ARMY MEP-831A Operator

ARMY TM 9-6115-639-13&P*

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

OPERATOR, UNIT, AND DIRECT SUPPORT

MAINTENANCE MANUAL

(INCLUDING REPAIR PARTS AND SPECIAL TOOLS LIST)

OPERATING

INSTRUCTIONS 2-1

OPERATOR

TROUBLESHOOTING 3-4

UNIT LEVEL PMCS 4-8

UNIT LEVEL

TROUBLESHOOTING 4-14

UNIT MAINTENANCE

PROCEDURES 4-38

DIRECT SUPPORT

TROUBLESHOOTING 5-4

DIRECT SUPPORT

MAINTENANCE 5-6

MAINTENANCE

ALLOCATION CHART

(MAC) B-1

REPAIR PARTS AND

SPECIAL TOOLS LIST

(RPSTL) C-1

3kW TACTICAL QUIET GENERATOR SET

MEP-831A (60 Hz) (NSN: 6115-01-285-3012) (EIC: VG6)

MEP-832A (400 Hz) (NSN: 6115-01-287-2431) (EIC: VN7)

DISTRIBUTION STATEMENT A: Approved for public release; distribution is unlimited. DESTRUCTION NOTICE: Destroy

by any method that will prevent disclosure of contents or reconstruction of the document.

*This manual supersedes TM 9-6115-639-13 dated 1 November 2000 thru TM 9-6115-639-13, Change 1 dated 15

September 2002; and TM 9-6115-639-23P dated 15 October 2002.

DEPARTMENTS OF THE ARMY AND THE AIR FORCE

AND HEADQUARTERS, MARINE CORPS

15 AUGUST 2005

PCN 182 101550 00

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

WARNING SUMMARY

The following safety precautions are for personnel to understand and apply during many phases of operating

and maintaining the 3kW Tactical Quiet Generator (TQG). Disregarding these warnings and precautionary

information can result in serious injury or death.

Warning statements considered essential to the protection of personnel have been strategically placed

throughout this manual prior to operation or maintenance procedures. Before starting any task, be sure to

review and understand all warnings in the text for that task.

This manual describes physical and chemical processes that may require the use of chemicals, solvents,

paints, or other commercially available material. Users of this manual should obtain the material safety data

sheets (Occupational Safety and Health Act (OSHA) Form 20 or equivalent) from the manufacturer or

suppliers of materials to be used. Users must be completely familiar with manufacturer/supplier information

and adhere to their procedures, recommendations, warnings, and cautions for safe use, handling, storage,

and disposal of these materials.

WARNING

Do not replace components or make adjustments with

the voltage supply turned on. Dangerous potentials may

exist under certain conditions when the power control is

off. Avoid casualties by always removing power and by

discharging and grounding a circuit before touching it.

Failure to observe this warning could result in severe

personal injury or death.

WARNING

High voltage is produced when generator set is being

operated. Use care when working around an open control

panel when generator set is on. Improper operation of

generator set or failure to follow this warning could result

in severe personal injury or death by electrocution.

Do not stand or store heavy objects on generator set.

Never attempt to start generator set unless it is properly

grounded. Equipment must be grounded in accordance

with the procedures in para. 2-6.1. Failure to observe

this warning could result in serious personal injury or death by

electrocution.

WARNING

WARNING

a

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-13/1

DC voltages are present at generator set electrical

components even with generator set shut down. Avoid

shorting any positive terminal with ground or negative. If no

DC voltage is required, always disconnect DC power source

to generator set before working on it. Failure to observe

this warning could result in severe personal injury or death by

electrocution.

Never attempt to connect or disconnect load cables while

generator set is running. Failure to observe this

warning could result in severe personal injury or death

by electrocution.

Never service or perform maintenance on generator

set while engine is running. Always shut down

generator set before servicing. Allow engine to cool

before handling components. Failure to observe this warning

could result in severe personal injury or death.

Never work alone when reaching into generator set

to service or adjust it. Be sure to work with someone who

could provide aid in case of an emergency. Failure to

observe this warning could result in severe personal

injury or death.

Shut down generator set at first sign of failure.

Continued operation could result in injury to personnel

and will cause damage to equipment. If generator

set is shut down by activation of a safety device,

do not operate again until the cause of the shut down

has been determined and eliminated. Failure to

observe this warning could result in severe personal

injury or death.

WARNING

WARNING

WARNING

WARNING

WARNING

b

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

WARNING

If damaged or defective components are discovered,

repair must be performed before operations can begin.

Perform required repairs and adjustments before

proceeding. Do not operate generator set with

damaged components. Personal injury could occur if

damaged parts are left unfixed. Failure to observe this

warning could result in severe personal injury or death.

WARNING

Exhaust discharge contains deadly gases including

carbon monoxide. Do not operate generator set in an

enclosed area unless exhaust discharge is properly

vented outside. Position generator set as far away

from personnel, shelters, and occupied vehicles as

possible. Failure to observe this warning could result

in severe personal injury or death due to carbon

monoxide poisoning.

WARNING

Fuel used in this generator set is flammable and toxic to

skin, eyes, and respiratory tract. Avoid repeated or

prolonged contact. Handle only in a well-ventilated area.

Keep away from sparks, open flames, or other sources

of ignition. Do not splash fuel on hot components.

Do not fuel generator set while it is operating. Do not

overfill tank. Ensure generator set is properly grounded

before fueling. Failure to observe this warning could

result in personal injury and equipment damage due to

potential fuel ignition and possible explosion. Ensure

approved gloves and face shield are worn during

handling. Failure to observe this warning could result

in severe personal injury or death.

WARNING

Liquids under pressure are generated as a result of

operating this generator set. High-pressure leaks

could cause severe personal injury or death. Failure

to observe this warning could result in severe

personal injury or death.

c

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-13/1

Compressed air is dangerous and could cause serious

bodily harm, if protective means or methods are not

observed to prevent a chip or particle (of whatever size)

from being blown into the eyes or to prevent unbroken skin

of the operator or other personnel. Compressed air shall

not be used for cleaning purposes except where reduced to

less than 30 pounds per square inch gauge (psig). Use it

only with effective chip-guarding and personnel protective

equipment (industrial safety glasses and full face shield).

DO NOT use compressed air to dry parts when solvent

cleaners have been used. Failure to observe this warning

could result in severe personal injury or death.

Do not use TRICHLOROTRIFLUOROETHANE,

TRICHLOROETHANE, and similar chemical solvents

for ordinary cleaning of equipment. These substances

threaten public health and the environment by destroying

ozone in the Earths upper atmosphere. Use suitable

non-hazardous cleaning materials (see Appendix F)

such as a clean cloth, water, and mild detergent or an

approved substitute solvent, such as isopropyl alcohol.

Failure to observe this warning could result in severe

personal injury or death.

Handle solvents as combustible liquids. Do not use near

heat, sparks, or flame. Use solvents in well-ventilated

areas only. Avoid prolonged breathing of vapor. Avoid

bodily contact. Use chemical (solvent-resistant) gloves

and chemical splash goggles when using solvent materials.

Solvents may be reactive with acids and oxidizers; do not

mix or cross-apply with other cleaners or chemicals.

An organic vapor respirator with dust and mist filter is

recommended when solvent is applied as a spray.

Keep containers closed between applications.

Provide mechanical ventilation if used in confined spaces.

Store cleaning materials in a well-ventilated area away

from food or drink. To avoid the possibility of spontaneous

combustion, place solvent-saturated waste rags in a sealed

metal container after use. Coordinate the use of this

material with your supporting Industrial Hygiene and

Safety Offices. Ensure you read and understand the

Material Safety Data Sheet (MSDS) for the solvent before

use. Failure to observe this warning could result in severe

personal injury or death.

WARNING

WARNING

WARNING

d

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

WARNING

Adhesives used in maintaining this generator set

(see Appendix F) are flammable and toxic. Vapors may

ignite explosively. Avoid breathing in vapors. Provide

adequate ventilation to prevent vapor concentrations in

excess of permissible exposure levels. Keep away from

heat, sparks, and open flame. Do not smoke. Extinguish

all flames and turn off non-explosion-proof electrical

equipment during use until vapors are dissipated.

Close containers tightly. Failure to observe this warning

could result in severe personal injury or death.

WARNING

To prevent injury to personnel and damage to equipment,

use caution when lifting or moving generator set. Six

people are required for manual lifting. Use lifting rings for

lifting device and forklift openings for forklift only. Do not lift

generator set over personnel. Failure to observe this warning

could result in severe personal injury or death.

WARNING

Avoid contacting metal items with bare skin in extreme

cold weather. Failure to observe this warning could

result in severe personal injury or death.

WARNING

Metal jewelry could conduct electricity. Loose, dangling

articles and clothing could be caught in moving parts.

Remove jewelry and loose, dangling articles and clothing

before working on generator set. Failure to observe this

warning could result in severe personal injury or death.

WARNING

Chemical Agent Resistive Coating (CARC) paint dust is

a heath hazard. Wear protective eyewear, a mask, and

gloves when sanding CARC-painted surfaces. Failure to

observe this warning could result in severe personal injury

or death.

e

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-13/1

If battery is not installed, battery cable ends must be

isolated from each other, and positive end must be

isolated from ground. Failure to isolate battery cable

ends could result in severe electrical discharge. When

not connected to battery, connect battery cable ends to

plastic storage stud. Failure to observe this warning could

result in severe personal injury or death.

With access cover open, noise level of generator set

when operating could cause hearing damage. Hearing

protection must be worn when working near generator set

while it is running. Failure to observe this warning could

result in severe personal injury or death.

To prevent injury to personnel and damage to equipment,

use caution when lifting or moving generator set. Use lifting

rings for lifting device and forklift pockets for forklift only.

Do not lift generator set over personnel. Failure to observe

this warning could result in severe personal injury or death.

Class III oil leaks should be reported IMMEDIATELY to your

supervisor. Fuel leaks of any kind require immediate system

shutdown. Failure to observe this warning could result in severe

personal injury or death.

Make sure personnel are familiar with generator set before

operating. Follow proper procedures. Failure to observe this

warning could result in damage to equipment and could also

result in severe personal injury or death.

Battery acid can cause burns to unprotected skin.

Failure to observe this warning could result in severe

personal injury or death.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

f

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

WARNING

Batteries give off flammable gas. Do not smoke

or use open flame when performing maintenance.

Flames and explosion could result in severe personal

injury or death. Failure to observe this warning could

result in severe injury or personal death.

WARNING

Do not allow battery acid to contact skin or clothing.

Contact of skin with battery acid liquid or inhalation of

battery acid mist can cause severe burns, respiratory

tract infection, and chronic bronchitis. If any battery

acid liquid or mist contacts skin or eyes, immediately

flush affected areas thoroughly with water. If vapors

are inhaled, go to fresh air. Seek medical help

immediately. Failure to observe this warning could

result in severe injury or personal death.

WARNING

When disconnecting battery cables, always remove negative

cable first and positive cable last. Connect cable ends to

enclosure ground lugs to prevent contact. Failure to observe

this warning could result in severe personal injury or death.

WARNING

When connecting battery cables, always connect positive

cable first and negative cable last. Failure to observe this

warning could result in severe personal injury or death.

WARNING

The generator set is heavy. Provide lifting hoist capable of

lifting 100 lbs. Do not lift generator set over personnel.

Enlist the help of an aide to prevent damage to equipment.

Failure to observe this warning could result in severe personal

injury or death.

WARNING

The rotor assembly is held in the stator by magnets. The rotor

will snap into place in stator when installed. Use care to prevent

injury to fingers. Failure to observe this warning could result in

severe personal injury or death.

g/(h Blank)

ARMY TM 9-6115-639-13&P

AIR FPRCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

LIST OF EFFECTIVE PAGES

Below are the dates of issue For original and changed pages:

Original 0 15 August 2005

Total number of pages in this publication is 516, consisting of the Following:

Page *Change

No. No.

Cover......................................... 0 C-45 Blank ................................ 0 K-1 – K-2 .................................... 0

Blank.......................................... 0 C-46 – C-50 .............................. 0 L-1 – L-2..................................... 0

a-g.............................................. 0 C-51 Blank ................................ 0 Index-1 – Index-5....................... 0

h Blank....................................... 0 C-52 – C-70 .............................. 0 Index-6 Blank ............................. 0

A - B........................................... 0 C-71 Blank ................................ 0 FP-1............................................ 0

i-ix.............................................. 0 C-72 – C-75............................... 0 FP-2 Blank ................................. 0

x Blank....................................... 0 C-76 Blank ................................ 0 FP-3............................................ 0

Page *Change

No. No.

Insert latest change pages. Destroy superseded data.

Page Change

No. No.

1-1 – 1-28.................................. 0 C-77 – C-90 .............................. 0 FP-4 Blank ................................. 0

2-1 – 2-32 ................................. 0 C-91 Blank ................................ 0 FP-5............................................ 0

3-1 – 3-14.................................. 0 C-92 - C-100............................. 0 FP-6 Blank ................................. 0

4-1 – 4-176 ................................ 0 C-101 Blank .............................. 0 FP-7............................................ 0

5-1 – 5-18.................................. 0 C-102 – C-133 .......................... 0 FP-8 Blank ................................. 0

A-1 – A-2................................... 0 C-134 Blank............................... 0 FP-9............................................ 0

B-1 – B-9................................... 0 D-1 – D-6................................... 0 FP-10 Blank ............................... 0

B-10 Blank................................. 0 E-1 – E-3................................... 0 FP-11.......................................... 0

C-1 – C-6................................... 0 E-4 Blank .................................. 0 FP-12 Blank ............................... 0

C-7 Blank .................................. 0 F-1 – F-3.................................... 0 FP-13.......................................... 0

C-8 – C-13 ................................ 0 F-4 Blank ................................... 0 FP-14 Blank ............................... 0

C-14 Blank ................................ 0 G-1 ............................................. 0 FP-15.......................................... 0

C-15 – C-18 .............................. 0 G-2 Blank................................... 0 FP-16 Blank ............................... 0

C-19 Blank ................................ 0 H-1 – H-4 ................................... 0 FP-17.......................................... 0

C-20 – C-35 .............................. 0 I-1............................................... 0 FP-18 Blank ............................... 0

C-36 Blank ................................ 0 I-2 Blank .................................... 0 FP-19.......................................... 0

C-37 – C-44 .............................. 0 J-1 – J-4..................................... 0 FP-20 Blank ............................... 0

A

ARMY TM 9-6115-639-13&P

AIR FPRCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

Page *Change

No. No.

FP-21 ......................................... 0

FP-22 Blank ............................... 0

FP-23 ......................................... 0

FP-24 Blank ............................... 0

FP-25 ......................................... 0

FP-26 Blank ............................... 0

FP-27 ......................................... 0

FP-28 Blank ............................... 0

FP-29 ......................................... 0

FP-30 Blank ............................... 0

FP-31 ......................................... 0

Page *Change

No. No.

Page Change

No. No.

FP-32 Blank ............................... 0

B

ARMY TM 9-6115-639-13&P*

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

TECHNICAL MANUAL HEADQUARTERS

DEPARTMENT OF THE ARMY

NO. 9-6115-639-13&P Washington, DC, 15 AUGUST 2005

OPERATOR, UNIT, AND DIRECT SUPPORT

MAINTENANCE MANUAL

(INCLUDING REPAIR PARTS AND SPECIAL TOOLS LIST)

3kW TACTICAL QUIET GENERATOR SET

MEP-831A (60 Hz) (NSN: 6115-01-285-3012) (EIC: VG6)

MEP-832A (400 Hz) (NSN: 6115-01-287-2431) (EIC: VN7)

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this manual. If you find any mistakes, or if you know of a way to improve the procedures, please

let us know. We would prefer that you submit your recommended changes electronically, either by e-mail

(AMSEL-LC-LEO-PUBS-CHG@mail1.monmouth.army.mil

Alternatively, you may mail or fax your letter, DA Form 2028, or DA Form 2028-2 located in back of this manual to:

Commander, U.S. Army Communications-Electronics Command and Fort Monmouth, ATTN: AMSEL-LC-LEO-E-ED,

Fort Monmouth, NJ 07703-5006. The fax number is 732-532-3421, DSN 992-3421. For Air Force, use AFTO Form 22 in

accordance with TO 00-5-1 and mail directly to Commander, WR-ALC/LEET, Robins AFB, GA 31098. You may also email your form to http://wralc.tilta.afto@robins.af.mil

changes on a NAVMC 10722. The NAVMC may be submitted via the Internet using website

https://pubs.ala.usmc.mil/front.htm, scrolling down to the NAVMC 10772 Tracking Program, and following instructions

provided. The NAVMC may also be submitted by electronic mail to mbmatcommarlogbases@logcom.usmc.mil

mailing a paper copy NAVMC 10772 in an envelope addressed to Commander, Marine Corps Systems Command,

Attention: Assistant Commander Acquisition and Logistics (LOG/TP), 814 Radford Blvd., Suite 20343, Albany, GA

31704-0343.

*This manual supersedes TM 9-6115-639-13 dated 1 November 2000 thru TM 9-6115-639-13, Change 1 dated 15 September 2002;

and TM 9-6115-639-23P dated 15 October 2002.

TABLE OF CONTENTS

CHAPTER 1 INTRODUCTION………………………………………………………………………. 1-1

Section I General Information…………………………………………………………………… 1-2

Section II Equipment Description………………………………………………………………... 1-8

Section III Theory of Operation…………………………………………………………………… 1-24

CHAPTER 2 OPERATING INSTRUCTIONS……………………………………………………… 2-1

Section I Description and Use of Operator Controls and Indicators………………………... 2-2

Section II Operator Preventive Maintenance Checks and Services (PMCS)………………. 2-9

Section III Operation Under Usual Conditions………………………………………………….. 2-20

Section IV Operation Under Unusual Conditions……………………………………………….. 2-29

CHAPTER 3 OPERATOR MAINTENANCE INSTRUCTIONS…………………………………... 3-1

Section I Operator Lubrication Instructions …………………………………………………… 3-2

Section II Operator Troubleshooting Procedures ……………………………………………... 3-4

Section III Operator Maintenance Instructions………………………………………………….. 3-12

CHAPTER 4 UNIT MAINTENANCE INSTRUCTIONS…………………………………………… 4-1

Section I Unit Lubrication Instructions …………………………………………………………. 4-3

Section II Repair Parts; Tools; Special Tools; Test, Measurement, and Diagnostic

Equipment (TMDE); and Support Equipment………………………………………. 4-6

Section III Service Upon Receipt of Equipment.……………………………………………….. 4-7

) or online (http://edm.monmouth.army.mil/pubs/2028.html).

. For the Marine Corps, submit notice of discrepancies or suggested

or by

Page

i

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

TABLE OF CONTENTS (Continued)

Page

Section IV Unit Preventive Maintenance Checks and Services (PMCS)…………………….. 4-8

Section V Unit Level Troubleshooting Procedures…………………………………………….. 4-14

Section VI Unit Level Maintenance Instructions………………………………………………… 4-38

Section VII Preparation for Shipment and Storage………………………………………………

CHAPTER 5 DIRECT SUPPORT MAINTENANCE INSTRUCTIONS………………………….. 5-1

Section I Repair Parts; Tools; Special Tools; Test, Measurement, and Diagnostic

Equipment (TMDE); and Support Equipment……………………………………….

Section II Service Upon Receipt of Equipment…………………………………………………. 5-3

Section III Direct Support Troubleshooting Procedures………………………………………… 5-4

Section IV Direct Support Maintenance Instructions……………………………………………. 5-6

APPENDIX A REFERENCES…………………………………………………………………………. A-1

APPENDIX B MAINTENANCE ALLOCATION CHART (MAC)……………………………………. B-1

APPENDIX C REPAIR PARTS AND SPECIAL TOOLS LIST (RPSTL)………………………….. C-1

Section I Introduction……………………………………………………………………………… C-1

Section II Repair Parts List……………………………………………………………………….. C-8

Group 00 – Generator Set…………………………………………………….………. C-9

Group 01 – Engine Assembly, Diesel………………………………………………... C-10

Group 0101 – Governor Control Module…………………………………………….. C-11

Group 010101 – Governor Actuator Assembly……………….…………………….. C-13

Group 02 – Permanent Magnet Alternator (PMA)…………….. C-17

Group 03 – Electrical System Assembly……………………………………………. C-18

Group 0301 – Electrical System Assembly/Battery Charging Regulator…..…….. C-21

Group 0302 – Electrical System Assembly/Battery………………………………… C-23

Group 030201 – Electrical System Assembly/Battery Cables…………………….. C-25

Group 0303 – Electrical System Assembly/Contactor Assembly…………….…… C-27

Group 0304 – Electrical System Assembly/Frequency Converter (A8)………….. C-29

Group 0305 – Electrical System Assembly/Relays, Electromagnetic………….…. C-31

Group 04 – Control Box Assembly……………………… C-33

Group 0401 – Control Box Assembly/Control Panel Assembly…………………… C-35

Group 040101 – Control Panel Assembly/Panel Meters, Gauges, & Switches…. C-41

Group 0402 – Control Box Assembly/Receptacle, Filters, Terminals, and

Voltage Resistor………………………………………………………………………… C-43

Group 05 – Cooling System…………………………………………………………… C-44

Group 0501 – Cooling System/Cooling Fan Assembly…………………………….. C-47

Group 0502 – Cooling System/HI/LO Temperature Switches…………………….. C-49

Group 06 – Fuel System Assembly…………………………………………………... C-50

Group 0601 – Fuel System Assembly/Fuel Tank Strainer Assembly……………. C-53

Group 0602 – Fuel System Assembly/Fuel Tank…………………………………… C-55

Group 060201 – Fuel System Assembly/Fuel-Level Assembly…………………… C-57

Group 060202 – Fuel System Assembly/Fuel-Level Switch………….…………… C-59

Group 060203 – Fuel System Assembly/Fuel Tank Pickup Tube……. C-61

Group 0603 – Fuel System Assembly/Primary Fuel Pump………………………... C-63

Group 0604 – Fuel System Assembly/Auxiliary Fuel Pump……………………….. C-65

Group 0605 – Fuel System Assembly/Fuel Filter/Water Separator………………. C-67

Group 0606 – Fuel System Assembly/Air Cleaner Assembly……………………... C-69

Group 07 – Frame and Housing Assembly………………………………………….. C-70

Group 0701 – Frame and Housing Assembly/Main Access Cover……………….. C-77

Group 0702 – Frame and Housing Assembly/Frame and Housing Panels……... C-83

4-175

5-2

ii

ARMY TM 9-6115-639-13&P*

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

TABLE OF CONTENTS (Continued)

Page

APPENDIX C REPAIR PARTS AND SPECIAL TOOLS LIST (RPSTL) (Continued)

Group 706 – Frame and Housing Assembly/ID Plates…………………………….. C-91

Group 08 – Lubrication System……………………………………………………….. C-92

Group 0801 – Lubrication System/Oil Drain Assembly…………………………….. C-95

Group 0802 – Lubrication System/Oil Pressure Switch……………………………. C-97

Group 0803 – Lubrication System/Engine Oil Temperature Switch………………. C-99

Group 0804 – Lubrication System/Oil Filter…………………………………………. C-101

Group 09 – Exhaust System Assembly……………………………………….……... C-102

Group 0901 – Exhaust System Assembly/Muffler Assembly…..………………….. C-105

Group 0902 – Exhaust System Assembly/Bellows Assembly.……………………. C-107

Group 0903 – Exhaust System/Duct Assembly...…………………………………. C-109

Section III Cross-Reference Indexes……………………………………………………………… C-111

Part Number Index……………………………………………………………………... C-111

Figure and Item Number Index……………………………………………………….. C-124

APPENDIX D COMPONENTS OF END ITEM (COEI) AND BASIC ISSUE ITEMS (BII) LIST… D-1

APPENDIX E ADDITIONAL AUTHORIZATION LIST (AAL)………………………………………. E-1

APPENDIX F EXPENDABLE AND DURABLE ITEMS LIST………………………………………. F-1

APPENDIX G ILLUSTRATED LIST OF MANUFACTURED ITEMS………………………………. G-1

APPENDIX H TORQUE LIMITS………………………………………………………………………. H-1

APPENDIX I MANDATORY REPLACMENT PARTS……………………………………………… I-1

APPENDIX J WARRANTY INFORMATION………………………………………………………… J-1

APPENDIX K ON-BOARD SPARES…………………………………………………………………. K-1

APPENDIX L SPECIAL PACKAGING INSTRUCTIONS…………………………………………... L-1

ALPHABETICAL INDEX………………………………………………………………. Index-1

Group 0703 – Frame and Housing Assembly/Frame and Lifting Handles, Lifting

Rings……………….……………………………………………………………………. C-85

Group 0704 – Frame and Housing Assembly/NATO Slave Receptacle…………. C-87

Group 0705 – Frame and Housing Assembly/Skid Base ……………………….… C-89

iii

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

TABLE OF CONTENTS (Continued)

LIST OF ILLUSTRATIONS

Figure Title Page

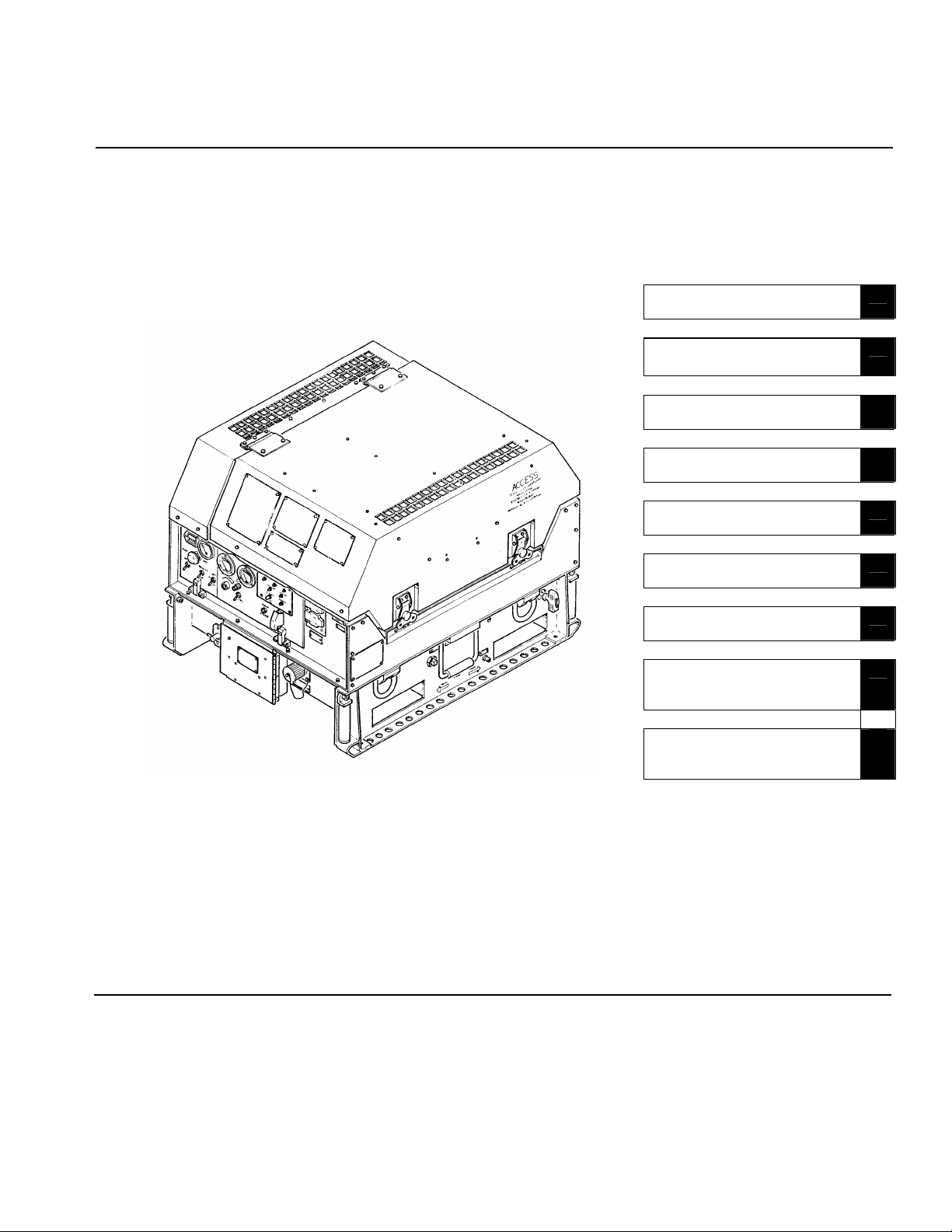

1-1 3kW Tactical Quiet Generator Set…………………………………………………… 1-2

1-2 Location of Generator Set Components…………………………………………….. 1-10

1-3 Diesel Engine/Generator Assembly…………………………………………………. 1-12

1-4 Generator Set Fuel System…………………………………………………………... 1-14

1-5 Generator Set Data, Instruction, and Warning Plates (Sheet 1 of 7)…………….. 1-17

1-5 Generator Set Data, Instruction, and Warning Plates (Sheet 2 of 7)…………….. 1-18

1-5 Generator Set Data, Instruction, and Warning Plates (Sheet 3 of 7)…………….. 1-19

1-5 Generator Set Data, Instruction, and Warning Plates (Sheet 4 of 7)…………….. 1-20

1-5 Generator Set Data, Instruction, and Warning Plates (Sheet 5 of 7)…………….. 1-21

1-5 Generator Set Data, Instruction, and Warning Plates (Sheet 6 of 7)…………….. 1-22

1-5 Generator Set Data, Instruction, and Warning Plates (Sheet 7 of 7)…………….. 1-23

1-6 Fuel System Schematic……………………………………………………………….. 1-28

2-1 Generator Set Controls and Indicators (Sheet 1 of 4)……………………………... 2-5

2-1 Generator Set Controls and Indicators (Sheet 2 of 4)……………………………... 2-6

2-1 Generator Set Controls and Indicators (Sheet 3 of 4 )…………………………….. 2-7

2-1 Generator Set Controls and Indicators (Sheet 4 of 4 )…………………………….. 2-8

2-2 Ground Rod and Cable Installation………………………………………………….. 2-22

2-3 Operating Procedures…………………………………………………………………. 2-24

2-4 Manual Engine Starting……………………………………………………………….. 2-32

3-1 Oil Fill Cap……………………………………………………………………………… 3-3

3-2 Air Filter Replacement………………………………………………………………… 3-14

4-1 Engine Oil Servicing…………………………………………………………………… 4-5

4-2 Diagnostic Test Points………………………………………………………………… 4-16

4-3 Generator Set………………………………………………………………………….. 4-37

4-4 Engine Assembly………………………………………………………………………. 4-39

4-5 Control Panel…………………………………………………………………………… 4-40

4-6 Governor Control Module……………………………………………………………... 4-41

4-7 Governor Actuator Assembly…………………………………………………………. 4-45

4-8 Governor Adjustment………………………………………………………………….. 4-45

4-9 Governor Control Module……………………………………………………………... 4-46

4-10 Governor Actuator……………………………………………………………………... 4-46

4-11 Engine Wiring Harness………………………………………………………………... 4-48

4-12 Permanent Magnet Alternator (PMA)………………………………………………... 4-50

4-13 Battery Charging Regulator…………………………………………………………... 4-53

4-14 Battery System…………………………………………………………………………. 4-59

4-15 Battery Cable Assembly………………………………………………………………. 4-62

4-16 Contactor Assembly…………………………………………………………………… 4-64

4-17 Frequency Converter (A8) Assembly……………………………………………….. 4-67

4-18 Relays, Electromagnetic………………………………………………………………. 4-69

4-19 Control Box Assembly…………………………………………………………………. 4-72

4-20 Control Panel Assembly………………………………………………………………. 4-74

4-21 HOURS Meter………………………………………………………………………….. 4-77

4-22 FUEL LEVEL Gauge…………………………………………………………………... 4-78

4-23 VOLTAGE Meter………………………………………………………………………. 4-79

4-24 LOAD Meter…………………………………………………………………………….. 4-80

4-25 Fault Indicator Module………………………………………………………………… 4-82

4-26 Operator Switches…………………………………………………………………….. 4-84

4-27 EMERGENCY STOP Button…………………………………………………………. 4-86

4-28 DC CIRCUIT BREAKER………………………………………………………………. 4-87

4-29 CIRCUIT INTERRUPTER Indicator Light.………………………………………….. 4-89

iv

ARMY TM 9-6115-639-13&P*

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

TABLE OF CONTENTS (Continued)

LIST OF ILLUSTRATIONS (Continued)

Figure Title Page

4-30 VOLTAGE ADJUST Rheostat………………………………………………………... 4-91

4-31 Control Box Relays…………………………………………………………………….. 4-93

4-32 Fuses, Diodes, and Terminal Block………………………………………………….. 4-96

4-33 Convenience Receptacle……………………………………………………………... 4-98

4-34 Ground Fault Circuit Interrupter (GFCI)……………………………………………... 4-100

4-35 Load Terminals and EMI Filter (Sheet 1 of 2)………………………………………. 4-102

4-35 Load Terminals and EMI Filter (Sheet 2 of 2)………………………………………. 4-103

4-36 Voltage Resistors………………………………………………………………………. 4-105

4-37 Control Box Wiring Harness………………………………………………………….. 4-106

4-38 Cooling System………………………………………………………………………… 4-108

4-39 Temperature Switch and Cooling Fan………………………………………………. 4-111

4-40 HI/LO Temperature Switches………………………………………………………… 4-113

4-41 Fuel System Assembly………………………………………………………………... 4-115

4-42 Fuel Tank Strainer Assembly………………………………………………………… 4-118

4-43 Fuel-Level Sender Assembly………………………………………………………… 4-120

4-44 Fuel-Level Switch……………………………………………………………………… 4-123

4-45 Fuel Tank Pickup Tube……………………………………………………………….. 4-125

4-46 Primary Fuel Pump……………………………………………………………………. 4-127

4-47 Auxiliary Fuel Pump…………………………………………………………………… 4-129

4-48 Fuel Filter/Water Separator…………………………………………………………… 4-131

4-49 Air Cleaner Assembly…………………………………………………………………. 4-133

4-50 Frame and Housing Assembly……………………………………………………….. 4-135

4-51 Main Access Cover (Sheet 1 of 3)…………………………………………………… 4-139

4-51 Main Access Cover (Sheet 2 of 3)…………………………………………………… 4-140

4-51 Main Access Cover (Sheet 3 of 3)…………………………………………………… 4-141

4-52 Frame and Housing Panels…………………………………………………………... 4-144

4-53 Frame and Lifting Handles……………………………………………………………. 4-146

4-54 NATO Slave Receptacle……………………………………………………………… 4-148

4-55 Skid Base………………………………………………………………………………. 4-150

4-56 ID Plates………………………………………………………………………………… 4-152

4-57 Lubrication System…………………………………………………………………….. 4-154

4-58 Oil Drain Assembly…………………………………………………………………….. 4-156

4-59 Oil Pressure Switch……………………………………………………………………. 4-158

4-60 Engine Oil Temperature Switch……………………………………………………… 4-160

4-61 Oil Filter…………………………………………………………………………………. 4-161

4-62 Exhaust System Assembly…………………………………………………………… 4-163

4-63 Muffler Assembly………………………………………………………………………. 4-166

4-64 Bellows Assembly……………………………………………………………………… 4-169

4-65 Duct Assembly…………………………………………………………………………. 4-172

5-1 Generator Set Engine/Alternator Assembly………………………………………… 5-8

5-2 Permanent Magnet Alternator………………………………………………………... 5-13

5-3 Control Box Wiring Harness………………………………………………………….. 5-16

5-4 Fuel Tank……………………………………………………………………………….. 5-18

v

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

TABLE OF CONTENTS (Concluded)

LIST OF TABLES

Table Title Page

1-1 Nomenclature Cross-Reference 1-4

1-2 Equipment Data 1-15

2-1 Operator PMCS for MEP-831A/MEP-832A 2-14

3-1 Operator Symptom Index 3-4

3-2 Operator-Level Troubleshooting 3-7

4-1 Lubricant Table for Generator Set MEP-831A/MEP-832A 4-3

4-2 Unit PMCS for MEP-831A/MEP-832A 4-12

4-3 Unit Symptom Index 4-15

4-4 Unit-Level Troubleshooting 4-17

5-1 Direct Support Symptom Index 5-4

5-2 Direct Support Level Troubleshooting 5-5

vi

ARMY TM 9-6115-639-13&P*

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

HOW TO USE THIS MANUAL

1. DESCRIPTION OF THE MANUAL

Chapter Organization. This manual has five chapters, covering introductory information, principles

a.

of operation, Operator maintenance instructions, Unit maintenance instructions, and Direct

Support maintenance instructions. Each chapter is divided into sections. These sections

contain the cleaning, inspection, troubleshooting, and repair tasks appropriate for the specific

maintenance level. Each chapter contains a table of contents containing the tasks within that

chapter. See the Table of Contents (page i) for the chapters and sections of this manual.

b. Paragraph and Task Numbering. All paragraphs and maintenance tasks are numbered.

This helps you find what you need when you need it. Use the Table of Contents (page i) or

alphabetical index (at the back of the manual) to find the paragraph or task you need.

Appendices. The appendices in this manual contain both general maintenance information and

c.

specific data for this generator set. Appendix A is a list of reference manuals and materials.

Appendix B is the Maintenance Allocation Chart (MAC). Appendix C is the Repair Parts and Special

Tools List (RPSTL). Appendix D lists Components of End Item (COEI) and Basic Issue Items (BII).

Appendix E is an Additional Authorization List (AAL). Appendix F is an Expendable and Durable

Items List. Appendix G is an Illustrated List of Manufactured Items. Appendix H contains Torque

Limits. Appendix I contains Mandatory Replacement Parts information. Appendix J contains

Warranty Information. Appendix K is a List of On-Board Spares. Appendix L contains Special

Packaging Instructions. See the Table of Contents (page i) for a complete list of the appendices

used in this manual.

2. HOW TO FIX A GENERATOR SET MALFUNCTION

a.

Determining the Cause. Figuring out the cause of the malfunction, or troubleshooting, is the first

step in fixing the generator set and returning it to operation. Follow the steps below to determine the

root of your problem:

(1) Turn to the Table of Contents section in this manual (page i).

(2) Locate Troubleshooting for your maintenance level, and turn to the page indicated.

(3) In the Troubleshooting section, find the troubleshooting symptom for the component affected by

the malfunction. See the Symptom Index for help.

NOTE

If the specific symptom is not addressed,

the maintenance required is most likely

more detailed than authorized for your level.

Notify personnel at a higher maintenance level.

(4) Begin troubleshooting. Carefully work your way down through the troubleshooting table.

Try to determine what the problem is.

(5) Once the trouble has been determined, go to the maintenance task called out. Remedy the

malfunction, test the generator set, and return it to service.

vii

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

Preparing for a Task

b.

NOTE

You must familiarize yourself with the entire

maintenance procedure before starting any

maintenance task. Ensure all parts, materials,

and tools are handy. Read through all steps

before beginning.

(1) PAY ATTENTION TO WARNINGS, CAUTIONS, AND NOTES.

(2) Maintenance tasks are arranged in a logical disassembly/assembly sequence and address only

the component or assembly to be replaced. Locator illustrations are included for removal and

replacement. These illustrations show you the area of the generator set on which to work.

(3) All mandatory replacement parts are listed, including gaskets, packings, cotter pins, and

lockwashers. They are listed by Repair Parts and Special Tools List (RPSTL) name. The

Expendable and Durable Items List (see Appendix F) and support materials are listed, including

solvents, rags, grease, and safety wire.

(4) Each maintenance task lists tools, tool kits, or shop sets needed to do the task. If tools from a

repairmans kit are needed, the kit is listed. Tools not in a kit or set are listed by name, type,

and size. Special tools and test equipment, if necessary, are listed by part number.

(5) Related technical manuals (TMs) needed to accomplish the task are listed. The steps tell when

these TMs are needed.

(6) Read the entire task carefully before starting. DO NOT START A TASK UNTIL:

You know which replacement parts, tools, and supplies are needed.

You have the things you need.

You understand what to do.

c. How to Do the Task. Before starting, read the entire task and familiarize yourself with the entire

procedure. Below are standard maintenance practices. Instructions about these practices will not

normally be included in the task steps. Task steps will tell you when standard maintenance practices

do not apply.

(1) Electrical wiring must be tagged before it is disconnected.

(2) Used packings, retainers, gaskets, cotter pins, lockwashers, and safety wire shall be discarded.

Do not reuse. New parts shall be installed.

(3) Packings shall be coated with lubricant before installation, in accordance with task instructions.

(4) Disassembly procedures list all steps required to support total authorized repair of a component.

You may not need to disassemble a part as far as described in the task. Follow the steps to

disassemble as far as required to replace worn or damaged parts.

(5) Before components or the disassembled parts of a component are inspected, they must be

cleaned as required.

(6) Components must be inspected for serviceable condition before installation.

viii

ARMY TM 9-6115-639-13&P*

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

(7) When a nut is tightened or loosened on a bolt, the bolt head must be held with a wrench.

(8) A special torque will be cited when the words TORQUE TO are used in the task. Standard

torques are used at all other times. See Torque Limits, Appendix H, for information.

(9) When tightening hardware, observe compliance with the drag torque as required. Drag torque

is defined as the torque required to begin turning the nut. To determine drag torque, thread nut

onto bolt until at least two threads protrude. The nut must not contact the mating part.

(10) After maintenance, inspect for foreign objects.

NOTE

This manual contains the new two-level Maintenance Allocation Chart (MAC) broken into

Field and Sustainment Maintenance. The procedures within the manual are still divided

by maintenance level (Operator, Unit and Direct Support for Field). If you cannot find a

generator set malfunction in the troubleshooting section for your maintenance level, or

cannot find the appropriate corrective actions in the maintenance section, notify

personnel at a higher maintenance level.

3. REPAIR PARTS AND SPECIAL TOOLS LIST

See Appendix C for the Repair Parts and Special Tools List (RPSTL). The RPSTL contains exploded-view

illustrations and parts lists keyed to the illustrations. It lists part number, part name, and quantity used in

each application. Use the RPSTL to identify and order replacement parts.

ix/(x Blank)

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

CHAPTER 1

INTRODUCTION

Section I GENERAL INFORMATION................................................................................................... 1-2

1-1 Scope ....................................................................................................................... 1-2

1-2 Consolidated Index of Army Publications and Blank Forms.................................... 1-2

1-3 Maintenance Forms, Records, and Reports ............................................................ 1-3

1-4 Reporting Equipment Improvement Recommendations (EIRs) .............................. 1-3

1-5 Corrosion Prevention and Control ..........................................................................1-4

1-6 Destruction of Army Materiel to Prevent Enemy Use .............................................. 1-4

1-7 Preparation for Storage and Shipment .................................................................... 1-4

1-8 Warranty Information ............................................................................................... 1-4

1-9 Nomenclature Cross-Reference List ....................................................................... 1-4

1-10 List of Abbreviations and Acronyms ........................................................................ 1-4

1-11 Quality of Material .................................................................................................... 1-7

1-12 Safety, Care, and Handling...................................................................................... 1-7

1-13 Administrative Storage............................................................................................. 1-7

Section II EQUIPMENT DESCRIPTION .................................................................................. 1-8

1-14 Equipment Characteristics, Capabilities, and Features........................................... 1-8

1-15 Location and Description of Major Components...................................................... 1-9

1-16 Differences Between Models .................................................................................1-13

1-17 Equipment Data ..................................................................................................... 1-13

1-18 Identification and Instruction Plates ....................................................................... 1-13

Section III THEORY OF OPERATION................................................................................................. 1-24

1-19 Theory of Operation ............................................................................................... 1-24

1-20 Electrical System ................................................................................................... 1-24

1-21 Direct Current System............................................................................................ 1-24

1-22 Alternating Current System.................................................................................... 1-25

1-23 Generator ............................................................................................................... 1-26

1-24 Fuel System ...........................................................................................................1

-26

1-1

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

Section I. GENERAL INFORMATION

1-1 SCOPE

a. This manual provides instructions on operating, troubleshooting, and maintaining the 3kW Tactical

Quiet Generator Set, MEP-831A (60Hz), NSN: 6115-01-285-3012, and MEP-832A (400Hz), NSN:

6115-01-287-2431. Information is provided on principles of operation, controls and indicators,

Preventive Maintenance Checks and Services (PMCS), lubrication, operation, troubleshooting, and

maintenance. See Figure 1-1 for a full-view illustration of the generator set, showing features

pertinent to set operation and maintenance.

b. See TM 9-2815-257-24 for detailed information regarding operation and maintenance of the Diesel

Engine Assembly, Model Number L70AE-DEGFR, NSN: 2815-01-465-5993, manufactured by

Yanmar Diesel Engine Company, Ltd.

Figure 1-1. 3kW Tactical Quiet Generator Set

1-2 CONSOLIDATED INDEX OF ARMY PUBLICATIONS AND BLANK FORMS

See the latest issue of DA Pam 25-30 to determine whether there are new additions, changes, or

additional publications pertaining to the equipment.

1-3 MAINTENANCE FORMS, RECORDS, AND REPORTS

Reports of Maintenance and Unsatisfactory Equipment. Department of the Army forms and

a.

procedures used for equipment maintenance will be those prescribed by DA Pam 738-750, as

contained in the current maintenance management update (The Army Maintenance Management

System (TAMMS)). Fill out and forward to the TAMMS clerk DD Form 5988-E, an automated form in

1-2

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

the Unit Level Logistics System (ULLS), Equipment Maintenance and Inspection Worksheet. If you

cannot access ULLS, fill out and forward to the TAMMS clerk DA Form 2404. Air Force personnel

will use AFR 66-1 for maintenance reporting and TO 00-35D-54 for unsatisfactory equipment

reporting. Marine Corps units using the Asset Tracking Logistics and Supply System (ATLASS) will

maintain forms and records information in accordance with applicable ATLASS requirements. All

other Marine Corps units will maintain forms and records associated with operating and maintaining

ground equipment, as prescribed by TM 4700-15.

Reporting of Item and Packaging Discrepancies. Army, Air Force, and Marine Corps users will

b.

fill out and forward SF 364 (Report of Discrepancy (ROD)) as prescribed in AR 735-11-2,

DLAR 4140.55, SECNAVINST 4355.18A, AFJ 23-215. For shipping discrepancies, Marine Corps

users will fill out and forward to the Source of Supply (SOS) SF 364,

as prescribed in UM 4400-123, UM 4400-124, and SECNAVINST 4355.18 As prescribed in

UM 4400-123, UM 4400-124, and SCENAVINST 4355.18, for packing discrepancies Marine Corps

users will fill out and forward to the applicable control point identified in the SECNAVINST SF 364.

c. Transportation Discrepancy Report (TDR) (SF 361)

. Army users will fill out and forward SF 361,

Transportation Discrepancy Report (TDR), as prescribed in AR 55-38, NAVSUPINST 4610.33C,

AFR 75-18, MCO P4610.19D, and DLAR 4500.15. Marine Corps users will fill out and forward

SF 361, as prescribed in DoD 4500.9-R, Defense Transportation Regulation, Part II, Cargo

Movement.

1-4 REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS (EIRs)

a. Army

. If your engine assembly needs improvement, let us know. Send us an EIR. You are the only

one who can tell us what you do not like about your equipment. Put it on an SF 368 (Product Quality

Deficiency Report (QDR)) and mail it to the address below:

Commander

U.S. Army Communications and

Electronics Command (CECOM)

ATTN: AMSEL-LC-LEO-E-ED

Fort Monmouth, NJ 07703-5006

We will send you a reply.

b. Air Force

. Air Force personnel should submit TO 00-35D-54 to the address below:

Commander

WRALC/LGMTC

375 Perry Street

Robins AFB, GA 31098-1865

c. Marine Corps

. Marine Corps units will submit all fit, form, or function deficiencies in accordance with

standard Product Quality Deficiency Report (PQDR) procedures contained in TM 4700-15/1 and

MCO 4855.10. Submit your PQDR to Navy PDREP automated systems by going to

http://www.nslcptsmh.navsea.navy.mil/pdrep/pdrep.htm, requesting access, and then filling out the

PQDR. For additional assistance, use this e:mail address:

mbmatcompqdrs@logcom.usmc.mil.

Only deployed units may mail PQDRs to the address below:

Marine Corps LogCom Command Element

Attn: Quality Assurance Office (L15)

814 Radford Boulevard, Suite 20330

Albany, GA 31704-0330

A reply will be furnished to you.

1-3

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

1-5 CORROSION PREVENTION AND CONTROL

a. Corrosion Prevention and Control (CPC) of Army materiel is a continuing concern. Be sure you

report any corrosion problems with the engine assembly so that the problem can be corrected and

improvements can be made.

b. Although corrosion is typically associated with rusting of metals, it may also include deterioration of

other materials, such as rubber or plastic. Unusual cracking, softening, swelling, or breaking of

these materials may be a corrosion problem.

c. If a corrosion problem is identified, report it using SF-368, Product Quality Deficiency Report. Use of

keywords such as corrosion, rust, deterioration, or cracking will ensure that the information is

identified as a CPC problem.

d. Submit SF-368 to the address specified in DA Pam 738-750. Air Force personnel will use

TO 35-1-3.

1-6 DESTRUCTION OF ARMY MATERIEL TO PREVENT ENEMY USE

For destruction of Army materiel to prevent enemy use, see TM 750-244-3.

1-7 PREPARATION FOR STORAGE AND SHIPMENT

Requirements for packaging, preservation, and administrative storage are in Chapter 4, section VII. See

also Appendix L for special packaging instructions and TB 740-97-2, Preservation of USAMECOM

Mechanical Equipment for Shipment and Storage.

1-8 WARRANTY INFORMATION

Components for the 3kW TQG are warranted in accordance with the component manufacturers latent

defect commercial warranty. The warranty starts on the date found in block 23, DA Form 2408-9, in the

log book. Report all defects in material and workmanship to your supervisor, who will take appropriate

action. See Appendix J for information on manufacturers component warranties and conditions.

1-9 NOMENCLATURE CROSS-REFERENCE LIST

Shortened nomenclature is used in this manual to make procedures easier for you to read.

Table 1-1 is a cross-reference between the shortened nomenclature and the official nomenclature.

Table 1-1. Nomenclature Cross-Reference

Common Name Official Nomenclature

Generator Set 3kW Tactical Quiet Generator Set,

1-10 LIST OF ABBREVIATIONS AND ACRONYMS

Below are the abbreviations and acronyms used in this manual:

A2 Fault Indicator Module

A5 Governor Control

AAL Additional Authorization List

AC Alternating Current

AFB Air Force Base

1-4

MEP-831A/MEP-832A

AIR FORCE TO 35C2-3-386-51W/IPB

AFR Air Force Regulation

AFTO Air Force Task Order

ALC Air Logistics Center

AOAP Army Oil Analysis Program

App Appendix

AR Army Regulation

ATLASS Asset Tracking Logistics and Supply System

BII Basic Issue Items

BT Battery/Battery Terminal

C Centigrade

CAGEC Commercial and Government Entity Code

CARC Chemical Agent Resistive Coating

CB1 DC CIRCUIT BREAKER

CB3 GFCI (60Hz only)

CECOM Communications and Electronics Command

cm Centimeter

CN Change Notice

COEI Components of End Item

CPC Corrosion Prevention and Control

CTA Consolidated Table of Allowance

DA Department of the Army

dBA Decibels referred to 1 kilowatt

DC Direct Current

DLAR Defense Logistics Agency Regulation

DS Direct Support

DS2 Decontaminating Solution 2

DS6 AC CIRCUIT INTERRUPTER Indicator

DSN Defense Switched Network

ECP Engineering Change Proposal

EIC End Item Code/Equipment Item Code

EIR Equipment Improvement Recommendation

EMI Electromagnetic Interference

ESD Electrostatic Discharge

F Fahrenheit

FL FUEL LEVEL Switch

FM Field Manual

FO Foldout

ft Foot

GFCI Ground Fault Circuit Interrupter

GND Ground

Hg Mercury

HP Horsepower

HT Engine Temperature Switch

Hz Hertz

J1 Convenience Receptacle

IPB Illustrated Parts Breakdown

JTA Joint Table(s) of Allowance

kg Kilogram

kW Kilowatt

L1 AC output terminal 1 (load)

L2 AC output terminal 2 (load)

LOEP List of Effective Pages

LOG/TP Logistics/Technical Publication

M1 VOLTAGE Meter

M2 LOAD Meter

M3 HOURS Meter

M5 FUEL LEVEL Meter

ARMY TM 9-6115-639-13&P

MARINE CORPS TM 10155A-OI/1

1-5

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

MAC Maintenance Allocation Chart

MCO Marine Corps Order

MCPDS Marine Corps Publication Data System

MEP Mobile Electric Power

MIL Military

MIL-HDBK Military Handbook

ml Milliliter

MST Maintenance Support Team

MT5 Fuel Level Sender

MTOE Modified Table of Organization and Equipment

N Neutral

NATO North Atlantic Treaty Organization

NAVMC Navy Marine Corps

NAVSUPINST Naval Supplementary Instruction

NBC Nuclear, Biological, and Chemical

NSN National Stock Number

OEA Office of Energy Assurance

OP Oil Pressure/Low Oil Pressure Switch

OSHA Occupational Safety and Health Act

P/N Part Number

Pam Pamphlet

PMCS Preventive Maintenance Checks and Services

P/O Part of

PQDR Product Quality Deficiency Report

psi Pounds per Square Inch

QC Quality Control

QDR Quality Deficiency Report

QTY Quantity

R1 VOLTAGE ADJUST Potentiometer

ROD Report of Discrepancy

RPM Revolutions per Minute

RPSTL Repair Parts and Special Tools List

RTV Room Temperature Vulcanizing

S1 START/RUN/STOP Switch

S17 AUX FUEL Switch

S18 PREHEAT Switch

S19 EMERGENCY STOP button

S20 Temperature Switch

S21 Temperature Switch

S5 CIRCUIT INTERRUPTER Switch

S7 BATTLE SHORT Switch

SAE Society of Automotive Engineers

SDR Supply Discrepancy Report

SE Support Equipment

SF Standard Form

SECNAVINST Secretary of the Navy Instruction

SMR Source, Maintenance, and Reliability

SOS Source of Supply

SPAWAR Space and Naval Warfare Center

SR1 NATO Slave Receptacle

SRA Specialized Repair Activity

STB Supertropical Bleach

TAMMS The Army Maintenance Management System

TB Technical Bulletin/Terminal Board

TDA Table of Distribution and Allowances

TDR Transportation Discrepancy Report

TM Technical Manual

1-6

TMDE Test, Measurement, and Diagnostic Equipment

TO Task Order (Air Force)

TOE Table of Organization and Equipment

TQG Tactical Quiet Generator

UM Unit of Measure, Unit Manual

U.S./US United States

USAMECOM U.S. Army

UUT Unit Under Test

V Volt

VAC Volts Alternating Current

VDC Volts Direct Current

1-11 QUALITY OF MATERIAL

Material used for replacement, repair, or modification must meet the requirements of this technical

manual. If quality or material requirements are not stated in this technical manual, the material must

meet the requirements of the drawings, standards, specifications, or approved Engineering Change

Proposals (ECPs) applicable to the subject equipment.

1-12 SAFETY, CARE, AND HANDLING

The following general precautions and safety regulations will be prepared: Electrostatic Discharge

(ESD) control standards for the protection of electrical and electronic parts, assemblies, and

equipment will be prepared. ESD classes will be identified. (See MIL-STD-1686 and

MIL-HDBK-263, which contains ESD control procedures and material necessary to protect these

items.

1-13 ADMINISTRATIVE STORAGE

Administrative storage of equipment issued to and used by Army activities will have Preventive

Maintenance Checks and Services (PMCS) performed before storing. When removing the

equipment from administrative storage, perform PMCS to ensure operational readiness.

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

1-7

ARMY TM 9-6115-639-13&P

AIR FORCE TO 35C2-3-386-51W/IPB

MARINE CORPS TM 10155A-OI/1

Section II. EQUIPMENT DESCRIPTION

1-14 EQUIPMENT CHARACTERISTICS, CAPABILITIES, AND FEATURES

a. Characteristics

• 3kW, 60Hz (MEP-831A)/400Hz (MEP-832A), Tactical Quiet Generator (TQG)

• Skid-mounted with forklift provisions

• Six lifting handles, four tie-down rings

• Hinged enclosure, allowing quick access for preventive and scheduled maintenance

• Thermostatically controlled, two-fan enclosure cooling system

• 24VDC cranking system

• Single-cylinder, air-cooled, direct-injection, four-stroke-cycle diesel engine

. The 3kW generator set has the following characteristics:

• Permanent Magnet Alternator (PMA) with frequency converter (A8)

• Four-gallon fuel tank (allowing 8 hours of continuous operation at full load)

b. Capabilities and Features

• 3000 to 3600 RPM operating speed

• 3.0kW, 1 phase, 2 wire, 120VAC or 1 phase, 3 wire, 120/240VAC

• Rated engine power of 6.7 HP at 3600 RPM

• Equipped with a 24VDC NATO slave receptacle

• Equipped with a 2-plug 120VAC convenience receptacle with Ground Fault Circuit Interrupter

(GFCI) for the 120VAC convenience receptacle (MEP-831A, 60Hz only)

• Audio noise rating less than 72 dBA at 23 feet from enclosure; less than 85 dBA at operators

position

• Weight: dry = 304.0 pounds (maximum) (MEP-831A), 302.0 pounds (maximum) (MEP-832A);

wet (fuel tank full) = 334.0 pounds (maximum)

• Dimensions: 34.8 x 27.8 x 26.5 inches

. The 3kW generator set has the following capabilities and features:

1-8

Loading...

Loading...