Artic Cat 700 diesel SD ATV Service Manual

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

FOREWORD

This Arctic Cat Service Manual contains service, maintenance, and troubleshooting information for the 2011

Arctic Cat 700 Diesel SD ATV. The complete manual is designed to aid service personnel in service-oriented

applications.

When using this manual as a guide, the technician should use discretion as to how much disassembly is needed

to correct any given condition.

The service technician should become familiar with the operation and construction of each component or system

by carefully studying the complete manual. This manual will assist the service technician in becoming more aware

of and efficient with servicing procedures. Such efficiency not only helps build consumer confidence but also saves

time and labor.

All Arctic Cat ATV publications and decals display specific symbols to emphasize important information. The

symbol ! WARNING identifies personal safety-related information. Be sure to follow the directive because it

deals with the possibility of severe personal injury or even death. A CAUTION identifies unsafe practices

which may result in ATV-related damage. Follow the directive because it deals with the possibility of damaging

part or parts of the ATV. The symbol NOTE: identifies supplementary information worthy of particular atten-

tion. The symbol

efficiency and to improve clarity.

At the time of publication, all information, photographs, and illustrations were technically correct. Some photographs used in this manual are used for clarity purposes only and are not designed to depict actual conditions.

Because Arctic Cat Inc. constantly refines and improves its products, no retroactive obligation is incurred.

AT THIS POINT directs the technician to certain and specific procedures to promote

All materials and specifications are subject to change without notice.

Keep this manual accessible in the shop area for reference.

Product Service and

Warranty Department

Arctic Cat Inc.

© 2011 Arctic Cat Inc. January 2011

®™ Trademarks of Arctic Cat Inc., Thief River Falls, MN 56701

www.mymowerparts.com

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

Note: To navigate through this manual, use the PAGE UP/PAGE DOWN buttons on the keyboard, click on the

Table of Contents bookmarks on the left side of the screen, or click the blue text below. To return to this page,

click the Manual Table of Contents button at the bottom of each page.

Click on the blue text to go.

TABLE OF CONTENTS

General Information ........................................................2

General Specifications.................................................. 2

Torque Specifications.................................................... 2

Torque Conversions (ft-lb/N-m)..................................... 3

Break-In Procedure ...................................................... 3

Fuel - Oil - Lubricant ..................................................... 4

Genuine Parts............................................................... 5

Preparation For Storage ............................................... 5

Preparation After Storage ............................................. 5

Periodic Maintenance/Tune-Up....................................... 6

Periodic Maintenance Chart ......................................... 6

Lubrication Points ......................................................... 7

Air Filter ........................................................................ 7

Valve Clearance............................................................ 8

Muffler/Spark Arrester .................................................. 8

Adjusting Throttle Cable ............................................... 8

Engine RPM (Idle) ........................................................ 9

Engine Oil - Filter.......................................................... 9

Transmission Lubricant ............................................... 10

Front Differential/Rear Drive Lubricant ....................... 10

Tires............................................................................ 11

Driveshaft/Coupling .................................................... 11

Nuts/Cap Screws/Screws/Bolts .................................. 11

Injector Timing ............................................................ 11

Lights .......................................................................... 11

Shift Lever................................................................... 13

Frame/Welds/Racks.................................................... 13

Hydraulic Brake Systems............................................ 13

Burnishing Brake Pads ............................................... 15

Coolant ....................................................................... 15

Checking/Replacing V-Belt ......................................... 16

Fuel Filter.................................................................... 17

Engine/Transmission..................................................... 19

Specifications ............................................................. 19

Removing Engine/Transmission ................................. 20

Top-Side Components ................................................ 24

Left-Side Components................................................ 53

Right-Side Components ............................................. 60

Center Components ................................................... 75

Installing Engine/Transmission ................................... 89

Troubleshooting .......................................................... 95

Fuel/Lubrication/Cooling ............................................... 98

Diesel Fuel Injection System ...................................... 98

Lift Pump .................................................................... 98

Unit Injectors............................................................... 99

Injector Timing ............................................................ 99

Fuel Filter.................................................................... 99

Fuel Solenoid Assembly ............................................. 99

Fuel Tank .................................................................. 100

Fuel/Vent Hoses ....................................................... 101

Oil Filter/Oil Pump..................................................... 101

Testing Oil Pump Pressure ....................................... 101

Liquid Cooling System.............................................. 101

Radiator .................................................................... 102

Hoses/Thermostat .................................................... 103

Fan............................................................................ 103

Water Pump.............................................................. 103

Troubleshooting ........................................................ 103

Electrical System......................................................... 104

Battery.......................................................................104

Testing Electrical Components ..................................105

Switches....................................................................105

Accessory Receptacle/Connector .............................105

Brakelight Switch (Auxiliary) ......................................105

Brakelight Switch (Handlebar Control) ......................106

Cooling Fan Switch ...................................................106

Engine Coolant Temperature (ECT) Switch/

Thermistor ..............................................................107

Glow Plug Controller/Relay .......................................107

Fan Motor..................................................................108

Fuse Block/Power Distribution Module......................108

Electronic Speedometer Speed Sensor ....................109

Ignition Switch ...........................................................110

Handlebar Control Switches......................................110

Drive Select Switch ...................................................111

Front Drive/Differential Lock Actuator........................111

Starter/Starter Solenoid ............................................112

Starter Relay .............................................................113

Alternator/Regulator ..................................................113

Headlights .................................................................114

Taillight - Brakelight ...................................................115

Fuel Solenoid ............................................................115

Troubleshooting.........................................................116

Drive System...............................................................117

Front Drive Actuator ..................................................117

Front Differential ........................................................118

Drive Axles ................................................................131

Rear Gear Case ........................................................134

Hub............................................................................135

Hydraulic Brake Caliper.............................................136

Troubleshooting Drive System...................................140

Troubleshooting Brake System..................................140

Suspension .................................................................141

Shock Absorbers.......................................................141

Front A-Arms.............................................................142

Rear A-Arms .............................................................144

Wheels and Tires ......................................................146

Troubleshooting.........................................................147

Steering/Frame............................................................148

Steering Post/Tie Rods .............................................148

Handlebar Grip..........................................................150

Steering Knuckles .....................................................150

Measuring/Adjusting Toe-In.......................................152

Front Rack.................................................................154

Front Bumper Assembly ............................................154

Front Body Panel/Side Panels...................................154

Footrests ...................................................................157

Belly Panel ................................................................157

Exhaust System ........................................................158

Rear Body Panel/Rack..............................................158

Adjusting Headlight ...................................................159

Taillight Assembly......................................................159

Seat...........................................................................159

Troubleshooting.........................................................160

Controls/Indicators ......................................................161

Hand Brake Lever/Master Cylinder Assembly ...........161

Throttle Control .........................................................162

Shift Lever .................................................................163

Speedometer/Tachometer/LCD.................................163

www.mymowerparts.com

1

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

General Information

General Specifications

FUEL INJECTION

Type Lombardini Unit Injectors

Idle RPM (engine warm) 800-900

Throttle Cable Free-Play (at lever) 1/4 in.

ELECTRICAL

Glow Plug Type Lombardini

Alternator Denso 12V/40 Amp

CHASSIS

Brake Type Hydraulic w/Brake Lever Lock and

Tire Size Front - 25 x 8-12

Tire Inflation Pressure 0.35 kg/cm² (5 psi)

Fuel Tank Capacity 20.81 L (5.5 U.S. gal.)

Coolant Capacity 5.6 L (5.9 U.S. qt)

Front Differential Capacity 275 ml (9.3 fl oz)*

Rear Drive Capacity 250 ml (8.5 fl oz)*

Engine Oil Capacity (with filter) 2.0 L (2.1 U.S. qt)

Engine Oil Capacity (without filter) 1.9 L (2.0 U.S. qt)

Transmission Capacity 600 ml (20.3 fl oz)

Fuel (recommended) Biodiesel Blend up to 20% (B20)/

Engine Oil (recommended) SAE 10W-40

Differential/Rear Drive Lubricant SAE Approved 80W-90 Hypoid

Transmission Lubricant SAE Approved 80W-90 Hypoid

Drive Belt Width (minimum) 31.25 mm (1.23 in.)

Brake Fluid DOT 4

Taillight/Brakelight 12V/8W/27W

Headlight 12V/27W (2)

Auxiliary Brake

Rear - 25 x 10-12

MISCELLANY

42-50 Cetane Diesel - #1 or #2/JP

5 or JP 8 Turbine

Specifications subject to change without notice.

* One inch below plug threads.

Torque Specifications

STEERING COMPONENTS

Part Part Bolted To

Handlebar Cap Steering Post 20 27

Steering Post Bearing Housing Frame 20 27

Steering Post Bearing Flange Frame 20 27

Tie Rod End Knuckle/Steering Post 30 41

EXHAUST COMPONENTS

Exhaust Pipe Exhaust Manifold 14 19

Spark Arrester Muffler 48

ELECTRICAL COMPONENTS

Ground Wire Transmission 8 11

CHASSIS COMPONENTS

Shift Lever*** Shift Axle 8 11

Tor que

ft-lb N-m

5

in.-lb

www.mymowerparts.com

DRIVE TRAIN COMPONENTS

Tor que

Part Part Bolted To

Front Mounting Bracket Engine 20 27

Engine Mount (Upper)** Frame 35 48

Engine Mount (Front/Rear) Frame 20 27

Front Differential*** Frame/Differential Bracket 38 52

Rear Drive Gear Case Frame 38 52

Input Housing Gear Case Housing 23 31

Output Drive Yoke Nut* Output Shaft 72 98

Differential Housing Cover** Differential Housing 23 31

Drive Bevel Gear Retaining

Nut**

Secondary Drive/Bevel Gear

Shaft

Pinion Housing Gear Case 25 34

Ring Gear/Thrust Button* Gear Case 8 11

Gear Case Cover Gear Case 23 31

Lock Collar Differential Housing 125 170

Hub Nut Shaft/Axle (min) 200 272

Drain Plug Front Differential/Rear Drive 42

Fill Plug Front Differential/Rear Drive 16 22

Oil Drain Plug Engine 18 24

Wheel Hub 45 61

BRAKE COMPONENTS

Brake Disc*** Hub 15 19

Brake Hose Caliper 20 27

Brake Hose Master Cylinder 20 27

Brake Hose Auxiliary Brake Cylinder 20 27

Auxiliary Brake Pedal Lever Axle 25 34

Caliper Holder Knuckle 20 27

Auxiliary/Hydraulic Caliper**** Knuckle 20 27

SUSPENSION COMPONENTS (Front)

A-Arm Frame 50 68

Ball Joint Cap Screw Knuckle 35 48

Shock Absorber Frame 50 68

Shock Absorber Upper A-Arm 50 68

SUSPENSION COMPONENTS (Rear)

A-Arm Frame 50 68

Shock Absorber (Upper) Frame 50 68

Shock Absorber (Lower) Lower A-Arm 20 27

Knuckle A-Arm 50 68

Secondary Output Shaft 87 118

Transmission Case 80 108

ft-lb

in.-lb

Nm

5

* w/Red Loctite #271

** w/Green Loctite #609

*** w/Blue Loctite #243

**** “Patch-Lock”

2

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

ENGINE/TRANSMISSION

Part Part Bolted To

Transmission Mounting

Plate

Connecting Rod Cap Connecting Rod (4 Steps) 29 40

Main Bearing Cap Engine Block (6 Steps) 44 60

Rocker Arm Support Cylinder Head 29 40

Cylinder Head Cylinder (5 Steps) 35 48

Valve Cover Cylinder Head 6.5 9

Driven Pulley Nut Fixed Face 125 170

Drive Clutch Flywheel/PTO Shaft 40 54

Movable Drive Face* Fixed Drive Hub 85 116

Oil Pump Engine Block 22 30

Output Shaft* Output Shaft Coupler 20 27

Output Shaft Nut* Output Shaft 80 108

Starter V-Belt Housing 35 48

Flywheel/PTO Shaft Crankshaft 40 54

Crankshaft Pulley Timing Belt Drive Pulley 9 12

Chamber Ring Nut Chamber (Step 1)

Glow Plug Cylinder Head 18 24

Crankshaft Pulley*** Crankshaft 260 354

Timing Belt Idler Nut Engine Block 29 39

V-Belt Cover V-Belt Housing 9 12

V-Belt Housing Crankcase/Transmission 25 34

Fuel Rail Unit Injectors 36

Gear Case (Left) Gear Case (Right) 8 11

Oil Pan Crankcase 7 10

Oil Pan Cover Oil Pan 7 10

Crankshaft Seal/Flange Engine Block 9 12

Camshaft Support Housing Cylinder Head 7 10

Fuel Injector Control Rack Unit Injector 11

Unit Injector Retainer Nut Cylinder Head (5 Steps) 15 20

Camshaft Drive Pulley Camshaft 59 80

Lift Pump Eccentric Camshaft 59 80

Water Pump Engine Block 22 30

Crankcase/Transmission 35 48

(Step 2)7213098177

* w/Red Loctite #271

*** w/Blue Loctite #243

Tor que

ft-lb N-m

4

in.-lb

1.2

in.-lb

Torque Conversions

(ft-lb/N-m)

ft-lb N-m ft-lb N-m ft-lb N-m ft-lb N-m

1 1.4 26 35.4 51 69.4 76 103.4

2 2.7 27 36.7 52 70.7 77 104.7

3 4.1 28 38.1 53 72.1 78 106.1

4 5.4 29 39.4 54 73.4 79 107.4

5 6.8 30 40.8 55 74.8 80 108.8

6 8.2 31 42.2 56 76.2 81 110.2

7 9.5 32 43.5 57 77.5 82 111.5

8 10.9 33 44.9 58 78.9 83 112.9

9 12.2 34 46.2 59 80.2 84 114.2

10 13.6 35 47.6 60 81.6 85 115.6

11 15 36 49 61 83 86 117

12 16.3 37 50.3 62 84.3 87 118.3

13 17.7 38 51.7 63 85.7 88 119.7

14 19 39 53 64 87 89 121

15 20.4 40 54.4 65 88.4 90 122.4

16 21.8 41 55.8 66 89.8 91 123.8

17 23.1 42 57.1 67 91.1 92 125.1

18 24.5 43 58.5 68 92.5 93 126.5

19 25.8 44 59.8 69 93.8 94 127.8

20 27.2 45 61.2 70 95.2 95 129.2

21 28.6 46 62.6 71 96.6 96 130.6

22 29.9 47 63.9 72 97.9 97 131.9

23 31.3 48 65.3 73 99.3 98 133.3

24 32.6 49 66.6 74 100.6 99 134.6

25 34 50 68 75 102 100 136

Break-In Procedure

A new ATV and an overhauled ATV engine require a

“break-in” period. The first 10 hours (or 200 miles) are

most critical to the life of this ATV. Proper operation

during this break-in period will help assure maximum

life and performance from the ATV.

During the first 10 hours (or 200 miles) of operation,

always use less than 1/2 throttle. Varying the engine

RPM during the break-in period allows the components to “load” (aiding the mating process) and then

“unload” (allowing components to cool). Although it

is essential to place some stress on the engine components during break-in, care should be taken not to

overload the engine too often. Do not pull a trailer or

carry heavy loads during the 10-hour break-in period.

When the engine starts, allow it to warm up properly.

Idle the engine several minutes until the engine has

reached normal operating temperature.

During the break-in period, a maximum of 1/2 throttle

is recommended; however, brief full-throttle accelerations and variations in driving speeds contribute to

good engine break-in.

www.mymowerparts.com

3

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

After the completion of the break-in period, the engine

oil and oil filter should be changed. Other maintenance

after break-in should include checking of all prescribed adjustments and tightening of all fasteners.

Fuel - Oil - Lubricant

NOTE: Arctic Cat recommends the use of genuine Arctic Cat lubricants.

RECOMMENDED FUEL

The recommended fuel to use is biodiesel blend up to

20% (B20), #1 or #2 diesel fuel (42-50 cetane), or JP 5

or JP 8 turbine fuel. At temperatures above -10° C (14°

F), use #2 diesel fuel or a biodiesel blend up to 20%.

At temperatures at or below -10° C (14° F), use #1 diesel fuel. Diesel fuel with a minimum cetane number

below 42 should not be used.

CAUTION

Never use biodiesel blends at temperatures at or

below -10° C (14° F).

RECOMMENDED ENGINE OIL

CAUTION

Any lubricant used in place of the recommended

lubricant could cause serious transmission damage.

RECOMMENDED FRONT DIFFERENTIAL/REAR DRIVE LUBRICANT

The recommended lubricant is Arctic Cat Gear Lube

or an equivalent gear lube which is SAE approved

80W-90 hypoid. This lubricant meets all of the lubrication requirements of the Arctic Cat ATV front differentials and rear drives.

CAUTION

Any lubricant used in place of the recommended

lubricant could cause serious front differential/rear

drive damage.

FILLING FUEL TANK

! WARNING

Always fill the fuel tank in a well-ventilated area.

Never add fuel to the ATV fuel tank near any open

flames or with the engine running. DO NOT SMOKE

while filling the fuel tank.

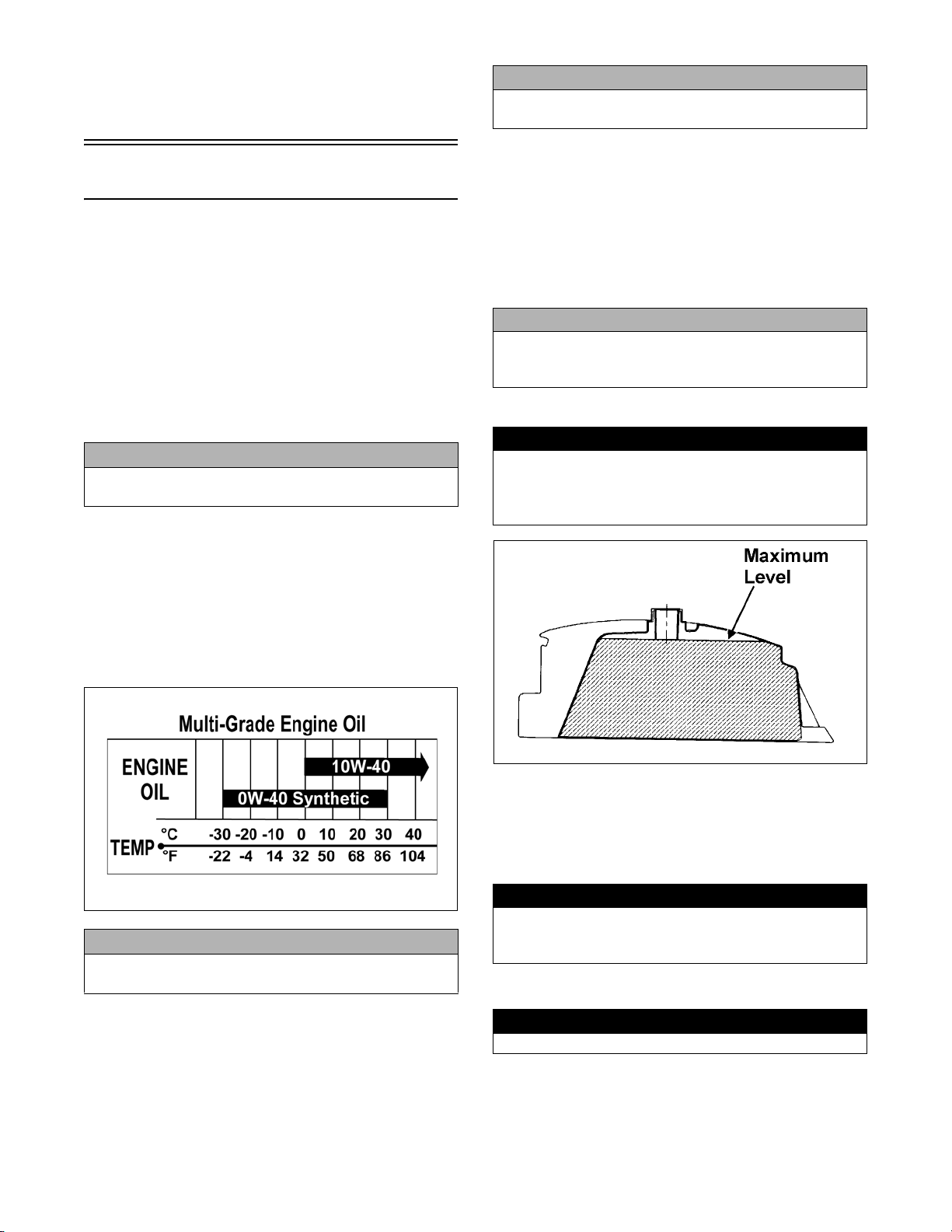

The recommended oil to use is an oil which is rated SJ/

CF under API service classification. These oils meet

all of the lubrication requirements of the Arctic Cat

engine. The recommended engine oil viscosity is SAE

10W-40. Ambient temperature should determine the

correct weight of oil. See the viscosity chart or an

authorized Arctic Cat ATV dealer for details.

OILCHARTE

CAUTION

Any oil used in place of the recommended oil could

cause serious engine damage.

ATV0049B

Since fuel expands as its temperature rises, the fuel

tank must be filled to its rated capacity only. Expansion room must be maintained in the tank particularly

if the tank is filled with cold fuel and then moved to a

warm area.

! WARNING

Do not overflow fuel when filling the fuel tank. A fire

hazard could materialize. Always allow the engine to

cool before filling the fuel tank.

Tighten the fuel tank cap securely after filling the tank.

RECOMMENDED TRANSMISSION LUBRICANT

The recommended transmission lubricant is SAE

approved 80W-90 hypoid. This lubricant meets all of

the lubrication requirements of the ATV transmission.

www.mymowerparts.com

4

! WARNING

Do not over-fill the fuel tank.

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

Genuine Parts

When replacement of parts is necessary, use only genuine Arctic Cat ATV parts. They are precision-made to

ensure high quality and correct fit. Refer to the appropriate Illustrated Parts Manual for the correct part

number, quantity, and description.

8. Disconnect the battery cables; then remove the

battery, clean the battery posts and cables, and

store in a clean, dry area.

9. Store the ATV indoors in a level position.

CAUTION

Avoid storing outside in direct sunlight and avoid

using a plastic cover as moisture will collect on the

ATV causing rusting.

Preparation For Storage

CAUTION

Prior to storing the ATV, it must be properly serviced

to prevent rusting and component deterioration.

Arctic Cat recommends the following procedure to

prepare the ATV for storage.

1. Clean the seat cushion (cover and base) with a

damp cloth and allow it to dry.

2. Clean the ATV thoroughly by washing dirt, oil,

grass, and other foreign matter from the entire

ATV. Allow the ATV to dry thoroughly. DO NOT

get water into any part of the engine or air intake.

3. Fill the fuel tank with fresh #1 or #2 diesel fuel

(according to ambient temperatures); then add a

quality anti-microbial additive. Run the engine in

a well-ventilated area for several minutes to make

sure fresh, treated fuel is circulated throughout the

entire injection system.

CAUTION

DO NOT store the ATV with biodiesel (B20) in the fuel

system. Severe damage to the fuel system may

occur.

4. Plug the exhaust hole in the muffler with a clean

cloth.

5. Apply light oil to the upper steering post bushing

and plungers of the shock absorbers.

6. Tighten all nuts, bolts, cap screws, and screws.

Make sure rivets holding components together are

tight. Replace all loose rivets. Care must be taken

that all calibrated nuts, cap screws, and bolts are

tightened to specifications.

Preparation After

Storage

Taking the ATV out of storage and correctly preparing

it will assure many miles and hours of trouble-free riding. Arctic Cat recommends the following procedure

to prepare the ATV.

1. Clean the ATV thoroughly.

2. Clean the engine. Remove the cloth from the muffler.

3. Check all control wires and cables for signs of

wear or fraying. Replace if necessary.

4. Change the engine oil and filter.

5. Check the coolant level and add properly mixed

coolant as necessary.

6. Charge the battery; then install. Connect the battery cables.

CAUTION

The ignition switch must be in the OFF position prior

to installing the battery or damage may occur to the

electrical system.

CAUTION

Connect the positive battery cable first; then the negative.

7. Check the entire brake systems (fluid level, pads,

etc.), all controls, headlights, taillight, brakelight,

and headlight aim; adjust or replace as necessary.

8. Tighten all nuts, bolts, cap screws, and screws

making sure all calibrated nuts, cap screws, and

bolts are tightened to specifications.

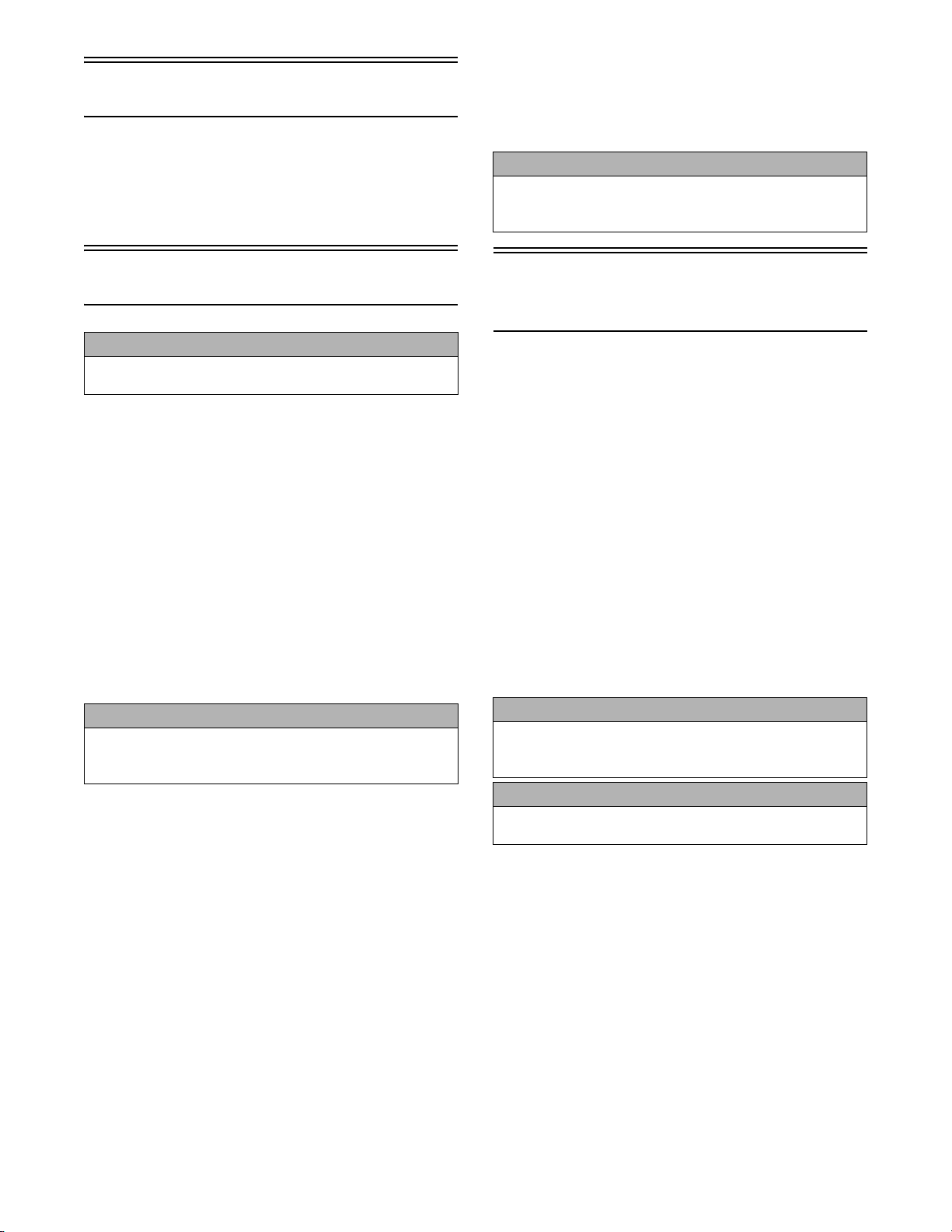

7. Fill the cooling system to the bottom of the stand

pipe in the filler neck with properly mixed coolant.

www.mymowerparts.com

9. Check tire pressure. Inflate to recommended pressure as necessary.

10. Make sure the steering moves freely and does not

bind.

5

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

Periodic Maintenance/

Tune-Up

NOTE: Some photographs and illustrations used

in this section are used for clarity purposes only

and are not designed to depict actual conditions.

Periodic Maintenance

Chart

A = Adjust L = Lubricate

C = Clean R = Replace

I = Inspect

Initial Service

Item

Battery I I C

Fuses/Relays/PDM I I R

Air Filter I R R

Valve Clearance IA

Muffler/Spark Arrester CR

Fuel/Vent Hoses I R

Fuel Injectors IA

Throttle Cable I C-L A-R

Engine Oil Level I

Engine Oil/Filter Replace after initial 300 miles. R R

Front Differential/Rear Drive Lubricant I R (4 Yrs)

Transmission Lubricant I I R (4 Yrs)

Tires/Air Pressure I R

Steering Components I I R

V-B elt I l R

Suspension (Ball joint boots, drive axle

boots front and rear, tie rods,

differential and rear drive bellows)

Nuts/Cap Screws/Screws/Bolts I I A

Injector Timing IA

Headlight/Taillight-Brakelight I R

Switches I R

Shift Lever IA-L

Handlebar Grips R

Handlebars I R

Gauges/Indicators I R

Frame/Welds/Racks I I l

Electrical Connections lC

Complete Brake System

(Hydraulic & Auxiliary)

Brake Pads I R

Brake Fluid I R

Brake Hoses I I R (4 Yrs)

Coolant/Cooling System I Replace coolant every 2 years.

Timing Belt R

Alternator Belt I I

After Break-In

(First Month or

100 Miles)

Il* R

IC L-R

Every

Month or

Every 100

Miles

Every 3

Months or

Every 300

Miles

Every 6

Months or

Every 500

Miles

Every Year

or Every

1250

Miles

Every 2

Years or

Every 5000

Miles

As

Needed

* Service/Inspect more frequently when operating in adverse conditions.

www.mymowerparts.com

6

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

Lubrication Points

It is advisable to lubricate certain components periodically to ensure free movement. Apply light oil to the

components using the following list as reference.

A. Throttle Lever Pivot/Cable Ends

B. Brake Lever Pivot/Cable Ends

C. Auxiliary Brake Cable Ends

D. Shift Lever Cable End

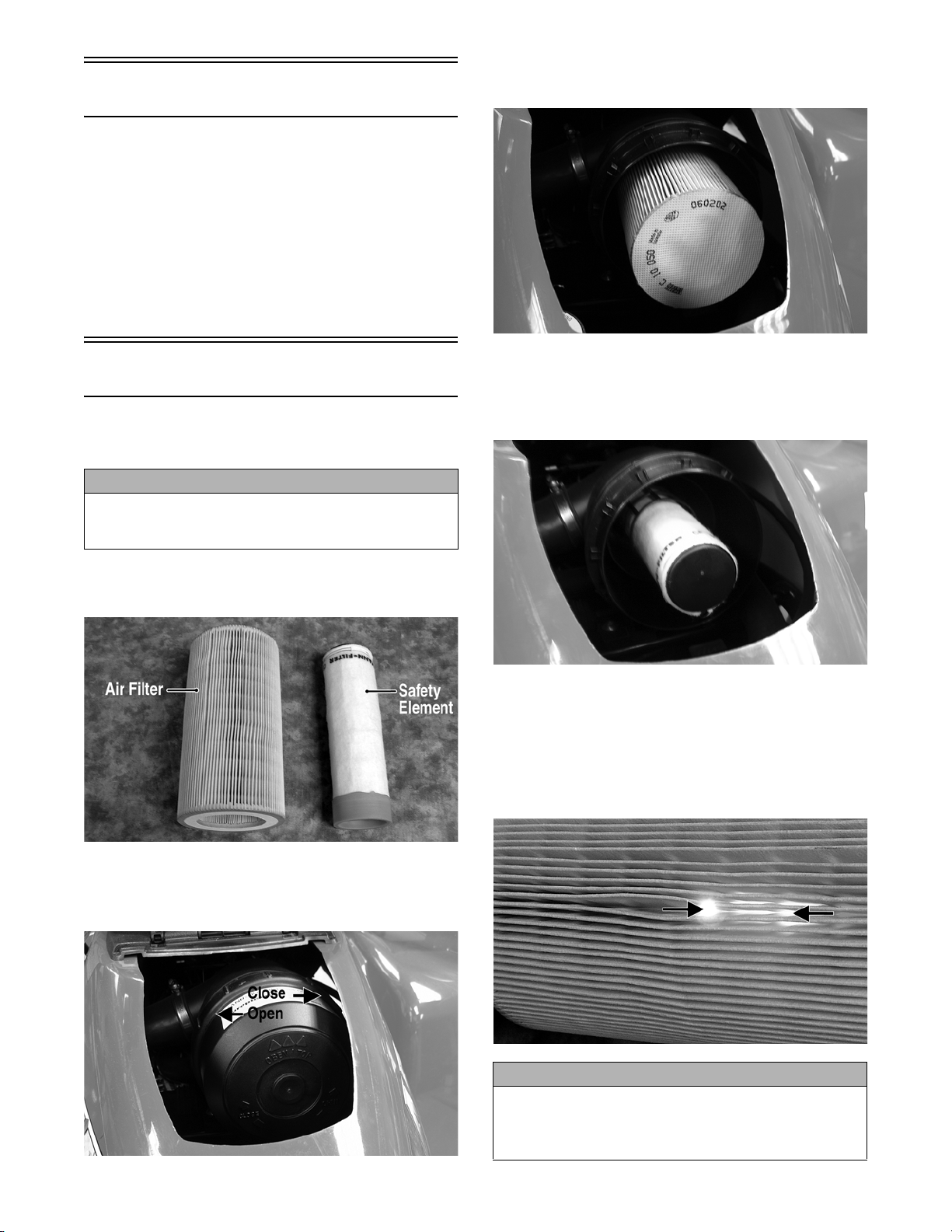

Air Filter

CLEANING AND INSPECTING FILTER

2. Remove the dry-paper air filter. Do not remove the

cotton-fabric safety element at this time.

DE007

3. Clean dust and debris from the air filter housing;

then remove the cotton-fabric safety element using

care not to allow dirt and debris to enter the

engine.

CAUTION

Failure to inspect the air filter frequently if the vehicle is used in dusty, wet, or muddy conditions can

damage the engine.

NOTE: This ATV is equipped with a dry-paper air

filter and a cotton-fabric safety element.

DE014A

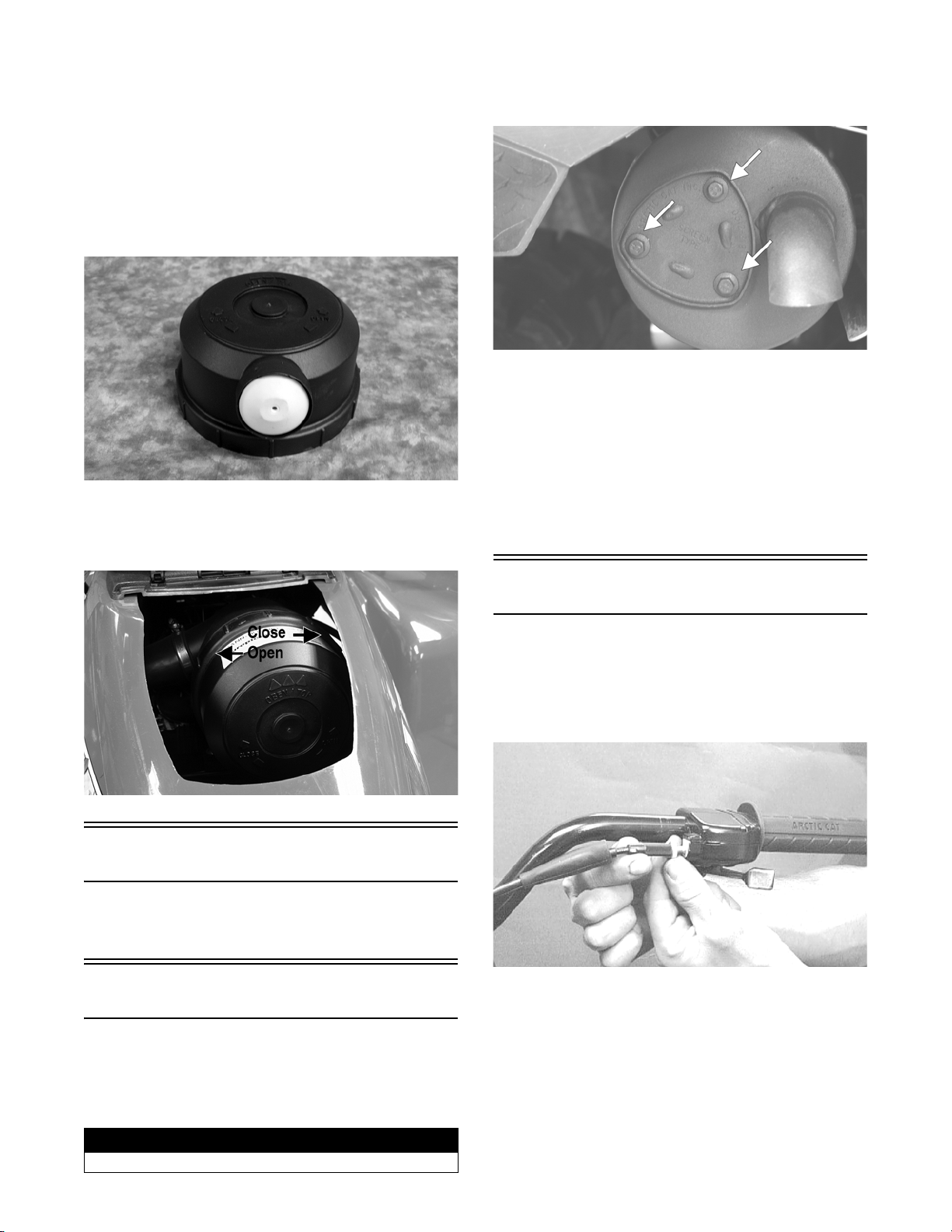

1. Open the air filter access cover and remove the operator’s seat; then rotate the air filter housing cover counterclockwise and remove from the filter housing.

DE008

4. Lightly tap the dry-paper air filter to dislodge the

dirt and dust. Do not use compressed air.

5. Insert a suitable light into the dry-paper air filter and

look for any “pin-points” of light shining out of the

filter medium. A bright “pin-point” of light indicates

a hole and the filter element must be replaced.

A torn air filter can cause damage to the engine. Dirt and

dust may enter the engine if the element is torn. Carefully

examine the element for tears before and after cleaning

www.mymowerparts.com

DE006A

it. Replace the element with a new one if it is torn.

DE028A

CAUTION

7

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

6. Check the safety element for signs of dirt build-up.

If dirt is present on the element, it indicates a leak

or hole in the dry-paper air filter element and both

elements must be replaced.

7. Install the safety element; then install the drypaper air filter.

8. Check the drain valve in the air filter housing

cover for dirt, deterioration, or poor sealing. Clean

or replace as required.

DE015

9. Install the air filter housing cover (drain facing

downward) and lock it in place by turning clockwise.

1. Remove the three cap screws securing the spark

arrester assembly to the muffler; then loosen and

remove the arrester.

CF105A

2. Using a suitable brush, clean the carbon deposits

from the screen taking care not to damage the

screen.

NOTE: If the screen or gasket is damaged in any

way, it must be replaced.

3. Install the spark arrester assembly with gasket;

then secure with three cap screws. Tighten to 48

in.-lb.

DE006A

Valve Clearance

To check/adjust valve clearance, see Top-Side Components in Engine/Transmission.

Muffler/Spark Arrester

Adjusting Throttle Cable

To adjust the throttle cable free-play, follow this procedure.

1. Slide the rubber boot away; then loosen the jam

nut from the throttle cable adjuster.

AL611D

2. Turn the adjuster until the throttle cable has proper

free-play of 1/4 in. at the lever.

The muffler has a spark arrester which must be periodically cleaned. At the intervals shown in the Periodic

Maintenance Chart, clean the spark arrester using the

following procedure.

! WARNING

Wait until the muffler cools to avoid burns.

8

www.mymowerparts.com

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

ATV-0047C

3. Tighten the jam nut against the throttle cable

adjuster securely; then slide the rubber boot over

the adjuster.

Engine RPM (Idle)

NOTE: The idle RPM is not adjustable on the 700

Diesel.

Engine Oil - Filter

Change the engine oil and oil filter at the scheduled

intervals. The engine should always be warm when the

oil is changed so the oil will drain easily and completely.

1. Park the ATV on level ground.

2. Remove the engine oil filler cap.

DE017A

4. Remove the right-side engine cover.

5. Using a suitable filter wrench, remove the oil filter.

NOTE: Clean up any excess oil after removing

the filter.

6. Apply oil to a new filter O-ring and check to make

sure it is positioned correctly; then install the new

oil filter. Tighten until contact is made; then

tighten an additional 3/4 turn.

DE025A

3. Remove the drain plug from the bottom of the

engine and drain the oil into a drain pan.

www.mymowerparts.com

DE018

NOTE: Install a new O-ring each time the filter is

replaced.

7. Install the engine drain plug and tighten to 18 ft-lb.

Pour the specified amount of the recommended oil

in the filler hole. Install the oil filler cap.

CAUTION

Any oil used in place of the recommended oil could

cause serious engine damage. Do not use racing,

vegetable, non-detergent, and castor-based oils.

8. Start the engine (while the ATV is outside on level

ground) and allow it to idle for a few minutes.

9. Turn the engine off and wait approximately three

minutes.

10. Remove the oil level stick and wipe it with a clean

cloth.

9

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

DE519D

11. Install the oil level stick and push in firmly.

12. Remove the oil level stick; the engine oil level

should be above the illustrated “L” mark but not

higher than the illustrated “F” mark.

CAUTION

Do not over-fill the engine with oil. Always make

sure that the oil level is above the

higher than the

“F” mark.

13. Inspect the area around the drain plug and oil filter

for leaks.

“L” mark but not

DE024A

DE026A

3. Remove the transmission drain plug from the bottom of the transmission and drain the lubricant

into a drain pan.

DE016A

4. Install the drain plug and tighten securely. Pour

recommended lubricant into the filler hole. Install

the filler plug.

5. Remove the transmission lubricant level stick and

wipe it with a clean cloth; then check the lubricant

level with the level stick.

14. Install the right-side engine cover.

Transmission Lubricant

Check and change the transmission lubricant according to the Maintenance Schedule. When adding or

changing the lubricant, use approved SAE 80W-90

hypoid and use the following procedure.

1. Place the ATV on level ground.

2. Remove the transmission fill plug. Make sure not

to allow contaminants to enter the opening.

www.mymowerparts.com

10

DE002A

Front Differential/Rear

Drive Lubricant

Check and change the lubricant according to the Periodic

Maintenance Chart. When adding or changing the lubricant, use approved SAE 80W-90 hypoid gear lube.

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

To check lubricant, remove each filler plug; the lubricant level should be 1 in. below the threads of the plug.

If low, add SAE approved 80W-90 hypoid gear lube as

necessary.

To change the lubricant, use the following procedure.

1. Place the ATV on level ground.

2. Remove each filler plug.

3. Drain the lubricant into a drain pan by removing in

turn the drain plug from each.

CF107B

! WARNING

Always use the size and type of tires specified.

Always maintain proper tire inflation pressure.

TIRE INFLATION PRESSURE

Front and rear tire inflation pressure should be 0.35

kg-cm² (5.0 psi).

Driveshaft/Coupling

The following drive system components should be

inspected periodically to ensure proper operation.

A. Spline lateral movement (slop).

B. Coupling cracked, damaged, or worn.

Nuts/Cap Screws/

Screws/Bolts

CF106C

4. After all the lubricant has been drained, install the

drain plugs and tighten to 42 in.-lb.

5. Pour the appropriate amount of recommended

lubricant into each filler hole.

6. Install the fill plugs. Tighten to 16 ft-lb.

NOTE: If the differential/rear drive lubricant is

contaminated with water, inspect the drain plug

and filler plug.

Tighten all nuts, cap screws, screws, and bolts. Make

sure rivets holding components together are tight.

Replace all loose rivets. Care must be taken that all

calibrated nuts, cap screws, screws, and bolts are tightened to specifications.

Injector Timing

To check/adjust injector timing, see Top-Side Components in Engine/Transmission.

Lights

Each time the ATV is used, lights should be checked

for proper function. Rotate the ignition switch to the

lights position; the headlights and taillight should illuminate. Test the brakelight by compressing the brake

lever. The brakelight should illuminate.

HEADLIGHT

Tires

TIRE SIZES

The ATV is equipped with low-pressure tubeless tires of

the size and type listed in General Specifications. Do not

under any circumstances substitute tires of a different

type or size.

www.mymowerparts.com

NOTE: The bulb portion of the headlight is fragile. HANDLE WITH CARE. When replacing the

headlight bulb, do not touch the glass portion of

the bulb. If the glass is touched, it must be cleaned

with a dry cloth before installing. Skin oil residue

on the bulb will shorten the life of the bulb.

11

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

! WARNING

Do not attempt to remove the bulb when it is hot.

Severe burns may result.

To replace the headlight bulb, use the following procedure.

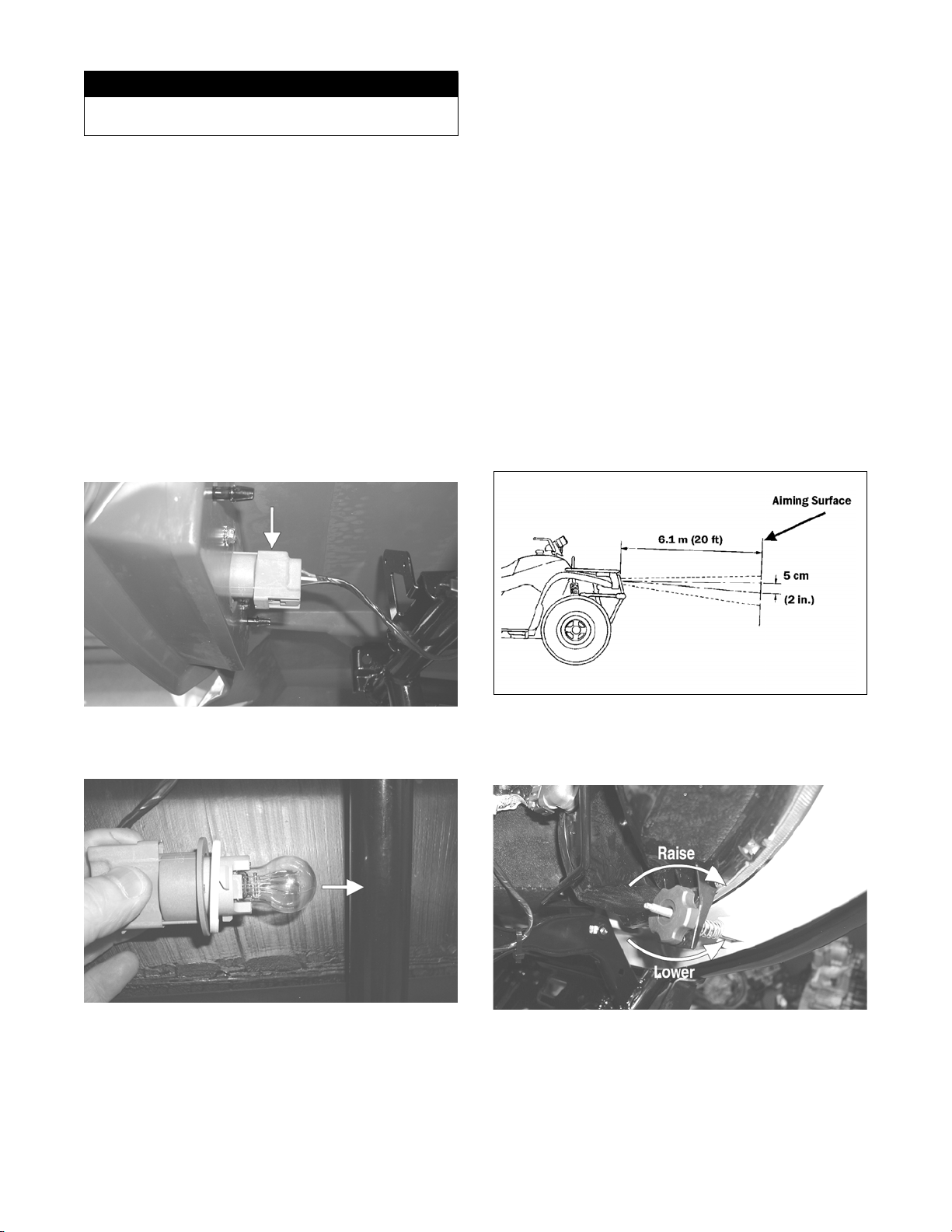

1. Position the ATV on a level floor so the headlights

are approximately 6.1 m (20 ft) from an aiming

surface (wall or similar aiming surface).

NOTE: There should be an average operating

load on the ATV when adjusting the headlight aim.

1. Remove the wiring harness connector from the

back of the headlight.

2. Grasp the bulb housing, turn it counterclockwise,

and remove the bulb.

3. Install the new bulb into the housing and rotate it

completely clockwise.

4. Install the wiring harness connector.

TAILLIGHT-BRAKELIGHT

To replace the taillight-brakelight bulb, use the following procedure.

1. Turn the bulb socket counterclockwise and remove

from the housing.

2. Measure the distance from the floor to the midpoint of each headlight.

3. Using the measurements obtained in step 2, make

horizontal marks on the aiming surface.

4. Make vertical marks which intersect the horizontal

marks on the aiming surface directly in front of the

headlights.

5. Switch on the lights. Make sure the HIGH beam is

on. DO NOT USE LOW BEAM.

6. Observe each headlight beam aim. Proper aim is

when the most intense beam is centered on the vertical mark 5 cm (2 in.) below the horizontal mark

on the aiming surface.

CF135A

2. Pull the bulb straight out of the socket; then insert

a new bulb.

CF132A

3. Insert the socket into the housing and turn it clockwise to secure.

CHECKING/ADJUSTING HEADLIGHT AIM

The headlights can be adjusted vertically and horizontally. The geometric center of the HIGH beam light

zone is to be used for vertical and horizontal aiming.

www.mymowerparts.com

ATV-0070C

7. Adjust each headlight by turning the adjuster knob

clockwise to raise the beam or counterclockwise to

lower the beam.

CD714A

12

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

Shift Lever

CHECKING ADJUSTMENT

NOTE: An E (Error) in the gear position icon indicates no signal or a poor ground wire connection

in the circuit. Troubleshoot the harness connectors, gear shift position connector, gear shift position switch, and LCD connector.

4. Install the seat and left-side engine cover.

Frame/Welds/Racks

The frame, welds, and racks should be checked periodically for damage, bends, cracks, deterioration, broken

components, and missing components. If replacement

or repair constitutes removal, see Steering/Frame.

CF130B

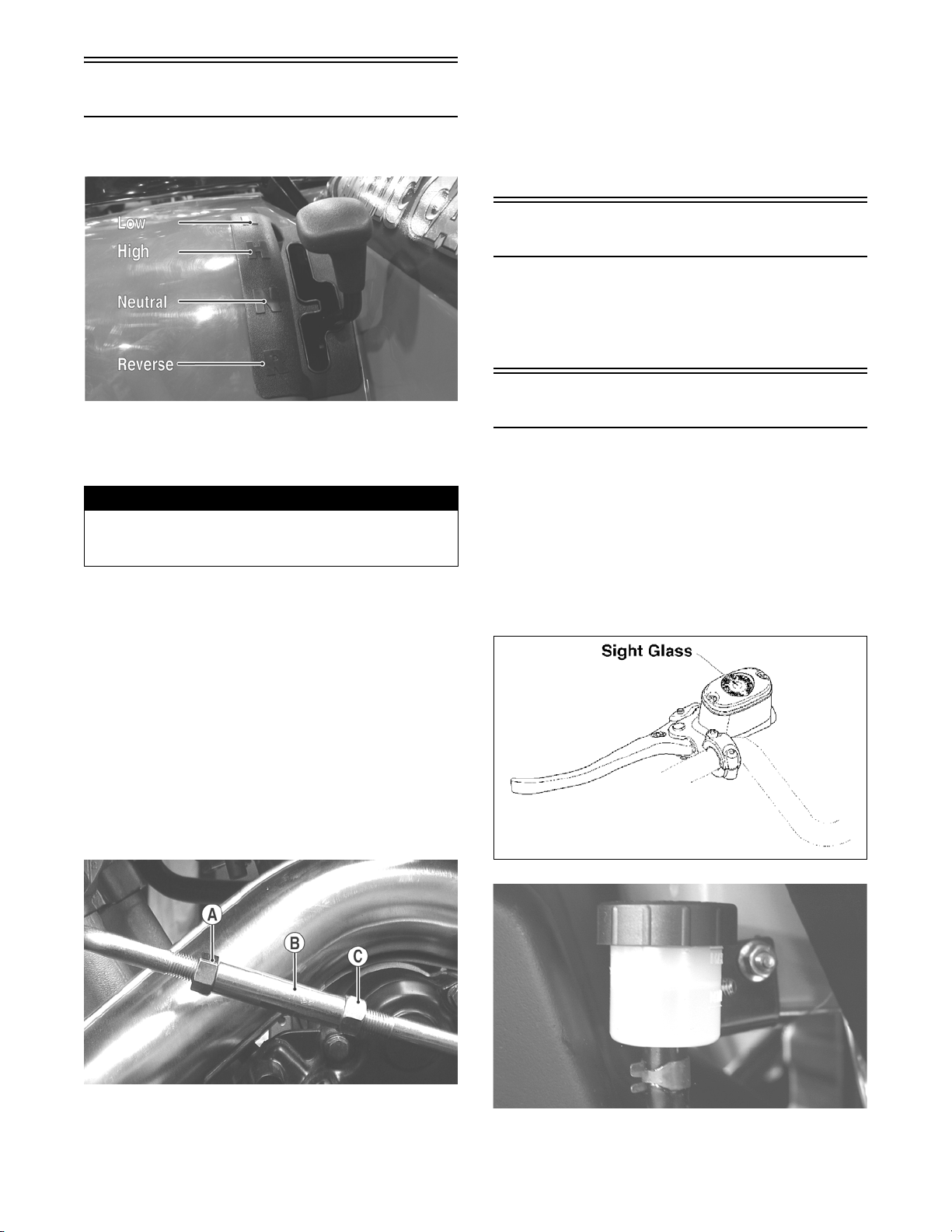

Stop the ATV completely and shift the transmission

into the R position. The reverse gear indicator light

should be illuminated.

! WARNING

Never shift the ATV into reverse gear when the ATV is

moving as it could cause the ATV to stop suddenly

throwing the operator from the ATV.

If the reverse light does not illuminate when shifted to

the reverse position, the switch may be faulty, the fuse

may be blown, the bulb may be faulty, a connection

may be loose or corroded, or the lever may need

adjusting. To adjust, proceed to Adjusting Shift Lever.

ADJUSTING SHIFT LEVER

1. Place the shift lever in the R position; then remove

the seat and left-side engine cover.

2. With the ignition switch in the ON position, loosen

jam nut (A) (left-hand threads); then loosen jam

nut (C) and with the shift lever in the reverse position, adjust the coupler (B) until the transmission

is in reverse and the (R) icon appears on the LCD.

Hydraulic Brake Systems

CHECKING/BLEEDING

The hydraulic brake systems have been filled and bled

at the factory. To check and/or bleed a hydraulic brake

system, use the following procedure.

1. With the master cylinder in a level position, check

the fluid level in the reservoir. If the level in the

reservoir is not visible in the sight glass, add DOT

4 brake fluid.

CF258A

3. Tighten the jam nuts securely; then shift the transmission to each position and verify correct adjustment.

www.mymowerparts.com

738-420A

AL681

13

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

2. Compress the brake lever/pedal several times to

check for a firm brake. If the brake is not firm, the

system must be bled.

3. To bleed the brake system, use the following procedure.

A. Remove the cover and fill the reservoir with

DOT 4 Brake Fluid.

B. Install and secure the cover; then slowly com-

press the brake lever several times.

C. Remove the protective cap, install one end of a

clear hose onto one FRONT bleeder screw, and

direct the other end into a container; then while

holding slight pressure on the brake lever, open

the bleeder screw and watch for air bubbles.

Close the bleeder screw before releasing the

brake lever. Repeat this procedure until no air

bubbles are present.

E. At this point, perform step B, C, and D on the

other FRONT bleeder screw; then move to the

REAR bleeder screw and follow the same procedure.

4. Carefully check the entire hydraulic brake system

that all hose connections are tight, the bleed

screws are tight, the protective caps are installed,

and no leakage is present.

CAUTION

This hydraulic brake system is designed to use DOT

4 brake fluid only. If brake fluid must be added, care

must be taken as brake fluid is very corrosive to

painted surfaces.

INSPECTING HOSES

Carefully inspect the hydraulic brake hoses for cracks

or other damage. If found, the brake hoses must be

replaced.

CHECKING/REPLACING PADS

The clearance between the brake pads and brake discs

is adjusted automatically as the brake pads wear. The

only maintenance that is required is replacement of the

brake pads when they show excessive wear. Check the

thickness of each of the brake pads as follows.

1. Remove a front wheel.

AF637D

PR377A

NOTE: During the bleeding procedure, watch the

reservoir sight glass very closely to make sure

there is always a sufficient amount of brake fluid.

When the sight glass changes from dark to light,

refill the reservoir before the bleeding procedure is

continued. Failure to maintain a sufficient amount

of fluid in the reservoir will result in air in the system.

2. Measure the thickness of each brake pad.

3. If thickness of either brake pad is less than 1.0 mm

(0.039 in.), the brake pads must be replaced.

PR376B

NOTE: The brake pads should be replaced as a set.

4. To replace the brake pads, use the following procedure.

A. Remove the wheel.

B. Remove the cap screws securing the caliper

holder to the knuckle; then remove the pads.

D. Repeat step C until the brake lever is firm.

14

www.mymowerparts.com

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

PR237

C. Install the new brake pads.

D. Secure the caliper holder to the knuckle and/or

axle housing with the cap screws. Tighten to 20

ft-lb.

5. Verify that the brakelight illuminates when the

hand lever is compressed or the brake pedal is

depressed.

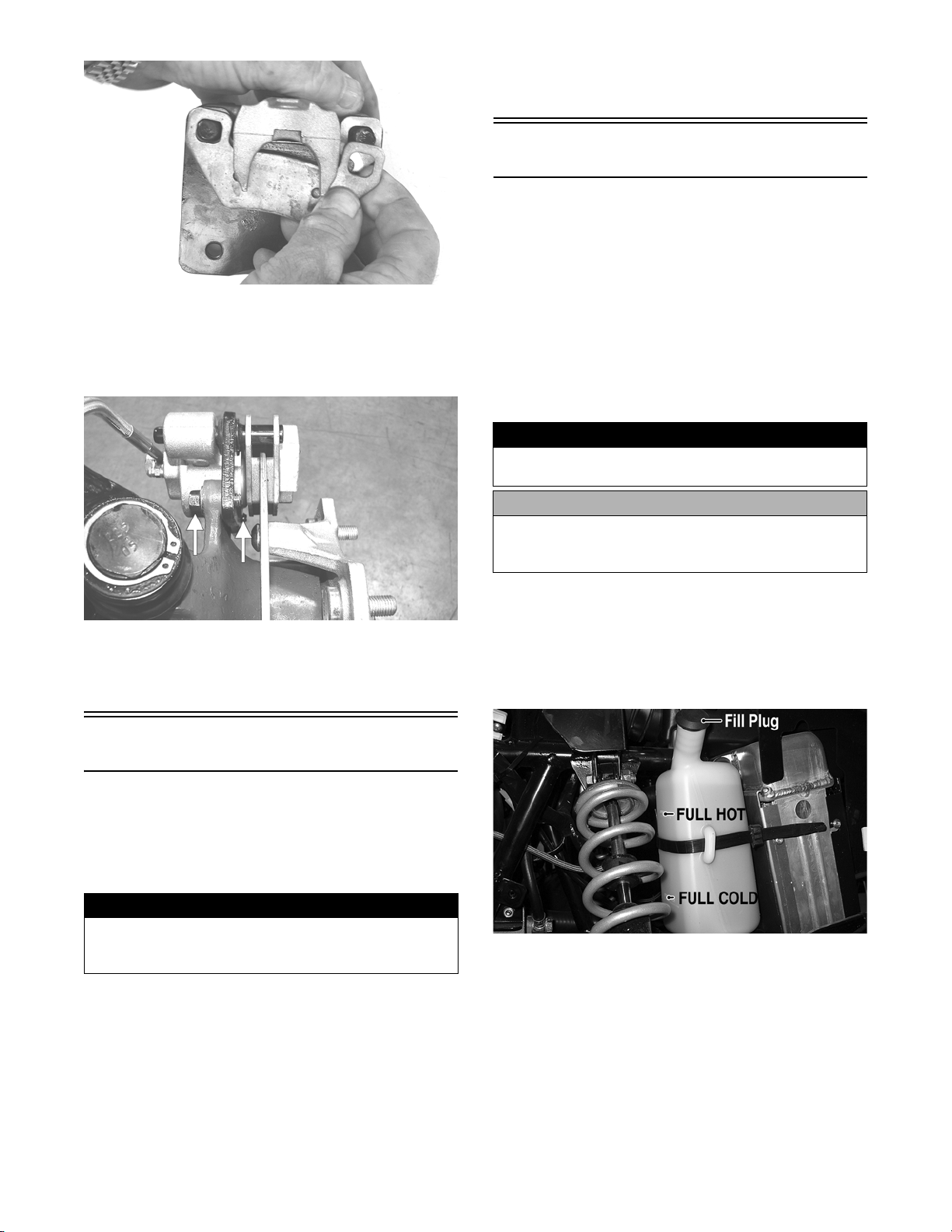

Coolant

When filling the cooling system, use a coolant/water

mixture which will satisfy the coldest anticipated

weather conditions of the area in accordance with the

coolant manufacturer’s recommendations. While the

cooling system is being filled, air may become trapped;

therefore, elevate the rear of the ATV 30-40 cm (12-16

in.) to allow air to bleed from the filler neck. Run the

engine for several minutes; then shut off the engine and

fill with coolant to the top of the filler neck.

NOTE: Use a good quality, biodegradable glycolbased, automotive-type antifreeze.

! WARNING

Never check the coolant level when the engine is hot

or the cooling system is under pressure.

PR377B

E. Install the wheel. Tighten to 45 ft-lb.

5. Burnish the brake pads (see Burnishing Brake

Pads).

Burnishing Brake Pads

Brake pads (both hydraulic and auxiliary) must be burnished to achieve full braking effectiveness. Braking

distance will be extended until brake pads are properly

burnished. To properly burnish the brake pads, use the

following procedure.

! WARNING

Failure to properly burnish the brake pads could lead

to premature brake pad wear or brake loss. Brake

loss can result in severe injury.

1. Choose an area large enough to safely accelerate

the ATV to 30 mph and to brake to a stop.

2. Accelerate to 30 mph; then compress brake lever or

apply the auxiliary brake to decelerate to 0-5 mph.

3. Repeat procedure on each brake system 20 times

until brake pads are burnished.

4. Adjust the auxiliary brake (if necessary).

CAUTION

After operating the ATV for the initial 5-10 minutes,

stop the engine, allow the engine to cool down, and

check the coolant level. Add coolant as necessary.

To check/add coolant, use the following procedure.

1. Check the level of coolant in the coolant expansion tank located under the right front fender. The

coolant level should be between the Full Cold and

Full Hot lines.

DE019A

2. Remove the rubber plug from the neck of the coolant expansion tank and add coolant as necessary;

then install the plug.

3. Remove the filler cap located under the service

access cover and add coolant as necessary to bring

coolant level to the top of the filler neck. Install

and tighten the filler cap.

www.mymowerparts.com

15

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

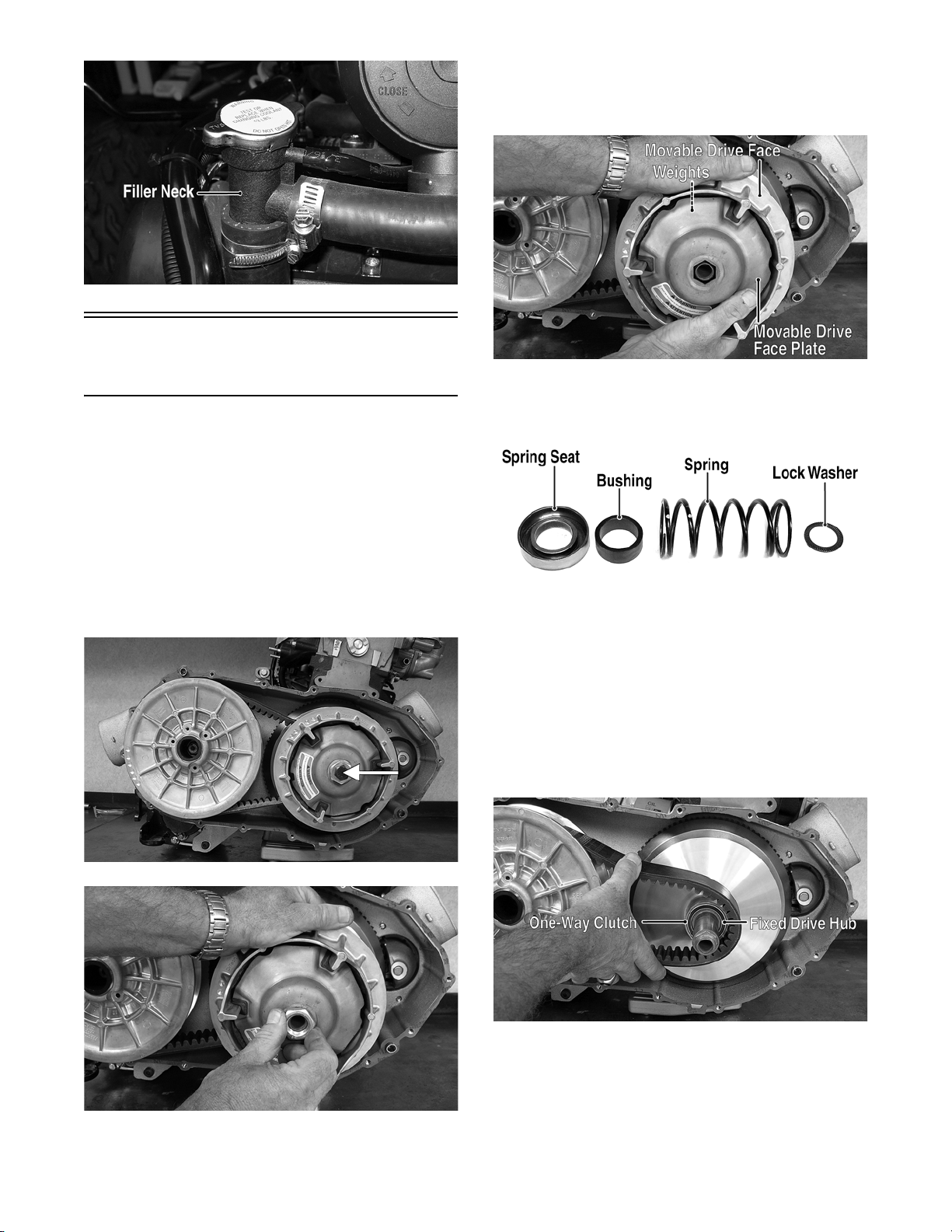

4. Remove the movable drive face using care to keep

the face plate tight against the drive face to prevent

the weights from falling out. Account for a spring

seat, spring, bushing, and lock washer.

DE073A

Checking/Replacing

V-Belt

REMOVING

1. Remove the right-side footrest (see Steering/

Frame).

2. Remove the cap screws securing the V-belt cover;

then using a rubber mallet, gently tap on the cover

tabs to loosen the cover. Remove the cover.

3. Remove the cap screw securing the drive clutch to

the flywheel stub axle; then remove the nut and

lock washer securing the movable drive face to the

fixed drive hub.

DE096A

DE094A

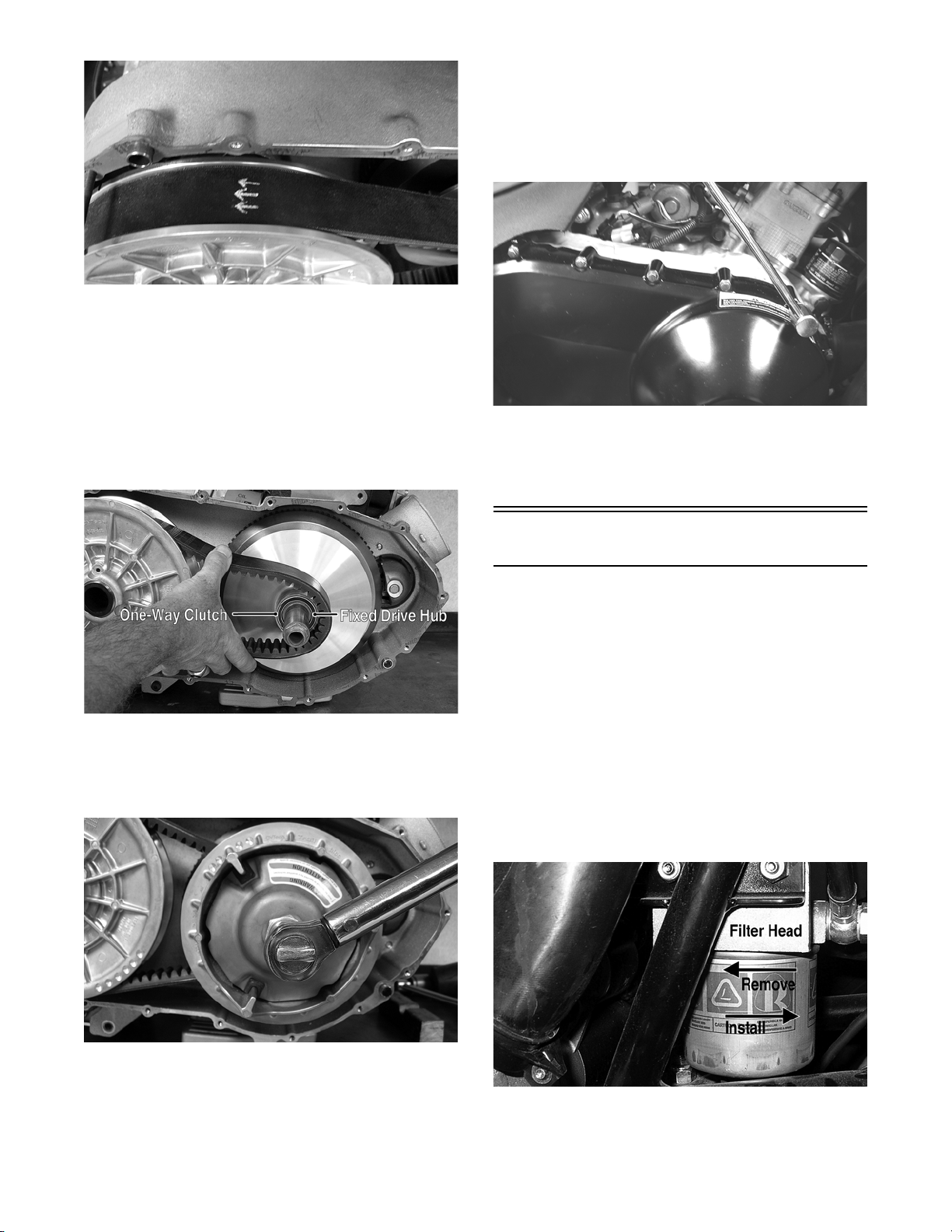

5. Thread one of the V-belt cover screws into the

fixed driven face and turn clockwise to open the

driven pulley faces.

6. Push the V-belt down between the sheaves of the

driven pulley approximately one inch; then making sure not to dislocate the one-way clutch from

the fixed drive hub, squeeze the belt together and

remove from the drive clutch.

16

DE093A

INSTALLING

1. Place the V-belt into position over the driven pul-

DE095

ley noting the directional arrows on the V-belt.

www.mymowerparts.com

DE098A

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

DE488

NOTE: The diesel engine in this ATV rotates

counterclockwise as viewed from the right side;

therefore, if directional arrows are printed on the Vbelt, they must be directed rearward.

5. Install the cap screw securing the drive clutch

assembly to the flywheel/PTO shaft and tighten to

40 ft-lb.

6. Place the V-belt cover gasket into position; then

install the cover and secure with the cap screws.

Tighten to 9 ft-lb.

2. Push the V-belt down into the driven pulley

approximately one inch; then squeeze the belt

together and slide over the fixed drive hub and

onto the one-way clutch.

DE098A

3. Pinch the V-belt together near its center and slide

the movable drive face onto the drive hub. Secure

the drive face with a nut (threads coated with red

Loctite #271). Tighten the nut to 85 ft-lb.

CD083

7. Secure the front fender to the footrest with the two

cap screws. Tighten securely.

8. Install the right-side footrest (see Steering/Frame).

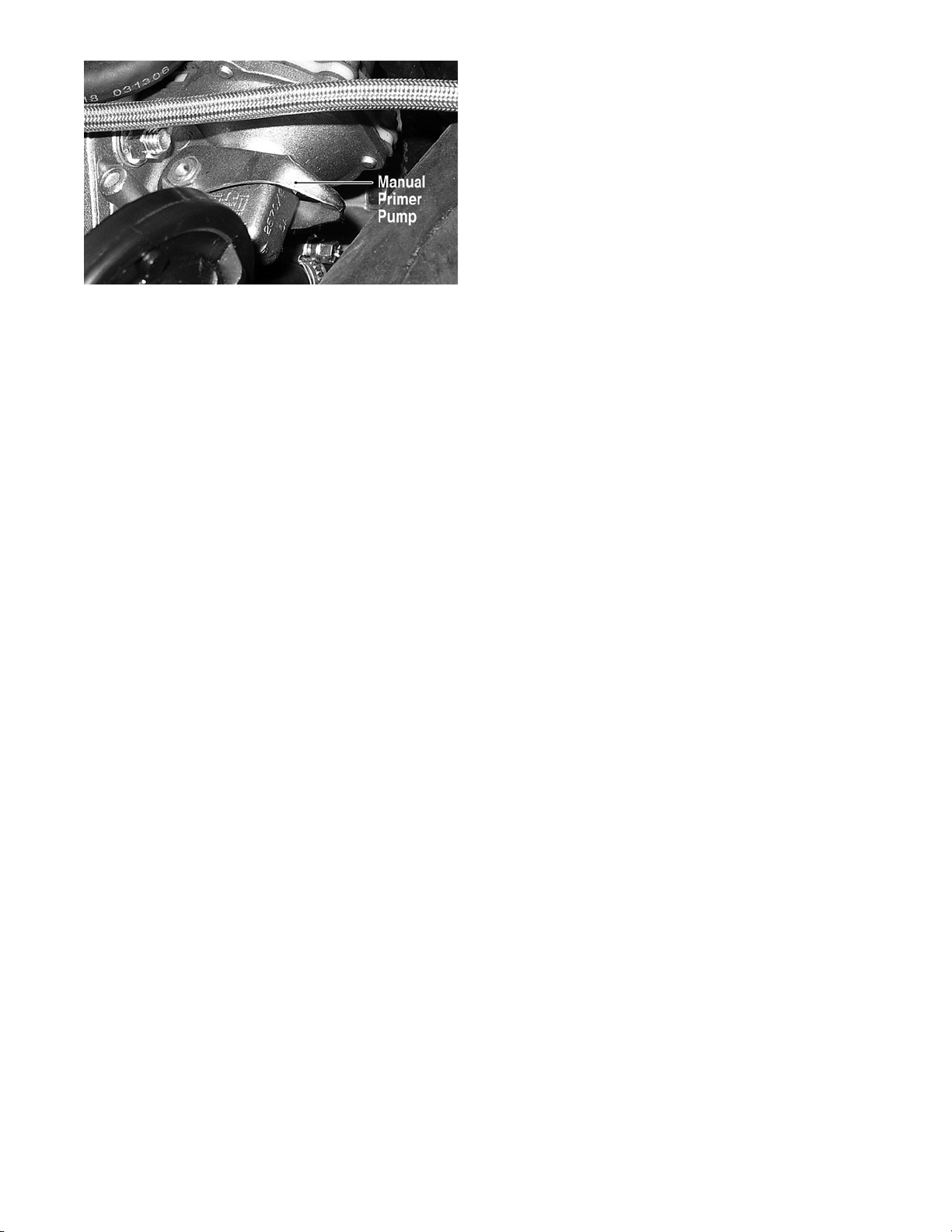

Fuel Filter

This diesel-powered ATV is equipped with a high efficiency fuel filter. The fuel filter should be changed in

accordance with the maintenance schedule or more

often if operated under severe conditions or winter

operation. To change the fuel filter, use the following

procedure.

1. Remove the right front fender splash panel; then

using an appropriate filter wrench, remove the fuel

filter.

2. Apply a light coat of oil to the seal ring of the new

fuel filter; then install the filter. Tighten until the

seal ring contacts the filter head; then tighten an

additional 3/4 turn.

DE483

NOTE: At this point, the cap screw can be

removed from the fixed driven face.

4. Rotate the V-belt and pulley until the V-belt is

flush with the top of the driven pulley.

www.mymowerparts.com

DE032D

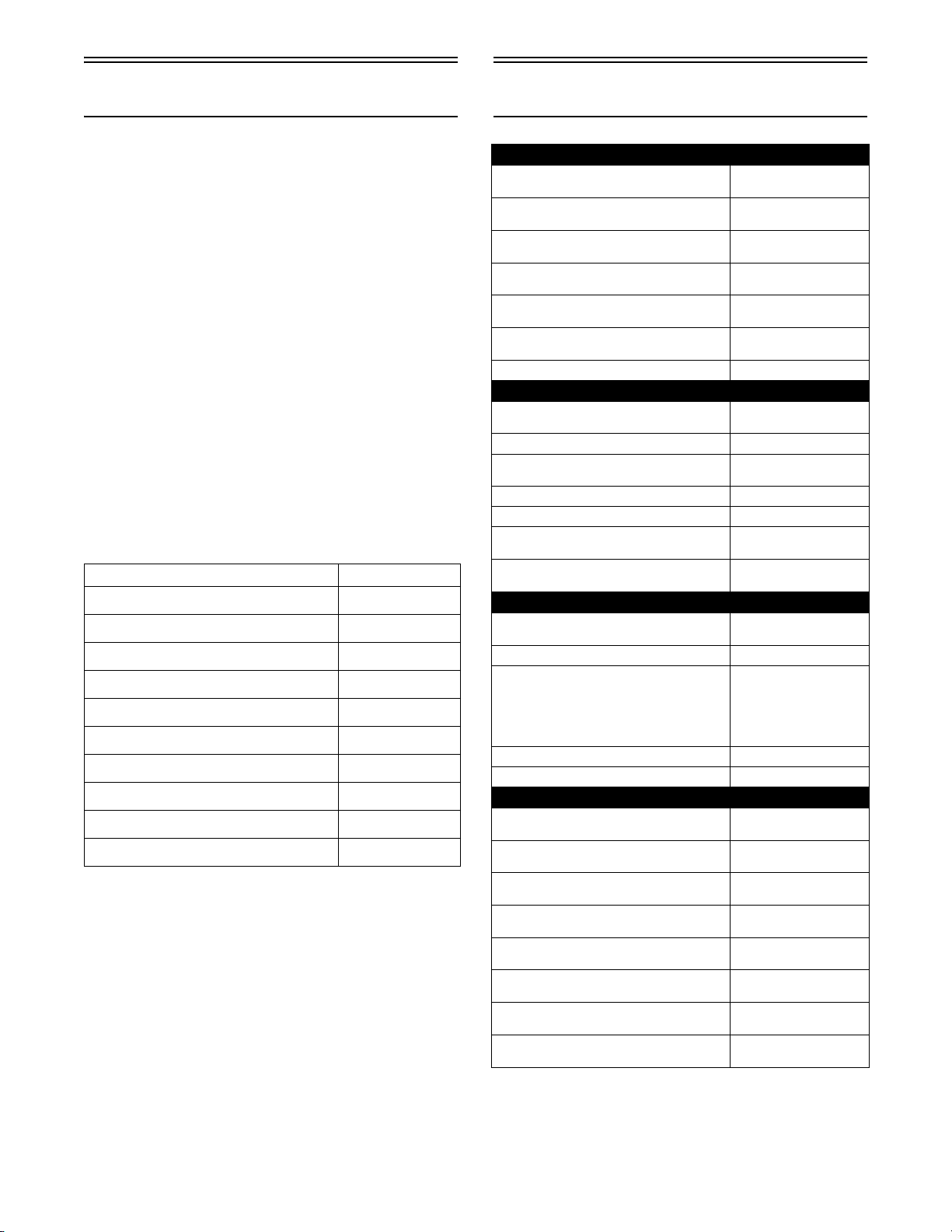

3. Depress and release the manual primer pump to

charge the fuel filter and purge any air from the

system.

17

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

NOTE: Cycle the manual primer pump until the lever

becomes firm and resistance is observed. The system will bleed itself through the tank return circuit.

4. Check for any fuel leaks; then start the engine and

check for normal engine operation.

DE031A

18

www.mymowerparts.com

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

Engine/Transmission

This section has been organized into sub-sections

which show a progression for the complete servicing

of the Arctic Cat ATV engine/transmission.

To service the crankcase, the engine must be removed

from the frame.

To service top-side, left-side, and right-side components (except cylinder head), the engine does not have

to be removed from the frame.

NOTE: Arctic Cat recommends the use of new

gaskets, lock nuts, and seals and lubricating all

internal components when servicing the engine/

transmission.

NOTE: Some photographs and illustrations used

in this section are used for clarity purposes only

and are not designed to depict actual conditions.

SPECIAL TOOLS

A number of special tools must be available to the

technician when servicing the engine/transmission.

Description p/n

Torx-Head Screwdriver - #30 0644-344

Drive Clutch Removal Tool 0444-226

Fuel Injector Timing Tool 0444-234

Timing Belt Tensioning Tool 0444-231

Main Bearing Seal Installation Tool 0444-233

Unit Injector Retainer Nut Tool 0444-227

Pre-Combustion Chamber Ring Nut Tool 0444-235

Pre-Combustion Chamber Removal Tool 0444-228

Pre-Combustion Chamber Index Tool 0444-229

Valve Seal Installation Tool 0444-230

NOTE: Special tools are available from the Arctic

Cat Service Parts Department.

Specifications

VALVES AND GUIDES

Valve Face Diameter (intake)

Valve Clearance (intake/exhaust)

(cold engine)

Valve Guide/Stem Clearance 0.015-0.060 mm

Valve Guide Inside Diameter 7.005-7.020 mm

Valve Stem Diameter 6.960-6.990 mm

Valve Face/Seat Width (intake/exhaust) 1.6-2.0 mm

Valve Spring Free Length (min) 43.0 mm (1.69 in.)

CAMSHAFT AND CYLINDER HEAD

Camshaft Lobe Height (min)

(intake/exhaust)

Camshaft Injection Lobe (min) 28.848 mm (1.136 in.)

Camshaft Journal Holder (max)

Inside Diameter

Camshaft Journal Diameter (min) 36.975 mm (1.456 in.)

Cylinder Head Distortion (max) 0.10 mm (0.004 in.)

Rocker Arm Bore 18.015-18.030 mm

Rocker Arm Shaft 17.989-18.000 mm

CYLINDER, PISTON, AND RINGS

Bore x Stroke 75 x 77.6 mm

Piston Ring End Gap - Installed (min) 0.25 mm (0.0098 in.)

Piston Ring Groove Width (1st)

Piston Pin Bore (max) 18.025 mm (0.7096 in.)

Piston Pin Outside Diameter (min) 17.996 mm (0.7085 in.)

Connecting Rod Piston Pin (max)

Bushing (inside diameter)

Crankshaft Main Bearing Journal 51.023-51.059 mm

Crankshaft Connecting Rod (min)

Journal

Connecting Rod Clearance 0.021-0.066 mm

Main Bearing Clearance 0.023-0.078 mm

Rod Bearing Diameter 40.021-40.050 mm

Oil Pump Pressure (min)

at 120° C (248° F)@900 RPM

Cooling Fan Thermo-Switch (offon)

Operating Temperature (onoff)

(exhaust)

CRANKSHAFT

34.4 mm (1.35 in.)

30.2 mm (1.19 in.)

0.20 mm (0.008 in.)

(0.0006-0.0024 in.)

(0.2758-0.2764 in.)

(0.2740-0.2752 in.)

(0.063-0.079 in.)

29.498 mm (1.161 in.)

37.060 mm (1.459 in.)

(0.7092-0.7098 in.)

(0.7082-0.7087 in.)

(2.95 x 3.05 in.)

0.090-0.125 mm

(0.0035-0.0049 in.)

(2nd)

0.050-0.085 mm

(0.0020-0.0033 in.)

(3rd)

0.040-0.075 mm

(0.0016-0.0030 in.)

18.025 mm (0.7096 in.)

(2.009-2.010 in.)

39.9 mm (1.57 in.)

(0.0008-0.0026 in.)

(0.0009-0.0031 in.)

(1.5756-1.5767 in.)

1.1 kg/cm² (15.6 psi)

93° C (199° F)

87° C (189° F)

Specifications subject to change without notice.

www.mymowerparts.com

19

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

Removing Engine/

Transmission

Many service procedures can be performed without

removing the engine/transmission from the frame.

Closely observe the note introducing each sub-section

for this important information.

AT THIS POINT

If the technician’s objective is to service/replace leftside components, right-side components, and/or

top-side components, the engine/transmission does

not have to be removed from the frame.

AT THIS POINT

If the technician’s objective is to service/replace the

transmission, the engine does not have to be

removed from the frame (proceed to Transmission in

this sub-section).

DE066A

ENGINE/TRANSMISSION

1. Remove the seat; then from the rear, remove the

battery cables (negative first) and the battery.

2. Remove the front rack, front body panel, and left

and right footrests (see Steering/Frame).

3. Drain the coolant, engine oil, and transmission

lubricant (see Periodic Maintenance/Tune-Up).

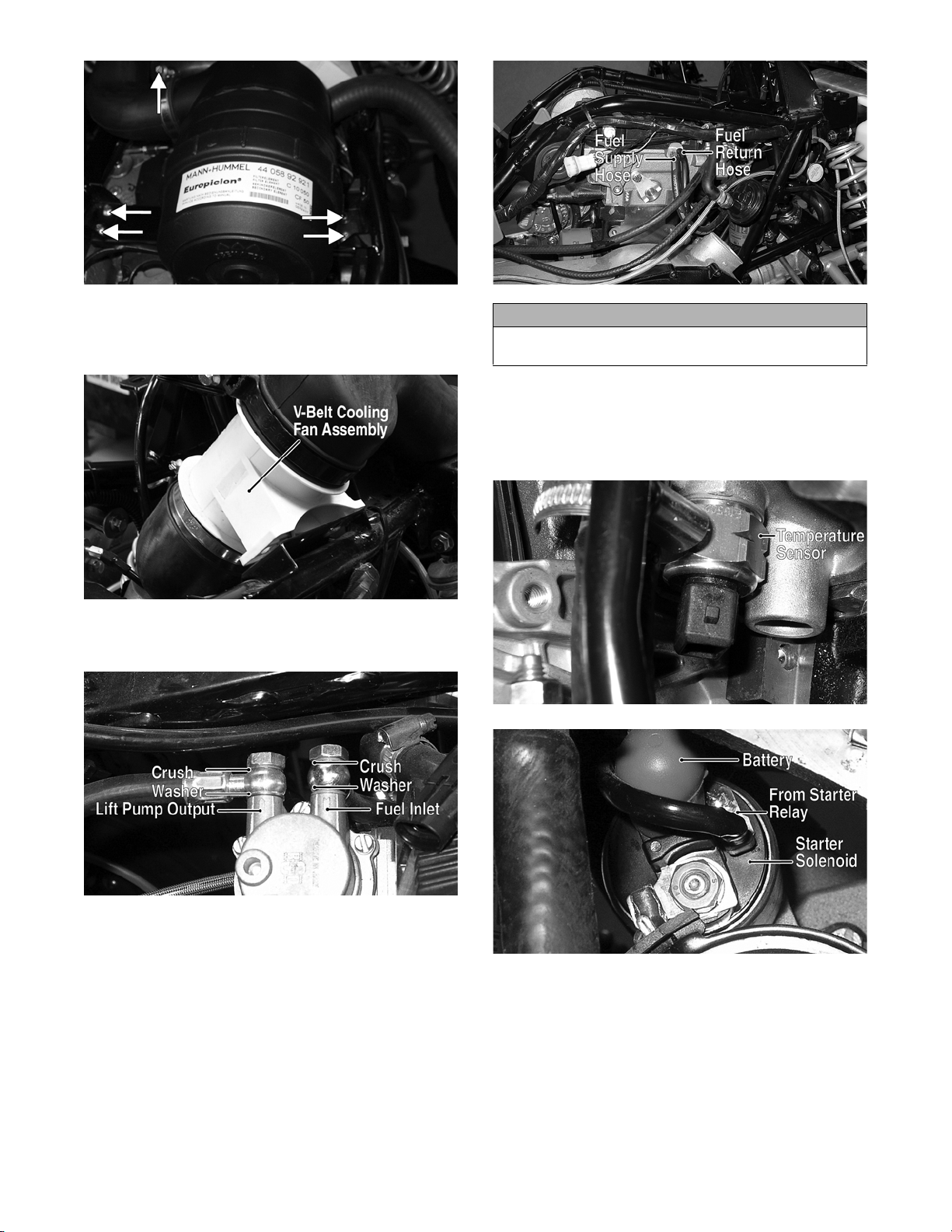

4. From the left side, remove the E-clip from the shift

arm; then disconnect the shift linkage from the

shift arm. Account for a bushing and washer.

DE071A

6. Loosen the two hose clamps securing the air

diverter to the inlet hoses; then remove the air

diverter.

7. Remove the upper radiator hose from the filler

neck; then loosen the hose clamp securing the

filler neck to the thermostat housing and remove

the filler neck.

DE064A

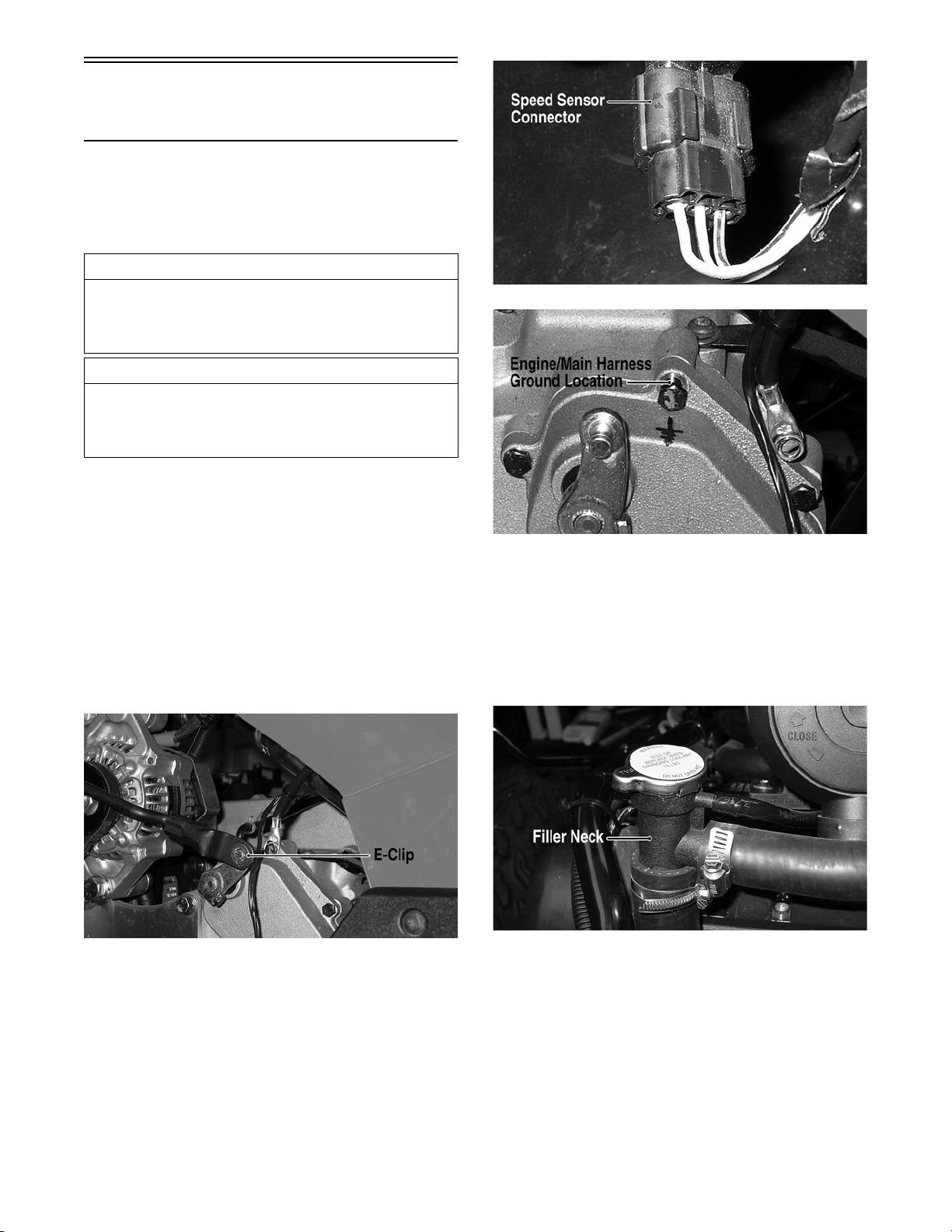

5. Disconnect the speed sensor connector from the

speed sensor; then remove the cap screw securing

the engine and main harness ground to the transmission.

www.mymowerparts.com

20

DE073A

NOTE: Filler neck can remain attached to the

overflow recovery hose.

8. Remove the upper radiator hose from the radiator.

9. Remove the four cap screws securing the air filter

housing assembly to the frame; then disconnect

the air inlet hose from the intake manifold and

remove the air filter housing assembly.

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

DE074A

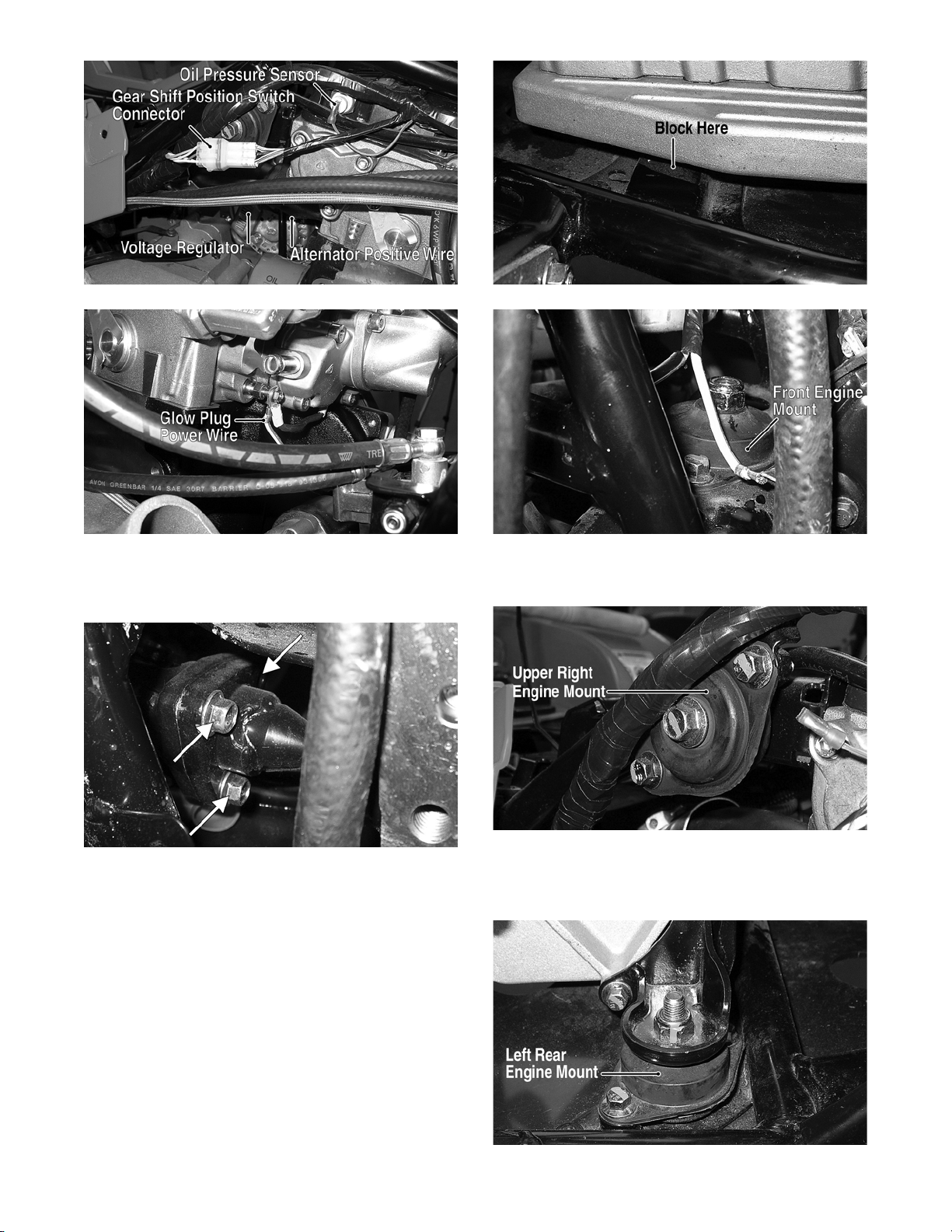

10. Remove the V-belt cooling fan assembly; then disconnect the V-belt inlet and outlet cooling boots

from the V-belt housing.

DE076A

11. Remove the fuel inlet and lift pump output hoses

from the lift pump. Discard four crush washers.

DE065A

CAUTION

The fuel rail connections are easily bent. Use care

when removing the hose clamps and hoses.

13. Disconnect the wire connectors from the temperature sensor, oil pressure sensor, gear shift position

switch connector, and voltage regulator; then disconnect the starter solenoid, glow plug power

wire, and the alternator positive wire.

DE104A

DE078A

12. Remove the fuel supply and fuel return hoses from

the fuel rail.

www.mymowerparts.com

DE067A

21

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

DE077A

DE494A

14. Apply the hand brake and engage the brake lever

lock; then remove the cap screws from the front

drive coupler.

DE089A

DE086A

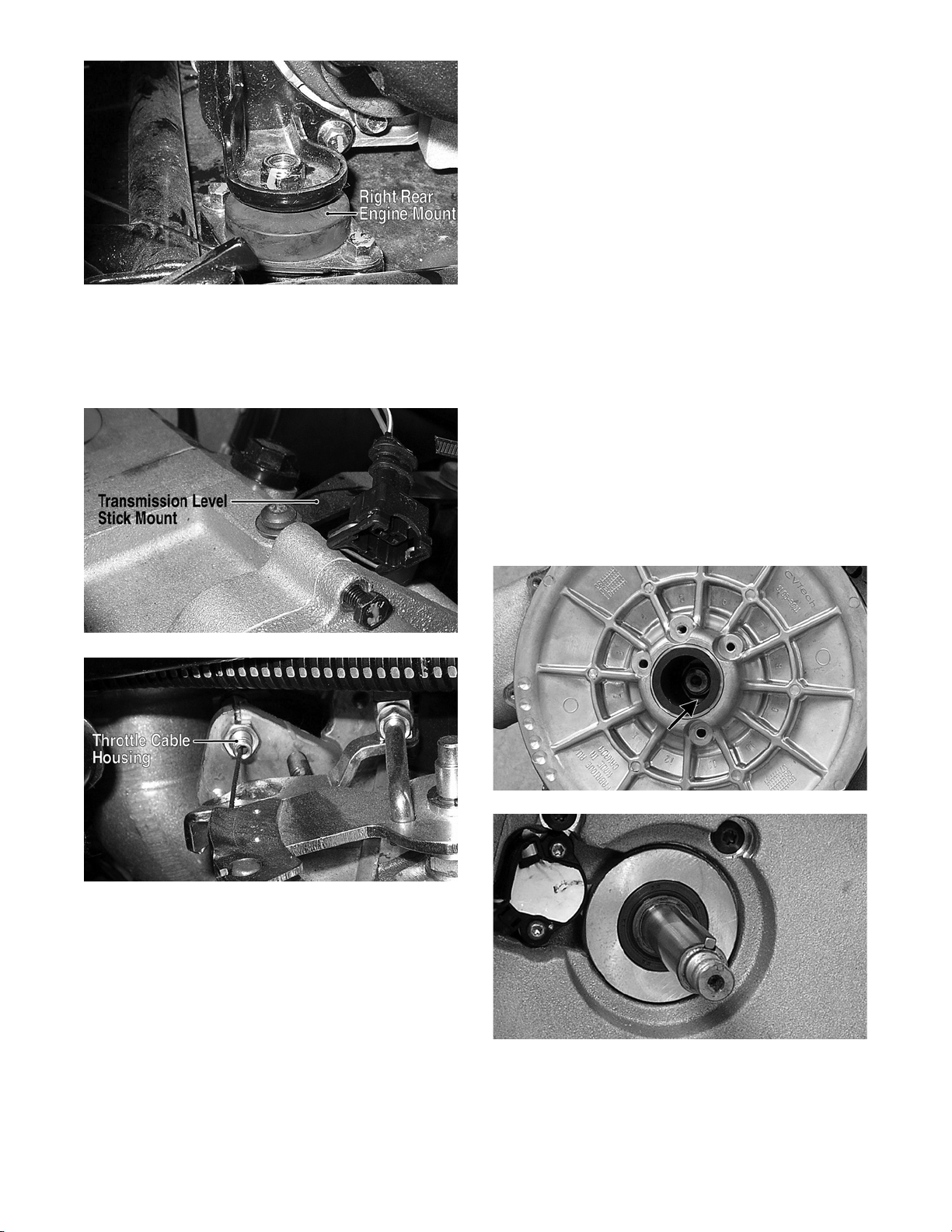

19. Remove the cap screw and nut from the upper

right engine mount. Account for a flat washer.

DE081A

15. Remove the cap screws from the rear drive coupler.

16. Remove the exhaust springs; then remove the muffler. Account for a grafoil seal.

17. Remove the nuts securing the exhaust pipe to the

exhaust manifold; then remove the exhaust pipe.

Account for a steel gasket.

18. Place a suitable block between the oil pan and

frame member; then remove the front engine

mount cap screw and nut. Account for a flat

washer.

www.mymowerparts.com

22

DE088A

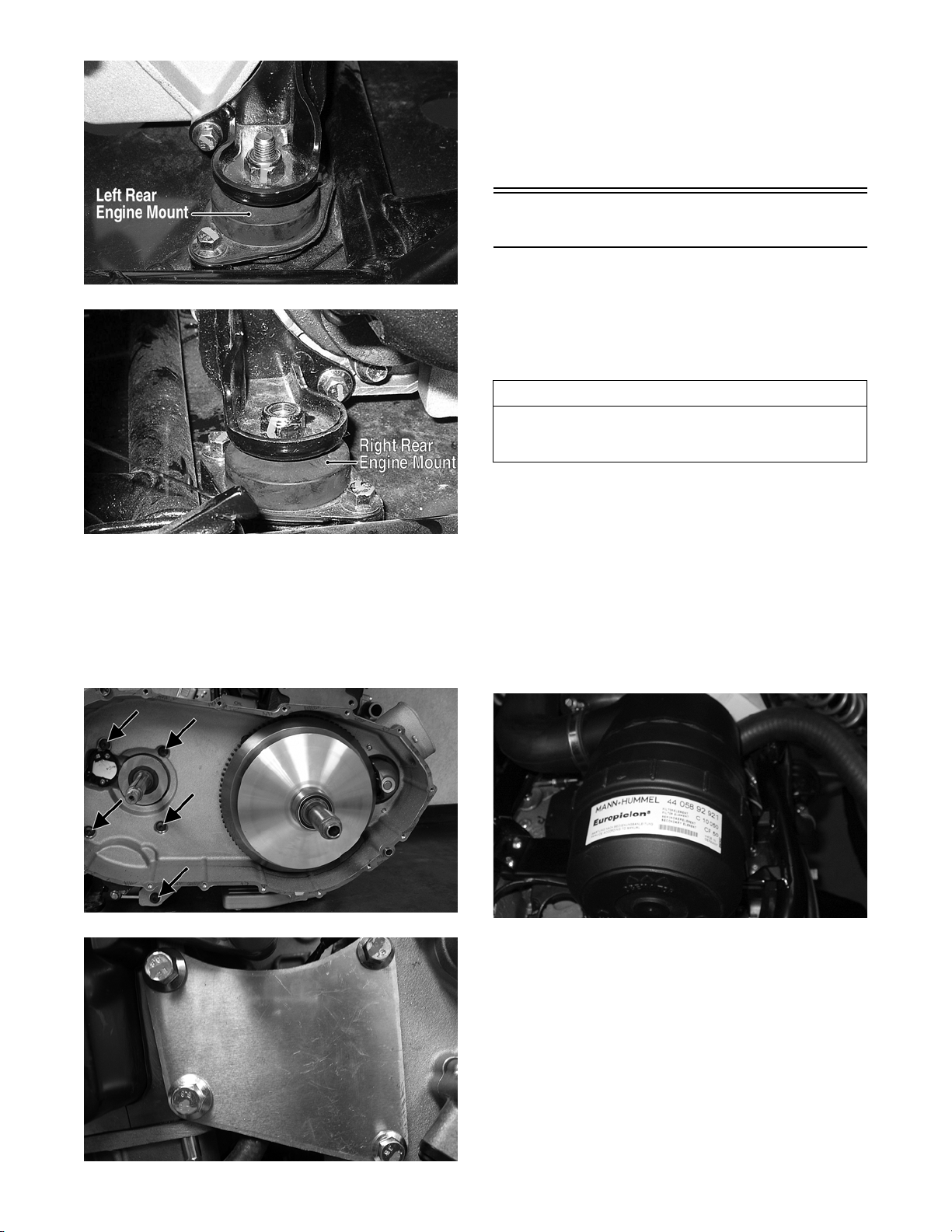

20. Remove the nuts and cap screws from the left rear

and right rear engine mounts. Account for two flat

washers.

DE085A

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

DE090A

21. Remove the transmission level stick mount and

housing; then disconnect the throttle cable from

the throttle control arm and unthread the throttle

cable housing. Route the throttle cable away from

the engine.

TRANSMISSION

NOTE: The transmission can be removed for servicing without removing the engine. To remove the

transmission, use the following procedure.

1. Remove the inner front splash shields, foot pegs,

and forward footwells (see Steering/Frame).

2. Remove three cap screws securing the front propeller shaft to the front differential input coupler.

3. Remove four cap screws securing the rear propeller shaft to the output drive flange.

4. Remove the transmission level stick housing and

account for an O-ring.

5. Drain the transmission lubricant into a suitable

container; then disconnect the transmission vent

hose, gear shift position switch connector, speed

sensor connector, and shift linkage.

6. Remove the V-belt (see Periodic Maintenance/

Tune-Up).

DE091A

DE080A

22. Move the engine/transmission slightly forward

and shift the rear propeller shaft to the right; then

rotate the rear of the assembly out of the left side.

7. Remove the nut securing the driven pulley to the

transmission input shaft; then remove the driven

pulley. Account for a flat washer, square key, and

four shims.

DE106A

NOTE: The front engine mount bracket and fuel

filter housing can be removed to allow more clearance at the front of the engine.

23. Remove the front propeller shaft from the transmission output yoke; then slide the engine/transmission out the left side lifting the transmission to

tilt the engine sufficiently forward for the top of

the engine to clear the upper frame tubes.

24. Attach a suitable lift and lift the engine free of the

frame.

www.mymowerparts.com

DE108

8. Remove the nuts from the left rear and right rear

engine mount bolts; then remove the bolts.

Account for two flat washers.

23

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

11. Slide the transmission to the left side until the rear

output flanges can be separated; then move the

transmission to the rear to expose the front output

yoke boot.

12. Slide the boot off the yoke and separate the front

propeller shaft from the front output drive yoke.

Top-Side Components

DE085A

DE090A

9. Block the rear of the engine up; then remove the

rear mounts from the transmission.

10. Remove five cap screws securing the transmission

to the V-belt housing; then remove four cap screws

securing the engine-to-transmission mounting

plate.

NOTE: For efficiency, it is preferable to remove

and disassemble only those components which

need to be addressed and to service only those

components. The technician should use discretion

and sound judgment.

AT THIS POINT

To service any one specific component, only limited

disassembly of components may be necessary. Note

the AT THIS POINT information in each sub-section.

NOTE: The engine/transmission does not have to

be removed from the frame for this procedure.

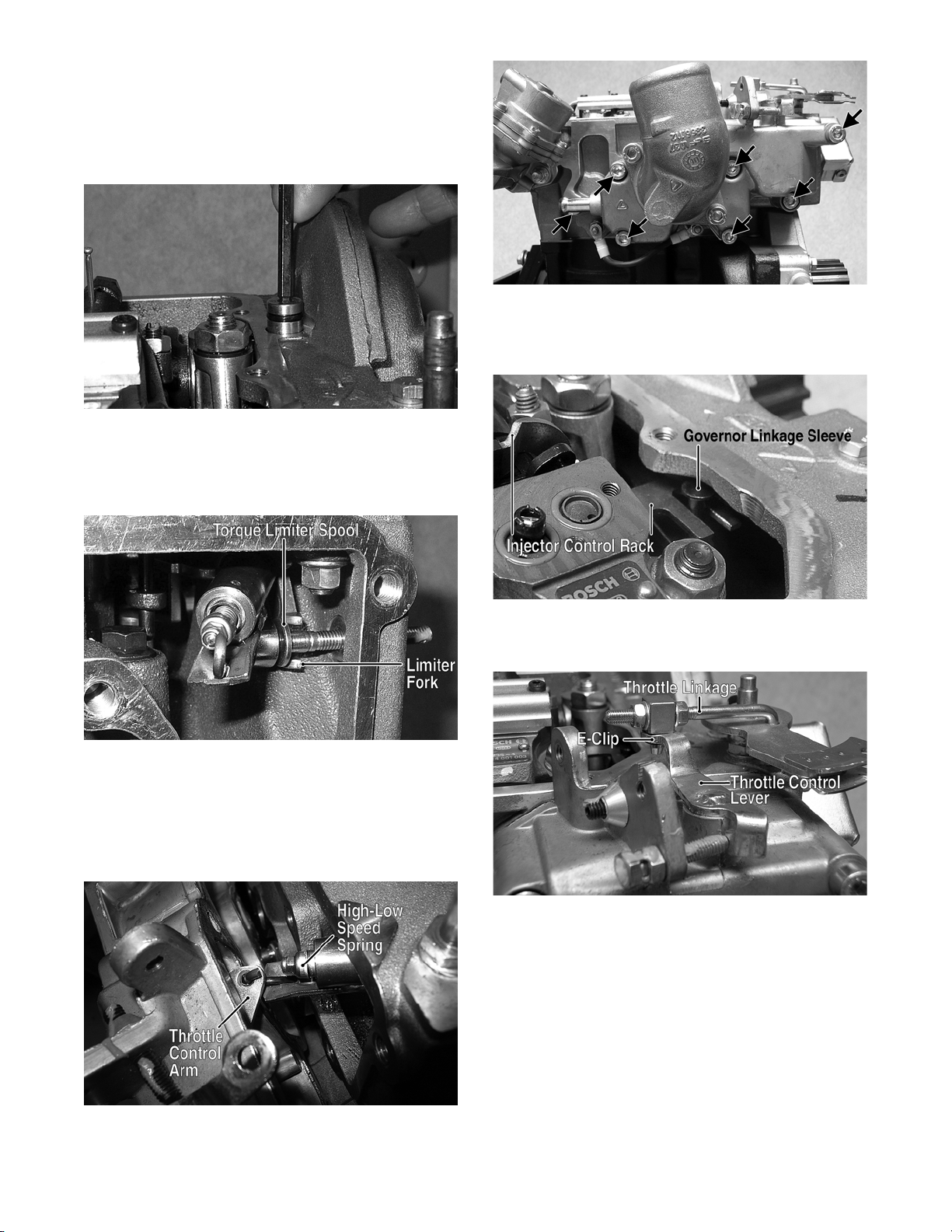

SPEED GOVERNOR

Removing/Disassembling

1. Remove the timing belt (see Left-Side Components in this section).

2. Remove the air filter assembly; then remove the

valve cover.

24

DE589A

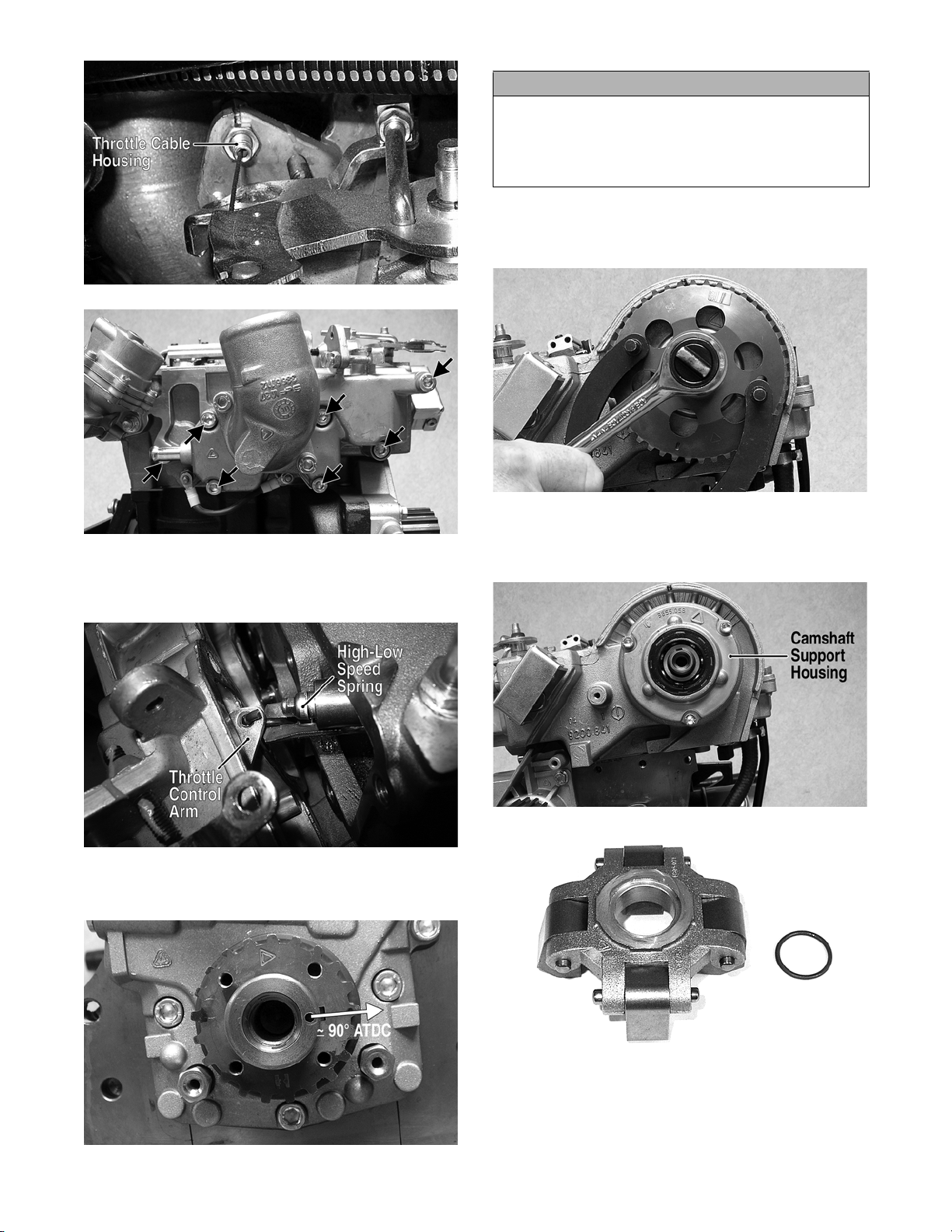

3. Disconnect the throttle cable; then remove the cap

screws securing the intake manifold/throttle cable

housing to the cylinder head.

www.mymowerparts.com

DE487

DE074

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

CAUTION

Failure to rotate the engine away from TDC will leave

the flywheel-side piston in close proximity to the

valves. If the camshaft is rotated while attempting to

remove the camshaft drive pulley, severe valve damage WILL occur.

6. Using a suitable holding tool, remove the cap

screw securing the camshaft drive pulley; then

remove the pulley.

DE080A

DE248A

4. Disconnect the high-low speed spring assembly from

the throttle control arm; then remove the intake manifold/throttle control housing. Account for a gasket.

DE258A

5. Rotate the crankshaft in the direction of rotation

approximately 90° from TDC.

DE276

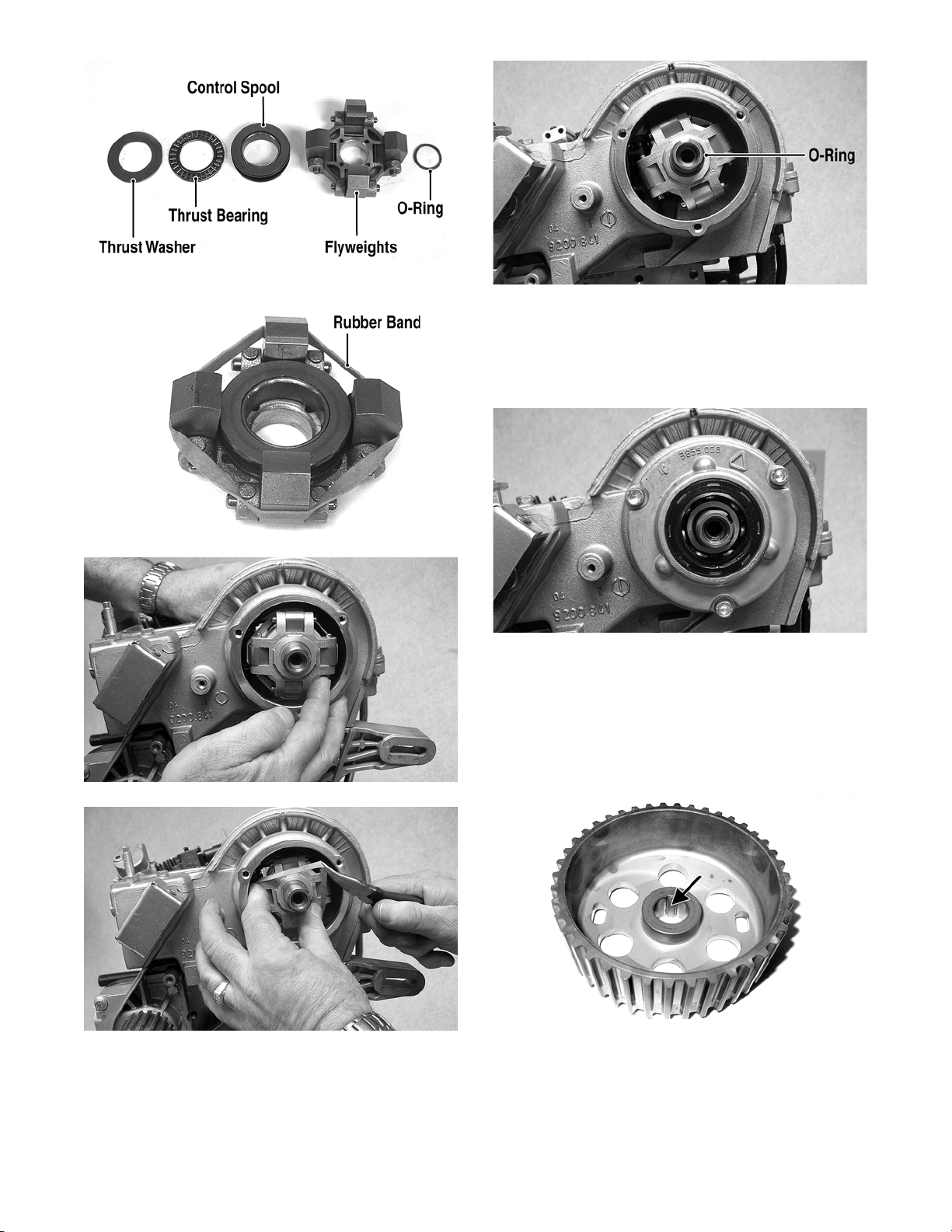

7. Remove the front camshaft support housing; then

remove the governor flyweight assembly. Account

for a small O-ring.

DE245A

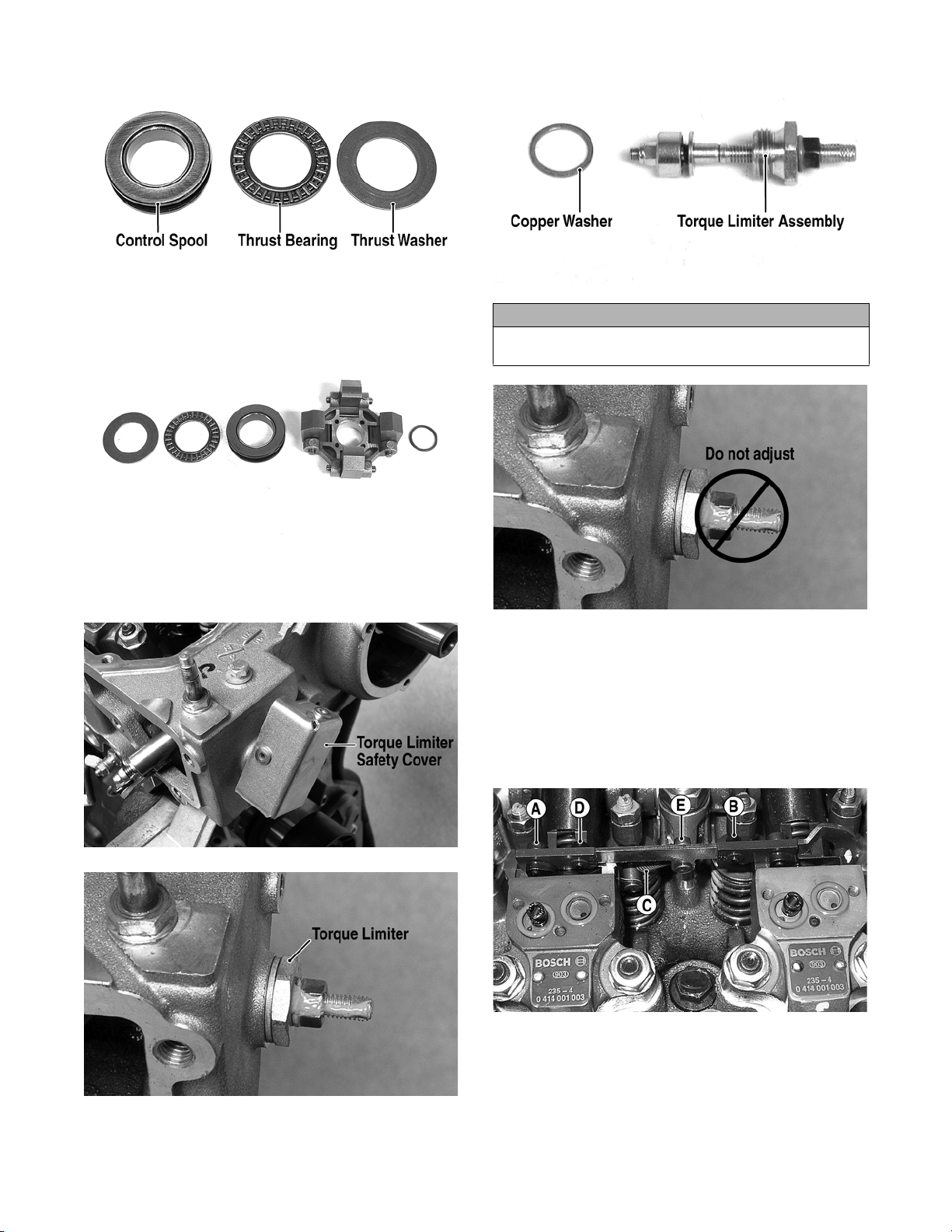

8. Remove the control spool, thrust bearing, and

thrust washer. Note the order of disassembly and

keep together and in order for assembling purposes.

DE275A

www.mymowerparts.com

DE277

25

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

DE278A

DE279

9. Remove the torque limiter safety cover; then

remove the torque limiter assembly. Account for a

copper washer.

DE286A

CAUTION

Do not break the seal or turn the torque limiter

adjuster screw. Severe engine damage could occur.

DE285B

10. Remove the fuel injection control rack by removing screws (A) and (B) and spring (C); then

remove the governor fork pivot pin. Account for

an O-ring.

NOTE: Do not loosen or remove screws (D) or (E)

or fuel delivery equalization will have to be performed.

26

DE252A

DE291A

DE285A

www.mymowerparts.com

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

DE327

DE282

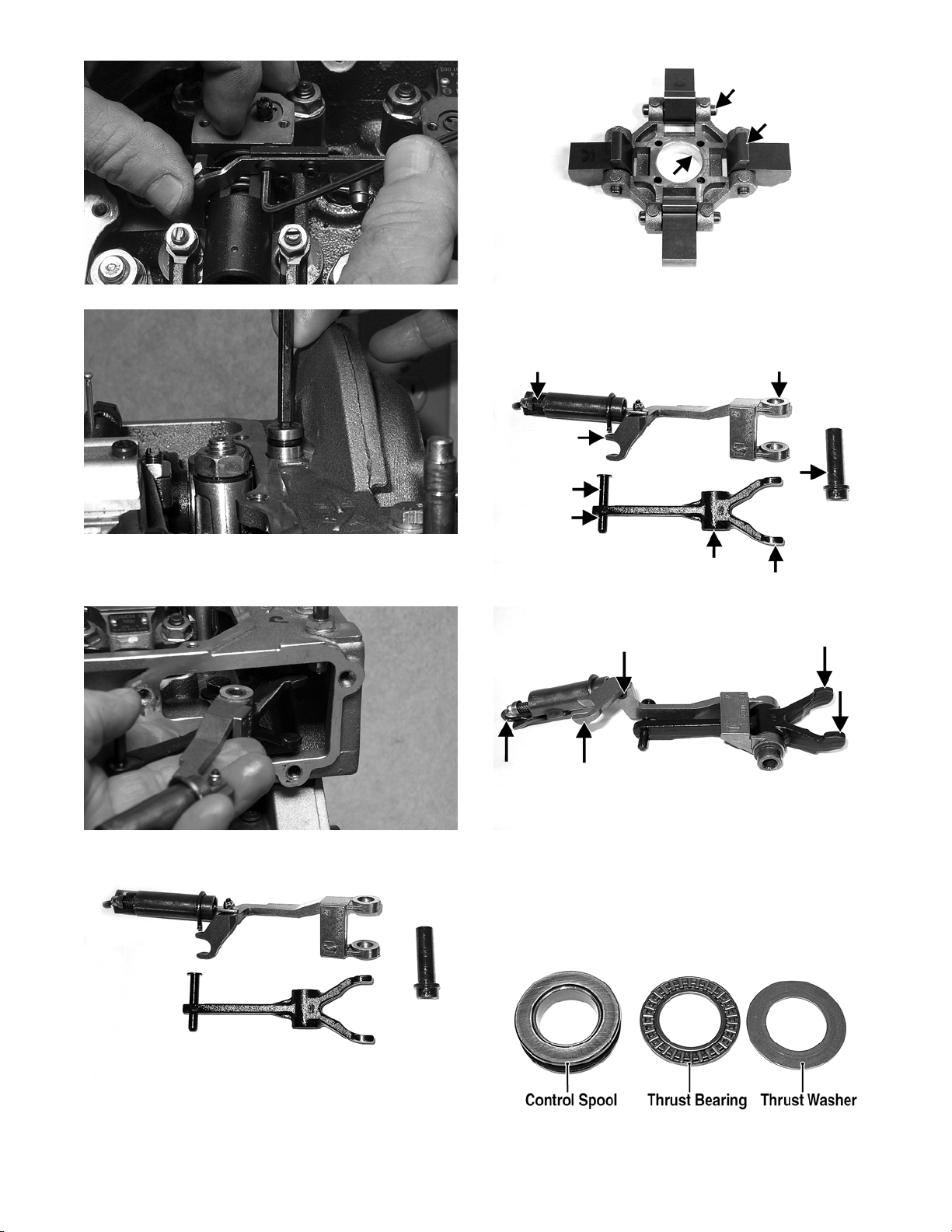

11. Remove the governor fork and governor spring

assembly through the opening on the linkage housing.

DE247A

2. Inspect all springs, links, and pivot pins for proper

tension, excessive wear, or loose fit.

DE254A

DE253

DE254

Inspecting

1. Inspect the flyweight assembly for loose pins,

worn contact points, or excessive pivot point wear.

www.mymowerparts.com

DE256A

3. Inspect the control spool, thrust bearing, and thrust

washer for scoring, excessive wear, or missing

bearing rollers.

DE278A

27

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

4. Coat all serviceable parts with clean engine oil.

Assembling/Installing

1. Install the governor fork assembly into the cylinder head and secure with the governor fork pivot

pin. Tighten securely.

DE282

2. Using a new copper washer, install the torque setting screw assembly and tighten securely; then

install the safety cover. Make sure the torque limiter spool engages the limiter fork.

DE248A

4. Install the fuel injector control rack making sure

the slotted end engages the governor linkage

sleeve; then tighten the cap screws to 11 in.-lb.

DE288A

3. Using a new gasket, install the intake manifold/

throttle control assembly by first connecting the

high/low speed spring assembly to the throttle

control arm; then place the manifold and gasket

into position and secure with the seven cap screws.

Tighten securely.

DE534A

5. Connect the throttle linkage into the throttle control lever; then secure with the E-clip.

DE249A

6. Place control spool, thrust bearing, and thrust

washer into the governor flyweight assembly and

secure the flyweights with a rubber band; then

place assembly onto the camshaft with a new Oring. Make sure to remove the rubber band.

28

DE258A

www.mymowerparts.com

For Discount Arctic Cat Parts Call 606-678-9623 or 606-561-4983

DE279A

DE531A

DE246A

7. Using a new O-ring, coat the flange of the camshaft bearing retainer and the camshaft support

housing with clean engine oil and install into the

cylinder head. Secure with the three cap screws

and tighten to 7 ft-lb.

DE296

8. Being careful not to damage the oil seal, lightly

coat the camshaft drive pulley flange with clean

engine oil and install on the camshaft.

NOTE: The camshaft drive pulley has a molded

extrusion in the pulley bore that must engage the

keyway in the camshaft.

DE535

DE536

9. Secure the camshaft drive pulley to the camshaft

with a washer and cap screw; then using an appropriate holding tool, tighten the cap screw to 59 ftlb.

www.mymowerparts.com

DE574A

29

Loading...

Loading...