Artisan 20, 53 Operators Manual

Af2.Ti5At\J®

20-53

Operators Manual

and

Spare Parts Booklet

CONTENTS

1. Application',' , '" .. 1

2.Secure operation··· , ;

3.Caution before

4.Lubrication..· , 1

5.The selection of thread···· , 2

6.Tthe Inserting of needle····..··· , 2

7.DismolJnting the bobbin case······· '" , , 2

8.Wind the bobbin case (20U33/43/53/53A163/143, 457A1B/D)···· 3

9.Tl1read the bobbin case (20U23/23D)..· '" 3

1O.Assemblage of the bobbin···· 3

11.Mounting of bobbin

12.Thread the surface

13.Adjustment of the thread length··· ..·..·.. · 5

14.Adjustment of pressure of presser foot······

15.Adjustment of surface thread

16.Regulating the take-up

17.Adjustment of bobbin thread

operation-: '" 1

case··················

stitch·············

sprinq-: " '" ... ... ... ... 6

tension-

.. ··· 4

tension············;····

'" 4

.......•.

···· ..·..·.. 6

'" .,. 6

5

18.Needle position selection (20U33/43/53/53A163)······ '" 6

19.Horizontal needle width regulate ·.. · , ' 7

20.Locl<ing unit for linear stitching'"

21.Assemblage of belt cover· .. ··· 7

22.Mount Knee lifter (20U23/23D/33/43/143/, 457A/B/D)· 8

23.Mount Knee lifter (20U53/53A163)···.., 8

24. Mode of sewing and application of

25. Main specification ..·····..··· ..

26. The maintain of machine'" 11

·····..·······

accessories-v- , '" 9

..·..

·······..·············

..··· ..·· ..

··········

..······ 11

7

I.Ai""SJL.U""AIIUl'll

--

Zigzag embroidery stitch

..

- Pertect locl(stitch

-Extra

perfect embroidery stitch

--applicable

accurate control stitch to assure the

This

kind of

10 thin/medium/heavy material

zigzag

sewing

machine

is

2. SECURE OPERATION

1.

The

operator

understand the operation manual.

2.Whiie using it ,the

expected to do well.

3.Turn off the power or draw the

while

unfix

some

thread and no operator is on the workplace of

maintain the machine.

4.The

machine

technique.

5.While maintain the pneumatic system, the

power

checked by professional technique.

6.The power equipment should be in charge

of by professional techmique.

7.00

security adjustment method to opeerate.

Meanings

maintain

must

system

maintain

of

tile

should

of the accessories, winding

and

be do

should

the

aymbols:

be

secure

by

be

machine,

equipment is

adjustment

the

professional

shut

rtained

power

of

off

and

as

per

and

off,

the

be

the

o,

""AU

IIVI~

'. machine,do care of the following:

1.The first time for the machine work.it

should

completely.

normally or the connection box is connect well.

operator direction.

be

2.Check the power of the motor whether it

3.The

added

upper

Des-urn:.

To avoid the damage of the A

enough

wheel

should

VrE:nJo\IIVi-.

oil

to

wash

rotate

it

do

in the

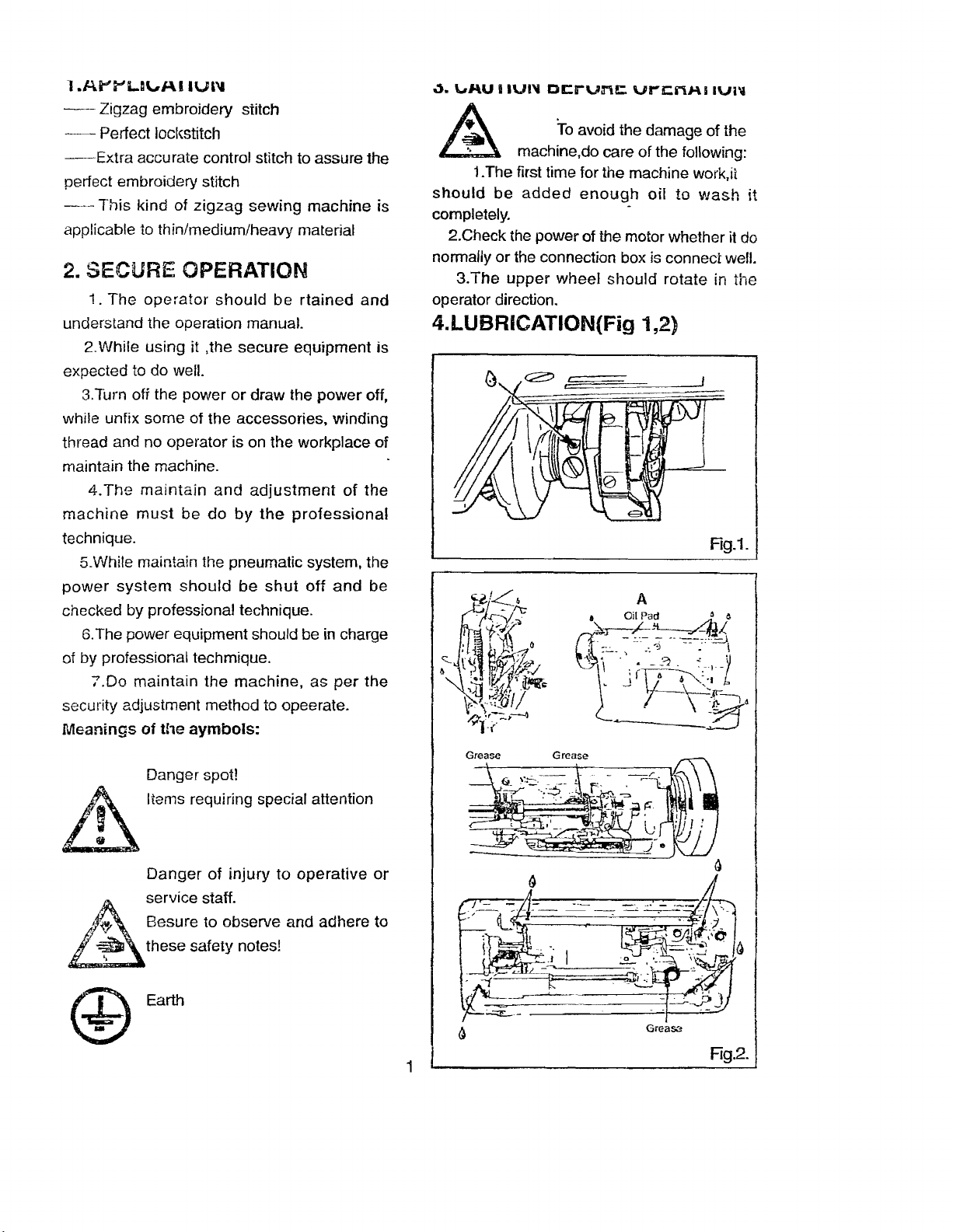

4.LUBRICATION(Fig 1,2)

Rg.i.

Danger spot!

A\

I Items requiring special attention

.

ill

Danger

service staff.

..

~

~

~

Besure to observe and adhere to

these safety notes!

'.

of

injury

to

operative

@ Earth

or

Rg.2.

1

i

.A.

Switch off the machine

Set sewing head upring again using

both hands.

I

I

Danger of crushing between sewing

Ihead and table top.

1.Rotate

,add

2.The

of oil,

3.Add

gear)

4.Pls

head.

5.Lubrication

sewing

oil.

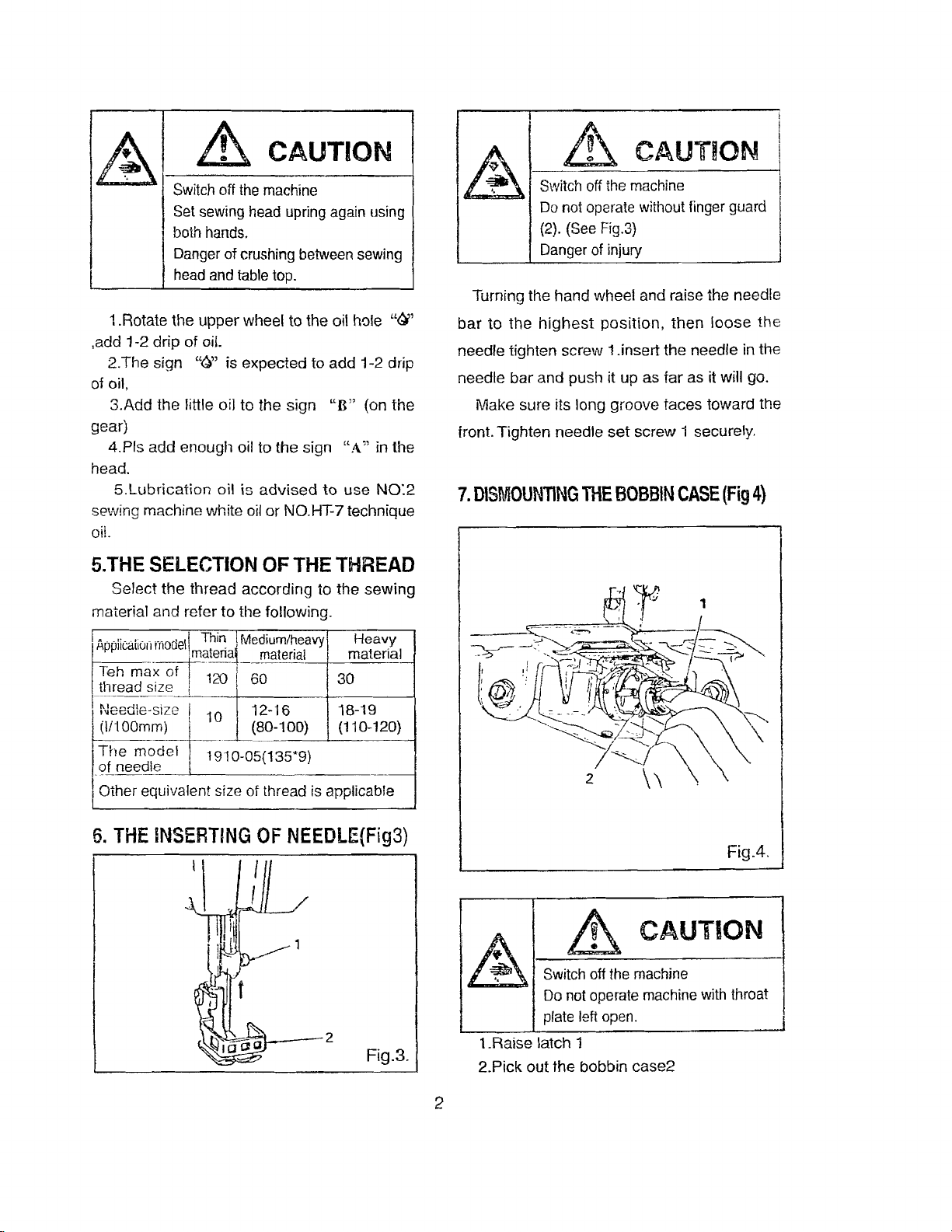

5.THE

Select

material

tile

1-2

drip

sign

the

add

machine

SELECTION OFTHE

the

and

It. CAUTION

upper wheel to the oil

of oil.

"Q" is

little oil to

enough

oil

white

thread

refer

to

expected

the

oil to

is

advised

oil or NO.HT-7 technique

according

the

to

sign

the

sign

to

to

following.

add

"B"

"A"

use

THREAD

the

hale

1-2

(on

in

NO:2

sewing

"(;j'

drip

the

the

&. CAUTION I

Switch off the machine II

Do not operate without finger guard

(2). (See Fig.3) I

Danger of injury

the

highest

tighten

bar

and

sure

hand

screw

push

its

needle

Turning the

bar

to

needle

needle

Make

front.

Tighten

7.

DISMOUNTING

wheel

position,

long

THE

and raise the

1.insert

it up as

groove

set

the

far

faces

screw

BOBBIN

then

loose

needle

as it will go.

toward

1 securely.

CASE

(Fig

needle

the

in the

the

4)

Appiic-cilion

Teh

_tbread~3.e

!Needle-size i

~1/100m?~

I

The

.()i

1Other equivalent size of thread is applicable

6.

mOdel1

.~?!~-.?-l

max

of I 120 I 60 I30

i

model

neeQle ,

THE

INSERTING

Thin.1

MediUrn!~eavy)

__

mat§nal

12-16

(80-100) I (11Q-120)

1910-05(135*9)

OF

NEEDLE(Fig3)

1----2

Heavy

matenal

08-19

Fig.3.

__

.&.

',AJ------t

t.Raise

2.Pick

Switch off the machine

Do not operate machine with throat

plate left open. I

latch 1

out

the

bobbin

CAUTION

case2

FigA

.

I

2

~.

"VaNU

(20U33/43/53/63/143, 457AlB/D)

I

til:.

tsUtst:HN

\1'''''9

1

0,0)

e.r-usn iatcruz] In

arrow

(A), bobbin winder spindle (3) rotates in

the

direction indicated by arrow (B), to

the

amount

screw(4} on latch (2) and swing

from you or

4.1f

loose

down,

toward

the

thread

the screw 5,

as required andtighten

me

of

thread

you, as required.

is

uneven

move

orrecuon mcrcateu oy

on

bobbin,loosen

the

on bobbin,

the

pre-tension up or

screw

latch

5.

adjust

away

firstly

Fig.5.

9.

(20U23/23D)

Fig.6.

I

I

A,I------------1

&. CAUTION

Do not guide or

winding

the bobbin.

110Id

thread when

shaft, push the thread adjustment plate 9, wrnd

the shuttle thread.

of

I

10.ASSEMBLAGE

1.Stop

molion screw 1, hold hand wheel with lett hand

and tUITl s!owmolion screw toward you with right

hand.

2. Place bobbin on bobbin

pushing it on as

+-----·---more tension

- ---------Iess tension

motion

needle

tar

by

loosening

winder

as it will go. pre-tension 1.

spindle 3,

stop-

into

2.(Fig.9)

1.(Fig.10)

th read

out

THREAD

THE

BOBBIN

CASE(Fig.

7)

Fig.7.

.& CAUTION

~

1.Put

2.Adjust the

the winding thread.

(FigS.9.1

1.Put the bobbin into bobbin case. Pull thread

notch 1 and

2.Draw thread

of the bobbin.(Fig.11)

Do not guide or hold thread when

windingthe

the

shuttle

screw

bobbin.

core

8, to

into

change

OFTHE

0.11)

draw

it

under

tension

out

form slot 2 on end of spring

and

pass

it

through

guide

(1),

allow

about

60mm

the

winding

the tension

BOBSiN

spring

bobbin

of

thread

case

I

I

3

4

Fig.9.

Fig.8.

Fig.10.

~

Switch off the machine. . I

Do not run machine

bed

s}ide.

12.

THREAD

HES(Fig.13,14,15,16)

CAUTION

Dandger

SURFACE STITC -

w~t~out

of

InJury!

I

I

Rg.12.!

!

I

closing i

J

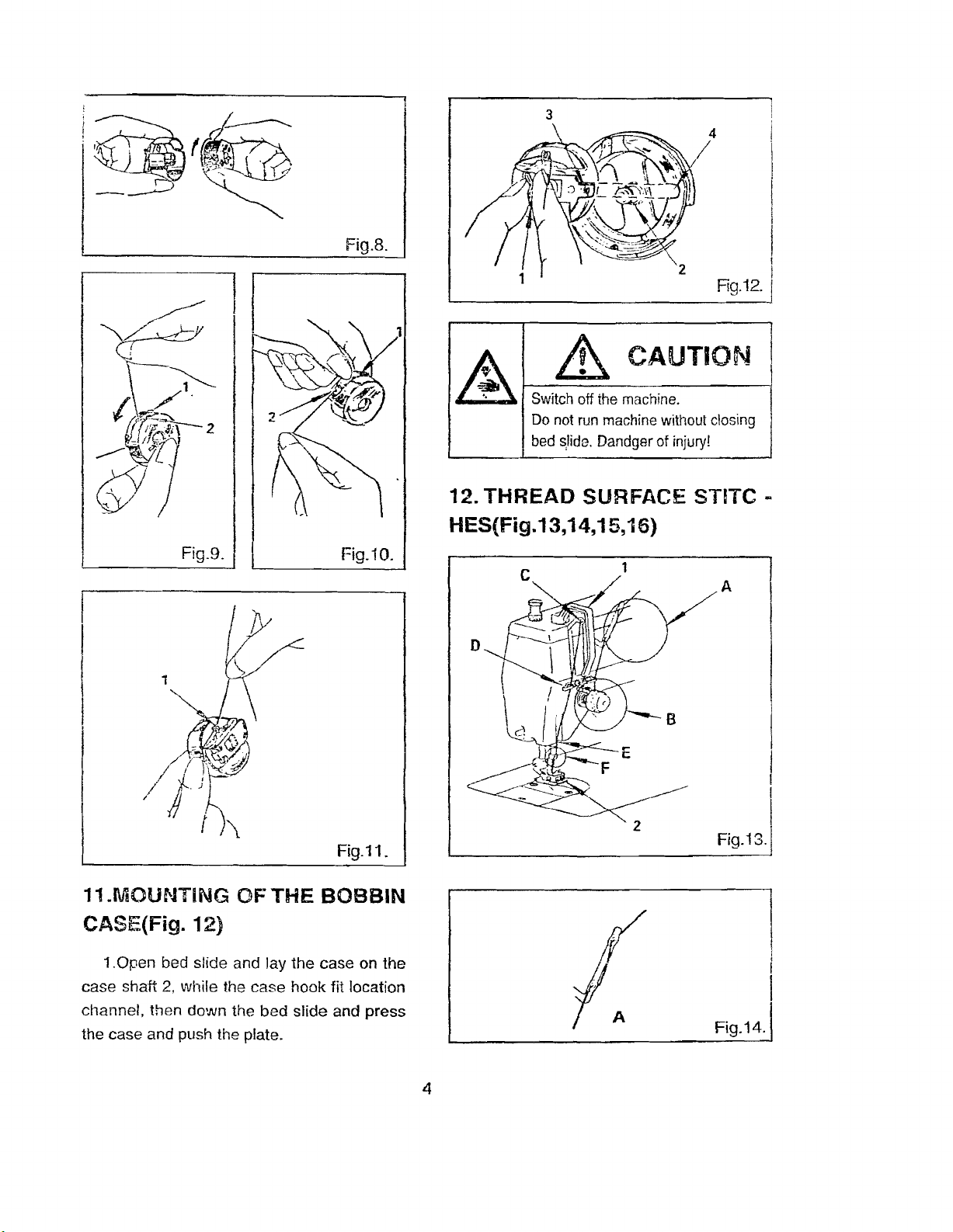

11.MOUNTiNG OF

CASE(Fig. 12)

t.Open

case shaft 2, while the

channel,

the case and push the plate.

bed slide and lay

then

down

the

THE

case

bed

Fig.ii.

BOBBIN

the

case on

hook

fit location

slide

and

the

press

B

I

I

I

Fi9.13.!

(

Fig.14.

4

1'::---3

Fig.i5.

F

~

Switch off the

Do not operate without thread take-

up guard.

Do not operate without finger guard

Danger

1.

Raise

position, then pull the

A(Fig.13}, B(Fig.14), C,D,E and F.(Fig,16)

2.As

3.Pull about 100mm of thread out.

thr

needle

fig.16, thread from forward to back.

CAUTION

machine.

of injury!

bar

thread

out

to

the

and

Fig.i6.

highest

through

2

2

Fig.i7.

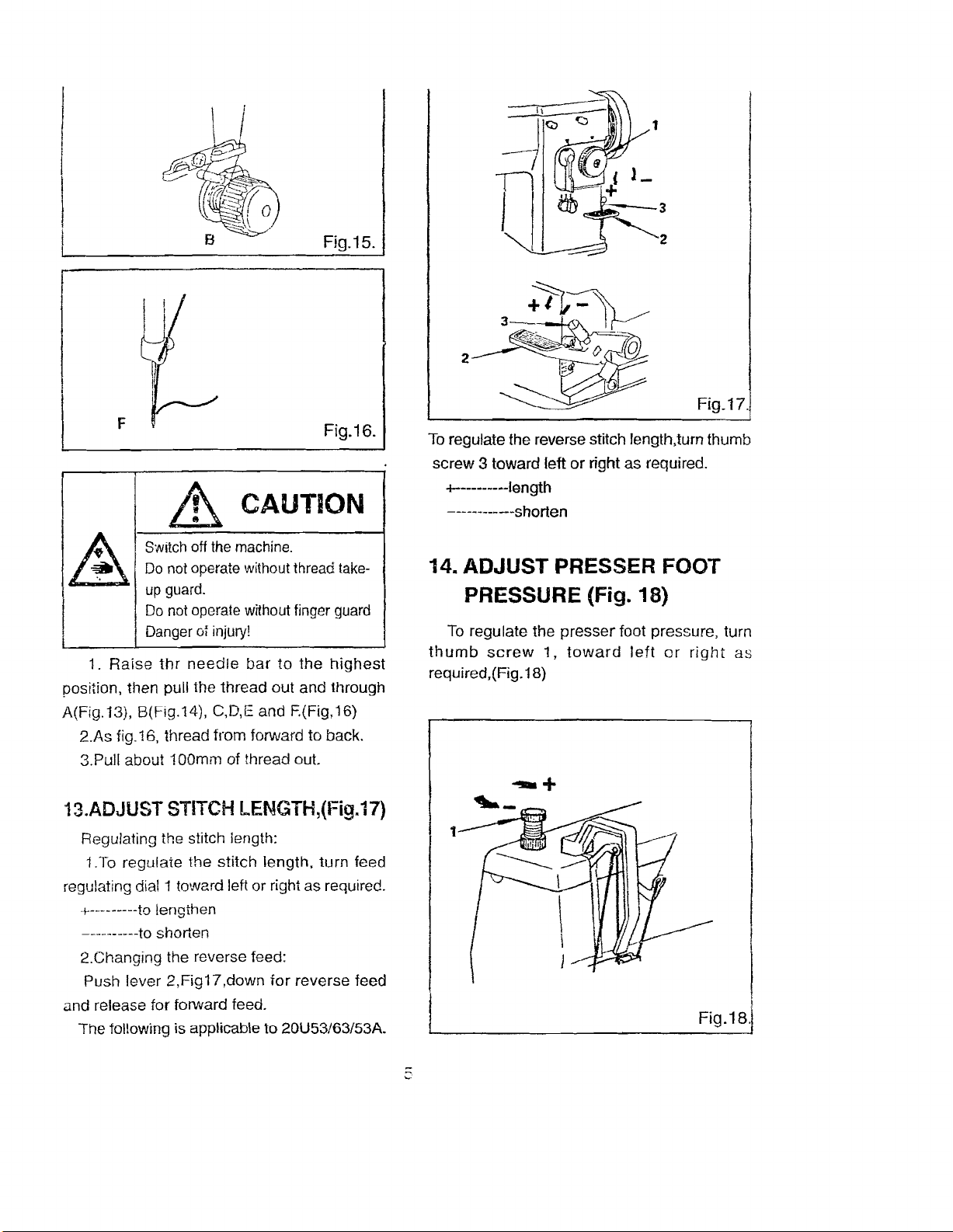

To regulate the reverse stitch length,turn thumb

screw

3 toward

+--------~-Iength

-----------shorten

left

or right as required.

14. ADJUST PRESSER FOOT

PRESSURE (Fig. 18)

To regulate the

thumb

required,(Fig.18)

screw

presser

1,

toward

foot pressure, turn

left

or

right

as

13.ADJUST

Regulating the stitch iength:

1.To

regulating dial 1 toward left or right as required.

+---------to lengthen

----------to

2.Changing the reverse feed:

Push lever

and release for forward feed.

The following is applicable to 20U53/63/53A.

STITCH

regulate

shorten

2,Fig17,down

the

LENGTH,(Fig.17)

stitch

length,

for

turn

reverse

feed

feed

I

Fig.i8·1

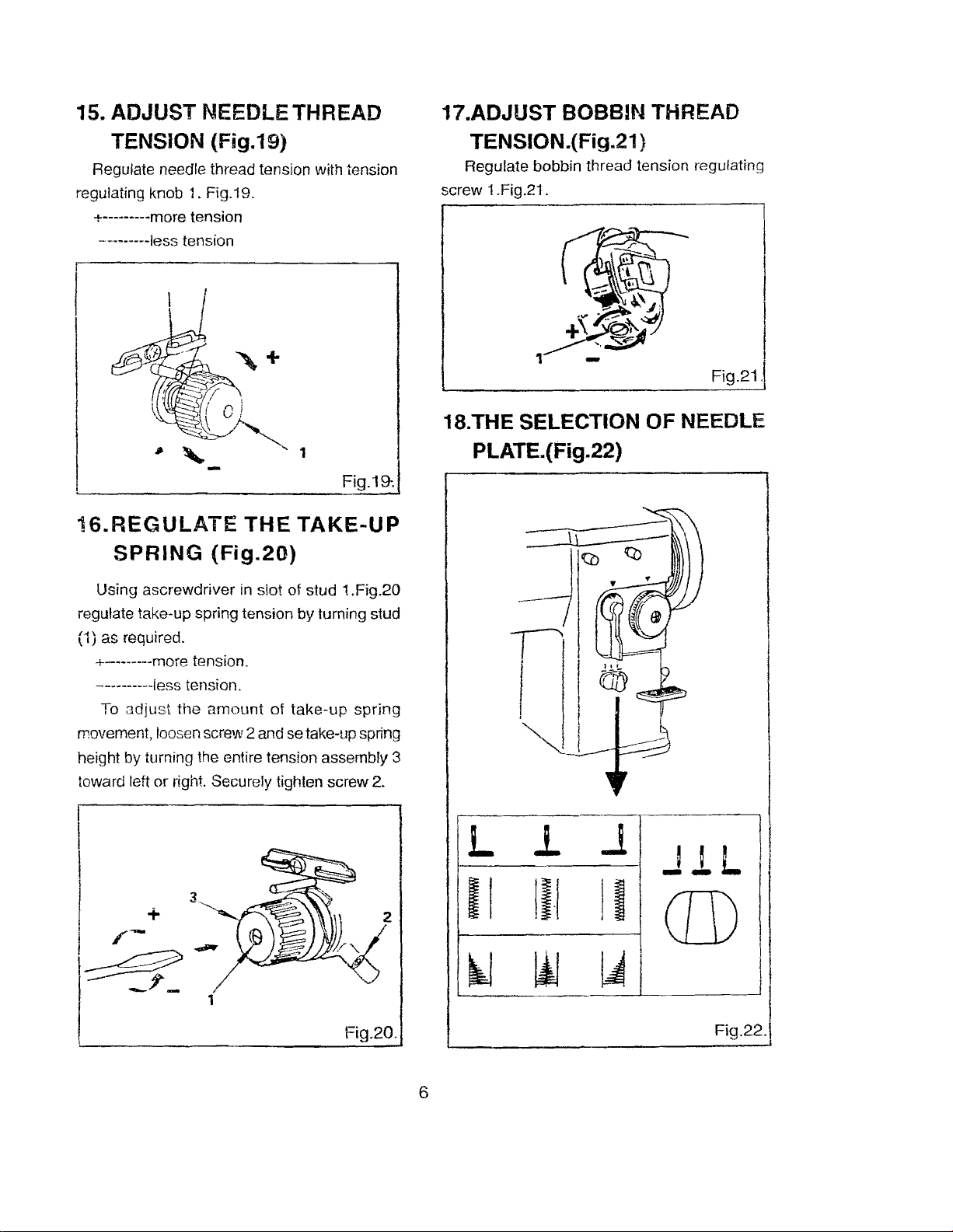

15. ADJUST NEEDLE THREAD 17.ADJUST BOBBIN THREAD

TENSION

Regulate needle thread tension with tension

reguiating knob

+---------more tension

---------les3 tension

i6.REGULATE

SPRING

Using ascrewdriver in slot of stud 1.Fig.20

regulate take-up spring tension by turning stud

(1) as required.

+--------more

----------iess tension.

To adjust the

movement,loosenscrew 2and setake-upspring

height by turning the entire tension assembly 3

toward left or right. Securely tighten screw 2.

(Fig.19)

1. Fig.19.

THE

(Fig.20)

tension.

amount

Fi9.19-·1

TAKE-UP

of take-up spring

TENSION.(Fig.21 }

Regulate bobbin thread tension regulating

screw 1.Fig.21.

l

I

Fig.21 J

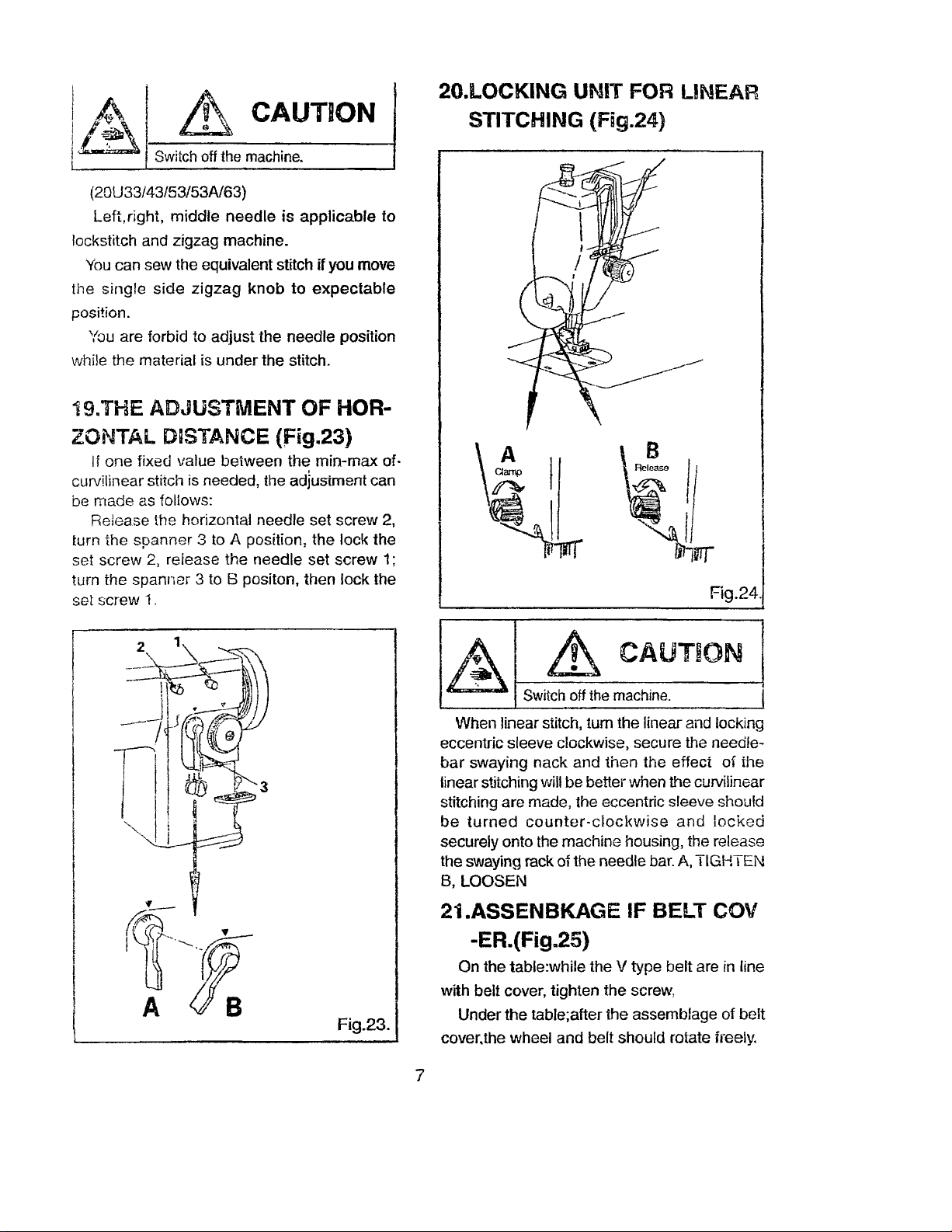

18.THE SELECTION OF NEEDLE

PLATE.(Fig.22)

I

I

I

I +

I r :

I~

_?'-

L

II

~

1

Fig.20.

6

Fig.22.\

I

~

lilll-----l

I" Switch off the machine.

(20U33/43/53/53A163)

Left,right,

lockstitch and zigzag

You

the

position.

You

while the material is

I 6 CAUTION

middle

can sew the equivalent stitch ifyou

single

side

are forbid to

needle

machine.

zigzag

adjust

under

is

knob

to

the

needle

the stitch.

applicable

move

expectable

position

20.LOCKING UNIT FOR LINEAR

STITCHING (Fag.24)

to

19.THE ADJUSTMENT

ZONTAL D;STANCE

If

one

fixed

value

between

curvilinear stitch is needed, the adjustment can

be

made

as follows:

Release

turn

set

screw

turn

the

set

screw

the

the horizontal needle

spanner

2, release

spanner

1.

3 to A position,

the

3 to 8 positon,

needle

Of

HOR-

(fig.23)

the

min-max

set

screw

the

lock

set

screw

then

lock

the

the

of-

2,

1;

Fig.24.

~

Switch off the machine.

When linear stitch,

eccentric sleeve clockwise, secure the needlebar

swaying

linear stitching will be better when the curvilinear

stitching are made, the eccentric sleeve should

be

turned

securely

the swaying rack of the needle bar. A,

B,

LOOSEN

nack

counter-clockwise

onto

the machine housing, the release

CAUTION

tum

the linear and locking

and

then

the

effect

and

TIGHTEN

of

the

locked

Fig.23.

21.ASSENBKAGE IF BELT COV

-ER.(Fig.25)

On the table:while the V type

with belt cover, tighten

Under

the

table;after

cover.the wheel

and

7

the

the

belt

should

belt

are in line

screw,

assemblage of

rotate freely.

belt

Loading...

Loading...