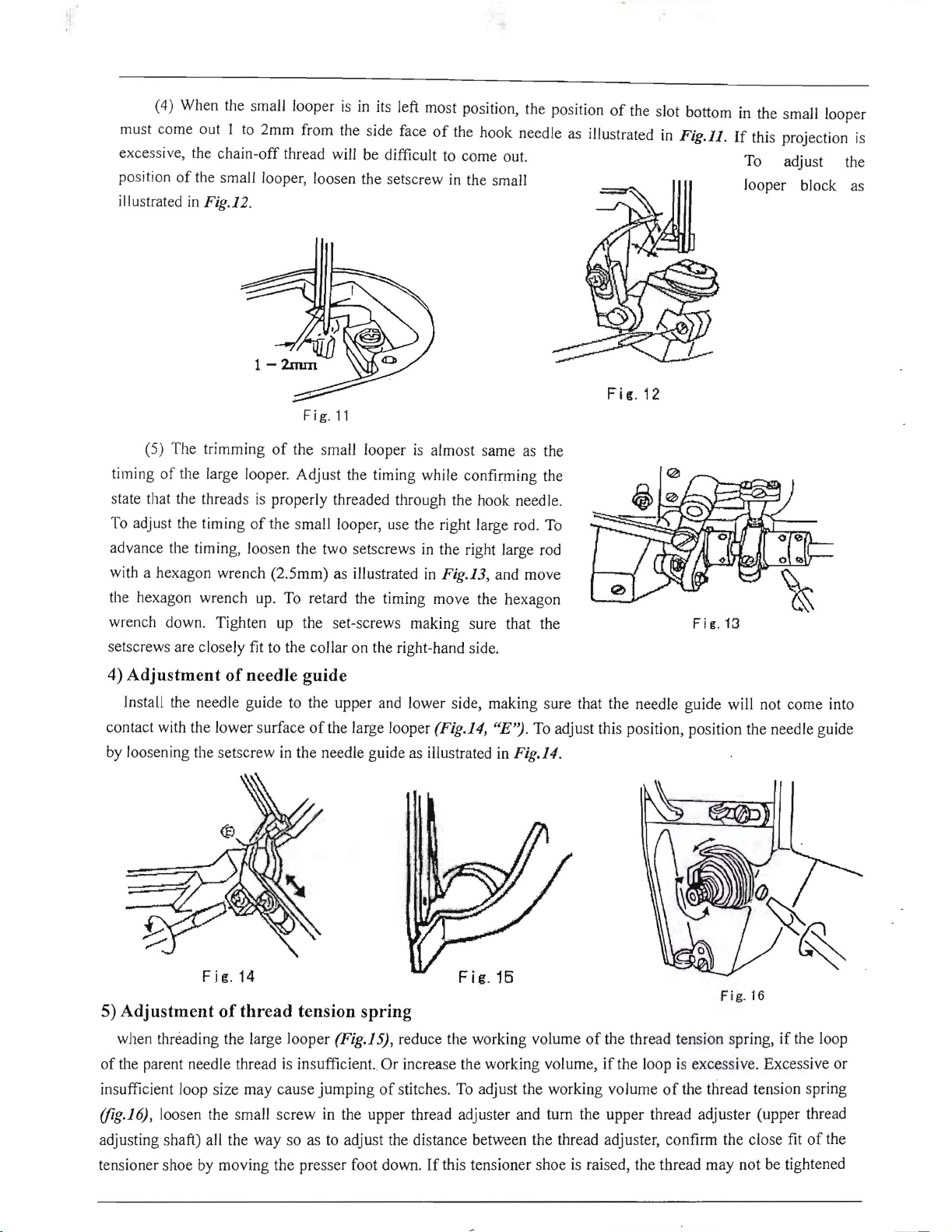

3) How to fit needle and looper

(l)

When the large looper is in its advance end position, the

size between the side

bottom

position

looper block as illustrated in

of

(angle

as illustrated in

the size

the large looper adjusting arm so that it clears the large looper shaft. To increase the travel amount, move the

large looper adjusting arm so that it comes closer to the large looper

shaft. Since the travel position

timing

adjustment, align the needle with the looper while confirming the

proper timing. Table 3

(Fig. 6, "C") shall be as given in Table 2. To adjust the

of

the large looper, loosen the tightening screw in the large

(2) When the needle bar is at the lowest dead point, the distance between the large looper top and the side

the parent needle (Fig.S,"D'') shall be as given in Table 3. To adjust this distance , adjust the travel amount

of

the oscillating block) by changing the position

Fig.9. Decrease the travel amount, if the size

"0"

is insufficient. To decrease the travel amount, loosen the tightening screw with a spanner and move

of

the large looper to the needle well be changed by this

of

the hook needle and the large looper slot

Fig. 7.

Fig

.6

of

the tightening screw in the large looper adjusting arm

of

the large looper (Fig.6,

"C')

Tetoron

------------

Cotton

"0"

is excessive, or increase the travel amount if

and the

------------

Tetoron

Cotton

thread

thread

thr

thread

Table 2

ead

Size

0-1

1-2

Si

ze 0 (mm)

C (rum)

1

-2

3

-5

Fig

.8

(3) When the top

the parent needle after the large looper has been advanced from its

back end position , the top

the upper end

Fig.Ill

. To adjust this position, loosen the setscrew

of

of

the large looper is aligned with the center

of

the large looper shall be 2 to

the needle hole in the parent needle as illustrated in

of

Fig.9

3mm

above

the large looper.

-5-

~FU.~=t2-3mm

of

Fig.10

(4) When the small looper is in its left most position, the position

must come out I to 2mm from the side face

excessive, the chain-off thread will be difficult to come out. To adjust the

position

illustrated in

of

the small looper, loosen the setscrew in the small looper block as

Fig.n.

Fig.11

of

the hook needle as illustrated in

of

the slot bottom in the small looper

Flg.Ll

.

If

this projection is

Fig

,12

(5) The trimming

of

timing

state that the threads is properly threaded through the hook needle.

To adjust the timing

advance the timing, loosen the two setscrews in the right large rod

with a hexagon wrench (2.5mm) as illustrated in Fig.13, and move

the hexagon wrench up. To retard the timing move the hexagon

wrench down . Tighten up the set-screws making sure that the

setscrews are closely fit to the collar on the right-hand side.

4)

Adjustment

Install the needle guide to the upper and lower side, making sure that the needle guide will not come into

contact with the lower surface

by loosening the setscrew in the needle guide as illustrated in

the large looper. Adjust the timing while confirming the

of

the small looper is almost same as the

of

the small looper, use the right large rod . To

of

needle guide

of

the large looper (Fig.14,

F j it. 13

"E")

. To adjust this position, position the needle guide

Fig.14.

I~l

F j g . 14

5)

Adjustment

when threading the large looper (Fig.I S}, reduce the working volume ofthe thread tension spring, if the loop

of

the parent needle thread is insufficient. Or increase the working volume, if the loop is excessive . Excessive or

insufficient loop size may cause

(fig.Iti), loosen the small screw in the upper thread adjuster and turn the upper thread adjuster (upper thread

adjusting shaft) all the

tensioner shoe by moving the presser foot down.

of

thread

tension

way

so as to adjust the distance between the thread adju

spring

jumping of

stitches. To adjust the working v

Fig.16

Fig

.16

olume

If

this tensioner shoe is raised, the thread may not be tightened

of

the thread tension spring

ster

, confirm the close fit ofthe

Loading...

Loading...