Artisan 196 R-2 User Manual

Model

Single Needle Lockstitch

Medium Speed Sewing Machine

196

R·2

With

Automatic

Instruction

&

Spare

Parts

lubrication

Manual

List

Operation Manual

1.

Introduction

2.

Main

technical

3.

Installation

3.1

lnstallatiOII

1)

Place

2)

Fitting

3)

Fitting

4)

Fitting

5)

Installing

6) Sketch map

3.2

Operation

1}

Cleaning

2) I n

3)

Lubrication

spec:tlon

··· ··•

··· ...

specltlc:alions ••· ·-......

and

opeution

of

machine

of

Installation

oil

pan

......... ·-·••

machine

thread

winder ... ... --·-·-.........

the

belt

of

machine stand lnstaUation .......

preparation

... ·-... ·-...

............

......... ·-...

CONTENTS

•••

......

···

.....................

••·

...............

preparattaa

.............. ~ ...

.....................

...............

head ·-........................................................................

cover

......

.........

·•·

..................

••• ·-...............

-·

..................

···

............

•••

... ·-... .

of

·••

·-

•••

••·

••·

·--

·•·

•··

···-

madalne

............... ·--····

...........................

·••

.....

.........

...... ·-··•

·••

... ·-......

·••

•••

............

·••

...

·••

.........

•••

............ ·-...

••·

···

.........

·••

......

......

•••

.........

····-

......... ·-..................... ·-... 7

......

•··

···

•··

···

-~

......

••·

...... ·-...

•·· .

.................

............... ·•·•··

--

........................

••· ·-.........

·.··

............ ·-...

...

...

···

............... ·-... ··· ···

·•·

... -···

·•·

... · ••

.....

... ·•·

...... ··•

••·

... ... ...

...

·•·

......

.......... ·..

......

·••

.........

.........

•••

... ... ... ...

...

•·•

••• •••

···

.........

.........

••·

... ... ...

.........

···

..• 4

···

...

......

......

......

......

4

5

5

5

s

5

5

6

7

7

7

7

-2-

4)

4.

Operation

4.1 Selecting

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

5.

Regulating

5.1

5.2

6.

Common

Testing

Needle

Fitting

Threading

Winding

Threading

Loading

Regulate

Threa

Adjusting

Regulating length

·•· ··• ··• ··• ··• •·• ••· ··• ••·

•·· ··· ••·

and

needle

bobbin···

and

d

tension

Regulating

Regulating

machine

troubles

Parts Book

1.

Accessories

2.

Components

3.

Upper

shaft,

4.

Presser

5.

Components

6.

Feedin9.

7.

lubricaton

8.

011

9.

components

10.

11.

bar

lifting

re

servo

Co

mponents

Components

···

·•• ··•

sewing

needle

thre:a d

...

... ···

bobbin

unloadng

thread

···

......

......

.......

ease

gauge

..................

pressure

thread

...

··•

looping

components ...

ir & !!nee

time

of

and

methods

of

machine

of

case

needle

components

oJ

lower

belt

of

thread

of

table

or

m

aclline

•••

............

...

· ·•

...

··· ... ··· ··· ...

.....................................................................

•··

···

··•

...

·•· ··· ··· •·• ··•

···••· ...

••·

hook

•••

...

............

........

..................................................................

bobbin····

•nd

of

pre~r

··•

•·· ··• ·•• ·•· · ··

··

feeding•··

···

............................................................

...............

...................................................

...........................

of

rotary

feed

dogs

.......

of

treatment

head

........................................

·•·

•••

...

··•

.........

............

......

hoolo;

.........

...

............

···

·••

•••

·•· ·•· ·•·

...

··•

··•

...

... ·••

......

.....

. ·•·

......

••·

•·•

...

·•·

··· ... ···

··• •··

···

•·· •··

•••·•••••••·

........................

·-

...

...

........................

·•• ••·

....................

··•

...

•••

...

...

···

•·•···

...

...

... ···

...

.......

....

..... •·•

............

...............................................................

bar

components

......................................................

shaft

and

components

....

..

lifter

componet~ts

winder,

plate,

electrical

stand

.........

rotary

...........................

•·••••

...

double

........................

··· ···

hoolc.

:"

·••

......... ·-...........................

·-

..................

1hread

equipment

·••

...

••·

bobbin

...

............

•••

..................

·.••

·••

.................................

......................

.....

·••

···

··• ...

···

...

··· ···

··•

···

...

···

··•

...

···

.........

...

•·· ···

···

......

..........

...

·•·

......

···

............

......

... ··· ··· ... ··· .•.... ···11

··•

...

··· ···

.........

.

··· .

..... ······

.......

..............................

.

···

... ... ... ...

..................

. • ·•

·•· ··•

...

••• .

......

............

....

......

............

.

..............

···

... •·•

............

... ···

...............

·••

... ...

···

......

......................

•··

···

.....................

.

...........

••·

.........

...

... ...

··•

···

..............

...

... ...

...

..

......

...

......

••·

...

···

......

··· ...

.....

·•·

--·18

...

---19

··· 28

...

... 38

...

s

9

9

10

i1

11

13

14

15

15

17

17

17

19

22

23

25

30

32

35

40

43

45

-3-

1.

#I.H~?t-

1. INTRODUCTION

i

~:

!1

f.)J

:lmilll·1"

1lt

;'-P..

:if~

~lilli!d~liJ~.

fflr~~nf.

?i!!JH~~

a

nd

llu

tomat

with

durability

cq

uiptmept

cotto

2.

2.

I

tf

J.ffi.P$1Jiftr~tt.

-

This

10in

gle

Dcedle

is

s

uUed

for sewing

ic

oil sys

control

n .

:±~lt*'~~

MAIN

v11

is

~:re:nly

used in

wool.

fobric and light leather,

TECHNICAL

tJl

Ji-

_.1Utt!J:t~Ijk

*ffliiii!U

mllchiue

tem. including

lve. For

i

nuE>a

the

tTade

i

fJJJ1nS:Ji!~HJl.#i.

tfi)

.

-

u~1.&fttf4J~r!b&~~~~~.

iB

man1.1!actared for

light

weight

adopting

se

of

SPECIFICATIONS

and

the

automat

high

a.nd

the stitch Is

garment, shoes

Jfl

~

m tit.

ii1f

~

fF~JJ

'*=*HBI

.medi1.1m we

ic

oil

of the

speed sewing machine

and hat

artisan

ight

.-otating

exq

uisi

s, which

T

r.tiamJnrt/k~ifl~~$

material.

te.

196

iill

itt

f:.

tT..

.

§

tiS~

~

f3 ~ ili1

.

j~

~IJR~. JUiHr~li~J.lll~

lockstitch

hook nod a

[t

which

feedint

is

the

is

suitable

sewinr;

ttQuiped

lso

struc

ide

for knitting

machine

equ\ped

tur

e. the

al sewi

with

ng

,

R 2

2 ,

~--+---------------------------~----------

3 '

·-4

5

l----1-----------

6 I It! t

1

2

3

4 ;

H;}f\l11Ht~Jll l 6::'~

1!6t!UI:

:k.

"ll

--~~--~-.ffl--l

;

i

-Lff----------

1trh

$

Max. u

Pr

Sewing

Needle

esse

eedle

T

lif

ting

ability of

------------

-

---------lc---·--

length

amount

tbick.oess

max.

----·-- --G-

5:"6

j

380V/370W

I

4mm

6mm(l0mm

Smm(Cree

Model

7.c

O!H~

;..T.i!

* < rl

d!tt

V-3(_1

._6_

x_2_3_l~

--

---

-

by

state

GVS.

#66-#110

lO;'l*

--

>

-----

:$ >

--65----#-l-l0--

--

----

knee

lift

ing)

)

~

~

-=----t

#10

5

6

Lubri

Pow

cati

ng oil

er

of electric

macbioe

- 4-

white oil

380V/370W

3.

~25~~~-fFXUi

3.

INSTALLATION

1.

til.~~~

\ 1)

~~-H!.#:

k~

m~#~•~"w~~. ~~~.~~~~w-~~oo•~m~~~.

ijx

~

ftl

Jt!uili..!

faJ

.ff~N-

t'JIJ

!

2)

i

lll:&ttt:J~'W

WJ±IiHi

ll!ft"t!f

t:im~

4.

<m

l

3)

I'll~

..

~'P

'll·~~.f~

JDIY-.Jtn~~~

1.

lnstah.lion

(

1)

PlnC".e

Th

t!

machine

r

et

1

Put

ers

(3

Put

oC

the

noise

:!1

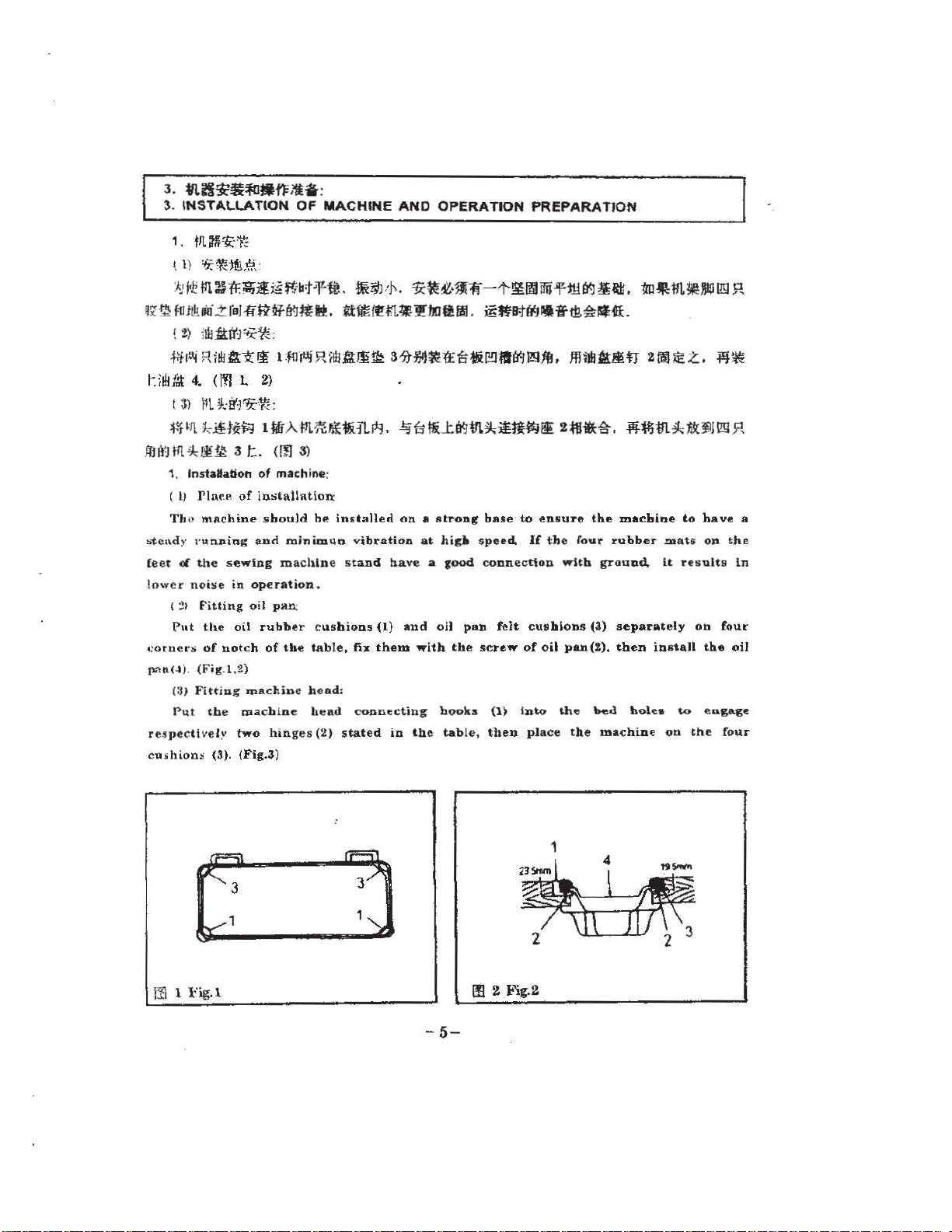

(Fig.l,2)

)

Fitting

unning

Fitting

tile

of

notch

the

(3).

"''teady

(e

lower

o.:oru

p.'ln(-1).

respectively

cushions

:

l:f1J'Jtli

t

z>

!'!':~~~:

f-1

HdJ

JdJl?i~

3/:.

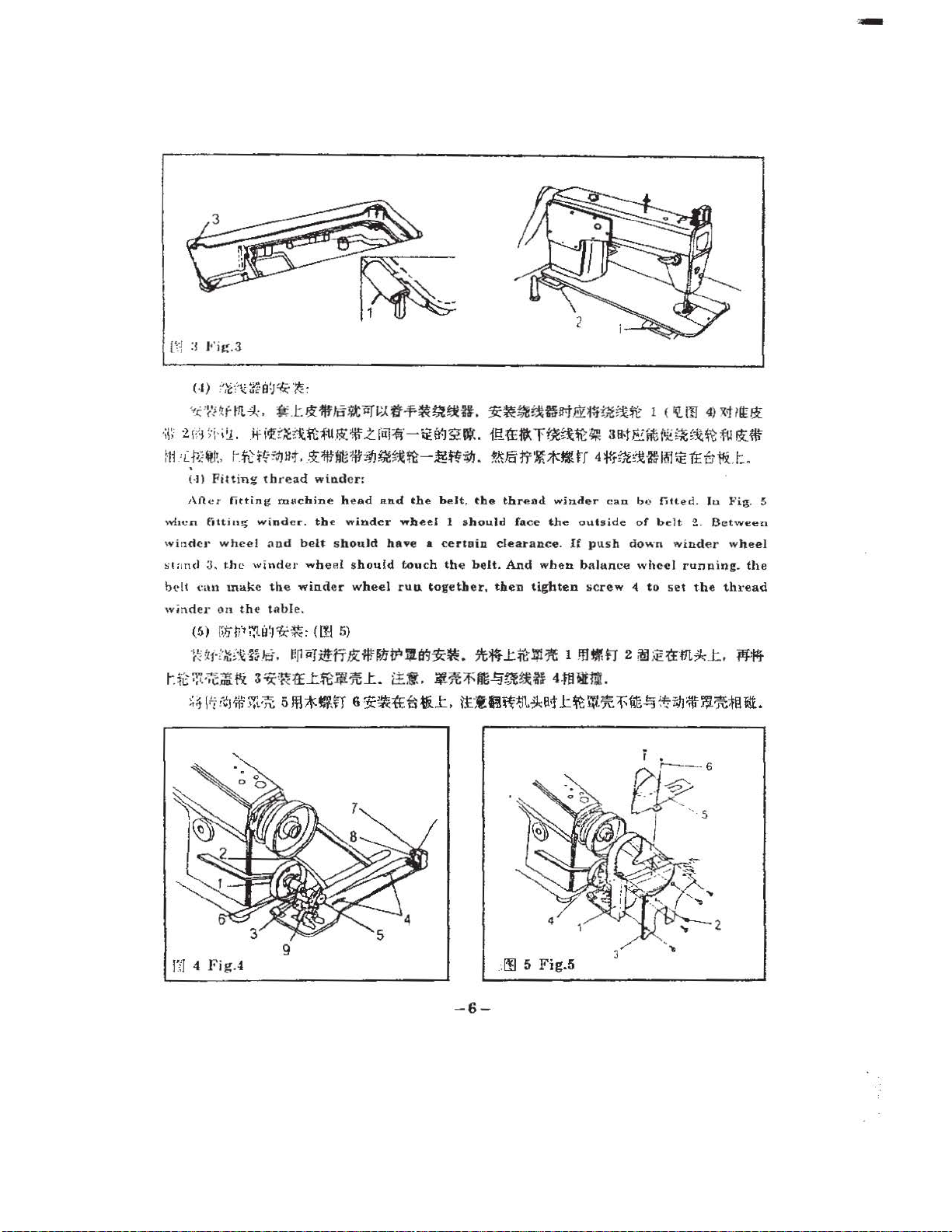

([!J 3)

of

machine:

of

installat

should

and

min

sewing mach

in

operation.

oil

pan:

oil

rubber

of

the

machine

machine

two

hing

(Fig.3)

:

OF

MACHINE

1t

t!.

it~ tl

Q

~f6:m~

ti.rt.~

ion:

be

installed

imun

vibration

ine

stand

c

~asbion:s

table,

fi:x

head:

bead

connecting

es

(2)

stated

AND

OPERATION

PREPARATION

~~m~~~g

m~

1!'

1.11

&

1M

.

jglf~(f.J

3%M~

.

have

(l)

them

in

t£~

~1!!111{f.J~IJJ.

.!ja1i.ti¥J111.~iitl~!l

on a strong

at

a

and

oil

...,ith

the

high

cood

the

hooks

table,

base

speed.

connection

pall

screw

(1)

then

felt

•

to

en•ure

If

the

cushiolls

of

oil

into

place

il-1B

~-~.

lf!i!:AtlitJ

2:m•*

the

four

with

ground.

(3)

PUI(!).

~e

bed

the

machine

200

·

.tij.~1fl.~:$:

machioe

rubber

separately

then

install

holes

~2:. M~

J.1Jl!Y.R

to

have

a

!llats

on

the

i.t

results

to engage

on

on

the

the

in

four

oil

four

ru

1

(_:

I'ig.l

__

T...,J

-

l!l 2l''ig.2

5-

(4)

:'

,'(;''~~e:J~·~:

-~d~~

ftll.*·

·i\i

:.?.(

}J

\·

h1.

t'!1

.

•i.PJ.~f!.,

(·I I

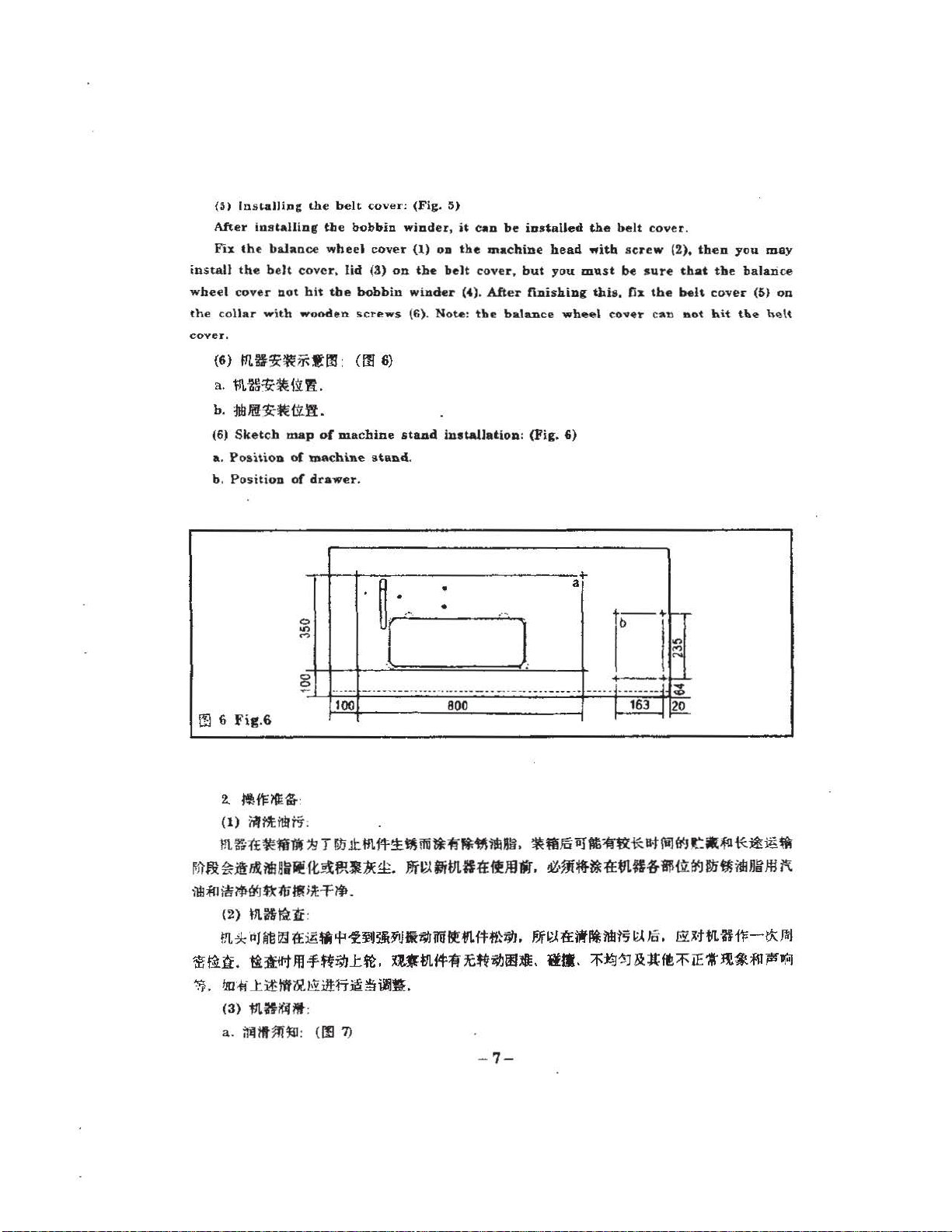

Fitting

All

c1·

fitting

when

fittin~

wi

nder

wheel

stand

a.

the

bdt

('0111

make

winder

1-:tl:

on

(5)

j;jj!J'

·f~~f··n~;;~,;-~~

:;u:r:;:

~H'F~Jffi'm-~

~-t~1Wrci~iiTVJ~.f-~~~H.

.ifift~iii.~:f11

:·.

fl:t

~~~~r

th,·ead

ro~t

winder. the

:tnd

wind

l!l'

the

the

table.

1

~.itJ~~:

.

lti.

P.faH!HrElm'~ntMltfJ~~.

fii 3 ~

'

}Hf_t.ffi

smi\C~tr

.

1R*

Z.flil~--~(t.JQ~.

...

~~1m'!#'~~

winder:

chine

head

belt should

whe

el

wind

e r

and

winder

have a certain

should

wheel

~~-

wheel

run

([!! 5)

4{

it:

_t.

B:

6~~t£fl*..t·

~~~-

the

belt, the

1

touch the

together,

:t..

il%

~~fi>'I!~GB:tEY:~~t't

1!!£:~Tm~W:~

?.~JiH

r~/fc

r.t

thr

ead

winder

shou

ld

fa

ce

the

clearance.

belt.

And

when

then

tighten

~~.t.~1J17f;

~

MP~i~~

~·:t:a~m.

1

ff

Htnltmi.

-

9.:~1

<tJ:~~~:r-~~l:j

#.

!H'\':

1 < '

i!.l1l

aR•tEfR.fl'.!i~f:"~~:fU

tJ

4

W~:~·~l~

can

outside

If

push

down

b

ala

nce

screw

m~tr 2 ~:@~mfk.t.

~

i'fti'

bo

fitted.

of

belt

2.

winder

wheel

running.

<t

to

set

t.he

~~14l*?.L

4) X

1'11tet

J!i.-*

'\fi..t.

lu 1-'

ig.

Between

wheel

thread

MJ~;

~t!

-

5

the

i!t.

n1

i .

rr:

9

.1!1

5

4

Fig

A

Fig.5

-6-

3

{5)

Installing

After

installing

Fix

the

install

wheel

the

cover.

the

cover

collar

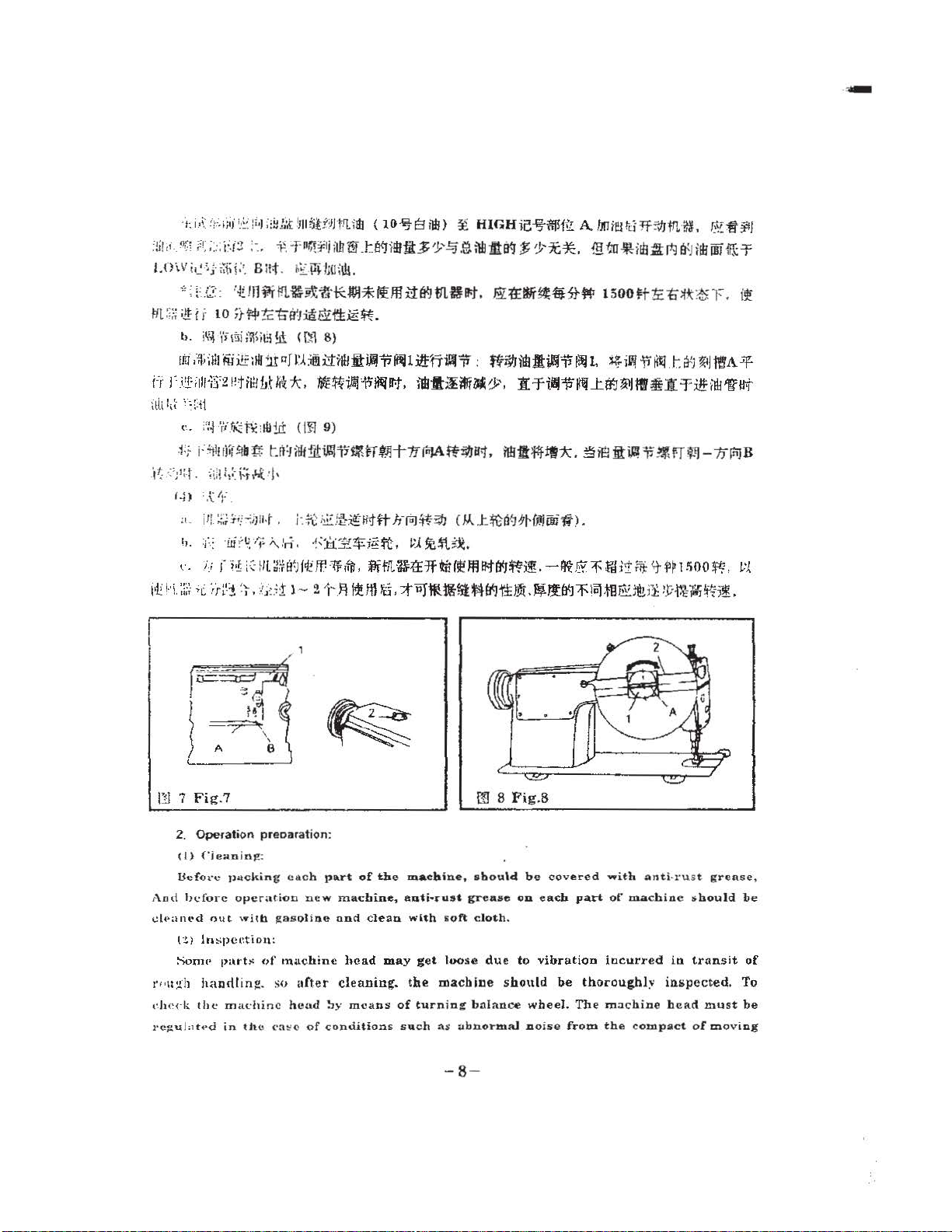

<6>

m.H:~~if-tm:

a.

m.g~~i~?i..

b.

:JIIllii!:£~~}1:.

(6)

Sketch

a.

Position

b.

Position

balance

belt

not

with

map

o(

o(

the

the

wheel

cover,

bit

the

wooden

of

machine

drawer.

belt

bobbin

lid

machine

cover:

cover

(3)

bobbin

screws

(m 6)

stand.

(Fig.

winder,

(1)

on

on

the

winder

(6).

Note:

sta~ul

•

•

5)

ic

c.n

be

the

~~tachine

belt

cover,

(4) .

After

the

balance

insta.Uatioa:

installed

head

but

you

finishing

(Fig.

must

wheel

6)

the

'l'fith

this,

cover

belt

screw

be

fix

cover.

sure

the

can

(2),

that

beh

not

then

you

the

covel" (5)

hit

may

balance

the

he\t

on

1

8

crJ

6

Fig.6

2.

~i"F~"i-

(1)

~~iltrt'I

m~T£~*i'ft:9

flil'

S~~flt~Bili!

l"lll

;f!J

iii

?i'tgq

tk

*

(2)

m.3~lf

100

:

:

T

ll}j.ti:#l.1!f'~~ffiiti:fiJ*~iSI8!i.

·

ft~~--~~-

iJ.{

iJt:

-F

Itt -

:

~lfJllrVI.fttfflJiliJT.

-- --------------

800

~~J5PJn;1iW*ll'tfileqt:JUu*ltiE~

!IIHJi:tf~:A:mft*li!H

m*~~~&~~~~~~~••w~m~m•.m~a~~~s~m.

*~~.~~m~~~~~.

~,

Jm#

..tl!!Wf&bi.i!fi~

<a>

mH=il':41f

a.

i'filtfffl~

:

:

(l!l

7)

~•m~~~"~m•.••·

~

iJU!t

-

7-

+--+-

-·

-----I--------~

T

163

~~~&~~~~~~~~~~

~

I~

~

!filtH!Sn!IH~Jff~

~Mm~~-~rn

.

,_

;t:i·'->·~;iii;

:!1!

<i

.

91?

LO

W

i·~·~j-

"; l'

l=

n~;

;

i.!!'/

h.

!iii

fi'

f.i!h!ll"l:i'2

ail

'•i

.,,,i1

t'

.•

.i;;.

1

-'rt.

.-:';

:-

t. iii! :,

l.j)

a.

h.

\'.

i•!::

h.:;;;

_

,~:i•L:~J;•

;;,; ::

:: H2

i';t

i

F'.

..

0::

'

-l!lfli'T

i·

10

7}-~:Ctia1:U[~1i~~

i~l'1'i1!ii

,'ij;i!il

~ili:lli

!!til:i!h.t

i':.j

'r'if~t~

i:

1111

iif $tb ft. r

::

Fr

; .\ ,,.. .

f!L

~;;:r;

_::-;!

:;::

·m"~

!:<

(Hi

>c:

!r1'1

~~. :~;::::t

.t1JII~4fJJt.fUliJ

:-

..

~-~

rn~i-'iilb

Bat .

b!{_.j:r~1iUill!.

m.

i$~tH~WI7fdtJtH!B9t11.JUt

;11~\l~

~

({}1

it

aftl.:iii.u~

Ia

1\,

:

lllid:

(1~

.ri11llt

>'-

t '

I,

Jii·t

. i

·.

.-:;

;

"!ri

·.

(:

!ll~~8~Jf<l!ff!·1Hn,

1--

(

10-i}Sill!)

@"

.te<J)mfi..t-'J-

-

S)

lll:itl.il17"'ll~tr~'$'

~~i!'31'~!J:t.

9)

:ill:i.l\1

i7~fr

f...li+n

:hl

i

~Jf!~li1

~;:tl3::

2.1-

ft

/irt:J~~

$j£~.

.1=!

11!ffl

v.a~.-*l~.

~tt't~1±fftii~JfJBfi¥J~:i!.

Jti.

/f"UJ*-:t!filMtfltl:mt.

¥:

HIGHiB%V$1i:

'.!:5"

.~

i\11

'l:t!Y-J

$

~-7C.*

•

.@::A:Wf~4l5t~

:

ftiYJidllt~'P~

l'lkt~jffl-

inJA

j>,

.K-Tilil'iJ~....t.tfJ~tl

t!'~ll:t,

(

illl'lt~ft*

M..l:~oq~~{;Jloo

-~@:1'

~JJ:~'l'lP'JWi!Y.Jt

A.

.

.

lt).

hrlreltri

ff:";

trm-~.

f!Ho

~i!B.:t

rt.J

1500

tt

ti:ti~,_~ 1~. i~

1.

~iL!'4

ii

if'!

..

~liT':i!r

.¥3

iE

:fit

i,Ll!-;;

?.'\H

fd

:l:t~

~

flpt

i~ ).P-

~~ifjtJ

S:

J illiiii

fFS:-=F

t

~J

~~

t!A

-'JZ-

~-"B'Il"f

U-'1-1f

-r.!~~j

~oo

~,

tnJ

B

t.:..{

!.

Ill

7

Fig.?

2.

Operation

C

l)

Cieaninj!:

~cfon:

And

hdorc

clt•ant•d

r•·u~h

··

-he\'1-.

rc:!(ula

out

I :!l

lnspcetiou

Sonw

hanrllin~

th"

t.-d

)Jacking

operation

"'itb

t>art>'

maehinc

in

tJtc

preoaration:

cll.

ch

new

j!;asol

ine

:

of'

•nachine

.

S(J

uftet

hllad

(":1:10

of

part

of

machine,

ond

clean

l1ead

cleaning.

!ly

means

conditions

the

machine, 11bou\cl

anti-rust

with

may

get

the

of

turning

such

00

grease

soft cloth

loose due

machine

balance

ns

ubnorntal

-8

-

8

Fig.B

on

.

to

should

be

cov

each

vibration

be

wheel.

noise

ered

with

anti-rust grease,

pan

or

machine

incurr

ed

in

thoroughly inspected.

The machine

from

the

bead

compact of

l>b

ould

transit

must

moving

be

of

To

be

parts.

parts.

sewing

When

will

that

amount

lower

usedforalong

at

l!y

when

maximun.

gntdually

Row

will

after

nature

the

(3)

Lubrications.

a.

Information

Before

machine

you

see

splashing

the

amount

of

than

..

Note:

firu.

b.

Adjusting

The

amount

regulating

dot

regulotor

c.

Adjusting

White

incrense;

(4)

Testing:

a.

When

b.

The

c.

At

one

of

difficulty

starting

operate

the

LOW

New

time)

valve

A

on

when

till

the

turing

while

m:ichine

mnchine

the

beginning

or

two

fab1·ics.

of

for

lubrication;

the

(101

white

the

oil

through

the

splashing

lubrication

mark

machine(or

must

the

amount

of

oil

supplied

of

the

regulating

l'otating

dot

on

is

closed.

the

oil

the

adjusting

turing

running,

can

months

the

machine

machine,

oil)

machine

oil,

B,

always

those

be

operated

of

amount

th<i!

the

of

rotary

the

:not

run

of

operating,

of

running,

(Fig.?)

fill

oil

u p

to

after

oil

eight

oil

is

u.nre)ated

But

if

refill

who

oil

supplied

in

the

of

oil(l):

valve

is

regulating

regulating

hook

screw

adjusting

the

balance

without

the

bead

to

pan

wit

HIGH

mark

lnbrieatioa.

window,

the

oil

th"

oil

.

have

not

at a •peed

in

oil

rnervoir

turn

parallel

valve,

valve

{Plg

9)

on

the

lower

screw

wheel

materials

the

s~ed

speed

run.

h

you

Note

to

level

been

of

the

the

to

is

to

of

of

ruaxuing

A.

the

is

1500

front

in

the

resulating

oil

i.Dlet

the

a:mount

vertical

shaft

"-"

the

should

after

JD&chine

the

machine

into

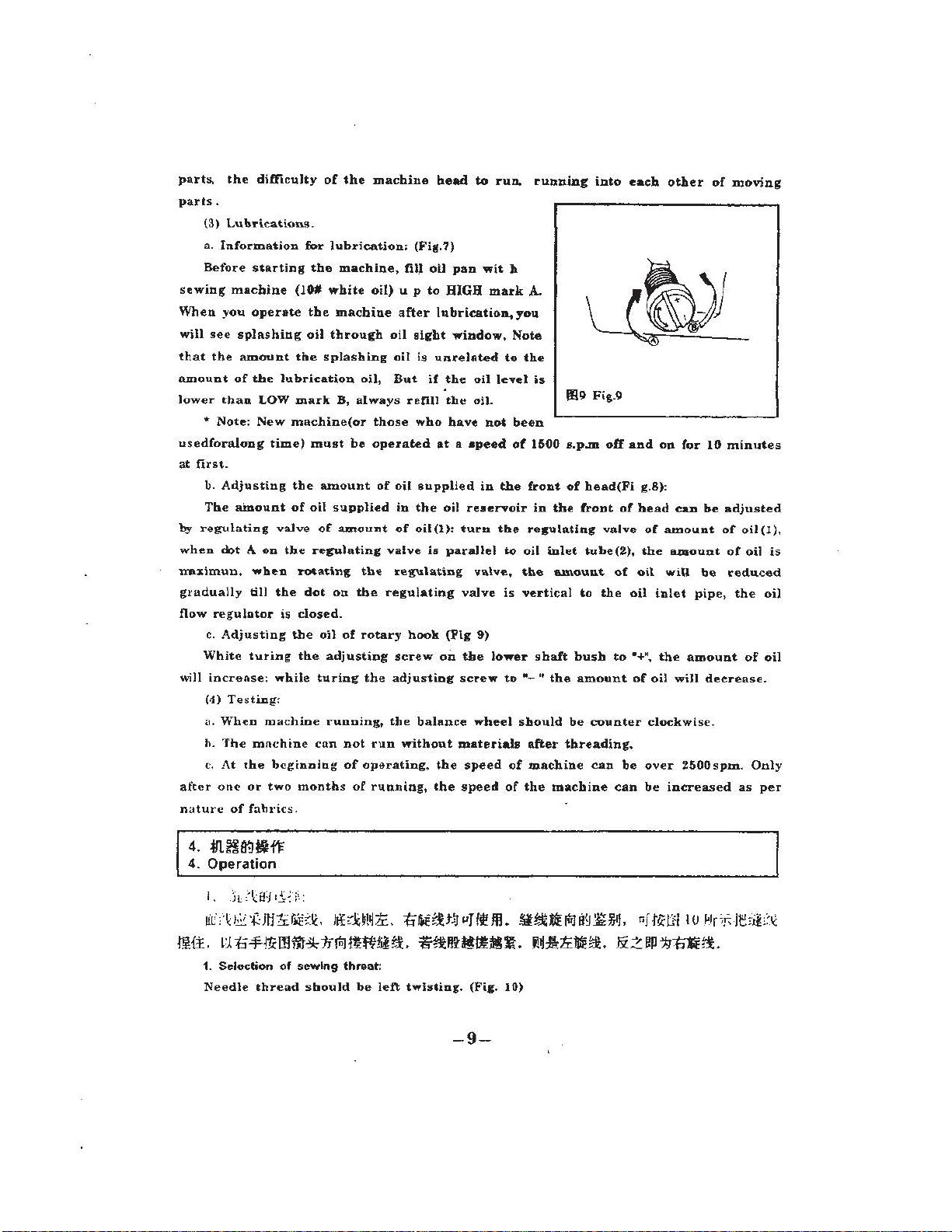

1119

Fig.9

.s.p.m

oil

of

head(Fi

front

of

valve

tube(2),

of

to

the

bush

to

amount

be

counter

threading.

can

can

each

and

g.8):

head

of

the

oi.l

oil

•+".

of

clockwise.

be

over

be

other

011

caD

amount

amount

witt

inlet

the

oil

will

increased

of

for

10

be

adjusted

of

b~

pipe,

amount

decrease.

2500spm.

moving

minutes

oil

(1),

of

oil

is

~:~duced

the

oil

of

oil

Only

as

per

4.

#l.H~tlfF

4.

Operation

1 .

~l

;-la~

u:c-:·~12

·e:mtr:~:::~e.

N.ft.

r..t

ti

-*f!(

1.

Selection

Needle

thread

.:; : :;.:

l!h'lf*

of

:

M:::--k~!~ti:.

1f(r;J

~fftki

sewing

threat:

sbould

be

tt~ii.t.lJ11Jfllm.

t;\;.

~f!U~t!~'Jt.

left

t..,.istiu.g.

(Fi~.

I())

~~~lila9~JII.

J!H~:li:~~.

-9-

r.ft~!11to

.&

.!

8P

~~r~f-Je;:.il:~~

1-JU!l:.

~I

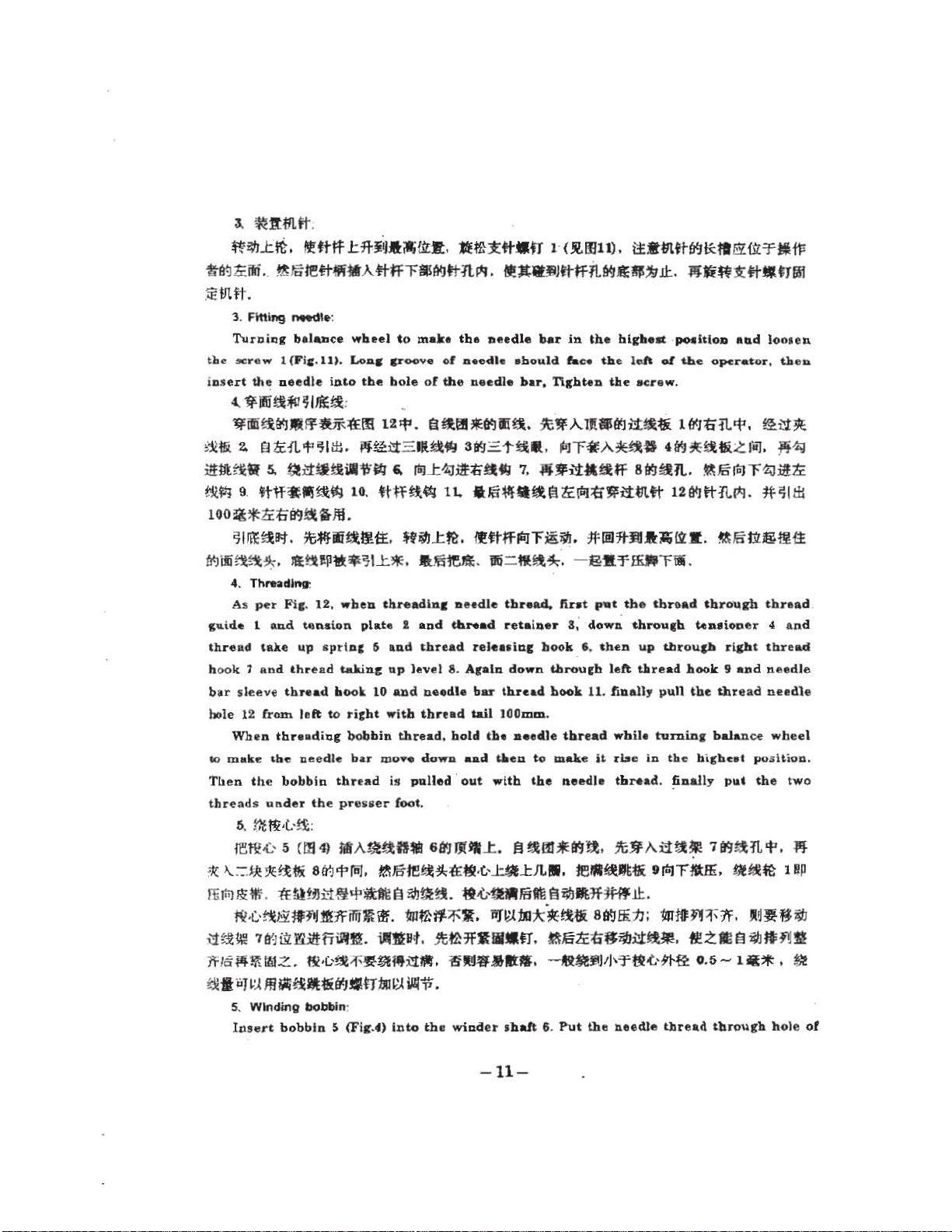

2.

(:Qordination

DP;: 5

with

H

--

N~;-

~0.

th~

#9

#il

#14.

!o!

l fi

#lR

..

ncedls

m01terial

i

I

~·

chosen

and

r~

100~120

8060-

40-60

30-40

No.

dle

i

ami

Cotton

--

#9

.. -····--··---+-·

tt)

·-···-

·-

#l•l

r---.---

#16

#IS

1~

Q0-120 1 30

--

..

i

l

...,

)-)0-1

I

..

... ~ ·---------f-··-

60-80

I

..

!

40-60

30-40

··-

00

of

needle

in

thread

f~~

(;i,;

I

I

i

;

t

100

I

80

kind

silk

I

i

-+----

24-:~a

-··-

;

20

ll6-18

·--

10-12

thread

preference.

24-30

16~

10-

of

and

used

(See

~

~

30

20

IS

12

thr.~ad

Nylon

3--56

material:

The

number

the

following

~

I

IE

3-56

Gauze,

Gunny·,

Coarse

Coarse

flannelette

Heavy

heavy

of

needle

table)

i

:Jt

....

~H::t!i.

illlff11i.

tli

till~~

.1Jbt:1Ji

For

light

silk

thin

cotton,

cloth,

and

flannelette,

woolen

khakt,

heavy

and

cloth

can

be

~!:jjt!*l

-

it~.

iltm:f!1.

ilL

-F

JttJi.

1fi'

llftt-1ii'

•••

J!.ffi.

sewing

and

thin

silk

light

cotton

corduroy

thin

canvas

selected

?t!l~i:y

oom.

llf.~'E

in

(

Wi})

1Wm~

r.T;t>ij£

1c

~~

haircords

and

poplin

woolen

coth,

c1oth

thin

and

line

-10-

3.

~ft.fUt

ff

i;~J..t

-t'tr.Jtt

iti

..

JE1JHt.

3.

Fhting

Turni11g

th e

!JC

re w 1

nsert

th':

i

.

~.

frtt~

.t1tiUtili&t

~~lettfiit

~le

ba)ul(:e

(J'

ic .

needle

ll)

A

#:tfr.~tHt.~.

:

wheel

to

.

Lonc

croo

i

nt.o

the

hole

make

ve

of

.

of

the

•*:tft•fr

f!)t.J1

the

Jlttedle

n-dle

needle

1bould

bar,

1·

(R.IJJll

J

tt1Ht~*IJ

'b4lr:

in

the

face

the left

ncbten

),

it

tmttB'J*ti

:'-J.rl:.

. l'U'i~1:fl".trif

high••

the

.

po~~l~loD

of

the

ac:rew.

Bfft=f'jjft:

a

tad

operator

loo•en

,

th

en

~M~~-~-m

~

~~

2.

€lli:.ft.

~

Yt

~

5,

tl

~~

9.

tt

1f«~~~

lOO~*liti

51

(lt)ifitl~~.

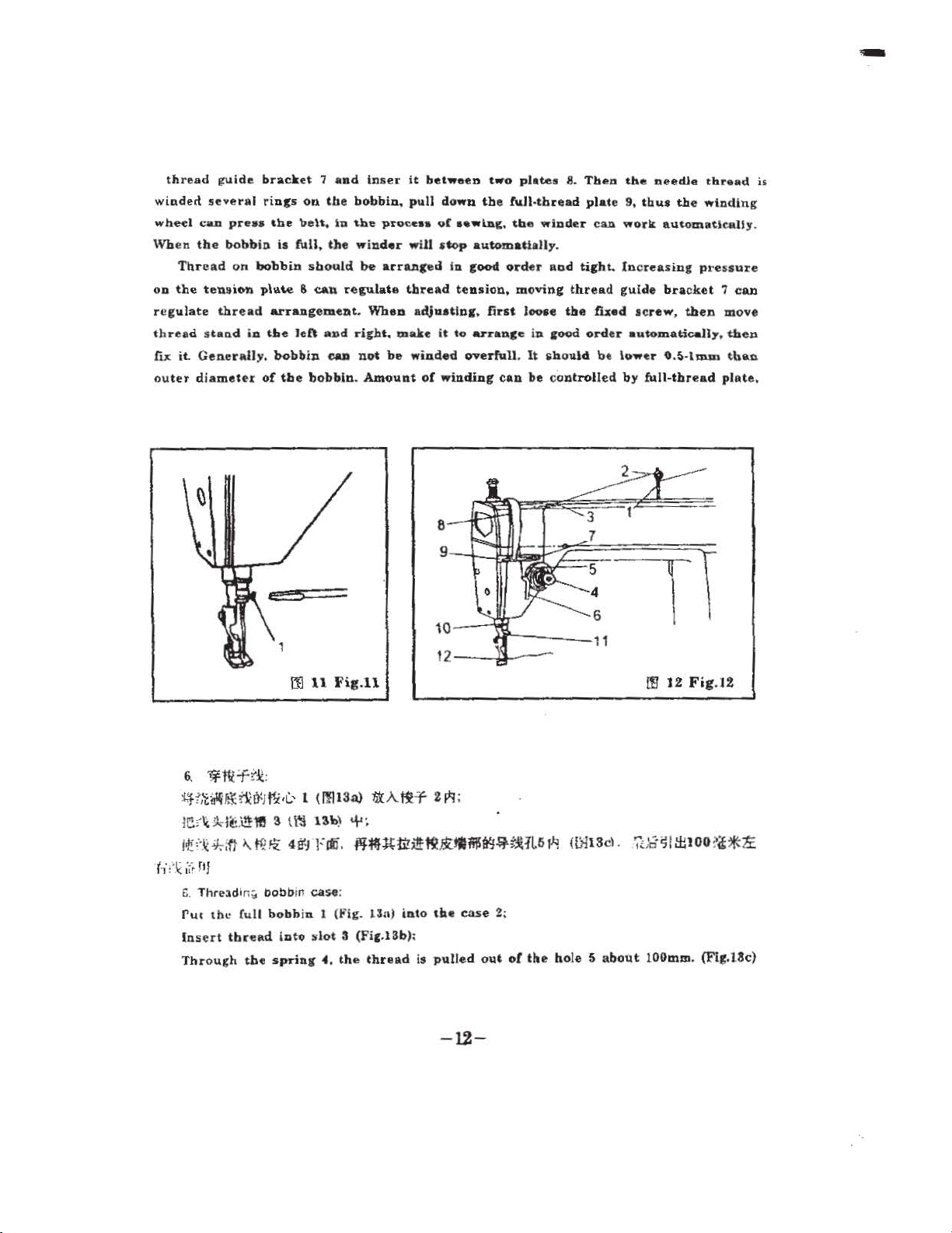

4.

As pn

1uide 1 and

thread

hook 1 an d

ba

r s l

ho

le

12

When

to

make

Tl.le n

threa

s.

re

;Jc;

\.::-

ffi(ci)

~*I'. tEM:

Ml·L.·ft~~fUfHFiffl

-crtx~

W!5~~~mz. ~-

••

~~m~~

5,

Ins

!ICJtlJ..

11\:

~ll't

.

ll~!P1i*91...t*·

Th,.adlng:

Fie

take

&&p

thread

eeve

thread

from

le

threading

the

needle

the

bobb

ds

under the

m ~

·t.-!3t

~

.C.·

s 0!

.

J;k

!Jt

~fi 8ftJ~fiiJ.

7{1':J~tolHr

Winding

ert

bobb

~m12~.

'P71/t.

:i:!

ffi:~xt=:

.t!ii"P'Jfl

10.

Jti.

]U

:fff

iitllH:£.

.

12

,

when

t4tnaion

ft

t.~i:t

-~(I(J•n~~~

bobbin

in S

pl..t

sprinC 6

~nr;

boolr. 10

to

rir;bt

bobbin

bar

in

thread

preuer

4}

fi8'A

§rf'~

~\!f. Ml-*11~¥.

iltt!.

c..-~

.r-

~~f4

:

(Fig.41) into

6.

#tH

*fiJJ

chreadlnc

e I

aud

up

and

with

thread, bold

move

is

Coot.

Qt.t

fttli

~

lff

re~~tf~·C

ft

~~~. ~.t

iJfJfB

i'1

~~~~m~

IIU:t411J 3(1(f~-t~·· ltlff~A~

ia

L..t

~~ti!t~

l4t.l

11.

-~~-~

l:

~.

{f#:tfl'iJ"F

lUs~Jl. Uli=1l~~. ~tlrBiJIJ

a e

edle

and

dlr.ad

thread

level

needle

thread

down

pulled

t.

l!ll

reJ.eafinr:

8.

AplD

bar

tail

and

·

out

6

tiCJ

1l

ta

~f'H

f•11•n. ~,e~;t;

.

1!it@.I.WJ&tt'l.

.~

~.A~-~~~~l~u

~tt

7,

llf.~ii:M

€1

~

thread,

retainer

ho

down

throucb

tbrcacl

IOOmm.

the

daen

with

..t.

.

-l:~Jt..tJL•.

,tfttJ5~

IIJ~:.fJJ

hook 11.

aeecl)e

to

the

ft

!.lm

ft

:k

~~ S~fi:h;

-

t.Uf

tr:

(.;I;E:i~i1~tt

~.

:tf:

lil7tJUU~i

lin

t

p-.t the

a

,'

down

through

ok S.

then

leA

finally

thread

make it

11eedle

*

i#JIIt

Ai~JlJ;J,r.tt <.-

wbile

rl.se

thNad. finall

t6

It

.

,;\;

" A

fell~lt~

* :Jfif

11:.

fJf/J

i!i

f(I(J~~I

8(1(JfilJL,

12

f2

'"F

IBI

tbnad

up

thro&&p

thread

puU

turnin~

in the higheet po.;;Uion

:i:!

tJ

9rt>lTM.ffi

111Tit

~.

*.Q

~.

the

wi11de r

shalt

6.

Put

th

e

needle

thread

R~. ~~~

U::

fil.

~~

~!8'!PJ

'"F.z.J

i!

~

1¥l

ttf

t.~.

JHII:l:l

• . ~ s

.

knlion

hook 9 and needle

the

~

ff=i'

f'l.Z11l

o.

tu~

tbro~p

~r

ri&ht

th-re

ad n

balan

ce

y

J>l&t

th

7 i5

t.

UL ~ •

.

Olhl~ 1 ~

1'f·

.-O

t3~ftJlJ!l

s-

lil*.

through

m

it

thread

4

and

thread

eedl

wheel

e two

liJ

'l-8

~

~

hol

e

.

e

.

p

ot

-11

-

-

thread

winded

wheel

Wh

on

rcculate

thread stand

ru

outeT dia

can

en

the

Thread

the

ten&iO'Il

it

.

Generally,

guide

several

bobbin

thread

meter

bracket

rin~s

on

pre

..

the

be\t,

is

full,

on

bobbin

p\1o1~

in

of

sbould

6 <:an

arrangemeDt. When

tbe

left

bobbiD

the

bobbin

7

and

inser

tbe

bobbin,

iu

the

the

winder

be

r~gulate

a»d

right.

CUUI

not

.

Amoun~

it

betweeD

pull

pro~u

will

arrured

thread

acijaatlnr

make

be

windri

of

down

o£

•••inc.

1top

automatially

in

(ood

ten•ion,

.

It

to

aTrance

overfull

winding

t.,o

the

order

first

Can

full-thread

plates

8.

the

winder

.

aod

moving

loose

. n

thread

the

iu

cood

tohould

be controlled

Then

the

plate

9,

can

work

tiCht. Inc

guide

fixed

order

automatically, then

be

\ower

by

needle

thus

the

automatically

reasing press

bracket 7 can

Ierew

,

then

0.~-lmm

fuJI-thread

thread

winding

ure

move

than

plate

is

.

,

6.

~ttl-fi'!(

~t'it~Ji\:rlCI¥J

m:~~~t!.~le

l•.fE'·

·

~-*;fl'

f-i:'

l

ii

~

rt

j

t:

.

Th

readir.;

rue

tbc Cull

Insert

Thr

ough

:

~·L.-1 (1!1

a t

"-~ 1Z

bobb

bobbin.

thread

tbe

sprin~

48'-J

iuto

t'3

in

1~b

Flfi.

case

1

Cl"ig

slot

4.

18~

"4IA.tt

-f-

2~

)

<tt

·.

M*'

~tl!:i!H~Jt:

:

.

Un

)

into

\he

3

(Fi(.lSb);

the

thread

is

pulled

-12

;

fln\Ht

9.$J.~Jt1Lli

case

2;

out

I~

o(

the hole 5

<L~l3cl. .

-

[£

12

';"Ud'~!

ti:llOO

about

lOOmm.

Fig.U

?Cf*li:

(FI(

.l3

c)

2

~

Ill

13a

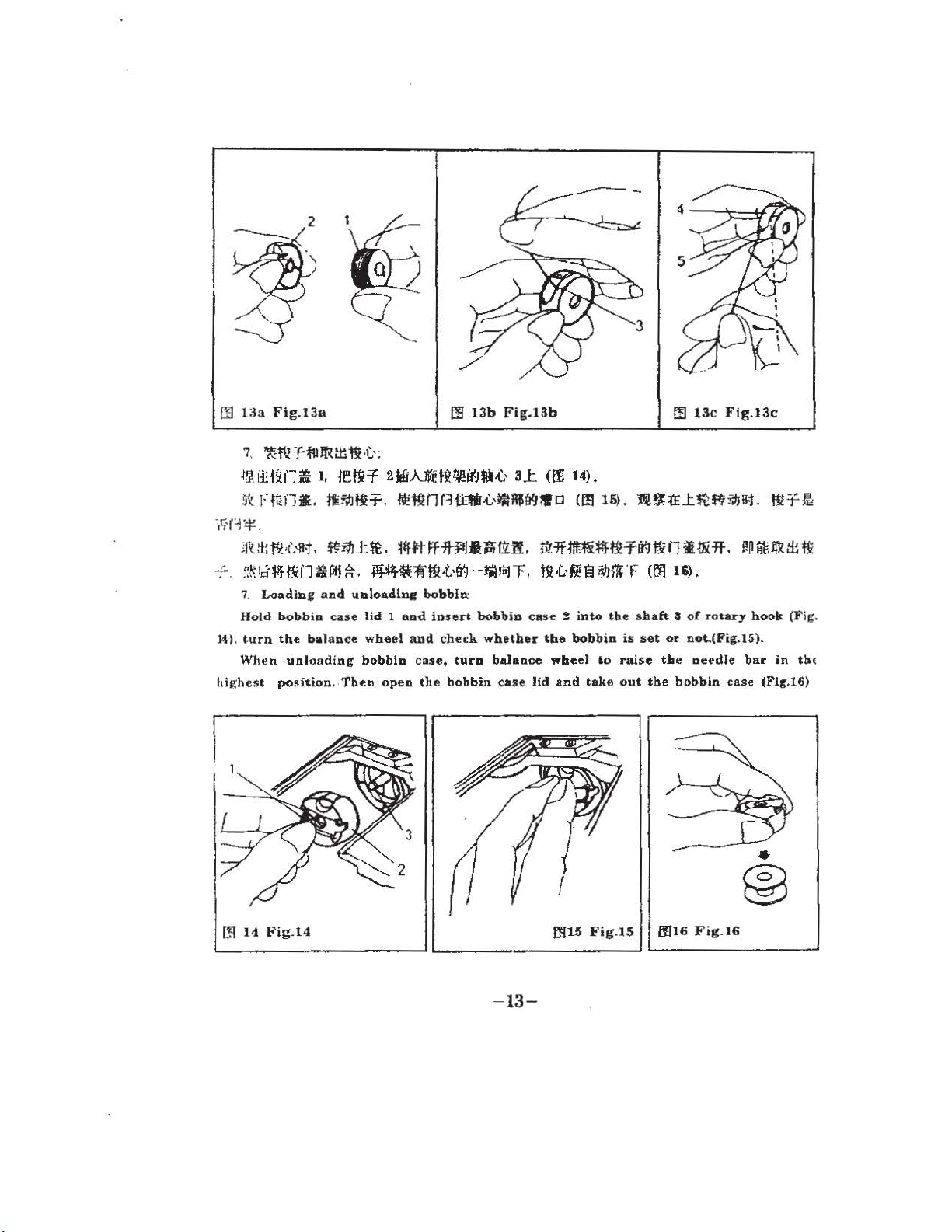

7.

-l!l!i.ttiHl~

st

H~nlt.

;~·r·P

t=:.

l

f'<tt:

,:._

~~

'r:it."H~n•lifi~.

7.

Loading

Ho

ld

14). turn

Wht!n

highest

i

Fig.I3a

~lQ-T~~1:h~·t·:

1, let!t+

ttMti-F.

tfi·L.·a:t.

bobb

the

position

~~.1:~.

and

in case

balance

unlo

ading bobbin

~~1fMl-t·~-$tnr

unloading

lid 1 and

wheel

..

Then

open the

l!l

13b

Fig.13b

2tafA.$

'H

¥~it-J-.t·

it1tnr=:~M*-t.,.,.$~11o

~IHtlfftJIIM:'tlii$Lil.

bobbin:

insert

and check

cas

e.

turn

bobbin

3_t

(IE

14).

ern

ts>.

~7fffE~:tff~-f-ll91'3Hl

F. ~·t.·~§iih~T

bobbin

whether

b.-lance

case

case ~ into

the

bobbin

'l'l'beel

Jid

and

take out

the

to

is

raise

!!I 13c

~~t£..t

~

<m

16).

shaft 3 of

set

or

the

the

bobbin

Fig.l3c

~~~11

~-Jf.

not.(Fig.lS).

needle

1. w~N::

P.Ptm~ti111i

rotary

hook

bar

case

(Fig

in

(Fig.

tht

.l6)

[11

14

Fig.l4

-

1!115

13-

Fig

.15

I!JI6

•

@

Fig.l6

s.

tt~~1-c

~il'l fi.

rr~:'t-JKit

~liP.~~

}R.

g

#)

i:

tiz.

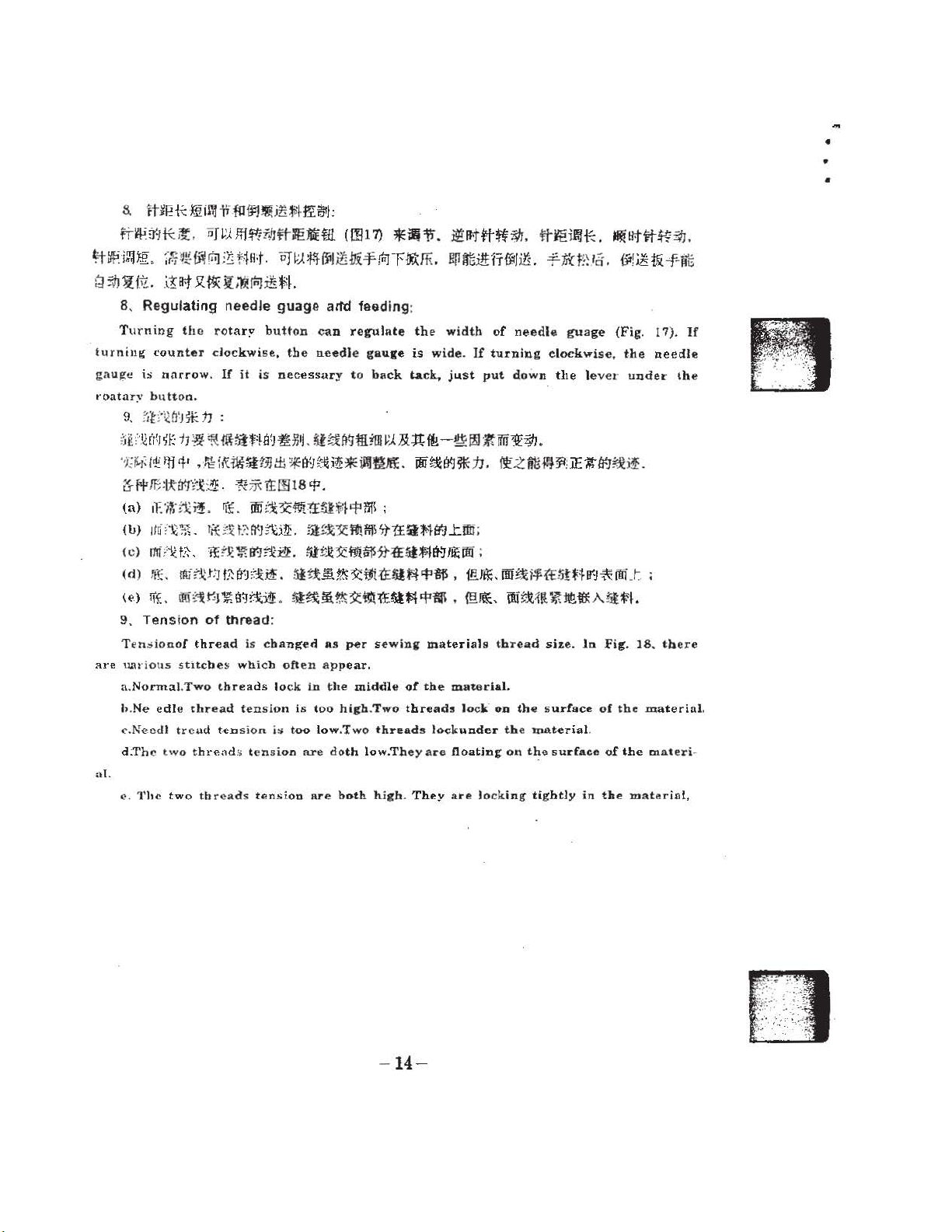

8,

Regulating

T

urning the

tu

rni11 g

~nugc

•·

is n

on

tar~

·

R

i!V\: !J~J*:h

?i~~·.Q£

··)~;;.,;I

. iif~Jffl$!fJJff-llfi11U11.

;-~~~

611

.i.!

fit

_Q_

*

~·ounte

r

nrro

w.

butto

n.

i(Jr)~

-J1!1:

~

~

ftl

r.f.•

,·~

frfirlt:ttttrr{i£.

(a)

,r·~t.

·£-t~.

( b >

111F~

'EL

<c>

rfli?

H~.

(d)

~-ffii-:"~.t!Jt~~·

((>.) li'f.

9, Ten

Tensionof thread

a1·e u.:u·

n.

Normal.Two

h.

Ne

<'.Need!

d:Thc two

a!.

e.

ious

The

oo~~J

sion of

stitches

cdle

trea

two

thread

d t.ension

t

hn~:1ds

tbreads

f1l@!~

jn$

H!lfj!J:

!1!:117)

(.;]

;~

r4Ht.

i:iJ

t:;

J~.lffSili

!

dli

-f-

tnrF W:ffi. RP

~

;R

inJ

:it£

14.

needle

rotary

clockwise,

If

guage

button ean regulate

it

is

necessury

the

artd

needle

feeding

gauge

to

back

:

~tiil''

~BH'Hl'/. !Jl~~{]tiljfjj

htM~tJ.!

rf~.

tif

r:H.

1!:#'9.~

~a~~:i'!E

thread

threads lock

.±.

*

9'Jt-lH!DJ

'N

~'il:fB

IS'P.

ifii;~3<-w!~lii:t"P

~

R''.l

~.i:!l.

1t-lti~.

~:'::IU~

.

tatl;~

.

flt~§i~)(~tE~U>t<?M

:

is

changed

which

often appear.

tension

t

is

is

too

ens

ion

ar1! doth

tension are

E)j\!fUt:.

l'lfl;

ilt£1t~

\li.1111

st

!a't~x#'ta!S?t.tf!l~a.Jnt;ilii

?.~X:

ffi-i'E

as

per

sewinll'

in

tlte

middle

too

high.Two

low.Two

both

threads

low.Tbe

higb. They

*ilii'i.

VJ.&

1f.stt-1-tfl

Q~<P~.

~lrtft~~.

:

the width

is wide

tack,

just

.:Jt~

-@1!1

fBi~l¥.!~

..t

,

materials

of

the

material.

threads lock·

lockunder

y a

re

floating

are lock

fl-~i

il6.i!11'ffllill.

of

needle guage

.

li

turning

put

down

~ffiP

:G:~.

.7J.

~Zfit5~j!J

ilii;

;

@.lij;,

ilii

~i-Ht5

@~,

iti

t.lt~lU~itii'XA?itt

thread

on

the surface

th e

material.

on

the

ing

tightly

g}¥.:,

~IM"Vt-~!41.

-=¥-

JJ{

r~

.1ci.

Uif

(Fig.

clockwise, the

the levet

tHB"~~iD'U:.

siz.e.

surface

!E~~

ln

Fig.

of the

of

in

the

·

under

~jf

the

~

=mt

-f-

17).

needle

L

18.

tbe

material.

mat

materinl,

eri

n5

th

•

•

•

If

e

r e

-

-

14-

Loading...

Loading...