Page 1

Installation and User Manual

4K-WISY Sensor System

Version: V45.2.3.6

Date: 2016-12-08

ODNF401EN01

Translation of the original installation and user manual.

Page 2

2

Copyright

© 2016

ARTIS GmbH

Buchenring 40

21272 Egestorf

Deutschland

www.artis.de

Page 3

3

1 General .................................................................................................................................................... 5

1.1 Information about the manual ............................................................................................................ 5

1.2 Manufacturer ...................................................................................................................................... 5

1.3 Contact details/customer service ....................................................................................................... 5

2 Safety ....................................................................................................................................................... 6

2.1 Information about safety instructions ................................................................................................. 6

2.2 Symbols and abbreviations................................................................................................................ 7

2.3 For member states of the European Union ....................................................................................... 8

2.3.1 WEEE and recycling ...................................................................................................................... 8

2.3.2 RoHS and chemicals ..................................................................................................................... 8

2.4 Transport, packaging and storage ..................................................................................................... 9

2.4.1 Transport inspection ...................................................................................................................... 9

2.4.2 Packaging ...................................................................................................................................... 9

2.4.3 Storage .......................................................................................................................................... 9

2.4.4 Ambient conditions during transport and storage .......................................................................... 9

2.5 Liability and warranty ....................................................................................................................... 10

2.6 Intended use .................................................................................................................................... 11

2.7 Warning against foreseeable misuse .............................................................................................. 11

2.8 Disturbances .................................................................................................................................... 12

2.8.1 Safety instruction ......................................................................................................................... 12

2.8.2 Behaviour in case of disturbances ............................................................................................... 12

2.9 Repair .............................................................................................................................................. 13

2.9.1 Warranty exemption ..................................................................................................................... 13

2.10 Requirements placed on user groups .............................................................................................. 14

2.11 Conditions on site ............................................................................................................................ 14

2.12 Electrical safety ................................................................................................................................ 14

3 Description ............................................................................................................................................ 15

4 Technical data ....................................................................................................................................... 16

4.1 4K-WISY-Rotor-Accu ....................................................................................................................... 16

4.2 4K-WISY Antenna Module ............................................................................................................... 18

4.3 4K-WISY-Visu .................................................................................................................................. 19

5 Installation ............................................................................................................................................. 20

5.1 Visualization software ...................................................................................................................... 20

5.2 Antenna module ............................................................................................................................... 20

5.3 Sensor .............................................................................................................................................. 21

5.4 Installation guidelines ...................................................................................................................... 22

5.4.1 Aligning the antenna module ....................................................................................................... 23

5.4.2 Positioning of the antenna module (examples) ........................................................................... 25

5.4.3 Positioning of more than one antenna module ............................................................................ 27

5.4.4 Machines positioned side by side ................................................................................................ 28

5.4.5 Alignment of the 4K-WISY-Rotor ................................................................................................. 29

5.4.6 Using the radio frequency channels ............................................................................................ 30

6 Commissioning ..................................................................................................................................... 33

6.1 Starting the visualization software ................................................................................................... 33

6.2 Logging in the rotor .......................................................................................................................... 33

Page 4

4

7 Basic settings ....................................................................................................................................... 36

7.1 Setting the visualization ................................................................................................................... 42

7.2 Setting the tool length ...................................................................................................................... 43

7.3 Setting the scaling of the visualization ............................................................................................. 44

7.4 Setting the trigger ............................................................................................................................ 44

7.5 Selecting the storage location of the report and process settings ................................................... 45

7.6 Setting the interface ......................................................................................................................... 45

7.7 Setting the rotor ............................................................................................................................... 46

8 Operation ............................................................................................................................................... 47

8.1 Process ON...................................................................................................................................... 47

8.2 Report settings ................................................................................................................................. 48

8.3 Operate ON...................................................................................................................................... 49

9 Evaluating the measurement data ...................................................................................................... 50

10 Creating a report ................................................................................................................................... 54

11 Maintenance .......................................................................................................................................... 58

12 Appendix ............................................................................................................................................... 59

12.1 Declaration of conformity ................................................................................................................. 59

12.1.1 FCC Konformitätserklärung ..................................................................................................... 59

Federal Communication Commission Interference Statement ................................................................ 59

12.1.2 Konformitätserklärung für Kanada ........................................................................................... 60

Industry Canada Statements .................................................................................................................... 60

13 Index ...................................................................................................................................................... 61

Page 5

General

5

Pos: 1 /ARTIS/Überschriften/H1/E/ÜS_ Einleitung @ 0\mod_1383142931025_1 8.docx @ 1989 @ 1 @ 1

1 General

Pos: 2 /ARTIS/Einleitung/Allgemein/Allg emein_Informationen zum Handbuch neutral formuliert (Produkt) @ 0\mod_1382 509319770_18.docx @ 1543 @ 2 @ 1

1.1 Information about the manual

The information available at the time of publishing is the base of this manual and is

deemed as correct. The manual does not claim to provide all possible details and

versions of hardware, software, installation and operation of the product. The manual

is part of the product and has to be kept accessible at any times for use by the

installation, operation, maintenance and cleaning staff.

For better representation of circumstances, the illustrations in this manual are not

necessarily to scale and may slightly vary from the actual design of the product.

All contradictory statements cease to be valid as of the date of the publication. ARTIS

GmbH reserves the right to implement changes in the interest of technical progress.

Pos: 3 /ARTIS/Einleitung/Allgemein/Allg emein_Hersteller @ 0\mod_1383135728 263_18.docx @ 1912 @ 2 @ 1

1.2 Manufacturer

The product was produced by:

ARTIS GmbH

Buchenring 40

21272 Egestorf

Germany

hereinafter called „manufacturer“ or “ARTIS”.

Pos: 4 /ARTIS/Einleitung/Allgemein/Allg emein_Kontaktdaten_Kundendienst @ 0\ mod_1383135741106_18.docx @ 1916 @ 2 @ 1

1.3 Contact details/customer service

ARTIS is a member of MARPOSS Group, which has 80 sales and marketing

companies in 23 countries. Via this sales and service network MARPOSS provides

direct and qualified customer service. Refer to the MARPOSS website for a full and

up-to-date address list: www.marposs.com

Please have the following information at hand before contacting the technical

customer service:

• Short description of the problem

• Information about machine type, machine control and operator panel of

machine

• Information about the monitoring system (type, version, possibly serial

number) and the visualization software

• Version of the sensor used.

Pos: 5 /ARTIS/Copyright/Copyright @ 0 \mod_1382511933549_18.docx @ 1559 @ @ 1

All rights reserved. No part of this document may be reproduced, stored, duplicated

and circulated or distributed in any form without the written permission of

ARTIS GmbH.

TM

Windows, PROFIBUS, PROFINET and ICP are registered trademarks.

Pos: 6 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 6

Safety

6

Pos: 7 /ARTIS/Überschriften/H1/S/ÜS_ Sicherheit @ 0\mod_1383143060949_ 18.docx @ 1998 @ 1 @ 1

2 Safety

Pos: 8 /ARTIS/Sicherheit/Allgemein_Sich erheitskapitel (Systeme und Messumform er) @ 0\mod_1385978340400_18.doc x @ 5535 @ @ 1

Notice

Read the complete chapter Safety before installing and commissioning the system.

Thoroughly observe all safety instructions!

Compliance with all safety instructions and directives given herein is essential to

operating safety. The local regulations for the prevention of accidents and the

general safety regulations for the location, in which the machine is used, also apply.

Warning

Risk of injury!

Improper installation may cause damage of devices, injuries or death.

In order to protect human life and to ensure safe and reliable use of the product, let

only qualified personnel install and operate the device.

Pos: 9 /ARTIS/Hinweise/Sicherheitshin weise @ 0\mod_1385977551711_18.d ocx @ 5530 @ 2 @ 1

2.1 Information about safety instructions

Safety instructions point out particular dangers for persons, property and the

environment. Observe these instructions and act correspondingly. Also, pass these

instructions on to other users.

Caution

Designates instructions, which – if not observed – may result in minor or moderate

injuries of persons. Thoroughly observe the instructions in order to avoid damage to

persons.

Warning

Designates dangers, which – if not observed – may cause impairments of health,

injuries, permanent bodily damages or death. Thoroughly observe all work safety

instructions and act with caution!

Dang er

Designates electrical hazards. Non-observance of these safety instructions can

result in severe injuries or death. The relevant operations may only be carried out by

skilled electricians, who are familiar with the product.

Pos: 10 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 7

Safety

7

Pos: 11 /ARTIS/Sicherheit/Allgemein_S ymbole & Abkürzungen @ 0\mod_138 5978894809_18.docx @ 5540 @ 2 @ 1

2.2 Symbols and abbreviations

Notice

Designates instructions, which – if not observed – may result in damage, malfunction

or failure of devices. Thoroughly observe the instructions in order to avoid partial or

total loss of devices.

The following symbols shall be used in this document.

Information

This symbol emphasizes practical tips and information. Observation of these tips

ensures efficient and trouble-free operation of the unit.

Function keys and parameters shall be emphasized using CAPITAL BOLD LETTERS.

Furthermore, the following abbreviations shall be used in our publications:

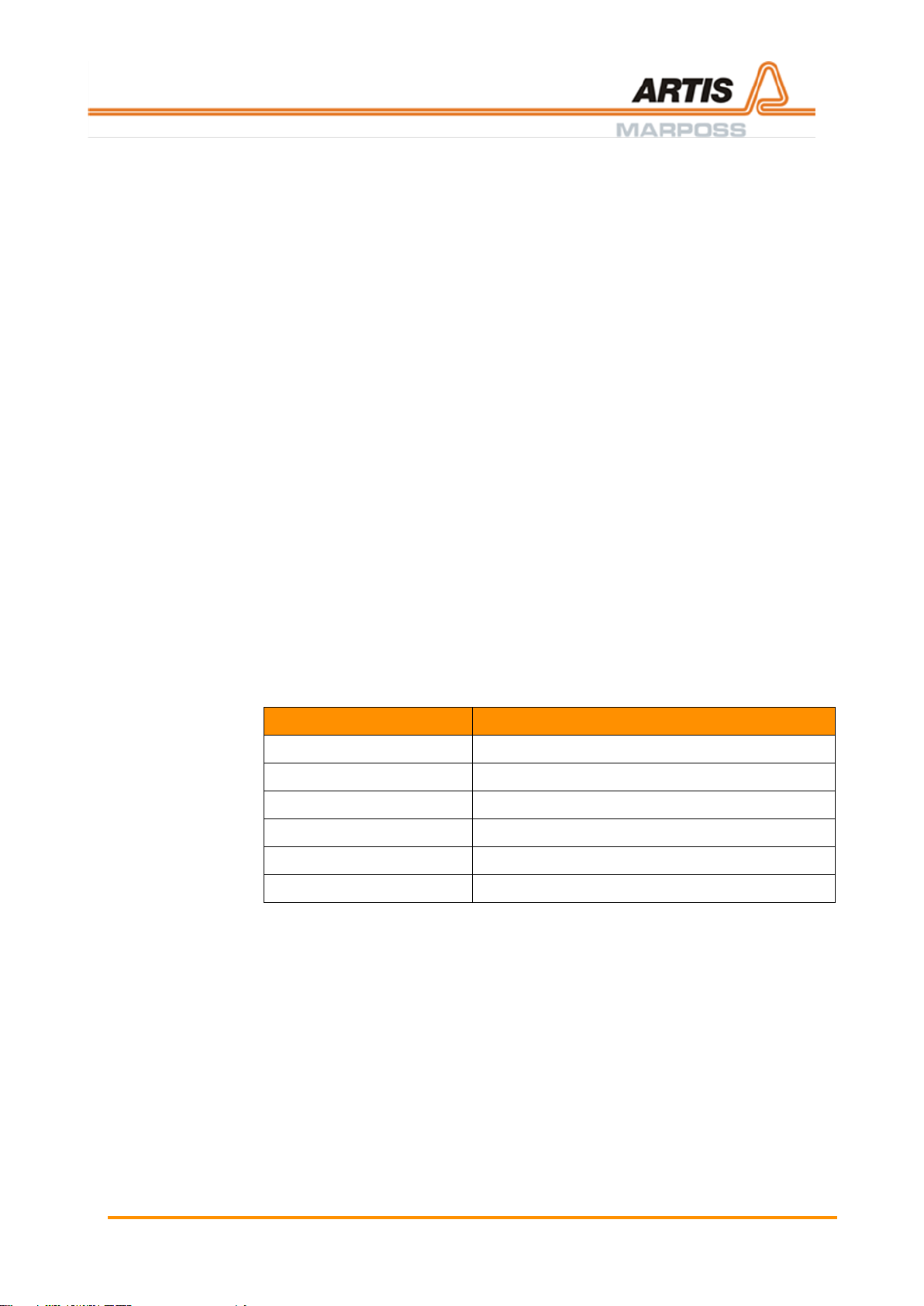

Abbreviation

Meaning

AC

Alternating current

AC Control

Adaptive Control

BA

Bridge amplifier

BN

Cutting number

DAC

Digital analog converter

DC

Direct current

DN

D number: cutting edge number

DTA

Digital torque adapter

F

Axial force

FFT

Fast Fourier Transformation

I/O

Input/output

in

Inch

lbf

Pound-force

lbs/in

Inch-pounds

MS

Microsoft

ms

Millisecond

N

Newton

Neg.

Negative

Nm

Newtonmeter

Page 8

Safety

8

Abbreviation

Meaning

OP

Operate (Feed active)

PLC

Programmable Logic Controller

PN

Program number

Pos.

Positive

PWM

Pulse-width modulation (control via frequency converter)

RF

Rapid feed

SAS

Self Adjusting System

SW

Software

T

Torque

TC

Tool change

TN

Tool number

TP

Low pass filter

Ts

Delay time

Visu

Visualization, user interface

Pos: 12 /ARTIS/Sicherheit/Allgemein_W EEE, Recycling, RoHS, Chemikalien @ 0\ mod_1382345046250_18.docx @ 121 4 @ 233 @ 1

2.3 For member states of the European Union

2.3.1 WEEE and recycling

Information

The product you bought is subject to the Directive 2002/96/EC of the European

Parliament on waste of electrical and electronic equipment (WEEE). This device

may not be disposed of with domestic waste. Please dispose of this device in

accordance with local regulations at the collecting point specified for electrical and

electronic equipment by your community or use a waste disposal company

specialized in separating waste electrical and electronic equipment.

The manufacturer is obligated to take back all the ARTIS waste equipment.

2.3.2 RoHS and chemicals

Information

The Directive 2002/95/EC of the European Parliament on the restriction of the use

of certain hazardous substances in electrical and electronic equipment prohibits the

introduction of new electrical and electronic equipment in the European market that

contains more than the maximum permitted amount of lead, mercury, cadmium,

hexavalent chromium, polybrominated biphenyls (PBB) or polybrominated diphenyl

ethers (PBDE).

Control and monitoring equipment is exempted from this requirement:

Therefore, it is not prohibited to use certain hazardous substances in monitoring

devices, tool monitoring systems and measuring transducers of ARTIS GmbH.

Pos: 13 /ARTIS/Sicherheit/Transport, V erpackung, Lagerung, Reparatur/Transport, Verpackung, Lagerung @ 0\mod_1 384437320788_18.docx @ 3450 @ 233 33 @ 1

Page 9

Safety

9

2.4 Transport, packaging and storage

2.4.1 Transport inspection

On receipt of delivery, immediately check for completeness and any transport

damage.

If transport damage can be detected externally, refuse the delivery or accept it only

with reservations. Make a note of the scope of the damage on the transport

documents/delivery note of the freight carrier and initiate a claim.

Make a claim against hidden defects as soon as they are identified because claims

for damages can only be made binding when raised within the valid claim periods.

2.4.2 Packaging

If no appropriate agreement has been made on return of the packaging material,

then it remains with the customer.

2.4.3 Storage

The following regulations apply when storing:

• Store dry.

• Do not leave packages outdoor.

• Make sure that the floor of the stockroom is dry during storage.

• Protect from direct sunlight.

• Store dust-free.

• Avoid mechanical vibrations and damages.

If storing for longer than approx. 3 months, then check the conservation measures.

In aggressive weather conditions, preservation may have to be renewed.

2.4.4 Ambient conditions during transport and storage

Name

Technical data

Ambient temperature

-20 °C – +65 °C

Temperature change

max. 5 °C/min

Relative humidity

max. 85%

Air pressure/elevation

max. 12.000 m above sea level

Condensation

none

Recovery time

2 h

Pos: 14.1 /ARTIS/Seitenumbruch/-----Seitenumbruc h---- @ 0\mod_1384520666314_18.docx @ 357 0 @ @ 1

Page 10

Safety

10

Pos: 14.2 /ARTIS/Überschriften/H2/H/ÜS_H aftung und Gewährleistung @ 1\ mod_1392216861649_18.docx @ 11162 @ 2 @ 1

2.5 Liability and warranty

Pos: 14.3 /ARTIS/Hinweise/Produktneutral e Sicherheitshinweise/Hinweis_Handbuc h vollständig durchlesen, Änderunge n vorbehalten @ 1\mod_139221657106 6_18.docx @ 11156 @ @ 1

Notice

This manual must be read carefully prior to any use of the system, notably prior to

commissioning.

The manufacturer does not accept any liability for damages or disturbances, which

originate from non-observance of the manual.

The manufacturer reserves the right of technical changes which improve the usability

or contribute to further technical development of the product.

Pos: 14.4 /ARTIS/Sicherheit/Systeme/CTM _Haftung und Gewährleistung @ 1\ mod_1392215973321_18.docx @ 11138 @ @ 1

All information and references in this user manual were compiled in consideration of

applicable regulations, the current technical engineering stage of technology as well

as our many years of findings and experiences.

Material defects are covered by the warranty with the following limitations:

• Guarantee period: The warranty covers the product and all repairs carried out

within the standard warranty terms.

• Subject of the guarantee: The warranty applies to the product and its parts

marked with the serial number or other identification number used by

Marposs.

The above warranty applies unless other agreements are reached between Marposs

and the customer.

No warranty is accepted after interference with or modifications of the product, which

were not carried out by the manufacturer!

The manufacturer accepts no liability for damages to persons or objects, which

originate from unauthorized interference with the product!

Furthermore, the obligations agreed upon in the delivery contract apply as well as

the manufacturer’s general terms and conditions and terms of delivery and the valid

legal regulations at the time of contract completion.

Pos: 15 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 11

Safety

11

Pos: 16 /ARTIS/Überschriften/H2/B/ÜS _Bestimmungsgemäßer Gebrauch @ 4\m od_1464354352161_18.docx @ 1969 21 @ 2 @ 1

2.6 Intended use

Pos: 17 /ARTIS/Sicherheit/Systeme/4K WISY_Bestimmungsgemäßer Gebrauch @ 5 \mod_1473330686727_18.docx @ 23 3287 @ @ 1

4K-WISY is a stand-alone sensor system for collecting measurement data of rotating

tools. It includes the following components:

• 4K-WISY-Rotor-Accu: Sensor based on strain gauge technology, individually

adapted to the customer’s tool holder, integrated rechargeable battery

• 4K-WISY-Antenna Module: Antenna module with USB interface for

measurement data transfer to a PC, radio frequency 2.4 GHz

• 4K-WISY-Visu: Visualization software

• Charging unit.

The sensor system has the following functions:

• Measurement of torque, feed force and bending moment at production

machinery

• Measurement data transfer via antenna module

• Visualization of measurement data via personal computer.

Pos: 19 /ARTIS/Hinweise/Produktneutral e Sicherheitshinweise/Warnung vor vorherse hbarem Fehlgebrauch @ 0\mod_ 1382087646527_18.docx @ 1170 @ 2 @ 1

2.7 Warning against foreseeable misuse

The intended use and the specified ambient conditions have to be observed during

operation to ensure trouble-free functioning.

Any other use is explicitly excluded.

Pos: 20 /ARTIS/Sicherheit/Allgemein_St örungen @ 0\mod_1384439144328_18. docx @ 3465 @ 233 @ 1

Page 12

Safety

12

2.8 Disturbances

Only specially qualified personnel from the relevant department is authorized to

remedy disturbances of electrical installations and mechanical components.

In case of disturbances, which cannot be resolved with the measures described in

this chapter the manufacturer or an authorized service partner of the manufacturer

has to be informed.

2.8.1 Safety instruction

Warning

Improper remedy of disturbances can result in damages to persons and/or material.

Only specially qualified and authorized personnel may remedy disturbances!

2.8.2 Behaviour in case of disturbances

In general, the following applies:

1. Take the device out of service immediately in case of danger for persons,

material and/or plant safety.

2. In case of disturbances, which do not imply any of these dangers, switch off

the device via the system control. Also, interrupt the power supply of the

device and secure against being switched on again.

3. Immediately inform the responsible person on site about the disturbance.

4. Let authorized qualified personnel determine the nature, extent and origin of

disturbance and have it eliminated.

Pos: 21 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 13

Safety

13

Pos: 22 /ARTIS/Sicherheit/Transport, V erpackung, Lagerung, Reparatur/Reparatur @ 0\mod_1384439471056_18.doc x @ 3468 @ 23 @ 1

2.9 Repair

All repairs of this device must be carried out by the manufacturer. The manufacturer

ensures a consistent high service quality, the required safety of the repaired devices

by comprehensive function and safety checks as well as the use of highly skilled

staff and suitable measuring and test equipment.

Dang er

Danger caused by electricity!

Electrical energy can cause extremely severe injuries. Damage to the insulation or to

single parts may result in danger to life. Disconnect the device from the power supply

before opening the housing.

Warning

Risk of injury from burns!

High temperatures of components in the device can persist up to approx. 10 minutes

after switching it off!

Let the device cool down to ambient temperature before performing any work on it.

Use only specified types when replacing defective fuses. Bypassing fuseholders is

forbidden!

Opening the device is only permitted to appropriately qualified staff.

2.9.1 Warranty exemption

Any liability and warranty is exempted after unauthorized tampering with and/or

modifying the device unless by the manufacturer has taken place!

The manufacturer does not take any liability for damages to persons or material,

caused by unauthorized external interference to the device by third parties!

Pos: 23 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 14

Safety

14

Pos: 24 /ARTIS/Sicherheit/Allgemein_A nforderungen (an Benutzergruppen)_Geräte @ 0\mod_1385976259488_18.doc x @ 5525 @ 2 @ 1

2.10 Requirements placed on user groups

Warning

Danger due to improper installation!

Installation and operation require qualified personnel. Improper installation and

handling can result in damage to the devices, injuries to persons and fatal accidents.

Let only qualified, instructed and trained personnel install and operate the device.

The requirements are subdivided into the user groups:

Group/Task

Requirements

Operator/operation

Instruction by the owner operator required

Service/installation/dismantling

Qualified electrician required

Pos: 25 /ARTIS/Sicherheit/Messumformer/ Allgemein_Umgebungsbedingungen b ei Betrieb @ 0\mod_1384438442389_1 8.docx @ 3461 @ 22 @ 1

Environmental conditions

2.11 Conditions on site

Name

Technical data

Ambient temperature

0 °C – +50 °C

Temperature change

max. 0.5 °C/min

Relative humidity

max. 10% to 85%

Absolute humidity

up to max. 30 g/m3

Air pressure/elevation

max. 3.000 m above sea level

Condensation

none

Vibration

1.0 g (20 to 50 Hz)

Shock

10.0 g (10 ms)

2.12 Electrical safety

Name

Technical data

Classification

DIN EN 61326-1

Protection class

3

Pos: 26 /ARTIS/Sicherheit/Systeme/Allgem ein_Qualitätssicherung @ 1\mod_ 1392216496311_18.docx @ 11150 @ @ 1

ARTIS GmbH's and Marposs SpA’s quality control system is certified according to

DIN EN ISO 9001:2008.

Pos: 27 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 15

Description

15

Pos: 28 /ARTIS/Überschriften/H1/B/ÜS _Beschreibung @ 0\mod_1383142851 737_18.docx @ 1986 @ 1 @ 1

3 Description

Pos: 29 /ARTIS/Beschreibung/4K_WISY/4 K-WISY Beschreibung_Blaser-S ystem @ 5\mod_1476360658501_18.doc x @ 235697 @ @ 1

Fig. 1: 4K-WISY sensor system

Properties

• Stand-alone sensor system for measurement data logging of rotating tools

• Contact-free operating principle

• Data transmission via radio

• No installation work.

The 4K-WISY sensor system includes the following components:

Component

Property

4K-WISY-Rotor-Accu

Sensor based on strain gauge technology,

attached to the customer’s tool holder, integrated

rechargeable battery

4K-WISY Antenna Module

Antenna module, USB interface for transmission

of measurement data to a PC, radio frequency

2.4 GHz

4K-WISY-Visu

Visualization software

Charging unit

The sensor system has the following functionalities:

• Measuring of torque, feed force and bending moment in production machines

• Data transmission via antenna module

• Visualization of measurement data via PC.

Pos: 31 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 16

Technical data

16

Pos: 32 /ARTIS/Überschriften/H1/T/ÜS_T echnische Daten @ 0\mod_138314313 1843_18.docx @ 2004 @ 1 @ 1

4 Technical data

Pos: 33 /ARTIS/Überschriften/H2/ÜS_4K- WISY-Rotor-Akku @ 4\mod_1461916 132466_18.docx @ 189587 @ 2 @ 1

4.1 4K-WISY-Rotor-Accu

Pos: 35 /ARTIS/Technische Daten/Sens oren/Drehmomentsensoren/4K-WISY-R otor Technische Daten_Blaser System @ 5\mod_1475746857341_18.docx @ 2 34175 @ @ 1

Fig. 2: 4K-WISY-Rotor-Accu

4K-WISY-Rotor-Accu

Marposs Code

O3PZ1021101

Dimensions

Depending on tool-holder

Degree of protection

IP67, resistant to cooling lubricants

Surface

High tenacy, protected against abrasion by

chips

Temperature range

15 °C – 50 °C

Measuring range

Depending on the application, separate

measuring ranges for torque, feed force and

bending force, technical consultation

required!

Measuring principle

Strain gauge technology in full-bridge circuit

Resolution

16 bit

Accuracy

± 5% of measuring end value

Repetitive accuracy

± 5% of measuring end value

Data transmission rate

0.5 ms (2 kHz)

Sampling rate

0.5 ms (2 kHz)

Maximum rotational speed

n max = 1 x 106/rotor diameter (mm) [rpm]

max. rotational speed = 55 m/s

Maximum transmission power

+4dBm = 2.5 mW

Maximum transmission distance

5 m , sight connection recommended

Total number of channels

70

Page 17

Technical data

17

4K-WISY-Rotor-Accu

Frequency range

2402 MHz – 2472 MHz

Charging principle

via magnetic charging plug 5 V, min. 0.5 A

Energy accumulator

Lithium polymer battery 300 mAh

Operating time

approx. 8 h

Charging time

approx. 3 h

Conformity

CE

Notice

The individual rotor properties depend on the employed tool-holder.

Pos: 36 /ARTIS/Technische Daten/Sens oren/Drehmomentsensoren/4KWisy_Hinweis e zum Akku @ 5\mod_14757395479 35_18.docx @ 234130 @ @ 1

Note

Risk of malfunction!

In order to avoid malfunction of the rotor after keeping it in the stock, thoroughly

follow the instructions concerning the integrated rechargeable battery as stated

below:

• Only store the rotor with fully charged battery.

• Recharge battery at least every 3 months.

• Fully charge battery prior to starting a measurement.

Pos: 37 /ARTIS/Technische Daten/Sens oren/Drehmomentsensoren/4KWisy_Informati onen zur Frequenzbereich @ 5\ mod_1475739402954_18.docx @ 234107 @ @ 1

Information about the radio application

Maximum transmission power

+4 dBm = 2.5 mW

Maximum transmission distance

5 m non-line-of-sight

Total number of channels

70

Frequency range

2402 MHz – 2472 MHz

A channel spacing of at least two channels is required for applications with more

than one antenna module.

Pos: 38 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 18

Technical data

18

Pos: 39 /ARTIS/Überschriften/H2/ÜS_4K- WISY-Antennenmodul @ 4\mod_146 1919363486_18.docx @ 189676 @ 2 @ 1

4.2 4K-WISY Antenna Module

Pos: 41 /ARTIS/Technische Daten/Sens oren/Drehmomentsensoren/4K-WiSy A ntenna Module_Blaser System @ 5\mod _1476092653462_18.docx @ 234827 @ @ 1

Fig. 3: 4K-WISY Antenna Module

4K-WISY Antenna Module

Marposs Code

O830Z711001

Weight

300 g

Operating temperature

0 °C – +60 °C

Housing

Metal

Dimensions

see drawing

Degree of protection

IP30

Supply voltage

via USB, max. 200 mA

Interfaces

USB 2.0 (table top device),

digital input 0…24 V

Connecting cable

Length 2 m

Radio frequency

2.4 GHz

Conformity

CE

Pos: 42 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 19

Technical data

19

Pos: 43 /ARTIS/Überschriften/H2/ÜS_4 K-WISY-Visu @ 4\mod_14619193874 32_18.docx @ 189699 @ 2 @ 1

4.3 4K-WISY-Visu

Pos: 44 /ARTIS/Beschreibung/4K_WISY/4 K_WISY Systemvoraussetzungen @ 4\ mod_1462264612888_18.docx @ 1 90977 @ @ 1

System requirements

• Windows 7 or higher

• 1 available USB 2.0 port

• for the installation: at least 60 MB free disk space

Pos: 45 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 20

Installation

20

Pos: 46 /ARTIS/Überschriften/H1/I/ÜS_In stallation @ 0\mod_1383143025232_ 18.docx @ 1995 @ 1 @ 1

5 Installation

Pos: 47 /ARTIS/Installation/Systeme/4K- WISY Vorgehensweise @ 4\mod_14 61919736561_18.docx @ 189722 @ 222 @ 1

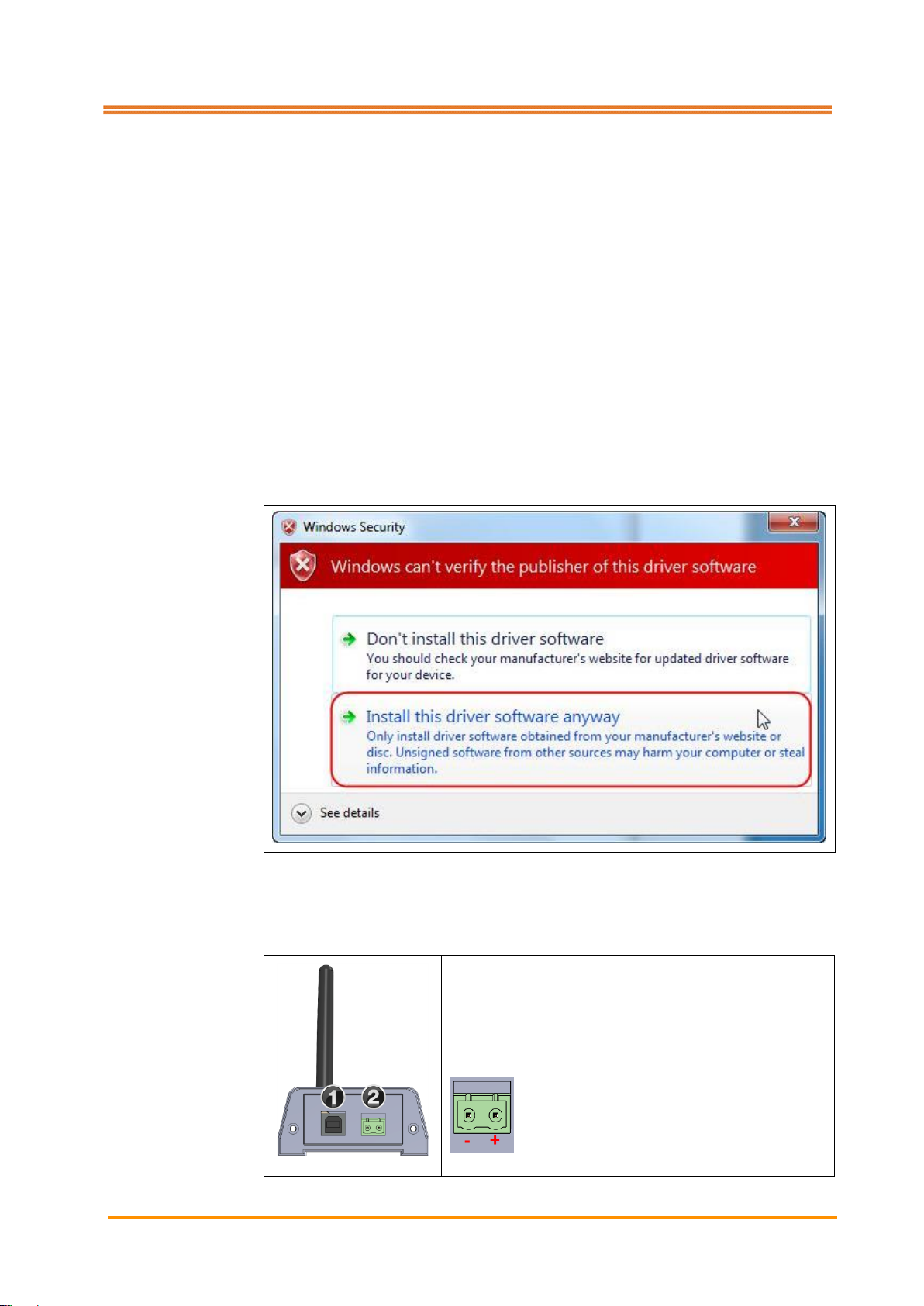

5.1 Visualization software

Copy the directory 4K-Visu into the file system on the PC.

Information

Administrator rights are required for the following steps

1 – 4.

Driver installation (not required with Windows 10):

1. Do not attach the 4K-WISYAntenna Module yet

2. Open directory Driver

3. Open file Setup.bat

4. A dialog is displayed. Select second option (Install this driver software

anyway).

5.2 Antenna module

Place the 4K-WISY Antenna Module at a suitable position and connect it to the PC,

which is intended for displaying the measurement data.

USB 2.0 port

Digital input, 0…24 V

Page 21

Installation

21

5.3 Sensor

The sensor, which is designed as a cylindrical rotor, is attached to the customer’s

tool holder and firmly connected to it.

Connect the rotor (sensor) to the

charging unit using the magnetic

charging plug (figure on the left side).

Connect charging unit to a power

source.

Rotor status

The LED, which indicates the rotor status is located at the tool side of the rotor.

Meaning of the different flash cycles:

Flash-cycle (4 s)

Description

|¯|____________

Idle state: no communication, no charging

|¯|_____|¯|_____

Communication

|¯¯¯|___|¯¯¯|___

Charging

|¯¯¯¯¯¯||¯¯¯¯¯¯|

Communication and charging

Rotor off

The rotor switches off automatically after 30 minutes without communication. Push

key [sF5] Power off rotor to switch off the rotor manually.

Pos: 49 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 22

Installation

22

Pos: 50 /ARTIS/Installation/Systeme/4K Wisy_Systeminstallation_Blaser System @ 5\mod_1476095260404_18.docx @ 234871 @ 233333 @ 1

5.4 Installation guidelines

Notice

Risk caused by moisture!

The antenna module complies with degree of protection IP30. Penetrating moisture

causes the destruction of the device. For this reason, do not install the antenna

module in the machine working area and protect it against moisture at all times.

Information

For any queries regarding the installation of the system, do not hesitate to contact

the Marposs customer service at any time.

The advantage of a radio-frequency system is the fact that communication is also

possible without being in direct line-of-sight. However, when installing a radiofrequency system, a direct communication line between transmitter and receiver

needs to be established. Only determine the final installation of the different

components after thorough tests (ranging from a few hours to several days). Also

consider the information stated below.

• All electrically conductive objects which come into contact with the system

may affect the power level.

• All metal containers reflect emitted radio waves. The machine working area

acts as Faraday Cage when its door is closed. The wavelength at 2.4 GHz is

approximately 120 mm.

• Any conductive object positioned in contact with or very close to the antenna

module or the 4K-WISY-Rotor may cause the antenna detuning.

• If the antenna module is not positioned directly in line with the 4K-WISY-Rotor,

the majority of the signal it receives has been reflected off the conductive

objects in the immediate environment (floors, ceilings, machines installed

nearby etc.)

• The immediate environment of the antenna module must be kept free from all

electrically conductive objects. This applies in particular if no line-of-sight can

be established between the 4K-WISY Rotor and the antenna module.

• The antenna module must not be fitted with any unauthorized accessories,

especially conductive material. If it is absolutely indispensable to install such

devices, please contact the customer service first.

• Evaluate the installation by performing or simulating a real working cycle.

Page 23

Installation

23

5.4.1 Aligning the antenna module

Follow the instructions stated below when aligning the antenna module:

Correct alignment

Install the antenna module on an even

surface on a wall and not inside a cavity or

any enclosure. Do not use any other

antenna or cable extension with the antenna

module.

Wrong alignment

A hemispherical space around the antenna

module must be kept free from all electrically

conductive objects (radius of the

hemisphere 500 mm).

Guarantee a direct path between the

antenna module and the 4K-WISY-Rotor,

even while parts are being machined.

Keep the immediate environment of the

antenna module free from all electrically

conductive objects.

Page 24

Installation

24

Correct alignment

An imaginary cone (having a hypotenuse

equivalent to 500 mm) projected in front of

the antenna module must be kept free from

all electrically conductive objects. The cone

shall be defined by a vertex positioned at the

center of the receiver contact plane and a

minimum angle of aperture of 90°.

Wrong alignment

The dimensions indicated above represent the minimum requirements. The quality

of communication improves if the free space beyond these limits increases.

Page 25

Installation

25

5.4.2 Positioning of the antenna module (examples)

Use below schematic drawing of the typical work environment of a machine tool for

understanding how to position the antenna module(s) optimally.

Fig. 4: Typical work environment of a machine tool

and in the figure below show typical ways of positioning the antenna

module(s).

Fig. 5: Typical ways of positioning the antenna module

Page 26

Installation

26

With emission direction to the 4K-WISY-Rotor

With emission direction parallel to the input direction of the machine window

These are just guidelines.

NEVER install antenna modules at the following positions:

• Inside metal structures

• Inside deep niches

• Directly in front of metal walls preventing the emission of radio waves to the

front of the receiver.

Correct positioning

Antenna module has

direct visibility toward the

4K-WISY-Rotor.

Communication takes place

correctly.

Correct positioning

Typical configuration if

antenna module and

4K-WISY-Rotor have no line-

of-sight.

Transmission takes place

through reflections of the

radio waves off floor, ceiling,

walls and other objects in the

area.

There must always be a

window (without metal grille)

for access to the radio waves

on the machine walls

because the metal walls

screen them.

The emission direction of the

4K-WISY-Rotors is parallel to

that of the window on the

machine so (after a few

reflections) the radio signal

can reach the antenna

module.

Page 27

Installation

27

For the following reasons, the conditions proposed in the second example (antenna

module ()) are more critical than the ones proposed above (antenna module ()):

1. The radio transmission path is longer.

2. The antenna module is exposed to external interferences (e.g. Wi-Fi®,

Bluetooth®).

3. The machine structure acts as an obstruction to transmission, rather than

shielding it from interferences.

4. Staff, who passes close to the machine or approaches it with other radio

transmission systems may interfere with the connection.

5. It is very important to ensure that the maximum transmission distance does

not exceed 5 m.

6. The antenna module should not be installed as in the drawing below if the

door is fitted with a metal grille.

5.4.3 Positioning of more than one antenna module

More than one antenna modules close to each other must be positioned in such a

way that the antennas do not interfere mutually.

Correct positioning

The two antenna modules

are installed at a sufficient

distance to each other;

mutual interferences do not

occur.

Ensure minimum distance

of 0.5 m between two

antenna modules!

Wrong positioning

The two antenna modules

are installed too close to

each other; mutual

interferences occur.

The radiation diagrams

change and sufficient

transmission quality in the

direction necessary for

entering the machine is not

ensured.

Ensure minimum distance

of 0.5 m between two

antenna modules!

Page 28

Installation

28

5.4.4 Machines positioned side by side

Correct positioning

The two antenna modules and are positioned correctly. Although they

receive the signal from the corresponding 4K-WISY rotors 1 and 2 only after it has

been reflected off the machine positioned in front of them, they also receive the

signal directly from the opposite transmitter. Cross-interferences can be

eliminated by using the appropriate channels.

Page 29

Installation

29

5.4.5 Alignment of the 4K-WISY-Rotor

The 4K-WISY-Rotor radiation diagram is practically circular in a plane lying

perpendicular to the transmitter axis. The intensity of radiation is at its maximum

level in this plane. Although the system will function correctly when using reflected

transmission paths, it is preferable to use the transmission direction recommended

below. Optimal alignment is attained when using the 90°-extension for the rotor.

Recommended solution

Milling machine. The

predominant radiation

directions of 4K-WISY-Rotor

and antenna module

coincide.

Non recommended

solution

Milling machine. The

predominant radiation

directions of 4K-WISY-Rotor

and antenna module do not

coincide.

Notice

Risk of significant attenuation of the radio signal!

Metal objects and other electrically conductive materials may affect the performance

of the antenna and result in attenuation of the radio signal.

Avoid these negative influences by reducing the number of metal objects near the

4K-WISY-Rotor to a minimum and keep the rotor and the antenna module free from

chips and coolants during operation.

Pos: 51 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 30

Installation

30

Pos: 52 /ARTIS/Installation/Systeme/Ver wendung von Funkfrequenzkanälen @ 5 \mod_1475822350401_18.docx @ 23 4442 @ 3 @ 1

5.4.6 Using the radio frequency channels

2.4 GHz ISM band

The 4K-WISY system uses the internationally reserved 2.4 GHz ISM-Band

(Industrial-Scientific-Medical) band which occupies the following frequency range:

• 2402 MHz – 2472 MHz (worldwide)

The 4K-WISY system emitted power is approximately +4 dBm (~2.5mW) which

means that it is classified as a class 2 transmission device. There are currently

numerous wireless systems which use this frequency range (2.4 GHz). So it is very

important to ensure that there is sufficient space available in the frequency spectrum

for the system to function reliably.

1. 4K-WISY channels

The 4K-WISY system features 70 frequency channels each occupying a bandwidth

of 2 MHz. To convert the channel number into the effective frequency range, use the

following formula:

Effective frequency = 2400 MHz + channel number x 1MHz

Selecting the most suitable working channel for each radio system is very important

for guaranteeing constant and reliable communication. When compared to other

systems such as FHSS (Frequency Hopping Spread Spectrum), 4K-WISY has the

advantage that it enables users to plan and allocate the way the frequency spectrum

is used by selecting and defining the channels.

If there are multiple systems in the same area (factory) it is possible to re-use

channels provided the correct distance is maintained.

Distance

Example

a) Minimum distance between antenna

module and 4K-WISY-Rotor (using

different channels)

0.5 m

27A 0.5 m 43A

b) Minimum distance before re-allocating

any given frequency channel

100 m

27A 100 m 27A

A. Machine with single antenna module installed

The most frequently used application consists of a machine equipped with a spindle

and one 4K-WISY antenna module. In this configuration, it is possible to use a

different frequency channel for each system installed.

B. Multiple antenna modules installed on a single machine

In the case of machines equipped with dual spindles, in order to measure two parts

simultaneously it is necessary to install an antenna module for each spindle. In this

configuration it is important to ensure that:

• The minimum distance between the devices is respected

• The antenna modules are positioned as far apart as possible

• Identical or adjacent frequency channels are avoided.

C. Installation with two or more machines positioned close together

Given the unpredictable way in which electromagnetic waves are propagated, the

machines must never be treated as though they are isolated systems; in other words,

whenever a radio frequency system is installed, it will influence and be influenced by

all the other machines that are installed around it.

Page 31

Installation

31

The 4K-WISY system has a wide communication range. Therefore, two machines

installed with a few meters of each other should be treated as a single, large machine

equipped with multiple spindles when planning the system layout. Therefore, the

suggestions listed in chapter B above need to be taken into consideration. This

especially applies if the antenna modules are installed outside the working zone,

since the 4K-WISY-Rotor signal may be more attenuated than those emitted by the

surrounding 4K-WISY systems.

2. Manual planning

When installing a system on equipment where other radio systems are already in

place, it is important to take the following factors into consideration:

A. Wi-Fi®

The PC wireless network is the most commonly used system and, as a class 1

device, it is capable of transmitting more power than other systems (+20 dBm, ~100

mW). Its typical frequency usage is shown below:

Fig. 6: Wi-Fi® channels

Each block marked in dark color corresponds to a different set of superimposed

channels, naturally a single set must be used for each area. 1, 6 and 11 are the most

commonly used frequency ranges. The generic Wi-Fi® name covers a range of

different standards; the new, faster communication networks can interfere

significantly with the 4K-WISY system, hence it is advisable to select channels at the

limits of the occupied band in each zone.

Page 32

Installation

32

Information

Example of the rule that should be followed in these types of installation:

Set one 4K-WISY to channel „n“ and set the other to channel „n+20“ when a Wi-Fi

®

system is present; assuming an initial bandwidth of 20 MHz, in this way one

4K-WISY will be positioned “to the left” of the Wi-Fi®-channel and the other “to the

right”.

B. Bluetooth® Wireless

This system has frequency and modulation characteristics that are very similar to

4K-WISY (channel bandwidth 1 – 2 MHz and typical output power level of +4 dBm

(~2.5mW)). It uses the FHSS (Frequency Hopping Spread Spectrum) in order to

minimize the effect of interference from other systems. In this standard, all channels

are used in turn, “hopping” from one channel to another at random. Devices that use

Bluetooth® wireless technology do not represent significant sources of interference.

The Bluetooth® mark and logo are registered trademarks of the Fa. Bluetooth SIG,

Inc.

C. Andon™

This system is used for wireless monitoring of OMRON® manufactured machines

and features the following specifications:

• 67 channels in frequency range 2401 MHz – 2480.2 MHz;

• Modulation in DSSS format;

• Equivalent output power 10 mW/MHz

Communications are practically continuous in the channels used by the Andon™

system, therefore they may represent a source of interference for the 4K-WISY

system. In order to co-exist correctly with this system it is necessary to observe the

following precautions when selecting the 4K-WISY frequency:

• Fc (4K-WISY) ≥Fc (Andon™) +2,5 [MHz] or:

• Fc (4K-WISY) ≤ Fc (Andon™) -2,5 [MHz]

Where:

• Fc (4K-WISY) = main frequency of the 4K-WISY system;

• Fc (Andon™) = main frequency of the Andon™ system.

D. IEEE 802.15.4 systems

These transceivers are sometimes used in customized protocols for industrial

environment and give rise to moderate levels of interference.

Pos: 53 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 33

Commissioning

33

Pos: 54 /ARTIS/Überschriften/H1/I/ÜS_In betriebnahme @ 0\mod_1383142983802_ 18.docx @ 1992 @ 1 @ 1

6 Commissioning

Pos: 55 /ARTIS/Inbetriebnahme/Sensore n/Drehmomentsensoren/4KWISY_Inbetri ebnahme_SW_starten @ 4\mod_14619 20476054_18.docx @ 189744 @ 2 @ 1

6.1 Starting the visualization software

1. Open directory 4K_Visu in your file system.

2. Execute file 4K_WiSy_Visu.exe by double-clicking.

The page Visualization is displayed.

Fig. 7: Visualization

Pos: 56 /ARTIS/Inbetriebnahme/Sensore n/4KWISY_Inbetriebnahme_Rotor an melden @ 4\mod_1467355370820_18.d ocx @ 205587 @ 2 @ 1

6.2 Logging in the rotor

1. Push key [F6] Configuration.

The page Visualization settings is displayed.

Page 34

Commissioning

34

Fig. 8: Visualization settings

2. Push key [sF4] Rotor in the vertical menu bar.

Pos: 57 /ARTIS/Beschreibung/4K_WISY/R otor-Einstellung @ 4\mod_146219181 0820_18.docx @ 190659 @ @ 1

The page Rotor settings is displayed.

Fig. 9: Rotor settings

Page 35

Commissioning

35

3. Push key [sF2] Add rotor in the vertical menu bar. Any number of rotors

may be added.

4. Adjust rotor parameters:

Name: Rotor name

Serial number: Enter serial number (printed on the rotor)

RFChannel: Enter radio channel. The channel number, which

is entered here, must correspond to the channel

of the antenna module

(see lower left corner of the display).

Version: Software version recognized by the rotor

Battery voltage: Battery voltage/charging voltage

Calibration date: Last calibration date. If the field is highlighted in

yellow, the recommended calibration period has

elapsed and re-calibration of the sensor is

recommended.

Setting of the calibration period in file:

4K_WiSy_Visu: 24 = 24 months

Selection: Tick the rotors in use

5. Push key [sF4] Set RF channel in the vertical menu bar.

6. If necessary, push key [sF4] Connect rotor in order to select the rotor for

communication.

The serial number is displayed left to the symbol .

The color of the control display in the header changes from red to gray .

This indicates that the system has recognized the rotor and that the radio connection

has been established successfully.

7 Push key [sF3] Remove rotor in order to disconnect unused rotors.

8. Push key [sF8] Back in the vertical menu bar after completing all entries.

The page Visualization settings is displayed again.

9. Push key [sF8] Back again.

The page Visualization is displayed again.

Rotor off

Push key [sF5] Power off rotor to switch off the rotor manually. The rotor switches

off automatically after 30 minutes without communication (visualization stopped).

Pos: 58 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 36

Basic settings

36

Pos: 59 /ARTIS/Überschriften/H1/G/ÜS _Grundeinstellungen @ 4\mod_14673 78177594_18.docx @ 206385 @ 1 @ 1

7 Basic settings

Pos: 60 /ARTIS/Beschreibung/4K_WISY/Ü bersicht Bildschirmaufbau @ 4\mod _1461921607301_18.docx @ 189811 @ @ 1

There are three screen areas in the 4K-WISY visualization:

• Header: general status information about the system

• Main screen: 4 freely configurable windows for displaying the measurement

data

• Menu bar(s).

Pos: 61 /ARTIS/Beschreibung/4K_WISY/Scr een_Hauptbildschirm @ 4\mod_146 1921897774_18.docx @ 189833 @ @ 1

Fig. 10: 4K-WISY main screen

Pos: 62 /ARTIS/Beschreibung/4K_WISY/H eader @ 4\mod_1461921869772_18. docx @ 189921 @ @ 1

Page 37

Basic settings

37

Header

General status information about the system is given on the right side of the header:

<User name>

Name of currently logged in user

SN

Rotor serial number

Rotor control display

Gray: Rotor detected

Red: No rotor detected

Control display: charging level of battery, the yellow flash on

the battery symbol indicates that the battery is currently

being charged.

4 green bars: Battery fully charged = 100 %

3 green bars: Charging level = 75 %

2 green bars: Charging level = 50 %

1 amber bar: Charging level 25 %

1 red bar: Charging level 10 %

No bar: Flat battery

Pos: 63 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 38

Basic settings

38

Pos: 64 /ARTIS/Beschreibung/4K_WISY/H auptbildschirm @ 4\mod_1461923904 883_18.docx @ 189943 @ @ 1

Main screen

The 4 windows of the 4K-WISY visualization are freely configurable. These are the

available display options:

• XY-plot (scatter-plot)

Note that the display option XY-plot is only sensible for illustrating the signals

Bending 0° and Bending 90°. The example diagram below shows:

Yellow: Reference values

Green: Bending forces during one turn of the tool.

• Force level during time

Page 39

Basic settings

39

• Trend curve

Right-click the different windows in order to open the context menu Visualization

Settings. The different setting options are explained in detail in the chapter Setting

the visualization of this manual.

Fig. 11: Context menu Visualization settings

For more information refer to chapter Setting the visualization.

Pos: 65 /ARTIS/Beschreibung/4K_WISY/M enüleiste @ 4\mod_1461924165581 _18.docx @ 189965 @ @ 1

Page 40

Basic settings

40

Menu bar

The menu bar is located in the lower part of the screen. Depending on the current

user level, the display of active [F]-keys may vary.

Other pages of the visualization have an additional vertical menu bar on the right

side of the screen.

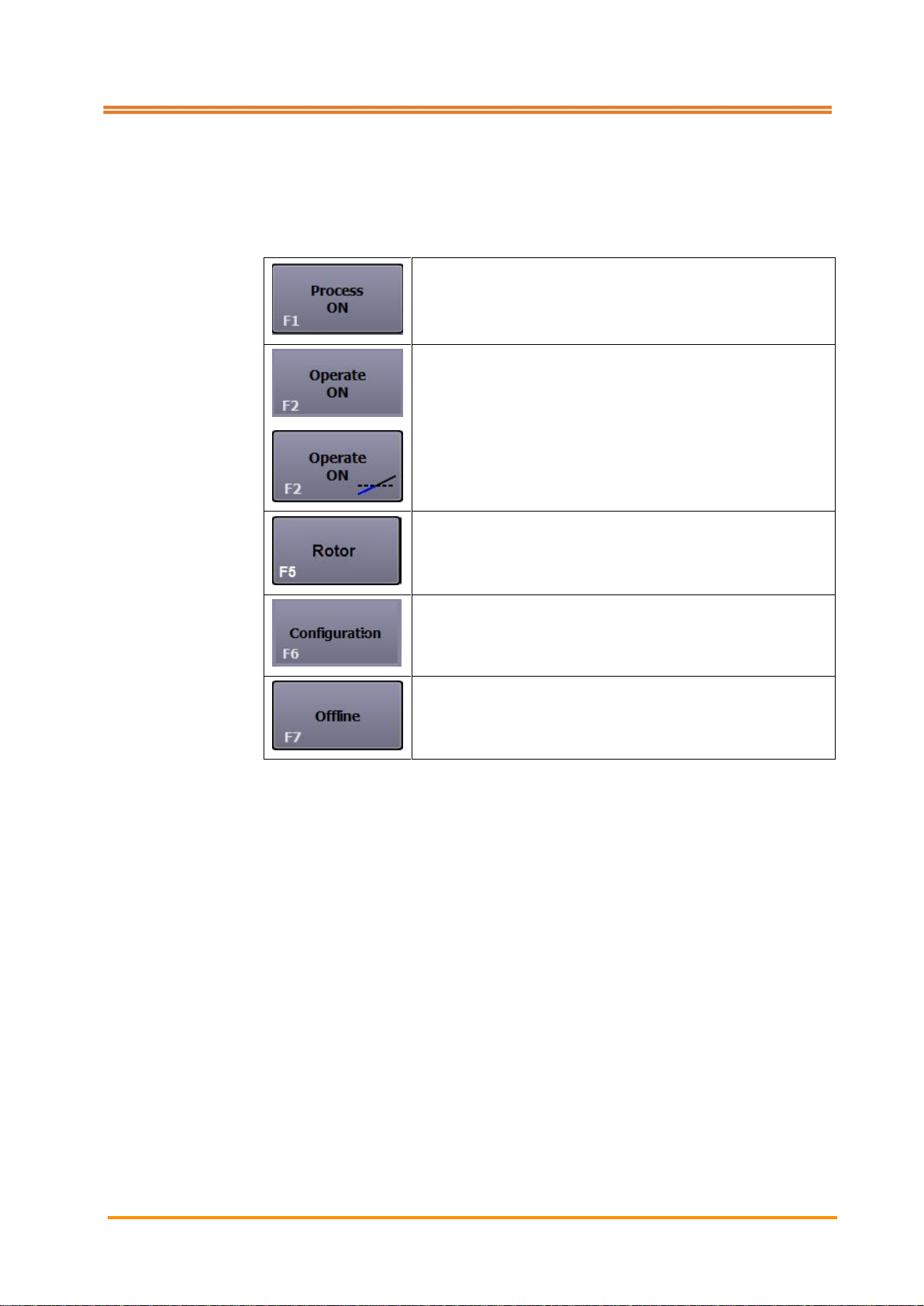

[F1] Process ON

[F2] Operate ON

or

[F2] Operate ON Trigger active

In this case, recording of measurement data only starts

after the trigger level has been exceeded

[F5] Rotor

[F6] Configuration

[F7] Offline

Pos: 66 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 41

Basic settings

41

Pos: 67 /ARTIS/Beschreibung/4K_WISY/V ertikale Menüleiste @ 4\mod_1461 930777117_18.docx @ 190318 @ @ 1

Push key [F6] Configuration on page Visualization. Page Visualization settings

with a vertical menu bar on the right side is displayed.

[sF1] Rotor

Push Shift + [F1] and navigate to page Rotor settings,

see chapter Commissioning

[sF6] User level

Push Shift + [F6]. The authentication dialog is displayed

(for service purposes only)

[sF7] About

Push Shift + [F7]. Information about the Qt-class library

[sF8] Back

Push Shift + [F8] to step back

Pos: 68 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 42

Basic settings

42

Pos: 69 /ARTIS/Überschriften/H2/V/ÜS _Visualisierung einstellen @ 4\mod_146 1927995005_18.docx @ 190097 @ 2 @ 1

7.1 Setting the visualization

Pos: 70 /ARTIS/Beschreibung/4K_WISY/Vis ualisierung einstellen @ 4\mod_14 62182766053_18.docx @ 190437 @ @ 1

The settings for the 4 freely configurable windows which display the measurement

data are carried out on page Visualization settings.

1. Right-click the desired window.

The page Visualization settings is displayed.

2. Use drop-down list to select the desired display parameters in field View.

Plot type

Off

No data displayed

XY-plot

2 signals in XY-plot

Timeline

1 - 2 signals in timeline

Trend

Trend of measurement data

1st – 4th signal

No signal

Signal not assigned

Torque

Select torque signal

Force

Select axial force signal

Bending 0°

Select bending 0° signal

Bending 90°

Select bending 90° signal

Bending value

Bending angle

Show legend

Set checkmark

Color assignment of the

different signals is displayed in

the plot

Ratio 1:1

Set checkmark

Activate square display option

(only available with XY-Plot)

Filter active

Set checkmark

Activate filter (only available

with Plot type = Timeline)

Filter

Mean

Moving average value based

on x points

Max

Maximum value

Min

Minimum value

Peak to Peak

Peak to Peak

Time

Enter value

(max. 99)

Time in seconds for mean filter

value

3. Push key [sF8] Back.

Pos: 71 /ARTIS/Überschriften/H2/W/ÜS_ Werkzeuglänge einstellen @ 4\mod_1 467294837514_18.docx @ 205424 @ 2 @ 1

Page 43

Basic settings

43

7.2 Setting the tool length

Pos: 72 /ARTIS/Beschreibung/4K_WISY/W erkzeuglänge einstellen @ 4\mod_14 67294798035_18.docx @ 205402 @ @ 1

Move back to the page Visualization settings in order to enter the tool length.

Abb. 12: Visualization setting

The system requires information about the tool length if the function Convert

bending to Newton is selected.

1. Set checkmark Convert bending to Newton.

2. Enter total throat depth in mm into the designated field.

Pos: 73 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 44

Basic settings

44

Pos: 74 /ARTIS/Überschriften/H2/S/ÜS _Skalierung der Visualisierung festlegen @ 4\mod_1467295166097_18.docx @ 20 5447 @ 2 @ 1

7.3 Setting the scaling of the visualization

Pos: 75 /ARTIS/Beschreibung/4K_WISY/S kalierung der Visualisierung festlegen @ 4\mod_1467295248753_18.docx @ 2 05470 @ @ 1

Set checkmark Use fixed scaling, in order to deactivate the automatic auto scaling

function of the measurement data in the visualization.

Pos: 76 /ARTIS/Überschriften/H2/T/ÜS_Trig ger einstellen @ 5\mod_14758348 07958_18.docx @ 234553 @ 2 @ 1

7.4 Setting the trigger

Pos: 77 /ARTIS/Beschreibung/4K_WISY/T rigger einstellen @ 5\mod_147583498 2680_18.docx @ 234598 @ @ 1

With activated Trigger function, measuring starts once the trigger level is exceeded.

Active

Set checkmark

Activate trigger

Signal

No signal

Signal not assigned

Torque

Select torque signal

Axial force

Select axial force signal

Bending 0°

Select bending 0° signal

Bending 90°

Select bending 90° signal

Bending value

Select bending value signal

Bending angle

Select bending angle signal

Level

Enter value

Define height of trigger level

Filter mean time (sec)

Enter value

Automatic Trigger

Enter value

Define lead/lag and delay time

Trigger with duration

Enter value

Define lead time, delay,

duration and total length of

time

Pos: 78 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 45

Basic settings

45

Pos: 79 /ARTIS/Überschriften/H2/R/ÜS_R eport_Prozesseinstellungen @ 5\m od_1476797987016_18.docx @ 236381 @ 2 @ 1

7.5 Selecting the storage location of the report and process settings

Pos: 80 /ARTIS/Beschreibung/4K_WISY/S peicherort der Report_Prozesseinstellu ngen auswählen @ 4\mod_1462190284 016_18.docx @ 190503 @ @ 1

All measurements are stored automatically to the directory, which was selected after

pushing Process ON (page Visualization). The path to the process settings leads

into the file system of the computer, which is used for running the 4K-WISY-Visu.

Open the file system and select a directory

Pos: 81 /ARTIS/Überschriften/H2/S/ÜS _Schnittstelle einstellen @ 4\mod_146 2191131554_18.docx @ 190569 @ 2 @ 1

7.6 Setting the interface

Pos: 82 /ARTIS/Beschreibung/4K_WISY/Sc hnittstelle einstellen @ 4\mod_14621 91225388_18.docx @ 190592 @ @ 1

The desired I/O parameters are defined on the page I/O settings.

Digital input

: External input active

: External input inactive

Low active

Radio button

Level for external input (0 V)

High active

Radio button

Level for external input (24V)

Pos: 83 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 46

Basic settings

46

Pos: 84 /ARTIS/Überschriften/H2/R/ÜS_R otor-Einstellungen @ 4\mod_146219 1702369_18.docx @ 190636 @ 2 @ 1

7.7 Setting the rotor

Pos: 85 /ARTIS/Hinweise/Hinweis_Rotor-Ei nstellungen @ 4\mod_1462192397 652_18.docx @ 190703 @ @ 1

Information

More information about adding and removing rotors can be found in chapter

Commissioning.

Pos: 86 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 47

Operation

47

Pos: 87 /ARTIS/Überschriften/H1/B/Ü S_Bedienung @ 0\mod_13831428218 04_18.docx @ 1983 @ 1 @ 1

8 Operation

Pos: 88 /ARTIS/Bedienung/Sensoren/ 4K-WISY/Prozess EIN @ 4\mod_14621 94053333_18.docx @ 190757 @ 2 @ 1

8.1 Process ON

All measurement data are saved and stored automatically into the directory, which

has been selected after pushing key [F1] Process ON (page Visualization).

1. Push key [F1] Process ON. The system automatically displays the

measurement directory, which was used last. If this measurement is to be

continued, confirm by pushing OK.

2. If another directory is to be used or if a new directory is to be created, proceed

as follows:

1. Push the icon Browse klicken .

The dialog Choose or create directory is displayed.

2. Select directory or enter a new directory name, push Select folder to

confirm.

3. Push OK to confirm.

Fig. 13: Process ON

Pos: 89 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 48

Operation

48

Pos: 90 /ARTIS/Überschriften/H2/R/ÜS_R eport-Einstellungen @ 5\mod_14758 40484982_18.docx @ 234664 @ 2 @ 1

8.2 Report settings

Pos: 91 /ARTIS/Bedienung/Sensoren/ 4K-WISY/Report-Einstellungen @ 5\mo d_1475840562233_18.docx @ 234687 @ @ 1

The following screen is displayed if empty (newly created) measuring folders are

selected. All entry fields may be edited.

Process

Preconfigured:

The list of processes can be

adapted arbitrarily*. Process

parameters depend on the

selected process type.

Drilling

Threading

Reaming

Milling

User

Enter name

Product

Enter name

Process parameters

Enter value

Depending on process type

User sets

Select settings

Select pre-configured settings

Save

Save process

parameters

Name is adopted from the list

User sets.

Delete

Delete process

parameters

Selcted configuration is

deleted form the list User

sets.

* Adaptation of file 4K_WiSy_ProcessingSet.ini

Pos: 92 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 49

Operation

49

Pos: 93 /ARTIS/Bedienung/Sensoren/ 4K-WISY/Bearbeitung EIN @ 4\mod_1462 274570242_18.docx @ 191293 @ 2 @ 1

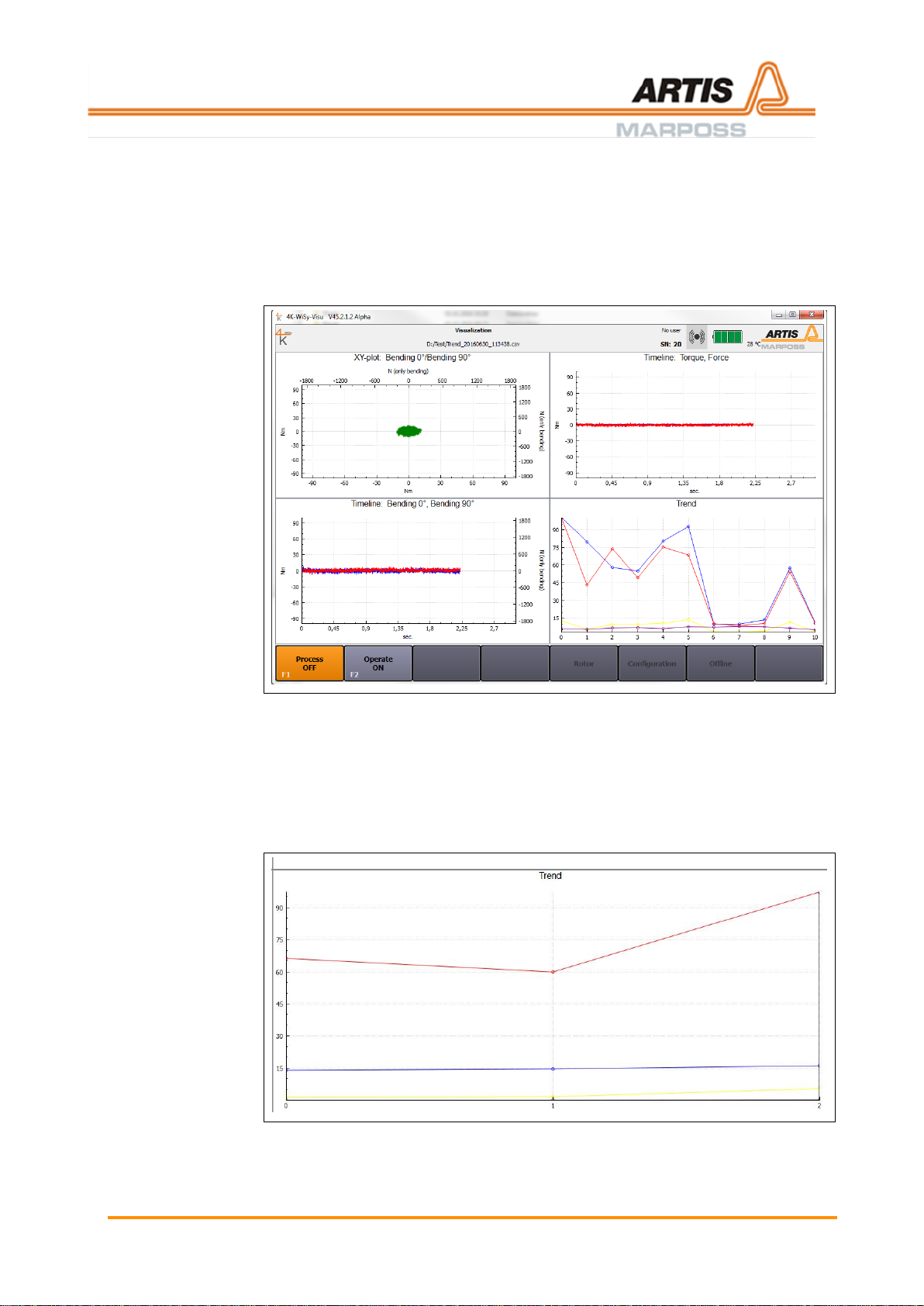

8.3 Operate ON

Key [F2] or the external output are assigned alternatively with either Operate ON

or Operate OFF. Measurement data are logged while the key [F2] is displayed in

orange color.

1. Push key [F2] Operate ON. Measurement data are logged. The color and the

labelling of the key [F2] switches to orange and Operate OFF.

Fig. 14: Operate ON

2. The measurement data are displayed in the windows, which have been

configured beforehand (see chapter Commissioning).

3. Shift key [F2] Operate OFF. Logging of measurement data is stopped. With

each ON/OFF, another cycle is added to the directory, which has been

selected after pushing Process ON.

4. A Trend curve is now displayed in the trend-window.

Fig. 15: Trend-window

Pos: 94 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 50

Evaluating the measurement data

50

Pos: 95 /ARTIS/Überschriften/H1/M/ÜS_M essdaten evaluieren @ 4\mod_1462 277979573_18.docx @ 191360 @ 1 @ 1

9 Evaluating the measurement data

Pos: 96 /ARTIS/Bedienung/Sensoren/ 4K-WISY/Offline-Rekorderöffnen @ 4\ mod_1462278124841_18.docx @ 191405 @ @ 1

The collected measurement data can be retrieved from the Offline recorder.

Push key [F7] Offline in the horizontal menu bar for switching to the Offline recorder.

The page Offline recorder is displayed.

Fig. 16: Offline recorder

Information

This function is only available if process recording is switched to Process OFF.

Pos: 97 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 51

Evaluating the measurement data

51

Pos: 98 /ARTIS/Bedienung/Sensoren/ 4K-WISY/Offline-Rekorder Menüleiste @ 4\ mod_1462278919171_18.docx @ 191 449 @ @ 1

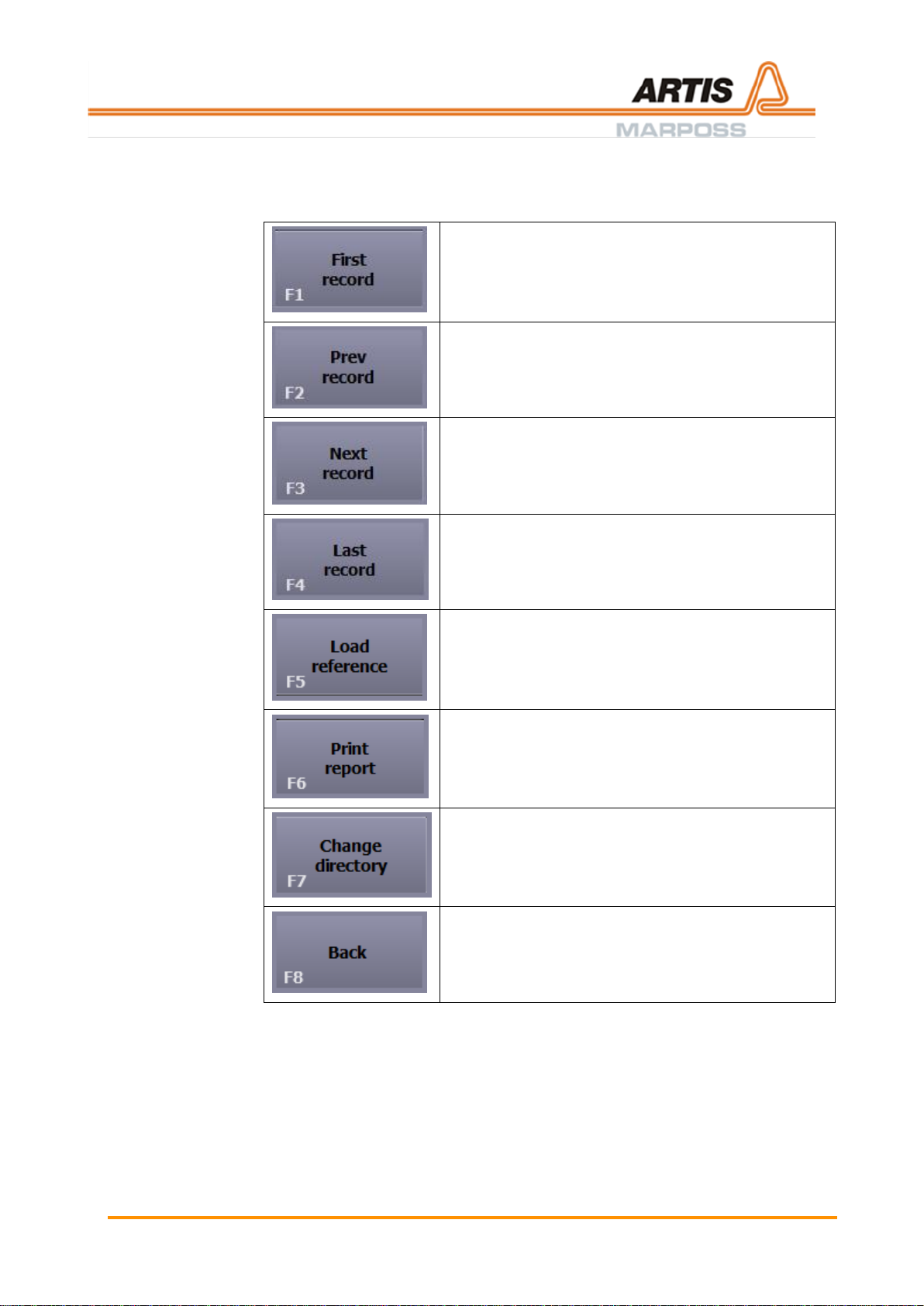

Menu bar

The menu bar is located in the lower part of the screen. Depending on the current

user level, the display of active [F]-keys may vary.

[F1] First record

Move to first recording

[F2] Prev record

Move to previous recording

[F3] Next record

Move to following record

[F4] Last record

Move to last recording

[F5] Load reference

Load reference recording. The loaded recording is

displayed in yellow and shows deviations between the

current and the reference recording

[F6] Print report

Print current cut

[F7] Change directory

Move to another recording directory

[F8] Back

Step back

Pos: 99 /ARTIS/Seitenumbruch/-----Seitenumbruch---- @ 0\ mod_1384520666314_18.docx @ 3570 @ @ 1

Page 52

Evaluating the measurement data

52

Pos: 100 /ARTIS/Bedienung/Sensoren/4 K-WISY/Offline-Modus Cursor-Optione n @ 4\mod_1462280477686_18.docx @ 191647 @ @ 1

Double-clicking the headline of a window opens this particular window in

full screen mode.

The tool bar for setting the display options is located beneath the recording

windows.

Slide control

The slide control is used for moving the cursor

area within the display.

Show cursor

: A certain part of the display is selected by a

cursor. The number of points in the spin box

determines the size of the cursor area.

: No part selected.

Synchronous

zooming

: all timeline views scroll synchronously

: only the selected timeline view scrolls

Ctrl-key + mouse wheel: Y-axis is zoomed

Alt-key + mouse wheel: X-axis is zoomed

Position cursor in

timeline view

Select any point of the curve by mouse clicking

and display time of measurement and

measurement values for the selected point.

Position cursor in

trend view

Select any point of the curve by mouse clicking

and display measurement values for the selected

point.

Page 53

Evaluating the measurement data

53

Context menu in the Trend view (right-click to display)

Show this

measurement

Click measurement

The selected measurement

is displayed in all windows

Set as reference

Click measurement

The selected measurement

is set as reference

measurement

Show in Explorer

Click measurement

Explorer is opened, the

selected measurement is

highlighted

Ignore measurement

/ Insert measurement

Click measurement

Measurement is either

ignored or displayed in the

Trend view

Visualization

settings

Select entry

Context menu Visualization

Settings is displayed

Pos: 101 /ARTIS/Seitenumbruch/-----Seitenumbruc h---- @ 0\mod_1384520666314_18.docx @ 3570 @ @ 1

Page 54

Creating a report

54

Pos: 102 /ARTIS/Überschriften/H1/R/ÜS _Report erstellen @ 5\mod_1479885 627592_18.docx @ 238997 @ 1 @ 1

10 Creating a report

Pos: 103 /ARTIS/Bedienung/Sensoren/4 K-WISY/Offline-Rekorderöffnen @ 4\mo d_1462278124841_18.docx @ 191405 @ @ 1

The collected measurement data can be retrieved from the Offline recorder.

Push key [F7] Offline in the horizontal menu bar for switching to the Offline recorder.

The page Offline recorder is displayed.

Fig. 17: Offline recorder

Information

This function is only available if process recording is switched to Process OFF.

Pos: 104 /ARTIS/Bedienung/Sensoren/4 K-WISY/Report erstellen @ 5\mod_14 79885858915_18.docx @ 239030 @ @ 1

In order to navigate to the report tool, push key [F6] Print report in the horizontal

menu bar.

The following screen with the report dialog is displayed.

Page 55

Creating a report

55

Entry field

(at the upper edge of the screen)

Enter report title

Report settings

These fields cannot be edited in

this dialog.

The data basis for the report is the

measurement directory which was

selected when recording the

measurements Process ON.

In order to create a report using

data from a different measurement

directory, carry out the following

steps:

• Push Cancel and end report

dialog

• Push key [F7] Change

directory

• Push key Select folder.

• Push key [F6] Print report

and return to the report

dialog.

Visualization

(here: trend curve)

One visualization window is already

opened.

The context menu (right-click to

display) is used for navigating in the

visualization window.

This context menu allows the

following actions:

• Show this measurement

• Set as reference

• Visualization settings

(see chapter Evaluating the

measurement data)

Page 56

Creating a report

56

Keys Plus-/Minus

Reports can be added to/removed

from the report using the keys Plus

and Minus.

Record number

Direct selection of certain

measurements for the report.

Visualization settings

Right-click in any of the

visualization windows in order to

open the menu Visualization

settings. This context menu allows

the following actions:

• Select plot type

• Select signal type

• Show legend

• Ratio 1:1

• Filter active

• Filter

• Time

(see chapter Setting the

visualization).

Notes

Field for additional information.

Page 57

Creating a report

57

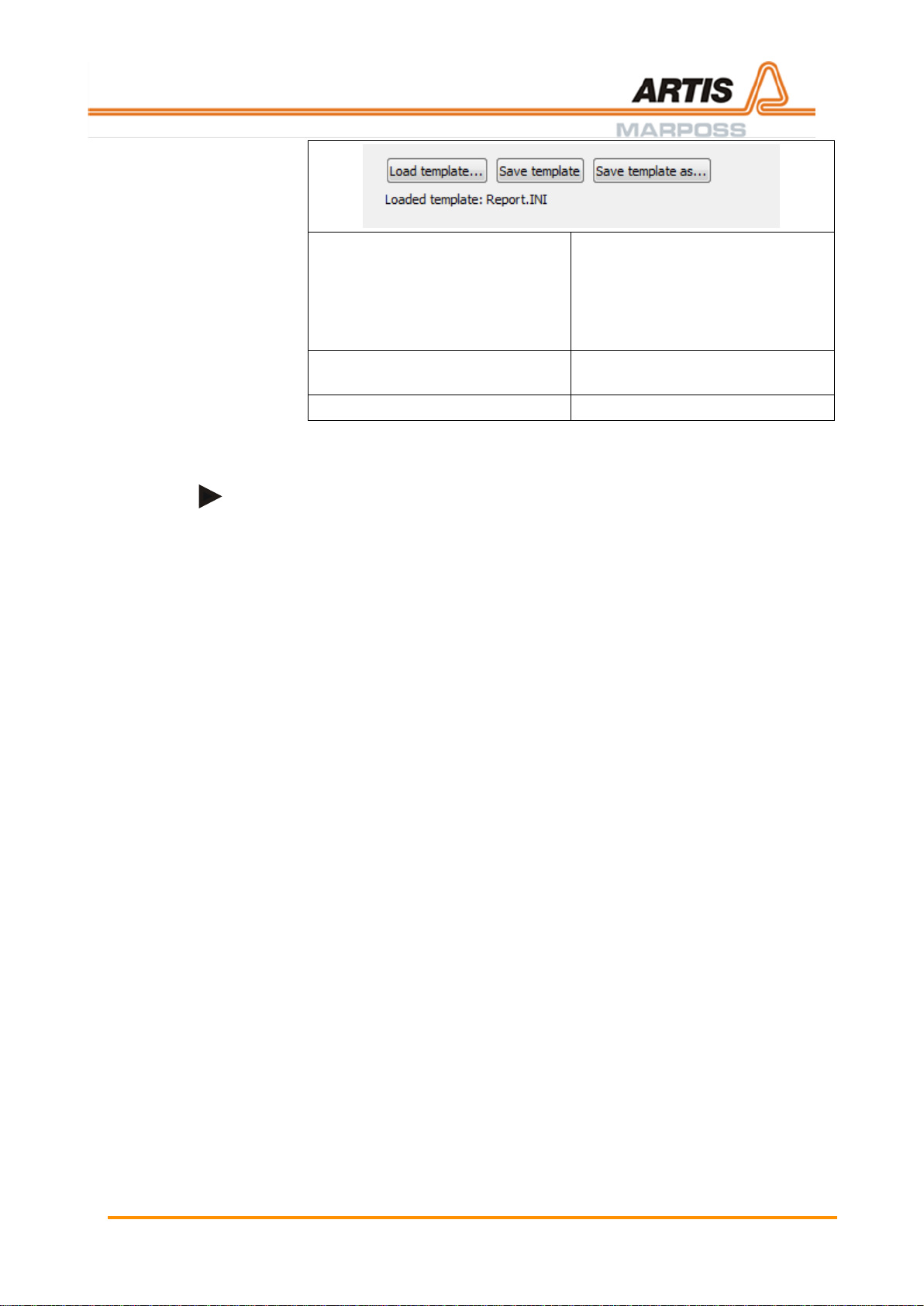

Load template

Save template

Save template as …

In this example, the report bases on

the template Report.INI.

Administration of report templates

is carried out with the keys Load

template/Save template/Save

template as.

Printing

Printing the report with all selected

viaualizations as PDF-file.

Cancel

End report dialog.

Information zur Anpassung des Report-Layouts

Im Verzeichnis 4K-Visu befindet sich ein Unterverzeichnis Report. In diesem

Unterverzeichnis sind zwei PNG-Dateien abgelegt:

• Logo-Left.png

• Logo-Right.png

Das Report-Layout lässt sich individualisieren, indem diese Datei(en) ausgetauscht

werden.

Pos: 105 /ARTIS/Seitenumbruch/-----Seitenumbruc h---- @ 0\mod_1384520666314_18.docx @ 3570 @ @ 1

Page 58

Maintenance

58

Pos: 106 /ARTIS/Überschriften/H1/W/ÜS _Wartung @ 0\mod_1383143161374_ 18.docx @ 2007 @ 1 @ 1

11 Maintenance

Pos: 107 /ARTIS/Wartung/Kalibrierinter vall @ 5\mod_1479822950381_18.docx @ 238969 @ @ 1

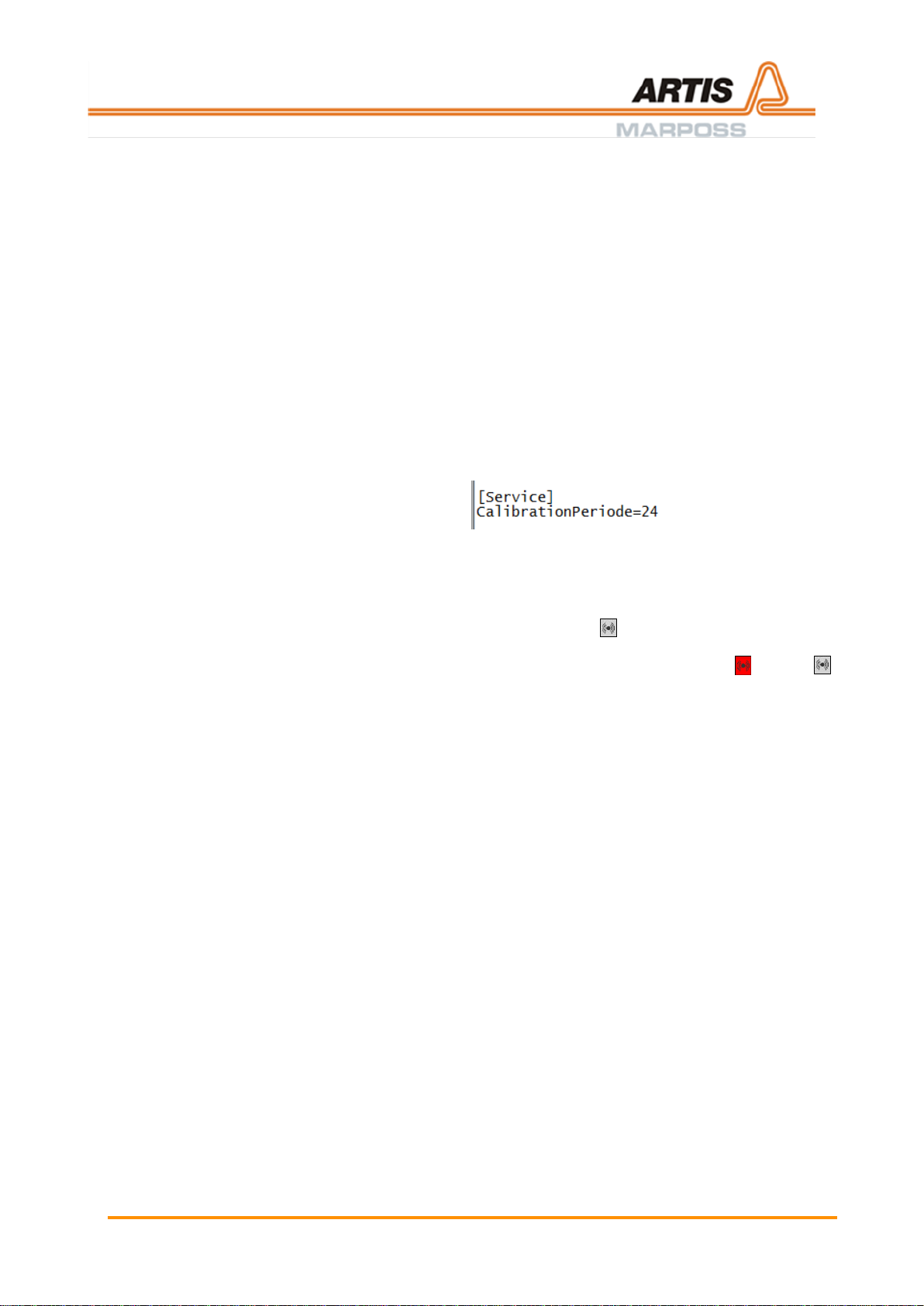

The rotor applies to the specifications stated in this document and is calibrated

ex works.

The recommended calibration interval is 24 months.

In order to adhere to the recommended calibration interval, the field Calibration date

on the page Rotor settings is highlighted in yellow after the period of 24 months

has elapsed.

The configuration of the calibration interval is carried out in the file 4K_WiSy_Visu:

24 = 24 months.

Pos: 108 /ARTIS/Seitenumbruch/-----Seitenumbruc h---- @ 0\mod_1384520666314_18.docx @ 3570 @ @ 1

Page 59

Appendix

59

Pos: 109 /ARTIS/Überschriften/H1/A/ÜS_ Anhang @ 0\mod_1383128782297_18. docx @ 1873 @ 1 @ 1

12 Appendix

Pos: 110 /ARTIS/Überschriften/H2/K/ÜS_ Konformitätserklärungen @ 5\mod_ 1481117944660_18.docx @ 240727 @ 2 @ 1

12.1 Declaration of conformity

Pos: 111 /ARTIS/Konformitätserklärung en/FCC @ 5\mod_1481114441033_0.d ocx @ 240657 @ 33 @ 1

12.1.1 FCC Konformitätserklärung

Federal Communication Commission Interference Statement

This equipment has been tested and found to comply with the limits for a Class B