Page 1

Circuit balancing valves

Easy sizing and selection

Flexible configuration and line-sizing

makes installation fast

Multi-turn ‘Y’ pattern globe-style

design for accurate flow control

Perfect for control in variable speed

pump systems

solution outline

½"–2" models

great value

proven reliability

Armstrong Circuit Balancing

Valves (CBVs) deliver great

value with advanced product

design and proven reliability.

file no: 36.10

date: april 2018

supersedes: 36.10

date: november 2016

Page 2

he choice of circuit

balancing valves for any

T

makes an important dierence to

the long-term energy eciency of

the building and the satisfaction

of tenants. Sizing and selection, as

well as ease of installation are important considerations. In addition

to those factors, contractors will

want a balancing solution that

have considerable benefits:

construction project

key benefits

Fits easily into confined spaces

Provides accurate flow control for fast and accurate balancing

Simplifies the process of adjusting and fine tuning system flow

Our industry-leading design innovations have made Armstrong Circuit Balancing Valves

the trusted choice of balancing valves for contractors, engineers and building owners.

½" – 2" Armflo valves oer

Easy installation:

installs at any angle

Extreme flow control accuracy

Stable pressure drop across the

Both the ½" – 2" Armflo valves

and the 2½"– 6" valves oer

Easy pressure measurement

Simplified process of adjusting

and fine-tuning balancing

valve improves balancing accuracy

Page 3

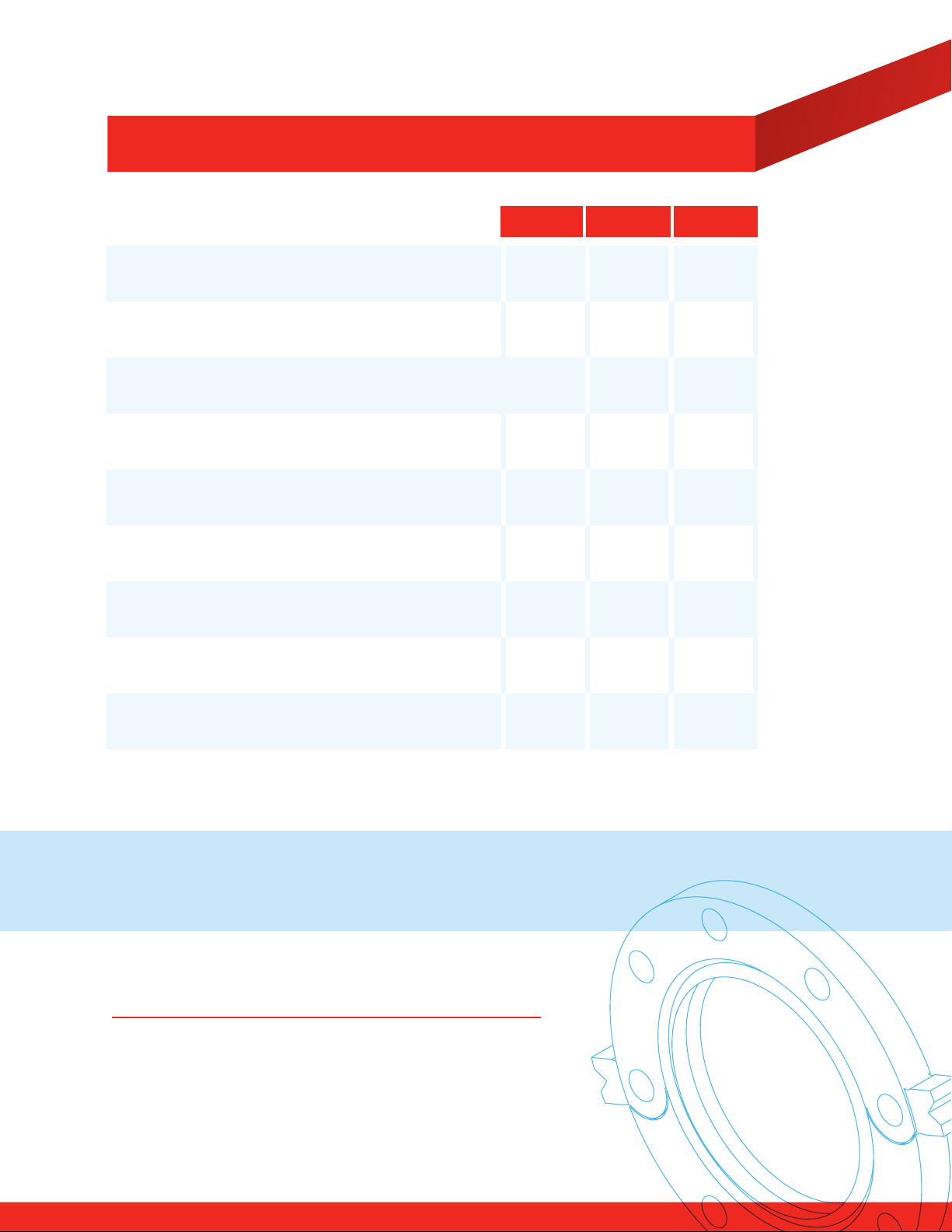

key features

½"– 2" 2½"– 6" 8"– 12"

Minimum 5 Turn Micrometer style handle –

unparalleled adjustment precision

“Y”-pattern globe valve design, minimizes

flow turbulence

Handle set-point indicator –

easily return to an earlier setting

Integral High Precision Fixed Orifice, minimum of +/- 5%

accuracy, p independent of handle position.

Line Size optimization – no reducers required

Lead Free Certified to nsf 372 for North America

Non-rising handle – for installation in tight spaces

Flexible Installation – convertible design allows field

adjustment to either straight or angled configuration

Re-packing valve under full system pressure

key features

Armstrong has a wide range of accessories

to complement our balancing valves, including:

Flange adapters

Pressure meters

Orifice Plates and venturis

pmp ports and extension ports

Page 4

½"–2" cbv

Technical data

flow rate ranges

valve size min. flow max. flow

½" lf

¾" lf

½"

¾"

1"

1¼"

1½"

2"

Note: flow in USgpm (L/s)

0.26 (0.02) 1.98 (0. 12)

0.41 (0.03) 3. 11 (0 . 20)

1.22 (0.08) 9.57 (0.60)

1.9 9 (0.1 3) 13. 76 (0 . 87 )

4.57 (0 .29 ) 22 .9 7 (1. 4 5)

6.17 (0. 3 9) 38. 0 0 (2.39 )

9.02 (0.57) 50 . 07 (3 .15)

15.50 (0.98) 81 .92 (5 . 16)

Models: cbv-vs (solder) & cbv-vt (npt)

Max. working pressure 300 psi/20 bar (pn 20)

Operating temperature range -4°f to 300°f

(-20°c to 150°c)

materials of construction

Body, bonnet Brass -c46500

Stem and disk Brass -c46500

Elastomers epdm

Handwheel Reinforced nylon; abs

Dimension data – inches (mm)

shipping

model pipe size a b c

cbv050vs-lf

cbv050vt-lf 2.99 (76) 4. 60 (117) 1.07 (0.49)

cbv075vs-lf

cbv075vt-lf 3. 26 (83) 4.90 (125) 1. 21 (0. 55)

cbv050vs

cbv050vt 2.99 (76) 4. 60 (117) 1.07 (0.49)

cbv075vs

cbv075vt 3.26 (83) 4.9 0 (125) 1 .21 (0.55)

cbv100vs

cbv100vt 3 .80 (97) 5 .2 9 (126) 1.86 (0.84)

cbv125vs

cbv125vt 4.32 (110) 5.6 0 (142) 2. 34 (1.06)

cbv150vs

cbv150vt 5.07 (129) 5.90 (150) 3. 49 (1 .59)

cbv200vs

cbv200vt 6. 00 (153) 6.68 (170) 5.97 (2.46)

½" (dn15) low flow

¾" (dn20) low flow

½" (dn15)

¾" (dn20)

1" (dn25)

1¼" (dn32)

1½" (dn40)

2" (dn50)

3.19 (81) 4.56 (116)

3.64 (93) 4. 65 (118)

3.19 (81) 4.56 (116)

3.64 (93) 4. 65 (118)

4. 26 (108) 4.95 (126)

4.94 (12 5) 5.4 0 (137)

5. 67 (144) 5.6 0 (142)

7.0 3 (179) 6. 36 (162)

2.76 (70)

2.76 (70)

2.76 (70)

2.76 (70)

2.76 (70)

2.76 (70)

2.76 (70)

2.76 (70)

weight

1.05 (0.48)

1.0 9 (0.49)

1.05 (0.48)

1.0 9 (0.49)

1.68 (0.76)

2. 26 (1.0 3)

3. 22 (1.46)

5.40 (2.45)

solder joint connection

sweat

threaded connection

threaded

Part numbers

model – solder part number mo del-threaded part number

cbv050vs-lf 571110lf-370 cbv050vt-lf 571110lf-360

cbv075vs-lf 571110lf-371 cbv075vt-lf 571110lf-361

cbv050vs 571110lf-350 cbv050vt 571110lf-340

cbv075vs 571110lf-351 cbv075vt 571110lf-341

cbv100vs 571110lf-352 cbv100vt 571110lf-342

cbv125vs 571110lf-353 cbv125vt 571110lf-343

cbv150vs 571110lf-354 cbv150vt 571110lf-344

cbv200vs 571110lf-355 cbv200vt 571110lf-345

Page 5

2 ½"–12" cbv

Technical data

flow rate ranges

stem: no. of 360°

connection sizes

2½" dn65 5 60 70 1.9 (30) 4.4 (71)

3" dn80 5 85 100 3. 8 (60) 8. 8 (140)

4" dn100 6 239 280 8 .2 (130) 17.0 (27 0)

5" dn125 6 281 330 15.8 (250) 31.6 (500)

6" dn150 6 392 460 25.2 (40 0) 50.5 (800)

8" dn200 12 1024 1200 50. 5 (800) 107.3 (1700)

10" dn250 12 1877 2200 94.7 (1500) 189.3 (300 0)

12" dn300 14 2815 3300 151.4 (2400) 315.5 (5000)

turns kv (open) cv (open)

min. flow rate

L/s ( USgpm)

max. flow rate

L/s ( USgpm)

Dimension data – inches (mm)

model cbv-fs (straight) / cbv-fa (angle) cbv-g (straight) / cbv-a (angle)

Connection size

ansi 125# flange

Handwheel −

number of 360° turns

Maximum working pressure 250 psi (1725 kpa)

2½ 3 4 5 6 8 10 12 2½ 3 4 5 6 8 10 12

5 5 6 6 6 12 12 14 5 5 6 6 6 12 12 14

· 250 psi (1725 kPa) when used with class 125/150

flange adapter

· 375 psi (2575 kPa) when used with class 250/300

flange adapter

Maximum working temperature 230°f (110°c) 230°F (110°C)

Body Cast iron astm a48 class 30b Ductile iron astm a536 gr65-45-12

Disc Bronze astm b584 c-84400 Bronze astm b584 c-84400

Materials of

construction

Pressure metering ports ¼" (2) npt brass body with epdm1 check and gasketted cap

Drain tappings ¼"(2) brass plug Brass plug

Note: 1 epdm is not suitable for oil service.

Note: 1. epdm is not suitable for oil service

Seat epdm elastomer Ultra high strength engineered resin

Stem Brass as tm b-16 Brass a stm b-16 Stainless steel a st m

a582 type 416

Tri m Brass astm b283 c-37700 Brass c-3770 0

O-ring Buna & epdm Elastomer Buna

Page 6

grooved

model cbv-gs - 2.5" to 6" model cbv-ga - 2.5" to 6"

f

a

c

b

d

e

Dimension data – inches (mm)

model

cbv-2½gs 57010 9-3 86

cbv-2½ga 570109-486 7. 40 (187) 4. 60 (117) 1.00 (25)

cbv-3gs 570109 -387

cbv-3ga 570109-487 8. 30 (208) 3.9 0 (98) 1.00 (25)

cbv-4gs 570109-388

cbv-4ga 570109-488 9.60 (244) 4.30 (111) 1.25 (32)

cbv-5gs 570109-389

cbv-5ga 570109 -489 12.00 (305) 5. 50 (140) 1. 25 (32)

cbv-6gs 570109-390

cbv-6ga 570109-490 14.10 (359) 6. 63 (168) 2.00 (51)

cbv-8gs 570109-391

cbv-8ga 570109- 491 18.93 (481) 9.19 (233) 2.00 (51)

cbv-10gs 570109-392

cbv-10ga 570109 -492 20.3 0 (516) 9.80 (248) 2.0 0 (51)

cbv-12gs 57010 9-393

cbv-12ga 570109-493 24.10 (611) 14.00 (356) 2.00 (51)

part

number

pipe

size dimensions inches (mm)

a b (o pe n) c d e f

dn65

dn80

dn100

dn125

dn150

dn200

dn250

dn300

12.00 (3 05)

12.00 (3 05)

14.00 (356)

17. 50 (44 5)

20.70 (525)

28.19 (716)

30.00 (762)

38 .10 (9 67)

9.62 (244) 2.75 (70)

10. 50 (267) 2.44 (62)

10. 56 (268) 3.00 (76)

12.80 (324) 3.60 (92)

13.10 (332) 4. 40 (113)

24.62 (625) 5 .69 (144)

26.50 (673) 6.60 (167)

28.40 (722) 7. 60 (19 4)

n/a 1. 00 (25)

n/a 1. 00 (25)

n/a 1. 25 (32)

n/a 1. 25 (32)

n/a 2.00 (51)

n/a 2.00 (51)

n/a 2.00 (51)

n/a 2.00 (51)

weight

lbs (kg)

2.56 (65) 19 (9.0)

3.00 (76) 24 (11.0)

3.44 (87) 42 (19.0)

4.94 (12 5) 81 (37.0)

5. 88 (149) 54 (120.0)

7.88 (20 0) 310 (141.0)

9.47 (241) 460 (209.0)

12.63 (321) 870 (395.0)

angle design

cbv-ga – 2.5" to 12"

b

e

d

c

a

f

straight design

cbv-gs – 2.5" to 12"

b

c

e

a

f

Page 7

b

g

d

(diamete r)

e

model cbv-fs - 2.5" to 6" model cbv-fa - 2.5" to 6"

flanged

Dimension data – inches (mm)

model

125 # ansi flange

cbv-2½fs 570109-376

cbv-2½fa 570109-476

cbv-3fs 570109-377

cbvg-3fa 570109 -477

cbv-4fs 570109-378

cbv-4fa 570109 -478

cbv-5fs 570109-379

cbv-5fa 570109-479

cbv-6fs 570109-380

cbv- 6fa 570109-4 80

cbv-8fs 57010 9-3 81

cbv-8fa 570109-4 81

cbv-10fs 570109-382

cbv-10fa 57010 9-482

cbv-12fs 570109-383

cbv-12fa 570109-483

250 # ansi flange

cbv-8fs 570109-661

cbv-8fa 570109-681

cbv-10fs 570109-662

cbv-10fa 570109-682

cbv-12fs 570109-663

cbv-12fa 570109-683

part

number

pipe

size

2.5

3

4

5

6

8

10

12

8

10

12

a b (full open) c d e f g s

7.38

(187)

8.19

(208)

9.63

(245)

12

(30 5)

14.13

(359)

19

(48 3)

20.33

(516)

24.07

(611)

19.11

(48 5)

20.33

(516)

24.05

(611)

9.62 (244)

10. 50 (267)

10. 56 (268)

13.06 (332)

13.75 (349)

24.62 (625)

26.50 (673)

28.43 (722)

24.62 (625)

26.50 (673)

28.43 (722)

2.75

(70)

2.44

(62)

3.00

(76)

3.63

(92)

4.44

(113)

5.69

(145)

6.56

(167)

7.63

(194)

5.69

(145)

6.56

(167)

7.63

(194)

4.63

(118)

3.88

(99)

4.38

(111)

5.50

(140)

6.63

(168)

9.19

(233)

9.78

(248)

14.05

(357)

9.69

(246)

9.80

(249)

14.03

(356)

1.00

(25)

1.00

(25)

1.25

(32)

1.25

(32)

2.00

(51)

2.25

(57)

2.25

(57)

2.25

(57)

2.25

(57)

2.25

(57)

2.25

(57)

2.56

(65)

3.00

(76)

3.44

(87)

4.94

(125)

5.88

(149)

7.88

(20 0)

9.47

(241)

12.63

(321)

7.88

(20 0)

9.47

(241)

12.63

(321)

7.00

(178)

7.5

(191)

9.00

(229)

10.00

(254)

11.00

(279)

13.50

(343)

16.00

(40 6)

19.00

(48 3)

15.00

(380)

17. 50

(445)

20.50

(521)

weight

lbs (kg)

12.00

(30 5)33(15.0)

12.00

(30 5)39(17.7)

14.00

(356)59(26.8)

17. 50

(445)

20.69

(526)

28.00

(711)

30.01

(762)

38.09

(967)

28.20

(716)

30.01

(762)

38.05

(966)

108

(49. 0)

167

(75.7)

344

(156.0)

603

(273.0)

1006

(45 6.0)

396

(180)

712

(323 .6)

1163

(528 .6)

model cbv-fa - 2.5" to 12"

(diamete r)

e

model cbv-fs - 2.5" to 12"

b

g

d

c

a

f

c

b

g

(diameter)e

s

f

Page 8

tm

toronto

+1 416 755 2291

buffalo

+1 716 693 8813

birmingham

+44 (0) 84 44 145 145

manchester

+44 (0) 84 44 145 145

bangalore

+91 (0) 80 4906 3555

shanghai

+86 (0) 21 5237 0909

são paulo

+55 11 4781 5500

armstrong fluid technology

established 1934

For more information, contact your

Armstrong representative or visit

us at:

ArmstrongFluidTechnology.com/

ContactUs

armstrongfluid technology.com

Loading...

Loading...