MCM User's Manual

© 2009 Artesis A.S.

Document ID: MCM-OP-UM-EG-0091.0000

1

MCM User's Manual

WARNING

Lethal voltages and currents are present at the input terminals of this device. Accordingly, this MCM unit

should be installed and maintained only by qualified, competent personnel who have the necessary training

and experience appropriate to high voltage and current devices. MCM must be used in accordance with all

local and national codes for the installation and operation of electrical equipment.

Recommended safety precautions should be followed at all times. Both current and voltage transformers can

present lethal currents and voltages when their primaries are energized and standard practices (i.e. shorting

the secondaries of current transformers and removing voltage transformer fuses) must be respected during

installation or any subsequent service.

The unit is designed for operation in a control cabinet with restricted access to the rear terminals and should

not be used in any environment where this is not the case. MCM should not be used for the purpose of

primary protection of electrical equipment.

2

MCM User's Manual

Motor Condition Monitor (MCM) and MCMSCADA

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted

in any form or by any means, mechanical, photocopying, recording or otherwise, without prior written

permission of Artesis AS. No patent liability is assumed with respect to the information contained herein.

Whilst every effort has been made to ensure that the information presented in this document is accurate and

up to date, Artesis AS reserves the right to make changes without notice. Neither Artesis AS nor its

designated agents can be held responsible for any errors or omissions, or problems arising from the

application of information contained herein.

Neither Artesis AS nor its affiliates shall be liable to the purchaser of this product or third parties for damages,

losses, costs, or expenses incurred by purchaser or third parties as a result of: accident, misuse or abuse of

this product or unauthorized modifications, repairs, or alterations to this product, or failure to comply strictly

Artesis AS’s operating and maintenance instructions.

Artesis AS shall not be liable against damages or problems arising the use of any options or any consumable

products other than those designated as Artesis original products or Artesis approved products by Artesis

AS.

Product names other than those owned by Artesis AS are used for identification purposes only and may be

trademarks of their respective owners. Artesis AS disclaims any and all rights in those marks.

Copyright © Artesis 2009 by Artesis A.S., Gebze, Kocaeli, Turkey.

i

MCM User's Manual

Table of Contents

Table of Contents

Section I

Section II

Section III

Welcome to MCM

................................................................................................................................... 11 Introduction

................................................................................................................................... 12 Use of this manual

MCM Installation

................................................................................................................................... 31 Preliminary checks

................................................................................................................................... 32 MCM Unit Installation

................................................................................................................................... 43 Current and Voltage Sensor Installation

.......................................................................................................................................................... 4Low voltage line driven systems

.......................................................................................................................................................... 4Low voltage inverter driven systems

.......................................................................................................................................................... 5Medium/High voltage systems

................................................................................................................................... 54 Rear panel connections

................................................................................................................................... 65 Applying power to the MCM unit

................................................................................................................................... 76 Installing with soft-starter systems

................................................................................................................................... 77 Installing with inverter drives

MCM Use

................................................................................................................................... 81 Introduction

................................................................................................................................... 82 The front panel

................................................................................................................................... 93 Configuring for use

.......................................................................................................................................................... 9Entering the password

.......................................................................................................................................................... 10The Edit Settings menu

......................................................................................................................................................... 10First time use

......................................................................................................................................................... 11Calibration factors

......................................................................................................................................................... 11Motor settings

......................................................................................................................................................... 11Communications settings

................................................................................................................................... 124 Running MCM

.......................................................................................................................................................... 12Introduction

.......................................................................................................................................................... 12Alarm messages and status indication

.......................................................................................................................................................... 13Running CHECK MOTOR

.......................................................................................................................................................... 14Setting and checking the input connections

.......................................................................................................................................................... 14Running LEARN and IMPROVE

.......................................................................................................................................................... 16Running RESUME and UPDATE

.......................................................................................................................................................... 17Advanced use

.......................................................................................................................................................... 19Equipment Faults and Their Diagnoses Using MCM

.......................................................................................................................................................... 21Interpreting MCM fault indications

......................................................................................................................................................... 21MCM status values

......................................................................................................................................................... 22Changes in line voltages

......................................................................................................................................................... 22Load changes

......................................................................................................................................................... 22Error messages

......................................................................................................................................................... 23Using the relay output

......................................................................................................................................................... 24Connecting to the serial port

1

3

8

ii

MCM User's Manual

Table of Contents

Section IV

Section V

Troubleshooting

................................................................................................................................... 261 Introduction

................................................................................................................................... 262 Use of the MCM Config utility

................................................................................................................................... 293 Fault diagnosis

................................................................................................................................... 304 Servicing

Appendices

................................................................................................................................... 311 Appendix 1: MCM Error, alarm and warning conditions

................................................................................................................................... 342 Appendix 2: Current and voltage sensor selection

................................................................................................................................... 363 Appendix 3: Connection Diagrams

................................................................................................................................... 394 Appendix 4: Menu settings and parameters

................................................................................................................................... 405 Appendix 5: Edit Settings Menu items

................................................................................................................................... 456 Appendix 6: Flowcharts for MCM use

................................................................................................................................... 517 Appendix 7: Continuous device ratings

26

31

iii

MCM User's Manual

enquiry@artesis.com

1 Welcome to MCM

1.1 Introduction

MCM is a revolutionary tool in the battle to keep electric motors and machinery running at peak

performance, whilst maintaining high plant productivity levels. Used correctly, this unique instrument is

capable of monitoring three phase AC motors of all sizes and power levels to provide clear, unambiguous

indications when the performance of a particular motor (or even the machinery it is connected to) begins

to degrade. The numerous transducers employed by other, less advanced instruments have been

replaced by three current sensors and three voltage sensors, familiar to all those involved with the

measurement of electrical quantities, making the system straightforward to install and use without indepth training of personnel.

In addition to its unique capabilities as an intelligent condition-monitoring device, MCM can also perform

many of the functions of, and indeed replace the more traditional energy monitoring and data-logging

instruments.

For applications involving the monitoring of many motors and associated machinery, the networking

options available with MCM allow units to be connected together to a host terminal where they can all be

viewed together.

Section 1 - Welcome to MCM

Furthermore, the monitoring software package allows examination of the various parameters MCM uses

to determine the status of a motor and to trend the parameters as a visual indication of degradation over

time.

Despite its simplicity and ease of use, like any intelligent electronic, software-based device, it is

important that MCM is installed and used correctly. We recommend strongly that you take the time to

study the information contained within the accompanying manuals and to familiarize yourself with the

operating principles and practices.

Customer service: Please contact either your supplier or Artesis AS Customer Service if you

experience any problems in the installation or use of MCM.

1.2 Use of this manual

This manual explains the basic concepts needed to install and use MCM. The appendix at the end of the

manual provides information that may be useful to the general user. For further, specific details please

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

1

MCM User's Manual

contact Artesis AS.

Section 1 - Welcome to MCM

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

2

MCM User's Manual

In common with any device connected to high power electrical

supplies, only suitably qualified personnel should install and maintain

MCM.

2 MCM Installation

2.1 Preliminary checks

Please inspect the contents of the MCM package and ensure that they agree with the information in the

Packing list. In the event of any missing or damaged items, please contact your supplier immediately.

Check also that the power range of the MCM unit is suitable for the motor to be monitored. The device

type can be found on the MCM label. Artesis A.S. will not accept responsibility for damage caused to or

by any MCM unit that has been incorrectly installed or installed on a motor system outside the indicated

power range.

2.2 MCM Unit Installation

Section 1 - Welcome to MCM

MCM has been designed to mount directly onto the front panel of the motor switchgear cabinet. Any

other usage is not recommended due to the lethal voltages present at the terminals. To mount,

insert the MCM unit into the prepared 91x91 mm cutout on the cabinet panel and push until the front of

the unit is flush with the panel. Insert the side retainers and tighten the thumbscrews on each retainer

until the MCM unit is held securely in place.

Mounting MCM on a panel

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

3

MCM User's Manual

Dangerous and lethal voltages can develop across the secondary

terminals of open circuit current and voltage transformers. Before

disconnecting any MCM unit to or from a current transformer, the

secondary terminals of the transformer should be shorted using a link

capable of carrying at several times the nominal output current (i.e. at

least 10A). Before performing any work on a voltage transformer, its

fuse must be removed or switch opened. Contact breakers or fuses at

their sources must protect all voltage inputs.

2.3 Current and Voltage Sensor Installation

2.3.1 Low voltage line driven systems

Three standard 5A secondary, current transformers of appropriate ratings are recommended for current

sensing (please refer to the appendix at the end of this manual for full specifications). The secondary

terminals of each transformer should be connected to the corresponding current measurement terminal

pairs, I11-I

Voltage line connections VR, VS, VT should be made directly to their respective voltage measurement

terminals V1, V2, V3 at the rear of the unit.

12, I21-I22, I31-I32

, on the rear of the MCM unit.

Section 2 - MCM Installation

Please refer to the connection diagrams in the appendix at the end of this manual for further details.

2.3.2 Low voltage inverter driven systems

The current sensors employed by MCM for inverter driven systems are Hall-effect type requiring an

external DC power supply. The motor current rating should be checked carefully to ensure compatibility

with the sensors provided. Please refer to the appendix at the end of this manual for further details on

sensor selection.

High current sensors (for currents greater than 200 A) need to be mounted separately at a convenient

location within the switchgear cabinet together with their external power supplies. Smaller sensors are

mounted on the same circuit board as the power supply and should be placed together at the chosen

location. In both cases, the cable carrying power to a single phase of the motor must be passed through

the central hole in the appropriate current sensor and secured.

The power supply ground should be connected directly to the I12, I22, I32 pairs of current measurement

terminals on the rear of the MCM unit.

Voltage connections VR, VS, VT should be made directly to their respective voltage measurement

terminals V1 V2 V3 at the rear of the unit.

Note that MCM is not recommended for use with inverters operating at a chopping frequency

lower than 2 kHz.

Please refer to the connection diagrams in the appendix at the end of this manual for further details.

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

4

MCM User's Manual

If compensation capacitors are employed, it is essential that the current

transformers be placed between the motor and the capacitor bank so that only

the true motor currents are measured.

REMOVE ALL POWER PRIOR TO CHANGING CONNECTIONS

2.3.3 Medium/High voltage systems

Three standard 5A secondary, current transformers of appropriate ratings are recommended for current

sensing (please refer to the appendix at the end of this manual for full transformer specifications). The

secondary outputs from each transformer should be connected to the corresponding current

measurement terminal pairs, I11-I

Standard 100V, 110V and 120V secondary voltage transformers should be used to drop the voltage to

usable levels. Connections from the secondary outputs of the transformers should be made to the

respective voltage measurement terminals V1, V2 V3 at the rear of the unit.

Please refer to the connection diagrams in the appendix at the end of this manual for further details.

12, I21-I22, I31-I32

Section 2 - MCM Installation

, on the rear of the MCM unit.

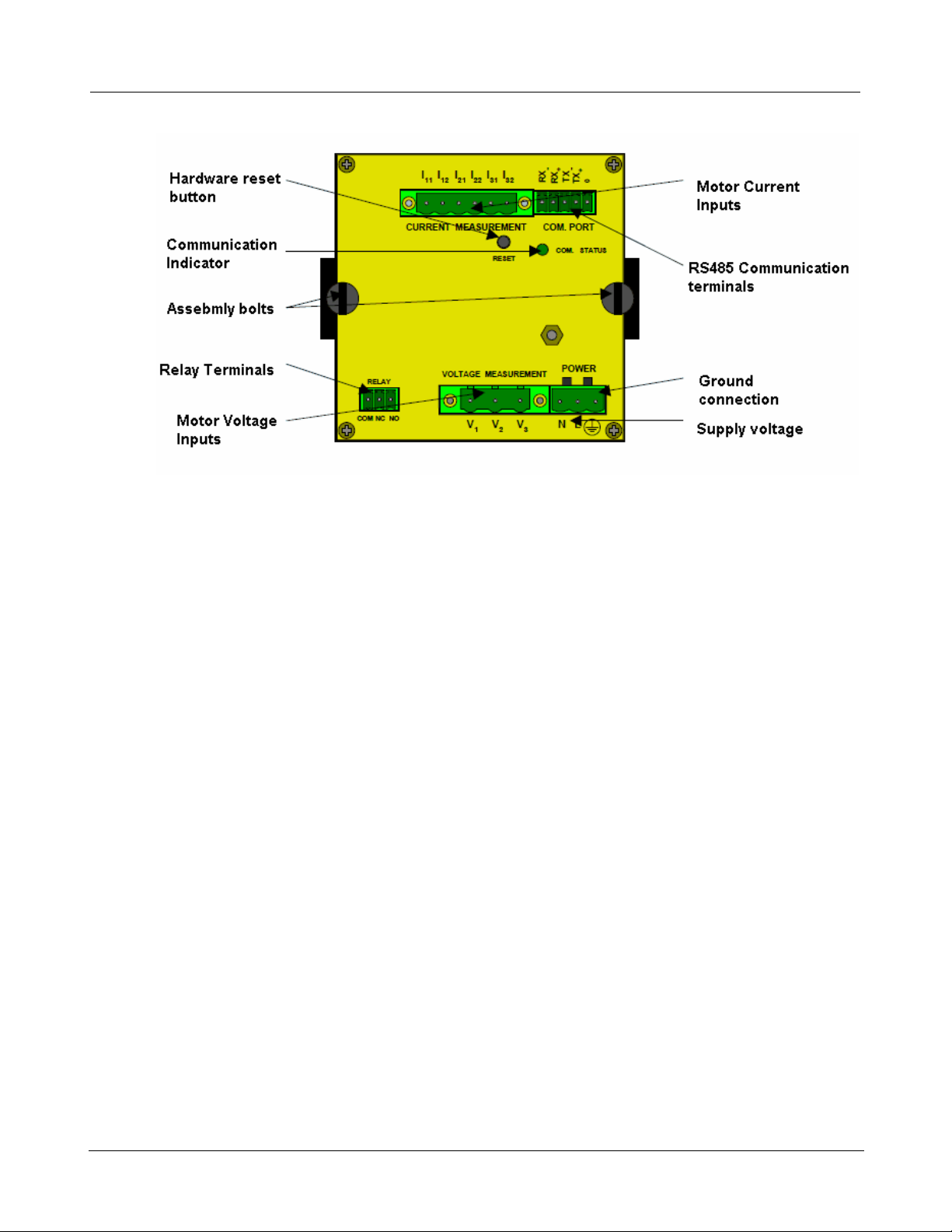

2.4 Rear panel connections

Connections to the MCM rear panel are given in the following figure. Lethal voltages can be present at

the voltage and current terminals and it is vitally important that power is removed from both the motor

and the MCM unit prior to any connections being changed.

The three motor power voltages should be connected to the corresponding measurement terminals on

the MCM rear panel (R phase to V1, S phase to V2, and T phase to V3) using the connectors provided.

Similarly, the IR, IS, IT connections from the current sensors should be made to the appropriate current

terminal pairs, I11-I

12, I21-I22, I31-I32,

sets of phases have the correct phase relationship as the phase ordering is determined by MCM.

The order of these voltage and current pairs is not important as MCM determines the correct ordering

when CHECK MOTOR is first run on the device

on the upper part of the rear panel. It is not essential that the all three

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

5

MCM User's Manual

Protection against pickup of electromagnetic interference on the power lines:

Section 2 - MCM Installation

In order for the unit to function within the harsh electrical environments often found in switchgear

enclosures and to conform fully with emission standards, it is strongly recommended that all attached

cables be passed twice through the ferrite rings delivered with the product to their MCM sockets.

A circuit breaker should be provided on the power line in close proximity to the MCM

unit. The circuit breaker should be clearly marked as the power switch for the device.

Please note that in order to function at its full capability, MCM requires that the case be

connected using a low impedance cable (12 – 14 AWG cable is recommended) directly to a

high quality ground via the ground terminal on the power connector. If a suitable ground is not

provided, fault free operation within specifications cannot be guaranteed.

2.5 Applying power to the MCM unit

Once the motor connections have been made to the rear panel, power should be applied to the unit.

MCM requires between 85 and 240VAC obtained from a single phase, neutral and ground. At this stage,

the Power indicator at the left of the front panel will light. If this does not occur, please check that the

correct voltages have been applied.

Immediately on application of power, the LED condition indicators should briefly flash and activity should

be seen on the main display. The text "Initialising" followed by a series of dots will appear.

"Initializing.... "

After a few seconds, the display should indicate that it is in the IDLE mode. MCM is now ready for use.

When using a device for the first time the message "Bad flash data! Press Clear" may be displayed. In

this case press the CLEAR button several times until the message disappears. Once a valid learn mode

has been completed, this message should not occur again.

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

6

MCM User's Manual

2.6 Installing with soft-starter systems

MCM can be installed with standard soft-starter systems provided that they are automatically bypassed

immediately after motor start-up and during subsequent use. Un-bypassed, soft-starter systems can

introduce considerable distortion into the current waveforms and thus prevent MCM from modeling the

properties of the motor itself. If MCM is to be used with such a system, it is essential that the maximum

current limit of the starter be above the nominal running motor current so that it is bypassed effectively

during all normal operation. MCM should never be used on a system that employs soft-starters for

speed control or other un-bypassed uses. Please refer to the diagrams in the appendix for details of

the connections needed for soft starter systems. Soft-starters should always be bypassed.

2.7 Installing with inverter drives

Using MCM with inverter driven motors requires the same voltage connections specified for line driven

systems. External Hall-effect current sensors must be used with inverter systems, as normal current

transformers have insufficient bandwidth for use with the range of frequencies obtainable from inverters.

Please refer to the diagram in the appendix for details of the connections needed for inverter driven

systems.

Section 2 - MCM Installation

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

7

MCM User's Manual

3 MCM Use

3.1 Introduction

Use of MCM is both simple and straightforward once the basic concepts and principles are understood.

This section of the manual is designed to introduce these concepts and to demonstrate how MCM is set

up, how to check all the connections and settings, how MCM learns the characteristics of the system it

will monitor and finally how to actually monitor the motor system. It is recommended that first time users

read this section carefully, as successful operation requires that MCM is set up and used correctly.

Flowcharts for the main operations are provided in the appendix at the end of this manual to help users

navigate their way through the various steps involved with setting and running MCM for the first time.

3.2 The front panel

Section 2 - MCM Installation

Confirming ENTER and CLEAR:

Once the sensors have been connected and power has been applied to the MCM unit, the Power

indicator light and the Liquid Crystal Display (LCD) on the front panel should both be lit. The LCD should

display the message IDLE on the top line, indicating that the unit is idle and waiting input from the user.

When being used for the first time, the message Bad flash data! Press Clear may be displayed. The

user should repeatedly press the CLEAR button until the message disappears. Once data has been

written to flash this message should not occur again.

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

8

MCM User's Manual

Using the front panel buttons:

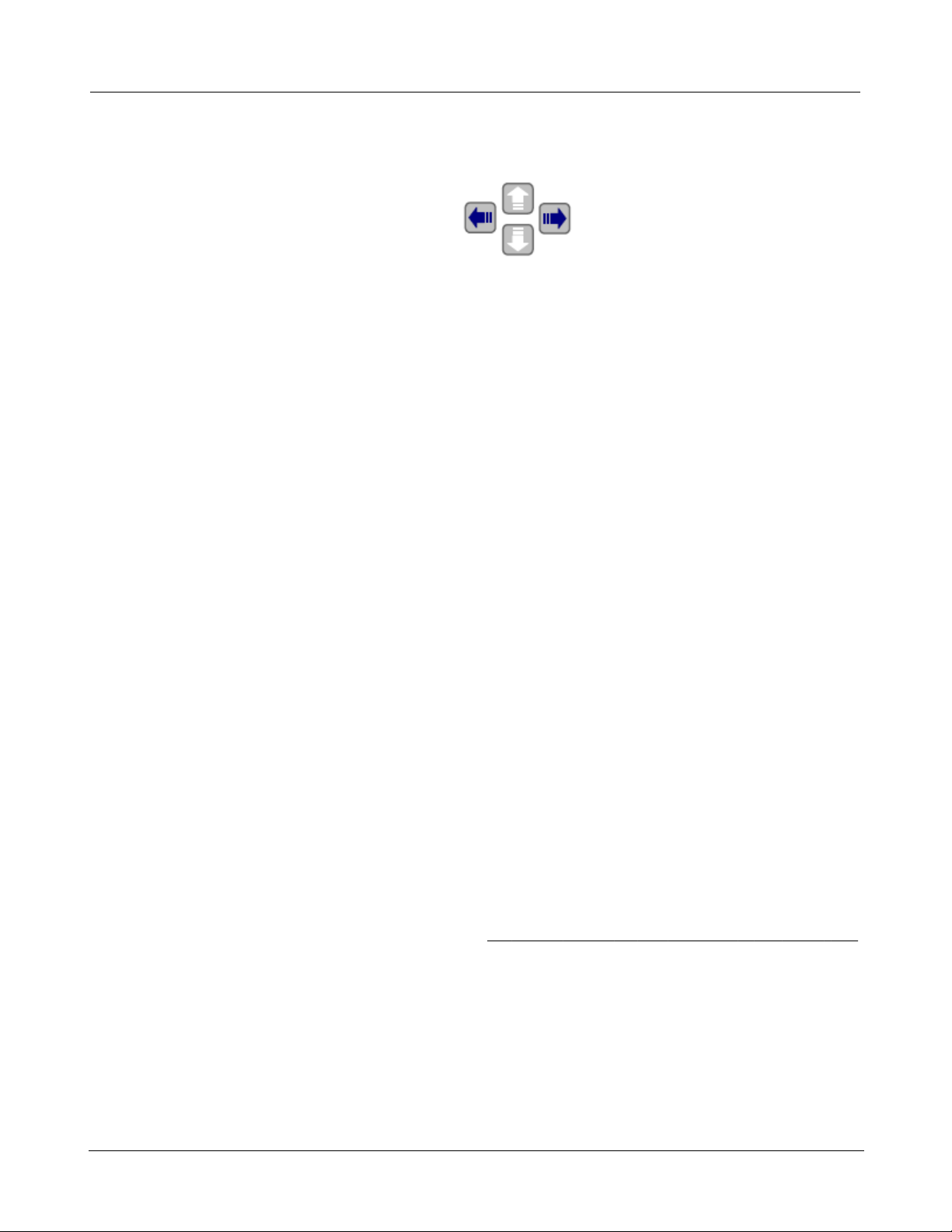

Commands are input by pressing one of the six selection buttons on the front of the unit, UP, DOWN,

LEFT, RIGHT, ENTER and CLEAR. For instance, the user can cycle through the various modes (IDLE

to CHECK MOTOR to RUN to RESUME … and finally back to IDLE), by repeatedly pressing the UP

button. A particular mode can be selected by pressing ENTER when the desired mode is displayed on

the LCD. The menus are set up on a hierarchical basis, with each level representing commands of the

same precedence which the user can cycle through by pressing the UP or DOWN buttons. Pressing

CLEAR has the effect of stopping a particular action and rising up a level in the hierarchy. Only Edit

Settings has nested hierarchy levels more than two deep. In general whenever ENTER or CLEAR is

pressed, it will be necessary to confirm the action with a second press of the button; pressing the other

button (i.e. CLEAR after ENTER and vice versa) will cancel the action.

Setting numeric values:

Section 3 - MCM Use

Similarly, numeric values can be entered using the arrow buttons. When a value is to be changed, use

the LEFT or RIGHT buttons to move the LCD flashing cursor to the first digit to be edited and repeatedly

press either the UP or DOWN buttons to scroll through the available alphanumeric characters until the

desired one is displayed. Subsequent digits can be edited by moving to the next digit using the LEFT or

RIGHT buttons and again scrolling with the UP and DOWN buttons.

A schematic diagram showing the menu hierarchy is shown in the appendix at the end of this manual.

3.3 Configuring for use

Master reset:

When first installed, the MCM unit will be configured for the default, factory settings which will need to be

changed prior to use. At later times, the factory settings can be restored by pressing and holding down

the LEFT button for about 4 seconds during power up of the device, until the string; Press ENTER for

general reset appears. At this stage pressing ENTER will initiate the reset. Pressing any other button

will cause the reset to be ignored and the device will continue.

3.3.1 Entering the password

To configure the unit, select the Edit Settings mode and press and confirm ENTER. In order to proceed

further, it will be necessary to enter a password. The factory setting for this password is the string “m“

and can be entered using the UP and DOWN buttons to cycle through the alphanumeric characters (‘a’

through ‘z’, ‘0’ through ‘9’). The LEFT and RIGHT buttons are used to shift the active character in the

string. To input the password “m”, repeatedly press the UP button until the letter ‘m’ appears in the first

position. Press and confirm ENTER and then press ENTER again to enter the Edit Settings menu.

It is recommended that at a later time the password be changed, in order to prevent unauthorized

access to the device.

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

9

MCM User's Manual

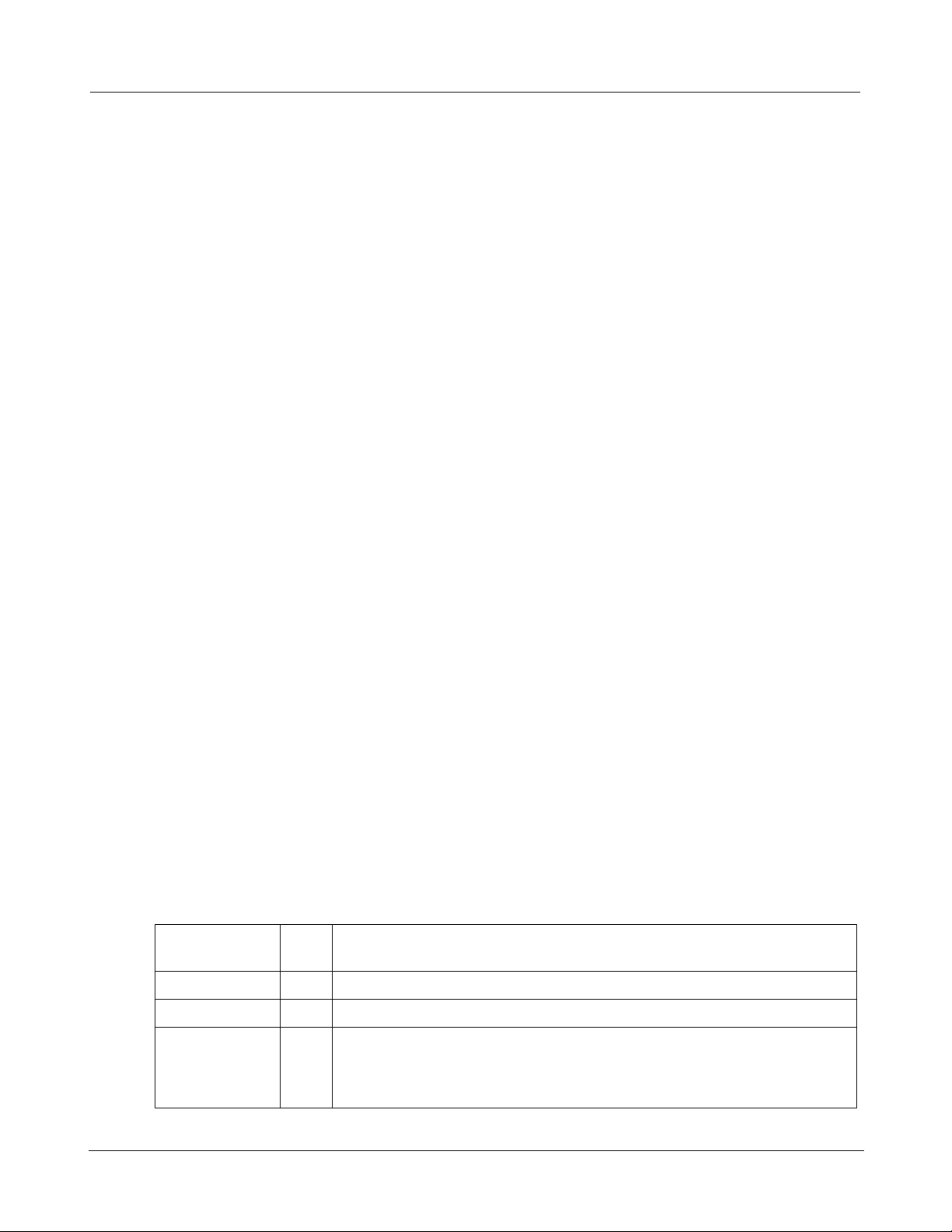

Motor values

Harmonic values

Comm. settings

Motor settings

Calibration

Alarm thresholds

Versions

Run settings

Phase Ordering

Change password

3.3.2 The Edit Settings menu

At this level the following Edit Settings menu items are accessible:

Editing and displaying menu items:

Please refer to the appendix for a table of these menus and their sub-menu items. To edit a particular

item, first select the item to edit and press and confirm ENTER. As before use the UP and DOWN

buttons to scroll vertically through individual digits and the LEFT and RIGHT buttons to change the digit

being edited. Some variables can only take discrete values represented by character strings and in this

case vertical scrolling will shift through the allowed values. For example, the Parity value under the

Communications settings menu can only have the values EVEN or ODD and scrolling will repeatedly

cycle through these values.

Section 3 - MCM Use

Menu paths:

Throughout this manual, paths to menu items are represented by the word MENU: followed by the list of

sub-menus required to reach the item separated by a forward slash. For example the path of the Parity

value given in the preceding paragraph would be given as:

MENU: Edit Settings / Password / Comm. Settings / Parity

The forward slash can be thought to represent the action of pressing and confirming ENTER.

Local Lockout and passwords:

Some modes can be protected for supervised access by setting the local lockout setting.

MENU: Edit Settings / Password / Run Settings / Local Lockout

If this mode is set, access to the following modes is password protected:

(i) CHECK MOTOR

(ii) RUN

(iii) RESUME

(iv) UPDATE

In addition, canceling any of these modes by pressing CLEAR also requires the user to supply a

password. All passwords are the same as that used to access Edit Settings.

3.3.2.1 First time use

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

Before MCM can be used for the first time it is necessary to change various settings from their default

values (a table outlining the MCM settings is shown in the appendix). Values relevant to the connected

motor must be set for the quantities described in the following sections.

10

MCM User's Manual

3.3.2.2 Calibration factors

Hall-effect current sensors and assemblies supplied with MCM should be accompanied by a calibration

document containing the sensor’s calibration factor. The values of each calibration factor should be

entered into the correct setting under the Calibration menu. It is important that the correct factor be

entered for each channel, as MCM will not function correctly if the calibration factors are incorrect.

For channels connected to transformer sensors, the calibration factor should be equal to the nominal

ratio of the primary to secondary turns. For example a 100A current transformer with a 5A output and a

single primary turn would require a calibration factor of 20. The same transformer with two primary turns

would require a calibration factor of 10. A 6500V voltage transformer with a nominal secondary voltage of

100V would require a calibration factor of 65. Any channel connected directly to the motor without an

external sensor (i.e. voltage connections on low voltage units) requires a calibration factor of 1.

3.3.2.3 Motor settings

Nominal voltage, current and frequency:

The nominal voltage, current and speed (in rpm) of the attached motor must be entered under the Motor

Settings menu. These values can be obtained from the motor specifications. MCM uses these values to

determine whether the motor complies with its specifications and incorrect values are likely to raise

alarms. The nominal line frequency (or most commonly expected frequency in the case of an inverter)

should also be set. Similarly, the motor connection type must be set to one of Star or Delta.

Section 3 - MCM Use

3.3.2.4 Communications settings

Setting the device address:

If the MCM networking options are to be used, the MCM network address must be supplied. By default

this is set to 0, which by convention is the address of the host terminal. Use of this address will

therefore disrupt communications over the network and must be changed prior to connection. Any

address between 1 and 255 can be selected although it is important to check that the selected address

is not in use by any other device on the same node. Please refer to the MCMViewPro networking

documentation for full details of address selection.

It is recommended that the motor serial number (or any other short identifier string) be entered as a

means of identifying the motor to the software. This is not obligatory, and both the networking software

and MCM can function without this information.

Other communications settings:

All other communications settings should be left at the factory defaults if the MCMSCADA networking

software is being used. If another software package is employed (i.e. SCADA software), please refer to

its documentation for communication settings.

MCM can use both 2 and 4 wire (RS 422 and RS485 standards respectively) communications at up to

19200 Baud. Please refer to section 4.4.12 for further information.

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

11

MCM User's Manual

STATUS

STRING

LED

No

Fault Severity

LEARN

MCM has insufficient data to assess the status of equipment

NORMAL

1

Motor is healthy or level of failure is under alarm thresholds

WATCH LINE

2

There is a changing on the supply voltage of the motor. Temporary

changes in supply voltage cause this alarm. If alarm is persistent check;

harmonic levels, capacitors, isolation of cables, motor connector or terminal

slackness, loose contactors, etc.

3.4 Running MCM

3.4.1 Introduction

Having configured MCM for a particular motor, it can now be used for its intended purpose of monitoring

and assessing the condition of the motor. In general, this involves first running MCM to measure and

learn the properties of the motor and then running MCM in its test mode to perform the actual

monitoring. Without the learning period MCM has insufficient information on which to base its

decisions as the motor ages and will not perform to its specifications. For this reason, MCM

ensures that a valid learning period is first performed before allowing the user to request the device to

monitor the motor.

3.4.2 Alarm messages and status indication

Alarms specific to the motor:

MCM divides warning messages into the categories of warnings, alarms and errors. Warnings inform the

user that non-critical conditions have arisen that the user should be aware of but do not affect the

performance of MCM. Alarms provide information specific to the motor being tested and are indications

of faults caused by incorrect connections to the motor, the supplied line voltage and/or motor currents

being outside the specified limits and other conditions that prevent MCM from correctly determining the

state of the motor. Alarms do not cause MCM to stop monitoring completely, but generally are

indications that there is something that needs to be investigated and possibly changed before MCM can

function to its full extent. In some cases an alarm may indicate a transient event such as high line

voltages, which although damaging to the motor in the long term, do not indicate an immediate need for

action. Of course if the frequency of such events is sufficiently high, the cause should be located and

corrective action taken to remedy the problem. It is important to realize that when an alarm is

displayed, MCM cannot monitor the motor status. It is therefore important to ascertain the cause of

the alarm at the earliest opportunity.

Section 3 - MCM Use

Viewing alarm messages:

An alarm is indicated on the front panel of MCM by the message Alarm followed by a hexadecimal value.

The bits of the hexadecimal value refer to which alarm is raised. Repeatedly pressing the RIGHT or

LEFT buttons cycles through a list of all active alarms. Please refer to the appendix for a complete list of

possible alarm conditions and their remedies. The measured physical motor values can be viewed during

an alarm by pressing the UP or DOWN buttons. This is often useful in determining the reason for an

alarm.

Fault status indication:

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

12

MCM User's Manual

WATCH LOAD

3

There is a possibility of load changing : If the process load has not been

altered deliberately, check for leakage, valve & vane adjustment, pressure

gauge faults, manometer, dirty filters (fans, compressors). If the process is

altered deliberately, MCM/PCM should be updated.

EXAMINE 1

4

Plan Maintenance ( First Level Alarm) : There are developing mechanical

and/or electrical fault(s). Although the level of the failure is not serious, the

maintenance should be done in next planned stop or latest in 3 months

EXAMINE 2

5

Do Maintenance (Second Level Alarm) : There are developing

mechanical and/or electrical fault(s).Maintenance and corrective action

should be performed as soon as possible.

When monitoring a motor in test mode (MONITOR, IMPROVE or UPDATE), MCM provides a status

indication on the right side of the upper display line. This consists of one of the items in the table above.

In addition, one of the five LED indicators on the front panel is lit showing the color corresponding to the

motor status in the table above. As with all grading schemes, there is always some overlap between the

bands and it is possible for a healthy motor sometimes to indicate a fault severity greater than 1.

However, in healthy motor systems such false alarms should be transitory and prolonged display of a

fault should indicate the need for maintenance. A prolonged fault indication should always be

investigated.

Section 3 - MCM Use

3.4.3 Running CHECK MOTOR

On first use of MCM and each time any maintenance is performed on the motor, it is essential that the

motor together with its connections are checked by running the CHECK MOTOR function. In this mode

MCM performs a short check on all motor connections to determine the phase ordering and that a motor

is connected and running. It also checks among other things, that the voltage and current levels are

within set limits, and that the phase angle between the V1 and I11 - I

detects that some condition is not met, an alarm is raised which the user should investigate and remedy

before proceeding further.

Check mode command:

The CHECK MOTOR mode is entered using the menu item:

MENU: Check Motor (/ Password )

Please note that if the Local Lockout setting is ON it is necessary to supply a password before access

to the CHECK MOTOR mode is granted. The password is the same as used to access the Edit Settings

menu.

Once CHECK MOTOR has finished, it will display either the message "Motor values" or a warning or

alarm indication. At this point the UP and DOWN buttons can be used to cycle through a list of

calculated physical parameters. If an alarm is present, pressing LEFT or RIGHT buttons will cycle

through the list of alarms. Many of the alarm conditions relate to the calculated physical values and it is

often useful to check the calculated values of the relevant parameters when trying to understand the

origin of an alarm condition. Pressing CLEAR will return to the IDLE state.

channels is appropriate. If MCM

12

The software utility MCM Config found on the companion cdrom, can be of help diagnosing problems

during initial Edit Settings. The program should be installed on a portable pc and the pc connected (via a

RS232 - 485 converter) to the communications port on the rear of the MCM device. Using the software it

is possible to upload and display the voltage and current waveforms measured by MCM. Inspection of

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

13

MCM User's Manual

these waveforms can reveal problems caused by missing phases, phase ordering, phase imbalance etc.

Please refer to the MCM Config documentation and to the trouble shooting section of this manual for

further details.

3.4.4 Setting and checking the input connections

When the CHECK MOTOR menu option is selected, MCM first determines the relative order of the

voltage phases using the V

channel pairs in the correct order and polarity. The order determined by MCM can be displayed by

entering the EDIT SETTINGS menu and selecting:

MENU: Edit Settings / Phase Ordering / Phase Order

On this menu, the voltages are denoted by the letters R, S, T and currents by r, s, t. A – sign preceding

each letter indicates that the corresponding signal has an extra 180º of phase shift (i.e. that the polarity

of the signal is reversed). Similarly, a + sign preceding a letter indicates that the polarity is correct. For

example:

The above phase ordering display would indicate that relative to the first voltage (R) phase on input V1,

the S and T phases (on V3 and V2 respectively) are reversed. The order of the current inputs is also

incorrect with IS connected to I

polarities of the two currents, IS and I

Please note that once MCM has determined the correct phases, the user should not change the input

connections without running CHECK MOTOR again.

channel as an arbitrary reference. It then attempts to place the current

1

11 - I12, IR

connected to I

have been reversed (I

T,

21 - I22

and IT connected to I

has been exchanged with I

11

31 - I32

Section 3 - MCM Use

. Furthermore, the

12

and I

with I32).

31

The algorithm used by MCM to determine the phase order yields two solutions depending on the motor

loading and extra information is required to obtain the correct sequence. To this end, MCM compares

the measured RMS values for the currents with the nominal current entered by the user. If the ratio of the

measured current to the nominal current is greater than the value of the Load threshold (expressed as a

percentage), the motor is assumed to be working under loaded conditions and the appropriate solution is

chosen. Otherwise the motor is assumed not to be loaded. It is thus important to enter an accurate

value for the nominal current. Even so, it is still possible for MCM to choose the wrong solution which will

yield unrealistic values for the phase angle when the loading on the motor changes in use. MCM

provides the possibility of overriding the detected phase sequence from the menu item Order Override

under:

MENU: Edit Settings / Phase Ordering / Order Override

Changing the value of this item from OFF to ON allows the detected phase ordering to be altered by

moving the cursor to the required position and scrolling UP/DOWN to select the desired value.

It is also possible to fine-tune the algorithm by altering the value of the load threshold. A higher value will

tend to favour the unloaded solutions and vice versa. The load threshold can be found under:

MENU: Edit Settings / Alarm Thresholds / Load threshold

3.4.5 Running LEARN and IMPROVE

LEARN:

MCM should learn the motor under normal operating conditions. The LEARN period consists of a preset

number of data acquisition cycles and periods of data analysis. Once the preset number of cycles has

been reached, the acquired and pre-processed data are further processed to produce a database

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

14

MCM User's Manual

consisting of a collection of data sets representing the behavior of the motor system under the load

conditions that the motor has met in practice. It is therefore important to have the motor operating under

its expected running conditions during a learning period. In order to cover adequately the range of load

conditions experienced by a motor system, a sufficient number of acquisition cycles or iterations is

required. It has been found that 4000 iterations provides adequate coverage under most conditions and it

is recommended that between 3000 and 4000 iterations are used. Since additional learning can also be

performed if needed during the testing phase, a larger number of learning iterations is not generally

required. The number of learning iterations can be set from the menu path:

MENU: Edit Settings / Password / Run settings / Learn iterants

IMPROVE:

Selecting RUN from the main menu will initiate a new LEARN period. If data from a previous leaning

period exist, the following message will be displayed:

"Lose learn Data? Clear to exit"

The user should press the CLEAR button if it is not desired to overwrite the existing data and ENTER if it

is.

Once the initial learning period is complete, the MCM unit automatically will try to improve its estimation

of the motor characteristics. To update the database obtained during the learning mode for different load

and line conditions until sufficient data have been amassed, as determined by the number of Improve

iterations set from the menu path

Section 3 - MCM Use

MENU: Edit Settings/Password / Run settings / Improve Iterations

It is recommended that this value be set to between 8000 – 10000 iterations.

An important difference between this mode and the initial learning period is that MCM monitors the motor

status during IMPROVE but does not during LEARN.

Once the IMPROVE stage is complete, the MONITOR phase will automatically continue without user

intervention. This is the main operating mode and MCM is expected to spend most of its time in this

mode monitoring attached motor systems. In order to start monitoring, MCM must first have learnt the

characteristics of the motor it is to monitor and have a valid learning mode.

Iteration cycle time:

In general a data processing cycle takes between 60 – 120 seconds depending on several factors.

Firstly, MCM requires relatively unchanging data over a minimum time period during its data acquisition

phase and will repeat the data acquisition until it obtains stable data, thus varying the iteration time

cycle. If the amplitude or frequency of the voltage and current phases varies excessively and stable data

cannot be found, an alarm is raised. Secondly, if harmonic values are being calculated, extra processing

cycles are required. Finally, if MCM encounters an error, it may repeat the cycle several times.

Please note that if the Local Lockout setting is ON it is necessary to supply a password before access

to any learning or monitoring mode is granted.

Once started, the monitoring process will continue until one or other of the following conditions is

fulfilled:

1. An error condition is generated and cancelled

2. The user presses the CLEAR button to cancel the process. In order to prevent unauthorized access, if

the Local Lockout setting is set a password must first be entered.

3. Power to the MCM unit is cut.

Alarms during the monitoring process:

Alarm conditions may occur during any monitoring phase. If CHECK MOTOR has previously been run on

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

15

MCM User's Manual

the motor, it is likely that the alarms represent transient conditions present on the power lines. However,

it is suggested that any alarm representing a condition that could affect the performance of the motor

should be recorded and investigated as a potential cause of motor degradation. As in CHECK MOTOR, if

an alarm is indicated, the most recent physical values available for the motor can be displayed using the

UP and DOWN buttons. Examination of these values can often indicate the precise reason for the alarm

condition. A complete list of alarm conditions can be found in the appendix at the end of this manual.

Using an inverter drive:

If an inverter is being used to drive the motor, several additional precautions are needed. The voltage

frequency is expected to be constant (within well defined limits) for direct line driven motors, but can vary

considerably when an inverter is used. MCM can handle the range of frequencies typical of an inverter,

but first needs to learn the motor at a single frequency representative of the conditions it will meet in

practice. The value of this dominant frequency must be entered from the Edit Settings menu. If MCM

measures the frequency to be out of the expected range, it will issue an alarm in both the CHECK

MOTOR and LEARN modes and the user should adjust the frequency setting accordingly. During

IMPROVE, UPDATE and MONITOR, this requirement is relaxed and the frequency can assume any

value within the allowed frequency range. Please note that MCM is not suitable for following

applications :

1.

If motor supply voltage is changing over 15% in 6 seconds,

2.

If motor current is changing over 15% in 6 seconds,

3.

DC motors,

4.

If motor is driven by a inverter whose chopping frequency is under 2 kHz.

Section 3 - MCM Use

3.4.6 Running RESUME and UPDATE

Canceling running:

All the operating modes LEARN, IMPROVE, MONITOR and UPDATE can be stopped and started at

any time without significant effect on monitoring performance, by pressing the CLEAR button (and

providing the correct password if Local Lockout is ON). Subsequent restart of MCM can be achieved by

selecting RESUME from the main menu, which will cause MCM to continue in its incomplete mode at

the point of interruption. Thus if it is necessary to stop MCM for any reason, it can be restarted without

affecting any existing data.

UPDATE:

At subsequent times it may be desirable to learn a new operating point of the motor. This can be done

using the UPDATE function. This can be reached either from the main menu in IDLE mode or by

pressing first the RIGHT and then the ENTER button during MONITOR.

Updating the internal database:

When MCM first starts in the MONITOR, IMPROVE or UPDATE modes, it has insufficient data to

indicate the motor status accurately. Under such conditions a blank string may be displayed instead of

the motor status. This is a temporary condition and should last only for the first data cycle. As a result

of internal error handling, the blank string may occasionally be seen. Again, this is temporary and will

pass by the start of the next data cycle.

Although MCM should have met the majority of working conditions in the learning mode, it is still

possible for it to fail to recognize a particular working point. In such a case, the user can elect to add the

current operating point to the internal database using the UPDATE feature. Running UPDATE will cause

the internal database to be updated with the new information over a preset number of cycles. Once the

count of iterations exceeds the preset number, MCM will automatically return to MONITOR without user

intervention. The number of update cycles can be set from

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

16

MCM User's Manual

MENU: Edit Settings / Password / Run settings / Update iterations

If it is necessary to learn the new operating conditions of the motor in order to add them to the existing

database, UPDATE can be started in two ways. Firstly, in IDLE mode, the Update option should be

selected and ENTER pressed. Secondly, from MONITOR, the RIGHT button should be pressed to

display the message:

"Press ENTER for UPDATE"

and then ENTER pressed to select the mode.

As in the learning mode, sequentially pressing the UP or DOWN buttons allows the user to select and

display the most recent values for the parameters calculated by MCM.

3.4.7 Advanced use

It is possible to customize the behavior of MCM by adjusting various settings. As usual a valid password

must be supplied before the Edit Settings menu can be entered. The following table summarizes the

settings that can be changed together with their significance. It is recommended that the original values

of each setting be recorded prior to changing them. After changing certain settings it may be necessary

to relearn the motor.

Section 3 - MCM Use

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

17

MCM User's Manual

Settings functions and their use

Menu group

Setting

Usage

Harmonic

values

Harmonic calc

Switch on/off calculation of harmonic values. Note that the

calculation of harmonic values can significantly lengthen the cycle

time

Signal select

The channel number (1-6) of the channel to be used for harmonic

calculations

Calibration

Calibration

The calibration constants for the sensors on each channel

Alarm

Thresholds

Voltage balance %

Maximum permitted voltage imbalance

Current balance %

Maximum permitted current imbalance

Voltage range %

Maximum voltage range

( as ± percentage range around nominal)

Max Current%

Maximum permitted current upper limit

( as percentage above nominal)

Low voltage %

Minimum acceptable level below which voltage is considered to be

zero for line and power fault alarms ( as percentage of nominal)

Low current %

Minimum acceptable level, as percentage of nominal, below which

current is considered to be zero for motor not running alarm

Load threshold %

Used by the phase ordering algorithm to set the loading threshold.

If the ratio of actual current to nominal current is more than the

value of the Load threshold (in %) then the motor is considered to

be working under load and the appropriate phase ordering selected.

Otherwise the motor is assumed to be unloaded

Run settings

Learn iterations

The number of data acquisition iterations required for a LEARN

period. A value between 3000 – 4000 is recommended

Improve iterations

The number of data acquisition iterations required for the

IMPROVE phase. A value between 8000 – 10000 is recommended

Update iterations

The number of data acquisition iterations required for an UPDATE

phase. A value between 1000 - 2000 is recommended

Flash update rate

MCM does not update the flash with new values at each iteration,

as this could shorten the flash lifetime. On the other hand, the

longer data are stored in volatile memory, the greater the potential

for data loss if power fails. As a compromise, the user can set a

suitable time (measured in complete iterations) after which all

outstanding data are automatically saved to flash

Local lockout

When this setting is on, passwords have to be supplied in order to

start or quit a Check Motor or Monitor modes. Its purpose is to

prevent any unauthorized tampering with MCM. Remote

commands over the serial line are unaffected

Relay thresholds

Set the fault level for activating the output relay in MONITOR mode.

If set, the relay is triggered by a change from a lower to a higher

fault level any time the level is equal to or above the set level

Current stability %

When obtaining data, MCM requires relatively unchanging current

signals. If the variation in the amplitude of the current exceeds this

threshold, MCM will reject the data. The alarm UNSTABLE LINE is

often seen when the current stability is set too low

Section 3 - MCM Use

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

18

MCM User's Manual

Displayed parameter

Unit

Admittance

A/V

Phase angle

º

Power factor

-

Active power

W

Voltage balance

%

Current balance

%

V1 RMS

V

V2 RMS

V

V3 RMS

V

I1 RMS

A

I2 RMS

A

I3 RMS

A

Line frequency

Hz

Fit Parameter 1

-

Fit Parameter 2

-

Total Harmonic Distortion (THD)

%

1st – 13th Odd harmonic levels

%

Monitoring motor and line parameters:

In all operating modes (and after CHECK MOTOR has finished), it is possible for MCM to display

selected parameters. Sequentially pressing the UP or DOWN buttons allows the user to select to

display the most recent values for the parameters in the following table:

Section 3 - MCM Use

3.4.8 Equipment Faults and Their Diagnoses Using MCM

MCM uses a model based fault detection and diagnostics technique. In this technique, the expected

dynamic behavior (model) of the three phase system under varying conditions, such as load, is

determined and compared with the measured dynamic behavior to monitor abnormalities. MCM first

learns the system for a period of time through acquiring and processing the real-time data from the

system. The data is processed using system identification algorithms for the calculation of expected

dynamic behavior and the model parameters. The changes in the parameters of the system indicate to

abnormalities developing in the system. Further processing of these parameters is used for diagnosis.

As opposed to traditional vibration and current signature analysis, this approach uses a cause-effect

(input-output) relationship and therefore immune to the surrounding noise or noise in inputs. Also the

difference between expected and actual behavior filters out and enhances ONLY abnormalities generated

by the system which allows to earlier and accurate warnings. The expert system approach eliminates

the needs for data base or record keeping, expert personnel, time consuming data gathering and

analysis. It provides comprehensive (mechanical and electrical as well as driven system) fault coverage

though it measures only voltages and currents.

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

19

MCM User's Manual

MCM uses the electric motor of the equipment as a sensor. Therefore, any fault of the equipment that

affects the motor or the three phase system is also observed by MCM.

MCM first learns the motor-based system for a period of time by acquiring and processing the motor

data. The results of the processed data are stored in its internal database and a reference model is

established. This reference model basically consists of model parameters, their mean values and their

standard deviations. While monitoring, MCM processes the acquired motor data and compares the

results to the data stored in its internal database. If the results obtained from the acquired data are

significantly different from the reference model, MCM indicates a fault level. The level is determined by

taking into account the magnitude and the time duration of the difference. In total, MCM monitors and

compares 22 different parameters (model parameters). These parameters are classified into three

groups, electrical parameters, mechanical parameters and fit parameters. These are explained in detail

in the following sections.

1. Electrical Parameters

There are 8 parameters in the first group which are called electrical parameters. These are the network

equivalent parameters and are correlated to the physical parameter of the motor, like inductances,

resistances, etc. They are sensitive to electrical faults developing in the motor. MCM evaluates and

analyzes the differences between the model parameters at any instant and the average value of the

same parameters that are obtained during the learn stage. These differences are normalized with respect

to their standard deviations obtained during the learn stage. Hence the values indicate the number of

standard deviations they are away from the average values obtained during the learn stage. If they

exceed threshold values, than an alarm is given. The changes in their values are associated with the

faults that are developing in the system. As an example an isolation problem in winding will affect the

parameters associated with resistances. Their change will allow MCM to detect the isolation problem at

an early stage. Though they are primarily used to detect electrical problems, they also can indicate

mechanical problems as well. As an example an imbalance or gear problem would cause dynamic

eccentricity in the air gap. This eccentricity will cause a change in the induction parameters and

therefore in the model parameters. By monitoring the changes in these model parameters imbalance can

be detected at an early stage. This eccentricity eventually affects bearing and it will also eventually

damage the bearing. Therefore its detection at an early stage can prevent further damages

Section 3 - MCM Use

The electrical parameters are further classified in two groups, E1 (internal) and E2 (external)

parameters. Electrical parameters 1-4 (E1) indicate problems associated with rotor, stator, winding etc.

while 5-8 (E2) indicate electrical supply problems such as voltage imbalance, isolation problem of

cabling, capacitor, motor connector, terminal slackness, defective contactors etc.

2. Mechanical Parameters

The parameters in the second group are sensitive to mechanical faults such as load imbalance,

misalignment, coupling and bearing problems. They are called Mechanical Parameters 1-12. These

parameters are obtained from the frequency spectrum of the electrical signals by extracting information

from the line current and voltage supplied to a motor. The variances in the stator-rotor air gap are

reflected back in the motor’s current through the air gap flux affecting the counter electromotive force.

Therefore current carries information related to both mechanical and electrical faults. Hence faults will

exhibit a change in the frequency spectrum of the current in specific frequencies.

MCM uses the power spectral density (psd) obtained from the differences between the expected current

obtained from the model and the actual current. These differences include only abnormalities generated

by the motor. Therefore, they are immune to the noise or harmonics present in the supply voltages. The

mechanical parameters indicate the power level of the difference between measured and estimated

current at frequencies they occur in terms of number of standard deviations. If they exceed the threshold

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

20

MCM User's Manual

Bit

Value

Condition

0

1

Voltage values are outside the range encountered during the learning

phase.

1

2

The vector sum of the three phase voltages (voltage balance) is out of

the range encountered during the learning phase.

2

4

Fluctuations in the three phase voltages have changed in comparison

with the fluctuations encountered previously over a moving window

3

8

Loading conditions are different from the loading conditions encountered

during the learning phase.

value, which is 8, an abnormality is indicated.

The mechanical parameters (M1-M12) correspond to the 12 maximum values obtained in the frequency

spectrum. These parameters are also used for diagnoses. The frequencies they occur indicate the type

of fault, i.e., an imbalance, loose foundation, oil whip, fan blades, inner or outer race of bearing etc.

These parameters provided to the user for trending and diagnostic purposes.

3.4.9 Interpreting MCM fault indications

3.4.9.1 MCM status values

MCM employs two different measures for calculating the motor status: Motor Status 1 and Motor Status

2. In addition to these, MCM also monitors load and line changes and summarizes the results of this

monitoring via the Load line status parameter. Motor Status 1 monitors the maxima of each of the three

groups of parameters introduced in the previous section, over a window (with a default window size of 14

iterations in a monitoring mode) and compares them with four different internal thresholds calculated

following the initial learning phase. Motor Status 1 takes value between 1 to 5 and is calculated as

follows:

Section 3 - MCM Use

Motor Status 2 also takes values between 1 and 5. The calculation of Motor Status 2 is based on

counting the frequency of the values of Motor Status 1, that are greater than one, and the frequencies of

any load and line changes over larger windows. Window sizes and frequency thresholds used for the

calculation of Motor Status 2 are selected so that temporary a change in Motor Status 1 does not cause

any change in Motor Status 2.

The Load line status parameter of MCM takes values between 0 and 15. Its possible values correspond

to combinations of the bits of a binary number, with each bit having the significance given in the following

table:

Thus a Load line status value of 9 would result from the arithmetic sum of 8 and 1, and would correspond

to conditions 0 and 3 holding and conditions 1 and 2 being false. This would mean that both the voltage

values and the loading conditions differ from the conditions met during the learning period but that the

voltage balance and voltage fluctuations were consistent.

The motor status values displayed on the front panel of the MCM unit and reported by the MCMSCADA

monitoring software are actually the values of the Motor Status 2 parameter. Motor Status 1 is not

available from the front panel and can only be monitored using the trending plots of MCMSCADA. The

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

21

MCM User's Manual

LED indicators on the front panel of MCM correspond to the values of Motor Status 2, starting with OK

(value of 1) on the left and increasing up to Examine 2 (value of 5) on the right.

3.4.9.2 Changes in line voltages

Motor status alarms associated with the changes in the line conditions are indicated by the "Watch

Line" message on the front panel, the second (3.) LED indicator being lit and Motor Status 2 having the

value of 2. They are usually temporary in nature and generally the user does not need to take any action.

However, it is recommended that when this status level occurs, the user should at least assess the

extent of the change in the line conditions, as significant changes in the line voltages and currents may

be dangerous to the motor. If the line status change is persistent, the user should assess the root cause

of this change. For instance, it may be due to a problem in the contactors or for inverter driven motors

the settings of the inverter may have been changed. In any case, if the root cause cannot be remedied

easily and quickly and the new voltage supply condition presents no danger to the motor, the user has

the option to send MCM to the UPDATE mode. This will allow MCM to learn the new voltage supply

conditions, after which the status will eventually return to normal.

3.4.9.3 Load changes

Motor status levels associated with changes in the loading conditions occur with the "Watch Load"

Message on the front panel, the second (orange) LED indicator being lit, and Motor Status 2 taking a

value of 3. They are also temporary in nature but they should be treated more carefully than line

changes, as some faults developing in motor based systems can cause changes in the loading

conditions. For instance, leakages from pump seals can cause pressure drops, which will be interpreted

by MCM as changes in the loading conditions. Similarly, clogging in a pipe or membrane or an increase

in the friction of moving parts will be detected as changes in the apparent load. It is, therefore, important

to assess the root cause of the load change. In certain cases, (for instance, closing or opening a valve or

changing a pipe), the changes in the loading conditions are intentional and should already be known by

the user. In such cases, the user should send MCM to the UPDATE mode so that it will learn the new

loading conditions. When no obvious cause can be found, it is likely that a fault is indeed developing and

the situation should be monitored more carefully.

Section 3 - MCM Use

3.4.9.4 Error messages

Unlike alarms, errors refer to failures of the MCM hardware and software rather than the monitored motor.

When MCM discovers an error condition it makes several attempts to recover, and only if these attempts

are unsuccessful is an error message generated. All errors stop MCM from functioning and must be

cleared before proceeding further. Errors are indicative of a serious problem within MCM and their source

should always be investigated. An error indication consists of two parts: Firstly the displayed error

string; and secondly the associated error number. When reporting device malfunctions, please be sure

to include both the message and its associated number. Please refer to the appendix for a full list of

error messages.

Viewing error messages and numbers:

MCM indicates an error to the user by the string Error on the first line of the display followed by the error

string on the lower line. Pressing the RIGHT or LEFT buttons will display the error number.

Canceling errors and Performing a master reset:

Pressing the CLEAR button will cancel the error and return to IDLE in most cases. If the error occurs

during an error recovery operation it will not be possible to cancel the error in this manner but will require

a full master reset. This is accomplished by holding down the LEFT button, whilst simultaneously either

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

22

MCM User's Manual

Relay output absolute maximum ratings

Current (A)

Voltage (V)

0.6

110 (AC)

2.0

30 (DC)

switching on the device power or pressing and releasing the reset button at the rear of the device. Note

that the unit must be in the IDLE state before removing the power or pressing the reset button or this

procedure will not work. The button must remain held down for at least four seconds until the message:

"Press Enter for general reset"

appears on the display. At this point ENTER should be pressed to perform the reset. If this does not

clear the error, it is likely that the MCM device is experiencing a hardware fault and that the unit should

be returned for servicing.

Please note that performing a hardware reset in this manner resets all settings to the factory

defaults and all previously saved information will be lost. This includes all learning mode and

Edit Settings data, so a hardware reset should be used only as a last resort.

3.4.9.5 Using the relay output

MCM is equipped with two connections on the rear panel internally connected to a low power, normally

open relay. Closure conditions of the relay can be programmed from

MENU: Edit Settings / Password / Run settings / Relay Threshold

Section 3 - MCM Use

and selecting the desired fault level. During MONITOR, IMPROVE and UPDATE, the relay will become

active anytime the fault level rises above the selected relay level, and the following message will be

displayed:

"Relay active"

When the relay is active and the previous message displayed, pressing the LEFT or RIGHT buttons

cycles through the messages:

"Acknowledge"

"Reset relay"

Pressing the CLEAR button while either of these messages is displayed deactivates the relay. Selecting

Acknowledge will cause the relay to activate again only when the motor status exceeds the current value

whilst Reset relay will allow the relay to activate again when the same preset conditions are next met,

possibly as soon as the next data cycle.

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

23

MCM User's Manual

Relay output states

State

Relay Contacts

NO

COM

NC

COM

Relay active

Closed

Open

Relay inactive

Open

Closed

RS 422 port connections

Pin

Description

Notes

1

Receive A

Rx+

For 2-wires connect to Tx+

2

Receive B

Rx-

For 2-wires connect to Tx-

3

Transmit A

Tx+4Transmit B

Tx-

5

Common

0

Optional connection to local

ground via 100 Ω resistor

3.4.9.6 Connecting to the serial port

MCM can be connected to a PLC or other monitoring system such as MCMSCADA via the RS485 port

on the rear of the device. Artesis A.S. makes available its proprietary protocol on request in document

MCM-OP-SI-EG-0002 entitled MCM System Communications Protocol Document for End Users. Please

contact Artesis A.S. to obtain this document.

Section 3 - MCM Use

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

24

MCM User's Manual

Connecting devices to a RS422 4-wire network

Section 3 - MCM Use

MCM uses 2 or 4-wire RS 422/RS485 communications with optically isolated (to 2500V) inputs and

outputs. MCM is configured as a slave device and needs to be addressed before it will communicate over

the bus. It will support communication rates of up to 19,200 Baud over distances exceeding 1000m, but

this rate can be degraded if the environment is especially noisy.

For 2-wire connections, each terminal pair Tx+ - Rx+ and Rx- - Tx-must be connected together on

each MCM device. In some cases, particularly with slow PC hosts that do not release the transmit line

rapidly; it may be necessary for the MCM device to delay its response. This can be achieved by

adjusting the value of the menu setting:

MENU: Edit Settings / Comm. Settings / Response Delay

In the diagrams given above, the terminals marked 0 on each MCM device are connected together and

with the 0 terminal on the converter. Internally, these terminals are connected to the local ground via 100

Ω resistors. This optional connection is provided in order to have a quality return path for the differential

signals, which can in some circumstances reduce noise and lead to better communications. In cases

where the ground quality is adequate, this connection can be left unused. Similarly, terminating resistors

between the terminals on the last device in the daisy chain (star topologies are not recommended) are

indicated. These resistors (typically of value 120 Ω, depending on the impedance of the cable used)

may not be needed in short networks with few devices, but at higher baud rates and as the network

length increases, their inclusion becomes essential.

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

25

MCM User's Manual

4 Troubleshooting

4.1 Introduction

During installation and running a number of checks should be made to ascertain whether the MCM unit

is performing correctly and to determine possible causes if not.

4.2 Use of the MCM Config utility

The MCM Config software is a simple test utility provided by Artesis for examination of waveforms, and

can connect to a single MCM unit using the RS485 serial line on the rear of the instrument. If a network

is available, MCM Config can be installed on the host computer, otherwise a portable laptop machine

equipped with a suitable RS232 – 485 converter should be made available for this purpose.

Section 3 - MCM Use

MCM Config view:

When connecting to a MCM unit, the following steps should be observed:

Select the pc communications settings by pressing the Port Settings button at the top of the view. This

will bring up the Communications Settings window shown below.

© 2009 Artesis A.S. Document ID: MCM-OP-UM-EG-0091.0000

26

MCM User's Manual

Section 4 - Troubleshooting