Arrow Hart - Cooper Wiring Devices Pin & sleeve families General Product Line Information

arrowhart

EATON 2016 Arrow Hart Buyers Guide

SECTION

G

Pin & sleeve families

Arrow Hart

Arrow Hart's pin & sleeve devices

and mechanical interlocks

Pin & sleeve devices Pin & sleeve mechanical interlocks

Sturdy nylon construction, rugged design with corrosion

resistant components for lasting electrical performance.

Watertight sealing that provides IP69K protection so you

can feel confident in even the most severe washdown

environments.

Factory-wired in a single unit for easy installation, our

watertight pin & sleeve mechanical interlocks provide

an interlocked switch and overload protection within an

enclosure that prevents plugs from being engaged or

disengaged under load.

IP69K

certified

G-2

G-2

Compliances, specifications and availability are subject to change without notice.

arrowhart

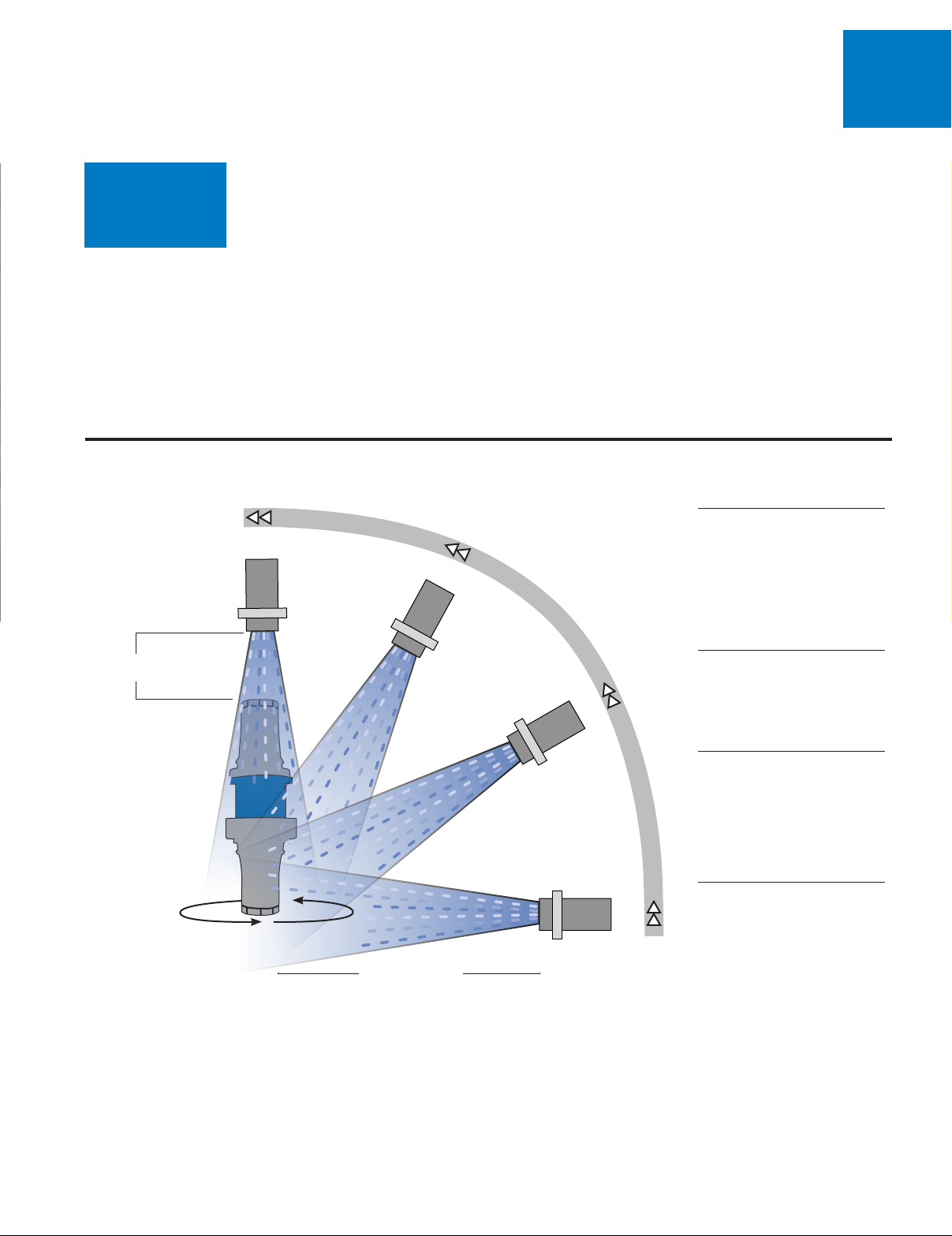

IP69K testing

IP69K testing

The IP69K test was designed specifically for rating protection against a high pressure jet

stream (1160 to 1450 psi), high liquid temperature (176°F) and close nozzle distances

(4" to 6") from the device surface

What does IP69K testing mean to you

IP69K

certified

The IP69K rating is designed to tackle high pressure, high temperature washdown

applications. The “6” applies to external protection from dust. The “9” signifies

protection from close-range high pressure spray downs, and the “K” applies to

the high temperature of the water used. Arrow Hart’s new pin & sleeve devices

are designed to face some of the most severe operating conditions, often in the

most challenging environments making them ideal for a wide range of markets,

including food and beverage, mining, and industrial facilities.

How IP69K testing works

To obtain an IP69K protection rating – a strong water jet is directed at the device

from 4 directions and to achieve the rating it must not have any harmful effects.

A jet nozzle at 0°, 30°, 60° and 90° to the rotating table at 176°F, 4–6 inches away

at 1160–1450 psi. The test time is 2 minutes.

IP69K Test

Water temperature = 176°F (80°C)

Spray water at 1450 psi

for 30 seconds

90°

60°

G

SECTION

1 The IP69K standard requires

the water pressure to be

between 1160-1450 psi, at a

rate of about 4 gallons/minute,

and at the temperature of

176°F

4" to 6" from device

Rotate device at 5 RPM

4" - 6" from device

After testing, water must not be present inside the device

Spray in 30° steps

30°

2 The nozzle from which the

water is sprayed is between

4 and 6 inches from device

3 Spray is applied at angles of

0°, 30°, 60°, and 90 for duration of 30 seconds at each

angle, while the product is

rotated at 5 RPM

0°

4 IP69K ratings mean product

is dust tight and protected

against effects of high pressure, high temperature liquids

Compliances, specifications and availability are subject to change without notice.

EATON 2016 Arrow Hart Buyers Guide

G-3

G-3

Loading...

Loading...