Page 1

Hydronic solutions

catalog

e.2 circulators

file no: 10.01

date: november 2014

supersedes: 10.01

date: august 2014

contents

commercial & residential pumps 3

Design Envelope Compass Circulators 3

Astro 2 Circulators 5

Astro 2 Hot Water Recirculation Systems 11

Astro 2 24-hour timer 15

Aquastat controls 17

Astro Express 2 Hot Water Recirculation 19

S&H 3-Piece Circulators 21

1050 & 1060 3-Piece Circulators 29

E.2 Circulators 33

E.2 Circulator Spool Pieces 37

4270 Motor Mounted Pumps 39

4360 Pump-in-a-Box

(4360, 4380, DE 4300 & DE 4380) 41

hydronic specialties 53

Air Vents (Automatic & Float) 53

Air Removal Trap 57

Diaphragm Expansion Tanks 59

Relief and Reducing Valves 61

circuit balancing valves (cbv) 63

Circuit Balancing Valves - Mini Sweat 63

Circuit Balancing Valves - Venturi 65

Circuit Balancing Valves - ANSI Flanged 69

Circuit Balancing Valves - ANSI Grooved 73

Flange Adapter Kits 77

PT Port & Extensions 79

Meters 81

Orifice Indicators 85

compass

parts section

Hardware Kits 95

Flange Hardware Kits - Cross Reference 97

Flex Flange 99

Flange Kits 101

Seal Bearing Assemblies 105

Coupler Assemblies 109

Motors 111

Seal Kits 113

Impellers 114

Gaskets 118

Pump Bodies 119

parts look up 121

s-25 121

s-35 122

h-32 123

s-35 124

s-45 125

s-46 127

h-41 128

4030 Base Mounted Pumps - Parts

Cross Reference 149

4280 Motor Mounted Pumps - Parts

Cross Reference 161

Shell & Tube Heat Exchangers - Parts

Cross Reference 171

4380 & 4360 VIL Pumps - Parts

Cross Reference 173

competition circulator

cross reference 175

Design Envelope COMPASS

Circulators Cross Reference 175

S&H Circulators Cross Reference 176

s-55 129

s-57 130

h-51 131

h-52 132

h-53 133

h-54 134

s-69 135

cbv

CBV Balancing Wheel 87

replacement parts 89

S&H Circulator Less Volute 89

Companion Flanges 91

E.2 Circulators Cross Reference 177

Astro 2 Circulators Cross Reference 179

technical data 181

Page 2

Page 3

back to

<

contents

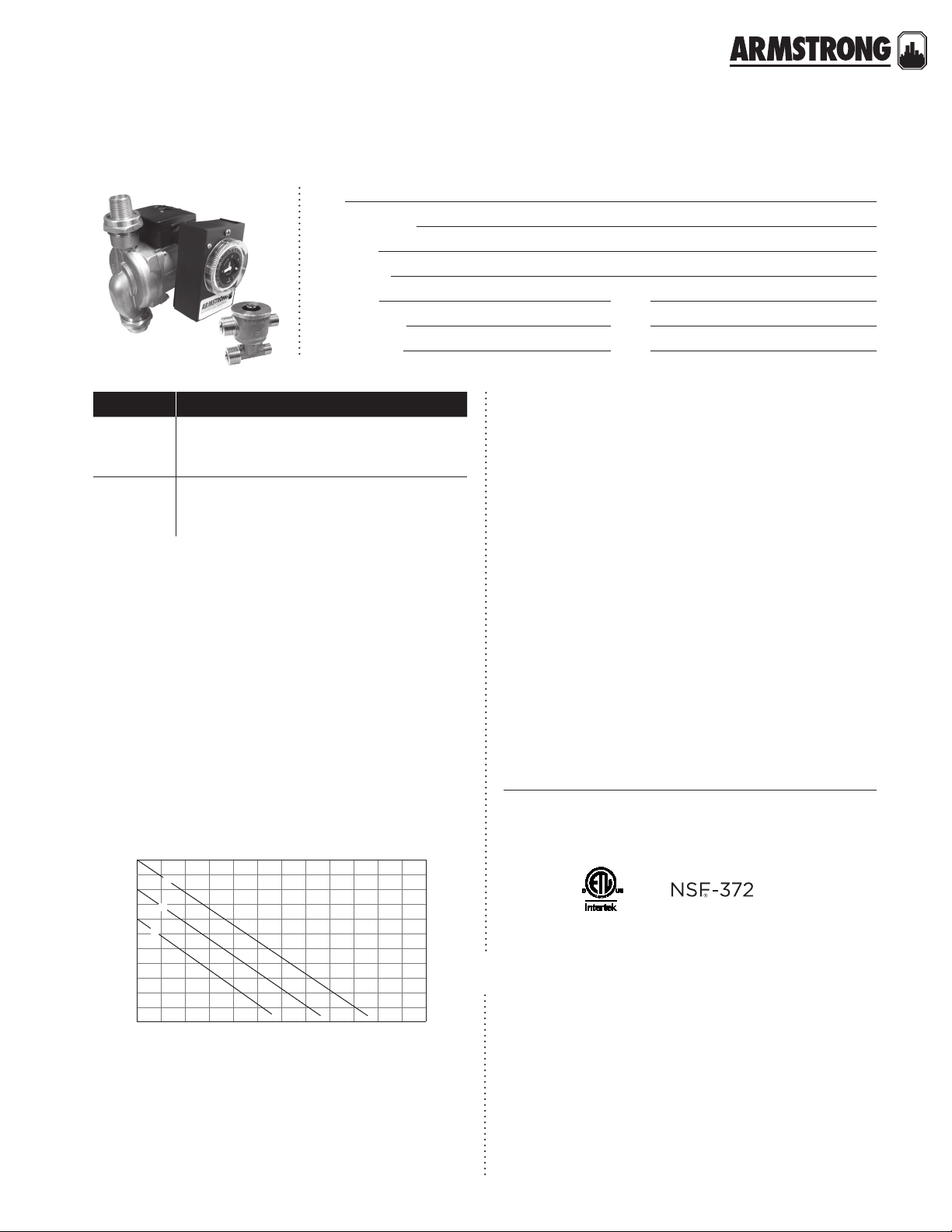

DESIGN ENVELOPE COMPASS CIRCULATORS

VARIABLE SPEED WET ROTOR

|

SUBMITTAL

Job:

Representative:

Engineer:

Contractor:

Order no: Date:

Submitted by: Date:

Approved by: Date:

technical data

Supply voltage: 1 × 115 v – 10%/+ 6%, 60 Hz

minimum maximum

Amp 0.05 0.65

Watt 5

Motor protection: The pump requires no external

motor protection.

Maximum working temperature: 230°f (110°c) maximum

Maximum working pressure: 150 psi (10 bar).

Maximum relative air humidity (rh): 95%.

Flow range: 0 – 20 USgpm (0 to 1.26 L/s)

Head range: 0 – 20.0 feet (0 to 6.09 m)

Enclosure class: Type 2

Insulation class: h

Certification:

ulstd.778 certified to csa std. c22.2 no.108-01)

*nsf 372 (for stainless steel models)

etl listed for US and Canada (conforms to

45

inlet pressure

Minimum inlet pressure in relation to liquid temperature:

To avoid condensation in the control box and stator, the

liquid temperature must always be higher than the

ambient temperature.

ambient

temperature

32°f (0°c) 35.6°f (2°c) 230°f (110°c)

50°f (10°c) 10°c (50°f) 230°f (110°c)

68°f (20°c) 68°f (20°c) 230°f (110°c)

86°f (30°c) 86°f (30°c) 230°f (110°c)

95°f (35°c) 95°f (35°c) 194°f (90°c)

104°f (40°c) 104°f (40°c)

liquid temperature

min. max.

materials of construction

Pump body: Cast iron (closed systems)

Stainless steel* (open s ystems)

Impeller: Noryl

Shaft: Ceramic

Bearings: Ceramic

Gasket material: epdm

158°f (70°c)

liquid temperature minimum inlet pressure

150°f (65°c) 3.0 ft (0.91 m)

167°f (75°c) 4.4 ft (1.34 m)

194°f (90°c) 9.2 ft (2.8 m)

230°f (110°c) 36.1 ft (11.0 m)

Sound pressure level:

lower than 43 dB(A).

Ambient temperature: 32°f (0°c) – 104°f (40°c)

Pumped liquids: Water or water Glycol mix.

Liquid temperature: 36°f (2°c) – 230°f (110°c)**

The sound pressure level of the pump is

hardware kit

Companion flange kit (contains two (2) flanges,

hardware and gaskets)

Cast iron: 0.75", 1", 1.25", 1.5"

Bronze: 0. 75", 1 ", 1 . 2 5", 1 .5"

HYDRONIC SOLUTIONS CATALOG

|

3

Page 4

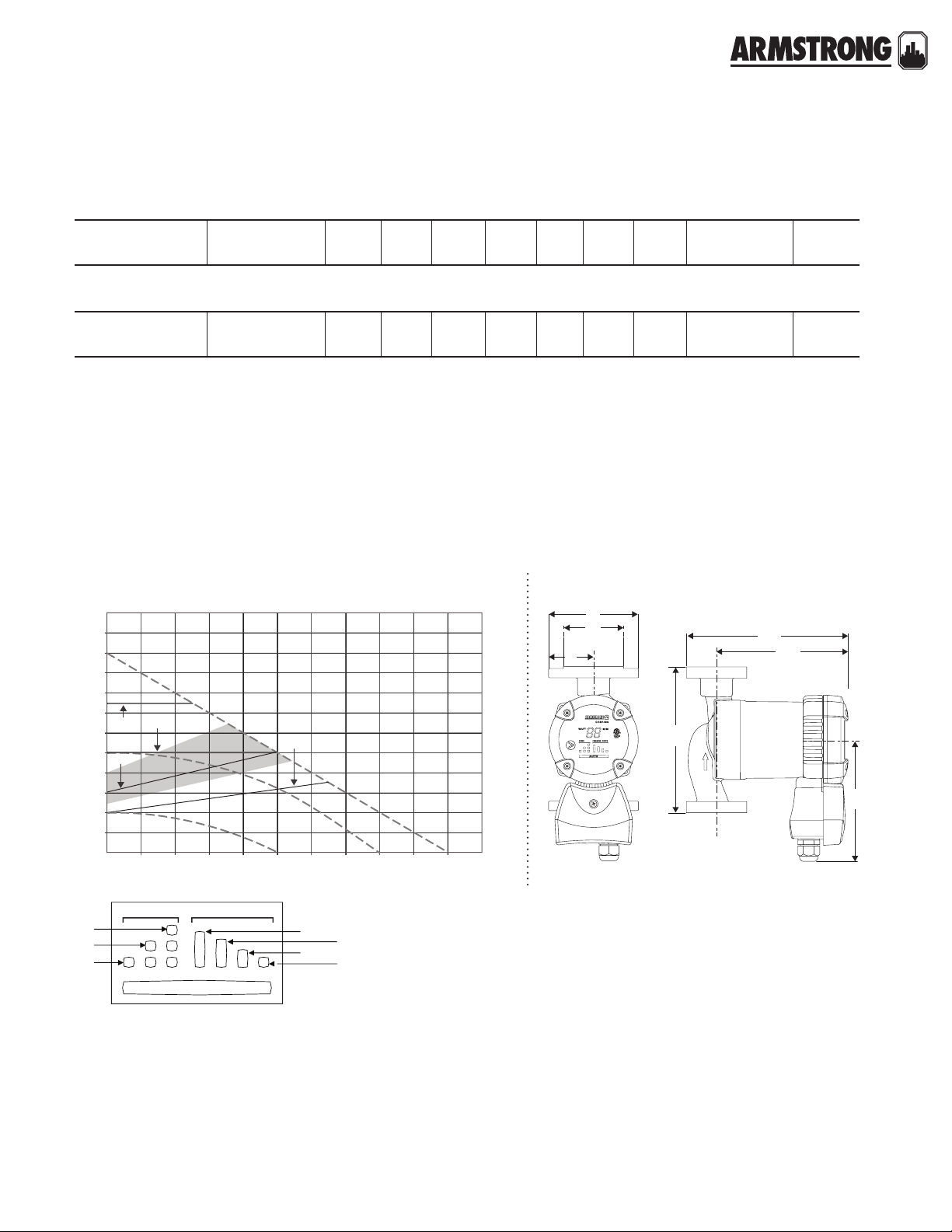

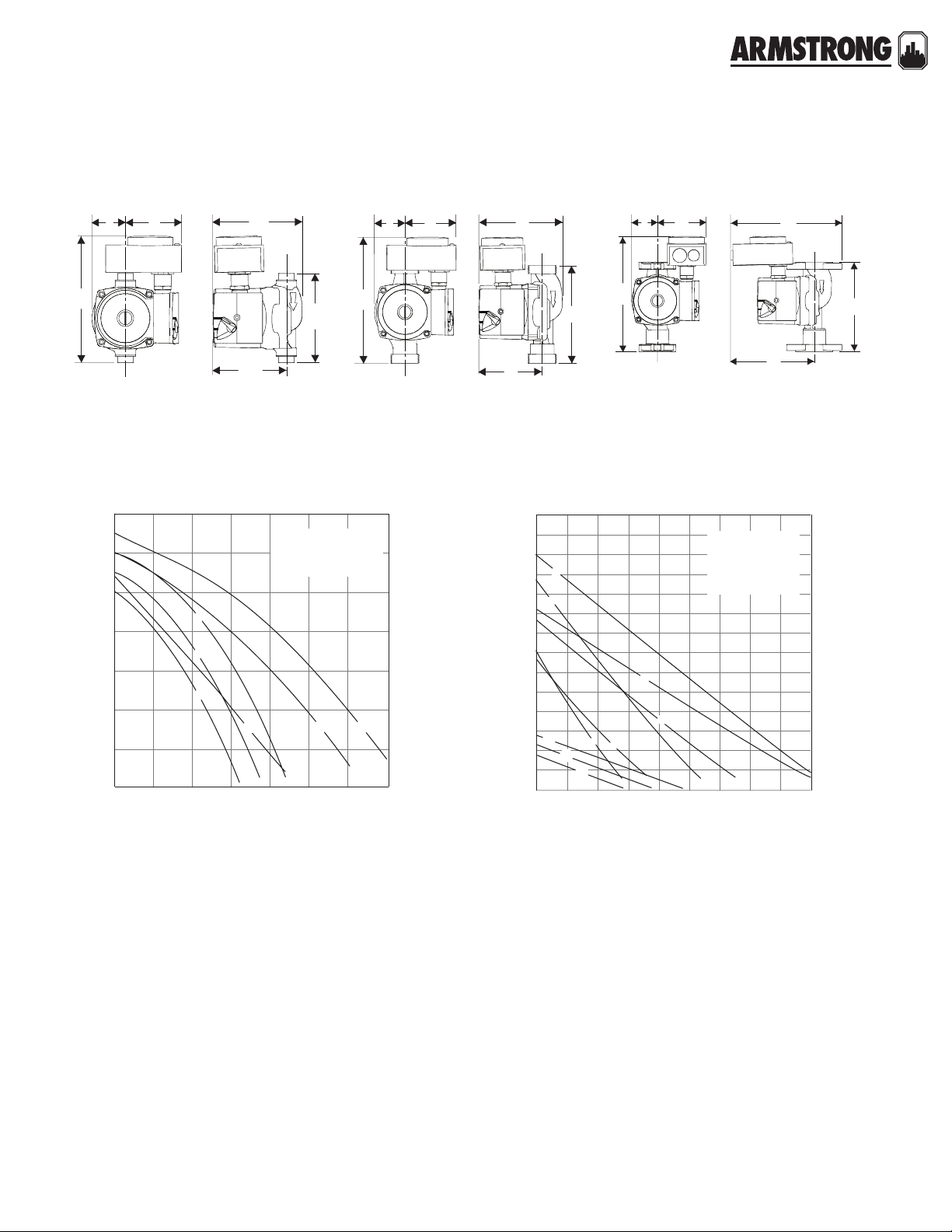

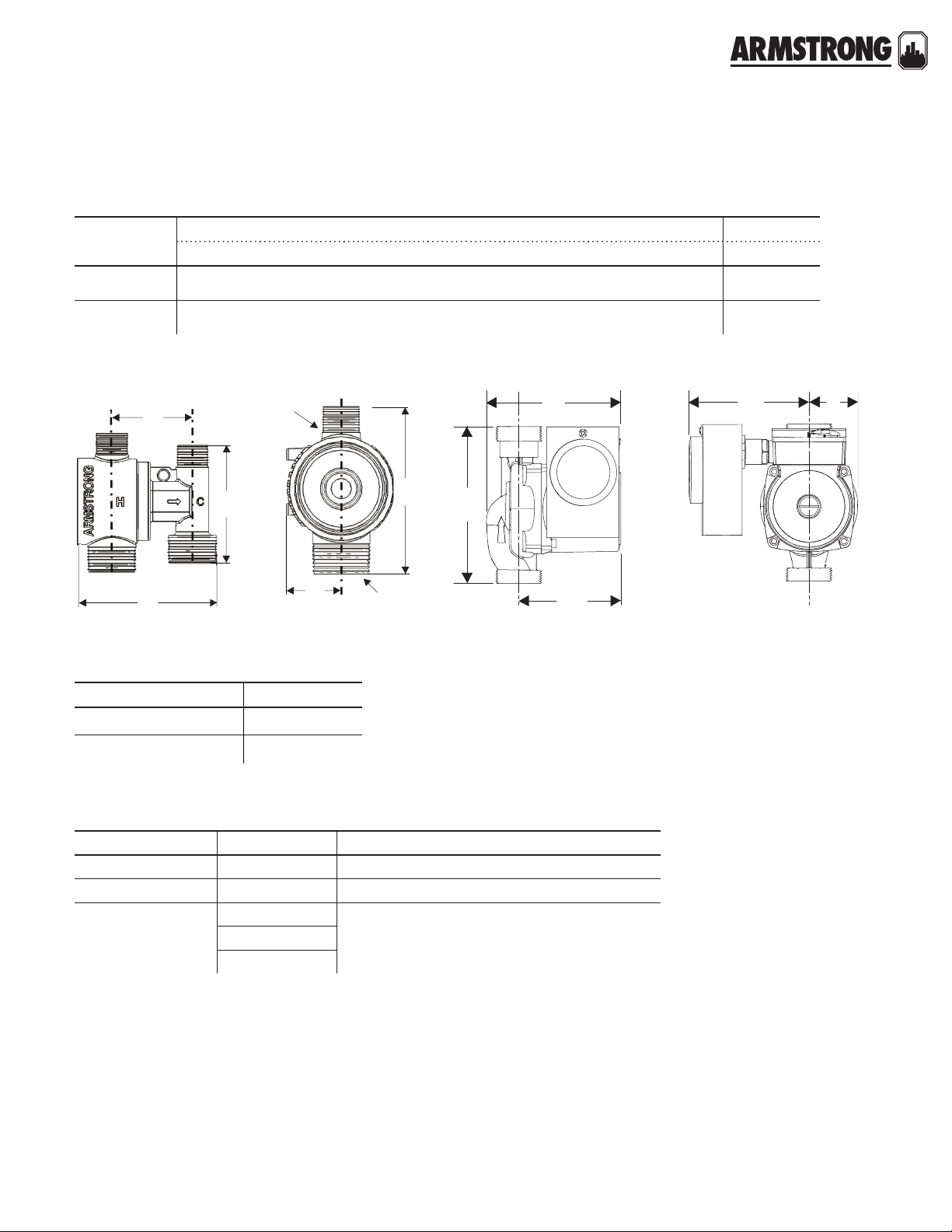

DESIGN ENVELOPE COMPASS CIRCULATORS

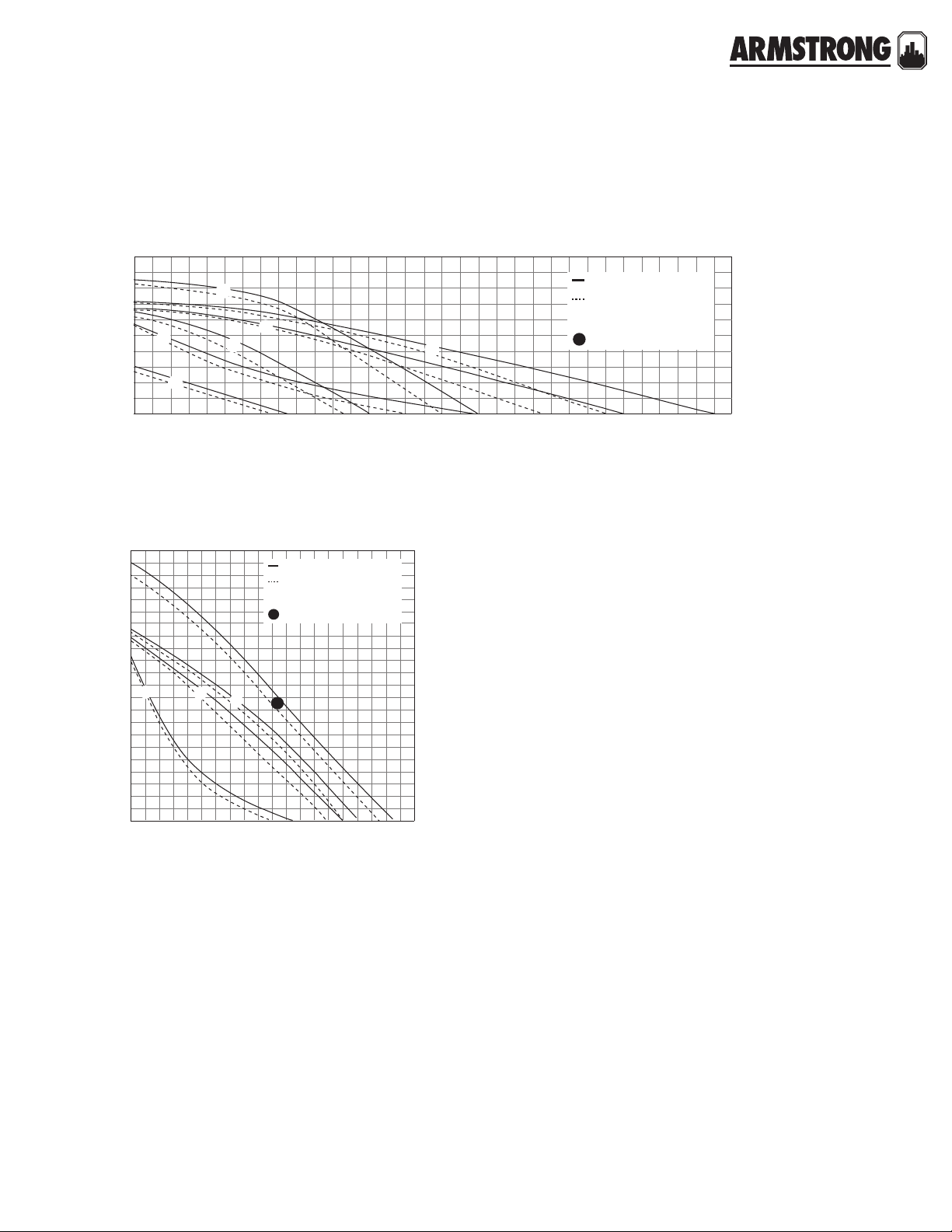

compass performance curves

head - ft.wg.

d

VARIABLE SPEED WET ROTOR

dimensions and weights

|

SUBMITTAL

stainless steel* part number a b c d e f g

Compass 20-20 ss

flange

180203-607

cast iron part number a b c d e f g

Compass 20-20 ci

flange

note:

All dimensions are in inches (mm) and weights in lbs (kg).

*Certified <0.25 weighted average percent lead and complies with California Health and

Safety Code Section 116875 (commonly known as ab 1953).

** For open systems, it is recommended that the liquid temperature be less than 150°f

(65°c) to avoid precipitation of calcium.

180203-606

compass performance curves

24

22

20

18

16

14

12

10

8

4

2

0

pc3

pc4

pc2

2

0

auto

466

i

10

8

flow - usgpm

pc1

6.50

(165)

6.50

(165)

7.08

(180)

7.08

(180)

5.75

(146)

5.75

(146)

4.00

(102)

4.00

(102)

2.00

(50)

2.00

(50)

3.25

(80)

3.25

(80)

5.31

(135)

5.31

(135)

connection

type& size

Flange – (2) ½"

dia. bolt holes

connection

type & size

Flange – (2) ½"

dia. bolt holes

weight

8.0 (3.6)

weight

8.0 (3.6)

compass flange

f

(on center)

e

a

ii

16

14

12

iii

20 22

18

b

c

g

speed pressure curve

iii

ii

i

auto

pc4

pc2

pc3

pc1

Lights on the display indicate the Control mode selected.

HYDRONIC SOLUTIONS CATALOG

|

4

Page 5

back to

<

contents

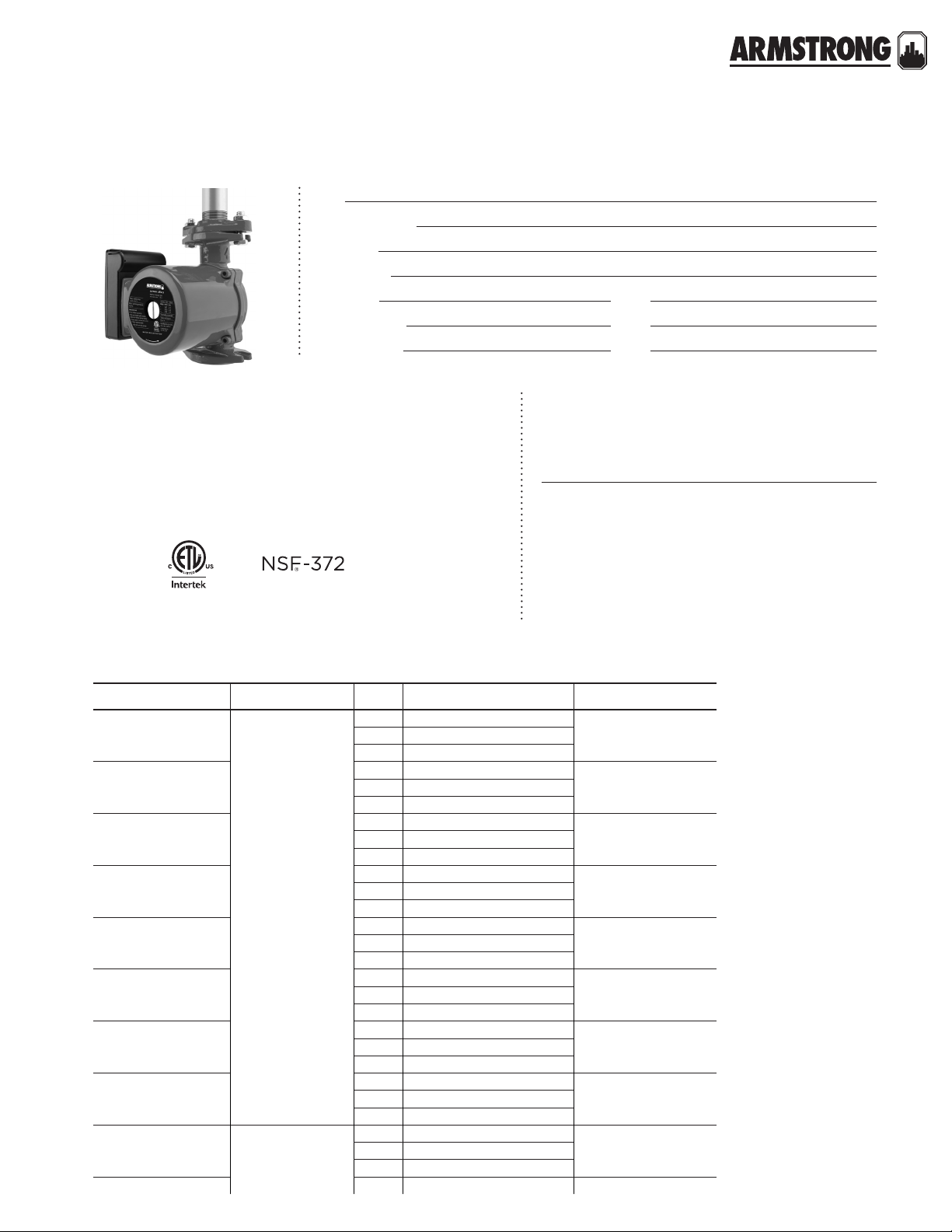

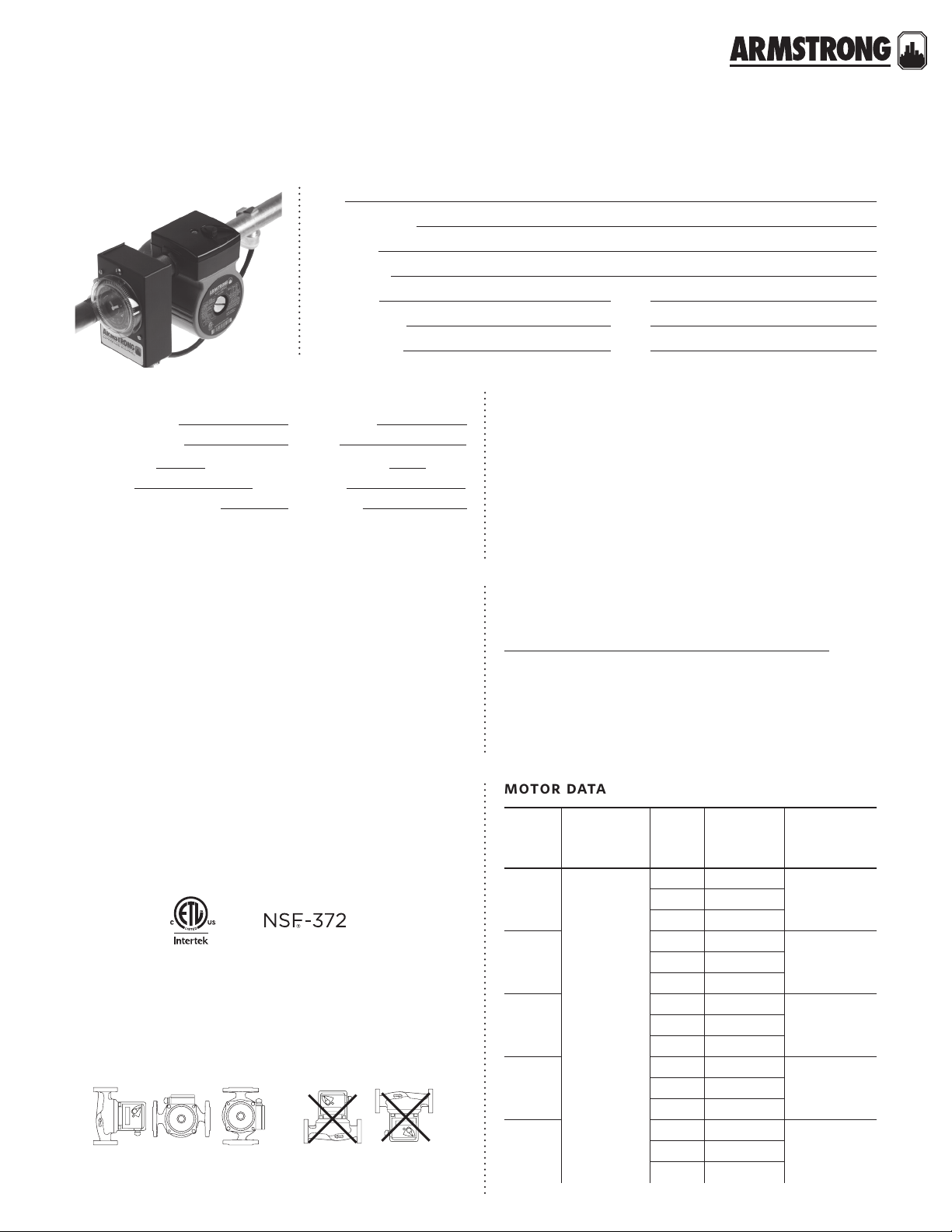

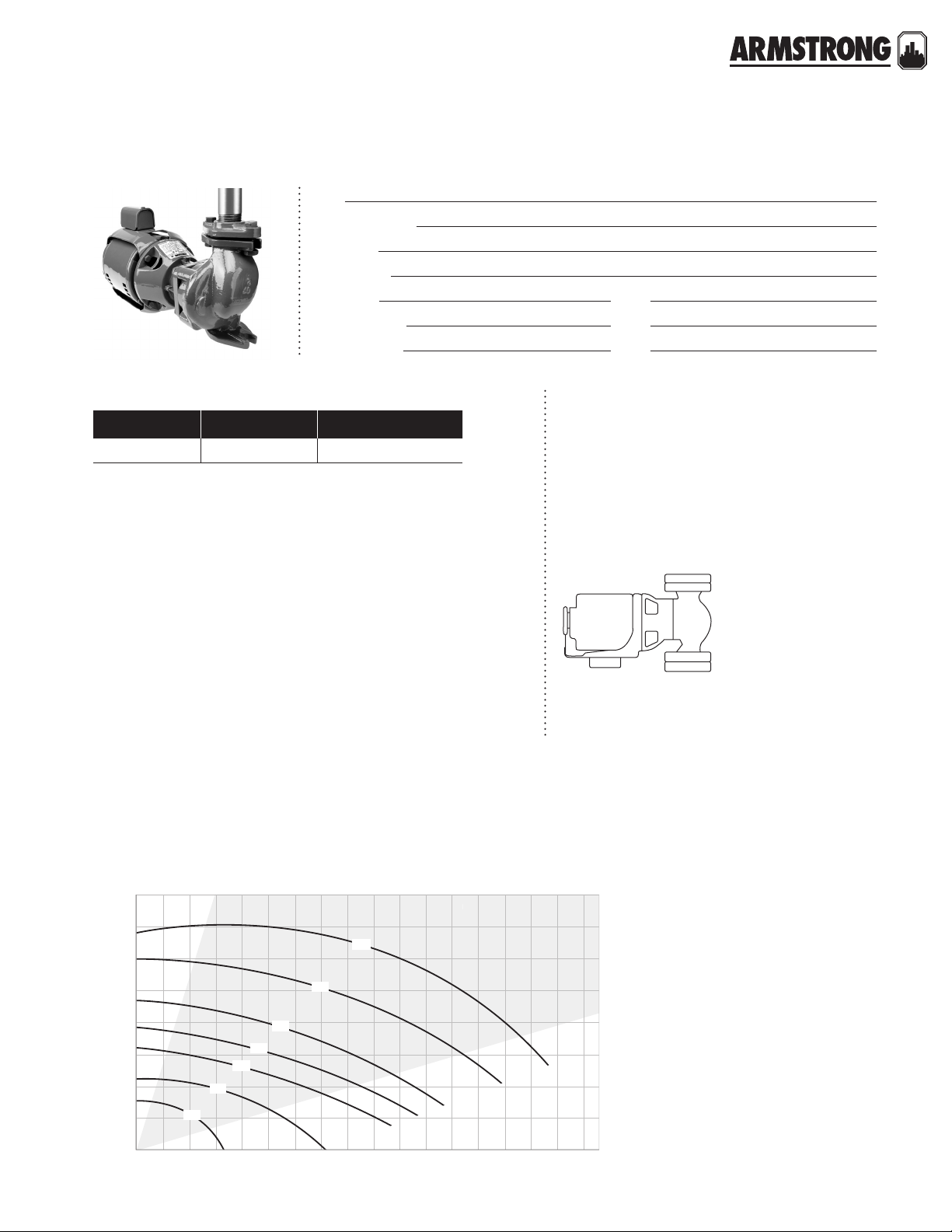

ASTRO 2 CIRCULATORS

THREE SPEED

|

SUBMITTAL

Job:

Representative:

Engineer:

Contractor:

Order no: Date:

Submitted by: Date:

Approved by: Date:

technical data

Flow range: 0 to 64 USgpm (0 to 4.04 L /s)

Head range: 0 to 42.0 feet (0 to 12.8 m)

Maximum fluid temperature: 185°f / 85°c (astro 286 up to 1.35a)

150°f / 65°c (astro 286 over 1.35a)

230°f / 110°c† (all others)

Maximum working pressure: 150 psi (1034 kPa)

Approvals: listed certified

†

For open systems, it is recommended that the fluid temperature be less

than 150°f (66°c) to avoid precipitation of calcium.

materials of construction

Pump body: Cast iron (closed systems)

Lead free bronze* (open systems)

Stainless steel* (open systems)

Impeller: Noryl

Bearings: Ceramic Gasket material: epdm

* Certified <0.25 weighted average percent lead and complies with

California Health and Safety Code Section 116875 (commonly known

as ab 1953).

Shaft: Ceramic

motor data

model electrical input speed full load amp draw (a) nominal power (w)

3 1.06

Astro 210ci/ss

Astro 220ssu

Astro 225bs

Astro 225ssu

Astro 230ss/ci/ci–r

Astro 250ss/ci/ci–r

Astro 280ci/ss

Astro 290ci/ss

Astro 280ci/ss 230v

Astro 286ci/ss

115v, 60hz

Single phase

23 0v, 60hz

Single phase

2 1.50

1 1.72

3 0.29

2 0.27

1 0.20

3 0.64

2 0.49

1 0.38

3 0.69

2 0.55

1 0.43

3 0.81

2 0.58

1 0.45

3 0.98

2 0.79

1 0.65

3 1.90

2 1.80

1 1.50

3 1.90

2 1.60

1 1.40

3 0.90

2 0.86

1 0.80

1 1.60

200

33

75

83

97

117

218

218

210

370

HYDRONIC SOLUTIONS CATALOG

|

5

Page 6

ASTRO 2 CIRCULATORS

THREE SPEED

|

SUBMITTAL

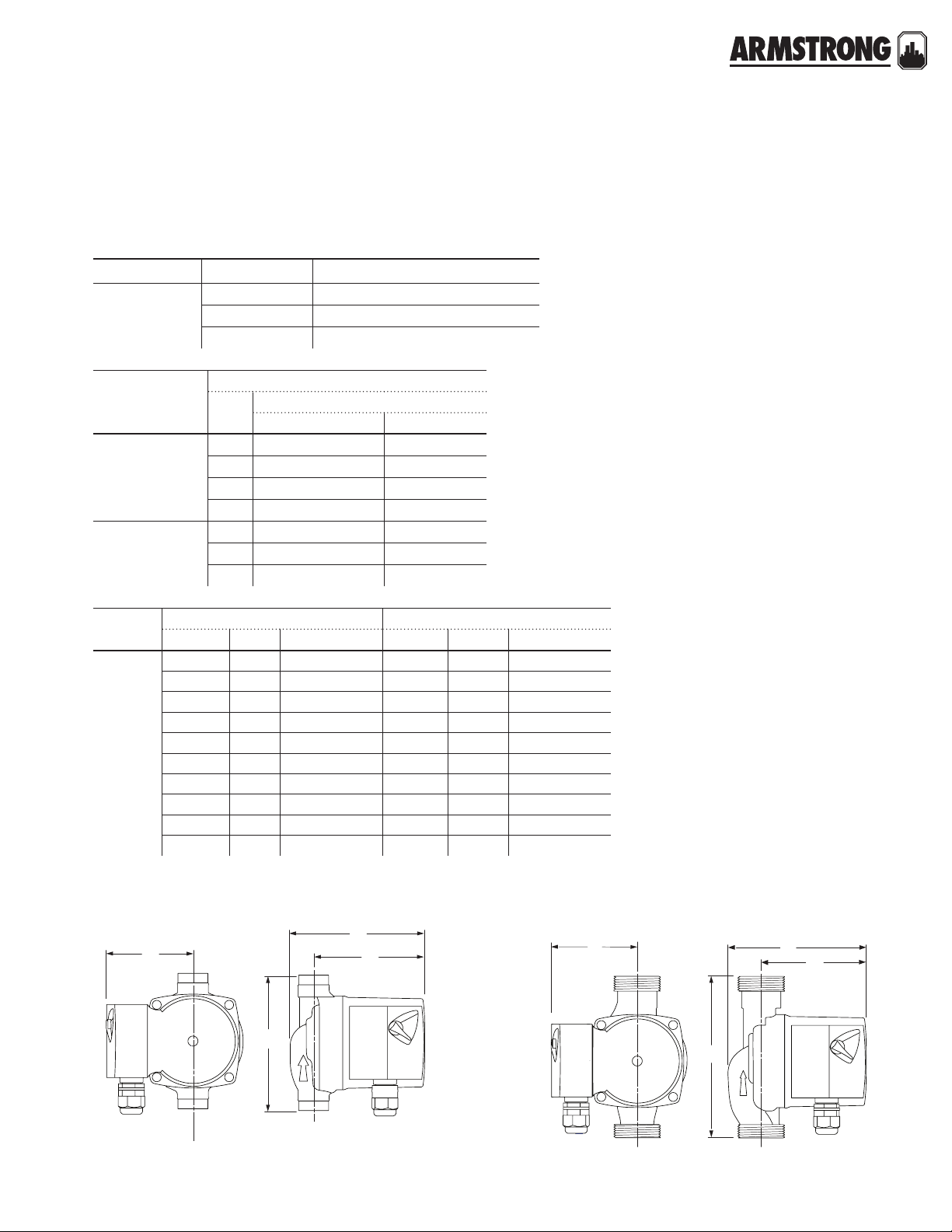

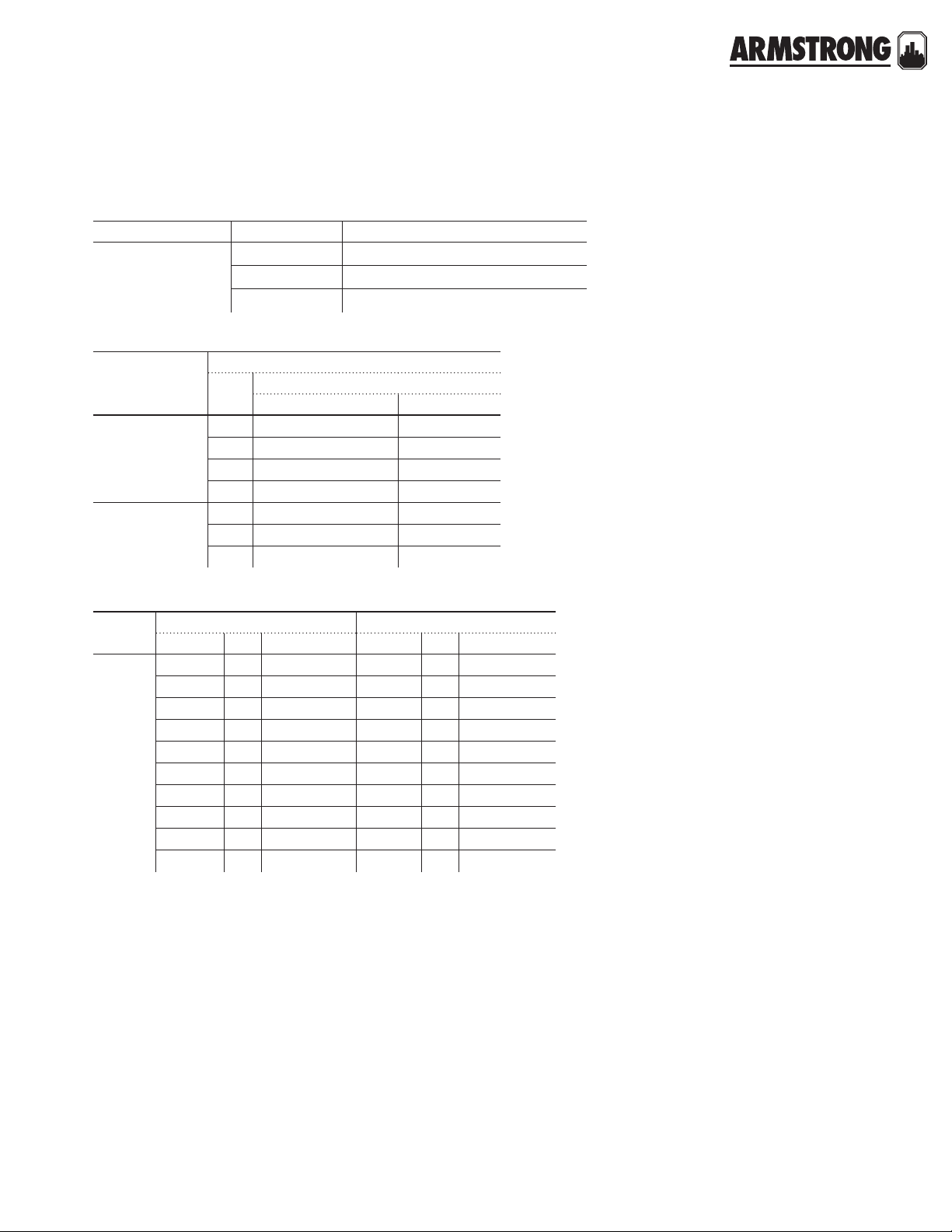

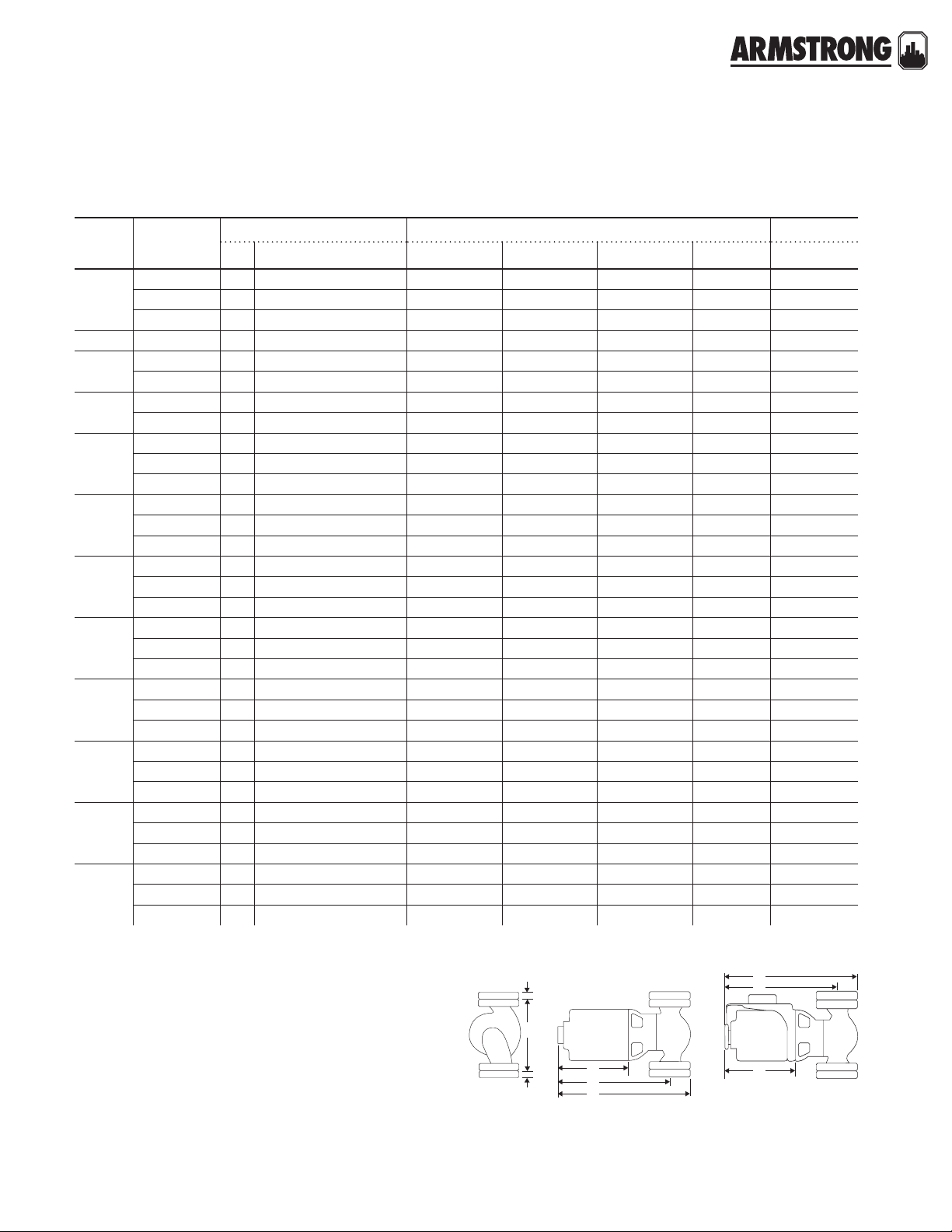

dimension data - inches (mm)

lead free bronze* a b c d e f connection type & size weight

Astro 225bs ½" swt 5.00 (127) 5 .0 0 (127) 4.13 (105) — 3 .00 (76) — Sweat – ½" 6.0 (2.7)

Astro 225bs ¾" swt 5.0 0 (127) 5.0 0 (127) 4.13 (105) — 3.0 0 (76) — Sweat – ¾" 6.0 (2.7)

stainless steel* a b c d e f connection type & size weight

Astro 220ssu** 6.00 (152) 5 .00 (127) 4.0 0 (102) — 3 .00 (76) — Union – 1¼" npsm 6.5 (2.9)

Astro 225ssu** 6.00 (152) 5 .0 0 (127) 4.0 0 (102) — 3 .00 (76) — Union – 1¼" npsm 6.5 (2.9)

Astro 230ss** 6 . 3 8 (162) 6. 0 0 (150) 4.00 (102) 4.0 0 (102) 3.00 (76) 3.25 (80) Flange – (2) ½" dia. bolt holes 8 .0 (3. 6)

Astro 250ss** 6.38 (162) 6.0 0 (150) 4.00 (102) 4. 0 0 (102) 3.00 (76) 3.25 (80) Flange – (2) ½" dia. bolt holes 8 .0 (3.6)

Astro 210ss** 6. 5 0 (165) 7. 25 (18 4) 4 .87 (124) 4 .0 0 (102) 3.5 0 (9 0) 3.13 (80) Flange – (2) ½" dia. bolt holes 10 .1 (4.6)

Astro 280ss (230v)** 6.50 (165) 6.75 (171) 4 . 87 (124) 4 .0 0 (102) 3.5 0 (9 0) 3.13 (80) Flange – (2) ½" dia. bolt holes 10 .1 (4.6)

Astro 286ss** 6.50 (16 5) 6 . 3 8 (162) 4.87 (124) 4 .00 (102) 3.5 0 (90) 3.13 (80) Flange – (2) ½" dia. bolt holes 10.1 (4.6)

Astro 29 0ss** 8.5 0 (216) 6. 65 (169) 5.20 (13 2) 4 .0 0 (102) 3.50 (9 0) 3.45 (88) Flange – (2) ½" dia. bolt holes 13.2 (6.0)

cast iron a b c d e f connection type & size weight

Astro 230ci** 6.38 (162) 6.0 0 (15 0) 4.00 (102) 4.0 0 (102) 3 .00 (76) 3.25 (80) Flange – (2) ½" dia. bolt holes 8 .0 (3.6)

Astro 230ci-r** 6.38 (162) 5 . 63 (137) 4. 0 0 (102) 4.00 (102) 3.0 0 (76) 3. 25 (80) Flange – (2) ½" dia. bolt holes 8.0 (3 .6)

Astro 250ci** 6 . 3 8 (162) 6.00 (150) 4.0 0 (102) 4.0 0 (102) 3 .00 (76) 3.25 (80) Flange – (2) ½" dia. bolt holes 8 .0 (3.6)

Astro 250ci-r** 6. 3 8 (162) 5.6 3 (137) 4.00 (10 2) 4.0 0 (102) 3.0 0 (76) 3.25 (8 0) Flange – (2) ½" dia. bolt holes 8.0 (3.6)

Astro 210ci** 6.50 (16 5) 7.2 5 (184) 4 . 87 (124) 4.0 0 (102) 3.5 0 (9 0) 3.13 (80) Flange – (2) ½" dia. bolt holes 10 .1 (4.6)

Astro 280ci (230v)** 6.50 (16 5) 6 . 3 8 (162) 4.87 (124) 4 .00 (102) 3.50 (90) 3.13 (80) Flange – (2) ½" dia. bolt holes 10.1 (4.6)

Astro 286ci** 6.50 (16 5) 6 . 3 8 (162) 4.87 (124) 4 .00 (102) 3.50 (90) 3.13 (80) Flange – (2) ½" dia. bolt holes 10.1 (4.6)

Astro 290ci** 8.50 (216) 6.6 5 (169) 5.20 (132) 4. 0 0 (102) 3.50 (90) 3.45 (88) Flange – (2) ½" dia. bolt holes 13.2 (6.0)

note: All dimensions are in inches (mm) and weights in lbs (kg).

** Removable check valve installed at pump outlet.

mounting orientation

right wrong

part numbers

model part number

Astro 220ssu w½" swt 110223-301

Astro 220ssu w¾" swt 110223-302

Astro 220ssu 110223-309

Astro 225bs ½" swt 110223-303

Astro 225bs ¾" swt 110223-304

Astro 225ssu 110223-310

Astro 230ci 110223-305

Astro 230ci-r 110223-315

Astro 230ss 110223-306

HYDRONIC SOLUTIONS CATALOG

|

6

model part number

Astro 250ci 110223-307

Astro 250ci-r 110223-317

Astro 250ss 110223-308

Astro 280ci 110223-320

Astro 280ss 110223-321

Astro 280ci (230v) 110223-322

Astro 280ss (230v) 110223-323

Astro 286ci (230v) 110223-324

Astro 286ss (230v) 110223-325

model part number

Astro 210ci 110223-326

Astro 210ss 110223-327

Astro 290ci 110223-328

Astro 290ss 110223-329

Page 7

ASTRO 2 CIRCULATORS

THREE SPEED

|

SUBMITTAL

accessories

lead free* union fitting sets (contains two (2) half unions and gaskets)

model part number connection

Astro

220ssu/225ssu

model

Astro

210/230/250

/280/286

Compass

Astro 290

810120-320 1.25" npsm × 0.5" sweat lead free

810120-322 1.25" npsm × 0.75" sweat lead free

810120-324 1.25" npsm × 0.75" fnpt lead free

flange kits

size

lead free bronze* cast iron

0.75" 816013-841 816013 -111

1" 816012-841 816012-111

1.25" 816011- 841 816011-111

1.5" 8160 09-841 816009-111

1" 806073-841 806073-111

1.25" 804300-841 804300-111

1.5" 804301-841 804301-111

item number

model

cif-050t ½" 110124-100 ff-050t ½" 110124-200

cif-075t ¾" 110124-00 0 ff-075t ¾" 110124-201

cif-100t 1" 110124-001 ff-100t 1" 110124-202

All Astro

flange

models

astro 225bs

cif-125t 1¼" 110124-002 ff-125t 1¼" 110124-203

cif-150t 1½" 110124-003 ff-150t 1½" 110124-204

cif-050s ½" 110124-150 ff-050s ½" 110124-250

cif-075s ¾" 110124-050 ff-075s ¾" 110124-251

cif-100s 1" 110124-051 ff-100s 1" 110124-252

cif-125s 1¼" 110124-052 ff-125s 1¼" 110124-253

cif-150s 1½" 110124-053 ff-150s 1½" 110124-254

e

cif flex flanges

model size item number model size item number

astro 220ssu, 225ssu

b

c

a

e

b

c

a

HYDRONIC SOLUTIONS CATALOG

|

7

Page 8

ASTRO 2 CIRCULATORS

head - feet

head - metres

flow - usgpm

flow - l/s

head - feet

head - metres

flow - usgpm

flow - l/s

THREE SPEED

|

SUBMITTAL

astro 230ss/ci, 250ss/ci

e

a

f

(on center)

d

astro 280ci, 290ci/ss, 286ci/ss

e

astro 230ci-r, 250ci-r

b

c

b

c

e

f

(on center)

d

astro 280ss, 210ci/ss

e

a

b

c

b

c

performance curve

astro 225bs, 225ssu astro 250, 230, 220

HYDRONIC SOLUTIONS CATALOG

|

8

(on center)

d

00.130.25

14

12

10

8

6

4

2

0

024

a

f

0.38 0.50 0.63

3

0.76 0.88

astro 225bs

astro 225ssu

4.3

3.7

3.0

2.4

0 0.13 0.25 0.38 0.50 0.63 0.76 0.88 1.01 1.14

28

24

3

20

2

16

a

f

(on center)

d

astro 250

astro 230

astro 220

8.5

7.3

6.1

4.9

2

1

1 2 3

1.8

1.2

0.6

12

3

8

2

3

1

4

2

1

3.7

2.4

1.2

1

6810

12 14

0

0

024681012141618

0

Page 9

ASTRO 2 CIRCULATORS

flow - usgpm

flow - l/s

head - feet

head - metres

flow - usgpm

flow - l/s

head - feet

head - metres

THREE SPEED

|

SUBMITTAL

astro 210, 290

0.250 0.50 0.76 1.01 1.26 1.51 1.77 2.02 2.27 2.78 3.03 3.79 4.043.533.282.52

20

16

12

1

8

4

1

0

0481216202428323644486064565240

3

2

2

astro 280, 286

0 0.50 1.01 1.51 2.02 2.52

44

40

32

without check valve

with check valve

astro 280

astro 286

13.4

12.2

9.8

3

without check valve

with check valve

astro 210

astro 290

6.1

4.9

3.7

2.4

1.2

0

24

1

16

8

0

0816 24 32 40

2

3

7.3

4.9

2.4

0

HYDRONIC SOLUTIONS CATALOG

|

9

Page 10

10

HYDRONIC SOLUTIONS CATALOG

|

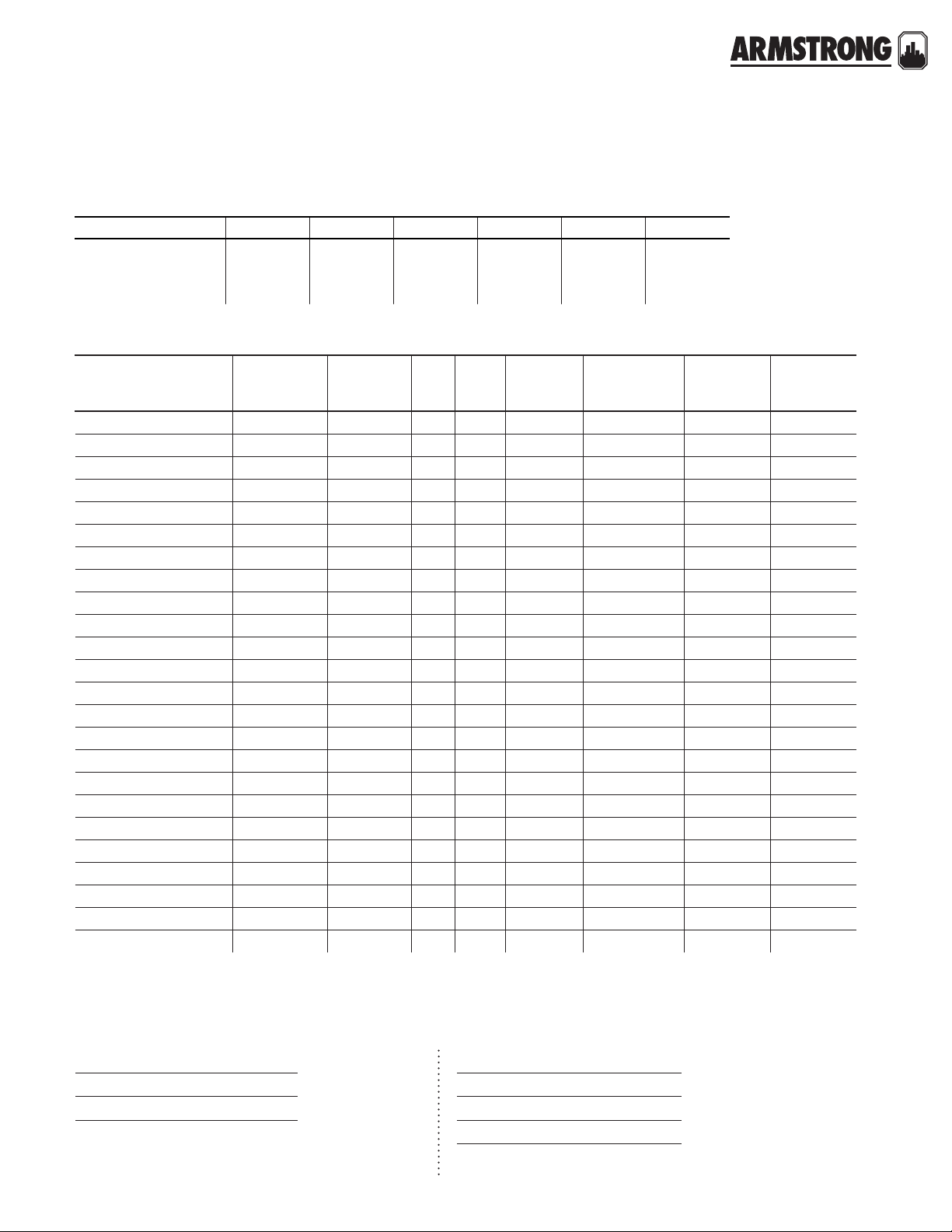

Page 11

motor data

back to

<

contents

ASTRO 2

|

HOT WATER RE-CIRCULATION SYSTEMS

SUBMITTAL

Job:

Representative:

Engineer:

Contractor:

Order no: Date:

Submitted by: Date:

Approved by: Date:

pump design data

Pump model: Flange size:

No. of pumps:

Capacity:

Head:

ft (m) Liquid:

Companion flanges: Included:

Note:

USgpm (L/s) Temperature: °f (°c)

application

Armstrong Astro 2 hot water re-circulation systems

automatically circulate water through domestic hot water

distribution pipes. This helps to ensure that everyone in the

household has ‘instant’ hot water at the tap when they need

it, while also helping to conserve water and save water heating energy costs. All systems are assembled, wired, tested

and then shipped, ready for installation.

technical data

Power connection: 6.0 ft. (1.8 m) power cord, molded duplex

plug with ground

Environment: Indoor use only

Flow range: 0 to 64 USgpm (0 to 4.04 L /s)

Head range: 0 to 42.0 feet (0 to 12.8 m)

Max. working pressure: 150 psi (1034 kPa)

Max. water temperature: 230°f (110°c)

Ambient temperature: 39°f (4°c) to 104°f (40°c)

Low temperature switchpoint

High temperature switchpoint

Clock/timer: 12 hour analog clock with am/pm indication

Timer settings: Individual mechanical toggles for each 15

minute interval over 24 hours

Manual override: Three position slide switch; on/auto/o

Approvals: listed certified

1 High/low temperature switchpoints are as measured on pipe surface with the

Aquastat (ta models only).

†

For open systems, it is recommended that the fluid temperature be less

than 150°f (66°c) to avoid precipitation of calcium.

mounting orientation

right wrong

†

1

: 85°f (29°c) ± 10%

1

: 105°f (40°c) ± 10%

materials of construction

Pump body: Lead free bronze* (bs models)

Stainless steel* (ss models)

Impeller: Noryl

Bearings: Ceramic Gasket material: epdm

* Certified <0.25 weighted average percent lead and complies with California

Health and Safety Code Section 116875 (commonly known as ab 1953).

model

astro

220ssu

astro

225bs

astro

225ssu

astro

230ss

astro

250ss

Shaft: Ceramic

electrical

input

115v, 60hz

Single phase

speed

3 0.29

2 0.27

1 0.20

3 0.64

1 0.38

3 0.69

1 0.43

3 0.81

1 0.45

3 0.98

2 0.79

1 0.65

full load

amp

draw (a)

nominal

power (w)

33

752 0.49

832 0.55

972 0.58

117

11

HYDRONIC SOLUTIONS CATALOG

|

Page 12

ASTRO 2

SUBMITTAL

|

HOT WATER RE-CIRCULATION SYSTEMS

dimension data - inches (mm)

model a b c d e f

astro 225bs

astro 220/225ssu

astro 230/250ss

note: All dimensions are in inches (mm)

5. 0 (127) 6 . 5 (165) 5.6 (142) 7.1 (180) 4.3 (110) 1.8 (4 6)

5. 0 (127) 5 . 3 (134) 4.4 (112) 6.3 (160) 3.4 (86) 1 . 8 (46)

6.4 (162) 8 .7 (221) 6.8 (173) 7.0 (178) 3.7 (93) 1.8 (46)

electrical

model connection size cord timer aquastat

data @ 115

Vac, 60 Hz

astro 220ssu050s-ta*

astro 220ssu075s-ta*

astro 225bs050s-ta

astro 225bs075s-ta Sweat ¾"

astro 220ssu-ta npsm union 1¼"

astro 225ssu-ta npsm union 1¼"

astro 230ss-ta 2 bolt flange 2 bolt flange

astro 250ss-ta 2 bolt flange 2 bolt flange

astro 220ssu050s-t* Sweat ½"

astro 220ssu075s-t* Sweat ¾"

astro 225bs050s-t Sweat ½"

astro 225bs075s-t Sweat ¾"

astro 220ssu-t npsm union 1¼"

astro 225ssu-t npsm union 1¼"

astro 230ss-t 2 bolt flange 2 bolt flange

astro 250ss-t 2 bolt flange 2 bolt flange

astro 220ssu050s-lc* Sweat ½"

astro 220ssu075s-lc* Sweat ¾"

astro 225bs050s-lc Sweat ½"

astro 225bs075s-lc Sweat ¾"

astro 220ssu-lc npsm union 1¼"

astro 225ssu-lc npsm union 1¼"

astro 230ss-lc 2 bolt flange 2 bolt flange

astro 250ss-lc 2 bolt flange 2 bolt flange

note: All weights are in lbs. (kg) *Union model with sweat hardware kit.

Sweat ½"

Sweat ¾"

Sweat ½"

ü ü ü

ü ü ü

ü ü ü

ü ü ü

ü ü ü

ü ü ü

ü ü ü

ü ü ü

ü ü

ü ü

ü ü

ü ü

ü ü

ü ü

ü ü

ü ü

ü

— — 0.29 A, 33W 7.00 (3.18) 110223-340

ü

— — 0.29 A, 33W 7.00 (3.18) 110223-341

ü

— — 0.64 A, 75W 6.50 (2.95) 110223-342

ü

— — 0.64 A, 75W 6.50 (2.95) 110223-343

ü

— — 0.29 A, 33W 7.00 (3.18) 110223-344

ü

— — 0.69 A, 83W 7.00 (3.18) 110223-345

ü

— — 0.81 A, 97W 9.00 (4.08) 110223-348

ü

— — 0.98 A, 117W 9.00 (4.08) 110223-349

— 0.29 A, 33W 7.50 (3.40) 110223-240

— 0.29 A, 33W 7.50 (3.40) 110223-241

— 0.64 A, 75W 7.00 (3.18) 110223-242

— 0.64 A, 75W 7.00 (3.18) 110223-243

— 0.29 A, 33W 7.50 (3.40) 110223-244

— 0.69 A, 83W 7.50 (3.40) 110223-245

— 0.81 A, 97W 10 .0 0 (4.54) 110223-248

— 0.98 A, 117W 10.00 (4. 54) 110223-249

0.29 A, 33W 7.50 (3.40) 110223-140

0.29 A, 33W 7.50 (3.40) 110223-141

0.64 A, 75W 7.00 (3.18) 110223-142

0.64 A, 75W 7.00 (3.18) 110223-143

0.29 A, 33W 7.50 (3.40) 110223-144

0.69 A, 83W 7.50 (3.40) 110223-145

0.81 A, 97W 10.0 0 (4.54) 110223-148

0.98 A, 117W 10.00 (4. 54) 110223-149

weight

pa r t

numbe r

12

accessories

24 hour timer

model part number

24 hour timer 810123-130

See page 49 for the details on 24-Hour Timer

HYDRONIC SOLUTIONS CATALOG

|

aquastat

model part number

½" 110123-120

¾" 110123-121

See Page 85 for the details on Aquastat models.

Page 13

ASTRO 2

|

HOT WATER RE-CIRCULATION SYSTEMS

SUBMITTAL

lead free* union fitting sets (contains two (2) half unions and gaskets)

model part number connection

810120-320 1.25" npsm × 0.5" sweat lead free

Astro 220ssu/225ssu

model

Astro

210/230/250

/280/286

Compass

Astro 290

810120-322 1.25" npsm × 0.75" sweat lead free

810120-324 1.25" npsm × 0.75" fnpt lead free

flange kits

size

lead free bronze* cast iron

0.75" 816013-841 816013-111

1" 816012-841 816012-111

1.25" 816011- 841 816011-111

1.5" 8160 09-841 816009-111

1" 806073-841 8 0 6073-111

1.25" 804300-841 804300-111

1.5" 804301-841 804301-111

item number

model

All Astro

flange

models

cif flex flanges

model size item number model size item number

cif-050t ½" 110124-100 ff-050t

cif-075t ¾" 110124-000 ff-075t

cif-100t 1" 110124-001 ff-100t

cif-125t 1¼" 110124- 002 ff-125t

cif-150t 1½" 110124-003 ff-150t

cif-050s ½" 110124-150 ff-050s

cif-075s ¾" 110124-050 ff-075s

cif-100s 1" 110124-051 ff-100s

cif-125s 1¼" 110124-052 ff-125s

cif-150s 1½" 110124-053 ff-150s

½" 110124-200

¾" 110124-201

1" 110124-202

1¼" 110124-203

1½" 110124-204

½" 110124-250

¾" 110124-251

1" 110124-252

1¼" 110124-253

1½" 110124-254

13

HYDRONIC SOLUTIONS CATALOG

|

Page 14

ASTRO 2

b

c

a

fe

b

c

f

e

b

c

a

f

e

head - feet

head - metres

flow - usgpm

flow - l/s

head - feet

head - metres

flow - usgpm

flow - l/s

|

HOT WATER RE-CIRCULATION SYSTEMS

SUBMITTAL

astro 225bs astro 230/250ssastro 220/225ssu

d

d

d

performance curve

astro 225bs, 225ssu astro 250, 230, 220

00.130.25

14

12

10

8

6

4

2

0

024

0.38 0.50 0.63

3

2

1

1 2 3

6810

0.76 0.88

astro 225bs

astro 225ssu

12 14

4.3

3.7

3.0

2.4

1.8

1.2

0.6

0

0 0.13 0.25 0.38 0.50 0.63 0.76 0.88 1.01 1.14

28

24

3

20

2

16

12

8

3

1

4

2

1

1

0

024681012141618

3

2

astro 250

astro 230

astro 220

a

8.5

7.3

6.1

4.9

3.7

2.4

1.2

0

HYDRONIC SOLUTIONS CATALOG

|

14

Page 15

back to

<

contents

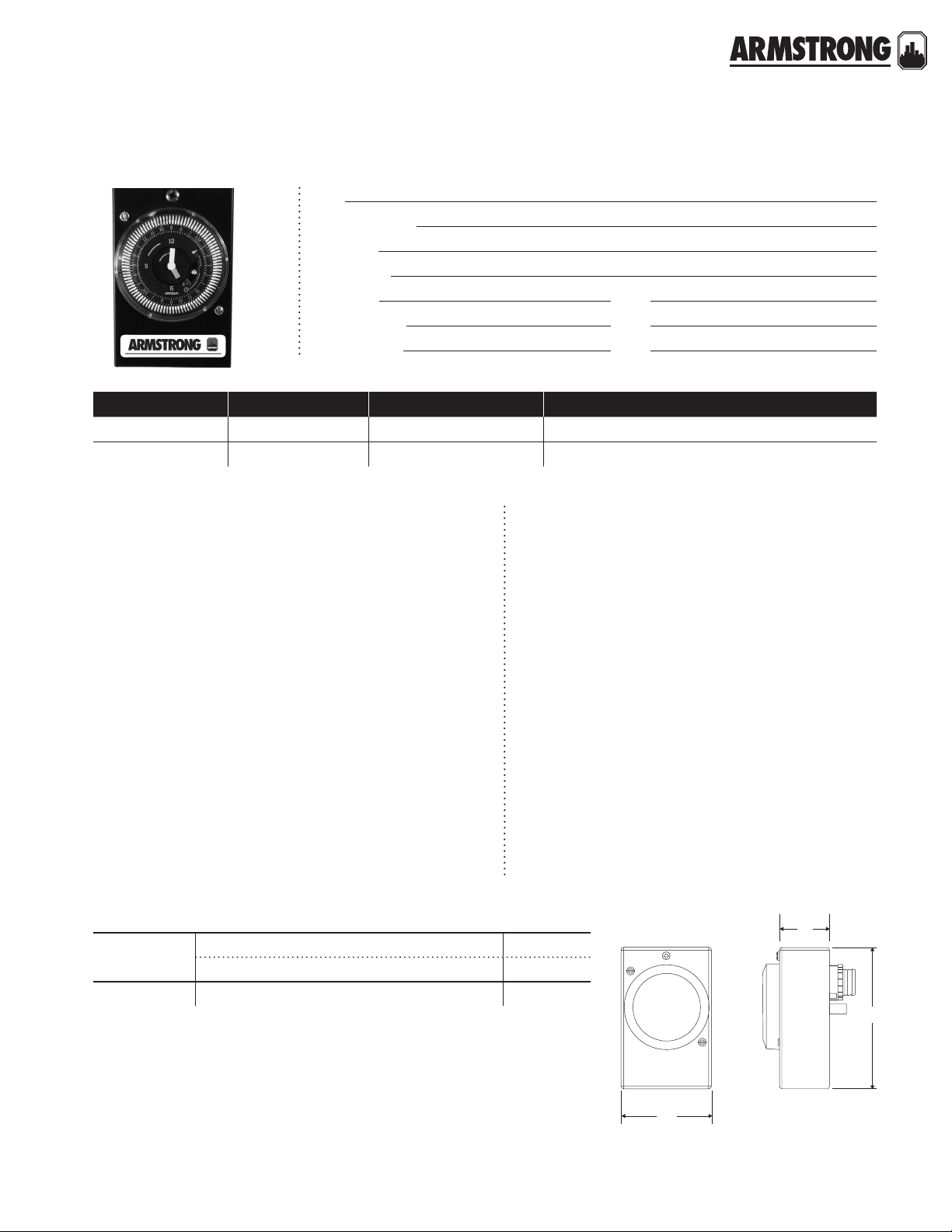

ASTRO 2

quantity tag no. model no. comments

|

24 HOUR TIMER

Job:

Representative:

Engineer:

Contractor:

Order no: Date:

Submitted by: Date:

Approved by: Date:

|

SUBMITTAL

technical data

Description: 24 hour timer

Application: Time actuated

Shortest switching interval: ¼ hour (15 minutes)

Manual switch modes: Timer,

Ambient temperature range: -40°f to 180°f (-40°c to 82°c)

Power consumption: 120 v, 0.5 w

Supply voltage: 110-120 vac, 60 Hz

Terminals: ¼" spade terminals

Switch rating: Type: Spot

Resistive: 21a

Tungsten: 1350 w

Inductive: 1 hp @ 120 vac; 2 hp @ 240 vac

on/o pump control

on override, o override

part numbers

24 hour timer: 810123-130

application

Armstrong 24 hour timers provide on/o pump control

according to preset operating times in order to increase

occupant comfort and improve the overall eciency

of domestic hot water re-circulation systems. The 24

hour timers are designed only for use with specified

Armstrong Astro series wet rotor circulators installed in

indoor hot water re-circulation applications.

Typical timer applications will cycle the pump at preset

times, allowing the user to select operation of the circulating pump during high peak usage periods in order to

decrease the delivery time to outlet fixtures and reduce

wasted water.

The timer control is programmable to ¼ hour intervals

within a 24 hour time frame utilizing a user-friendly

analog clock timer with hour and minute hands, two

directional arrows, and am/pm time setting.

dimension data - inches (mm)

model

hour timer

24

dimensions inches (mm) weight

a b c lbs (oz.)

2.74 (70) 1.50 (38) 4.23 (107) 0.19 (3.0)

b

c

a

HYDRONIC SOLUTIONS CATALOG

|

15

Page 16

16

HYDRONIC SOLUTIONS CATALOG

|

Page 17

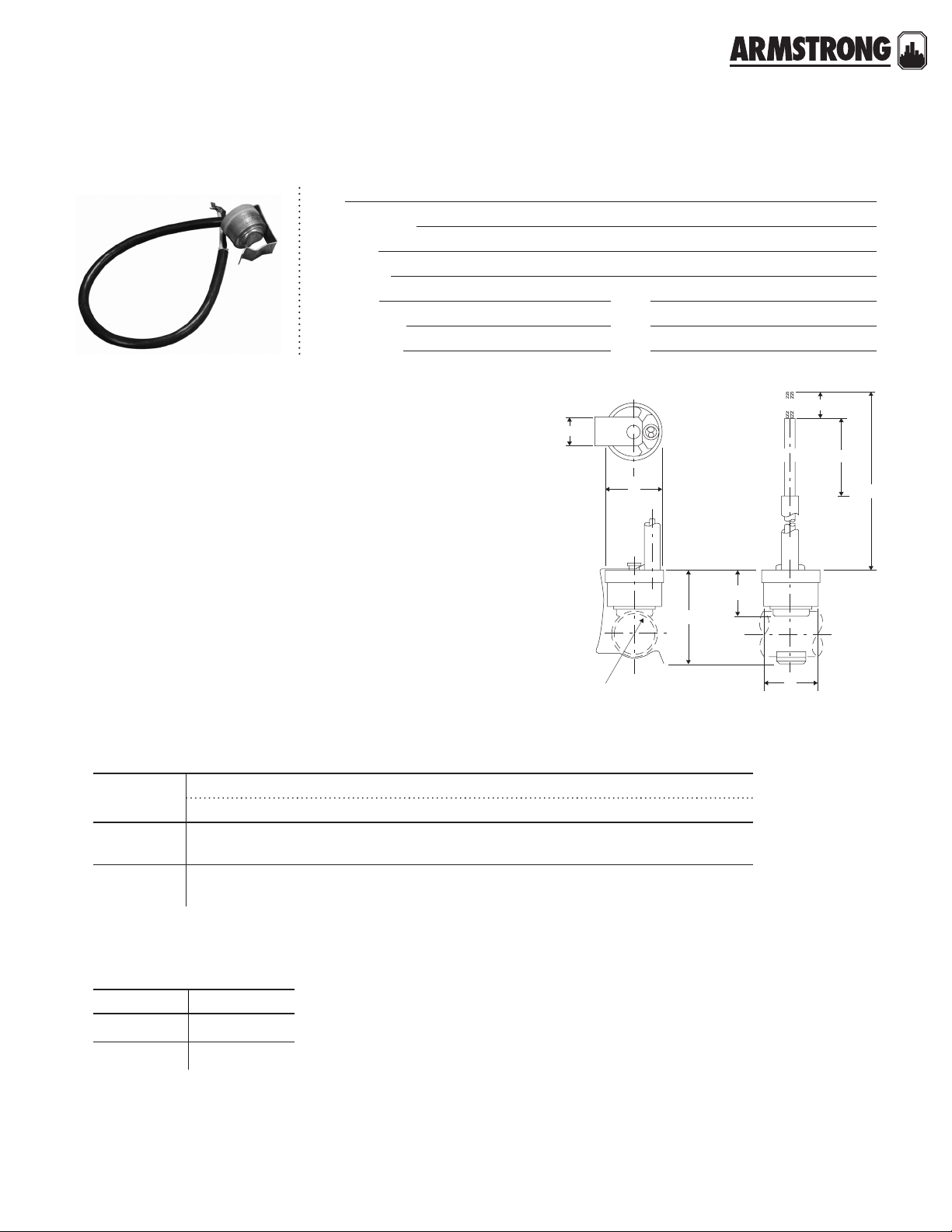

a

c

back to

<

contents

AQUASTAT CONTROLS

½” & ¾”

|

SUBMITTAL

Job:

Representative:

Engineer:

Contractor:

Order no: Date:

Submitted by: Date:

Approved by: Date:

technical data

Description: Aquastat (thermostatic) switch

Application: Clip-on thermostatic control for Astro circulators

Type: Bi-metallic disc, snap-acting

Enclosure: Environmentally sealed

Mounting: Clip-on mount for ½" ( 12.7 mm) i.d. copper tube [X" (15.8 mm) o.d.]

Clip on mount for ¾" (19.0 mm) i.d. copper tube [Y" (22.2 mm) o.d.]

Contact rating: 10 a @ 120 v, 60 Hz resistive; 5 a @ 240 v, 60 Hz resistive

Temperature Rating* : 105±5°f (40±2°c) pump switches o

85±6°f (29±3°c) pump switches on

Leads: 2 Leads, awg 18, 14" (356 mm)

12" (305 mm), black insulation, silicon or epoxy overmold

½" (12.7 mm) strip length

* Temperatures indicated are at pipe surface

dimension data - inches (mm)

model

½" Aquastat

¾" Aquastat

dimensions inches (mm)

a b c d e f g h j

0.56

(14.2)

0.56

(14.2)

1.1 2

(28.4)

1.1 2

(28.4)

0.62 5 (15. 8)

nominal pipe o.d.

0.875 (22.2)

nominal pipe o.d.

1.7

(43 . 2)

1.8

(45 .7)

0.9 6

(24.4)

0.9 6

(24.4)

1.04

(2 6. 4)

1.04

(26.4)

14.0

(355.6)

14.0

(355.6)

b

2.0

(50.8)

2.0

(50.8)

j

h

g

e

d

f

0.5

(12.7)

0.5

(12.7)

part numbers

model part numer

½" Aquastat 110123-120

¾" Aquastat 110123-121

17

HYDRONIC SOLUTIONS CATALOG

|

Page 18

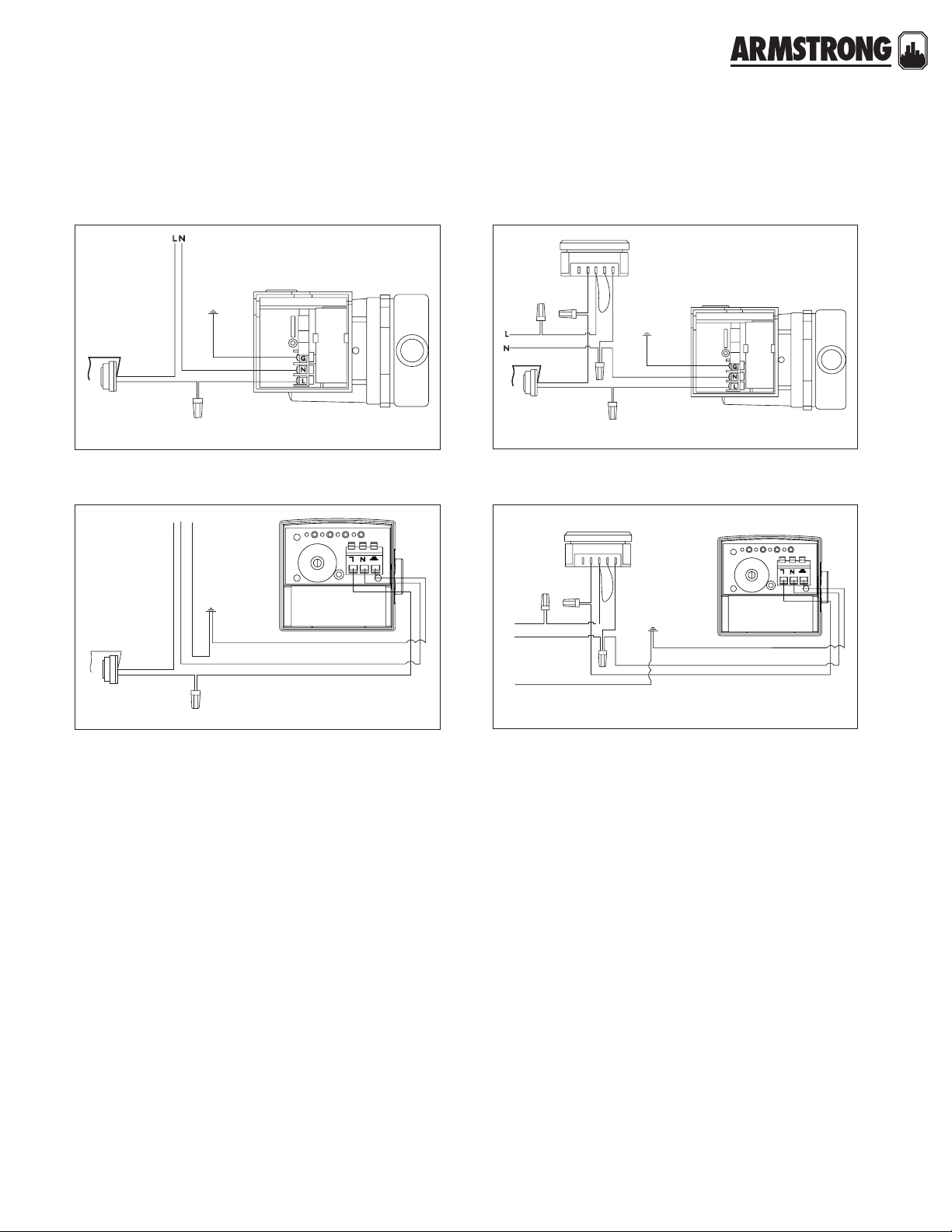

AQUASTAT CONTROLS

½” & ¾”

|

SUBMITTAL

wiring diagram

green

black

white

aquastat

astro series circulator with aquastat control wiring diagram

black

white

aquastat

astro 2 series circulator with aquastat control wiring diagram

white

black

pump

GNL

green

white

black

pump

54321

black

black

white

black

white

aquastat

astro series circulator with 24 hour timer and aquastat control wiring diagram

timer

black

L

white

N

green

G

astro 2 series circulator and 24 hour timer wiring diagram

black

timer

black

ground

screw

white

black

black

ground screw

in timer box

white

black

green

white

black

green

green

white

black

pump

18

HYDRONIC SOLUTIONS CATALOG

|

Page 19

5.5

12

head - feet

flow - usgpm

back to

<

contents

ASTRO EXPRESS 2

HOT WATER RECIRCULATION

Job:

Representative:

Engineer:

Contractor:

Order no: Date:

Submitted by: Date:

Approved by: Date:

|

SUBMITTAL

quantity description

*Astro Express 2 system (Wet rotor circulator

with timer, line cord, union hardware, and one

Astro Express lf valve)

*Astro Express lf valve (only) for lengthy

branches to additional faucets o main

distribution pipe

materials of construction

astro express 2 circulator

Pump casing: Astro 220ssu with 1¼” npsm union threads

Power connection: 6.0 ft (1.8

plug with ground

Impeller: pa66

Shaft: Ceramic

Bearings/seal: Ceramic/epdm

Union tailpieces: Brass, ¾" fpt (two) and ¾" mpt (one)

Union gaskets: epdm (two)

m) power cord, molded duplex

performance curve

5

3

4

2

1

3

2

technical data

astro express 2 circulator

Power requirements: 115 vac, 60 Hz, 33 w, 0.29 a max.

Max. head (Astro 220ssu): 5.3 ft (1.6 m)

Max. flow (Astro 220ssu): 10.0 gpm (0.63 L/s)

Ambient temperature: 39°f (4°c) to 104°f (40°c)

Clock timer: 12 hour analog clock with am/pm indication

Timer settings: Individual toggles for each 15

interval over 24 hours

Manual override: 3 position slide switch, on/o/auto

astro express lf valve

Housing: Forged eco brass* with noryl cap

Internal components:

epdm o-rings

Connections: Threaded, ½" hot & cold inlets, W"

& cold outlets

Flowrate adjustment: 0 – 100%, multi-turn slotted screw

Mounting: Plastic wall anchor with screw

Environment: Indoor use only

Max. working pressure: 100 psi (689 kPa)

Max. water temperature: 140°f (60°c)

Approvals:

*Complies with Section 116875 of the California Health and Safety Code and

Vermont Act 193. (Lead content of all wetted surface is 0.25% or less.)

Stainless steel and plastic with

listed certified

minute

hot

1

0

024

6810

mounting orientation

Connect the hot and cold water supply to the Astro

Express lf valve K" threaded inlets. (Stainless steel flex

hose recommended.)

Connect the hot and cold Astro Express lf valve W"

threaded outlets to the faucet. (Stainless steel flex hose

recommended.)

Secure the valve to the wall under the sink, using the plastic

wall anchor and screw.

19

HYDRONIC SOLUTIONS CATALOG

|

Page 20

ASTRO EXPRESS 2

ef

c

d

cold

hot

HOT WATER RECIRCULATION

|

SUBMITTAL

dimension data - inches (mm)

product

Astro Express

2 circulator

Astro Express

lf valve

hot

dimensions inches (mm) weight

a b c d e f g lbs (kg)

6.00(152) 5.00 (127) 4.0 0 (102) — 5.00 (127) 1. 80 (46) —

2.50 (63) 1.50 (38) 2.10 (53) 2 . 60 (6 6) 0.8 0 (20) W"ips K" ips

f

b

faucet

supply

c

cold

e

10.00 (4.45)

0.50 (0.23)

astro express 2 circulatorastro express lf valve

b

a

a

g

part numbers

model part numer

Astro Express 2 circulator 110223-401

Astro Express lf valve 561100LF- 001

replacements parts

product part no.

Astro Express lf valve 561100LF- 001 See page 84 for the details on Astro Express lf valve

Timer 810123-130 See page 49 for the details on 24 hour timer

Union kits

(Lead free brass*)

810120-320

See page 181 for the details on Union Fitting Sets810120-322

810120-324

20

HYDRONIC SOLUTIONS CATALOG

|

Page 21

p

a

Based on 1800 rpm, 60 Hz motors. For 50 Hz motors write for special capacity charts.

flow - usgpm

flow - l/s

head - feet

head - meters

horizontal mounting

back to

<

contents

S&H 3-PIECE CIRCULATORS

S MODELS

|

SUBMITTAL

Job:

Representative:

Engineer:

Contractor:

Order no: Date:

Submitted by: Date:

Approved by: Date:

materials of construction

part name bronze fitted lead free bronze*

Pump Body Cast iron Lead free Bronze

Impeller: Non-ferrous

Bearings: Sleeve - Oil lubricated**

Maintenance free - Permanently lubricated***

Seal: Mechanical

Stationary seal face: Sintered silicon carbide

Coupler: s25-s46: Flexible, 4 - Spring;

s55-s69: Flexible spacer type

Motor: Single phase - 1800 rpm - Resilient mounted

Three phase - 1800 rpm - Resilient mounted

mounting orientation

The pump should be installed in a position to

permit proper lubrication of bearings and servicing.

Motor and bearing bracket are to be kept free

of insulation. Pump and motor unit are designed

to be supported by the in line piping only. Do

not support in any other manner. A height of

approximately 4 feet above floor is recommended.

* Contains less than 0.25% lead, weighted average.

** Alloy shaft with copper sleeve.

*** Stainless steel shaft.

maximum pump oper ating conditions

125 psig at 225°f (863 kPa at 107°c)

performance curve

0 0.63 1.89 3.15 4.41 5.68 6.94 8.209.4610.73

40

35

30

25

20

15

10

5

S3

S2

S4

S5

S4

referred selection are

S6

S5

Based on 1800 rpm, 60 Hz

12.1

10.7

9.1

7.6

6.1

4.6

3.0

1.5

motors. For 50 Hz motors

write for special capacity charts.

0

01030507090 110 130 150 170

0

HYDRONIC SOLUTIONS CATALOG

|

21

Page 22

S&H 3-PIECE CIRCULATORS

a

resilient mountend view side view

S MODELS

dimension data - inches (mm)

model

S25

S35 2 T 1 phase 115 v 15.00 (581) 8.50 (216) 12.50 (318) 0.88 (22) 38 (17.2)

S45

S46 3 L 1 phase 115 v 15.75 (400) 10.00 (254) 12.50 (318) 1.00 (25) 51 (23.1)

S55

S57

S69

|

SUBMITTAL

flange

size (n.p.t)

O A⁄a b 1 phase 115 v 13.75 (349) 6.50 (165) 11.50 (292) 0.75 (19) 19 (8.6)

1 A⁄a b 1 phase 115 v 13.75 (349) 6.50 (165) 11.50 (292) 0.75 (19) 19 (8.6)

1N A⁄ab 1 phase 115 v 13.75 (349) 6.50 (165) 11.50 (292) 0.88 (22) 19 (8.6)

1K A⁄ab 1 phase 115 v 13.75 (349) 6.50 (165) 11.50 (292) 0.88 (22) 19 (8.6)

2K N 1 phase 115 v 15.75 (400) 10.00 (254) 12.50 (318) 1.00 (25) 45 (20.4)

3 N 1 phase 115 v 15.75 (400) 10.00 (254) 12.50 (318) 1.00 (25) 45 (20.4)

3 K 1 phase 115/230 v 19.50 (495) 12.00 (305) 16.00 (406) 1.00 (25) 82 (37.2)

3 K 3 phase 208-230/460 v 19.50 (495) 12.00 (305) 16.00 (406) 1.00 (25) 74 (33.6)

3 K 3 phase 575 v 19.50 (495) 12.00 (305) 16.00 (406) 1.00 (25) 74 (33.6)

3 O 1 phase 115/230 v 20.00 (508) 12.00 (305) 16.50 (419) 1.00 (25) 82 (37.2)

3 O 3 phase 208-230/460 v 20.00 (508) 12.00 (305) 16.50 (419) 1.00 (25) 76 (34.5)

3 O 3 phase 575 v 20.00 (508) 12.00 (305) 16.50 (419) 1.00 (25) 76 (34.5)

3 1 1 phase 115/230 v 25.00 (635) 14.25 (362) 20.25 (514) 1.00 (25) 130 (59.0)

3 1 3 phase 208-230/460 v 25.00 (635) 14.25 (362) 20.25 (514) 1.00 (25) 125 (56.7)

3 1 3 phase 575 v 25.00 (635) 14.25 (362) 20.25 (514) 1.00 (25) 125 (56.7)

motor** dimensions inches (mm) weight

hp phase and volt a b c d lbs (kg)

22

Dimensions shown are for reference only. For exac t dimensional data,

contact factory.

Companion flanges are not furnished as standard on s-25, s-45 and h-32.

Conduit box not supplied on K hp or greater.

** All single phase motors are equipped with a built-in thermal overload

protection. Three phase motors require external overload protection.

part numbers

standard design maintenance free design

model

S25 174031-013 1740 31LF-043 174031MF-013 174 0 31MF-043

S35 174033-013 174033LF-043 174033MF-013 174033MF-043

S45 174036-113 174036LF-143 174036MF-113 174036MF-143

S46 174 037-113 174037LF-143 174037MF-113 174037MF-14 3

S55 (1 Phase) 106284-132 106284LF-133 106284MF-132 106284MF-133

S55 (3 Phase) 106284-136 106284LF-137 106284MF-136 106284MF-137

S55 (3 pH 575 V) 106284-010 106284LF-011 106284MF-010 106284MF- 011

S57 (1 Phase) 106285-132 106285LF-133 106285MF-132 106285MF-133

S57 (3 Phase) 106285-136 106285LF-137 10 6285MF-136 106285MF-137

S57 (3 pH 575 V) 106285-010 106285LF-011 106285MF-010 106285MF- 011

S69 (1 Phase) 116531-132 116532LF-133 n /a n/a

S69 (3 Phase) 116535-136 11653 6LF-137 n/a n/a

S69 (3 pH 575 V) 116539-000 116540LF-000 n/a n/a

HYDRONIC SOLUTIONS CATALOG

|

bronze fitted lead free* bronze bronze fitted lead free* bronze

item no. item no. item no. item no.

a

d

b

d

k

c

note:

standard design circulators are with

Sleeve Bearing sba and maintenance

free design circulators are with ball

bearing sba.

c

k

Page 23

S&H 3-PIECE CIRCULATORS

S MODELS

|

SUBMITTAL

companion single flange part numbers

size cast iron lf bronze

O 116013- 011 116013-841

1 116012-011 116012-841

1N

1K

2

2K

3

116011-011 116 011-841

1160 0 9 - 011 1160 0 9 - 841

105210-011/106074-011 105210-841/106074-841

105189 - 011 105189-841

105188- 011/133615- 010 105188-841/106466-841

23

HYDRONIC SOLUTIONS CATALOG

|

Page 24

24

HYDRONIC SOLUTIONS CATALOG

|

Page 25

S&H 3-PIECE CIRCULATORS

Based on 1800 rpm, 60 Hz motors. For 50 Hz motors write for special capacity charts.

flow - usgpm

flow - l/s

head - feet

head - metres

horizontal mounting

H MODELS

|

SUBMITTAL

Job:

Representative:

Engineer:

Contractor:

Order no: Date:

Submitted by: Date:

Approved by: Date:

materials of construction

part name

Pump body Cast iron Cast iron Lead free bronze Lead free bronze

Coupler

Impeller: Non-ferrous

Bearings: Sleeve - Oil lubricated**

Maintenance free - Permanently lubricated***

Seal: Mechanical

Stationary seal face: Sintered silicon carbide

* Contains less than 0.25% lead, weighted average.

** Alloy shaft with copper sleeve.

*** Stainless steel shaft.

h-32 to h-54

bronze fitted

h-32 & h-41 flexible, 4-spring

h-51 to h-54 flexible, spacer type

h-63 to h-68

bronze fitted

Flexible, spacer type

mounting orientation

The pump should be installed in a position to permit proper

lubrication of bearings and servicing. Motor and bearing

bracket are to be kept free of insulation. Pump and motor

unit are designed to be supported by the in line piping

only. Do not support in any other manner. A height of

approximately 4 feet above floor is recommended.

h-32 to h-54

lead free bronze*

h-32 & h-41 flexible, 4-spring

h-51 to h-54 flexible, spacer type

h-63 to h-68

lead free bronze*

Flexible, spacer type

maximum pump oper ating conditions

125 psig at 225°f (863 kPa at 107°c)

performance curve

0 0.63 1.89 3.15 4.41 5.68 6.94 8.209.4610.73

50

40

30

20

10

0

01030507090 110 130 150 170

H6

H4

H6

H3

H6

H5

H5

H6

H5

H5

H6

H6

Based on 1800 rpm, 60 Hz

15.2

12.1

9.1

6.1

3.0

0

motors. For 50 Hz motors write

for special capacity charts.

25

HYDRONIC SOLUTIONS CATALOG

|

Page 26

S&H 3-PIECE CIRCULATORS

resilient mountend view side view

H MODELS

dimension data - inches (mm)

model

H32

H41 1 T 1 phase 115 v 15.25 (387) 8.50 (216) 12.50 (318) 0.75 (19) 34 (15.4)

H51

H52

H53

H54

H63

H64

H65

H66

H67

H68

|

SUBMITTAL

flange

size (n.p.t)

1 T 1 phase 115 v 15.00 (381) 8.50 (216) 12.50 (318) 0.88 (22) 30 (13.6)

1N T 1 phase 115 v 15.00 (381) 8.50 (216) 12.50 (318) 0.88 (22) 30 (13.6)

1K T 1 phase 115 v 15.00 (381) 8.50 (216) 12.50 (318) 0.88 (22) 30 (13.6)

1 N 1 phase 115 v 17.25 (438) 11.50 (292) 13.50 (343) 0.75 (19) 48 (21.8)

1 N 3 phase 208-230/460 v 17.25 (438) 11.50 (292) 13.50 (343) 0.75 (19) 48 (21.8)

1N L 1 phase 115 v 17.25 (438) 11.50 (292) 13.50 (343) 0.88 (22) 48 (21.8)

1N L 3 phase 208-230/460 v 17.25 (438) 11.50 (292) 13.50 (343) 0.88 (22) 48 (21.8)

1K K 1 phase 115 v 20.00 (508) 11.50 (292) 16.50 (419) 0.88 (22) 58 (26.3)

1K K 3 phase 208-230/460 v 20.00 (508) 11.50 (292) 16.50 (419) 0.88 (22) 58 (26.3)

1K K 3 phase 575 v 20.00 (508) 11.50 (292) 16.50 (419) 0.88 (22) 58 (26.3)

2 O 1 phase 115 v 20.00 (508) 11.50 (292) 16.50 (419) 0.88 (22) 68 (30.8)

2 O 3 phase 208-230/460 v 20.00 (508) 11.50 (292) 16.50 (419) 0.88 (22) 68 (30.8)

2 O 3 phase 575 v 20.00 (508) 11.50 (292) 16.50 (419) 0.88 (22) 68 (30.8)

1K K 1 phase 115 v 23.00 (584) 13.50 (343) 19.75 (502) 0.88 (22) 86 (39.0)

1K K 3 phase 208-230/460 v 23.00 (584) 13.50 (343) 19.75 (502) 0.88 (22) 86 (39.0)

1K K 3 phase 575 v 23.00 (584) 13.50 (343) 19.75 (502) 0.88 (22) 86 (39.0)

1K O 1 phase 115 v 23.00 (584) 13.50 (343) 19.75(502) 0.88 (22) 89 (40.4)

1K O 3 phase 208-230/460 v 23.00 (584) 13.50 (343) 19.75(502) 0.88 (22) 89 (40.4)

1K O 3 phase 575 v 23.00 (584) 13.50 (343) 19.75(502) 0.88 (22) 89 (40.4)

1K 1 1 phase 115 v 23.00 (584) 13.50 (343) 19.75(502) 0.88 (22) 92 (41.7)

1K 1 3 phase 208-230/460 v 23.00 (584) 13.50 (343) 19.75(502) 0.88 (22) 92 (41.7)

1K 1 3 phase 575 v 23.00 (584) 13.50 (343) 19.75(502) 0.88 (22) 92 (41.7)

2 O 1 phase 115 v 23.25 (591) 14.00 (356) 19.75 (502) 0.88 (22) 110 (49.9)

2 O 3 phase 208-230/460 v 23.25 (591) 14.00 (356) 19.75 (502) 0.88 (22) 110 (49.9)

2 O 3 phase 575 v 23.25 (591) 14.00 (356) 19.75 (502) 0.88 (22) 110 (49.9)

2 1 1 phase 115 v 23.25 (591) 14.00 (356) 19.75 (502) 0.88 (22) 115 (52.1)

2 1 3 phase 208-230/460 v 23.25 (591) 14.00 (356) 19.75 (502) 0.88 (22) 115 (52.1)

2 1 3 phase 575 v 23.25 (591) 14.00 (356) 19.75 (502) 0.88 (22) 115 (52.1)

2 1K 1 phase 115 v 21.75 (552) 14.00 (356) 18.25 (464) 0.88 (22) 120 (54.0)

2 1K 3 phase 208-230/460 v 21.75 (552) 14.00 (356) 18.25 (464) 0.88 (22) 120 (54.0)

2 1K 3 phase 575 v 21.75 (552) 14.00 (356) 18.25 (464) 0.88 (22) 120 (54.0)

motor** dimensions inches (mm) weight

hp phase and volt a b c d lbs (kg)

26

Dimensions shown are for reference only. For exac t dimensional data,

contact factory.

Companion flanges are not furnished as standard on s-25, s-45 and h-32.

Conduit box not supplied on K hp or greater.

** All single phase motors are equipped with a built-in thermal overload

protection. Three phase motors require external overload protection.

HYDRONIC SOLUTIONS CATALOG

|

a

c

d

b

d

k

c

a

k

Page 27

S&H 3-PIECE CIRCULATORS

H MODELS

|

SUBMITTAL

companion single flange part numbers

size cast iron lf bronze

O

1

1N 116011- 011 116011-841

1K 116009-011 116009-841

2

2K

3

116013-011 116013-841

116012-011 116012- 841

105210-011/106074-011 105210-841/106074-841

105189 - 011 105189-841

105188- 011/133615- 010 105188-841/106466-841

part numbers

standard design maintenance free design

model

H32 174034-013 174 034LF-043 174034MF-013 174 0 34MF-043

H41 174035-113 174035LF-143 174035MF-113 174035MF-143

H51 (1 Phase) 116431-132 116432LF-133 116431MF-132 116432MF-133

H51 (3 Phase) 110119 -100 110119LF-101 110119MF-100 110119MF-101

H52 (1 Phase) 116435-132 116436LF-133 116435MF-132 11643 6MF-133

H52 (3 Phase) 110119 -102 110119LF-103 110119MF-102 110119MF-103

H53 (1 Phase) 116439-132 116440LF-133 116439MF-132 11644 0MF-133

H53 (3 Phase) 116443-136 116444LF-137 116443MF-136 116444MF-137

H53 (3 pH 575 V) 116447-000 116448LF-000 116447MF-000 116448MF-000

H54 (1 Phase) 116451-132 116452LF-133 116451MF-132 116452MF-133

H54 (3 Phase) 116455-136 116456LF-137 116455MF-136 116456MF-137

H54 (3 pH 575 V) 116459-000 116460LF-000 116459MF-000 116460MF-000

H63 (1 Phase) 116463-132 116464LF-133 n/a n/a

H63 (3 Phase) 116467-136 116468LF-137 n/a n/a

H63 (3 pH 575 V) 116471- 0 0 0 116472LF-000 n/a n/a

H64 (1 Phase) 116475-132 116476LF-133 n /a n/a

H64 (3 Phase) 116479-136 11648 0LF-137 n/a n/a

H64 (3 pH 575 V) 116483-000 116484LF-000 n /a n/a

H65 (1 Phase) 116487-132 116488LF-133 n /a n/a

H65 (3 Phase) 116491-136 116492LF-137 n/a n/a

H65 (3 pH 575 V) 116495-000 11649 6LF-000 n/a n/a

H66 (1 Phase) 116499-132 116500LF-133 n/a n/a

H66 (3 Phase) 11650 3-13 6 116504LF-137 n/a n/a

H66 (3 pH 575 V) 116507-000 116508LF-000 n/a n/a

H67 (1 Phase) 116511-132 116512LF-133 n/a n/a

H67 (3 Phase) 116515-136 116516LF-137 n/a n/a

H67 (3 pH 575 V) 116519 - 0 0 0 116520LF-000 n/a n/a

H68 (3 Phase) 116523-136 116524LF-137 n/a n /a

H68 (3 pH 575 V) 116527-000 116528LF-000 n/a n/a

note:

standard design circulators are with Sleeve Bearing sba and maintenance free design circulators are with ball bearing sba.

bronze fitted lead free* bronze bronze fitted lead free* bronze

item no. item no. item no. item no.

27

HYDRONIC SOLUTIONS CATALOG

|

Page 28

28

HYDRONIC SOLUTIONS CATALOG

|

Page 29

horizontal mounting

back to

<

contents

1050 & 1060 3-PIECE CIRCULATORS

CUSTOM IN-LINE

|

SUBMITTAL

Job:

Representative:

Engineer:

Contractor:

Order no: Date:

Submitted by: Date:

Approved by: Date:

pump design data

Pump model: Flange size:

No. of pumps:

Capacity:

Head:

ft (m) Liquid:

Companion flanges: Included

Note:

USgpm (L/s) Temperature: °f (°c)

motor design data

kW: rpm: 1800 Hertz:

Frame size: Enclosure:

mounting orientation

The pump should be installed in a

position to permit proper lubrication

of bearings and servicing. Motor and

bearing bracket are to be kept free of

insulation. Pump and motor unit are

designed to be supported by the in line

piping only. Do not support in any other

manner. A height of approximately 4

feet above floor is recommended.

materials of construction

part name bronze fitted all bronze

Pump body Cast iron Bronze

Impeller: series 1050: Non–ferrous

series 1060: Bronze

Shaft: Alloy steel–copper sleeve Coupler: Flexible spacer type

Mechanical seal assembly: Carbon/SiC, stainless steel trim, Viton seal

Bearings: Sleeve–oil lubricated

maximum pump oper ating conditions

175 psig at 225°f (1207 kPa at 107°c)

29

HYDRONIC SOLUTIONS CATALOG

|

Page 30

1050 & 1060 3-PIECE CIRCULATORS

resilient mount

d

d

rigid mount

discharge

m

CUSTOM IN-LINE

|

SUBMITTAL

motor data - inches (mm)

pump

size

1050

1060

1.5D

1060

2D

1060

3D

motor resilient mount inches (mm) rigid mount inches (mm) shpg.weight

hp phase and volt a c k l m n lbs (kg)

N

1 phase 115 v 17. 25 (43 8) 13. 50 (343) 7.38 (187)

L — — —

K

1 phase 115/230 v

or 3 phase 208-

O 20.0 0 (508) 16 .50 (419) 10. 38 (264) — — — 75 (34)

230/460 v or 575 v

1 20.75 (527) 17.0 0 (4 31) 10. 88 (276) — — — 80 (36)

K

¾ 23.00 (584) 19.75 (502) 10.3 8 (264) — — — 82 (37)

1 23. 50 (597) 20.2 5 (514) 10.8 8 (276) — — — 92 (42)

1 phase 115/230 v

1K* — — — 21.50 (546) 18 . 25 (4 64) 8.88 (225) 115 (52)

or 3 phase 208-

K 22.75 (578) 19. 2 5 (4 8 9) 9.88 (251) — — — 90 (41)

230/460 v or 575 v

¾ 23.75 (603) 19.75 (5 02) 10. 3 8 (264) — — — 96 (44)

1 23.75 (603) 20.25 (514) 10.8 8 (276) — — — 100 (45)

1K* — — — 21.75 (552) 18 . 25 (4 64) 8.88 (225) 120 (54)

3 phase 208-

2*

230/460 v or 575 v

1 phase 115/230 v

1

or 3 phase 208-

1K* — — — 24.00 (610) 19.00 (4 83) 8.88 (225) 138 (63)

230/460 v or 575 v

2*

3 phase 208230/460 v or 575 v

3* — — — 27.75 (705) 22.75 (578) 9. 88 (251) 150 (68)

19.75 (502) 16.00 (406) 9.88 (251) — — — 58 (26)

22.00 (559) 18.75 (476) 9.88 (251) — — — 8 6 (39)

— — —

— — — 22.75 (578) 19.25 (489) 9.88 (251) 124 (56)

— — — 23. 50 (597) 18.50 (470) 8.88 (225) 135 (61)

— — — 25.0 0 (635) 20.0 0 (508) 9.8 8 (251) 143 (65)

48 (22)

dimension data - inches (mm)

flange

pump size

size

(n.p.t)

1050 1B 1 11. 50 (292) 0.75 (19) 1. 38 (35) 3 .75 (95) 4.12 (105)

1050 1.25B 1N

1050 2B 2

1060 1.5D 1K 13.50 (343) 0.88 (22) 1 .00 (25) 4. 6 2 (117) 4.88 (124)

1060 2D 2 14.00 (3 56) 0.8 8 (22) 1.0 0 (25) 4 .75 (1 21) 5.12 (130)

1060 3D 3 18.00 (457) 1.00 (25) - 5 . 8 8 (149) 5.00 (127)

e

f

c

otor

l

h

HYDRONIC SOLUTIONS CATALOG

|

30

dimensions inches (mm)

b d e f h

11. 50 (292) 0.8 8 (22) 1. 38 (35) 3 . 75 (95) 4.12 (10 5)1050 1.5B 1K

suction

Dimensions shown are for reference only. For exac t

dimensional data, contact factory.

Pumps are shipped for up discharge.

Tapped openings are provided in the pump body for

venting and draining.

Motors are equipped with a built-in thermal overload

protection. Motor resilient mount.

All single phase motors are equipped with a built-in

thermal overload protection. Three phase motors rigid

mount, require external thermal overload protection.

* Motors rigid mount.

l

m

n

d

b

d

a

c

b

k

Page 31

1050 & 1060 3-PIECE CIRCULATORS

(4.42)

head - feet (m)

(4.42)

head - feet (m)

5.25 in

hp

head - feet (m)

head - feet (m)

CUSTOM IN-LINE

|

SUBMITTAL

performance curve

rpm: 1800 Availability: 1050 all ratings

• bhp based on shown Fluid’s sp. gr.

• Performance guaranteed only at operating point indicated.

• Curve shown for clear, cold water – sp. gr. 1.0000

Curve number: pt25-0-0-1800 Size: 1b

(7.6) 25

(6.1) 20

(4.6) 15

(3.0) 10

(1.5) 5

(0.0) 0

(0.00)

5.25 in

5.00 in

4.75 in

4.50 in

4.25 in

4.00 in

0

npshr

10

(0.63)

29

36

41

45

48

49

50

51

48

20

(1.26)

30

(1.89)

52

40

(2.52)

45

41

0.333 hp

0.25 hp

36%

0.167 hp

50

(3.15)60(3.79)

0.5 hp

flow - USgpm (l/s)

Curve number: pt1-1-0-1800 Size: 1.25b

5.25 in

5.00 in

(7.6) 25

4.75 in

4.50 in

(6.1) 20

4.25 in

(4.6) 15

4.00 in

(3.0) 10

(1.5) 5

70

(0.0) 0

0

(0.00)10(0.63)20(1.26)

npshr

29

36

41

45

48

49

50

51

48

30

(1.89)

52

40

(2.52)

45

0.5 hp

0.333 hp

0.25 hp

41%

0.167 hp

50

(3.15)60(3.79)

70

flow - USgpm (l/s)

Curve number: pt5-0-0-1800 Size: 1.5b

29

39

47

20

(1.26)

flow - USgpm (l/s)

53

(2.52)

(8.5) 28

(7.3) 24

(6.1) 20

(4.9) 16

(3.7) 12

(2.4) 8

(1.2) 4

(0.0) 0

5.00 in

4.75 in

4.50 in

4.25 in

4.00 in

npshr

0

(0.00)

Curve number: pt26-0-0-1800 Size: 2b

5.25 in

38

46

56

58

59

58

56

53

0.75

47

0.5 hp

0.333 hp

0.25 hp

0.167 hp

40

60

(3.79)

80

(5.05)

(8.5) 28

(7.3) 24

(6.1) 20

(4.9) 16

(3.7) 12

(2.4) 8

(1.2) 4

(0.0) 0

5.00 in

4.75 in

4.50 in

4.25 in

4.00 in

npshr

0

(0.00)

52

55

40

(2.52)

flow - USgpm (l/s)

58

61

0.25 hp

80

(5.05)

60

58

0.333 hp

55

52

0.5 hp

120

(7.57)

1 hp

0.75 hp

160

(10.09)

HYDRONIC SOLUTIONS CATALOG

|

31

Page 32

1050 & 1060 3-PIECE CIRCULATORS

flow - USgpm (l/s)

head - feet (m)

flow - USgpm (l/s)

head - feet (m)

flow - USgpm (l/s)

head - feet (m)

CUSTOM IN-LINE

|

SUBMITTAL

performance curve

rpm: 1800 Availability: 1060 all ratings

• bhp based on shown Fluid’s sp. gr.

• Performance guaranteed only at operating point indicated.

• Curve shown for clear, cold water – sp. gr. 1.0000

Curve number: pt8-0-0-1800 Size: 1.5d

7.00 in

23

33

40

45

(15.2) 50

(12.2) 40

(9.1) 30

(6.1) 20

(3.0) 10

(0.0) 0

6.50 in

6.00 in

5.50 in

5.00 in

0

(0.00)

npshr

20

(1.26)

48

40

(2.52)

50

0.333 hp

51

0.5 hp

50

48

60

(3.79)

45

0.75 hp

40

1 hp

(5.05)

Curve number: pt29-0-0-1800 Size: 2d

(15.2) 50

(12.2) 40

(9.1) 30

33

1.5 hp

(6.1) 20

7.00 in

6.50 in

6.00 in

5.50 in

5.00 in

(3.0) 10

80

(0.0) 0

0

(0.00)

npshr

35

40

(2.52)

43

49

54

56

58

59

56

59

0.5 hp

80

(5.05)

0.75 hp

(7.57)

120

1 hp

54

49

43

2 hp

1.5 hp

160

(10.09)

Curve number: pt41-0-0-1800 Size: 3d

7.00 in

38

49

58

80

(5.05)

65

69

71

71

71

49%

1 hp

0.75 hp

160

(10.09)

(15.2) 50

(12.2) 40

(9.1) 30

(6.1) 20

(3.0) 10

(0.0) 0

6.50 in

6.00 in

5.50 in

5.00 in

npshr

0

(0.00)

69

1.5 hp

240

(15.14)

65

58

3 hp

2 hp

320

(20.19)

HYDRONIC SOLUTIONS CATALOG

|

32

Page 33

head – feet

flow – usgpm

recommended optionalnot recommended

back to

<

contents

E. 2 CIRCULATORS

|

SUBMITTAL

Job:

Representative:

Engineer:

Contractor:

Order no: Date:

Submitted by: Date:

Approved by: Date:

materials of construction

Pump body: Cast iron (closed sytems)

Bronze (lead free for open systems)

Face plate:

Impeller: 30%

Bearings:

Seal: Silicon carbide enviroseal c/w viton elastomer

Stainless steel Shaft: Stainless steel

Glass-filled noryl Volute gasket: epdm

Permanently lubricated stainless steel

technical data

Flow range: 0 to 128.0 USgpm (0 to 8.1 L/s)

Head range: 0 to 61.0 feet (0 to 18.6 m)

Max/Min fluid temp: 230°f/40°f (110°c/4°c)

Max. Working pressure: 150 psi (1034 kPa)

mounting orientation

For indoor use only

performance curve

2

7

8

flow – l/s

2

1

1

1

1

flow – usgpm

0123456

40

35

30

25

20

1

15

10

5

0

10 0 20 30 40 50 60 70 80 90 100

Circled numbers denote E.2 Series model number

(Performance guaranteed only at operating

point indicated).

12

10

8

6

4

head – metres

2

0

2

1

flow – l/s

3

3

2

0123456789

60

1

55

50

1

45

40

35

9

30

head – feet

25

20

15

10

5

0

0

2

1

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

18

16

14

12

10

8

head – metres

6

4

2

0

33

HYDRONIC SOLUTIONS CATALOG

|

Page 34

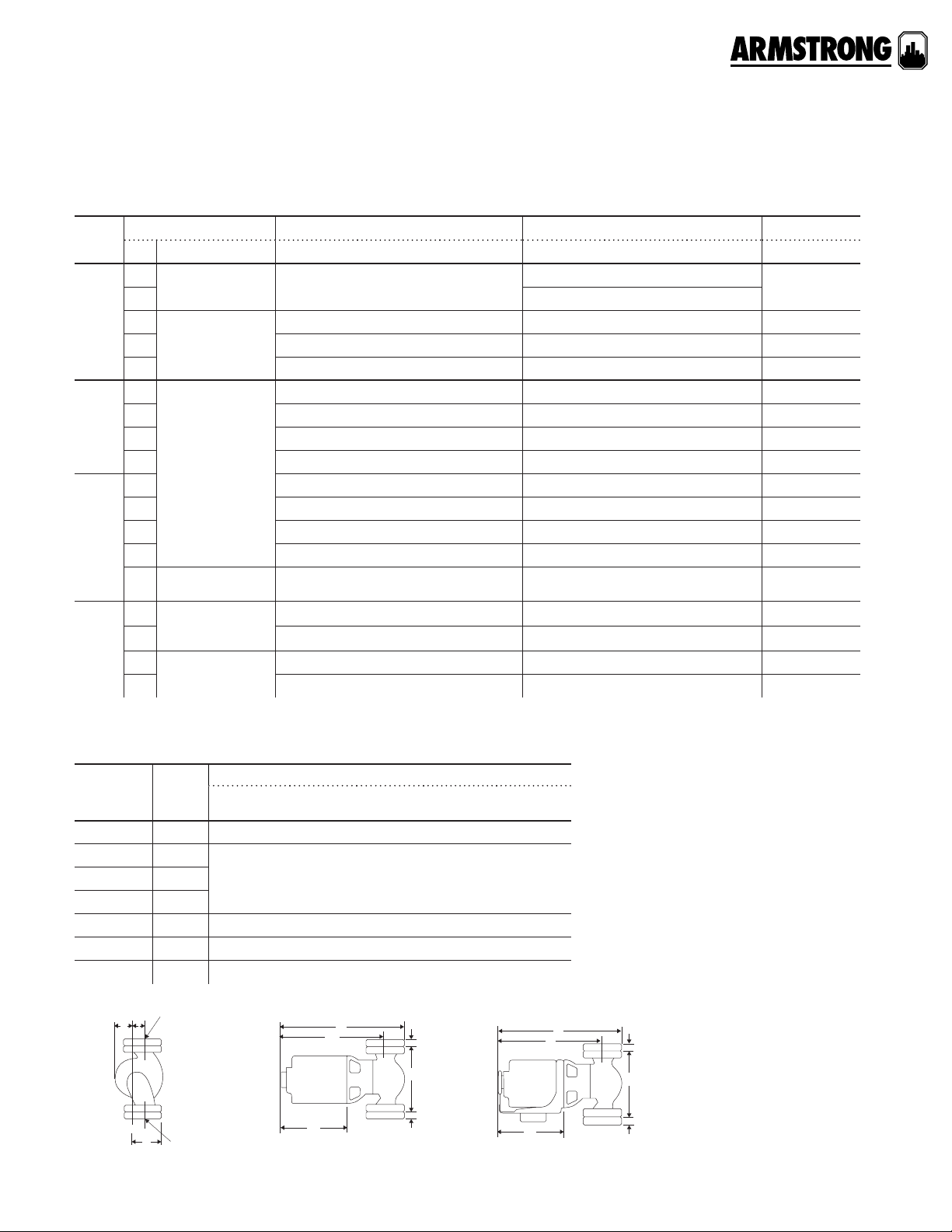

E. 2 CIRCULATORS

a

d

f

b

|

SUBMITTAL

dimension data - inches (mm)

model body

e7.2 cast iron

e7.2b bronze 13.3 (6.03)

e8.2 cast iron 13.1 (5.94)

e8.2b bronze 13.3 (6.03)

e9.2 cast iron 13.1 (5.94)

e9.2b bronze 13.3 (6.03)

e10.2 cast iron

e10.2b bronze

e11.2 cast iron

e11.2b bronze

e13.2 cast iron

e13.2b bronze 14.8 (6.71)

e16.2 cast iron

e16.2b bronze 20.9 (9.48)

e30.2–2” cast iron

e30.2b–2” bronze 25.7 (11.66)

e30.2–3” cast iron

e30.2b–3” bronze 29.2 (13.24)

e33.2–2” cast iron

e33.2b–2” bronze 25.7 (11.66)

e33.2–3” cast iron

e33.2b–3” bronze 29.2 (13.24)

e12.2 cast iron

e12.2b bronze 18.4 (8.35)

e14.2 cast iron 17.8 (8.07)

e14.2b bronze 18.4 (8.35)

e15.2 cast iron

e15.2b bronze 21.2 (9.62)

e17.2 cast iron 20.9 (9.48)

e17.2b bronze 21.2 (9.62)

e19.2 cast iron

e19.2b bronze 20.9 (9.48)

e21.2 cast iron 20.7 (9.39)

e21.2b bronze 20.9 (9.48)

e22.2 cast iron 20.7 (9.39)

e22.2b bronze 20.9 (9.48)

34

e23.2 cast iron 20.7 (9.39)

e23.2b bronze 20.9 (9.48)

e24.2 cast iron 20.7 (9.39)

e24.2b bronze 20.9 (9.48)

e28.2 cast iron

e28.2b bronze 29.2 (13.24)

e29.2 cast iron 26.8 (12.16)

e29.2b bronze 29.2 (13.24)

HYDRONIC SOLUTIONS CATALOG

|

connection

type & size

1.25" diameter

2 bolt flanges

1.5" diameter

2 bolt flanges

2" diameter

4 bolt flanges

3" diameter

4 bolt flanges

2" diameter

4 bolt flanges

3" diameter

4 bolt flanges

1.25" diameter

2 bolt flanges

1.5" diameter

2 bolt flanges

3" diameter

4 bolt flanges

dimensions inches (mm)

a b c d e f lbs (kg)

7.10

(180)

7.50

(191)

8.40

(212)

10.90

(276)

11.30

(286)

10.90

(276)

11.30

(286)

9.30

(235)

10.30

(261)

10.30

(261)

11.35

(286)

6.40

(164)

8.50

(215)

8.50

(215)

8.50

(215)

8.50

(215)

8.50

(215)

8.50

(215)

6.40

(164)

8.50

(215)

8.50

(215)

8.50

(215)

5.50

(140)

5.60

(142)

5.80

(147)

8.30

(210)

8.30

(210)

8.30

(210)

8.30

(210)

7.80

(197)

8.00

(202)

8.00

(202)

8.35

(210)

3.80

(97)

3.80

(97)

3.80

(97)

4.00

(101)

4.00

(101)

4.00

(101)

4.00

(101)

4.00

(101)

4.00

(101)

4.00

(101)

4.00

(101)

3.20

(81)

3.40

(86)

2.90

(73)

2.90

(73)

3.50

(89)

2.90

(73)

3.50

(89)

3.20

(81)

3.20

(81)

3.40

(86)

3.50

(89)

4.20

(107)

4.20

(107)

5.20

(131)

5.20

(131)

6.00

(152)

5.20

(131)

6.00

(152)

4.20

(107)

4.20

(107)

4.20

(107)

6.00

(152)

shipping

weight

13.1 (5.94)

15.1 (6.85)

18.8 (8.53)

17.2 (7.80)

26.8 (12.16)

17.2 (7.80)

26.8 (12.16)

17.8 (8.07)

20.9 (9.48)

20.7 (9.39)

26.8 (12.16)

c

e

Page 35

E. 2 CIRCULATORS

|

SUBMITTAL

motor data

model voltage

e7.2/ e7.2b

e8.2/ e8.2b

e9.2/ e9.2b 3250

e10.2/ e10.2b

e11.2/ e11.2b 3300

e13.2/ e13.2b 3400

e16.2/ e16.2b 3400

120v

208v

240v

120v

240v

full load amp

draw (a)

2.0

1.0

1.0

2.0

1.0

nominal

power (w)

T hp (125w)

frequency

(hz)

motor type speed (rpm)

3400

Two pole,

Single phase

3300

e30.2/ e30.2b

e33.2/ e33.2b

e12.2/ e12.2b

e14.2/ e14.2b

e15.2/ e15.2b

e17.2/ e17.2b

e19.2/ e19.2b

e21.2/ e21.2b

e22.2/ e22.2b

e23.2/ e23.2b

e24.2/ e24.2b

e28.2/ e28.2b

e29.2/ e29.2b

120v

208v

240v

277v

120v

208v

240v

277v

120v 4.8

120v

208v

240v

277v

120v

208v

240v

277v

120v

208v

240v

277v

120v

208v

240v

277v

120v

208v

240v

277v

120v

208v

240v

277v

120v

208v

240v

277v

120v

208v

240v

277v

4.1

2.4

2.4

2.4

5.7

3.1

3.1

3.1

2.5

1.8

1.8

1.8

3.0

1.6

1.6

1.6

3.4

1.8

1.8

1.8

3.8

2.0

2.0

2.0

5.7

3.0

3.0

3.0

5.0

2.6

2.6

2.6

3.3

1.7

1.7

1.7

3.8

2.0

2.0

2.0

Q hp (300w)

60 Hz

Two pole,

Single phase

odp

Two pole,

Single phase

Two pole,

Single phase

odp

3350

3300

3500

3450

3350

3400

3450

3400

35

HYDRONIC SOLUTIONS CATALOG

|

Page 36

E. 2 CIRCULATORS

|

SUBMITTAL

part numbers

model 120 v 240 v

e7.2 182202- 643 182202- 671

e7.2b 182202- 644 182202- 672

e8.2 182202-657 182202- 645

e8.2b 182202- 658 182202- 646

e9.2 182202-659 182202- 647

e9.2b 182202- 660 182202- 648

e10.2 182202- 649 182202- 661

e10.2b 182202-650 182202-662

e11.2 182202-651 182202-663

e11.2b 182202- 652 182202- 664

e13.2 182202- 655 182202- 667

e13.2b 182202- 656 182202- 668

e16.2 182202- 653 182202- 665

e16.2b 182202-654 182202-666

e30.2–2" 182212- 645 182212- 604

e30.2b–2" 182212- 646 182212- 605

e30.2–3" 182212- 671 182212- 630

e30.2b–3" 182212- 672 182212- 631

e33.2–2" 182222- 669 182212- 628

e33.2b–2" 182212-670 182212- 629

e33.2–3" 182212- 675 182212- 634

e33.2b–3" 182212-676 182212-635

e12.2 182212- 841 182212- 800

e12.2b 182212- 842 182212- 801

e14.2 182212- 843 182212- 802

e14.2b 182212- 844 182212- 803

e15.2 182212- 661 182212- 620

e15.2b 182212- 662 182212- 621

e17.2 182212- 663 182212- 622

e17.2b 182212- 664 182212- 623

e19.2 182212- 649 182212- 608

e19.2b 182212-650 182212-609

e21.2 182212- 665 182212- 624

e21.2b 182212- 666 182212- 625

e22.2 182212- 667 182212- 626

e22.2b 182212-668 182212-627

e23.2 182212- 651 182212- 610

e23.2b 182212-652 182212-611

e24.2 182212- 653 182212- 612

e24.2b 182212-654 182212-613

e28.2 182212- 655 182212- 614

e28.2b 182212- 656 182212- 615

e29.2 182212- 657 182212- 616

e29.2b 182212- 658 182212- 617

accessories

model flange kits

e7.2/ e7.2b

e8.2/ e8.2b

e9.2/ e9.2b

e12.2/ e12.2b

e14.2/ e14.2b

e15.2/ e15.2b

e17.2/ e17.2b

e10.2/ e10.2b

e11.2/ e11.2b

e13.2/ e13.2b

e19.2/ e19.2b

e21.2/ e21.2b

e22.2/ e22.2b

e23.2/ e23.2b

e24.2/ e24.2b

e16.2/ e16.2b

e30.2-2"/ e30.2-2"b

e33.2-2"/ e33.2-2"b

e28.2/ e28.2b

e29.2/ e29.2b

e30.2-3"/ e30.2-3"b

e33.2-3"/ e33.2-3"b

• Timer

• Aquastat

• Spool pieces

¾" Flange kits

1" Flange kits

1¼" Flange kits

1½" Flange kits

1" Flange kits

1¼" Flange kits

1½" Flange kits

2" Flange kits

3" Flange kits

36

HYDRONIC SOLUTIONS CATALOG

|

Page 37

e.

spool piece

back to

<

contents

E.2 CIRCULATOR SPOOL PIECES

Job:

Representative:

Engineer:

Contractor:

Order no: Date:

Submitted by: Date:

Approved by: Date:

model

esp-1 1.25 (32) 3.00 (75) 3.16 (80) 180221- 011

esp-2 1.25 (32) 2.50 (64) 3.16 (80) 180222-011

esp-4 1.50 (38) 3.0 0 (75) 3.44 (87) 180224- 011

esp-5 1.50 (38) 5. 0 0 (125) 3.44 (87) 180225 - 011

es p - 6 3.00 (75) 1.50 (3 8) 5 . 0 6 (129) 180226 - 011

esp-7 3.00 (75) 2. 62 (67) 5.06 (129) 180227-011

esp-8 3.00 (75) 3.50 (89) 5.06 (129) 180228-011

esp-9 3 .00 (75) 5.12 (130) 5.0 6 (129) 180229 - 011

esp-10 2.0 0 (50) 5. 0 0 (125) 4.00 (100) 180230-011

esp-11 1.50 (38) 2.50 (64) 3.44 (87) 18 0231-011

esp-12 2.0 0 (50) 3.00 (75) 4.00 (100) 180232-011

esp-13 2.0 0 (50) 5.50 (140) 4.00 (100) 180233- 011

pipe size a

inches (mm)

spool length b

inches (mm)

bolt holes c

inches (mm)

|

SUBMITTAL

part no.

mounting orientation

2 series

e.2 series

circulator

original

flange-to-flange

37

HYDRONIC SOLUTIONS CATALOG

|

Page 38

E.2 CIRCULATOR SPOOL PIECES

|

SUBMITTAL

38

pump model to be replaced

and upgraded

bell & gossett

2.5" / ld3 e28 esp-6

hd3 e29 esp-6

pd35 e30 - 3" esp-8

* 60-11 e17 esp-2

* 60-15 e23 esp-5

* 60-13 e24 esp-4

60-14 e33 - 2" esp-12

* 601 e15 esp-2

* 602 e17 esp-2

* 607 e19 esp-4

* 605 e21 esp-2

* 622 e22 esp-5

* 606 e24 esp-11

615 e33 - 2" esp-10

pl55 e12 not required

pl130 - 2" e30 - 2" not required

pl130 - 3" e30 - 3" not required

taco

121 / 122 e28 esp-7

131 e29 esp-9

132 e30 - 3" esp-9

133 e33 - 3" esp-9

1400-50 e12 not required

1400-70 e33 - 2" not required

grundfos

* ups 32-80 e17 esp-2

up 43-70 e19 not required

* ups 32-160 e22 esp-11

up 43-110 e23 not required

* ups 40-80/2 e24 esp-5

* ups 50-80/2 e33 - 2" esp-12

armstrong

* h51 e15 esp-1

* h52 e17 esp-1

* h63 e23 esp-5

h53 e24 esp-4

s45 e28 esp-6

s46 e28 esp-6

s55 e30 - 3" esp-8

HYDRONIC SOLUTIONS CATALOG

|

h54 e33 - 2" esp-12

upgrade with

e model +

esp model to use

with e series

Page 39

water, spgr = 1.0000

flow - usgpm

flow - l/s

head - feet

back to

<

contents

4270 PUMPS

MOTOR MOUNTED

|

SUBMITTAL

Job:

Representative:

Engineer:

Contractor:

Order no: Date:

Submitted by: Date:

Approved by: Date:

materials of construction

Construction: Bronze Fitted

Impeller: Ultem

Casing/Volute:

Cast iron

O-ring: Viton

Adapter: Aluminum

Shaft: 416 Stainless steel

maximum pump oper ating conditions

150 psig at 275°f (1034 kPa at 135°c)

mechanical seal design data

Seal type: 21

Insert : Carbon

Seal: Ceramic

Bellows: Viton

L-cup: Viton

Retainer: Stainless steel

Spring: Stainless steel

mounting orientation

Mount the pump on a foundation suciently

substantial to absorb any vibration. A good

foundation should weigh approximately two-and

one-half times the shipping weight of the pump.

motor design data

kW:

Enclosure : 50j

rpm: 3500

Hertz: 60 Hz

Eciency: Standard

optional equipment

o Flush line for vertical mounting

performance curve

0 37.9 75.7 113.6 189.3 227.1 265.0151.4 302.8 340.7 378.5 416.4 454.2

710

100

706

80

705

709

707

60

704

702

40

20

0

010203050607040 80

1

3

2

1

1

3

2

1.25x1x5 @ 3600 rpm

1.5x1.25x5.5 @ 3600 rpm

2x1.5x5.5 @ 3600 rpm

90

100

110

120

30.5

24.4

18.3

12.2

6.1

0

head - metres

HYDRONIC SOLUTIONS CATALOG

|

39

Page 40

4270 PUMPS

location

discharge

7"

MOTOR MOUNTED

dimension data - inches (mm)

model suction discharge

702** 1.25 (31) 1.00 (25) 3.50 (88) ¾

70 4 * * 1.25 (31) 1.00 (25) 4.00 (100) 1 40 (88)

70 5 * * 1.25 (31) 1.00 (25) 4.50 (114) 1½ 49 (108)

706** 1.50 (38) 1.25 (31) 4.50 (114) 2 51 (113)

70 7 * * 2.00 (50) 1.50 (38) 4.00 (100) 1½

709T 2.00 (50) 1.50 (38) 4.38 (111) 2 56 (124)

710T 2.00 (50) 1.50 (38) 5.00 (125) 3 60 (132)

All dimensions are in inches (mm) and weights in lbs (kg)

*Motors are available with open drip-proof enclosures only.

**Add sux to the end of the model number.

Sux number: s: for 60 hz - 1 phase - 115 v / 230 v (230 v

only for 3 hp and 5 hp)

t: for 60 hz - 3 phase - 208-230 v / 460v

|

SUBMITTAL

impeller

size

motor dimensions inches (mm) weight

hp

a b c l* t w x y

2.90

4.80

3.80

8.80

3.10

8.30

4.20

(73)

(121)

(95)

(222)

(79)

(210)

(106)

2.90

4.80

3.80

8.80

3.10

8.50

4.20

(73)

(121)

(95)

(222)

(79)

(216)

(106)

l

vent

b

a

suction

4.80

(121)

4.80

(121)

w

t

lbs (kg)

38 (84)

53 (117)

std ¼"npt drain

plug at 3

y

part numbers

model bronze fitted all bronze

702S 410133-201 410133-241

702T 410133-301 410133-341

704S 410133-203 410133-243

704T 410133-303 410133-343

705S 410133-204 410133-244

705T 410133-304 410133-344

706S 410134-200 410134-240

706T 410134-300 410134-340

707S 410135-200 410135-240

707T 410135-300 410135-340

709T 410135-302 410135-342

710T 410135-303 410135-343

3Y"

¼" npt

c

3Y"

5½"

x

W × 1" slot

W × 1½" slot

40

HYDRONIC SOLUTIONS CATALOG

|

Page 41

flow - usgpm

flow - L/s

head- feet

back to

<

contents

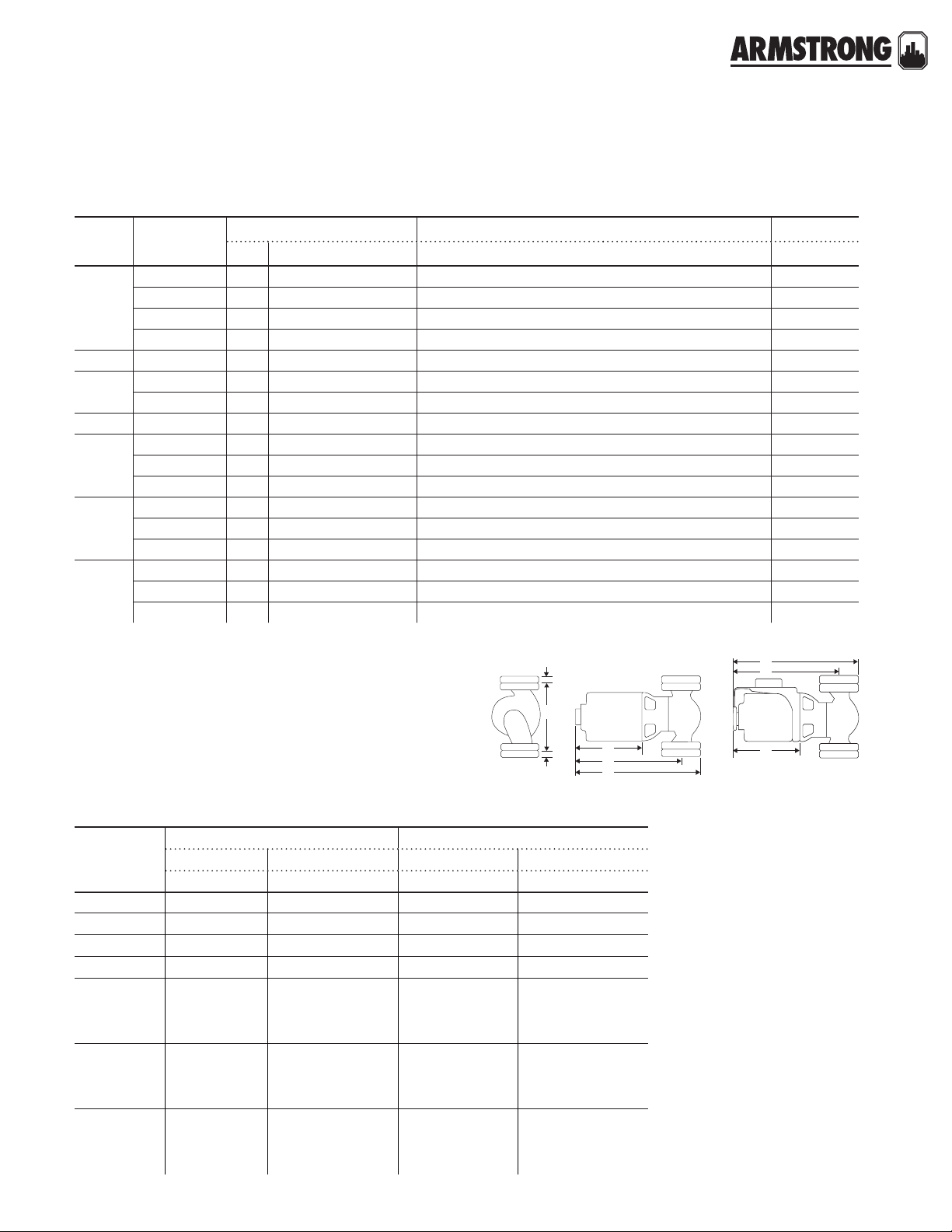

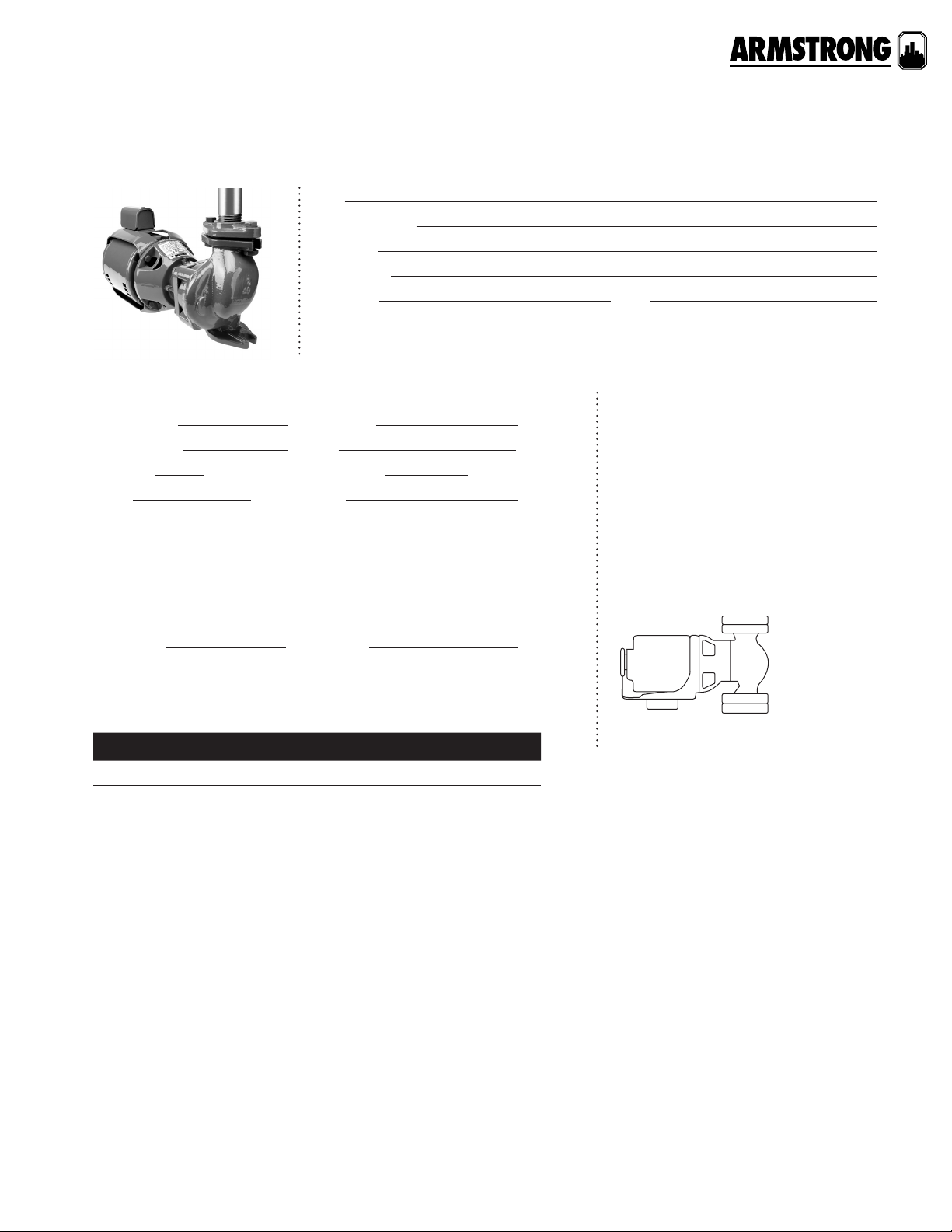

4360 PUMP-IN-A-BOX

CLOSE-COUPLED VIL PUMPS

|

SUBMITTAL

Job:

Representative:

Engineer:

Contractor:

Order no: Date:

Submitted by: Date:

Approved by: Date:

materials of construction

Casing: Cast iron Motor shaft: Carbon steel

Companion flanges: Cast iron Stub shaft (4360 b): Stainless steel

Motor/pump bracket: Cast iron Shaft sleeve (4360 d): Bronze

Impeller: Bronze

technical data

Maximum working pressure: 175 psi (12 bar)

Maximum working temperature: 225°f (107°c )

npt end connections (companion flanges included)

motor design data

mechanical seal design data

style inside single spring

Type

Rotating face Carbon

Stationary face

Secondary seal

Springs Stainless steel

Rotating hardware Stainless steel

* Not suitable for use on oil service

Armseal (4360b)

Armstrong 2a (4360d)

Ceramic (4360b)

Silicon-carbide (4360d)

buna-n (4360b)

epdm* (4360d)

Frequency: 60 hz Voltage: See below Enclosure: odp (4360b)

Eciency: std (4360b)

tefc (4360d)

Energy ecient nema 12.11 (4360d)

performance curve

0.5 1.0 1.5 2.0 3.05.0 7.010.0

100

80

60

50

40

30

20

10

5

10 20 30 40 50 60 80 100 200

7

02d

02b

04b

08f

08d

04f

10d

12b

06d

06b

30

20

15

9

6

head- metres

3

2

HYDRONIC SOLUTIONS CATALOG

|

41

Page 42

4360 PUMP-IN-A-BOX

CLOSE-COUPLED VIL PUMPS

motor data - inches (mm)

performance

curve

02b 4360b-1205t-1.5/2 4360b00ah-083 4360b00ah-068 1.25"µ1.25"

02d 4360b-1205t-2.0/2 4360b00aj-083 4360b00aj-068 1. 25"µ1.25"

04b 4360b-1505t-0.5/4 4360b00bc-062 (115/230v only) 1.5"µ1.5"

04f 4360b-1505t-3.0/2 4360b00bm-083 4360b00bm-083 1. 5"µ1.5"

06b 4360b-2205t-0.5/4 4360b00cc-062 (115/230v only) 2"µ2"

06d 4360b-2205t-0.7/4 4360b00cd-068 4360b00cd-083 2"µ2" 0.75

08d 4360d-1507t-1.0/4 4360d00ag-083 4360d00ag-068 1.5"µ1.5" 1

08f 4360d-1507t-1.5/4 4360d00ai-083 4360d00ai-068 1. 5"µ1.5" 1.5

10d 4360d-2207t-2.0/4 4360d-2207t-2.0/4 4360d00bl-068 2"µ2" 2

12b 4360d-3307t-1.5/4 4360d00ci-083 4360d00ci-068 3"µ3" 1.5

model

dimension data - inches (mm)

model

4360b-1205t-1.5/2 11. 50 (292) 8.75 (222) 12.75 (324) 3.56 (90) 42 (19.0)

4360b-1205t-2.0/2 11.50 (292) 8.75 (222) 13.13 (334) 3.56 (90) 47 (21. 3)

4360b-1505t-0.5/4 11.63 (295) 8.75 (222) 12.75 (324) 3.56 (90) 43 (19. 5)

4360b-1505t-3.0/2 11.63 (295) 8.75 (222) 13.13 (334) 5 . 20 (132) 58 (26.3)

4360b-2205t-0.5/4 11.75 (298) 8.88 (226) 12.75 (324) 3.50 (89) 49 (22. 2)

4360b-2205t-0.7/4 11.75 (298) 8.88 (226) 12.75 (324) 3.50 (89) 51 (23.1)

4360d-1507t-1.0/4 13. 50 (343) 10.75 (273) 13.75 (349) 3.25 (83) 110 (49.9)