Page 1

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

PWC Series "Magic-Pak"

Self-Contained Heat Pump

[ WARNING

Improper installation, adjustment, alteration, service or maintenance can cause injury

or property damage. Refer to this manual. For assistance or additional information,

consult a qualified installer or service agency.

I _'WARNING I

For your safety, do not store or use gasoline or

other flammable vapors and liquids in the

vicinity of this or any other appliance. Such

actions could result in property damage, per-

sonal injury or death.

TABLE OF CONTENTS

INSTALLATION ....................................... 2

OPERATION .......................................... 5

MAINTENANCE ..................................... 6

Installation and servicing of air conditioning

equipment can be hazardous due to internal

refrigerant pressure and live electrical compo-

nents. Only trained and qualified service

personnel should install or service this equip-

ment. Installation and service performed by

unqualified persons can result in property

damage, personal injury or death.

] A CAUTION I

These units are not approved for mobile home

applications. Such use could result in prop-

erty damage, p_rsonal injury or death.

WIRING DIAGRAMS .............................. 7

WARRANTY ......................................... 10

ManufacturedBy

A.A.C.

A Lennox International Company

421 MonroeStreet

Bellevue,OH 44811

IIIIIIIIIIII)llllllllllllllllllllllllll}lilllllll

I A CAUTION [

The installation of this appliance must conform to the requirements of the National Fire Protection Associa-

tion; the National Electrical Code, ANSl/NFPA No. 70 (latest edition) in the United States; the Canadian

Electrical Code Part 1, CSA 22.1 (latest edition) in Canada; and any state or provincial laws or local ordi-

nances. Local authorities having jurisdiction should be consulted before installation is made. Such appli-

cable regulations or requirements take precedence over the general instructions in this manual.

Save these instructions for future reference

Page 2

INSTALLATION

General

=.seinstructions explain the recommended method of

,llation of the PWC heat pump unit and associated

e_uctricalwiring.

the unit inside the carton ifthe carton isdamaged. File a

cfaimwith the transportation company. If any damages

are discovered and reported to the carrier DO NOT

INSTALL THE UNIT, as claim may be denied.

Check the unit rating p'late to confirm specifications

are as ordered.

This unit is designed and approved for use as a self-

contained air to air heat pump system.

These instructions, and any instructions packaged with

mating components and/or accessories, should be carefully

read prior to beginning installation. Note particularly any

CAUTIONS or WARNINGS in these instructions and all la-

bels on the units.

These instructions are intended as a general guide only,

for use by qualified personnel and do not supersede any

national or local codes in any way. Compliance with all

local, state, provincial or national codes pertaining to this

type of equipment should be determined priorto installa-

tion.

Inspection

Upon receipt of equipment, carefully inspect itfor possible

shipping damage. If damage is found, it should be noted

on the carrier's freight bill. Take special care to examine

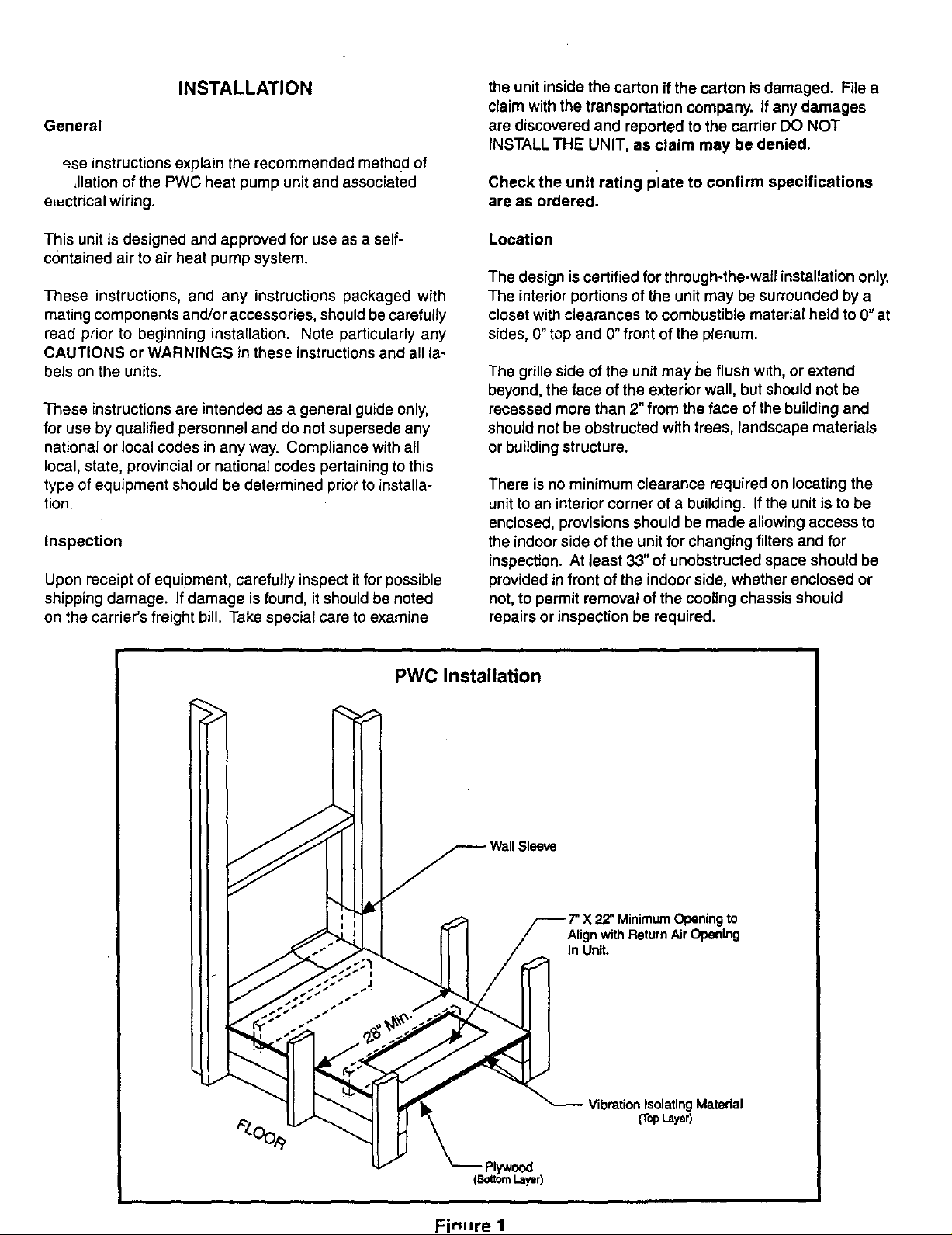

PWCInstallation

Location

The design is certified for through-the-wall installation only.

The interior portions of the unit may be surrounded by a

closet with clearances to combustible material held to 0" at

sides, 0" top and 0" front ofthe plenum.

The grille side of the unit may be flush with, or extend

beyond, the face of the exterior wall, but should not be

recessed more than 2" from the face of the building and

should not be obstructed with trees, landscape materials

or building structure.

There is no minimum clearance required on locating the

unit to an interior corner of a building. If the unit is to be

enclosed, provisions should be made allowing access to

the indoor side of the unit for changing filters and for

inspection. At least 33" of unobstructed space should be

provided infront of the indoor side, whether enclosed or

not, to permit removal of the cooling chassis should

repairs or inspection be required.

Fin-re 1

Sleeve

F MinimumOpening to

Align with Return Air Opening

In Unit.

VibrationIsolating Matedal

{TopLayer)

Page 3

If the unitis installed in a residential garage, it must be

located or protected to avoid physical damage by vehicles.

The unit must be installed so that no electrical compo-

nents are exposed to water.

I

[A CAUT,ON]

This unit must be installed level to allow for

proper drainage of the chassis base pan and

unit drain pan.

Installing With a Wall Sleeve

.

Seal the space between the unit and building opening

using a non-hardening caulking compound. The seal

mustbe weathertight to prevent entrance of moisture

and water into the building. Make sure the drain holes

in the base are not plugged withcaulking,

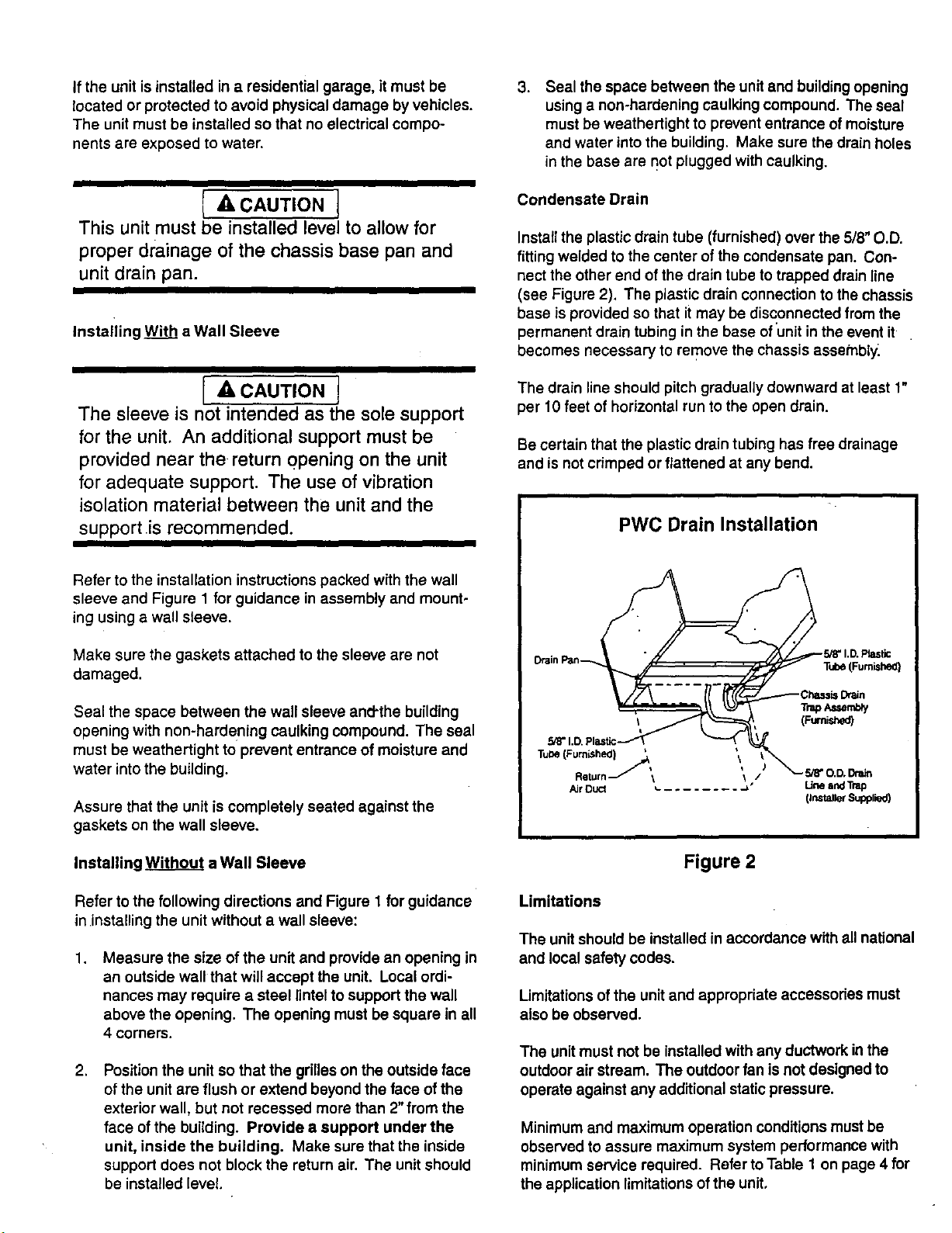

Condensate Drain

Install the plastic drain tube (furnished) over the 5/8" O.D.

fitting welded to the center ofthe condensate pan. Con-

nect the other end of the drain tube to trapped drain line

(see Figure 2). The plastic drain connection to the chassis

base is provided so that it may be disconnected from the

permanent drain tubing in the base of unitin the event it

becomes necessary to remove the chassis assetnbly.

[ _, CAUTION l

The sleeve is not intended as the sole support

for the unit. An additional support must be

provided near the return opening on the unit

for adequate support. The use of vibration

isolation material between the unit and the

support is recommended.

Refer to the installation instructions packed with the wall

sleeve and Figure 1 for guidance in assembly and mount-

ing using a wall sleeve.

Make sure the gaskets attached to the sleeve are not

damaged.

Seal the space between the wall sleeve and-the building

opening with non-hardening caulking compound. The seal

must be weathertight to prevent entrance of moisture and

water into the building.

Assure that the unit is completely seated against the

gaskets on the wall sleeve.

The drain line should pitch gradually downward at least 1"

per 10feet of horizontal run to the open drain.

Be certain that the plastic drain tubing has free drainage

and is not crimped or flattened at any bend.

PWC Drain Installation

Drain Pan_

Installing Without a Wall Sleeve

Refer to the following directions and Figure I for guidance

in installing the unit without a wall sleeve:

.

Measure the size of the unit and provide an opening in

an outside wall that will accept the unit. Local ordi-

nances may require a steel lintel to support the wall

above the opening. The opening must be square in all

4 corners.

,

Position the unit so that the grilles on the outside face

of the unit are flush or extend beyond the face of the

exterior wall, but not recessed more than 2" from the

face of the building. Provide a support under the

unit, inside the building. Make sure that the inside

support does not block the return air. The unit should

be installed level

Figure 2

Limitations

The unit should be installed in accordance with all national

and local safety codes.

Limitations of the unit and appropriate accessories must

also be observed.

The unit must not be installed with any ductwork in the

outdoor air stream. The outdoor fan is not designed to

operate against any additional static pressure.

Minimum and maximum operation conditions must be

observed to assure maximum system performance with

minimum service required. Refer to Table 1 onpage 4 for

the application limitations of the unit.

Page 4

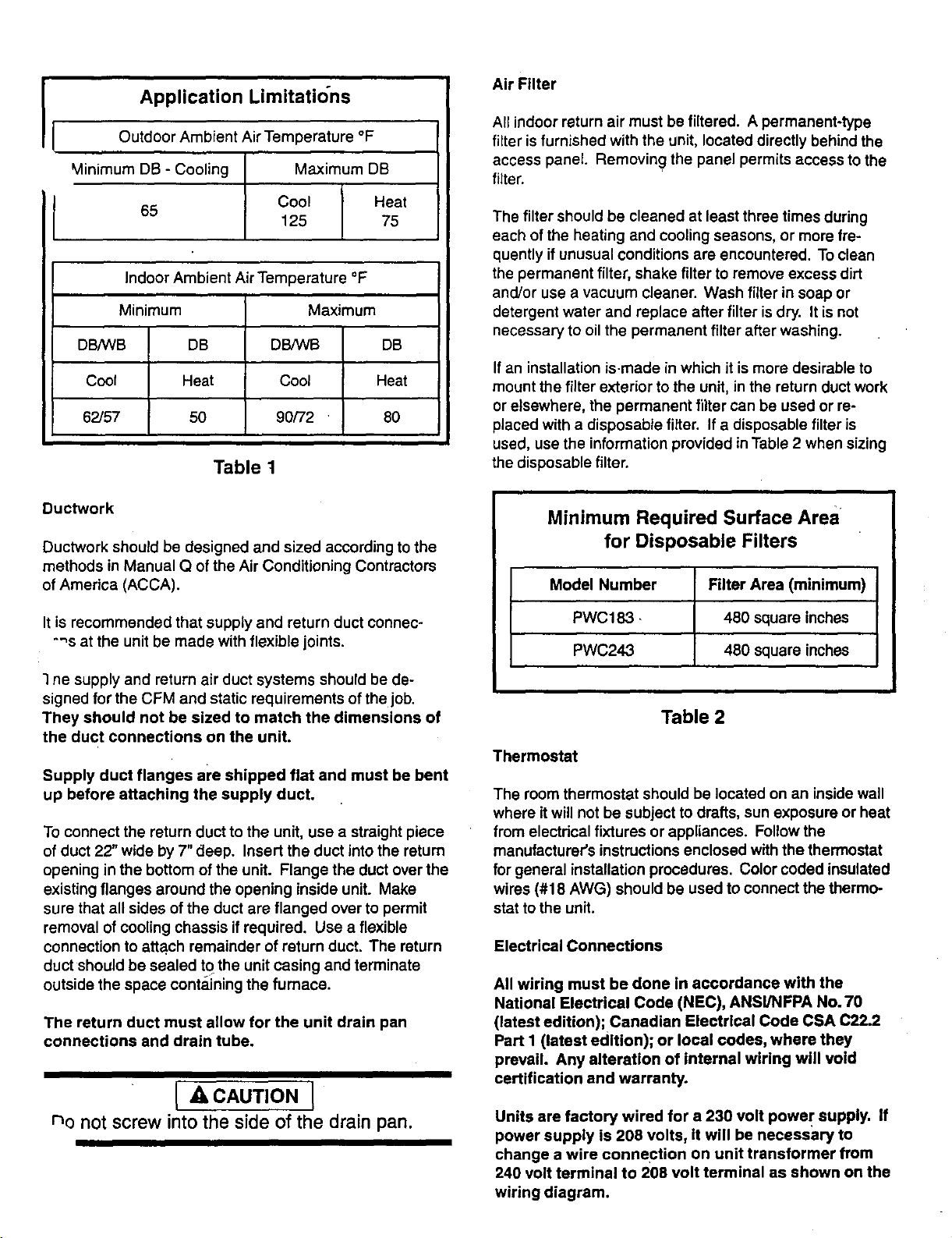

Application Limitations AirFilter

Outdoor Ambient Air Temperature °F

Minimum DB - Cooling Maximum DB

65

Indoor Ambient Air Temperature °F I

Minimum Maximum

DB/WB DB DB,_VB DB

Cool Heat Cool Heat

62/57 50 90/72 80

Table t

Cool Heat

125 75

All indoor return air must be filtered. A permanent-type

filter is furnished with the unit, located directly behind the

access panel. Removing the panel permits access to the

filter.

The filter should be cleaned at least three times during

each of the heating and cooling seasons, or more fre-

quently if unusual conditions are encountered. To clean

the permanent filter, shake filter to remove excess dirt

and/or use a vacuum cleaner. Wash filter in soap or

detergent water and replace after filter is dry. It is not

necessary to oil the permanent filter after washing.

If an installation is.made in which it is more desirable to

mount the filter exterior to the unit, in the return duct work

or elsewhere, the permanent filter can be used or re-

placed with a disposable filter. If a disposable filter is

used, use the information provided in Table 2 when sizing

the disposable filter.

Ductwork

Ductwork should be designed and sized according to the

methods in Manual Q of the Air Conditioning Contractors

of America (ACCA).

It is recommended that supply and return duct connec-

-'_s at the unit be made with flexible joints.

1ne supply and return air duct systems should be de-

signed for the CFM and static requirements of the job.

They should not be sized to match the dimensions of

the duct connections on the unit.

Supply duct flanges are shipped flat and must be bent

up before attaching the supply duct.

To connect the return duct to the unit, use a straight piece

of duct 22" wide by 7" deep. Insert the duct into the return

opening in the bottom of the unit. Flange the duct over the

existing flanges around the opening inside unit. Make

sure that all sides of the duct are flanged over to permit

removal of cooling chassis if required. Use a flexible

connection to attach remainder of return duct. The return

duct should be sealed to the unit casing and terminate

outside the space contai_ningthe furnace.

The return duct must allow for the unit drain pan

connections and drain tube.

[ ACAUTION J

no not screw intothe side of the drain pan.

Minimum Required Surface Area

for Disposable Filters

Model Number Filter Area (minimum)

PWC183 - 480 square inches

PWC24,3 480 square inches

Table 2

Thermostat

The room thermostat should be located on an inside wall

where it will not be subject to drafts, sun exposure or heat

from electrical fixtures or appliances. Follow the

manufacturer's instructions enclosed withthe thermostat

for general installation procedures. Color coded insulated

wires (#18 AWG) should be used to connect the thermo-

stat to the unit.

Electrical Connections

All wiring must be done In accordance with the

National Electrical Code (NEC), ANSl/NFPA No. 70

(latest edition); Canadian Electrical Code CSA C22.2

Part I (latest edition); or local codes, where they

prevail. Any alteration of internal wiring will void

certification and warranty.

Units are factory wired for a 230 volt power supply. If

power supply is 208 volts, it will be necessary to

change a wire connection on unit transformer from

240 volt terminal to 208 volt terminal as shown on the

wiring diagram.

Page 5

Usewiringwithatemperaturelimitation of 75 =C mini-

mum. Run the 208 or 230 volt, 60 hertz electric power

supply through a fused disconnect switch to the control

box of the unit and connect as shown in the wiring dia-

gram located onthe inside of the control access panel.

The unit must be electrically grounded in accordance with

local codes or, in the absence of local codes, with the

National Electrical Code ANSI/NFPA No. 70 (latest edition)

or CSA C22.2 Part 1 (latest edition).

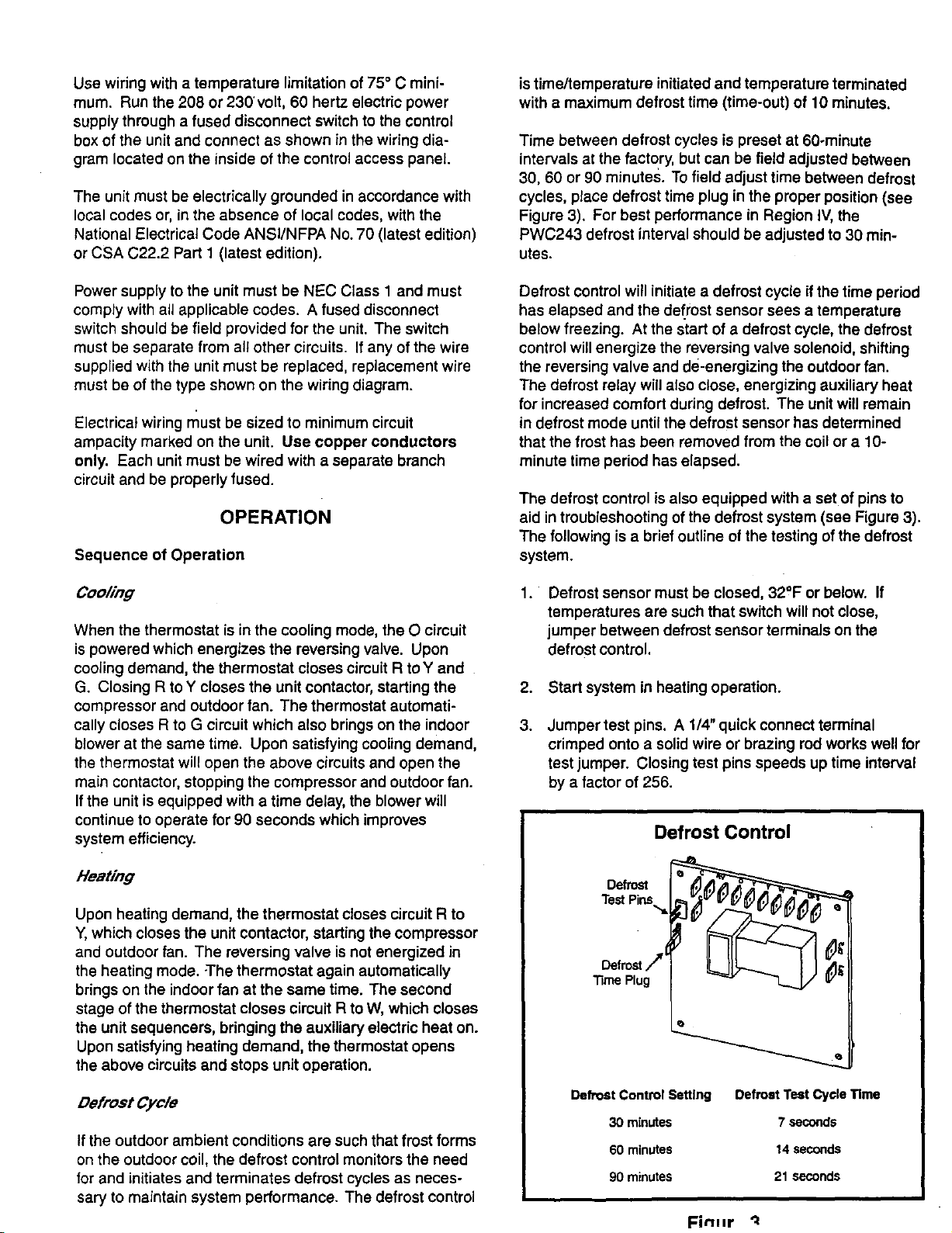

is time/temperature initiated and temperature terminated

with a maximum defrost time (time-out) of 10 minutes.

Time between defrost cycles is preset at 60ominute

intervals at the factory, but can be field adjusted between

30, 60 or 90 minutes. To field adjust time between defrost

cycles, place defrost time plug in the proper position (see

Figure 3). For best performance in Region IV, the

PWC243 defrost interval should be adjusted to 30 min-

utes.

Power supply to the unit must be NEC Class 1 and must

comply with all applicable codes. A fused disconnect

switch should be field provided for the unit. The switch

must be separate from all other circuits. If any of the wire

supplied with the unit must be replaced, replacement wire

must be of the type shown on the wiring diagram.

Electrical wiring must be sized to minimum circuit

ampacity marked on the unit. Use copper conductors

only. Each unitmust be wired with a separate branch

circuit and be properly fused.

OPERATION

Sequence of Operation

Cooling

When the thermostat is in the cooling mode, the O circuit

is powered which energizes the reversing valve. Upon

cooling demand, the thermostat closes circuit R toY and

G. Closing R to Y closes the unit contactor, starting the

compressor and outdoor fan. The thermostat automati-

cally closes R to G circuit which also brings on the indoor

blower at the same time. Upon satisfying cooling demand,

the thermostat will open the above circuits and open the

main contactor, stopping the compressor and outdoor fan.

If the unit is equipped with a time delay, the blower will

continue to operate for 90 seconds which improves

system efficiency.

Defrost controlwill initiate a defrost cycle ifthe time period

has elapsed and the defrost sensor sees a temperature

below freezing. At the start of a defrost cycle, the defrost

control will energize the reversing valve solenoid, shifting

the reversing valve and de-energizing the outdoor fan.

The defrost relay will also close, energizing auxiliary heat

for increased comfort during defrost. The unit will remain

in defrost mode until the defrost sensor has determined

that the frost has been removed from the coil or a 10-

minute time period has elapsed.

The defrost control is also equipped with a setof pins to

aid in troubleshooting of the defrost system (see Figure 3).

The following is a brief outline of the testing of the defrost

system.

. Defrost sensor must be closed, 32°F or below. If

temperatures are such that switch will not close,

jumper between defrost sensor terminals on the

defrost control,

2. Start system in heating operation.

.

Jumper test pins, A 1/4" quick connect terminal

crimped onto a solid wire orbrazing rod works well for

test jumper. Closing test pins speeds up time interval

by a factor of 256.

Defrost Control

Heating

Upon heating demand, the thermostat closes circuit R to

Y, which closes the unit contactor, starting the compressor

and outdoor fan. The reversing valve is not energized in

the heating mode. -The thermostat again automatically

brings on the indoor fan at the same time. The second

stage of the thermostat closes circuit R to W, which closes

the unit sequencers, bringing the auxiliary electric heat on.

Upon satisfying heating demand, the thermostat opens

the above circuits and stops unit operation.

Defrost Cycle

Ifthe outdoor ambient conditions are such that frost forms

on the outdoor coil, the defrost control monitors the need

for and initiates and terminates defrost cycles as neces-

sary to maintain system performance. The defrost control

Defrost

TestPins.,,,=i

Defro=/

TimePlug

Defrost Control Setting Defrost Test Cycle Time

30 minutes 7 seconds

60 minutes 14 seconds

90 minutes 21 seconds

FinHr

Page 6

After closing test pins and appropriate cycle time has

elapsed, the reversing valve should shiftto defrost mode

and the outdoor fan should stop. After 2 seconds of

defrost operation, the reversing valve should shift back to

",tingoperation and the outdoor fan should start.

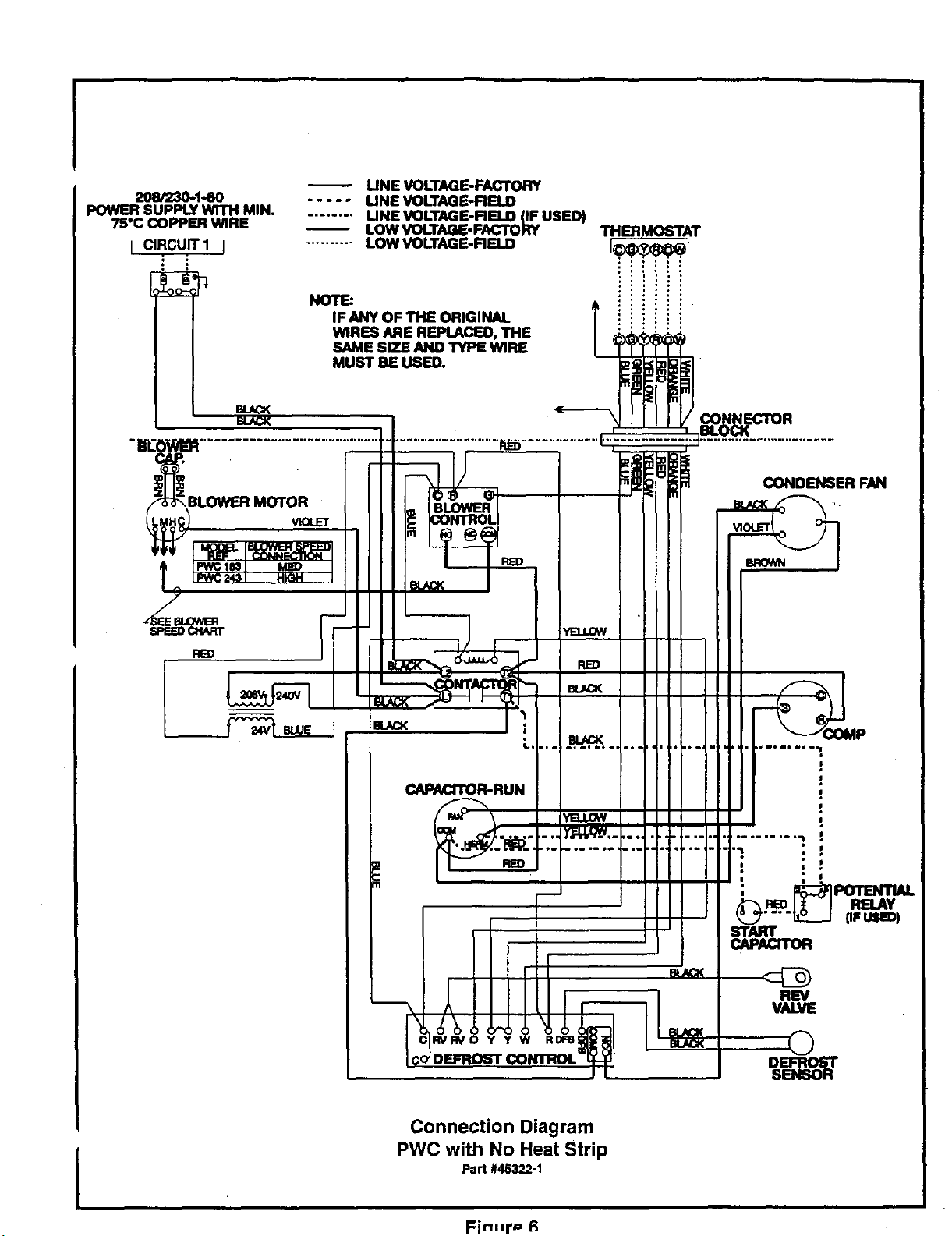

System Performance

For maximum performance of this heat pump system, the

operating temperatures and pressures should be checked

and superheat determined at Standard ARI test conditions

of 82°F outdoor - 80°F indoor dry bulb/67°F wet bulb. If

superheat measured deviates from the values given in

Table 3, refrigerant charge should be adjusted accordingly

for maximum performance.

Motors

The indoor and outdoor fan motors are permanently

lubricated and require no maintenance.

Outdoor Coil

Foreign material should notbe allowed to accumulate on

the outdoor coil surface or other parts in the air circuit.

Cleaning should be as often as necessary to keep the coil

clean. Use a brush, vacuum cleaner attachment or other

suitable means. Be sure power to unit is shut off

before using water to clean the coil.

Care should be used when cleaning the coils so that

the coil fins are not damaged.

Suction Superheat

Outdoor

Unit

Model

PWC183 18° - 20° F

PWC243 17° - 19° F

Suction Superheat

@ ARI Conditions

82 ° OD

80° IDDB/67 ° IDWB

Table 3

MAINTENANCE

Shutoff all electrical power to the unit before

conducting any maintenance procedures.

Failure to do so could cause personal injury.

Outdoor Base Drain

Foreign material should not be allowed to clogthe drain

hole. inspect and clear drain opening priorto heating

season.

Periodic inspection and maintenance normally consists of

changing or cleaning filters and (under some conditions)

cleaning the coils.

Filter

Inspect the filter once a month. Replace disposable filter

or clean the permanent-type filter as necessary (a mini-

mum ofthree times each heating or cooling season is

recommended). Do not replace permanent-type filter with

a disposable filter unless an installation was made in

which the filter was mounted exterior to the unit (see Air

Filter section on page 4).

Page 7

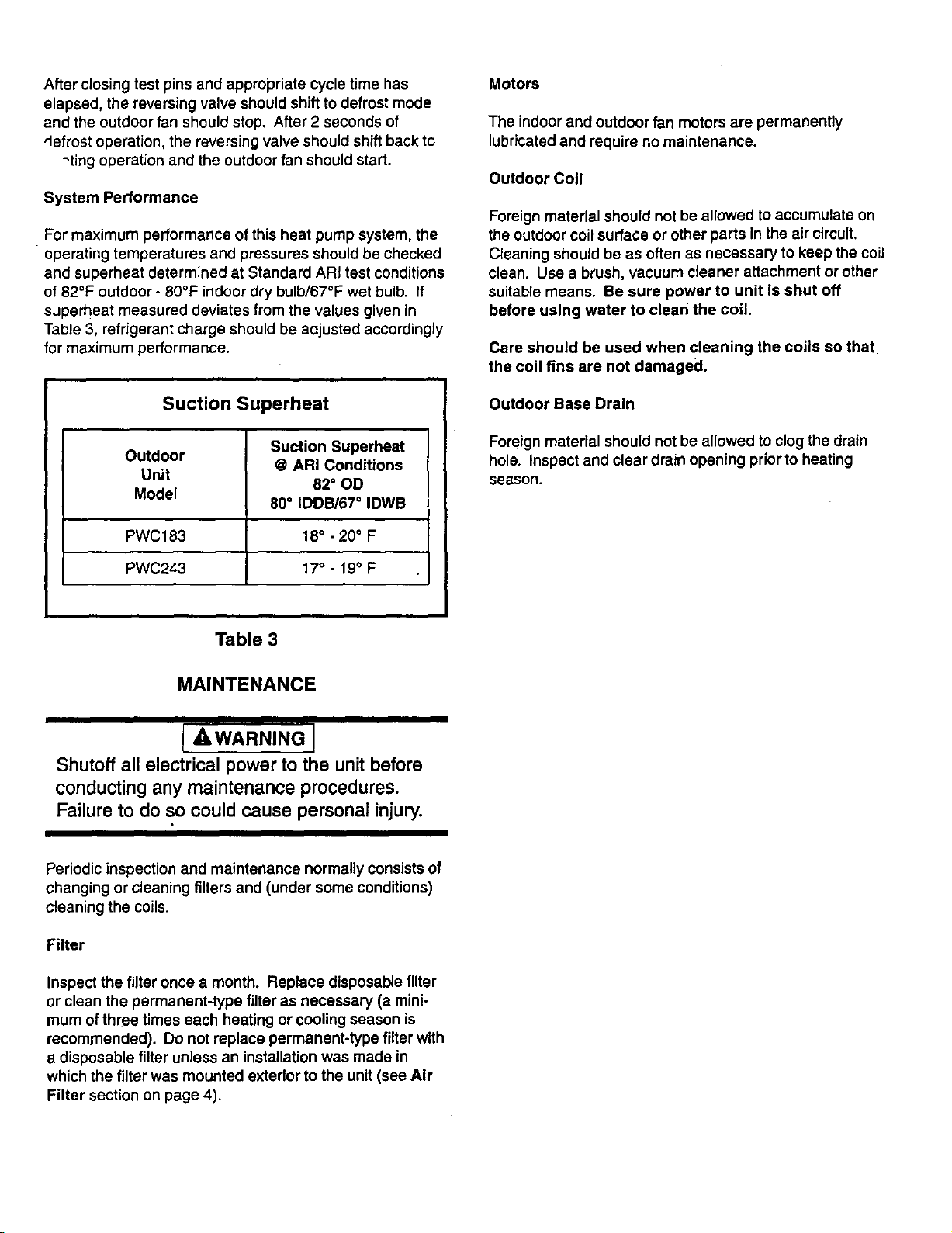

POWERSUPPLYWITHMIN.

208/230-1-60

75"CCOPPERWIRE

I CIRCUIT1I I (lo_cO_L'qCIRCUIT2I

•; ..; : :

P_D

BLACK

LOWER MOTORvloI_rr

UNE VOLTAGE-FACTORY

UNE VOLTAGE-RELD

........ UNE VOLTAGE-RELD (IF USED)

LOW VOLTAGE-FACTORY

.......... LOWVOLTAGE-FIELD

BLUE

7 AND 10 PWC ONLY

I

BLOWER

(

NOTE:

IF ANY OF THE ORIGINAL

WIRES ARE REP_, THE

SAME SIZE AND TYPE WIRE

MUST BE USED.

CONNECTOR

CONDENSER FAN

BLACK

BROWN

RED

M1

CAPACr_R-RUN

REV

VALVE

©

DEFROST

SENSOR

Connection Diagram

PWC with 5, 7 or 10 KW Heat Strip

Part #41164-3

Fin.r== 4

Page 8

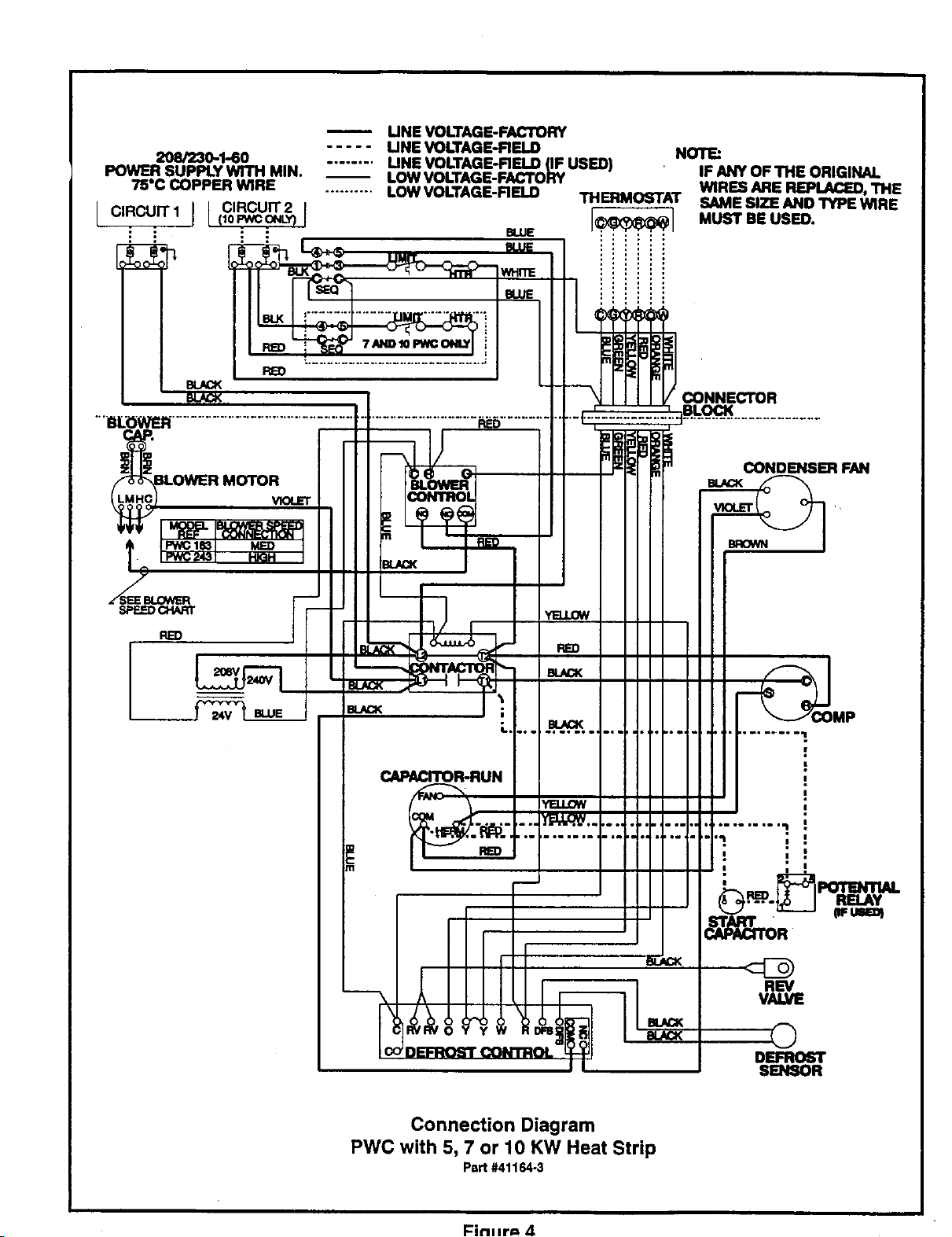

208/230-1-60

:OWER SUPPLY WITH MIN.

75"C COPPER WIRE

I CIRCUIT 1 I CIRCUIT 2

: i : :

: •

..... LINE VOLTAGE-RELD

UNE VOLTAGE-FACTORY

........ LINE VOLTAGE-FIELD (IF USED)

LOW VOLTAGE-FACTORY

.......... LOW VOLTAGE-R ELD

BLUE

NOTE:

IF ANY OF THE ORIGINAL

WIRES ARE REPLACED, THE

SAME SIZE AND TYPE WIRE

MUST BE USED.

RED

F_

UMrT

BLOWER

m

NT

CAPACITOR-RUN

CONNECTOR

BLOCK

CONDENSER FAN

E_CK

¥

I

I

RED

REV

VALVE

O

DEFROST

Connection Diagram

PWC with 15 KW Heat Strip

Part #42203-2

Page 9

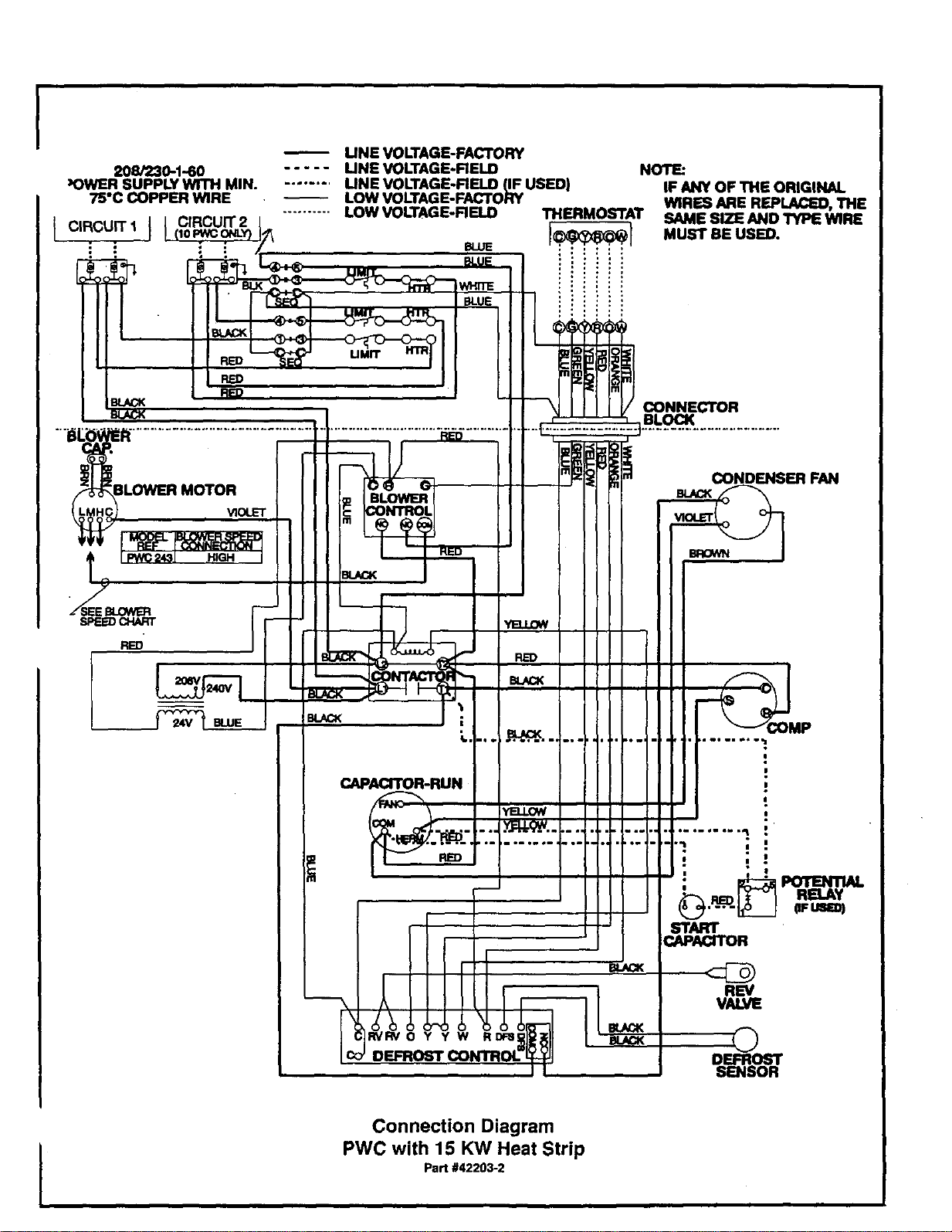

POWER SUPPLY WITH MIN.

208/230-1-60

75"C COPPER WIRE

BLOWER MOTOR

..... UNE VOLTAGE-FIELD

........ UNE VOLTAGE-FIELD (IF USED)

.......... LOWVOLTAGE-FIELD

NOTE:

LINE VOLTAGE-FACTORY

LOWVOLTAGE-FACTORY THERMOSTAT

IF ANY OF THE ORIGINAL

WIRES ARE REPLACED, THE

SAME SIZE AND TYPE WIRE

MUST BE USED.

BLOWER

CONDENSER FAN

_-RUN

I_)

RE)

RED

BROWN

: : °

!

, POTENTIAL

RELAY

pFUSe_

I

Connection Diagram

PWC with No Heat Strip

Part #45322-1

Fin-r== 6

Page 10

I

Limited Warranty

August 1, 1997

Thiswarran(ygivesyou specificlegalrightsand you may have otherrights

which vary from state/provincetostate/province.

Warrantor: Armstrong Air Conditioning Inc., 421 Monroe St., Bellevue, OH 44811

Armstrong Air Conditioning Inc products are available under the following names: Air Ease, Armstrong Air, American Airs, Concord

Subject to the limitafions.stated in this warranty, we warrant to the first buyer for use the residential heating, cooling or heat pump unit, when

installed, operated and maintained as required by this warranty, to be free of defects in workmanship or material for a pehod of five years (two years

for commercial equipment) from the time of installation. We will replace any defective component without cost or expense to you except for the costs

of delivery and labor for removal and replacement of the defective component.

Warranty Begins

The warranty period begins when the installafion is complete and the product is ready to operate. You must be able to verity this date whenever a

warranty claim is made. Original bill of sale, installer's invoice or other similar document will suffice..If the beginnir_g date cannot be Verified. we will

consider warranty coverage to begin six months after the date the product was shipped from our factory.

Limitations on Implied Warranties

Implied warranties of merchantability or, to the extent applicable, fitness for a particular purpose are timited to five years, the same duration as the

basic limited written warranty provided herein. Some states/provincas do not allow limitations on how tong an implied warranty of merchantability or

fitness lasts, so the above limitations dr exclusions may not apply to you.

Only Warranty

This written Limited Warranty is the only warranty made by the warrantor; this warranty is in lieu of and excludes all other warranties, express or

implied. The warrantor does not authorize any person to provide any other warranty or to assume for it any further obligation in connection withthe

warranted product.

What is NOT Covered

I. Cabinets or cabinet pieces.

2. Normal maintenance items such as filters, fan belts, fuses or other consumable items.

3 Damage caused by misuse, failure to maintain properly, accidents or acts of God.

4 External wiring, piping, venting or attachment of accessory products not integral to our product, including without limitation, humidifier,

air cleaner, vent damper, thermostat or other mechanical devices not manufactured by the warrantor.

5 Products that have been operated in a corrosive atmosphere where e concentration of acids, halogenated hydrocarbons or other

corrosive elements causes deterioratfon to metsi surfaces or integral components. NOTE: Operation in a corrosive atmosphere is

considered abuse and voids this warranty

6 Products that have NOT been installed in accordance with our published installation instructions, applicable focal, state/provincial or

national codes, ACCA published standards.

7 Products that have NOT been installed by competent, qualified installers.

8 Products that have been moved from their odginai place of installation.

Warranty on Replacement Components

Any replscement component furnished by us will assume the remaining (unused) portion of the Limited Warranty.

Consequential Damages

The warrantor shall not be responsible for any consequential damages caused by any defect in the product. Some state/provinces do not allow the

exclusion or limitations of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

NOTE: After the first year, in the event that a gas or oil heat exchanger is no longer being manufactured by the warrantor, the warrantor will allow a

credit equal to the then current wholesale price of an equivalent heat exchanger towards the purchase of a new Armstrong gas or oil furnace.

This product must be installed, used and cared for in accordance with the instructiott manual You are responsible for required pedodic maintenance

or service, such as changing or cleaning of air filters and lubrication or cleaning of components. Failure to properly install, operate or maintain your

unit voids this warranty.

!

Model #

, INSTALLED BY:

Address

Telephone #

I ealer

Owner Record

Serial # Installation Date

License #

Page 11

INSTALLATION INSTRUCTIONS

Wall Sleeve Kit CA239

For Use With

HW/HWC/EWC/PWC Series

Magic-Pak Thru-the-Wall Unit

_WARNING

age_

General

Parts List

The wall sleeve isdesignedto facilitatethe installationof

Quantity Description

1 TopPanel

1 BottomPanel

1 Right Side Panel

1 LeftSide Panel

Magic-Pakunits by providingan accurateopeningduring

buildingconstruction.The use ofa wall sleeveallowsunits

toremain off-siteuntilbuildingconstructionapproaches

completion.

The wall sleeve iscomprisedof four assemblies

(top,bottom,and rightand left sides) which easily slip

togetheron the job toform a rectangularbox correctly

sizedto receive a Magic-Pak unit.

2 Squaring Braces

1 TopSupportAngle

2 Side SupportAngles

24 #8 x 3/8" Screws

1 InstallationInstructions

Manufactured By

A.A.C.

A Lennox International Company

421 Monroe Street

Bellevue,OH 44811

Save these instructionsforfuture reference

When inplace and securely fastened, the wall sleeve

openingprovideseasy access to the finishedwall pedm-

efarfor caulksealing.

The weather-seal caulkingiseasier to performwhen the

sleeveprotrudesbeyondthe finishedwall by 3/8" to 1".

Inspection of Shipment

Ifany damage tothe contentsof this kitis found at the

timeof delivery,propernotificationshouldbe made onthe

carrier's freight bill.Damage claimsshouldbe filedwith

thecarrierat once. Claimsofshortage shouldbe filedwith

the manufacturerwithin 5 days.

1111111Ill1111111111IllIllIIIIIIIIIRillIIIIIIII

Page 12

INSTALLATION

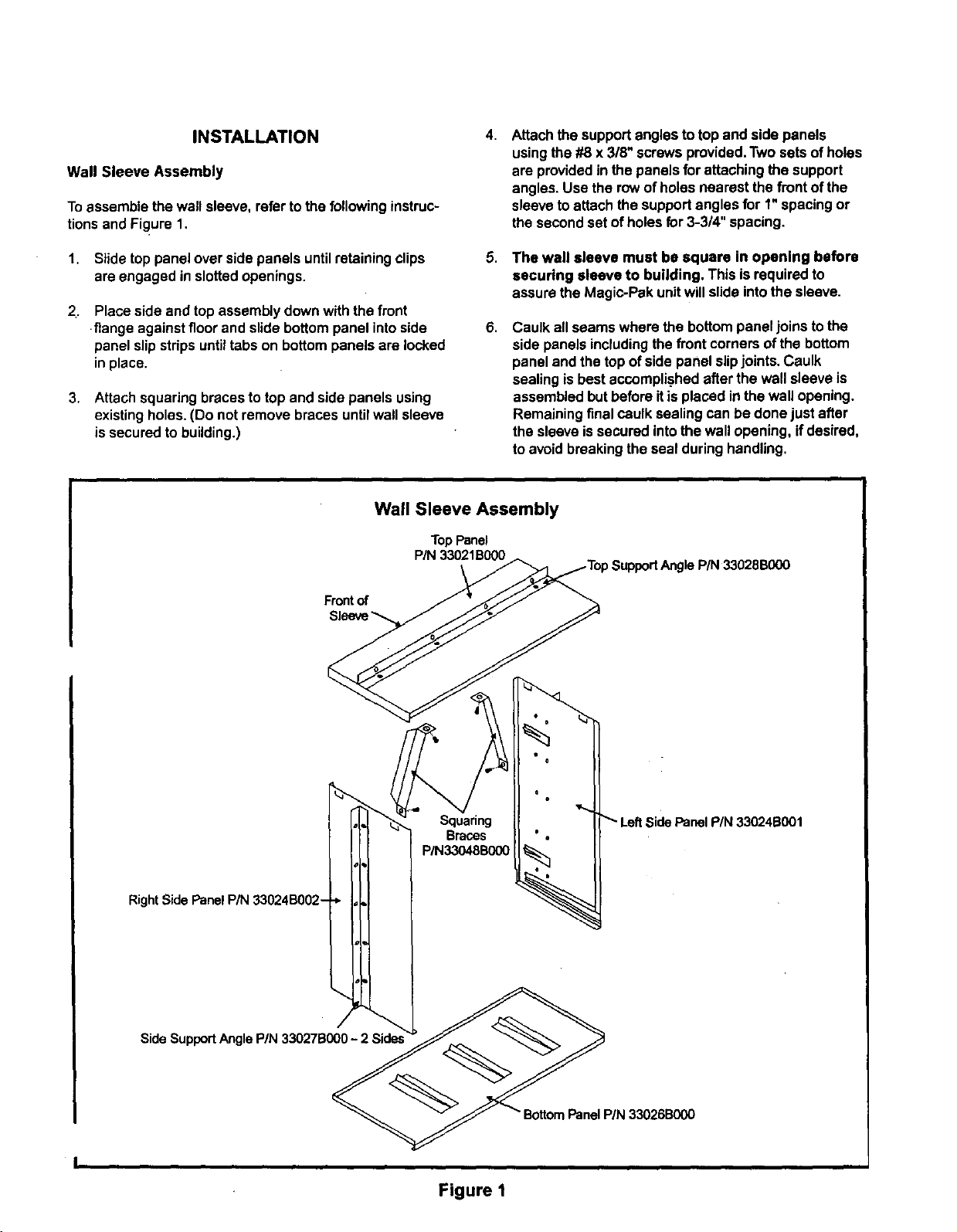

Wall Sleeve Assembly

Toassemble the wall sleeve, refer to the followinginstruc-

tionsand Figure 1.

4.

Attachthe supportanglesto top and side panels

usingthe #8 x 318"screwsprovided.Two sets of holes

are providedin the panels for attaching the support

angles. Use the rowof holes nearest thefront of the

sleeveto attach the support anglesfor 1"spacing or

the secondset of holesfor 3-3/4" spacing.

1. Slidetop panel over side panels untilretaining clips

are engaged in slottedopenings.

2_

Place side and top assemblydown withthe front

flange againstfloorand slide bottom panel intoside

panelslip strips untiltabs on bottom panels are locked

inplace.

3. Attach squaring bracesto top and side panels using

existingholes. (Do not remove braces untilwall sleeve

issecured to building.)

Wall Sleeve Assembly

P/N33021B000

Frontof

TopPanel

The wall sleeve must be square in opening before

securing sleeve to building. This is requiredto

assure the Magic-Pak unitwill slide intothe sleeve.

8.

Caulk all seams where the bottompaneljoins tothe

side panels includingthefront corners ofthe bottom

panel and the top of side panel slipjoints.Caulk

sealing is bestaccomplishedafterthe wall sleeve is

assembledbutbefore Risplaced inthe wall opening.

Remainingfinalcaulk sealing can be done just after

the sleeve issecured intothe wall opening, if desired,

to avoidbreakingthe seal duringhandling.

RightSide Panel P/N 33024B002-

Side SupportAngle PIN 33027BG00- 2 Side=

Squaring

Braces

P/N33048B000

Figure I

LeftSide Panel P/N 33024B001

Page 13

Furthersealing againstair infiltrationmustbe done alter

the Magic-Pak unitis installedin the wall sleeve and utility

connectionshavebeen completed (see Sealing/Weath-

erproofing Wall Sleeves section).

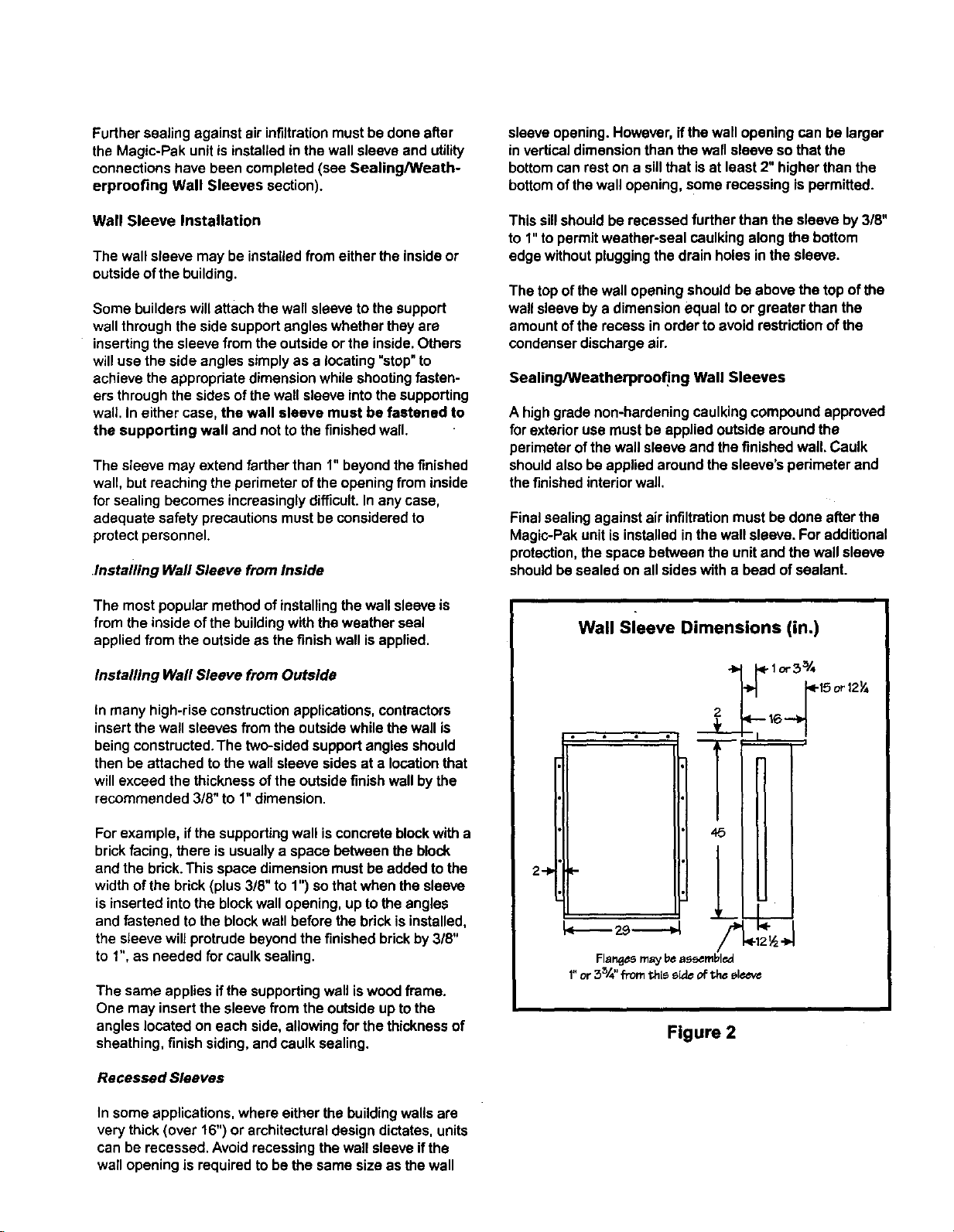

sleeveopening. However,if the wall openingcan be larger

inverticaldimensionthan the wall sleeve sothat the

bottomcan rest ona sill that isat least 2" higher thanthe

bottomof thewall opening,some recessing is permitted.

Wall Sleeve Installation

The wall sleeve may be installedfrom either the insideor

outsideofthe building.

Some builderswillattach the wall sleeve to the support

wallthroughthe side supportangleswhether they are

insertingthesleeve fromthe outsideor the inside.Othem

willuse the side angles simplyas a locating"stop"to

achievethe appropriatedimensionwhileshootingfasten-

ersthroughthe sides ofthe wallsleeve intothesupporting

wall.In either case,the wall sleeve must be fastened to

the supporting wall and notto thefinishedwall.

The sleeve may extend farther than 1"beyondthe finished

wall,but reachingtheperimeter ofthe openingfrom inside

for sealing becomes increasinglydifficult.In any case,

adequate safety precautionsmust beconsideredto

protectpersonnel.

Instailing Wall Sleeve from Inside

The most popular method of installingthe wallsleeve is

from the inside of the buildingwiththe weather seal

appliedfrom the outsideas the finishwall is applied.

Instalflng Wall Sleeve from Outside

Thissillshouldbe recessed further than the sleeve by3/8"

to 1"to permitweather-seal caulking along the bottom

edge withoutpluggingthe drain holes in the sleeve.

The topof the wall opening shouldbe above the topof the

wall sleevebya dimensionequal to or greater than the

amountof the recess in orderto avoid restrictionof the

condenserdischargeair.

Sealing/Weatherproofing Wall Sleeves

A highgrade non-hardeningcaulkingcompoundapproved

forexterioruse mustbe appliedoutsidearoundthe

perimeterofthe wall sleeveand the finishedwall. Caulk

shouldalso beapplied around the sleeve's perimeter and

thefinishedinteriorwall.

Final sealingagainst air infiltrationmust be donealter the

Magic-Pakunit is installedin thewall sleeve. For additional

protection,the space between the unit and the wall sleeve

shouldbe sealed on all sideswith a bead of sealant.

Wall Sleeve Dimensions (in.)

<.. 1or 3_/4

In manyhigh-rise constructionapplications,contractors

insertthe wall sleevesfrom the outsidewhilethewall is

beingconstructed.The two-sidedsupport anglesshould

then be attached to the wall sleeve sides at a locationthat

willexceed the thicknessofthe outsidefinish wall bythe

recommended3/8" to 1"dimension.

Forexample, ifthe supportingwall isconcreteblockwith a

brickfacing, there is usuallya space betweenthe block

and the brick.This space dimensionmust be addedto the

widthof the brick (plus3/8" to 1") so thatwhen the sleeve

is inserted intothe blockwall opening, up to the angles

and fastened to the blockwallbefore the brickisinstalled,

the sleevewilt protrudebeyondthe finishedbrickby 3/8"

to 1",as needed for caulk sealing.

The same applies if the supportingwall iswoodframe.

One may insertthe sleevefromthe outside upto the

angleslocated on each side,allowingforthe thicknessof

sheathing,finishsiding,and caulk sealing.

Recessed Sleeves

In someapplications,where either the buildingwallsare

verythick(over 16") or architecturaldesign dictates,units

can berecessed. Avoidrecessingthewall sleeve ifthe

wallopening is requiredto be the same size as the wall

2--I=

I.---- z9- -,4

Flar_es may b_ assembl_l

1"or 5_/4"from this e_e ofthe elc_v_

Figure 2

-$--

I

i

45

I

I

_t._

.16,.._15 or 12_

!

Page 14

I

I_A_T_°.I 4"948°96----I

INSTALLATION

ANDMAINTENANCE

INSTRUCTIONS

PWCSERIES

SELF-CONTAINEDHEATPUMP

ManufacturedBy

ARMSTRONG AIR CONDITIONING INC.

A LENNOXInternationalInc. Company

421 MonroeStreel

Page 15

I PART.OI .,,,,RO..I OATE12''0 I SUPERSEOESI I PAGE2OF,0

GENERAL

Theseinstructionsexplainthe recommendedmethodof installationof the PWCheatpumpunit and associatedelec-

tricalwiring.

This unit is designed and approvedfor use as a self-containedairto air heat pump system.

These instructions,and anyinstructions packagedwith maling componentsand/or accessories,shouldbe carefully

read priorto beginning installation.Note parliculady anyCAUTIONSor NOTESin theseinstructions andall labels on

the unit.

Theseinstructionsare intendedasa generalguideonly.for use byqualifiedpersonnel,anddo notsupersedeanyna-

tionalor localcodesinanyway. Compliancewithalllocal,state, provincial,or nationalcodespertainingtothistypeof

equipmentshouldhe determinedprior to installation.

INSPECTIONOFSHIPMENT

Uponreceiptof equipment,carefullyinspectit forpossibleshippingdamage.Ifdamageis found,it shouldbe noted

on the carder's freightbill. Take specialcareto examinethe unit insidethecartonif the cartonis damaged.File a

claimwith the transportationcompany.

If any damagesare discoveredand reportedto the carrierDONOTINSTALLTHE UNIT as claim may be denied.

Checkthe unitrating plate to confirmspecificationsare as ordered.

CAUTION:INSTALLATIONANDSERVICINGOFAIR CONDITIONINGEQUIPMENTCANREHAZARDOUSDUETO IN-

TERNALREFRIGERANTPRESSUREAND LIVE ELECTRICALCOMPONENTS.ONLYTRAINEDANOQUALIFIEDSER-

VICE PERSONNELSHOULDINSTALL,REPAIR,OR SERVICETHIS EQUIPMENT.

WARNING

FORYOURSAFETY

DONOTSTOREOR USEGASOLINEOROTHERFLAMMABLEVAPORSANDLIQUIDSINTHE VICINITYOFTHIS

ORANY OTHERAPPLIANCE.

NOMENCLATURE:

10 PWC 242 A-1A

1 2 3 4 5

1. ELECTRICHEATING

5 = 5kW

7 = .7kW

10 = 10kW

15 = 15kW

4. ElectricalRatingCode:

A=208/230 volts; OOHz; 1 phase,

5. RevisionCode

2. PWC=(HEAT) PUMPWITH COOLING

3. COOLINGCAPACITYTONNAGE

182 = 1½ TON

242 = 2 TON

302 = 2½ TON

Page 16

PARTNO. I 41194BOg6I DATE I 2-1-96 I SUPERSEDESI 411940094 I PAGE3OFIO

I

LOCATION

Thedesigniscertifiedfor through-the-wallinstallationonly. Theinteriorportionsof theunitmay besurroundedbya

closetwith clearancestocombustiblematerial heldto 0" at sides, 0" top and O" frontof the plenum.

Thegrillesideofthe unitmay be flushwith orextendbeyondthe faceof theexteriorwall, butshouldnotberecessed

morethan two(2) inchesfrom the face of the buildingand shouldnotbe obstructedwithtrees, landscapematerials,

or buildingstructure.

Thereis nominimumclearancerequiredonlocatinga unittoaninteriorcornerofa building. If theunitisto beenclos-

ed, provisionsshouldbemadeallowingaccesstothe indoorsideof the unitfor changingfilters.and forinspection.At

least33" of unobstructedspace shouldbeprovidedin front of the indoorside. whetherenclosedor noL to permit

removalof the coolingchassisshouldrepairsor inspectionbe required.

If this unit is installedina residentialgarage it mustbe locatedor protectedtoavoidph_,sicaldamageby vehicles.

Thisunit must be installedso that no electricalcomponentsare exposedto water.

INSTALLATION

CAUTION:THESLEEVEISNOTINTENDEDASTHESOLESUPPORTFORTHEUNIT. ANADDITIONALSUPPORTMUST

BE PROVIDEDNEARTHE RETURNOPENINGON THE UNIT FOR ADEQUATESUPPORT.THE USE OF VIBRATION

ISOLATIONMATERIALBETWEENTHE UNIT ANDTHE SUPPORTIS RECOMMENDED,

CAUTION:THIS UNITMUST BEINSTALLEDLEVELFORPROPERDRAINAGEOFTHE CHASSISBASEPANANDUNIT

DRAINPAN.

WITHOUTWALLSLEEVE

Measurethesizeoftheunit andprovideanopeninginanoutsidewallthat will accepttheunit. Localordinancesmay

require a steellintel tosupportthe wall abovethe opening. This openingmust be squarein all corners.

Positiontheunitsothat the grilleson the outsidefaceofthe unitare flush or extendbeyondthe faceof the exterior

wall,but notrecessedmorethantwo(2) inchesfromthefaceof the building. PROVIOEA SUPPORTUNDERTHE UNIT

INSIDETHE BUILDING.Makesure thattheinsidesupportdoesnotblockthereturnair. The unitshouldbe installed

level.

Sealthe spacebetweentheunit and the buildingopeningusinga non-hardeningcaulkingcompound.Thesealmust

beweather-tighttoprevententranceof moistureandwater intothe building.Make sure the drainholesin the base

are notpluggedwith caulking.

WITH WALL SLEEVE

Seethe installationinstructionspacked with Ihe wall sleeveto assembleand mountin a wall. Make sure that the

gasketsattachedtothe sleeveare notdamaged.Assurethatthe unit is completelyseatedagainstthegasketsonthe

wall sleeve.

Sealspacebetweenwall sleeveand buildingopeningusingnon-hardeningcaulkingcompound.Thisseal must be

watertight.

CONDENSATEDRAIN

Install theplasticdraintube(furnished)overthe5/8" O.O.fittingweldedto the condensatepan. Connectotherend

ofthe draintubeto trappeddrain line(See Figure2). Theplasticdrain connectiontothechassisbaseis providedso

thatit may bedisconnectedfromthe permanentdrain tubingin the baseof unit in theeventit becomesnecessaryto

removethe chassisassembly.

L

The drain line should pitch gradualtydownwardat least 1" per 10 footof horizontalrun to theopendrain.

Be certainthat the plasticdrain tubing has treedrainageand is notcrimpedor flattenedat any bend.

Page 17

PA.T.O.I ,,,,_,,.0_,I 0','_ I _'"_ I SU"ERSEOESI ""_"00_"I PA_E,'O_,O

FIGURE1

INSTRUCTIONFORSUPPORTINGPWCUNITS

Wall Sleeve

7 x 22 Min. OpeningTo

A#ignwith'Return Air

Openingin Unit.

FIGURE2

DRAINPAN

%

VibrationIsolatingMaterial

Plywood

5/8 " I.D. PLASTIC

(FURNISHED)

CHASSISDRAIN

'ASSEMBLY

(FURNISHED)

5/8" I,O. PLASTIC

TU"BE(FURNISHEO]

RETURN

AIR DUCT\

5/8" O.O. DRAIN

\

_LINEAND TRAP

(iNSTALLERSUPPLIED)

Page 18

.ARTNO.I "f9"Bog I OATEI 2"t'g6I .SUPERSEOESI 4119'0094[ PAGESOFtO

LIMITATIONS

The unit shouldbe installedin accordancewith all nationaland local safetycodes.

Limitationsof the unitand appropriateaccessoriesmustalso beobserved.

The unitmustNOTbe installedwithany ductwork in theoutdoorairstream,Theoutdoor fanisnotdesignedtooperate

againstany additionalstaticpressure.

Minimum and maximum operating conditionsmust be observedto assure maximumsystem performancewith

minimum servicerequired,

TABLE1 - APPLICATIONLIMITATIONS

OUTDOORAMBIENTAIR TEMP. OF INDOORAMBIENTTEMP. °F

MIN, DB- COOL MAX, DB MIN. MAX.

65 COOL HEAT OB/WB DB DB/WB DO

125 75

COOL HEAT COOL HEAT

62/57 50 90/72 80

DUCTWORK

Ductwork shouldbe designedand sized accordingto applicablemethods fromthe Air ConditioningContractorsof

America(ACCA).

It is recommendedthat supplyand return duct connectionsat the unit bemadewith flexible joints.

' The supplyand return airductsystemsshouldbe designedfortheCFM staiicrequirementsofthejob. Theyshould

NOT be sized Io match the dimensionsol the duct connectionson the unit.

NOTE:SUPPLYDUCTFLANGESARESHIPPEDFLATANDMUSTBEBENTUP BEFOREAFI'ACHINGTHESUPPLYDUCT,

ToconnectthereturnducttotheunJt,useastraightpieceofduct22" wideby 7" deep. Insert theductintothe return

openingin thebottomoftheunit. Flangetheductovertheexistingflangesaroundtheopeninginsideunit. Makesure

thatall sidesoftheductare flangedoverto permitremovalofcoolingchassisif required.Usea flexibleconnectionto

attachremainderofreturnduct.The returnductshouldbesealedto theunitcasingand terminateoutsidethe space

containingthe furnace,

NOTE:THE RETURNDUCTMUST ALLOWFORTHE UNIT DRAINPANCONNECTIONSAND DRAINTUBE.

CAUTION:00 NOTSCREWINTOTHE SIDEOF THE DRAIN PAN.

AIR FILTER

Allindoorreturn airmustbefiltered.Apermanent-type filter is furnished withtheunit. locateddirectly behindtheac-

cess panel. Removingthe panelpermitsaccessto the filter.

The tiltershouldbecleanedatleastthreetimesduringeachofthe heatingandcoolingseasons,ormorefrequently if

unusualconditionsare encountered.To cleanthe permanentfiller, shakefilterto removeexcessdirt and/or use

vacuumcleaner. Washtilter in soapor detergentwaterand replacealter filteris dry.

The filter suppliedneed not be oiledalter washing.

Page 19

I PA.TNoI .tt9..o96I DATE12196 I SUPERSEDESI ,rig.DO9.I PAGE,O.tO

It an installation is madein which it is moredesirableto mount the filter exterior totheunit, in the return duct work, or

olherwise, either the permanent filter supplied or a disposablefilter maybe used. If a disposable filter is used, the

minimum area required is as follows:

MOOELNO. FILTERAREA(MtN.)

PWC 182 480 sq. in.

PWC242 480 sq. in.

PWC302 480 sq. in.

THERMOSTAT

The room thermostatshouldbe locatedonan insidewall whereit wilt not be subjecttodrafts, sun exposureor heat

from electricalfixturesorappliances.Followthemanufacturer'sinstructionsenclosedwiththe thermostatforgeneral

installationprocedures.Colorcodedinsulatedwires(#18 AWG)shouldbeusedtoconnectthethermostattothe unit.

POWERAND CONTROLWIRING

ELECTRICALCONNECTIONS

ALLWIRINGSHOULDBEDONEIN ACCORDANCEWITH NATIONALELECTRICALCODE,ANSI/NFPA NO.70 (LATEST

EDITION).IN CANADA(_SAC22.2 Part 1 (LATESTEDITION),ORWITH LOCAL CODES,WHERETHEY PREVAIL.

NOTE:UNITSAREFACTORYWIREDFORA 230 VOLTPOWERSUPPLY.IF POWERSUPPLYIS 208 VOLTS.IT WILL

BENECESSARYTOCHANGEAWIRE CONNECTIONONUNIT TRANSFORMERFROM240VTERMINALTO20SV TER-

MINALAS SHOWNON WIRING DIAGRAM.

Usewiringwitha temperaturelimitationof 75°C rain. Runthe208 or 230 volt,60 hertzelectricpowersupplythrough

a fuseddisconnectswitchtothe controlboxof theunitandconnectas showninthewiringdiagramlocatedon the in-

sideof the controlaccesspanel.

The unitmustbe electricallygroundedin accordancewith local codesor in the absenceof localcodeswith the Na-

tionalElectricCodeANSI/NFPA No. 70 (latestedition)or CSAC22.2 Part 1 (latestedition).

Powersupplyto the unit must be N.E.C. Class1, and must complywithall applicablecodes.A fused disconnect

switchshouldbe field providedfor the unit. The switchmust be separatefromall othercircuits.If anyofthe wire

suppliedwith the unit must be replaced, replacementwiremustbe of the type shownon the wiring diagram.

Electricalwiringmust besized tominimumcircuitampacitymarkedonthe unit. USECOPPERCONDUCTORSONLYI

Eachunit must bewired with a separatebranchcircuitand be properlyfused.

SEQUENCEOFUNIT OPERATION

COOLING- WhenthethermostatisIn the coo[ingmode,theOcircuitis poweredwhichenergizesthereversing valve.

Uponcoolingdemand,thethermostatclosescircuitRtoYand G.ClosingR toY closesthe unitcontactor,startingthe

compressorandoutdoorfan. ThethermostatautomaticallyclosesRto Gcircuitwhichalsobringsonthe indoorblower

at thesametime. Uponsatisfyingcoolingdemand,thethermostatwillopentheabovecircuitsandopenthemaincon-

tactor,stoppingthe compressorand outdoorfan. If theunitis equippedwith a timedelay,the blowerwill continueto

operate.for 90 secondswhich improvessystemefficiency.

HEATING- Uponheatingdemandthe thermostatclosescircuit R to Y closingthe unitcontactor,startingthe com-

pressorandoutdoorfan. The reversing valveis notenergizedin the heating mode.Thethermostatagainautomatical-

ly bringsonthe indoorblower at thesametime. Thesecondstageofthethermostatclosescircuit RtoW closingthe

unitsequencers,bringthe auxiliaryelectricheaton.Uponsatisfyingheatingdemandthethermostatopensabovecir-

cuits and stopsunit operation.

DEFROSTCYCLE- If outdoor ambientconditionsare such that frost formson theoutdoorcoil, the defrost control

monitorsthe need for andinitiates and terminatesdefrost cyclesasneccessary to maintain system performance.The

defrost controlis time/temperatureinitiated and temperature terminated with a maximum defrost time (time-out)of

10 minutes. Timebetweendefrost cyclesis pre-set at 60 minuteintervalsat thefactory, but canbefield adjustedto

30, 60, or 90 minutes.See illustrationfor field adjustmentofdefrosttiming. For bestperformancein RegionIV, the

PWC242defrostinterval shouldbeadjustedto30 minutes.

Page 20

PA...o,I .,,9.o09.I

AN MAINTENANCE

IDNSTALLATION

INSTRUCTIONS

PWCSERIES

SELF-CONTAINEDHEATPUMP

PARTNO.] 4,,94°O94I OA_E] 4-,5-94I SU_RSEOESI .EWI _'AGE_O_IOI

Manulaclured By

ARMSTRONG AIR CONDITIONING INC,

A LENNOXInternationalInc. Company

421 Monroe Slreel

Bellevue, OH44811

Page 21

!

PART NO.

I 4,tg4ooB4I DATEI 4lsg, I SUPERSEOESI NEWI PAGE2OFlO

GENERAL

Theseinstructionsexplainthe recommendedmethodof installationof the PWChealpumpunitandassociatedelec-

trical wiring.

This unil is designed and approvedfor use as a self-contained air Io air heat pump system.

Theseinstructions, andany instructions packaged wilh mating componen[sandlor accessories,should becarefully

read prior to beginning inslallation, Nole parlicularly anyCAUTIONSor NOTESin these instructions and all labelson

the unit.

Theseinslructions areintended asa generalguideonly, foruse byqualifiedpersonnel, andtie notsupersedeanyna-

tionalorlocalcodesinanyway. Compliancewithall local, state,provincial,ornationalcodespertainingtothistypeof

equipmentshouldbe determinedpriorto instaltalion.

INSPECTIONOFSHIPMENT

Uponreceiptof equipment,carefullyinspectil for possibleshippingdamage. If damageis found, itshouldbenoied

on the carrier'sfreight bill. Take specialcare to examinetheunitinsidethe cartonif thecartonis damaged. Filea

claimwilh thetransportationcompany,

If anydamagesarediscovered and reportedtothe carrierDONOTINSTALLTIlE UNIT as claimmaybe denied.

Checkthe unitrating plateto confirmspecifications are asordered.

CAUTION:INSTALLATIONAND SERVICINGOFAIR CONDITIONINGEQUIPMENTCAN BEHAZARDOUSDUETOIN-

TERNALREFRIGERANTPRESSUREAND LIVE ELECTRICALCOMPONENTS.ONLYTRAINEDANDQUALIFIEDSER-

VICE PERSONNELSHOULDINSTALL,REPAIR,ORSERVICETHIS EQUIPMENT.

FORYOURSAFETY

DONOTSTOREORUSEGASOLINEOROTHERFLAMMABLEVAPORSANDLIQUIDSIN THEVICINITYOFTHIS

I WARNING

ORANY OTHERAPPLIANCE.

NOMENCLATURE:

10 PWC 242 A-1A

1 2 3 4 5

1. ELECTRICHEATING 4. ElectricalRatingCode:

5 = 5kW A=208/230 volts;60 Hz; 1 phase

7 = 7kW

10 = lOkW 5. RevisionCode

15 = 15kW

2. PWC=(HEAT) PUMPWITH COOLING

3. COOLING CAPACITYTONNAGE

182 = 1'IzTON

242 = 2 TON

302 = 2'/2TON

Page 22

I PA,,NO.I ,, g,o094I DATEI '-fS-g'I SUPERSEDESI ,EW I PAGE3OF,O

LOCATION

Thedesign iscertifiedfor through-the-wallinstallationonly.The interiorportionsoftheunit may be surroundedbya

cJosetwith clearancesto combustiblematerial heldto O" at sides, 0" topand 0" frontof the plenum.

Thegrille sideofthe unit maybe flush with or extendbeyond thefaceof theexteriorwall,but shouldnotberecessed

more than two (2) inchesfrom the face of thebuilding andshould notbeobstructed with trees, landscapematerials,

or building structure.

Thereis no minimum clearancerequired on locatinga unit to an interior cornerof a building. If the unit is tobeenclos-

ed, provisionsshouldbe madeallowing accessto the indoorside of the unit tot changingfilters andfor inspection. At

least 33" ol unobstructed space should be provided in fronl of the indoorside, whether enclosed or not, to permit

removalof the coolingchassis shouJdrepairs or inspection be required,

If this unit is installed in a residential garageit must be located or protectedto avoidphysical damageby vehicles.

This unit must beinstalled so that no electrical componentsare exposedtowater.

INSTALLATION

CAUTION:THESLEEVEIS NOTINTENDEDASTHESOLESUPPORTFORTHEUNIT.ANADDITIONALSUPPORTMUST

BEPROVIDEDNEARTHE RETURNOPENINGONTHE UNITFORADEQUATESUPPORT.THE USE OF VIBRATION

ISOLATIONMATERIALBETWEENTHE UNIT AND THESUPPORTIS RECOMMENDED.

CAUTION:THISUNITMUSTBE INSTALLEOLEVELFORPROPERDRAINAGEOFTHECHASSISBASEPANAND UNIT

DRAINPAN.

WITHOUTWALLSLEEVE

Measurethesizeofthe unit andprovideanopeningin an outsidewallthat willaccepttheunit. Localordinancesmay

require a steel lintelto supportthe wall abovethe opening.This opening must besquare in all corners.

Positionthe unitsothatthe gritles on theoutsideface oftheunit areflush or extendbeyondthe faceof theexterior

wall, but notrecessedmorethan two (2) inchesfromtheface ofthe building. PROVIDEA SUPPORTUNDERTHEUNIT

INSIDETHE BUILDING.Makesure that theinsidesupport does not block thereturn air. The unitshouldbe installed

level.

Sealthespacebetweenthe unitandthebuildingopening usinga non-hardeningcaulkingcompound.Thesealmust

be weather-tight toprevententrance ol moisture andwaterinto thebuilding. Make surethe drainholesin thebase

are not plugged with caulking.

WITH WALL SLEEVE

Seethe installationinstructionspacked with the wall sleeveto assembleandamountin a wall. Makesurethat the

gaskets attachedtothe sleevearenot damaged. Assurethat the unit iscompletelyseatedagainst the gaskets onthe

wall sleeve.

Sealspacebetweenwail sleeveand building opening using non-hardeningcaulkingcompound.This seal must be

watertight,

CONDENSATEDRAIN

Install theplastic drain tube(furnished) over the5/8" O.D. fitting weldedtothe condensatepan. Connectotherend

of the drain tubetotrapped drain line (See Figure2). Theplastic drain connectionto thechassisbaseis providedso

that it may be disconnected from thepermanentdrain tubingin the baseof unitin theeventit becomesnecessaryto

remove the chassis assembly.

The drain lineshouldpitch gradually downward at least 1" per 10 loot of horizontal run to the open drain.

Be certainthat the plaslic drain tubing has free drainage and is not crimpedor flattened at any bend,

Page 23

NEW [

I PART.O.I "(940094[ DArEI 4-_5-9'I SUPERSEDES

FIGURE1

INSTRUCTIONFORSUPPORTINGPWCUNITS

WallSleeve

7 x 22 Mio. OpeningTo

Align with ReturnAir

Opening _nUnit.

]

PAGE4 OF 10

FIGURE2

L_

VibrationisolatingMaterial

%

5/8 "I.D. PLASTIC

(FURNISHED)

CHASSISDRAIN

(FURNISHED)

5/8" I.D. PLASTIC

TUBE(FURNISHED)

RETURN

NR DUCT

518" O.O. DRAIN

\

\ \

\

"-UNE AND TRAP

(INSTALLERSUPPLIED)

Page 24

PA,TNOI 4tt94OOB4I DA EI 41594]SUPERSEDESI NEWI PAGE OFtO

LIMITATIONS

The unitshouldbe installedin accordancewith all national and localsafetycodes.

Limitationsofthe unit and appropriateaccessoriesmust alsobe observed.

TheunitmustNOTbeinstalledwithany ductworkin theoutdoorairstream.Theoutdoorfan is notdesignedto operate

againstany additionalstatic pressure.

Minimumand maximum,operatingconditionsmust be observed to assure maximumsystem performancewith

minimum servicerequired.

TABLE1 - APPLICATIONLIMITATIONS

OUTDOORAMBIENTAIR TEMP. OF

MIN. OB" COOL MAX. OB

65 COOL HEAT

125 75

DUCTWORK

Ductworkshouldbe designed_lndsized accordingtoapplicablemethodsfrom theAir Conditioning Contractorsof

America(ACCA).

It is recommendedthatsupplyand return duct connectionsat the unit be madewith flexible joints.

The supptyandreturn air ductsystemsshouldbedesignedfor the CFMstaticrequirementsof the job. Theyshould

NOTbe sizedtomatch the dimensionsof the ductconnectionsonthe unit,

NOTE:SUPPLYDUCTFLANGESARESHIPPEDFLATANDMUSTBEBENTUPBEFOREATTACHINGTHESUPPLYDUCT.

Toconnectthe returnducttotheunit.usea straightpieceof duct 22"wideby 7" deep.Insertthe ductintothereturn

openinginthebottomoftheunit. Flangetheductovertheexistingflangesaroundtheopeninginsideunit. Make sure

thatallsidesofthe ductare flangedovertopermitremovalofcoolingchassisif required.Usea flexible connectionto

attachremainderofreturnduct.Thereturnductshouldbesealedtothe unit casingandterminateoutsidethespace

containingthefurnace.

DB/WB DB DB/WB DB

COOL HEAT COOL HEAT

62/57 50 90/72 80

INDOORAMBIENTTEMP. OF

MIN. MAX.

NOTE:THE RETURNDUCTMUST ALLOWFORTHE UNIT DRAINPANCONNECTIONSAND DRAINTUBE.

CAUTION:DONOTSCREWINTOTHE SIDEOFTHEDRAINPAN.

AIR FILTER

Allindoor return airmust befiltered.A permanent-typefilter isfurnished withthe unit,locateddirectly behindtheac-

cess panel. Removingthe panel permits access to the filter.

Thefiltershouldbe cleanedat leastthreetimesduring eachof the heatingandcoolingseasons,ormorefrequently if

unusual conditionsare encountered. To clean the permanent filter, shake filter to removeexcessdirt and/or use

vacuum cleaner. Wash filter in soap or detergent water and replace after filter is dry.

.

The filtersupplied neednot be oiled afterwashing.

Page 25

PARTNO. ] 41194D094 ] DATE ] 4-15-94 ] SUPERSEDES ] NEW ] PAGE6 OF 10

If aninstallation is madein which it is more desirabletomount thefilter exterior totheunit, in the return duct work, or

otherwise, either the permanent filter suppliedor a disposable filter may be used. If a disposable filter is used, the

minimum area required is as follows:

MODELNO, FILTERAREA(MIN.)

PWC182 480 sq. in,

PWC242 480 sq. in.

PWC302 480 sq. in.

THERMOSTAT

The roomthermostatshouldbe locatedonan insidewallwhereit willnot be subject todrafts, sun exposureor heat

fromelectrical fixtures or appliances. Followthemanufacturer's instructions enclosedwith thethermostat for general

installationprocedures. Color codedinsulated wires (# !8 AWG)should be usedto connectthethermostat to the unit.

POWERANDCONTROLWIRING

ELECTRICALCONNECTIONS

ALL WIRINGSHOULDBEDONEIN ACCORDANCEWITHNATIONALELECTRICALCODE,ANSI/NFPANo. 70 (LATEST

EDITION).IN CANADACSAC22.2 Part 1 (LATESTEDITION),ORWITH LOCALCODES,WHERETHEYPREVAIL:

Usewiringwithatemperaturelimitationof75°C rain. Runthe 208or 230 volt,60 hertzelectric powersupplythrough

a fused disconnectswitch to thecontrolboxof the unit andconnectas showninthe wiringdiagramlocatedon the in-

side ofthe control access panel.

The unitmust beelectricallygrounded in accordancewithlocal codesor in theabsenceof localcodeswith the Na-

tional Electric CodeANSI/NFPA No. 70 (latest edition)or CSAC22.2 Part 1 (latest edition).

Powersupplyto the unit must be N.E.C. Class1, and mustcomplywith all applicable codes.A fused disconnect

switch should be field providedfor the unit. Theswitchmust be separatefrom all othercircuits. If any ofthe wire

supplied with the unit must be replaced, replacementwire must be of the type shown onthe wiringdiagram.

Electricalwiringmust be sized tominimumcircuitampacitymarked on theunit. USECOPPERCONDUCTORSONLY.

Eachunit must bewiredwith a separatebranchcircuitand be properlyfused.

SEQUENCEOFUNIT OPERATION

COOLING- Whenthe thermostatis inthe coolingmode,the 0 circuitispoweredwhichenergizesthereversing valve.

Uponcoolingdemand,the thermostat closescircuitRto YandG. ClosingRtoY closesthe unit contactor,startingthe

compressorandoutdoorfan. Thethermostatautomatically closesRtoGcircuitwhichalsobrings onthe indoor blower

atthe sametime. Uponsatisfying coolingdemand,the thermostatwill openthe abovecircuitsand openthe maincon-

tactor, stoppingthe compressorandoutdoorfan. If the unit is equippedwith a time delay, the blower will coritinueto

operatefor 90 seconds which improvessystemefficiency.

HEATING- Uponheating demand the thermostatclosescircuitRto Y closingthe unit contactor,starting the com-

pressor andoutdoorfan. Thereversingvalveis.no.t-energizedin the heating mode.Thethermostatagainautomatical-

ly brings on the indoorblowerat the sametime. Thesecondstage of thethermostatclosescircuftRto W closingthe

unit sequencers, bring theauxiliary electric heaton. Upon satisfying heating demandthethermostat opensabovecir-

cuitsand stops unit operation.

i

DEFROSTCYCLE- if outdoor ambient conditions are such that frost forms on theoutdoorcoil,the defrost control

monitorsthe need for andinitiatesandterminates defrost cycles as neccessarytomaintain systemperformance. The

defrost controlis time/temperature initiated and temperatureterminatedwith a maximum defrost time (time-out) of

10 minutes. Timebetweendefrost cycles is pre-set at 60 minute intervals at the factory, but can be field adjusted to

30, 80, or 90 minutes. Seeillustralion for field adjustment of defrost timing. For best performance in RegionIV, the

PWC242defrost interval should be adjusted to 30 minutes.

Page 26

PA,T,O.I ,tt,,O0,,( [ l SUPERSEOESI NEW l PAGE OFtO

The defrost controlwill initiatea defrosl cycle if the time period haselapsedand the defrost sensordetectsa

temperature below freezfng. At the slart of the defrost cycle, Ihe defrost ControlwUIenergize the reversing valve

solenoid,shift(ng the reversing valve and de-energizingthe outdoorfan. Thedefrost reraywilt alsoclose, energizing

auxiliary heat for increasedcomfortduring defrost. Theunit will remain in thedefrost mode until the defrost sensor

hasdetermined that lhe frost has been removedfrom the coil or a 10 minute time periodhas elapsed.

FIGURE3

OEFROST

TEST PINS

OEFROST

TIMEJUMPER

T2 = 60 MINUTES

T1 = 30 MINUTES

T3 = 90 MINUTES

Thedefrost controlis alsoequippedwitha setof testpinsto aidintroubleshootingof thedefrost system.Thefollow-

ing is a briefoutline of the testing of the defrost system.

Thedefrostsensorwilt be closedat 32° F or below.If temperaturesare suchthat the switchis notclosed,jumper

between the defrostsensorterminalson the defrostcontrol.

Start the systemin heating operation.

Jumper testpins. A 1/4" quick connectterminalcrimpedontoa solidwireor brazing rod workswellfor testjumper.

Closing test pins speedup time intervalby a factor of 256.

DEFROSTCONTROLSETTINGDEFROSTTESTCYCLETIME

T1-30 minutes 7 seconds

T2-60 minutes 14 seconds

T3-90 minutes 21 seconds

Afterclosingtest pinsand appropriatecycletimehaselapsed,the reversingvalveshouldshifttodefrostmodeand

theoutdoor fan should stop. Aftertwo secondsof defrostoperation, the reversing valveshouldshift back to heating

operation and the outdoor fan shouldstart.

SYSTEMPERFORMANCE

For maximumperformanceof this heatpumpsystem,theoperatingtemperaturesand pressureshouldbechecked

and superheat determined at StandardARItestconditionsof 82°F outdoor- 80°F indoordry bulb/67°F wet burb. If

the superheatmeasureddeviatesfrom thevalues in the tablebelow,the refrigerant chargeshouldbe adjustedaccor-

dinglyfor maximum performance.

PWCSUCTIONSUPERHEAT -TABLE2

OutdoorUnit Model

PWC182

PWC242

SuctionSuperheat@ A.R.I. Conditions

18° . 20OF

17° - 19%

Page 27

PARTNOI 4t_g4DOg4I DATE] 4iS-g,I SUPERSEOESI NEWI RAGE8OF_O

[

MAINTENANCE

NORMALMAINTENANCE

WARNING: PRIORTO ANY OF THE FOLLOWING MAINTENANCE PROCEDURESSHUT OFF

ALL ELECTRICALPOWERTO THE UNIT. FAILTURETO DOSOCOULDCAUSEPERSONALIN-

JURY.

Periodic inspectionand maintenancenormallyconsistsof changing or cleaningfilters and (under someconditions)

cleaning the coils.

FILTER- supplied. Inspectonceamonth.Replacedisposable,or clean permanenttypeasnecessary. DONOTreplace

permanenttypewith disposable.

MOTORS- indoorand outdoortan motors are permanentlylubricatedand requirenomaintenance.

OUTDOORCOIL- Foreignmaterialshouldnot beallowedtoaccumulateontheoutdoor coilsurfaceor otherparts inthe

air circuit. Cleaningshould beasoftenas necessaryto keepthe coil clean. Usea brush,vacuumcleanerattachment,

or other suitable means. If wateris used to cleanthecoil, be sure power to the unit is shutoff prior tocleaning.

NOTE:CARESHOULDBE USEDWHENCLEANINGTHE COILSSOTHATTHE COILFINSARENOTDAMAGED.

OUTDOORBASEDRAIN- Foreignmaterial shouldnotbeallowedtoclogthe drain hole.Inspect andclear'drain open-

ingprior to heatingseason.

PHYSICALANDELECTRICALDATA

1/4 _/4

Page 28

I _,,9_Do9.I OA_El .-_5-g_l SU_E.SEOESl .EW I ,_GEgOF,O

llllll

llllll

?AND 10 PVC 0NLY

RED

CAP.

_EE EV.OV_

UOI'CR VZOI.[T

Rm

HIGH

U

m.L0W

>(

CmTm

C/P/Z:IT_-RIJ_

eTI

O

/

lira

RE9

8L_X

B.UE

CONNECTION DIAGRAM

V/I.VE

©

im_E)"/_()s'r

Page 29

1PA'_RT N0. I 411941)094 I DATE I 4-15-94 I SUPERSEDES I NEW

3Ct/'ZsO-t-60

SUPPLTWI?H¥[N.

75'€ €_ WIIaE

CX_Z:_zT t i _ cz_qcuzT 2 ) -- -- Lof vo.T_4[_

_ LINK; tOLTAE_'II_O

BUJE

11.10_6?AT

IIIIII

IIIIII

VXa.k'T

HZOH

I PAGE10 OF 10

NO"_j

F AWlG_ THE CtqXOINAL

IrlRl_ _ _ T14£

SAUESIZE A_P TYPEWIRE

i_T 0£ USf_,

Ot.UE

aU_a_

Yn.LOW

'flg.LOw

€_rxcTOR

CAPACl TIOR-RUN

mAC=

I

I

V_

=lJu_

©

,.)NNECT I ON DIAGRAM

I

Page 30

,!

PWC

SELF CONTAINED

THRU-THE-WALL HEAT PUMP

Part No. 30790F08g Date 6-1-69

Supersedes 30790G082 Page_of 12

Installation and

Maintenance Instructions

_O,MSTP_,

Page 31

Part N_ 30790F089

Date. 6-1-89

$upereedes 30790G082

FORWARD

This is a self-contained heat pump designed for Installation through an exterior wall. The unit is Underwriters'

Laboratories listed under heat pumps and is in compliance with Underwriters Standard, UL 559.

The unit is also certified to the Air Conditioning and Refrigeration Institute as complying to ARI Standard 240.

To simplify the proper Installation and to assure that the unit will operate tn conformity with general ac-

cepted safety regulations, you should read carefully the instructions outlined In this manual.

Failure to comply with the Installation Instructions, Operating Instructions or Maintenance Instructions, or

Alterations of internal widng or parts not specifically outlined within this manual will void the Agency Listing's

and Manufacturer's limited warranty.

KEEP THIS MANUAL IN A SAFE PLACE FOR READY REFERENCE.

Page2__2__of 12

Page 32

PartNo. 307SOF089

Date 6-1-89

Supersedes 30790G082

INTRODUCTION

This manual is intended to familiarize the installer, serviceman, and the user with the installation, operation

and maintenance of this thru-the-wall heat pump.

This unit is shipped from the factory in one package completely assemblied and wired. A specially designed

trap assembly is shipped, secured to the air return area in lower front of unit.

Check the rating plate to confirm heating and cooling capacities are as ordered and are as shown on the

packaging label.

When this unit is unpacked, a check should be made for any damage. If any damages are discovered, DO

NOT INSTALL THE UNIT. Notify the transportation company and make proper notation on the carders freiaht

bill. Damage claims must be filed with the carrier at once.

The manufacturer can assume no responsibility for damages which Occur in transit or for improper Opera-

tion of the unit as a result of shipping damages.

Page _of 12

Page 33

Part No. 30?90F089 Date 6-149

Supersedes 30790G082 ,, Page _of 12

TABLE OF CONTENTS "

INSTALLATION

Site Preparation ............................ 5

Condensate and Defrost Drain ................. 6

Electrical Connections ........................ 7-8

Thermostat ............................... 9

Air Filter ......... ; ...................... 9

Duct Work ............................... 9

Unit Checkout Procedure ..................... 10

OPERATION INSTRUCTIONS

Heating Operation .......................... 11

Cooling Operation .......................... 11

System Shutdown .......................... 11

Page

MAINTENANCE AND SERVICE

Air Filter ................................. 12

Chassis Removal ........................... 12

Page 34

Part No. 307g0F089

Date. 6-1-89

Supersedes 30790G082

INSTALLATION

Site Preparation

Tills unit is approved for thru-the.wall installation, with zero clearance to combustible material. The unit must

be installed within a conditioned space to prevent freezing of defrost water in trap assembly and to avoid

jacket heat loss and surface condensation problem.

This unit must be installed with the wall sleeve specified for this unit. Refer to the manufacture's specifica-

tion sheet for complete information and demensions.

Assemble the wall sleeve in accordance with the instructions furnished with each wall sleeve.

Install the wall sleeve level and square in all comers. It is to extend a minimum of 114"to 3/8" maximum

beyond finished wall to permit caulking all around the sleeve without blocking drain holes at bottom front

of sleeve.

Before installing unit, Inspect wall sleeve. Make sure the gaskets located on the inside of the outer flanges

are firmly attached to the sleeve and are not damaged. Damage or loose gaskets must be repaired before

installing unit.

The sleeve is not intended as the sole support for the thru-the-wail unit. An additional support must be pro-

vided beneath the front of the unit for adequate support, The use of vibration insulation matedai between

the unit and the support is recommended.

See Figure 1.

Page_of 12

Wall Sleeve • Seal space between

wall sleeve and building opening

using non-hardening caulking com-

pound. The seal must be water tight+

g"x 22" rain. opening

to align with return

air opening in unit.

Hole for drain.

Ddll hole on left

or dgtht side

• through base after

unit is installed.

FIGURE 1.

Celotex, or equivalent

Plywood

Page 35

Part No. 30790F089 Date 6-1-89

Supersedes 30790G082 Page_of 12

INSTALLATION

Before sliding unit into sleeve, remove 5 screws and washers from top panel. Slide unit into sleeve until the

angle on top of the unit lines up with the top flange of the sleeve, and should almost touch. Fasten unit

to sleeve with the 5 screws and washers above.

Condensate and Defrost Drain

The condensate drain trap furnished with the unit is a copper tube assembly and is furnished with three

pieces of plastic tubing.

To install condensate drain (Reference Figure 2.), connect one of the plastic tube ends over the 5/8" O.D.

fitting welded to the center of indoor condensate drain pan and another end to.the 5/8" O.D. fitting on the

chassis base. Connect the third plastic tube end to the open drain trap,

The drain line should pitch gradually downward at least 1 inch per foot of horizontal run to open drain trap.

Be certain that plastic drain tube has free drainage and Is not cdmpad or flattened at any bend. Test drainage

by pouring water into drain pan under indoor coil and see that It Is removed rapidly through the drain tubing.

The plastic drain connection Is provided so that tt may be disconnected from the permanent drain tubing

in the building without unsoldering tn the event It becomes nceccesaary to remove the refrigeration drawer

assembly. TOTAL DEFROST DRAIN SYSTEM MUST BE LOCATED IN THE CONDITIONED AREA TO AVOID

FREEZING.

FIGURE 2.

Retum air

duct (if used)

One 5/8" O.D. copper

trap & plastic tubes (3)

(furnished)

i,ii_ II •

I

I

r-w

|

Drain line must not

be above lowest drain

pan fitting.

Alternate

route through

return air duct.

/

Indoor coil

Drain pan

Chassis base

Use hole provided

on either side of

base to exit unit.

5/8" rain. O.D. copper

or alum. drain tube

(shaded Item.

Pitch 1 In. per ft.

Installer supplied)

Open drain trap

in conditioned

space to prevent

freezing and

damage.

Page 36

PanNo. 307g0F089

Date 6-1_9

Supemedes 30790G082

INSTALLATION

Electrical Connections

All wiring to unit must comply with the national Electrical Code NFPA No. 70 or local codes, where they prevail.

ANY ALTERNATION OF INTERNAL WIRING CAN VOID UNDERWRITER'S APPROVAL, ARI CER-

TIFICATION AND MANUFACTURE'S LIMITED WARRANTY.

The series and rating plates indicate the operating voltages, phase, ampacities and maximum fuse size and

electric heater ratings. Units must never be installed where voltage exceeds 110% of higher voltage indicated

on rating plate, or less than the minimum operating voltage on rating plate,

Ratings and BTU output are based on 230 V, 60 HZ supply. Voltages other than this rated voltage will alter

the BTU output of this unit. For specific ratings at voltages or frequencies other than that designated con-

tact your distributor or the manufacture.

FAILURE OF THE COMPRESSOR AS A RESULT OF OPERATION ON IMPROPER VOLTAGE VOIDS

THE COMPRESSOR REPLACEMENT WARRANTY.

Multiple power supply connections must be used when total unit amp draw Is over 48 amps. If multiple power

supply connections are used, separate fused disconnects must be Installed for each circuit between the

main panel and the supply terminals In the unit.

Circuit No. 1, terminals L1 and L2 on the terminal block Is always used to supply power to the heat pump

section. See Figure 3, 4, and 5.

Page T of 12

Circuit No. 2, terminals L3 and L4 on terminal block (units up to 11.0 KW) or fuse block (units over 11.0

is always used to supply power to electdc heaters.

Single entry supply may be used on units, when total amp draw, (heat pump plus heaters) Is less then 48

amps, and is not In violation of prevailing electrical codes.

Units with 7.2 KW heaters or less are supplied with Internal jumpers between 1.1& 1.3,and L2 & L4 for single

entry supply. Remove jumpers between L1 & I..3 and 1.2 & L4 when multiple entry supply is to be used.

Fuse and wire sizing must be in accordance with prevailing electrical codes. See Product Specification sheets

or Unit Sedes and Rating Plate for ampacities end maximum fuse.

Page 37

Part No. 30790F089

Date 6-1-89

FIGURE 3.

SINGLE ENTRY SUPPLY

Remove internal

for multiple entry Supply.

[]

Supersedes 30790G082

208-230 voit

1 Ph. power supply

I

I

I

Page_ of 12

208-230V

1 Ph. power supply

t-_ Circuit I"_

ICircuit

I No.I No.2 I

FIGURE 4,

MULTIPLE ENTRY

SUPPLY

PWC18E4.8, PWGI8E7.2

PWC24E4.8, PWC24E7.2

r I Circuit

I

I

I

I

I

MULTIPLE ENTRY

208.230V

1 Ph power supply

Circuit

No. 2

! No.1

FIGURE 5.

SUPPLY

PWC18E9.2, PWC18E10.7

PWC24Eg.2, PVVC24ElO.7

PWC18E14.7

PWC24E14.7

Page 38

Part No. 30790F089 Date 6-1-89

Supersedes 30790G082 Page_of 12

Thermostat

This unit requires special thermostat for operation. See product specification sheets or label on unit for

manufacture's part number. Install the thermostat according to directions furnished with It. Select a loca-

tion in a room having the most wall or window area exposed to the outsid_ Locate on an inside wall, away

from drafts, sunlight or any heat producing appliances. Connect thermostat wires to pigtail leads on unit

with wire nuts following wire diagrams attached to unit.

Air Filter

This unit is supplied with a permanent type high filtration filter, located in front of the indoor coil. If an In-

tallation is made in which it Is more desirable to mount the filter extedor to the unit In the return duct, the

permanent filter supplied can be used or a disposable filter may be used. If a different filter or filters are

used the minimum total filter area required is 375 eq. in. of nominal 112inch thick media, if a remote filter

is Installed, the permanent filter supplied with this unit must be removed.

Duct Work

Provide duct work sufficiently large enough to handle the air volume at the total external static pressure

not exceeding the rating of the unit published in the Product Specification sheet for the rated cooling air

volume.

Connect supply duct to top of unit using canvas connections or other flexible connection to prevent sound

transmission Into the duct system.

To connect the return duct to the unit, use e straight piece of duct 21 _" by 9".

Insert duct into return opening in bottom of unit and flange duct over existing flanges around opening In-

side unit. Make sure that all sides of the duct are flanged over to permit removal of cooling chassis If re-

quired. Use a flexible connection to attach remainder of return air duct.

Adjustments

No adjustments are required or should be attempted regarding any of the components of the heat pump

chassis and supplementary electdc heaters.

The unit should be checked to see that none of the wiring is loose or missing. The plug-in electrical connec.

tors between the cooling chassis and the main control compartment should be checked to make sure the

plugs are firmly seated and none of the wires are loose.

Page 39

Part No. 30790F089

Date 6-1-89

Supersedes 30790G082

INSTALLATION

A. Unit Check-Out Procedure - IMPORTANT

1. Filter(s) must be clean and in place as to filter all air passing over

2. Set thermostat to "OFF" position.

3. Check that correct size fuses are installed for unit.

4. All panels must be in place.

5. Turn on main power to unit.

B. Heating Check

1. Set fan switch to "AUTO".

2. Set thermostat lever to lowest temperatuf'e.

3. Set thermostat switch to "HEAT" position (if indoor ambient temperature is near or colder

than thermostat setting, heat pump will start immediately).

4. Slowly adjust thermostat to warmer temperature until first stage heat is activated (com-

pressor will start).

5. If'possible, check outdoor fan to make sure it's rotating (this is especially important If heat

pump has been installed for sometime and not running in the winter such that the outdoor

fan plenum could be clogged with snow or ice build-up).

6. Check indoor air outlet to verify indoor fan is blowing air and getting warmer.

7. Adjust thermostat lever to at least 5"F warmer temperature So that second stage heat will

activate.

8. Check indoor air outlet for increased heating (higher temperature).

indoor coil,

Page 10 of 12

C. Cooling Check

1. Set thermostat switch, to "OFF" position for minimum of 5 minutes to allow heat pump

pressures to equalize.

2. Set thermostat lever to lowest temperature for cooling

3. Set thermostat switch to "COOl." position (compressor should start unless indoor ambient

is near or colder than thermostat setting).

D. Blower Operation

1. Set thermostat switch to "OFF" position.

2. Set fan switch to "ON". Indoor fan only will operate.

3. Return fan switch to "AUTO". Indoor fan will stop.

Page 40

Part No. 30790F089

Date. 6-1-89

Supersedes 30790G082

OPERATION INSTRUCTIONS

The following instructions are to be followed to obtain years of trouble free operation of your year-around

comfort system.